Development of a Rapid Method for Residence Time Distribution Measurement in Twin-Screw Wet Granulation Based on Image Processing with Lab Color Space

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

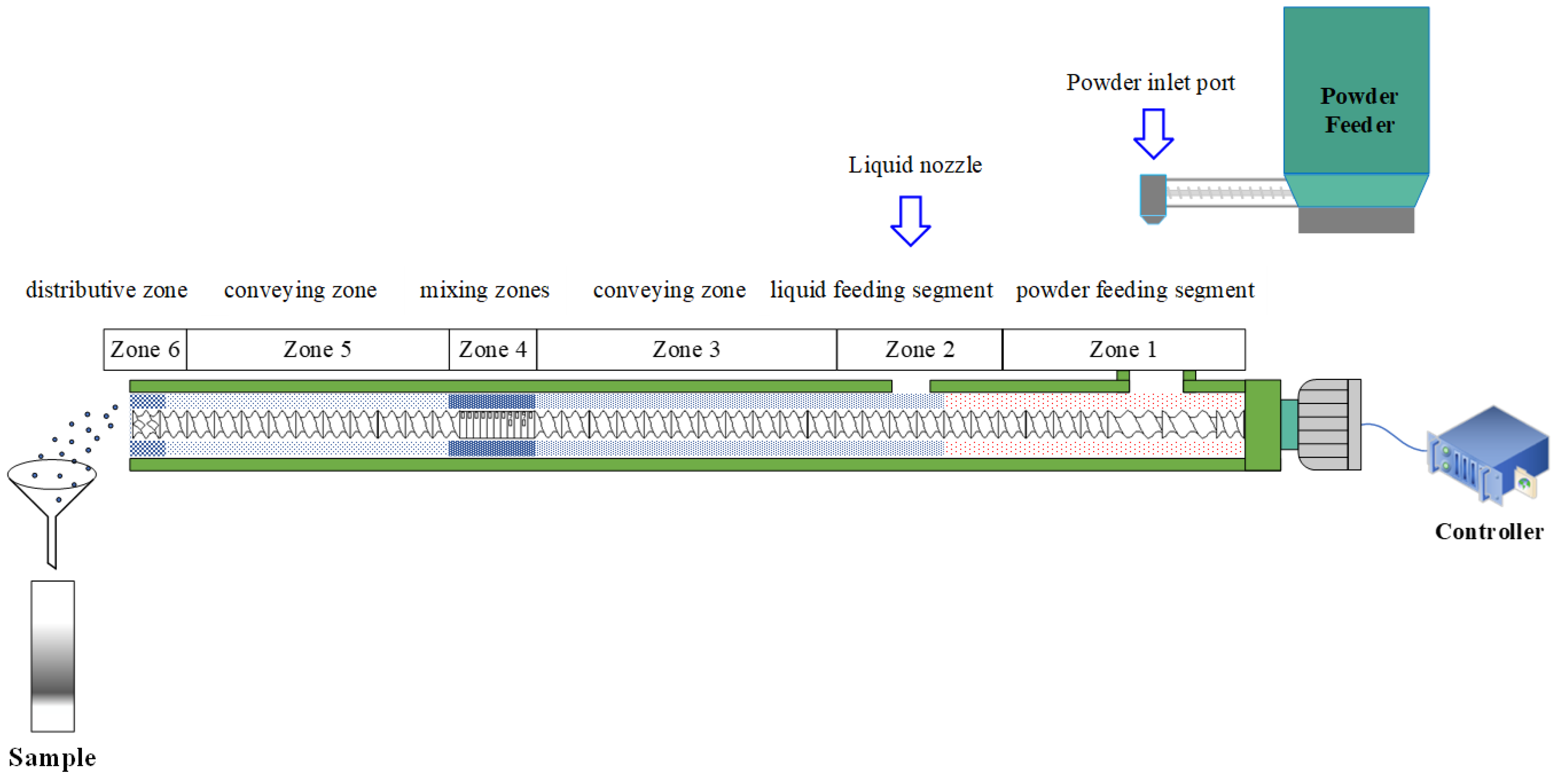

2.2. Granulation Experiments

2.3. RTD Model Development Based on Image Processing

