Influence of Talc Substitution with Starches from Different Botanical Origins on Rheological and Absorption Properties of Stiff Zinc Oxide Paste Formulations

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Zinc Oxide Paste Formulation Design and Preparation Method

2.3. Rheological Studies

2.4. Sorption Properties Measurement

2.5. Statistical Analysis

3. Results

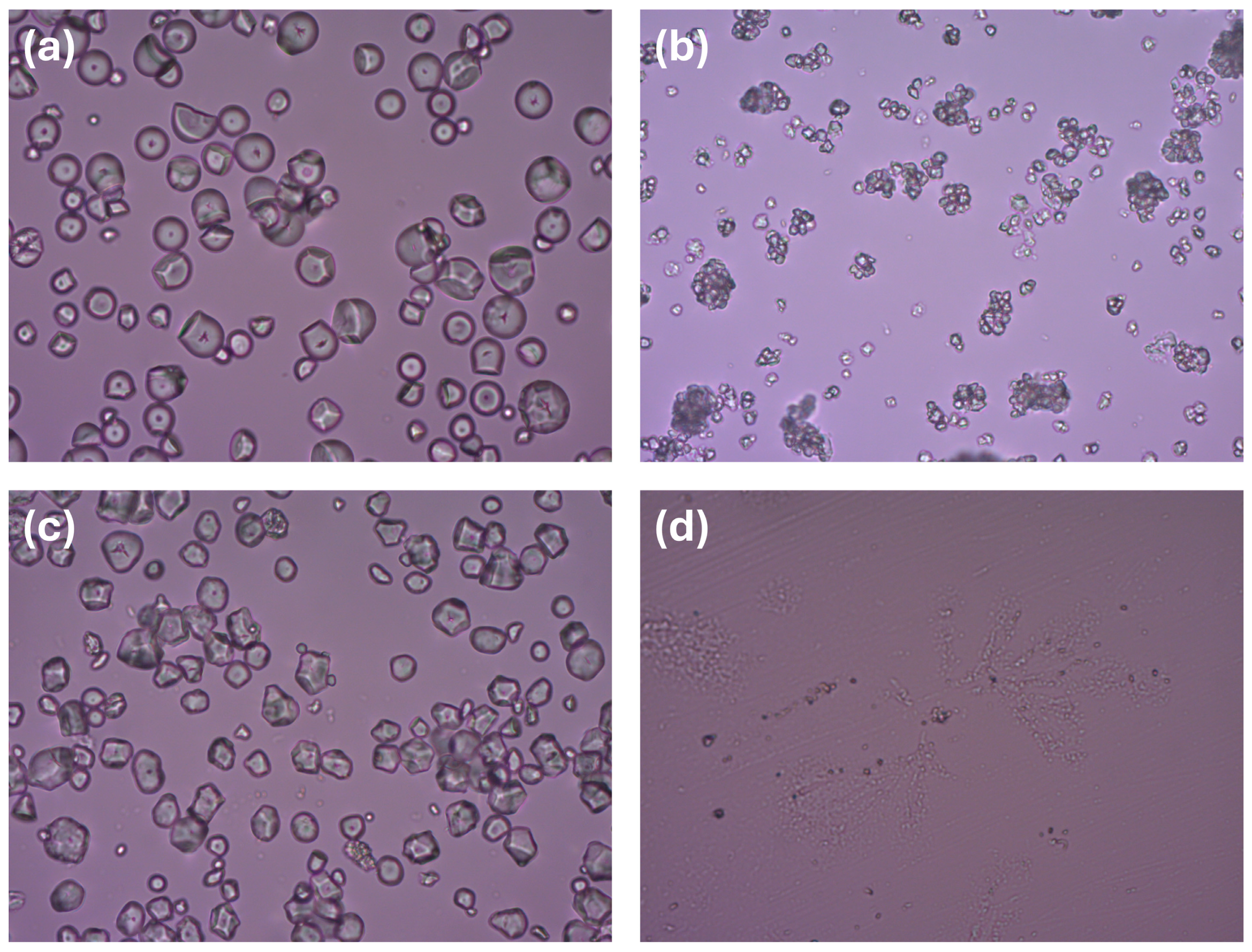

3.1. Visual Inspection of Zinc Oxide Pastes

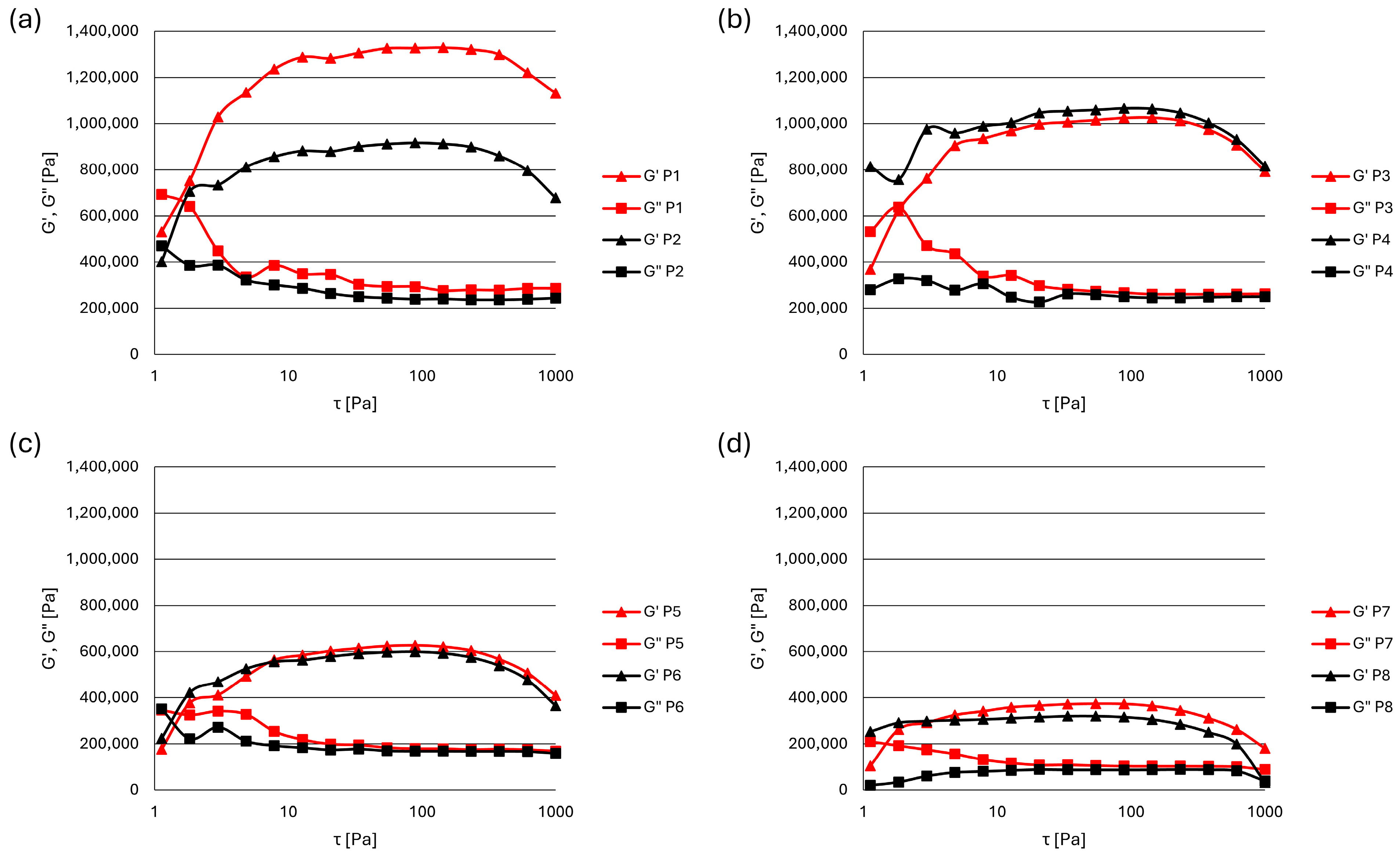

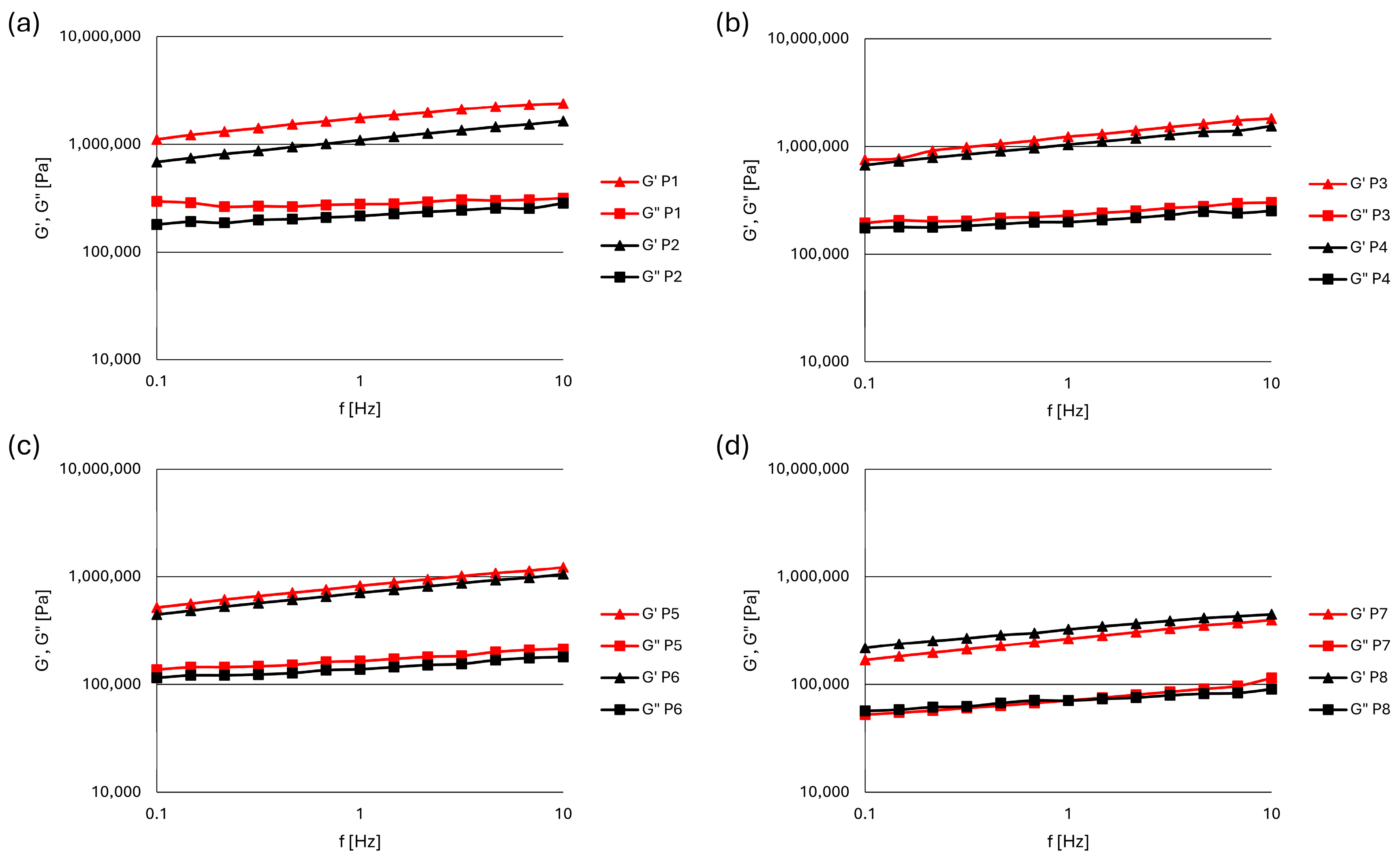

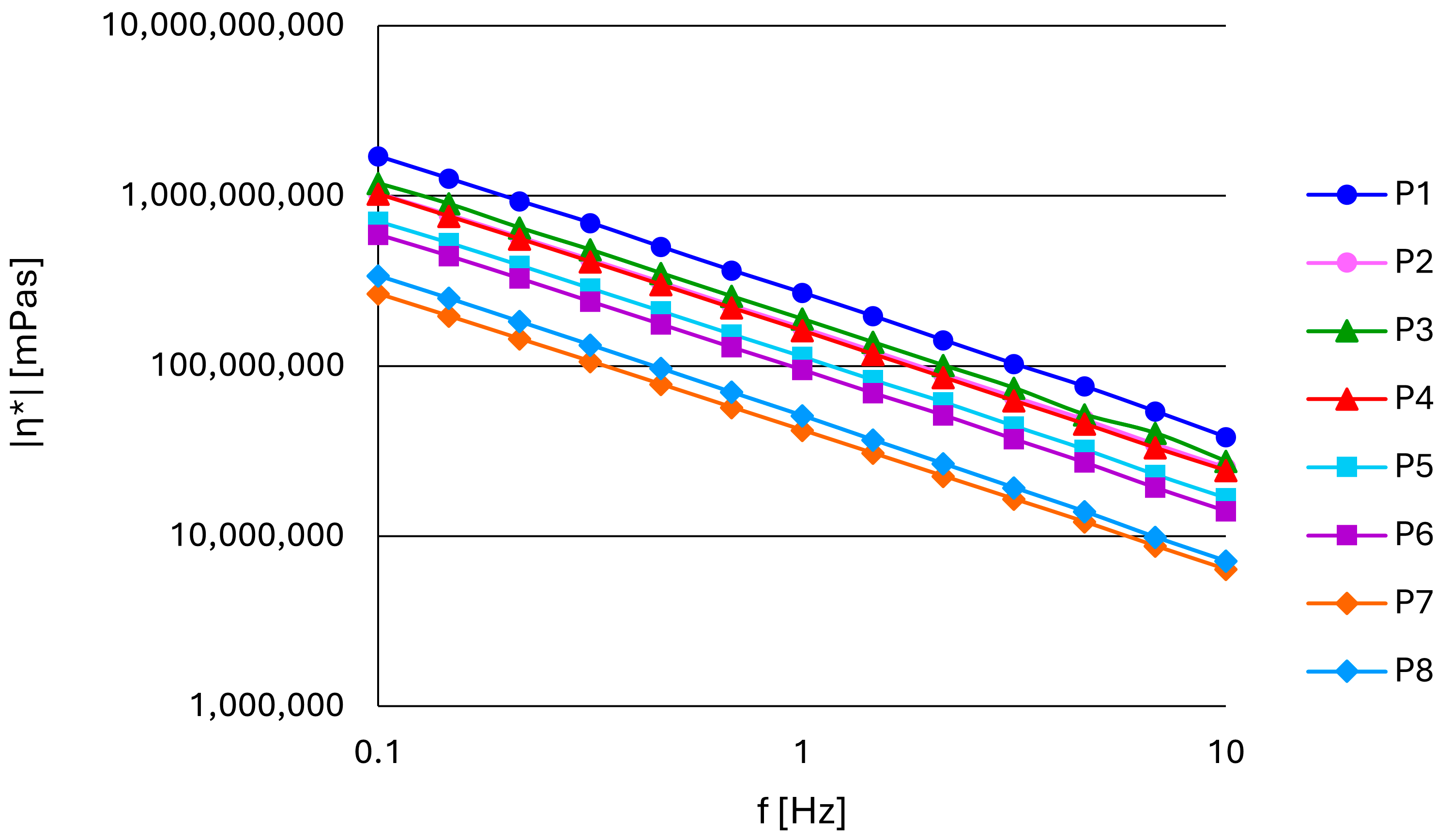

3.2. Rheological Properties of Zinc Oxide Pastes

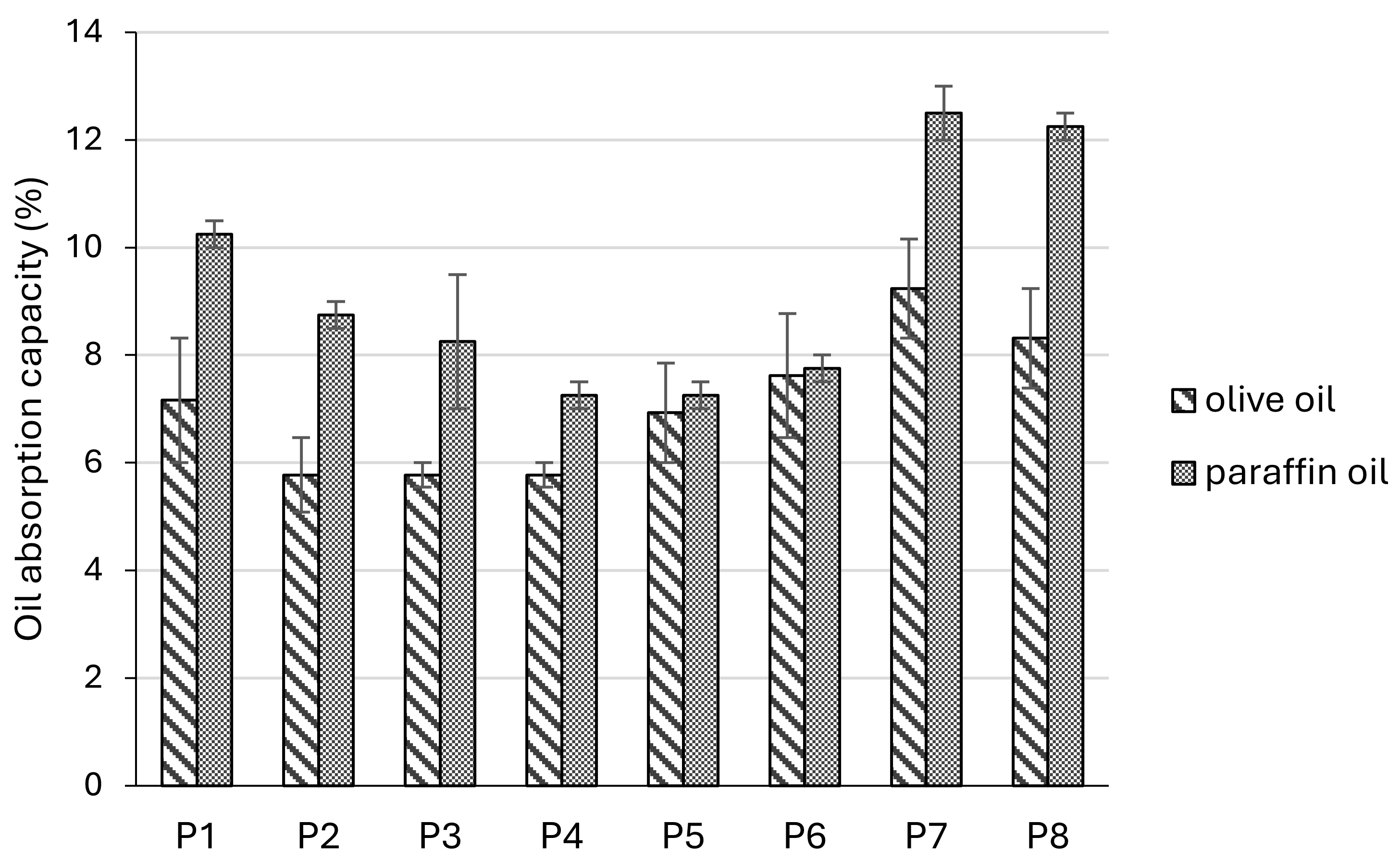

3.3. Sorption Properties of Zinc Oxide Pastes

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chang, R.