Electrospun Nanofiber and Cryogel of Polyvinyl Alcohol Transdermal Patch Containing Diclofenac Sodium: Preparation, Characterization and In Vitro Release Studies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

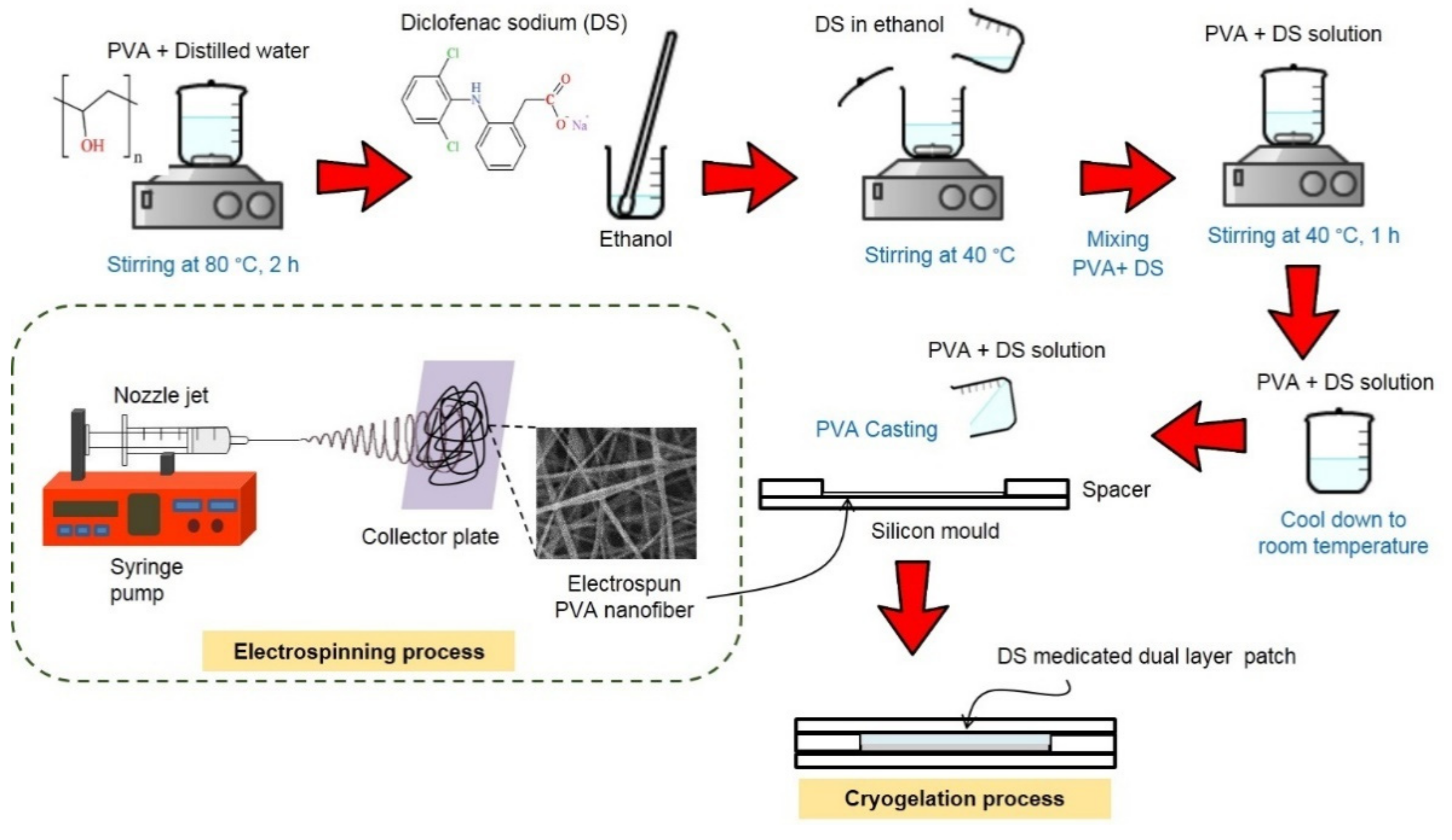

2.2.1. Production of the Electrospun PVA Nanofiber Membrane

2.2.2. Preparation of the PVA Cryogel Containing Diclofenac Sodium (DS)

2.2.3. Preparation of the Dual Layer PVA Patches

2.3. Morphological Observation

Morphology of Dual Layer PVA Patches (Unmedicated and DS-Medicated)

