AOSR 2.0: A Novel Approach and Thorough Validation of an Agent-Oriented Storage and Retrieval WMS Planner for SMEs, under Industry 4.0

Abstract

1. Introduction

2. Methodology

2.1. Objective

- stored in Racks;

- stuck at a RA; and

- placed in a EA.

2.2. Data

2.3. Methods: AOSR Heuristics

| Algorithm 1 Overview of Belief Builder Heuristics. |

|

| Algorithm 2 Overview of Percept Builder-ECU Heuristics. |

|

| Algorithm 3 Overview of Actuator-SearchRack Heuristics. |

|

| Algorithm 4 Overview of Percept Builder-CRM Heuristics. |

|

| Algorithm 5 Overview of Actuator-PlacementGen Heuristics. |

|

3. Results and Discussion

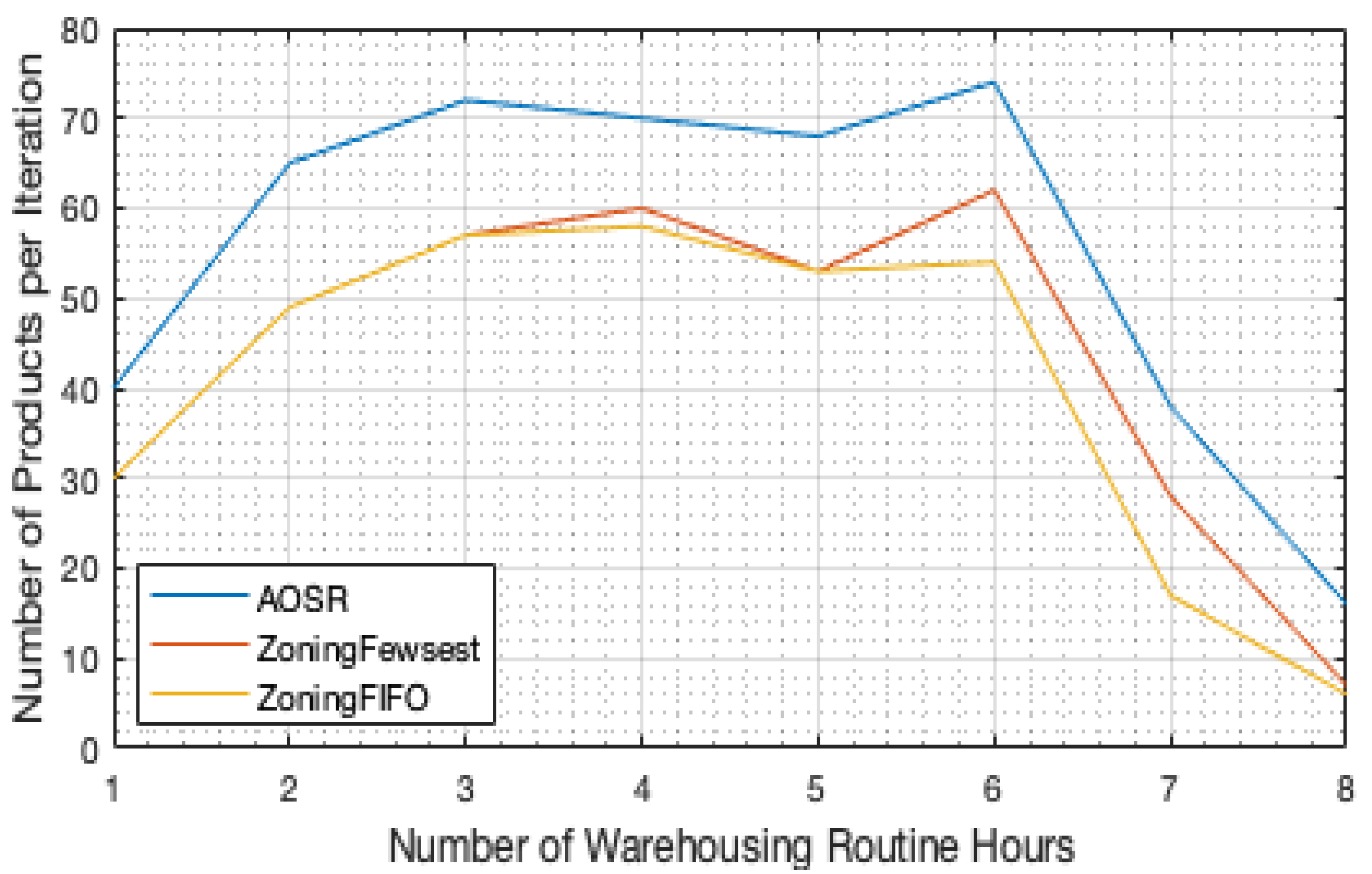

3.1. Scenario of Products in Racks