-K.; Raw, A.; Lionberger, R.; Yu, L. Generic Development of Topical Dermatologic Products: Formulation Development, Process Development, and Testing of Topical Dermatologic Products. AAPS J. 2013, 15, 41–52. [Google Scholar] [CrossRef] [PubMed]

- Stein Gold, L.; Kwong, P.; Draelos, Z.; Arekapudi, K.L.; Levy-Hacham, O.; Erlich, M.; Desai, S.R. Impact of Topical Vehicles and Cutaneous Delivery Technologies on Patient Adherence and Treatment Outcomes in Acne and Rosacea. J. Clin. Aesthet. Dermatol. 2023, 16, 26–34. [Google Scholar] [PubMed]

- Oliveira, R.; Almeida, I.F. Patient-Centric Design of Topical Dermatological Medicines. Pharmaceuticals 2023, 16, 617. [Google Scholar] [CrossRef] [PubMed]

- Juch, R.D.; Rufli, T.; Surber, C. Pastes: What do they contain? How do they work? Dermatology 1994, 189, 373–377. [Google Scholar] [CrossRef]

- Wohlrab, J. Topical preparations and their use in dermatology. J. Dtsch. Dermatol. Ges. 2016, 14, 1061–1070. [Google Scholar] [CrossRef]

- Gupta, M.; Mahajan, V.K.; Mehta, K.S.; Chauhan, P.S. Zinc therapy in dermatology: A review. Dermatol. Res. Pract. 2014, 2014, 709152. [Google Scholar] [CrossRef]

- United States Pharmacopeial Convention. The United States Pharmacopeia and the National Formulary; United States Pharmacopeial Convention: Rockville, MD, USA, 2021. [Google Scholar]

- Deutscher Apotheker Verlag. Deutsches Arzneibuch (DAB); Medpharm GmbH Scientific Publishers: Stuttgart, Germany, 2020. [Google Scholar]

- Joint Formulary Committee. British National Formulary, 88; BMJ Group and Pharmaceutical Press: London, UK, 2022. [Google Scholar]

- Farmaceutsko društvo Srbije. Magistralne Formule; Farmaceutsko društvo Srbije: Belgrade, Serbia, 2008. [Google Scholar]