2.4. Physicochemical Characterization

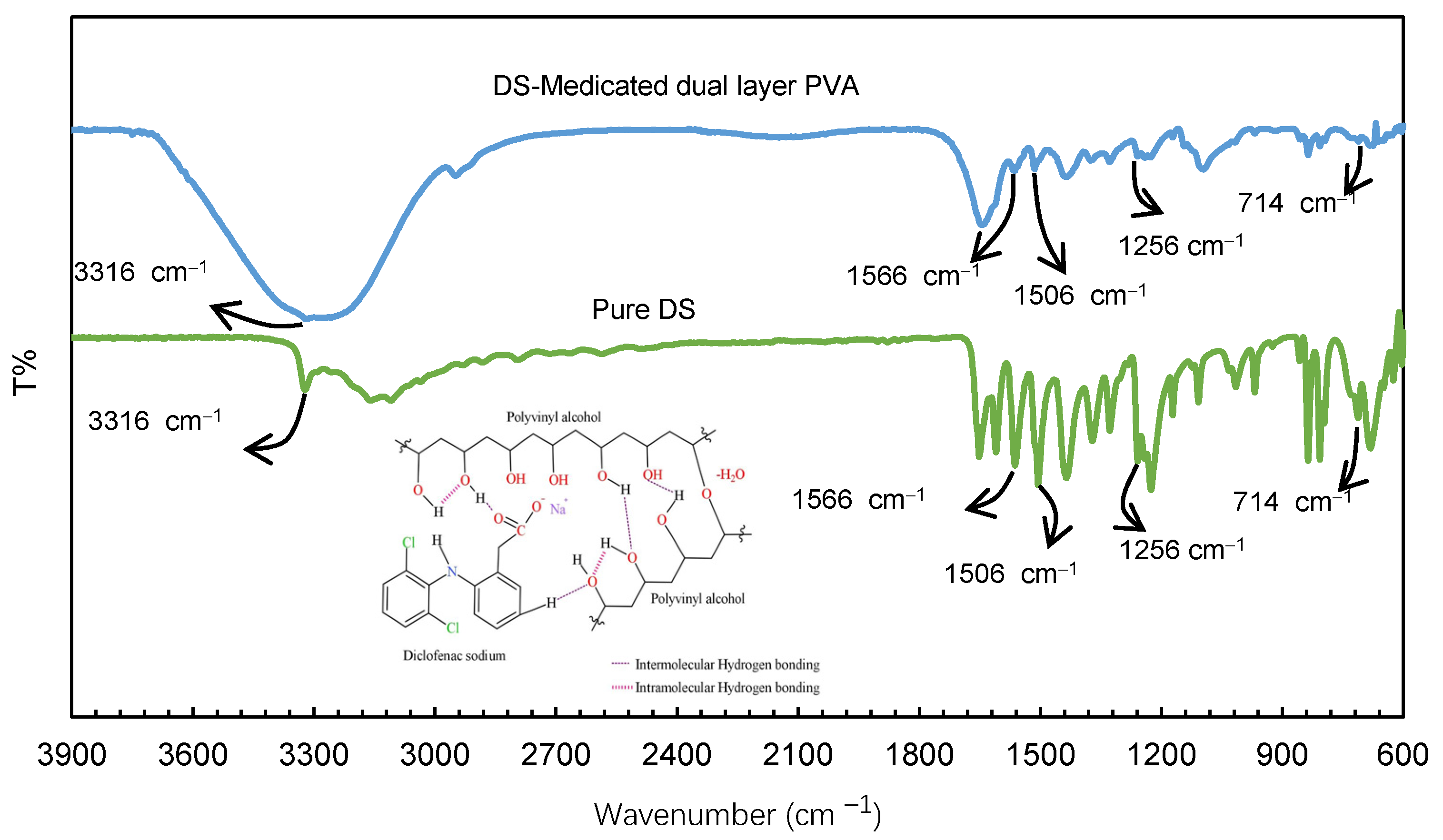

2.4.1. Fourier Transform Infrared Spectroscopy (FTIR) of the Dual Layer PVA Patch

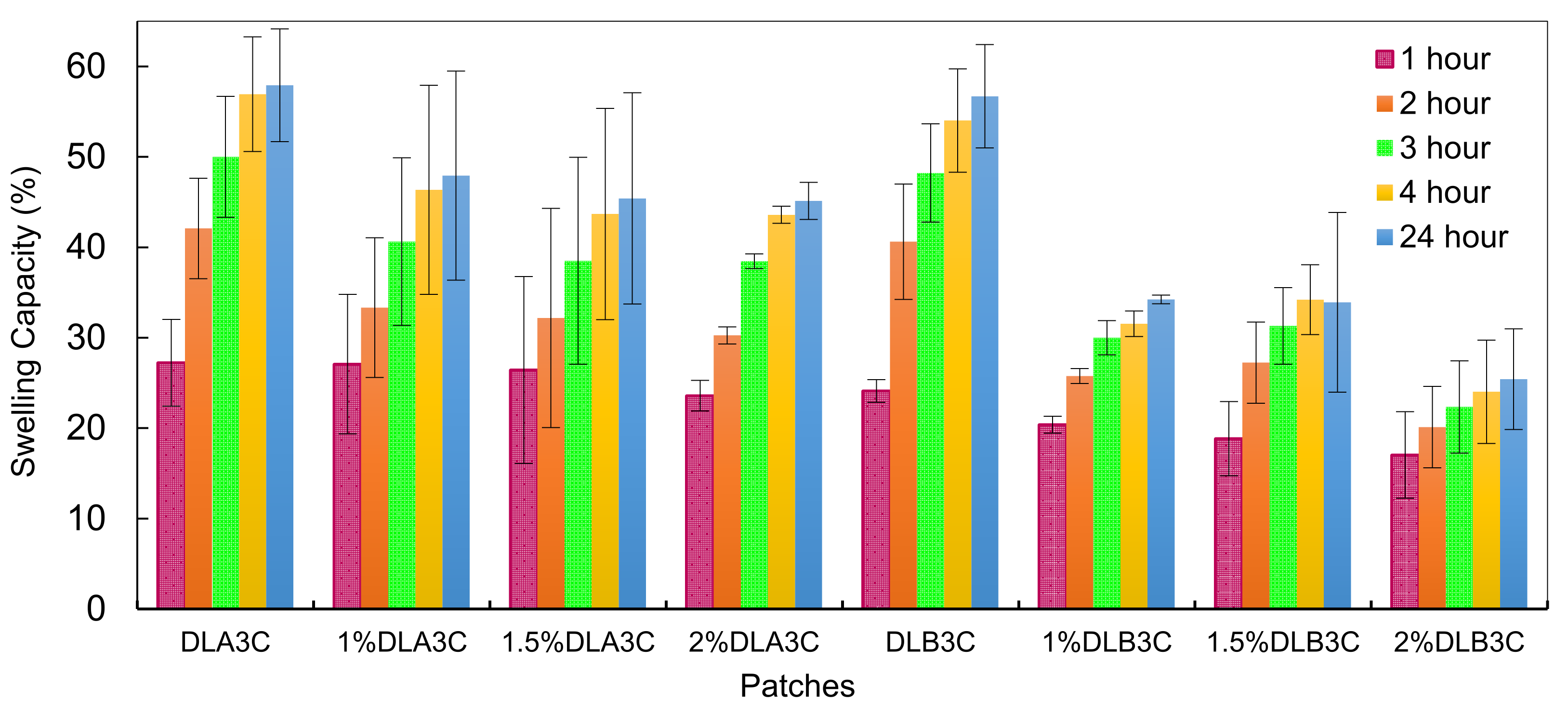

2.4.2. Swelling Capacity of the Dual Layer PVA Patches

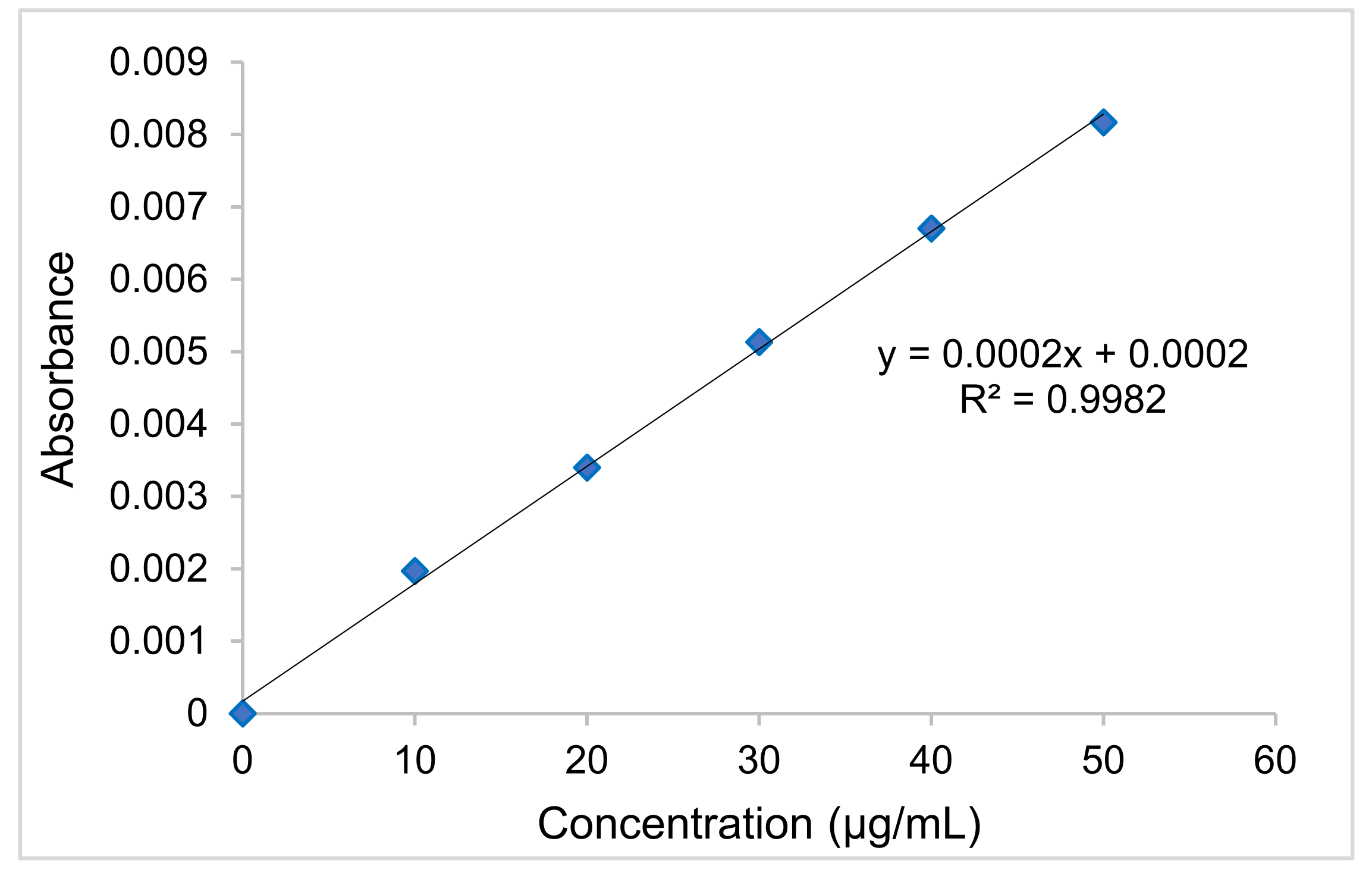

2.5. Preparation of Standard Calibration Curve of Diclofenac Sodium (DS)

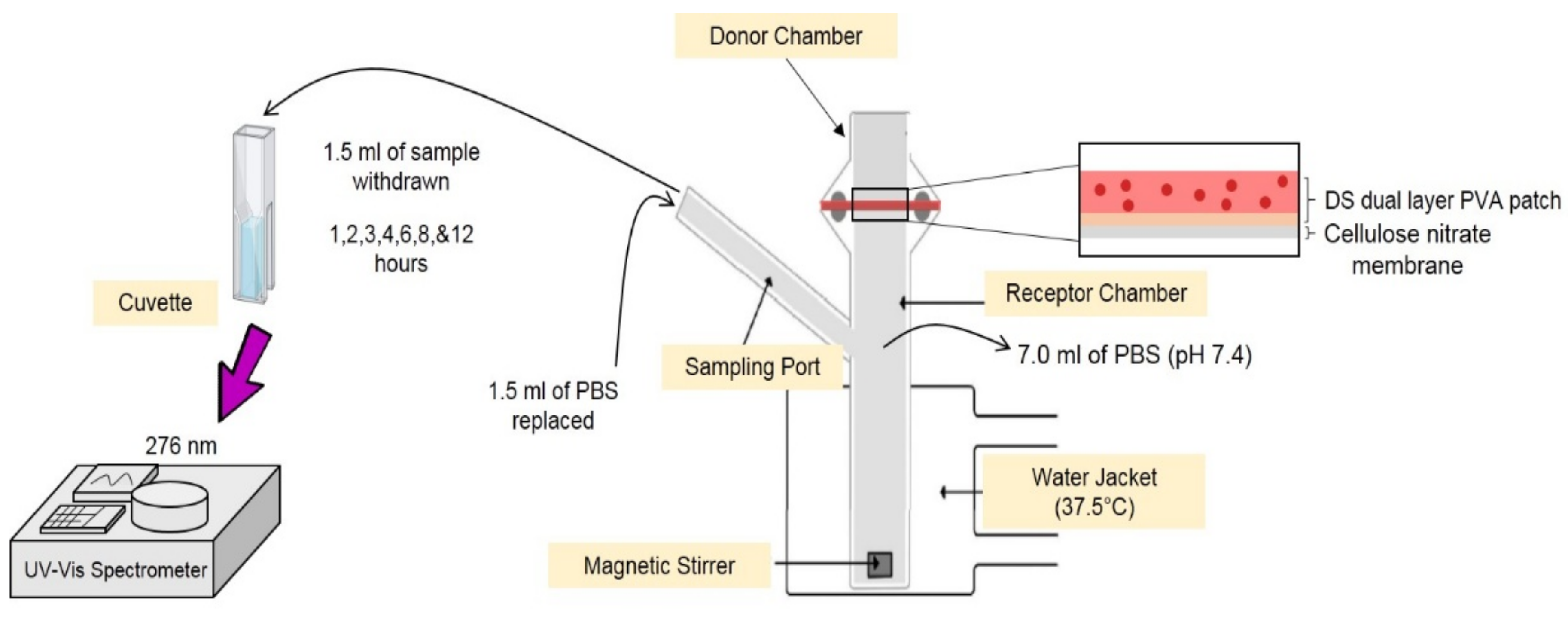

2.6. In Vitro Release Assessment of Diclofenac Sodium (DS) Dual Layer PVA Patches Using Franz Diffusion Cell