2.3.1. Definition of the Detection Region

2.3.2. Grid Division and Calculating L*

2.3.3. Determining the RTD Functions (E(t) and F(t))

3. Results and Discussion

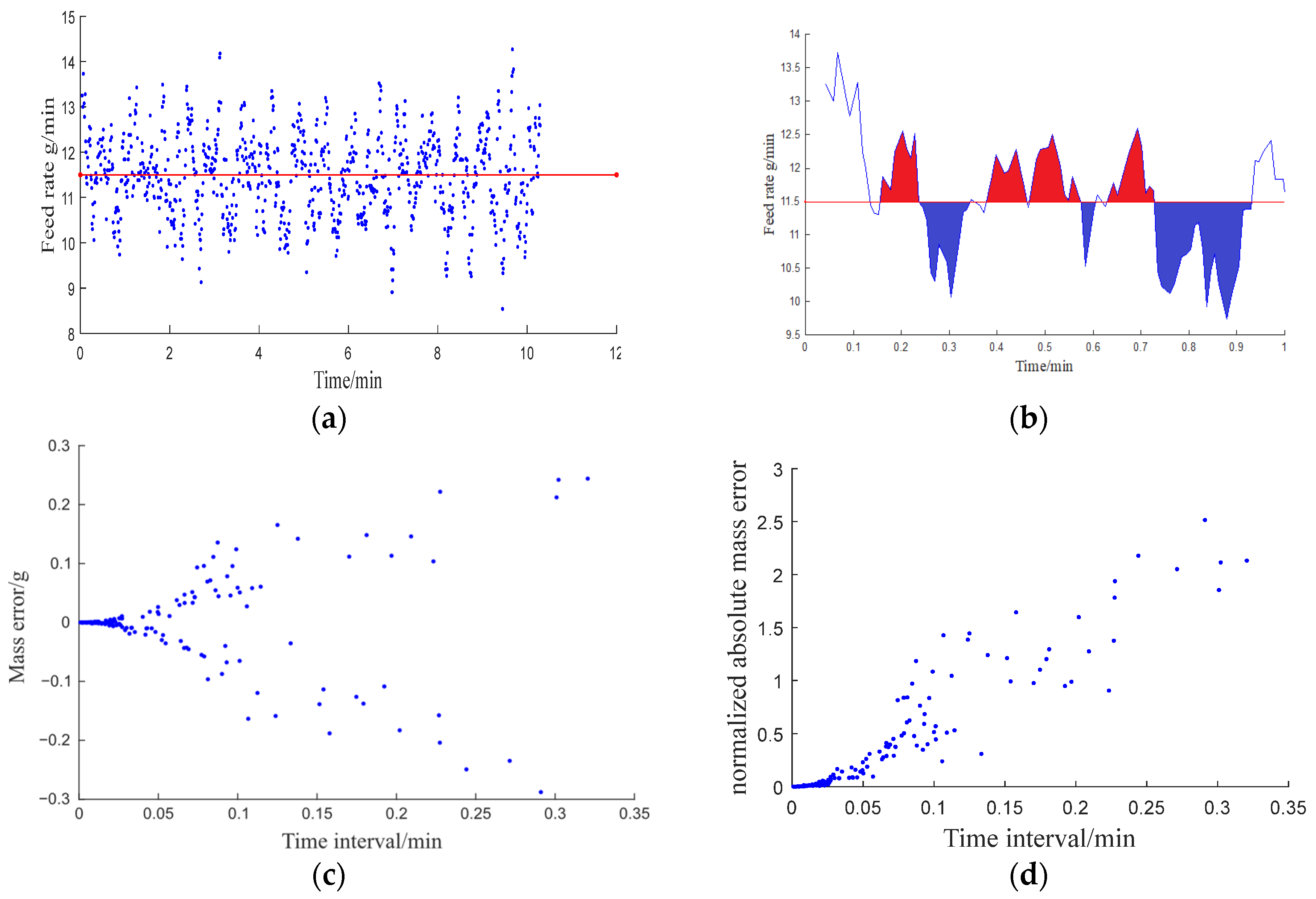

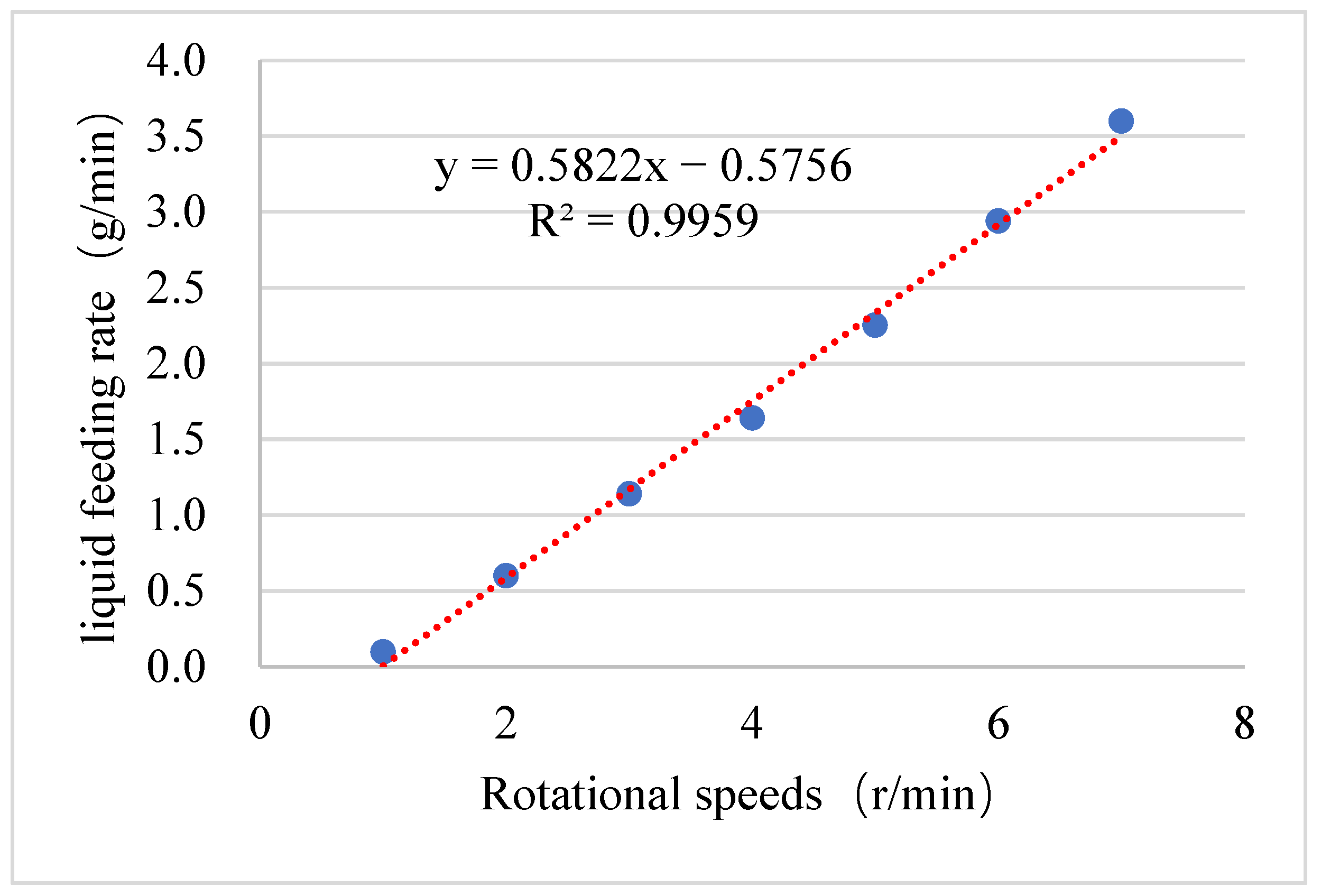

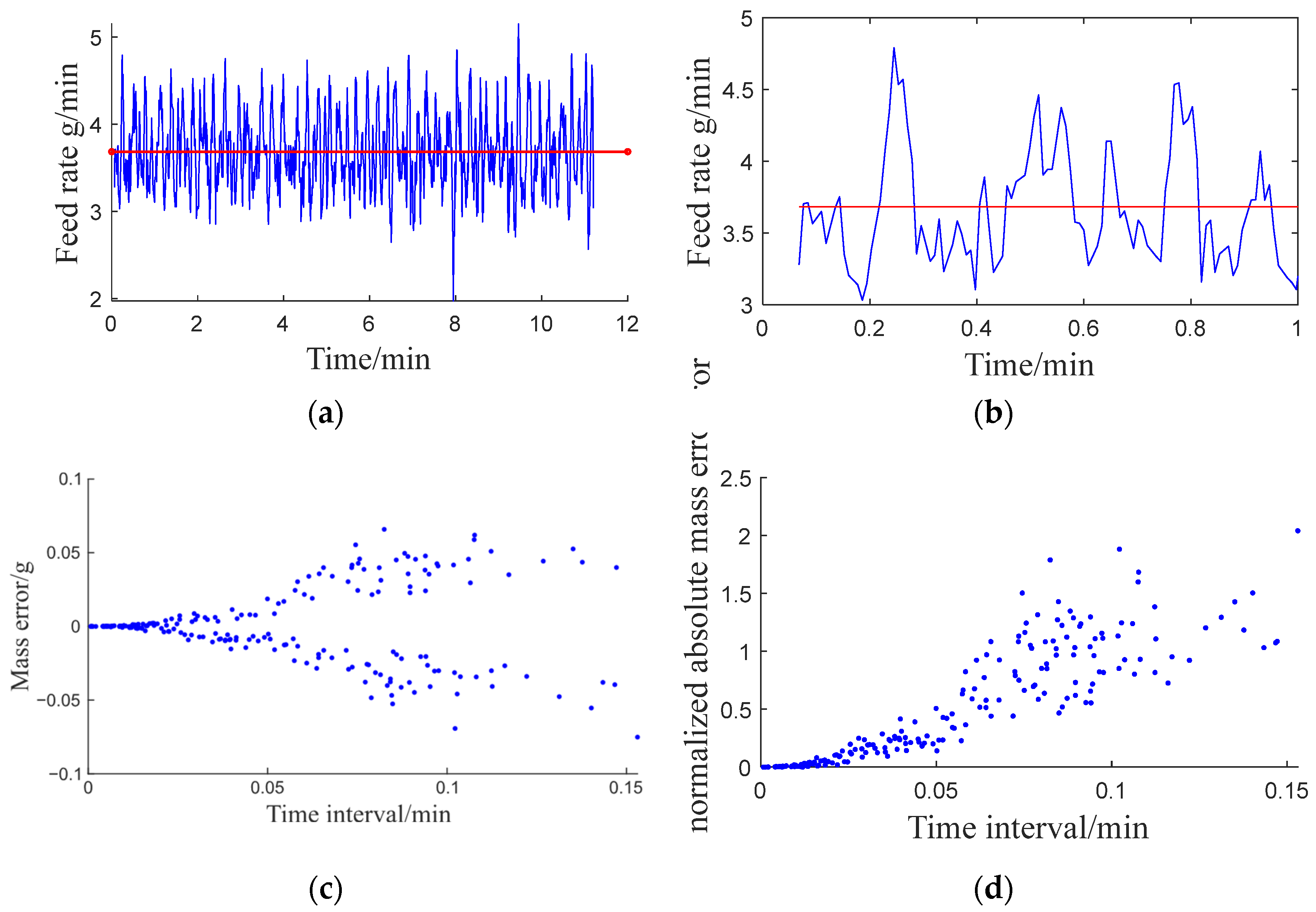

3.1. Calibration and Error Analysis of Powder Feeding Rate and Liquid Feeding Rate

3.1.1. Calibration and Error Analysis of Powder Feeding Rate

3.1.2. Calibration and Error Analysis of Liquid Feeding Rate

3.2. Calibration Between Tracer Concentration and Brightness Value

3.3. The Influence of Different Tracer Dosages on RTD

3.4. The Influence of Different Screw Speeds on the RTD

3.5. The Influence of Different Throughputs on the RTD

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.; Tian, G.; Qu, H. Pharmaceutical Application of Process Understanding and Optimization Techniques: A Review on the Continuous Twin-Screw Wet Granulation. Biomedicines 2023, 11, 1923. [Google Scholar] [CrossRef]