- Shimizu, I.; MacFarlane, D. Zinc oxide paste as sunscreen in the postoperative period. Dermatol. Surg. 2012, 38, 965–966. [Google Scholar] [CrossRef]

- Sogne, V.; Meier, F.; Klein, T.; Contado, C. Investigation of zinc oxide particles in cosmetic products by means of centrifugal and asymmetrical flow field-flow fractionation. J. Chromatogr. A 2017, 1515, 196–208. [Google Scholar] [CrossRef]

- Atherton, D.J. A review of the pathophysiology, prevention and treatment of irritant diaper dermatitis. Curr. Med. Res. Opin. 2004, 20, 645–649. [Google Scholar] [CrossRef]

- Khattar, J.A.; Musharrafieh, U.M.; Tamim, H.; Hamadeh, G.N. Topical zinc oxide vs. salicylic acid-lactic acid combination in the treatment of warts. Int. J. Dermatol. 2007, 46, 427–430. [Google Scholar] [CrossRef]

- Lansdown, A.B.; Mirastschijski, U.; Stubbs, N.; Scanlon, E.; Agren, M.S. Zinc in wound healing: Theoretical, experimental, and clinical aspects. Wound Repair Regen. 2007, 15, 2–16. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Dong, K.; Guo, M.; Lian, Z.; Zhang, B.; Wei, W. Preparation of Zinc Oxide Nanoparticles-Based Starch Paste and its Antifungal Performance as a Paper Adhesive. Starch-Stärke 2018, 70, 1700211. [Google Scholar] [CrossRef]

- Joint Formulary Committee. British National Formulary 83; BMJ Publishing and the Royal Pharmaceutical Society: London, UK, 2022. [Google Scholar]

- Österreichische Arzneibuchkommission. Österreichisches Arzneibuch (ÖAB); Verlag Österreich GmbH: Wien, Austria, 2012. [Google Scholar]

- López-Galindo, A.; Viseras, C.; Cerezo, P. Compositional, technical and safety specifications of clays to be used as pharmaceutical and cosmetic products. Appl. Clay Sci. 2007, 36, 51–63. [Google Scholar] [CrossRef]