2.7. In Vitro Drug Release from Diclofenac Sodium (DS)-Medicated Dual Layer PVA

2.7.1. Calculation of Cumulative Amount of Drug Release

2.7.2. Data Analysis of the In Vitro Permeation of DS-Medicated Dual Layer PVA Patch

3. Results and Discussions

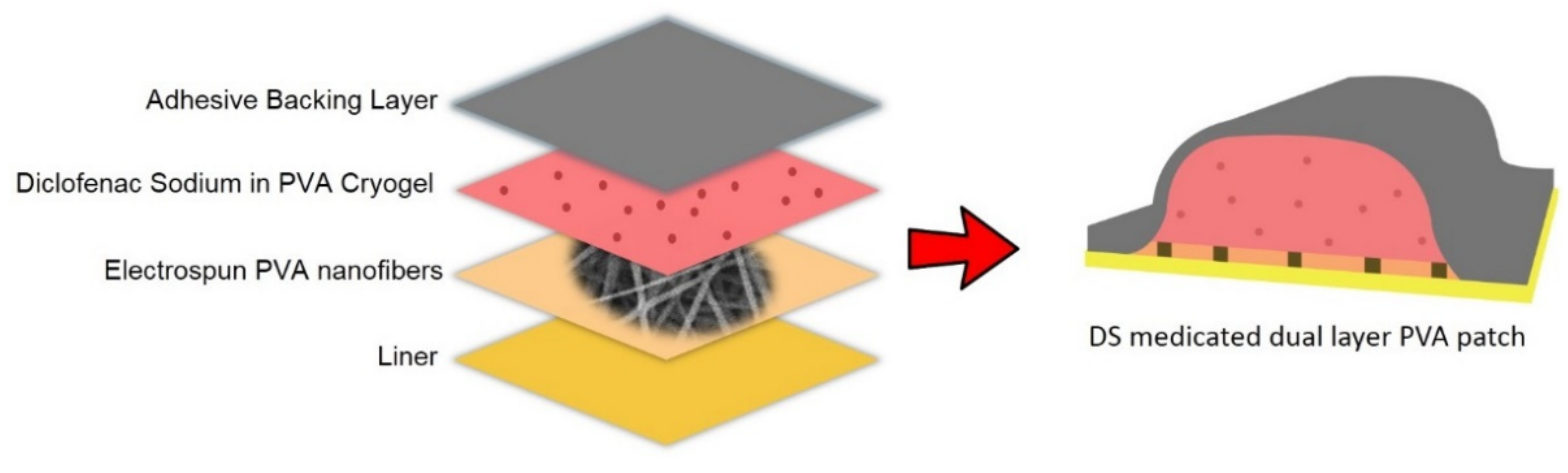

3.1. Preparation of Unmedicated and Diclofenac Sodium (DS)-Medicated Dual Layer PVA Patches

3.2. Morphological Structures of the Dual Layer PVA Patches

3.3. Compatibility of Diclofenac Sodium (DS) in the Dual layer PVA Patches

3.4. Effect of Nanofiber Thickness and Drug Loading Percentages on Swelling Capacity of the Dual Layer PVA Patches

