1. Introduction

As global natural disasters, forest fires can release huge amounts of energy in a short amount of time and seriously damage the structure and function of ecosystems [

1], leading to a significant loss of forest resources and soil erosion, the endangerment of the wild animals, damage to water resources and increased forest fire management costs, et al. [

2]. Forest fires are caused by humans, lightning, and other natural causes, with man-made fires accounting for the vast majority, especially in populated regions [

3,

4,

5]. Heilongjiang province, in Northeast China, endures severe forest fires, with the area burned in the province being among the highest of provinces in China [

6], according to historical data, since 2005, Heilongjiang province has experienced an average of 69.2 forest fires per year, with an average burned area of 1045.24 ha. When forest fires occur in Heilongjiang Province, they cause serious damage to the ecosystem and forest resources and pose a threat to people’s safety. According to a survey [

7], anthropogenic fires account for 64.5% of forest fires in Heilongjiang Province, and controlling the province’s man-made fire frequency is therefore very important. Anthropogenic fires are caused by fire sources that ignite the fuel, such as agricultural burning, cigarette butts, and prescribed burning. As such, it is very important in the field of forest fire prevention to study the ignition mechanism of fire sources.

Cigarette butts are a special forest firebrand, accounting for a significant percentage of the total number of fire sources [

8,

9]. According to the historical forest fire data, the forest fire caused by cigarette butts in Heilongjiang province accounts for 20.6% of the man-made fire. When a cigarette butt is dropped, it first makes fuel smolder, which is difficult to identify from an observation tower, allowing the forest fire to spread before smoke is discovered and before the fire can be fought in the optimal time [

10]. The ignition probability of cigarette butts is not fixed but rather is affected by the characteristics of the fuel and environment conditions. When the forest environment is hot and dry, it will decrease the fuel moisture content, and the ignition probability will significantly increase. Therefore, investigations into the response of the ignition probability of cigarette butts and the environmental characteristics needed are of great significance for the prediction and management of forest fires due to cigarette butts. While cigarette butts have received little scientific attention in terms of the conditions that cause a fire to start. Previous studies have suggested that the wind speed and moisture content of the fuel bed have a significant effect on the ignition probability of cigarette butts. For example, Hoffheins [

11] found that the ignition probability of grass and fine fuel via cigarette butts has a very significant relationship with wind speed; when wind speed is roughly 3 m·s

−1, the ignition probability is close to 100% for all types of fuel. Markalas [

12] used ignited cigarette butts when the moisture content was 4.5%–6.5% on a fuel bed of pine needles and grass and found the ignition probability via cigarette butts was zero when no airflow was applied, but increased to 3.3% and 10% under windy conditions for pine needles and grass, respectively. Satoh et al. [

13] lit dry leaves with cigarette butts and found that when the wind speed exceeded 4 m·s

−1, the cigarette butts were automatically extinguished and the ignition probability dropped, but when wind speeds increased from 0 to 1 m·s

−1, the ignition probability increased from 0% to 23%. Dainer [

14] conducted a study of the ignition probability of hay via cigarette butts and found that, when wind speed increases and moisture content decreases, the ignition probability increases. Some researchers also believe that the structure of the grass bed has a large impact on the ignition probability [

15,

16]. Ignition probability is also greatly influenced by the location that the cigarette butt comes in contact with the fuel bed, with Lawson et al. [

17], for example, believing that if a cigarette butt has good contact with the fuel, there is a higher ignition probability.

Although there are fewer studies of cigarette butts as a fire source, many other related ignition probabilities of fire sources have been studied and can provide a reference for studying the ignition probability of cigarette butts. Fuel can be ignited by fire sources depending on many factors, including fire size and state (flaming, glowing), environmental conditions (temperature, relative humidity, wind speed), and fuel bed characteristics (moisture content, packing ratio, fuel arrangement, temperature, porosity) [

18,

19,

20,

21]. Fuel moisture content is the most significant variable affecting ignition probability and is inversely related to the ignition probability [

22,

23,

24,

25,

26]. The effect of wind speed on the ignition probability is complex and related to firebrand statue (flaming and glowing), the type of wind, and the position of the firebrand in the bed layer. For example, glowing firebrands can only ignite fuel when airflow is applied [

27,

28,

29,

30,

31]. Ganteaume et al. [

31] found that when airflow is oblique or turbulent, the ignition probability increases. Additionally, there may be a dual influence of wind speed on ignition probability, as airflow can increase the oxygen concentration and promote ignition but also reduce ignition by reducing the fuel temperature [

24]. Packing ratio also has a significant influence on ignition probability; Banksia (

Banksia ericifolia L.f.) and Witch hazel (

Leptospermum laevigatum F.

