Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials

Abstract

:1. Introduction

2. Material and Methods

2.1. In-Service Testing

- 0 = not blue stained;

- 1 = weakly blue stained: few spots of blue stain on the surface;

- 2 = slightly blue stained: up to 1.5 mm in width and 4 mm in length;

- 3 = moderately blue stained: up to one-third of the surface;

- 4 = severely blue stained.

2.2. Artificial Weathering Test

2.3. Colour Analysis

2.4. Data Processing

3. Results and Discussion

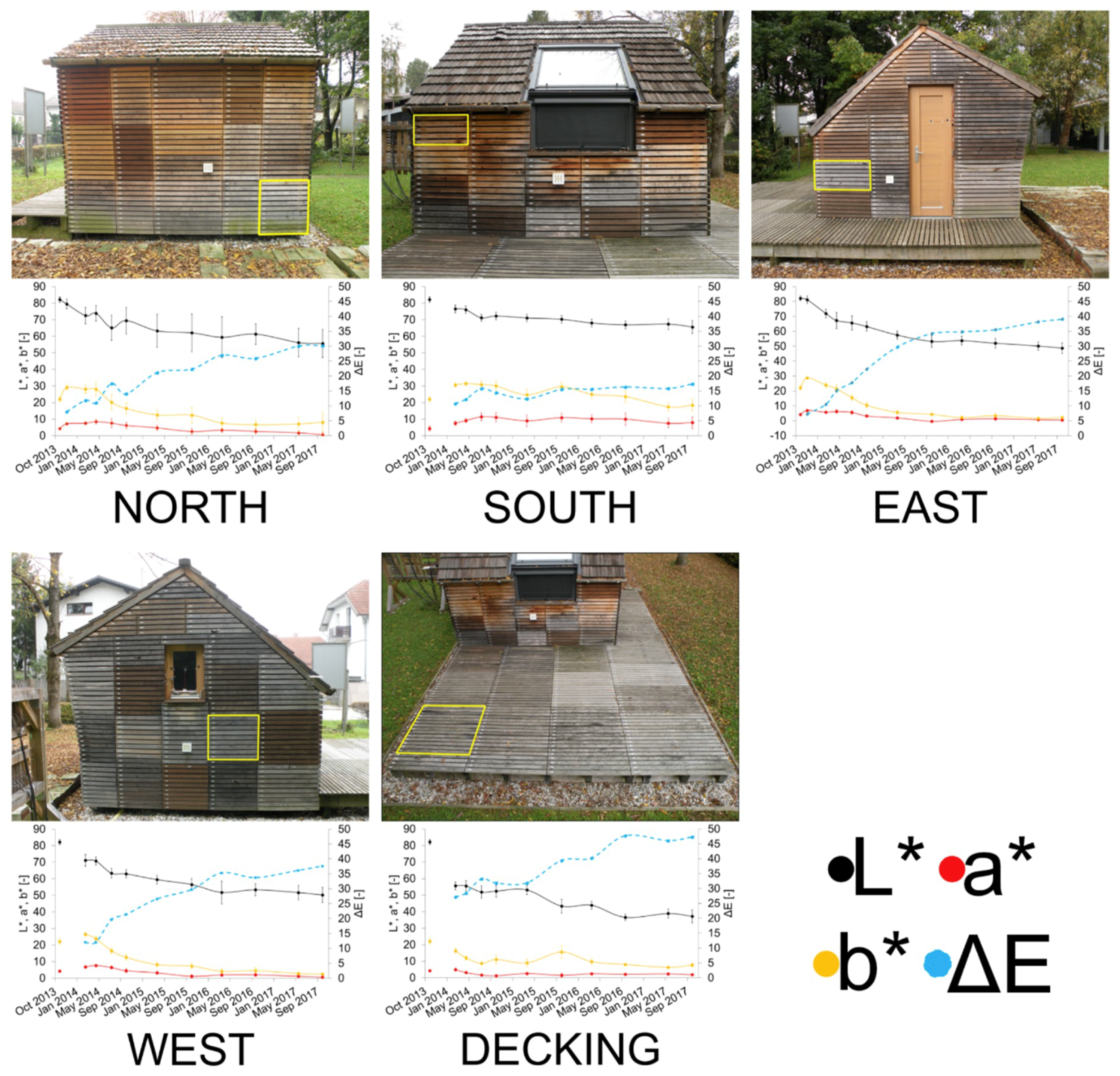

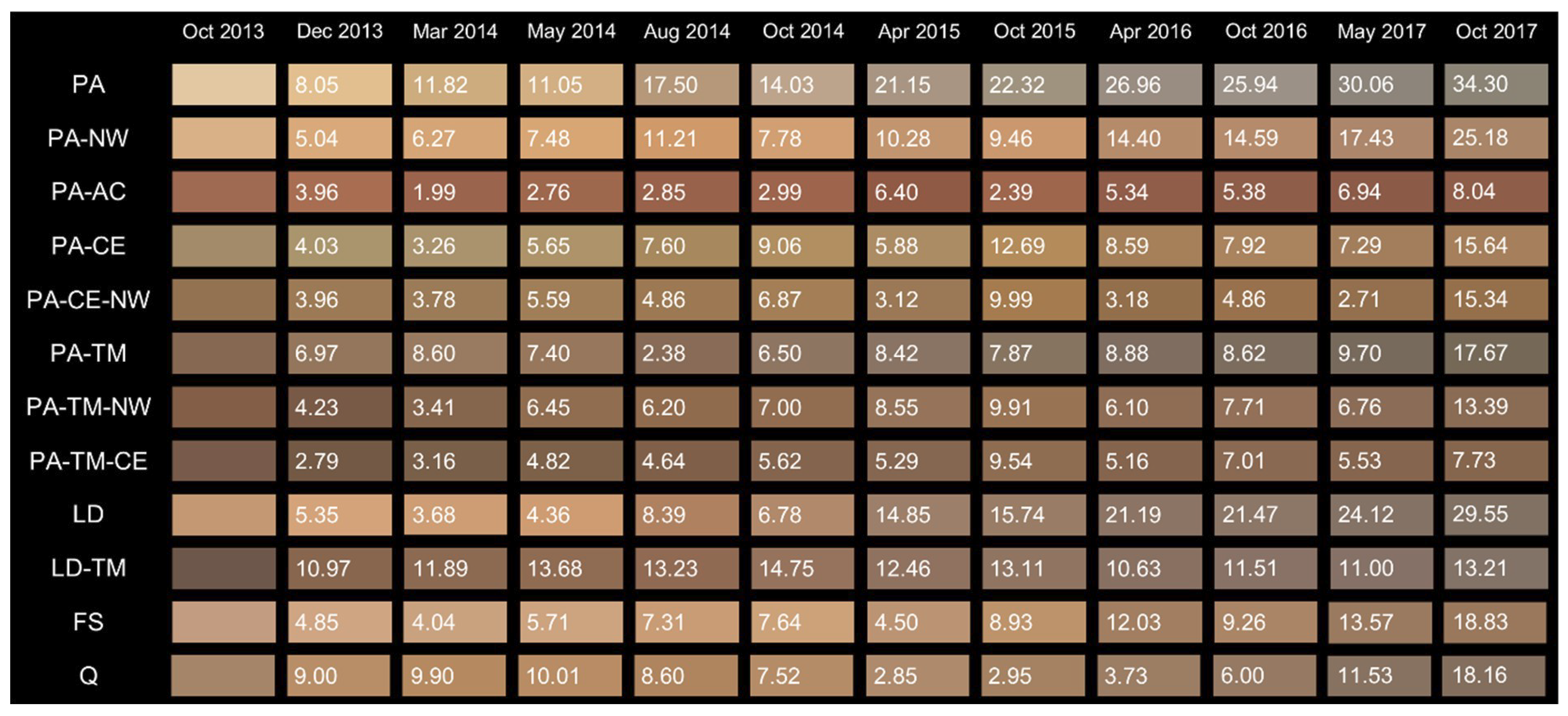

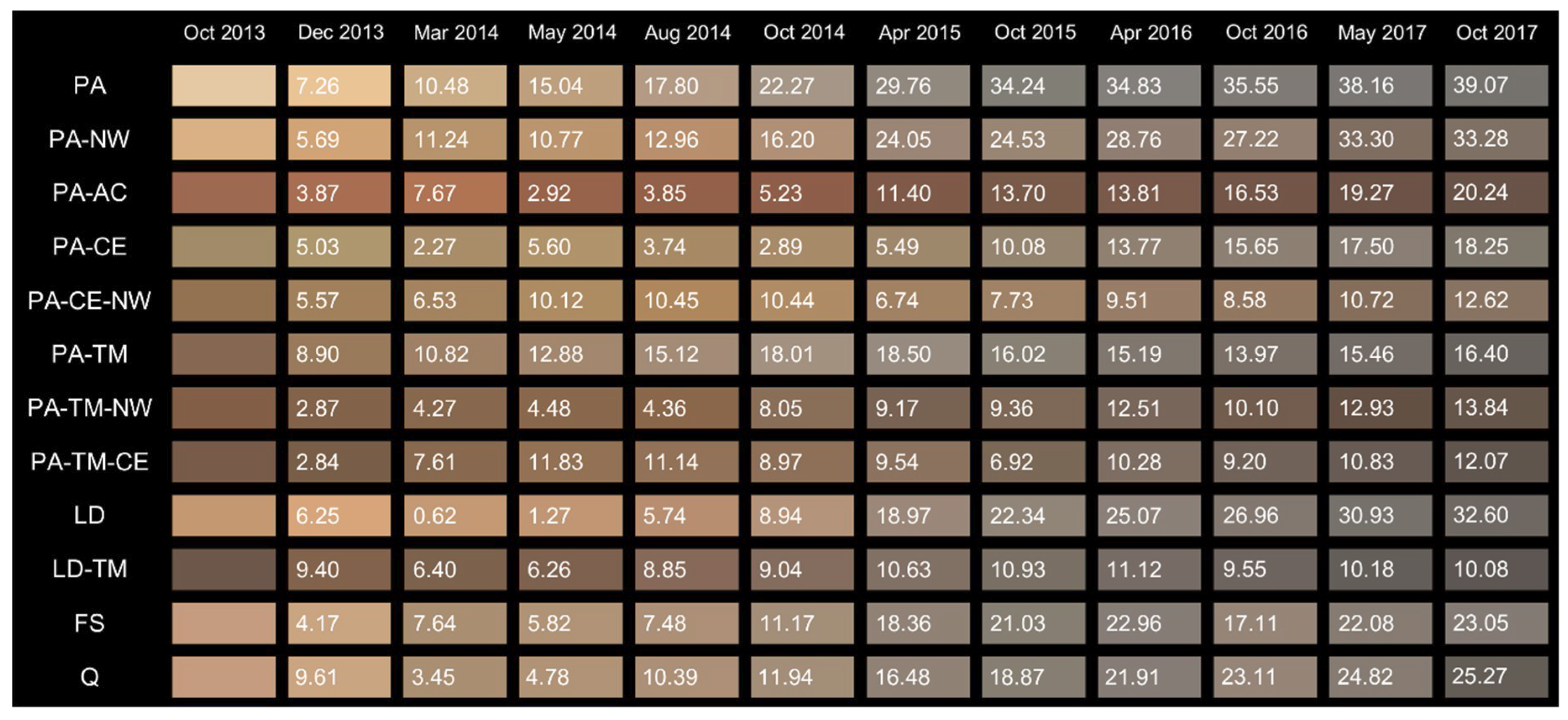