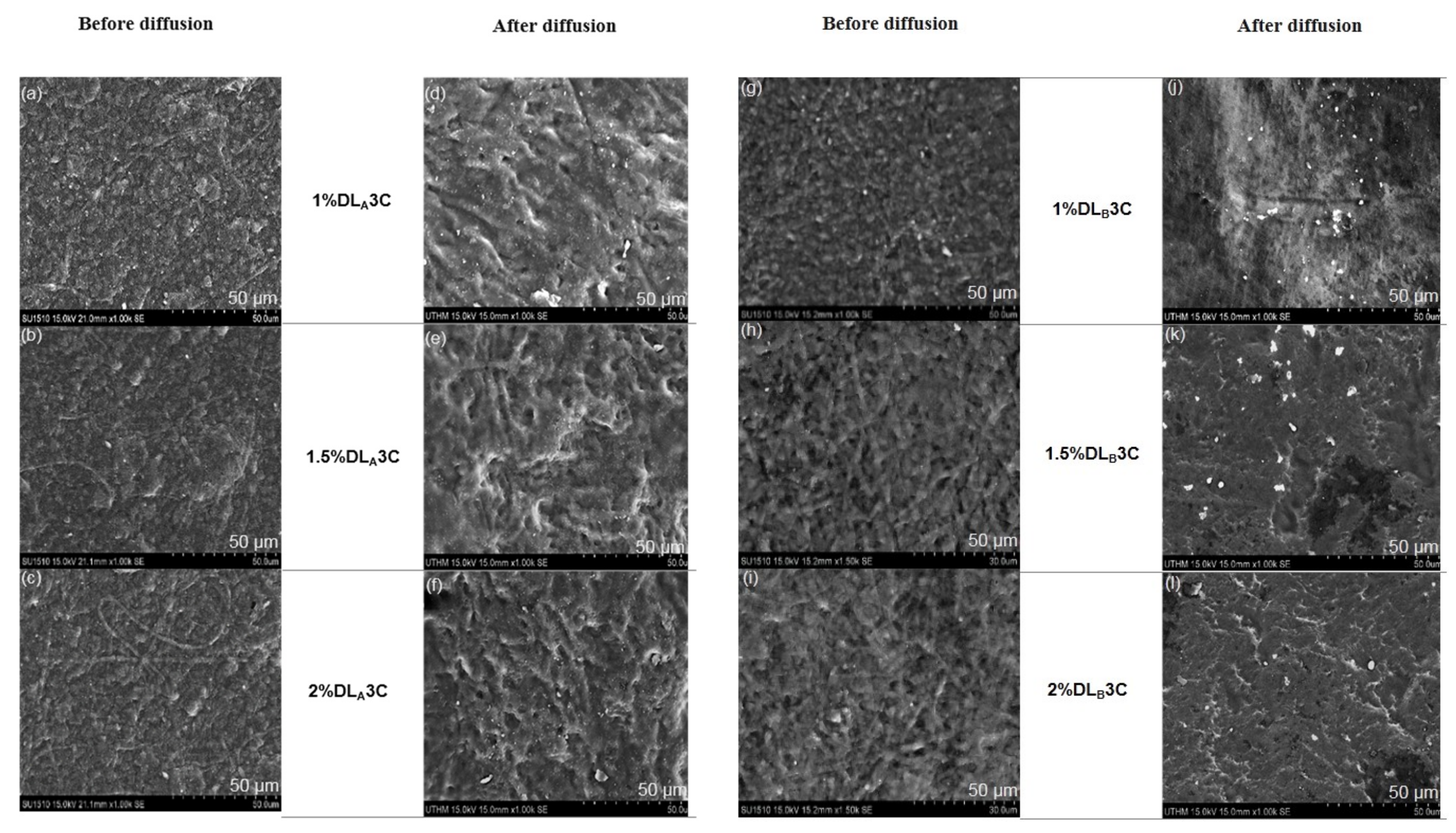

3.5. Morphological Structures of Electrospun PVA Nanofiber Layer Side after Diffusion Process

3.6. In Vitro Evaluation of Diclofenac Sodium (DS)-Medicated Dual Layer PVA Patches Release

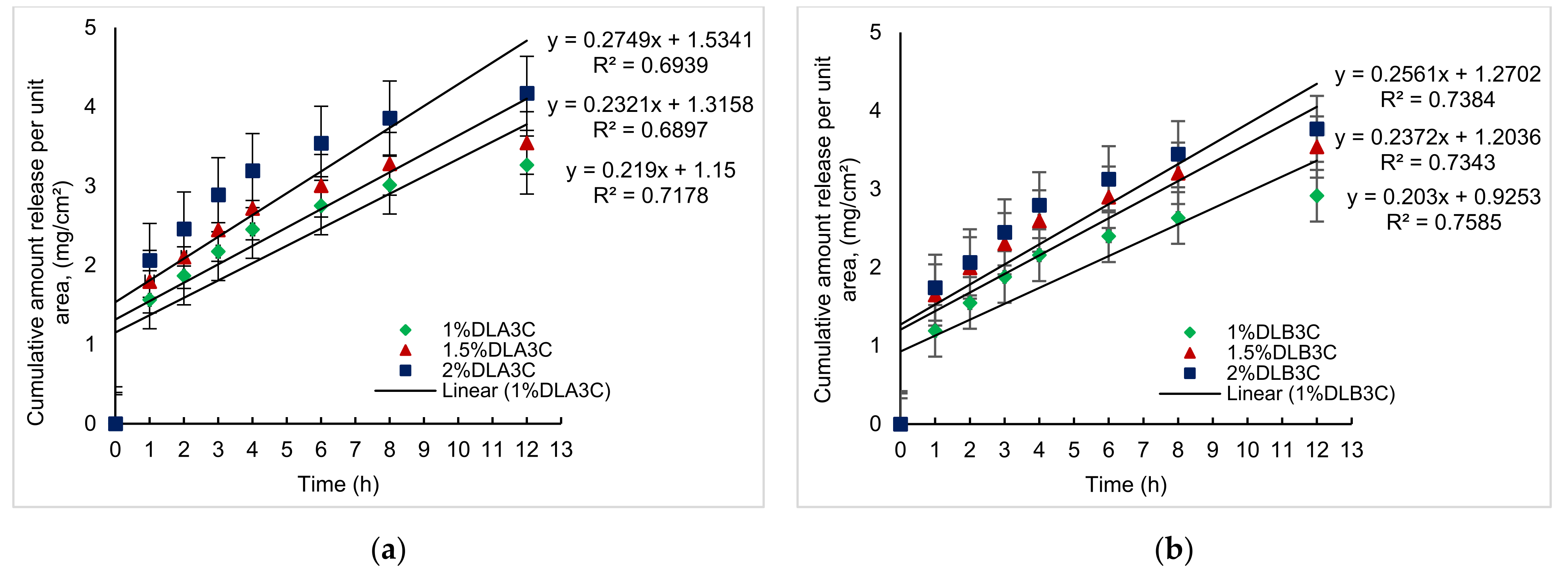

3.7. In Vitro Permeation Studies of the Diclofenac Sodium (DS)-Medicated Dual Layer PVA Patches through Cellulose Nitrate Membrane

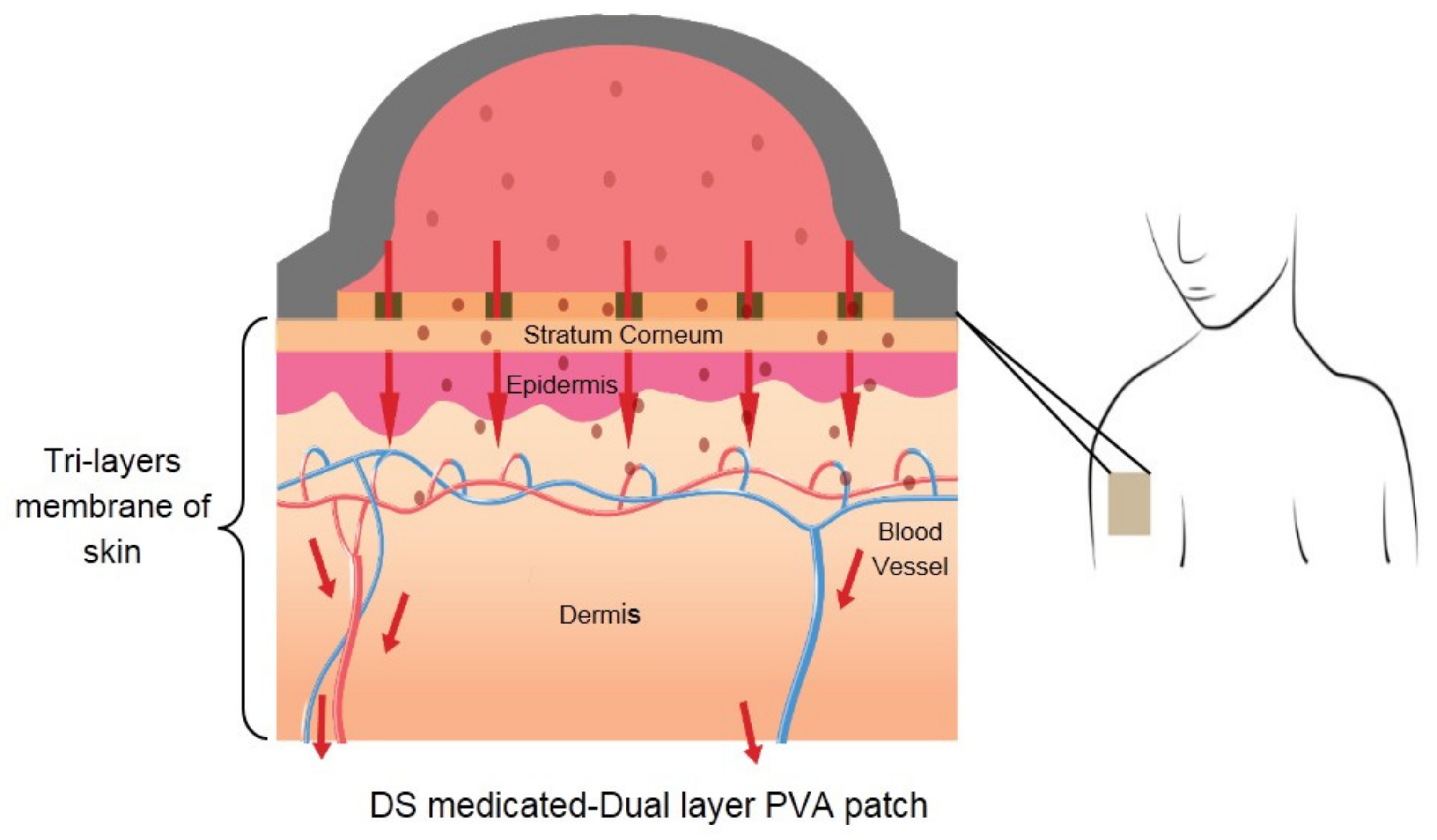

3.8. Proposed Diclofenac Sodium (DS)-Medicated Dual Layer PVA Patch for Commercial Use

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Homayun, B.; Lin, X.; Choi, H.-J. Challenges and Recent Progress in Oral Drug Delivery Systems for Biopharmaceuticals. Pharmaceutics 2019, 11, 129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Paskiabi, F.A.; Mirzaei, E.; Amani, A.; Shokrgozar, M.A.; Saber, R.; Faridi-Majidi, R. Optimizing parameters on alignment of PCL/PGA nanofibrous scaffold: An artificial neural networks approach. Int. J. Biol. Macromol. 2015, 81, 1089–1097. [Google Scholar] [CrossRef]