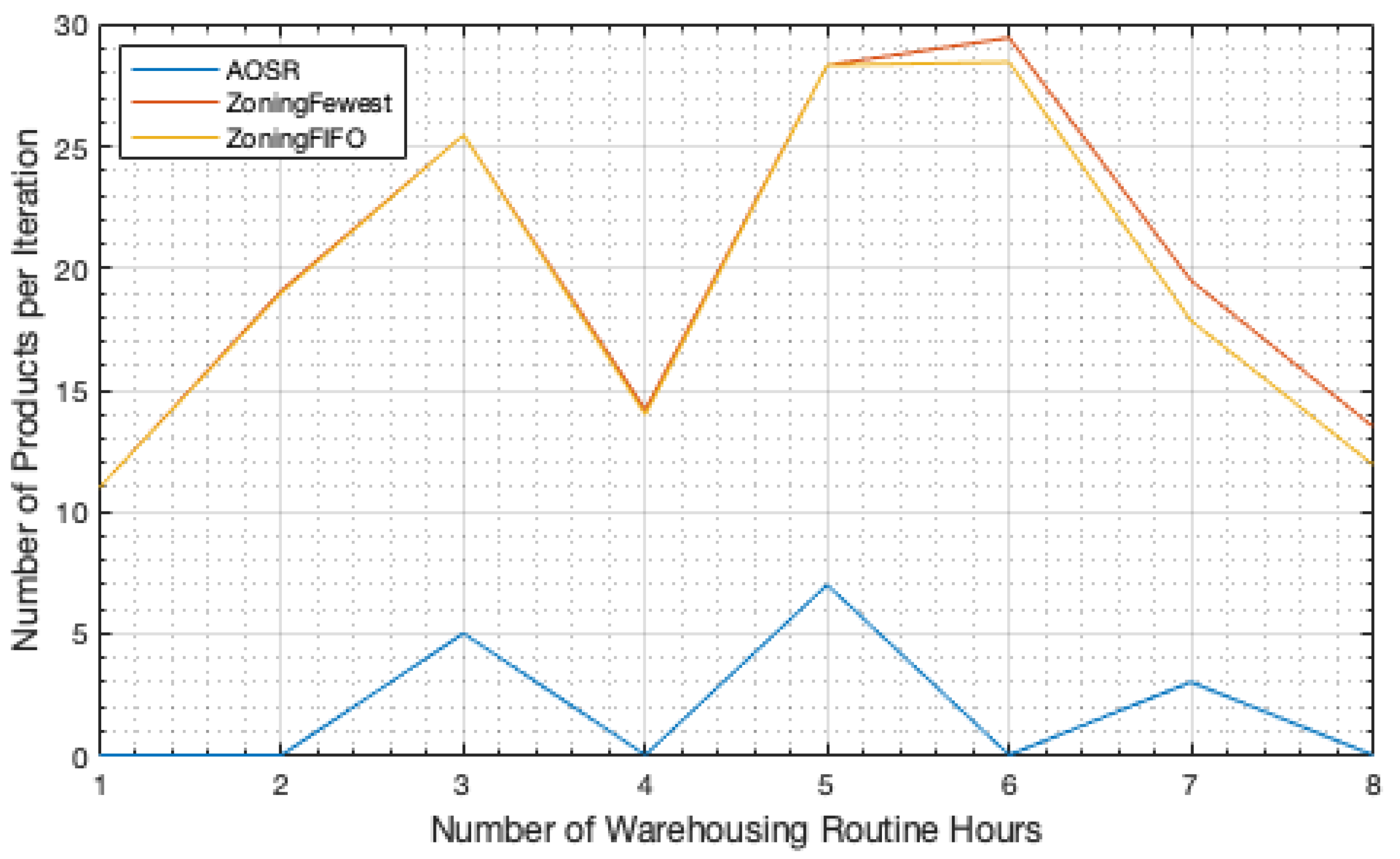

3.2. Scenario of Products in RA

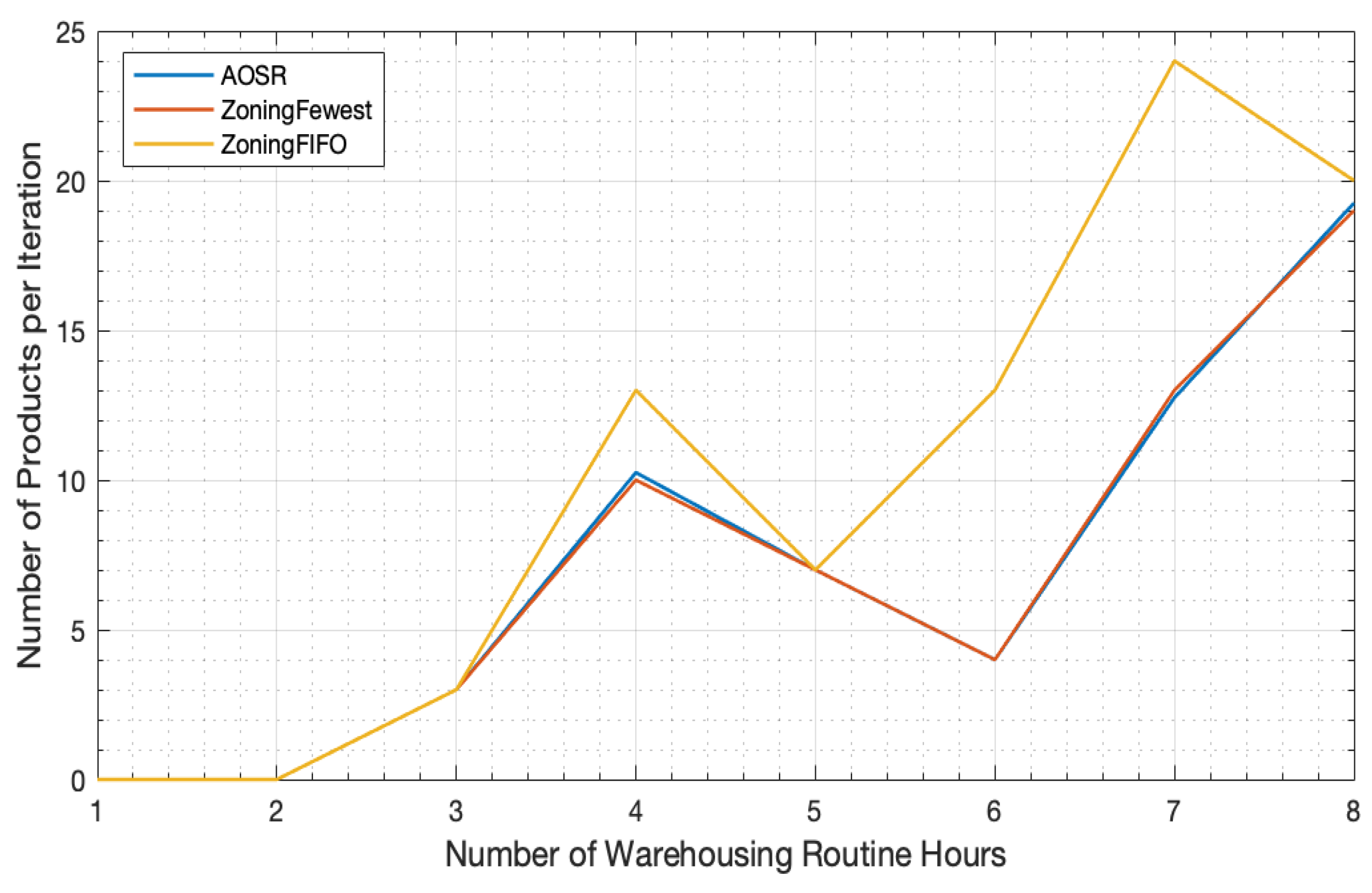

Scenario of Products in EA

4. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McKinsey, C. The Impact and Future of Manufacturing. 2019. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/the-future-of-manufacturing (accessed on 3 April 2019).