- Ajayi, O.M.; Amin, S. Flow and performance effects of talc alternatives on powder cosmetic formulations. Int. J. Cosmet. Sci. 2021, 43, 588–600. [Google Scholar] [CrossRef]

- Pierce, J.S.; Riordan, A.S.; Miller, E.W.; Gaffney, S.H.; Hollins, D.M. Evaluation of the presence of asbestos in cosmetic talcum products. Inhal. Toxicol. 2017, 29, 443–456. [Google Scholar] [CrossRef]

- Moline, J.; Patel, K.; Frank, A.L. Exposure to cosmetic talc and mesothelioma. J. Occup. Med. Toxicol. 2023, 18, 1. [Google Scholar] [CrossRef]

- Wentzensen, N.; O’Brien, K.M. Talc, body powder, and ovarian cancer: A summary of the epidemiologic evidence. Gynecol. Oncol. 2021, 163, 199–208. [Google Scholar] [CrossRef]

- Steffen, J.E.; Tran, T.; Yimam, M.; Clancy, K.M.; Bird, T.B.; Rigler, M.; Longo, W.; Egilman, D.S. Serous Ovarian Cancer Caused by Exposure to Asbestos and Fibrous Talc in Cosmetic Talc Powders-A Case Series. J. Occup. Environ. Med. 2020, 62, e65–e77. [Google Scholar] [CrossRef]

- Stoiber, T.; Fitzgerald, S.; Leiba, N.S. Asbestos Contamination in Talc-Based Cosmetics: An Invisible Cancer Risk. Environ. Health Insights 2020, 14, 1178630220976558. [Google Scholar] [CrossRef]

- United States Food and Drug Administration. Talc. Available online: https://www.fda.gov/cosmetics/cosmetic-ingredients/talc#2021testing (accessed on 6 October 2023).

- Rosner, D.; Markowitz, G. Baby Powders and the Precautionary Principle. Am. J. Public Health 2020, 110, 1378–1379. [Google Scholar] [CrossRef]

- American Cancer Society. Talcum Powder and Cancer. Available online: https://www.cancer.org/cancer/risk-prevention/chemicals/talcum-powder-and-cancer.html (accessed on 6 October 2023).

- Research and Markets. Starch—Global Strategic Business Report. Available online: https://www.researchandmarkets.com/reports/2832332/starch-global-strategic-business-report (accessed on 20 December 2023).

- Copeland, L.; Blazek, J.; Salman, H.; Tang, M.C. Form and functionality of starch. Food Hydrocoll. 2009, 23, 1527–1534. [Google Scholar] [CrossRef]

- Cornejo-Ramírez, Y.I.; Martínez-Cruz, O.; Del Toro-Sánchez, C.L.; Wong-Corral, F.J.; Borboa-Flores, J.; Cinco-Moroyoqui, F.J. The structural characteristics of starches and their functional properties. CYTA J. Food 2018, 16, 1003–1017. [Google Scholar] [CrossRef]

- Verma, D.K.; Srivastav, P.P. Isolation, modification, and characterization of rice starch with emphasis on functional properties and industrial application: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 6577–6604. [Google Scholar] [CrossRef]

- Builders, P.F.; Arhewoh, M.I. Pharmaceutical applications of native starch in conventional drug delivery. Starch-Stärke 2016, 68, 864–873. [Google Scholar] [CrossRef]

- Ali, A.; Skedung, L.; Burleigh, S.; Lavant, E.; Ringstad, L.; Anderson, C.D.; Wahlgren, M.; Engblom, J. Relationship between sensorial and physical characteristics of topical creams: A comparative study on effects of excipients. Int. J. Pharm. 2022, 613, 121370. [Google Scholar] [CrossRef]

- Benavent-Gil, Y.; Rosell, C.M. Morphological and physicochemical characterization of porous starches obtained from different botanical sources and amylolytic enzymes. Int. J. Biol. Macromol. 2017, 103, 587–595. [Google Scholar] [CrossRef]

- Lukic, M.; Jaksic, I.; Krstonosic, V.; Cekic, N.; Savic, S. A combined approach in characterization of an effective w/o hand cream: The influence of emollient on textural, sensorial and in vivo skin performance. Int. J. Cosmet. Sci. 2012, 34, 140–149. [Google Scholar] [CrossRef]

- Lee, J.; Lu, J.; Potanin, A.; Boyke, C. Prediction of Tactile Sensory Attributes of Facial Moisturizers by Rheology and Tribology. Biotribology 2021, 28, 100201. [Google Scholar] [CrossRef]

- Gilbert, L.; Savary, G.; Grisel, M.; Picard, C. Predicting sensory texture properties of cosmetic emulsions by physical measurements. Chemom. Intell. Lab. Syst. 2013, 124, 21–31. [Google Scholar] [CrossRef]