- Martin, C.; De Baerdemaeker, A.; Poelaert, J.; Madder, A.; Hoogenboom, R.; Ballet, S. Controlled-release of opioids for improved pain management. Mater. Today 2016, 19, 491–502. [Google Scholar] [CrossRef] [Green Version]

- Mali, A.D.; Bathe, R.; Patil, M. An updated review on transdermal drug delivery systems. Int. J. Adv. Sci. Res. 2015, 1, 244–254. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Wang, J.; Wang, Y.; Gao, H.; Wei, G.; Huang, Y.; Yu, H.; Gan, Y.; Wang, Y.; Mei, L. Recent progress in drug delivery. Acta Pharm. Sin. B 2019, 9, 1145–1162. [Google Scholar] [CrossRef]

- Marwah, H.; Garg, T.; Goyal, A.K.; Rath, G. Permeation enhancer strategies in transdermal drug delivery. Drug Deliv. 2016, 23, 564–578. [Google Scholar] [CrossRef]

- Verma, P.; Pathak, K. Therapeutic and cosmeceutical potential of ethosomes: An overview. J. Adv. Pharm. Technol. Res. 2010, 1, 274–282. [Google Scholar] [CrossRef] [Green Version]

- El Fawal, G.; Hong, H.; Song, X.; Wu, J.; Sun, M.; Zhang, L.; He, C.; Mo, X.; Wang, H. Polyvinyl alcohol/hydroxyethylcellulose containing ethosomes as a scaffold for transdermal drug delivery applications. Appl. Biochem. Biotechnol. 2020, 191, 1624–1637. [Google Scholar] [CrossRef]

- Rahmani, F.; Ziyadi, H.; Baghali, M.; Luo, H.; Ramakrishna, S. Electrospun PVP/PVA nanofiber mat as a novel potential transdermal drug-delivery system for buprenorphine: A solution needed for pain management. Appl. Sci. 2021, 11, 2779. [Google Scholar] [CrossRef]

- Fathi, A.; Khanmohammadi, M.; Goodarzi, A.; Foroutani, L.; Mobarakeh, Z.T.; Saremi, J.; Arabpour, Z.; Ai, J. Fabrication of chitosan-polyvinyl alcohol and silk electrospun fiber seeded with differentiated keratinocyte for skin tissue regeneration in animal wound model. J. Biol. Eng. 2020, 14, 27. [Google Scholar] [CrossRef] [PubMed]

- Sa’adon, S.; Razak, S.I.A.; Ismail, A.E.; Fakhruddin, K. Drug-loaded poly-vinyl alcohol electrospun nanofibers for transdermal drug delivery: Review on factors affecting the drug release. Procedia Comput. Sci. 2019, 158, 436–442. [Google Scholar] [CrossRef]

- Abbas, W.A.; Sharafeldin, I.M.; Omar, M.M.; Allam, N.K. Novel mineralized electrospun chitosan/PVA/TiO2 nanofibrous composites for potential biomedical applications: Computational and experimental insights. Nanoscale Adv. 2020, 2, 1512–1522. [Google Scholar] [CrossRef] [Green Version]

- Tekko, I.A.; Chen, G.; Domínguez-Robles, J.; Raj Singh Thakur, R.; Hamdan, I.M.N.; Vora, L.; Donnelly, R.F. Development and characterization of novel poly (vinyl alcohol)/poly (vinyl pyrrolidone)-based hydrogel-forming microneedle arrays for enhanced and sustained transdermal delivery of methotrexate. Int. J. Pharm. 2020, 586, 119580. [Google Scholar] [CrossRef]

- Kharaghani, D.; Gitigard, P.; Ohtani, H.; Kim, K.O.; Ullah, S.; Saito, Y.; Khan, M.Q.; Kim, I.S. Design and characterization of dual drug delivery based on in-situ assembled PVA/PAN core-shell nanofibers for wound dressing application. Sci. Rep. 2019, 9, 12640. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, O.; Minhas, M.U.; Ahmad, M.; Ahmad, S.; Barkat, K.; Ahmad, A. Synthesis, optimization, and evaluation of polyvinyl alcohol-based hydrogels as controlled combinatorial drug delivery system for colon cancer. Adv. Polym. Technol. 2018, 37, 3348–3363. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, X.; Tang, Y.; Mao, J. Composition, isolation, purification and biological activities of Sargassum fusiforme polysaccharides: A review. Carbohydr. Polym. 2020, 228, 115381. [Google Scholar] [CrossRef] [PubMed]

- Vandghanooni, S.; Eskandani, M. Electrically conductive biomaterials based on natural polysaccharides: Challenges and applications in tissue engineering. Int. J. Biol. Macromol. 2019, 141, 636–662. [Google Scholar] [CrossRef]

- Sessarego, S.; Rodrigues, S.C.; Xiao, Y.; Lu, Q.; Hill, J.M. Phosphonium-enhanced chitosan for Cr(VI) adsorption in wastewater treatment. Carbohydr. Polym. 2019, 211, 249–256. [Google Scholar] [CrossRef]

- El-Fawal, G. Preparation, characterization and antibacterial activity of biodegradable films prepared from carrageenan. J. Food Sci. Technol. 2014, 51, 2234–2239. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kataria, K.; Gupta, A.; Rath, G.; Mathur, R.; Dhakate, S. In Vivo wound healing performance of drug loaded electrospun composite nanofibers transdermal patch. Int. J. Pharm. 2014, 469, 102–110. [Google Scholar] [CrossRef] [PubMed]

- Jurca, T.; Józsa, L.; Suciu, R.; Pallag, A.; Marian, E.; Bácskay, I.; Muresan, M.; Stan, R.L.; Cevei, M.; Cioara, F.; et al. Formulation of topical dosage forms containing synthetic and natural anti-inflammatory agents for the treatment of rheumatoid arthritis. Molecules 2021, 26, 24. [Google Scholar]