- Freeman, C.; Louçã, F. As Time Goes by: From the Industrial Revolutions to the Information Revolution, 1st ed.; Oxford University Press: Oxford, UK, 2001. [Google Scholar]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the Art and Future Trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Lu, W.; Giannikas, V.; McFarlane, D.; Hyde, J. The Role of Distributed Intelligence in Warehouse Management Systems; Springer: Cham, Swizerland, 2014; pp. 63–77. [Google Scholar]

- Majeed, A.A.; Rupasinghe, T.D. Internet of things (IoT) Embedded Future Supply Chains for Industry 4.0: An Assessment from an ERP-based Fashion Apparel and Footwear Industry. Int. J. Supply Chain. Manag. 2017, 6, 25–40. [Google Scholar]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards Smart Factory for Industry 4.0: A Self-Organized Multi-Agent System with Big Data based Feedback and Coordination. Comput. Net. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Lützenberger, M.; Küster, T.; Masuch, N.; Fähndrich, J. Multi-agent Systems in Practice: When Research Meets Reality. In Proceedings of the 2016 International Conference on Autonomous Agents & Multiagent Systems, Singapore, 9–13 May 2016; pp. 796–805. [Google Scholar]

- Jazdi, N. Cyber Physical Systems in the Context of Industry 4.0. In Proceedings of the 2014 IEEE International Conference on Automation, Quality and Testing, Robotics, Cluj-Napoca, Romania, 22–24 May 2014; pp. 1–4. [Google Scholar]

- Henning, K.; Wolfgang, W.; Johannes, H. Recommendations for Implementing the Strategic Initiative Industrie 4.0. AcaTech Natl. Acad. Sci. Eng. 2013, 1, 13–57. [Google Scholar]

- Riley, C.; Vrbka, J.; Rowland, Z. Internet of Things-enabled Sustainability, Big Data-driven Decision-Making Processes, and Digitized Mass Production in Industry 4.0-based Manufacturing Systems. J. Self Gov. Manag. Econ 2021, 9, 42–52. [Google Scholar]

- Sommer, L. Industrial Revolution Industry 4.0: Are German Manufacturing SMEs the First Victims of this Revolution? J. Ind. Eng. Manag. 2015, 8, 1512. [Google Scholar] [CrossRef]

- Andulkar, M.; Le, D.T.; Berger, U. A multi-case study on Industry 4.0 for SMEs in Brandenburg Germany. In Proceedings of the 51st Hawaii International Conference on System Sciences, Waikoloa Village, HI, USA, 2–6 January 2018; pp. 4544–4553. [Google Scholar]

- Müller, J.M.; Buliga, O.; Voigt, K.I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Abu Al-Rejal, H.M.; Abu Doleh, J.D.; Salhieh, L.M.; Udin, Z.M.; Mohtar, S. Barriers of Supply Chain Management Practices in Manufacturing Companies in Republic of Yemen: Pre-War Perspective. Int. J. Supply Chain. Manag. 2017, 6, 246–251. [Google Scholar]

- Centobelli, P.; Converso, G.; Murino, T.; Santillo, L. Flow Shop Scheduling Algorithm to Optimize Warehouse Activities. Int. J. Ind. Eng. Comput. 2016, 7, 49–66. [Google Scholar] [CrossRef]

- Ma, H.; Su, S.; Simon, D.; Fei, M. Ensemble Multi-Objective Biogeography-Based Optimization with Application to Automated Warehouse Scheduling. Eng. Appl. Artif. Intell. 2015, 44, 79–90. [Google Scholar] [CrossRef]

- Santos, F.A.; Mateus, G.R.; Da Cunha, A.S. The pickup and delivery problem with cross-docking. Comput. Oper. Res. 2013, 40, 1085–1093. [Google Scholar] [CrossRef]

- Duft, G.; Durana, P. Artificial Intelligence-based Decision-Making Algorithms, Automated Production Systems, and Big Data-driven Innovation in Sustainable Industry 4.0. Econ. Manag. Financ. Mark. 2020, 15, 9–18. [Google Scholar]

- Hyers, D. Big Data-driven Decision-Making Processes, Industry 4.0 Wireless Networks, and Digitized Mass Production in Cyber-Physical System-based Smart Factories. Econ. Manag. Financ. Mark. 2020, 15, 19–28. [Google Scholar]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Business2Community. Issues in Warehouse Management Systems. 2018. Available online: https://www.business2community.com/product-management/top-5-warehouse-management-problems-solve-02027463 (accessed on 17 July 2018).