- Lukic, M.; Jaksic, I.; Krstonosic, V.; Dokic, L.; Savic, S. Effect of Small Change in Oil Phase Composition on Rheological and Textural Properties of w/o Emulsion. J. Texture Stud. 2013, 44, 34–44. [Google Scholar] [CrossRef]

- Korhonen, M.; Niskanen, H.; Kiesvaara, J.; Yliruusi, J. Determination of optimal combination of surfactants in creams using rheology measurements. Int. J. Pharm. 2000, 197, 143–151. [Google Scholar] [CrossRef] [PubMed]

- Akanny, E.; Kohlmann, C. Predicting tactile sensory attributes of personal care emulsions based on instrumental characterizations: A review. Int. J. Cosmet. Sci. 2024, 46, 1035–1063. [Google Scholar] [CrossRef] [PubMed]

- Adejokun, D.A.; Dodou, K. Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics 2020, 7, 2. [Google Scholar] [CrossRef]

- von Borries-Medrano, E.; Jaime-Fonseca, M.R.; Aguilar-Méndez, M.A. Tapioca starch-galactomannan systems: Comparative studies of rheological and textural properties. Int. J. Biol. Macromol. 2019, 122, 1173–1183. [Google Scholar] [CrossRef]

- Gleissle, W.; Hochstein, B. Validity of the Cox–Merz rule for concentrated suspensions. J. Rheol. 2003, 47, 897–910. [Google Scholar] [CrossRef]

- Ahuja, A.; Lee, R.; Latshaw, A.; Foster, P. Rheology of starch dispersions at high temperatures. J. Texture Stud. 2020, 51, 575–584. [Google Scholar] [CrossRef]

- Rhazi, L.; Méléard, B.; Daaloul, O.; Grignon, G.; Branlard, G.; Aussenac, T. Genetic and Environmental Variation in Starch Content, Starch Granule Distribution and Starch Polymer Molecular Characteristics of French Bread Wheat. Foods 2021, 10, 205. [Google Scholar] [CrossRef]

- Lindeboom, N.; Chang, P.; Tyler, R. Analytical, Biochemical and Physicochemical Aspects of Starch Granule Size, with Emphasis on Small Granule Starches: A Review. Starch-Stärke 2004, 56, 89–99. [Google Scholar] [CrossRef]

- Singh, N.; Kaur, S.; Isono, N.; Ichihashi, Y.; Noda, T.; Kaur, A.; Rana, J.C. Diversity in characteristics of starch amongst rice bean (Vigna umbellate) germplasm: Amylopectin structure, granules size distribution, thermal and rheology. Food Res. Int. 2012, 46, 194–200. [Google Scholar] [CrossRef]

- Bhat, F.M.; Riar, C.S. Effect of amylose, particle size & morphology on the functionality of starches of traditional rice cultivars. Int. J. Biol. Macromol. 2016, 92, 637–644. [Google Scholar] [CrossRef]

- Ai, Y.; Jane, J.-l. Chapter 3—Understanding Starch Structure and Functionality. In Starch in Food, 2nd ed.; Sjöö, M., Nilsson, L., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 151–178. [Google Scholar]

- Mauro, R.R.; Vela, A.J.; Ronda, F. Impact of Starch Concentration on the Pasting and Rheological Properties of Gluten-Free Gels. Effects of Amylose Content and Thermal and Hydration Properties. Foods 2023, 12, 2281. [Google Scholar] [CrossRef] [PubMed]

- Qi, X.; Tester, R.F. Effect of native starch granule size on susceptibility to amylase hydrolysis. Starch-Stärke 2016, 68, 807–810. [Google Scholar] [CrossRef]

- Sun, D.; Yoo, B. Effect of tapioca starch addition on rheological, thermal, and gelling properties of rice starch. LWT-Food Sci. Technol. 2015, 64, 205–211. [Google Scholar] [CrossRef]

- Nuutila, K.; Eriksson, E. Moist Wound Healing with Commonly Available Dressings. Adv. Wound Care 2021, 10, 685–698. [Google Scholar] [CrossRef]

- Schirmer, M.; Höchstötter, A.; Jekle, M.; Arendt, E.; Becker, T. Physicochemical and morphological characterization of different starches with variable amylose/amylopectin ratio. Food Hydrocoll. 2013, 32, 52–63. [Google Scholar] [CrossRef]

- Yousif, E.I.; Gadallah, M.G.E.; Sorour, A.M. Physico-chemical and rheological properties of modified corn starches and its effect on noodle quality. Ann. Agric. Sci. 2012, 57, 19–27. [Google Scholar] [CrossRef]

- Chiotelli, E.; Meste, M. Effect of Small and Large Wheat Starch Granules on Thermomechanical Behavior of Starch. Cereal Chem. 2002, 79, 286–293. [Google Scholar] [CrossRef]