- Ailincai, D.; Dorobanțu, A.M.; Dima, B.; Irimiciuc, Ș.A.; Lupașcu, C.; Agop, M.; Olguta, O. Poly (vinyl alcohol boric acid)-diclofenac sodium salt drug delivery systems: Experimental and theoretical studies. J. Immunol. Res. 2020, 2020, 3124304. [Google Scholar] [CrossRef] [PubMed]

- Suhail, M.; Khan, A.; Rosenholm, J.; Minhas, M.; Wu, P.-C. Fabrication and characterization of diclofenac sodium loaded hydrogels of sodium alginate as sustained release carrier. Gels 2021, 7, 10. [Google Scholar] [CrossRef]

- Shewaiter, M.A.; Hammady, T.M.; El-Gindy, A.; Hammadi, S.H.; Gad, S. Formulation and characterization of leflunomide/diclofenac sodium microemulsion base-gel for the transdermal treatment of inflammatory joint diseases. J. Drug Deliv. Sci. Technol. 2021, 61, 102110. [Google Scholar] [CrossRef]

- Suhail, M.; Wu, P.-C.; Minhas, M.U. Using carbomer-based hydrogels for control the release rate of diclofenac sodium: Preparation and In Vitro evaluation. Pharmaceuticals 2020, 13, 399. [Google Scholar] [CrossRef]

- Van Walsem, A.; Pandhi, S.; Nixon, R.M.; Guyot, P.; Karabis, A.; Moore, R.A. Relative benefit-risk comparing diclofenac to other traditional non-steroidal anti-inflammatory drugs and cyclooxygenase-2 inhibitors in patients with osteoarthritis or rheumatoid arthritis: A network meta-analysis. Arthritis Res. Ther. 2015, 17, 66–79. [Google Scholar] [CrossRef] [Green Version]

- Depeigne, L.; Zdraveva, E. Electrospun biomaterials’ applications and processing. J. Biomim. Biomater. Biomed. Eng. 2021, 49, 91–100. [Google Scholar]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and electrospun nanofibers: Methods, materials, and applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

- Vass, P.; Szabó, E.; Domokos, A.; Hirsch, E.; Galata, D.; Farkas, B.; Démuth, B.; Andersen, S.K.; Vigh, T.; Verreck, G.; et al. Scale-up of electrospinning technology: Applications in the pharmaceutical industry. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnology 2020, 12, e1611. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Tang, K.; Zheng, X. Electrospinning and crosslinking of COL/PVA nanofiber-microsphere containing salicylic acid for drug delivery. J. Bionic Eng. 2016, 13, 143–149. [Google Scholar] [CrossRef]

- Li, X.; Kanjwal, M.A.; Lin, L.; Chronakis, I.S. Electrospun polyvinyl-alcohol nanofibers as oral fast-dissolving delivery system of caffeine and riboflavin. Colloids Surf. B Biointerfaces 2013, 103, 182–188. [Google Scholar] [CrossRef] [PubMed]

- Rianjanu, A.; Kusumaatmaja, A.; Suyono, E.A.; Triyana, K. Solvent vapor treatment improves mechanical strength of electrospun polyvinyl alcohol nanofibers. Heliyon 2018, 4, e00592. [Google Scholar] [CrossRef] [Green Version]

- Peresin, M.S.; Vesterinen, A.-H.; Habibi, Y.; Johansson, L.-S.; Pawlak, J.J.; Nevzorov, A.A.; Rojas, O.J. Crosslinked PVA nanofibers reinforced with cellulose nanocrystals: Water interactions and thermomechanical properties. J. Appl. Polym. Sci. 2014, 131, 40334. [Google Scholar] [CrossRef]

- Colloca, M.; Gupta, N.; Porfiri, M. Tensile properties of carbon nanofiber reinforced multiscale syntactic foams. Compos. Part B Eng. 2013, 44, 584–591. [Google Scholar] [CrossRef]

- Cai, J.; Chen, J.; Zhang, Q.; Lei, M.; He, J.; Xiao, A.; Ma, C.; Li, S.; Xiong, H. Well-aligned cellulose nanofiber-reinforced polyvinyl alcohol composite film: Mechanical and optical properties. Carbohydr. Polym. 2016, 140, 238–245. [Google Scholar] [CrossRef]

- Jensen, B.E.B.; Hosta-Rigau, L.; Spycher, P.R.; Reimhult, E.; Städler, B.; Zelikin, A.N. Lipogels: Surface-adherent composite hydrogels assembled from poly(vinyl alcohol) and liposomes. Nanoscale 2013, 5, 6758–6766. [Google Scholar] [CrossRef]

- Gupta, S.; Webster, T.J.; Sinha, A. Evolution of PVA gels prepared without crosslinking agents as a cell adhesive surface. J. Mater. Sci. Mater. Med. 2011, 22, 1763–1772. [Google Scholar] [CrossRef] [PubMed]

- Farooqui, N.; Singh, R.P.; Kar, M. Effects of Vehicles and penetration enhancers in transdermal delivery of ketorolac tromethamine. Int. J. Pharm. Life Sci. 2016, 7, 4872–4879. [Google Scholar]

- Păduraru, O.M.; Ciolacu, D.; Darie, R.N.; Vasile, C. Synthesis and characterization of polyvinyl alcohol/cellulose cryogels and their testing as carriers for a bioactive component. Mater. Sci. Eng. C 2012, 32, 2508–2515. [Google Scholar] [CrossRef]

- Hassan, C.M.; Peppas, N.A. Structure and applications of poly(vinyl alcohol) hydrogels produced by conventional crosslinking or by freezing/thawing methods. Adv. Polym. Sci. 2000, 153, 37–65. [Google Scholar]

- Bahadoran, M.; Shamloo, A.; Nokoorani, Y.D. Development of a polyvinyl alcohol/sodium alginate hydrogel-based scaffold incorporating bFGF-encapsulated microspheres for accelerated wound healing. Sci. Rep. 2020, 10, 7342. [Google Scholar] [CrossRef] [PubMed]

- Baghel, S.; Cathcart, H.; O’Reilly, N.J. Theoretical and experimental investigation of drug-polymer interaction and miscibility and its impact on drug supersaturation in aqueous medium. Eur. J. Pharm. Biopharm. 2016, 107, 16–31. [Google Scholar] [CrossRef]

- Da-Silva, T.L.; Martins, J.M.; da Silva Junior, A.C.; Gimenes, M.L.; Vieira, M.G.A.; da Silva, M.G.C. Evaluation of incorporation of diclofenac sodium in dried sericin-alginate particles prepared by ionic gelation technique. Chem. Eng. Trans. 2015, 43, 829–834. [Google Scholar]