Muell) leaves, for example, cannot be ignited because they are very small and form highly dense fuel beds. The packing ratio of these fuel beds is too high to allow sufficient oxygen for combustion [

24].

Although studies on the ignition probability of cigarette butts have been performed, the situations created by different fuel types ignited by the same firebrand have not been identical, and the ignition probability of cigarette butts has not been investigated for Chinese fuel types. Heilongjiang is the province hardest hit by forest fires in China with its annual fire area ranked first in the country [

6]. Mongolian oak (

Quercus mongolica) is an important broad-leaved tree in this region. Its leaves have a large surface area and this fuel therefore easily curls and can form a very thick fuel bed, which greatly influences forest fires. The aim of this study is to determine the ignition probability of a fuel bed composed of Mongolian oak leaves via cigarette butts, to analyze the influence of wind speed, moisture content, and the packing ratio of fuel beds on the ignition probability of cigarette butts, and to establish a forecasting model to provide a basis for forest fire prediction.

2. Materials and Methods

The study area is the Maoer Mountain Forest Farm in the city of Harbin, Heilongjiang Province with geographical coordinates ranging from 127°40′–127°34′ E, 45°24′–45°33′ N, as shown in

Figure 1. The highest altitude of the area is 805 m, and the average altitude is 300 m. The annual average temperature is 2.8 °C. The annual mean precipitation is 723 mm, and is mainly concentrated in July and August. The forest type is predominantly the natural secondary forest formed by the destruction of the original forest and is the typical distribution area of broad-leaved red pine (

Pinus koraiensis) forest in the temperate zone of China. The vegetation mainly includes Mongolian oak poplar (

Poplus dividiana L.), white birch (

Betula platyphylla Sukaczev.), and so on.

In May 2014, Mongolian oak leaves which fell in the autumn of the previous year were collected from the Mongolian oak forest in the Maoer Mountain Forest Farm. The information of the forest stand is shown in

Table 1. The structure of the leaves remained completely intact. The collected leaves were laid flat in the laboratory and prepared for burning.

2.1. Preparation of Burning Bed

The fuel beds used in the burning tests must be prepared in advance and must meet the natural conditions of the field bed. Fuel bed preparation mainly consisted of preparing the packing ratio and moisture content.

2.1.1. Packing Ratio

The quantity of fuel has a significant effect on the ignition probability [

32] and it is therefore necessary to ensure that the fuel involved in the burning experiments is complete and conforms to the actual situation in the field. Therefore, we investigated the height and packing ratio of the surface fuel of Mongolian oak forests. We found the minimum, average, and maximum packing ratios to be 0.0383, 0.0638, and 0.0893, respectively, and the average height to be 4 cm. Hence, the packing ratio of the fuel bed was set to three levels: 0.0383, 0.0638, and 0.0893.

The packing ratio is the ratio of the bulk density of the fuel bed to the density of the particles; the fuel bed density is the ratio of the fuel mass to volume, and the particle density of the Mongolian oak leaves was 548.3 kg·m

3 [

33]. The length, width, and height of the fuel bed were 17 cm, 17 cm, and 4 cm, respectively, for a bed volume of 1.16 × 10

−3 m

3. According to the selected fuel bed packing ratio, the volume and particle density of the Mongolian oak broadleaves can be obtained at different packing ratios corresponding to the fuel mass.

Table 2 shows the mass of the Mongolian oak leaves at different packing ratios.