- Peeters, M.; Jiménez, A.A.B.; Matsunami, K.; Ghijs, M.; dos Santos Schultz, E.; Roudgar, M.; Vigh, T.; Stauffer, F.; Nopens, I.; De Beer, T. Analysis of the effect of formulation properties and process parameters on granule formation in twin-screw wet granulation. Int. J. Pharm. 2024, 650, 123671. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, T.; Kashani-Rahimi, S.; Zhang, F. A review of twin screw wet granulation mechanisms in relation to granule attributes. Drug Dev. Ind. Pharm. 2021, 47, 349–360. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Tian, G.; Qu, H. Application of I-Optimal Design for Modeling and Optimizing the Operational Parameters of Ibuprofen Granules in Continuous Twin-Screw Wet Granulation. Biomedicines 2023, 11, 2030. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Vercruysse, J.; Toiviainen, M.; Panouillot, P.-E.; Juuti, M.; Vanhoorne, V.; Vervaet, C.; Remon, J.P.; Gernaey, K.V.; De Beer, T.; et al. Mixing and transport during pharmaceutical twin-screw wet granulation: Experimental analysis via chemical imaging. Eur. J. Pharm. Biopharm. 2014, 87, 279–289. [Google Scholar] [CrossRef] [PubMed]

- Muddu, S.V.; Kotamarthy, L.; Ramachandran, R. A Semi-Mechanistic Prediction of Residence Time Metrics in Twin Screw Granulation. Pharmaceutics 2021, 13, 393. [Google Scholar] [CrossRef]

- Tanimura, S.; Singh, R.; Román-Ospino, A.D.; Ierapetritou, M. Residence time distribution modelling and in line monitoring of drug concentration in a tablet press feed frame containing dead zones. Int. J. Pharm. 2021, 592, 120048. [Google Scholar] [CrossRef]

- Lee, S.L.; O’Connor, T.F.; Yang, X.; Cruz, C.N.; Chatterjee, S.; Madurawe, R.D.; Moore, C.M.V.; Yu, L.X.; Woodcock, J. Modernizing Pharmaceutical Manufacturing: From Batch to Continuous Production. J. Pharm. Innov. 2015, 10, 191–199. [Google Scholar] [CrossRef]

- Rodrigues, A.E. Residence time distribution (RTD) revisited. Chem. Eng. Sci. 2021, 230, 116188–116204. [Google Scholar] [CrossRef]

- Seem, T.C.; Rowson, N.A.; Ingram, A.; Huang, Z.; Yu, S.; de Matas, M.; Gabbott, I.; Reynolds, G.K. Twin screw granulation—A literature review. Powder Technol. 2015, 276, 89–102. [Google Scholar] [CrossRef]

- Arthur, T.B.; Rahmanian, N. Process Simulation of Twin-Screw Granulation: A Review. Pharmaceutics 2024, 16, 706. [Google Scholar] [CrossRef]

- Hurley, S.; Tantuccio, A.; Escotet-Espinoza, M.S.; Flamm, M.; Metzger, M. Development and use of a residence time distribution (RTD) model control strategy for a continuous manufacturing drug product pharmaceutical process. Pharmaceutics 2022, 14, 355. [Google Scholar] [CrossRef] [PubMed]

- Haser, A.; Kittikunakorn, N.; Dippold, E.; DiNunzio, J.C.; Blincoe, W. Continuous Twin-Screw wet granulation process with In-Barrel drying and NIR setup for Real-Time Moisture Monitoring. Int. J. Pharm. 2023, 630, 122377–122387. [Google Scholar] [CrossRef] [PubMed]

- Galata, D.L.; Meszaros, L.A.; Ficzere, M.; Vass, P.; Nagy, B.; Szabo, E.; Domokos, A.; Farkas, A.; Csontos, I.; Marosi, G.; et al. Continuous blending monitored and feedback controlled by machine vision-based PAT tool. J. Pharm. Biomed. Anal. 2021, 196, 113902. [Google Scholar] [CrossRef] [PubMed]

- Pedersen, T.; Karttunen, A.-P.; Korhonen, O.; Wu, J.X.; Naelapää, K.; Skibsted, E.; Rantanen, J. Determination of residence time distribution in a continuous powder mixing process with supervised and unsupervised modeling of in-line near infrared (NIR) spectroscopic data. J. Pharm. Sci. 2021, 110, 1259–1269. [Google Scholar] [CrossRef]

- Lin, L.; Yin, Y.; Li, Z.; Xu, H.; Hessel, V.; Ostrikov, K.K. Continuous microflow synthesis of fluorescent phosphorus and nitrogen co-doped carbon quantum dots. Chem. Eng. Res. Des. 2022, 178, 395–404. [Google Scholar] [CrossRef]