- Poon, T.; Choy, K.; Chow, H.K.; Lau, H.C.; Chan, F.T.; Ho, K. A RFID Case-based Logistics Resource Management System for Managing Order-Picking Operations in Warehouses. Expert Syst. Appl. 2009, 36, 8277–8301. [Google Scholar] [CrossRef]

- Richards, G. Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse; Kogan Page Publishers: London, UK, 2017. [Google Scholar]

- Ud Din, F.; Henskens, F.; Paul, D.; Wallis, M. Agent-Oriented Smart Factory (AOSF): An MAS Based Framework for SMEs Under Industry 4.0. KES International Symposium on Agent and Multi-Agent Systems: Technologies and Applications; Springer: Berlin/Heidelberg, Germany, 2018; pp. 44–54. [Google Scholar]

- Ud Din, Fareed. Agent Oriented Smart Factory (AOSF): A MAS Based Framework for SMEs under Industry 4.0. Ph.D. Thesis, The University of Newcastle, Callaghan, NSW, Australia, 2020; pp. 67–86.

- Ud Din, F.; Henskens, F.; Paul, D.; Wallis, M. Formalisation of Problem and Domain Definition for Agent Oriented Smart Factory (AOSF). In Proceedings of the 2018 IEEE Region Ten Symposium (Tensymp), IEEE, Sydney, NSW, Australia, 4–6 July 2018; pp. 265–270. [Google Scholar]

- Ud Din, F.; Paul, D.; Ryan, J.; Henskens, F.; Wallis, M. Revitalising and Validating the Novel Approach of xAOSF Framework Under Industry 4.0 in Comparison with Linear SC. In Agents and Multi-Agent Systems: Technologies and Applications 2020; Springer: Singapore, 2020; pp. 3–16. [Google Scholar]

- Ud Din, F.; Paul, D.; Ryan, J.; Henskens, F.; Wallis, M. Validating Time Efficiency of AOSR 2.0: A Novel WMS Planner Algorithm for SMEs, under Industry 4.0. Available online: http://www.jsoftware.us/vol15/415-MC3026.pdf (accessed on 4 June 2021).

- Ud Din, F.; Paul, D.; Ryan, J.; Henskens, F.; Wallis, M. Conceptualised Visualisation of Extended Agent Oriented Smart Factory (xAOSF) Framework with Associated AOSR-WMS System. Available online: http://www.jsoftware.us/index.php?m=content&c=index&a=show&catid=228&id=3040 (accessed on 4 June 2021).

- Preuveneers, D.; Berbers, Y. Modeling Human Actors in an Intelligent Automated Warehouse. In International Conference on Digital Human Modeling; Springer: Berlin/Heidelberg, Germany, 2009; pp. 285–294. [Google Scholar]

- Java Agent Development Framework. JADE Open Source Project: Java Agent Development Environment Framework. 2017. Available online: http://jade.tilab.com/ (accessed on 18 August 2017).

- Rodriguez Masdefiol, M.d.M.; Stävmo, F. Industry 4.0–Only designed to fit the German automotive industry: A multiple case study on the feasibility of Industry 4.0 to Swedish SMEs. 2016. Available online: https://www.diva-portal.org/smash/get/diva2:933316/FULLTEXT01.pdf (accessed on 18 November 2019).

- Pech, M.; Vrchota, J.; Bednář, J. Predictive Maintenance and Intelligent Sensors in Smart Factory. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef]

- Popescu, C.K.; Oasa, R.-S.; Geambazi, P.; Alexandru, B. Real-Time Process Monitoring, Industry 4.0 Wireless Networks, and Cognitive Automation in Cyber-Physical System-based Manufacturing. J. Self Gov. Manag. Econ. 2021, 9, 1. [Google Scholar]

- Jones, M.M.; Juneja, M.O.; Gnanamurthy, K.; Kandikuppa, K.; Sheu, J.Y.W.; William, E.R.V.; Hadagali, G.R.; Rawat, S.S.; Berry, V.; Agrawal, D.; et al. Consigned Inventory Management System. U.S. Patent 14,499,372, 2016. [Google Scholar]

- EuroSped. Dataset Information for Warehouse and Logistics. 2018. Available online: http://www.eurosped.bg/en/eurolog-warehouse-logistics-4pl/ (accessed on 25 July 2018).