2.1.2. Moisture Content

To determine the moisture content gradient, it is necessary to determine the maximum bed moisture content of Mongolian oak leaves that can be ignited by cigarette butts. Luke [

34] found that when the surface fuel moisture content is above 35% it is difficult to ignite fuel beds, therefore, we chose to begin at 35% and decrease the moisture content of the fuel bed in 5% intervals, in addition to varying the wind speed and packing ratio. Fuel beds with each specific moisture content and packing ratio were put into contact with cigarette butts 30 times under different wind speeds. As long as there was a flame that could spread, the moisture content of the Mongolian oak leaves was considered to be ignited by the cigarette butts, and based on this test, the maximum moisture content of the Mongolian oak leaves that can be ignited by cigarette butts is 15%. Thus, the moisture contents of the fuel beds were set at 0%, 5%, 10%, and 15%.

The fuel bed with each specific moisture content then needed to be prepared. Mongolian oak leaves were placed in an oven and dried at 105 °C until the mass no longer changed. The dry weight was recorded as

, and the leaves were placed on the ground. According to the moisture content formula:

(where

M = moisture content of the fuel bed and

= wet weight of the fuel), the wet weight of the fuel at the moisture content required for the test was obtained, and recorded as

, where

is the mass of water that must be added. The leaves were then placed onto the floor of the laboratory and the required water was quickly and evenly sprayed on the surface of the leaves before the fuel was sealed in a plastic bag for 24 h to allow it to absorb the water completely [

35,

36]. The fuel beds were then prepared with the moisture content required for the burning test. Before each ignition test, a subsample of fuel was taken and its moisture content was tested with a rapid moisture meter.

2.2. Setting the Wind Speed

The fuel bed is blown away and the burning test cannot be performed when airflow exceeds 6 m·s−1, therefore, the maximum wind speed used in this test was 6 m·s−1. With an interval of 1 m·s−1, starting from 0, seven wind speed velocities were established. For the experiment, a constant temperature blower (Philips HP8226/05, Philips, Shanghai, China) was selected as the wind source, and the wind speed was obtained by adjusting the distance between the blower and the fuel bed.

2.3. Burning Experiment

For the burning test, a 17 cm long by 17 cm wide by 5 cm high uncovered iron frame was used as the burning bed and is shown in

Figure 2. The bed layer was prepared with different fuel moisture contents and packing ratios.

The cigarette butts selected for the test were the Zhongnanhai brand (Beijing cigarette factory, Beijing, China) and had a length of 5 cm (with filter) and 2 cm (without filter) and a diameter of 0.7 cm. The cigarette butts generally fall from 1.5 m, thus, for a better simulation, the cigarette butts were thrown from a height of 1.5 m into the corresponding wind speed point on the fuel bed. The fuel bed moisture content, packing ratio, and wind speed were used as classification conditions, and each fuel bed combination of moisture content, packing ratio, and wind speed (84 combinations) was ignited via cigarette butts 30 times, for a total of 2520 burning tests. In each burning test, cigarette butts were considered to have ignited the fuel bed when there was a flame that could sustainably spread; this was marked as one, or otherwise marked as zero. The entire burning process was recorded with a digital camera (Panasonic HDC-TM900, Panasonic, Osaka, Japan). The experimental apparatus used is shown in

Figure 3.

2.4. Data Analysis

2.4.1. Analysis of Variance

Each bed’s moisture content, packing ratio, and wind speed ratio (84 combinations) were tested with 30 burning tests, and each match has a corresponding ignition probability for cigarette butts, for 84 match ratios. The variance of the ignition probability was analyzed by Statistica 10.0 (Publisher: Statsoft, Tulsa, OK, USA), with the moisture content, packing ratio, and wind speed as the independent variables so that variables that significantly influence ignition probability could be determined.

2.4.2. Analysis of Influencing Factors

According to the analysis of variance, the significant influencing factors were obtained, and the manner in which these factors affect the ignition probability of cigarette butts was then analyzed. If all of the factors had a significant impact, we chose different levels of any two factors as a classification variable and analyzed how the remaining factor alone affects the ignition probability. For example, to analyze the effect of moisture content on the ignition probability, the levels of packing ratio and wind speed were used as classification variables and a scatter plot was drawn using moisture content as the independent variable and the ignition probability as the dependent variable for different packing ratios and wind speeds. According to the scatter plot, the effect of the moisture content on the ignition probability can be analyzed. The other two-factor analysis methods used were the same as for moisture content.