- Lee, K.T.; Ingram, A.; Rowson, N.A. Twin screw wet granulation: The study of a continuous twin screw granulator using Positron Emission Particle Tracking (PEPT) technique. Eur. J. Pharm. Biopharm. 2012, 81, 666–673. [Google Scholar] [CrossRef]

- Deetman, A.; Bos, D.; Blaakmeer, J.; Salet, T.; Lucas, S. An in-line dye tracer experiment to measure the residence time in continuous concrete processing. Mater. Struct. 2024, 57, 104. [Google Scholar] [CrossRef]

- Ficzere, M.; Mészáros, L.A.; Madarász, L.; Novák, M.; Nagy, Z.K.; Galata, D.L. Indirect monitoring of ultralow dose API content in continuous wet granulation and tableting by machine vision. Int. J. Pharm. 2021, 607, 121008. [Google Scholar] [CrossRef]

- Kumar, A.; Ganjyal, G.; Jones, D.; Hanna, A. Digital image processing for measurement of residence time distribution in a laboratory extruder. J. Food Eng. 2006, 75, 237–244. [Google Scholar] [CrossRef]

- Koschan, A.; Abidi, M. Color spaces and color distances. Digit. Color Image Process. 2008, 1, 37–70. [Google Scholar]

- León, K.; Mery, D.; Pedreschi, F.; León, J. Color measurement in L*a*b* units from RGB digital images. Food Res. Int. 2006, 39, 1084–1091. [Google Scholar] [CrossRef]

- Ficarella, A.; Milanese, M.; Laforgia, D. Numerical study of the extrusion process in cereals production: Part I. Fluid-dynamic analysis of the extrusion system. J. Food Eng. 2006, 73, 103–111. [Google Scholar] [CrossRef]

- Tu, W.D.; Ingram, A.; Seville, J. Regime map development for continuous twin screw granulation. Chem. Eng. Sci. 2013, 87, 315–326. [Google Scholar] [CrossRef]

- Unlu, E.; Faller, J.F. RTD in twin-screw food extrusion. J. Food Eng. 2002, 53, 115–131. [Google Scholar] [CrossRef]

| Tracer Dosages/mg | tm/s | σ2/s2 | σθ2 |

|---|---|---|---|

| 1.00 | 113 | 7939 | 0.62 |

| 3.00 | 77 | 2673 | 0.46 |

| 5.00 | 106 | 6396 | 0.57 |

| Screw Speed (r/min) | tm/s | σ2/s2 | σθ2 |

|---|---|---|---|

| 150 | 111 | 4996 | 0.40 |

| 200 | 103 | 5451 | 0.52 |

| 250 | 102 | 5746 | 0.55 |

| Opening Percentage of Volumetric Feeder (%) | Peristaltic Pump Speed (r/min) | L/S | Throughput (g/min) | tm/s | σ2/s2 | σθ2 |

|---|---|---|---|---|---|---|

| 40 | 4.1 | 0.14 | 10.79 | 127 | 9392 | 0.58 |

| 60 | 6 | 0.14 | 16.48 | 84 | 3327 | 0.47 |

| 80 | 7.5 | 0.14 | 22.16 | 73 | 2022 | 0.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Tian, G.; Tian, Y.; Qu, H. Development of a Rapid Method for Residence Time Distribution Measurement in Twin-Screw Wet Granulation Based on Image Processing with Lab Color Space. Pharmaceutics 2025, 17, 929. https://doi.org/10.3390/pharmaceutics17070929

Zhao J, Tian G, Tian Y, Qu H. Development of a Rapid Method for Residence Time Distribution Measurement in Twin-Screw Wet Granulation Based on Image Processing with Lab Color Space. Pharmaceutics. 2025; 17(7):929. https://doi.org/10.3390/pharmaceutics17070929

Chicago/Turabian StyleZhao, Jie, Geng Tian, Ying Tian, and Haibin Qu. 2025. "Development of a Rapid Method for Residence Time Distribution Measurement in Twin-Screw Wet Granulation Based on Image Processing with Lab Color Space" Pharmaceutics 17, no. 7: 929. https://doi.org/10.3390/pharmaceutics17070929

APA StyleZhao, J., Tian, G., Tian, Y., & Qu, H. (2025). Development of a Rapid Method for Residence Time Distribution Measurement in Twin-Screw Wet Granulation Based on Image Processing with Lab Color Space. Pharmaceutics, 17(7), 929. https://doi.org/10.3390/pharmaceutics17070929