- Anggraini, V.; Sudarmonowati, E.; Hartati, N.S.; Suurs, L.; Visser, R.G.F. Characterization of Cassava Starch Attributes of Different Genotypes. Starch-Stärke 2009, 61, 472–481. [Google Scholar] [CrossRef]

- Rotenberg, B.; Patel, A.J.; Chandler, D. Molecular explanation for why talc surfaces can be both hydrophilic and hydrophobic. J. Am. Chem. Soc. 2011, 133, 20521–20527. [Google Scholar] [CrossRef]

- Bamford, E.; Grahn, A.; Århammar, C.; Ajaxon, I.; Annerén, C. Mesoporous magnesium carbonate for use in powder cosmetics. Int. J. Cosmet. Sci. 2021, 43, 57–67. [Google Scholar] [CrossRef]

- Palmeira-de-Oliveira, R.; Luís, C.; Gaspar, C.; Bogas, E.; Morgado, M.; Guardado, M.; Castelo Branco, M.; Fonseca, M.O.; Palmeira-de-Oliveira, A. Microbiological quality control of non-sterile compounded medicines prepared in a Portuguese hospital centre. Eur. J. Hosp. Pharm. 2016, 23, 228–232. [Google Scholar] [CrossRef] [PubMed]

- Sukamdi, D.; Dewinda, Z.; Damarwati, V.; Maziyyah, N.; Ningrum, D. Evaluation of physical and chemical stability of semi-solid preparations towards beyond-use date. Acta Pharm. Indo. 2024, 11, 9260. [Google Scholar] [CrossRef]

- USP Compounding Standards and Beyond-Use Dates (BUDs) [Fact Sheet]. Available online: https://www.usp.org/sites/default/files/usp/document/our-work/compounding/usp-bud-factsheet.pdf (accessed on 25 April 2025).

| Particle Size | P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | |

|---|---|---|---|---|---|---|---|---|---|

| Zinc oxide | 140 μM | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Tapioca starch | 140 μM | 25 | - | ||||||

| 355 μM | - | 25 | |||||||

| Rice starch | 140 μM | 25 | - | ||||||

| 355 μM | - | 25 | |||||||

| Maize starch | 140 μM | 25 | - | ||||||

| 355 μM | - | 25 | |||||||

| Talc | 140 μM | 25 | |||||||

| 355 μM | 25 | ||||||||

| Soft paraffin | - | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Formulation | tan δ * (G″/G′) | G′ Plateau [×105 Pa] | End of G′-Based LVR [Pa] | End of tan δ-Based LVR, τ0 [Pa] |

|---|---|---|---|---|

| P1 | 0.2221 | 13.060 | 846.6 | 736.7 |

| P2 | 0.2681 | 8.954 | 578.8 | 999.1 |

| P3 | 0.2694 | 10.030 | 630.9 | >1000 |

| P4 | 0.2450 | 10.430 | 592.4 | >1000 |

| P5 | 0.2946 | 6.109 | 445.2 | 630.5 |

| P6 | 0.2848 | 5.831 | 424.7 | 999.1 |

| P7 | 0.2827 | 3.676 | 292.5 | 331.6 |

| P8 | 0.2723 | 3.146 | 237.7 | 208.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaklan, D.; Davidović, N.; Milutinov, J.; Ćirin, D.; Krstonošić, V.; Pavlović, N. Influence of Talc Substitution with Starches from Different Botanical Origins on Rheological and Absorption Properties of Stiff Zinc Oxide Paste Formulations. Pharmaceutics 2025, 17, 627. https://doi.org/10.3390/pharmaceutics17050627

Zaklan D, Davidović N, Milutinov J, Ćirin D, Krstonošić V, Pavlović N. Influence of Talc Substitution with Starches from Different Botanical Origins on Rheological and Absorption Properties of Stiff Zinc Oxide Paste Formulations. Pharmaceutics. 2025; 17(5):627. https://doi.org/10.3390/pharmaceutics17050627

Chicago/Turabian StyleZaklan, Dragana, Nikola Davidović, Jovana Milutinov, Dejan Ćirin, Veljko Krstonošić, and Nebojša Pavlović. 2025. "Influence of Talc Substitution with Starches from Different Botanical Origins on Rheological and Absorption Properties of Stiff Zinc Oxide Paste Formulations" Pharmaceutics 17, no. 5: 627. https://doi.org/10.3390/pharmaceutics17050627

APA StyleZaklan, D., Davidović, N., Milutinov, J., Ćirin, D., Krstonošić, V., & Pavlović, N. (2025). Influence of Talc Substitution with Starches from Different Botanical Origins on Rheological and Absorption Properties of Stiff Zinc Oxide Paste Formulations. Pharmaceutics, 17(5), 627. https://doi.org/10.3390/pharmaceutics17050627