If there was only one factor that had no effect on the ignition probability, the burning test as a categorical condition in the test is meaningless. Therefore, this insignificant factor is removed, and the arithmetic mean of the ignition probability of each gradient of the insignificant factors is calculated under different combinations of the remaining two factors, in addition to the arithmetic mean value as the new ignition probability in different combinations of the two significant factors. A scatter plot was plotted with one of the factors as the independent variable and the ignition probability as the dependent variable at different gradients of the other factor. The effect of the factor on the ignition probability was then analyzed using the scatter plot.

If only one factor had a significant effect, the arithmetic mean of the ignition probability of this factor was calculated at different levels. A scatter plot was then made with the factor as the independent variable and the ignition probability as the dependent variable so that the effect of the factor on ignition probability could be analyzed.

2.4.3. Establishing a Probability Prediction Model for Cigarette Butts

We chose two methods to establish an ignition probability prediction model: A logistic prediction model and a self-built prediction model.

(1) Logistic prediction model: The logistic prediction model is widely used in probability modeling of forest fires [

6,

37,

38,

39]. In the logistic regression model, two types of discriminant problems were evaluated. The first type was cigarette butts that can ignite the fuel (assigned a value of 1); the other type was fuel that cannot be ignited by cigarette butts (assigned a value of 0). The fuel bed moisture content, packing ratio, and wind speed were taken as independent variables, and a logistic prediction model was established using a stepwise regression method in Statistica 10.0:

The prediction model of the ignition probability of cigarette butts lighting the Mongolian oak leaves is:

(2) Self-built prediction model: The logistic prediction model is widely applied to examine the ignition probability of forest fires, but is purely statistical and has no physical significance. Therefore, the self-built model used in this study is based on analysis of the mechanism of the influencing factors, and the appropriate model form is the model with the minimum mean absolute error (MAE).