- Global, D.G.I. Warehouse Prducts Classes. 2018. Available online: http://www.dgiglobal.com/classes (accessed on 25 July 2018).

- Russell, S.; Norvig, P.; Intelligence, A. A modern approach. Artif. Intell. Prentice Hall Englewood Cliffs 1995, 25, 27. [Google Scholar]

- FIPA ACL. FIPA ACL Message Structure Specification. Foundation for Intelligent Physical Agents. 2002. Available online: http://www.fipa.org/specs/fipa00061/SC00061G (accessed on 30 June 2004).

- Chen, J.C.; Cheng, C.H.; Huang, P.B.; Wang, K.J.; Huang, C.J.; Ting, T.C. Warehouse Management with Lean and RFID Application: A Case Study. Int. J. Adv. Manuf. Technol. 2013, 69, 531–542. [Google Scholar] [CrossRef]

- Li, L. Supply Chain Management: Concepts, Techniques and Practices: Enhancing Value Through Collaboration; World Scientific Publishing Co Inc.: Singapore, 2007. [Google Scholar]

- Demo3D-Simulation-Tool. Demo3D, A Product of SOLIDWORKS and Rockwell Automation Industry, USA, for Simulating Industrial Setups. 2019. Available online: https://www.demo3d.com/home/ (accessed on 31 May 2019).

- Rockwell-Automation. Rockwell Automation Industry, USA. 2019. Available online: https://www.rockwellautomation.com/site-selection.html (accessed on 31 May 2019).

- Warehousing, G.O. GrayOrange Autonomous Warehousing. 2018. Available online: https://www.greyorange.com/butler-goods-to-person-system (accessed on 25 July 2018).

- Warehousing, U. Information of Warehouse Product Management. 2018. Available online: https://www.unleashedsoftware.com/product/inventory/product-management (accessed on 25 July 2018).

- Grant, E. Big Data-driven Innovation, Deep Learning-assisted Smart Process Planning, and Product Decision-Making Information Systems in Sustainable Industry 4.0. Econ. Manag. Financ. Mark. 2021, 16, 9–19. [Google Scholar]

- Coatney, K.; Poliak, M. Cognitive Decision-Making Algorithms, Internet of Things Smart Devices, and Sustainable Organizational Performance in Industry 4.0-based Manufacturing Systems. J. Self Gov. Manag. Econ. 2020, 8, 9–18. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ud Din, F.; Paul, D.; Ryan, J.; Henskens, F.; Wallis, M. AOSR 2.0: A Novel Approach and Thorough Validation of an Agent-Oriented Storage and Retrieval WMS Planner for SMEs, under Industry 4.0. Future Internet 2021, 13, 155. https://doi.org/10.3390/fi13060155

Ud Din F, Paul D, Ryan J, Henskens F, Wallis M. AOSR 2.0: A Novel Approach and Thorough Validation of an Agent-Oriented Storage and Retrieval WMS Planner for SMEs, under Industry 4.0. Future Internet. 2021; 13(6):155. https://doi.org/10.3390/fi13060155

Chicago/Turabian StyleUd Din, Fareed, David Paul, Joe Ryan, Frans Henskens, and Mark Wallis. 2021. "AOSR 2.0: A Novel Approach and Thorough Validation of an Agent-Oriented Storage and Retrieval WMS Planner for SMEs, under Industry 4.0" Future Internet 13, no. 6: 155. https://doi.org/10.3390/fi13060155

APA StyleUd Din, F., Paul, D., Ryan, J., Henskens, F., & Wallis, M. (2021). AOSR 2.0: A Novel Approach and Thorough Validation of an Agent-Oriented Storage and Retrieval WMS Planner for SMEs, under Industry 4.0. Future Internet, 13(6), 155. https://doi.org/10.3390/fi13060155