- Younes, H.A.; Khaled, R.; Mahmoud, H.M.; Nassar, H.F.; Abdelrahman, M.M.; Abo El-Ela, F.I.; Taha, M. Computational and experimental studies on the efficient removal of diclofenac from water using ZnFe-layered double hydroxide as an environmentally benign absorbent. J. Taiwan Inst. Chem. Eng. 2019, 102, 297–311. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, F.; Qin, X. Adsorption of diclofenac onto goethite: Adsorption kinetics and effects of pH. Chemosphere 2017, 180, 373–378. [Google Scholar] [CrossRef] [PubMed]

- Maver, T.; Gradišnik, L.; Smrke, D.M.; Kleinschek, K.S.; Maver, U. Systematic evaluation of a diclofenac-loaded carboxymethyl cellulose-based wound dressing and its release performance with changing pH and temperature. AAPS PharmSciTech 2019, 20, 29. [Google Scholar] [CrossRef] [PubMed]

- Matty, F.S.; MohiALDeen, Z.M. Swelling Behavior and Drug Release of Interpenetrating Network Composed of PVA and Chitosan. Ibn AL- Haitham J. Pure Appl. Sci. 2018, 31, 145. [Google Scholar] [CrossRef]

- El-Newehy, M.H.; El-Naggar, M.E.; Alotaiby, S.; El-Hamshary, H.; Moydeen, M.; Al-Deyab, S. Preparation of biocompatible system based on electrospun CMC/PVA nanofibers as controlled release carrier of diclofenac sodium. J. Macromol. Sci. Part A 2016, 53, 566–573. [Google Scholar] [CrossRef]

- Carrer, V.; Guzmán, B.; Martí, M.; Alonso, C.; Coderch, L. Lanolin-based synthetic membranes as percutaneous absorption models for transdermal drug delivery. Pharmaceutics 2018, 10, 73. [Google Scholar] [CrossRef] [Green Version]

- Otto, D.P.; Combrinck, J.; Otto, A.; Tiedt, L.R.; De Villiers, M.M. Dissipative particle dynamics investigation of the transport of salicylic acid through a simulated In Vitro skin permeation model. Pharmaceuticals 2018, 11, 134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Geraili, A.; Xing, M.; Mequanint, K. Design and fabrication of drug-delivery systems toward adjustable release profiles for personalized treatment. View 2021, 20200126. [Google Scholar] [CrossRef]

- Mamatha, J.; Gadili, S.; Pallavi, K. Formulation and evaluation of zidovudine transdermal patch using permeation enhancers. J. Young Pharm. 2020, 12, s45–s50. [Google Scholar] [CrossRef]

- Alkilani, A.; McCrudden, M.T.; Donnelly, R. Transdermal drug delivery: Innovative pharmaceutical developments based on disruption of the barrier properties of the stratum corneum. Pharmaceutics 2015, 7, 438–470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kao, C.-C.; Chen, S.-C.; Sheu, M.-T. Lag time method to delay drug release to various sites in the gastrointestinal tract. J. Control. Release 1997, 44, 263–270. [Google Scholar] [CrossRef]

- Kumar, S.; Kotian, R.S. Design and development of transdermal drug delivery of nonsteroidal anti-inflammatory drugs: Lornoxicam. J. Rep. Pharm. Sci. 2019, 8, 277–283. [Google Scholar]

| Patches | Concentration of PVA (% w/v) | DS Loading (% w/v) | No. of Freeze–Thaw Cycles |

|---|---|---|---|

| * 2 mL—volume of electrospinning | |||

| DLA3C | 10 | - | 3 |

| 1%DLA3C | 1.0 | ||

| 1.5%DLA3C | 1.5 | ||

| 2%DLA3C | 2.0 | ||

| * 3 mL—volume of electrospinning | |||

| DLB3C | 10 | - | 3 |

| 1%DLB3C | 1.0 | ||

| 1.5%DLB3C | 1.5 | ||

| 2%DLB3C | 2.0 | ||

| Patches | Jss (mg/cm2/h) | R2 | KP (cm/h) | (tLag) |

|---|---|---|---|---|

| 1%DLA3C | 0.219 | 0.718 | 0.035 | 1.150 |

| 1.5%DLA3C | 0.232 | 0.690 | 0.025 | 1.316 |

| 2%DLA3C | 0.275 | 0.694 | 0.022 | 1.534 |

| 1%DLB3C | 0.203 | 0.759 | 0.032 | 0.925 |

| 1.5%DLB3C | 0.237 | 0.734 | 0.025 | 1.204 |

| 2%DLB3C | 0.256 | 0.738 | 0.020 | 1.270 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sa’adon, S.; Ansari, M.N.M.; Razak, S.I.A.; Yusof, A.H.M.; Faudzi, A.A.M.; Sagadevan, S.; Nayan, N.H.M.; Anand, J.S.; Amin, K.A.M. Electrospun Nanofiber and Cryogel of Polyvinyl Alcohol Transdermal Patch Containing Diclofenac Sodium: Preparation, Characterization and In Vitro Release Studies. Pharmaceutics 2021, 13, 1900. https://doi.org/10.3390/pharmaceutics13111900

Sa’adon S, Ansari MNM, Razak SIA, Yusof AHM, Faudzi AAM, Sagadevan S, Nayan NHM, Anand JS, Amin KAM. Electrospun Nanofiber and Cryogel of Polyvinyl Alcohol Transdermal Patch Containing Diclofenac Sodium: Preparation, Characterization and In Vitro Release Studies. Pharmaceutics. 2021; 13(11):1900. https://doi.org/10.3390/pharmaceutics13111900

Chicago/Turabian StyleSa’adon, Shafizah, Mohamed Nainar Mohamed Ansari, Saiful Izwan Abd Razak, Abdul Halim Mohd Yusof, Ahmad Athif Mohd Faudzi, Suresh Sagadevan, Nadirul Hasraf Mat Nayan, Joseph Sahaya Anand, and Khairul Anuar Mat Amin. 2021. "Electrospun Nanofiber and Cryogel of Polyvinyl Alcohol Transdermal Patch Containing Diclofenac Sodium: Preparation, Characterization and In Vitro Release Studies" Pharmaceutics 13, no. 11: 1900. https://doi.org/10.3390/pharmaceutics13111900

APA StyleSa’adon, S., Ansari, M. N. M., Razak, S. I. A., Yusof, A. H. M., Faudzi, A. A. M., Sagadevan, S., Nayan, N. H. M., Anand, J. S., & Amin, K. A. M. (2021). Electrospun Nanofiber and Cryogel of Polyvinyl Alcohol Transdermal Patch Containing Diclofenac Sodium: Preparation, Characterization and In Vitro Release Studies. Pharmaceutics, 13(11), 1900. https://doi.org/10.3390/pharmaceutics13111900