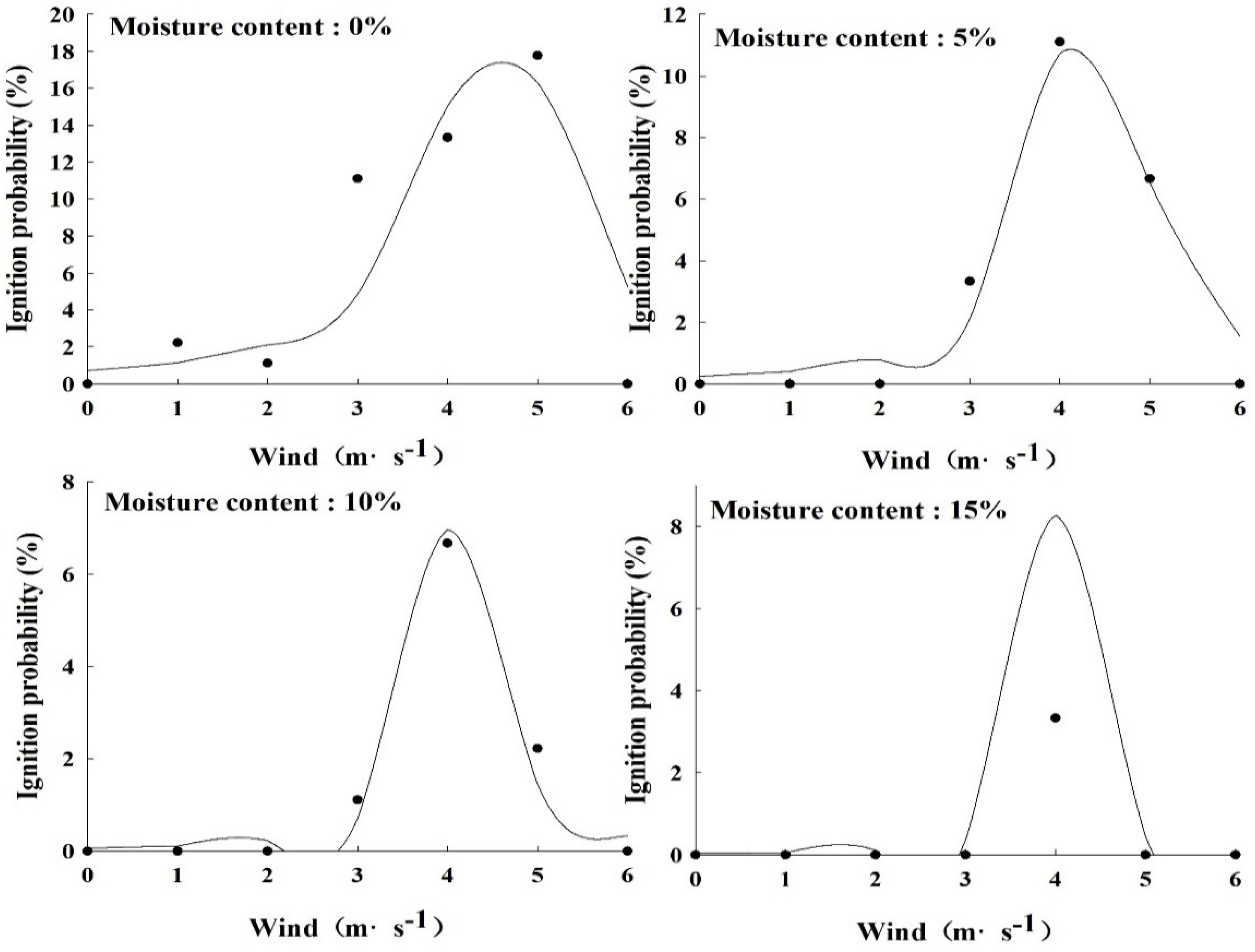

According to the analysis of variance, moisture content, and wind speed significantly affect ignition probability. First, the model was established with wind speed as the independent variable and ignition probability as the dependent variable for each moisture content. Select functional forms (p = a/(w − b)^2 + c, p = (w^a)exp(1 − wb), p = (w + a)exp(b − w), etc., where p = ignition probability of cigarette butts; w = wind speed; a, b, and c = model parameters) were used as the model, where the MAE value of the best model form is the smallest. Then the model was established with the parameters of the previous model as the dependent variable and moisture content as the independent variable. The equation was used as the model form (y = parameters of the previous model, mc = moisture content, d and f = model parameters). Finally, the parameter models were substituted into the previous model to obtain the ignition probability prediction model with wind speed and moisture content.

(3) Model comparison: The MAE values of the two models were calculated. The MAE is the arithmetic mean of the absolute value of the difference between all individual actual and predicted values. The MAE can better reflect the actual predicted error, and the method to calculate it is shown in Equation (3). The predictive effects of the two models with MAE were compared, where a smaller MAE indicates a better model.

where

Mi is the actual ignition probability (%),

is the predicted ignition probability (%), and

n is the number of samples.

To further compare the prediction efficiency of the two models, two-thirds of the data were chosen for logistic and self-built modeling and one-third for data validation, in triplicate. The MAE values of the modeling data for the two models, the validation data in triplicate, and a t-test were performed. If p < 0.05, the prediction efficiency for the small MAE model was significantly better than that of the other model.

5. Conclusions

This present study has shown that the ignition probability for Mongolian oak leaves ignited by cigarette butts is significantly correlated with the moisture content and wind speed, but not related to the packing ratio. In the absence of wind, the ignition probability was zero. The maximum moisture content of the Mongolian oak leaves that can be ignited by cigarette butts was 15%. The maximum moisture content of the fuel bed that can be ignited via cigarette butts first increased and then decreased when the wind speed was between 1 m·s−1 and 5 m·s−1. For different fuel bed moisture contents, the ignition probability increased and then decreased as wind speed increased, and the optimum wind speed decreased with increases in moisture content. The prediction model established in this study is significantly better than the logistic prediction model, which reveals the influencing factors for the ignition probability of cigarette butts and its mechanisms.

The results presented in this paper can further the understanding of the ignition mechanism of this fire source (cigarette butts). Nevertheless, there are currently very few reports of ignition tests in firebrand research; such experiments would be helpful for future research into this problem. In the future, a wider variety of fuel types should be tested, including needles, grasses, and mixtures of leaves and needles, to improve the prediction model for cigarette butts and provide a stronger basis for forest fire prediction.