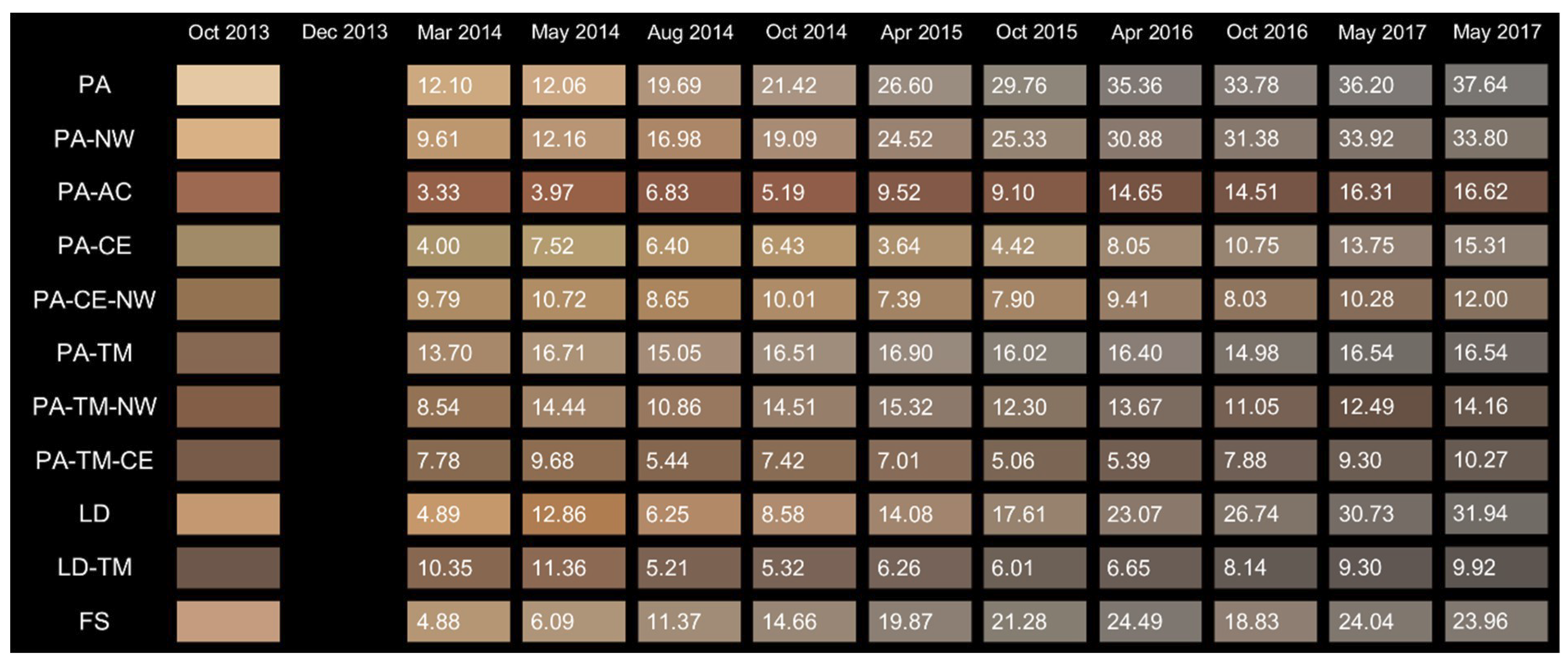

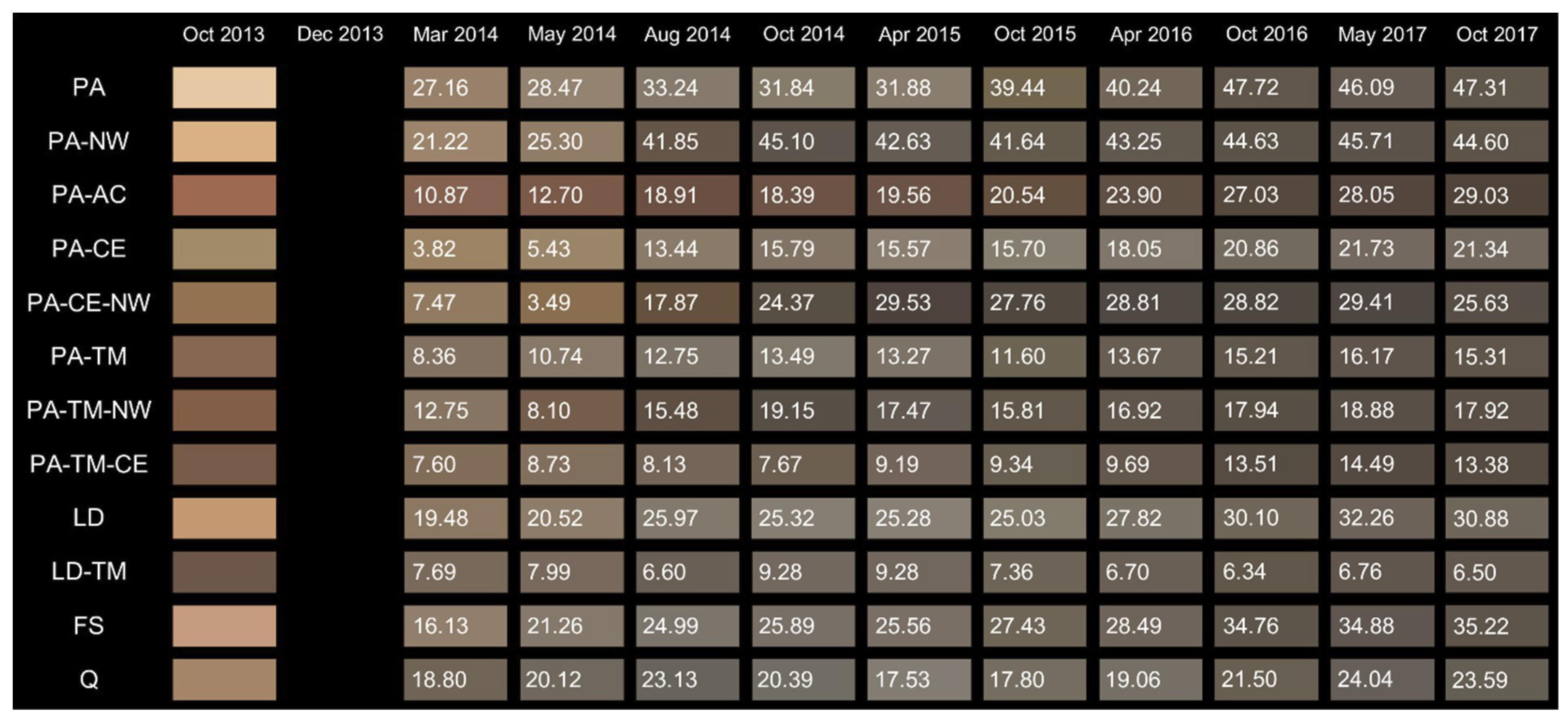

3.1. Colour Changes of In-Service Testing

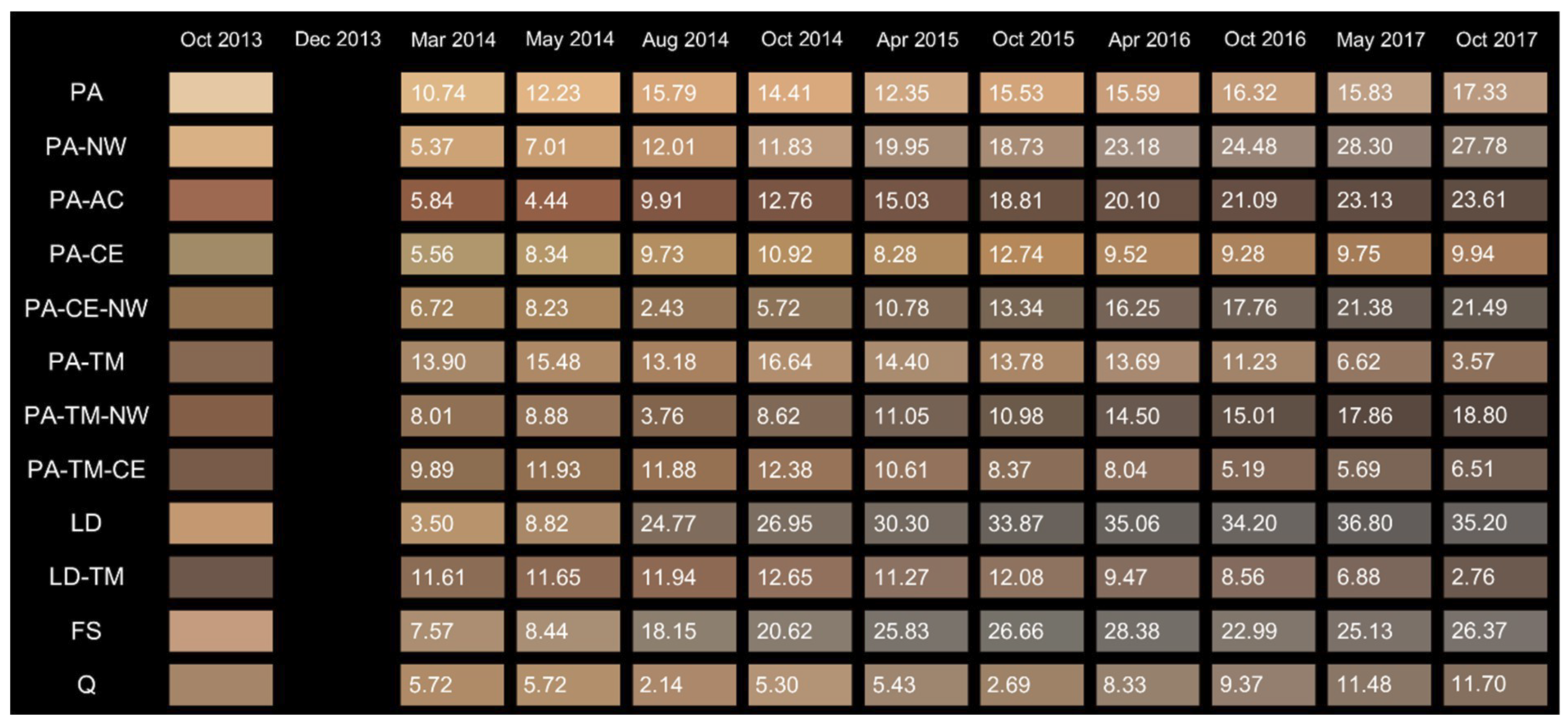

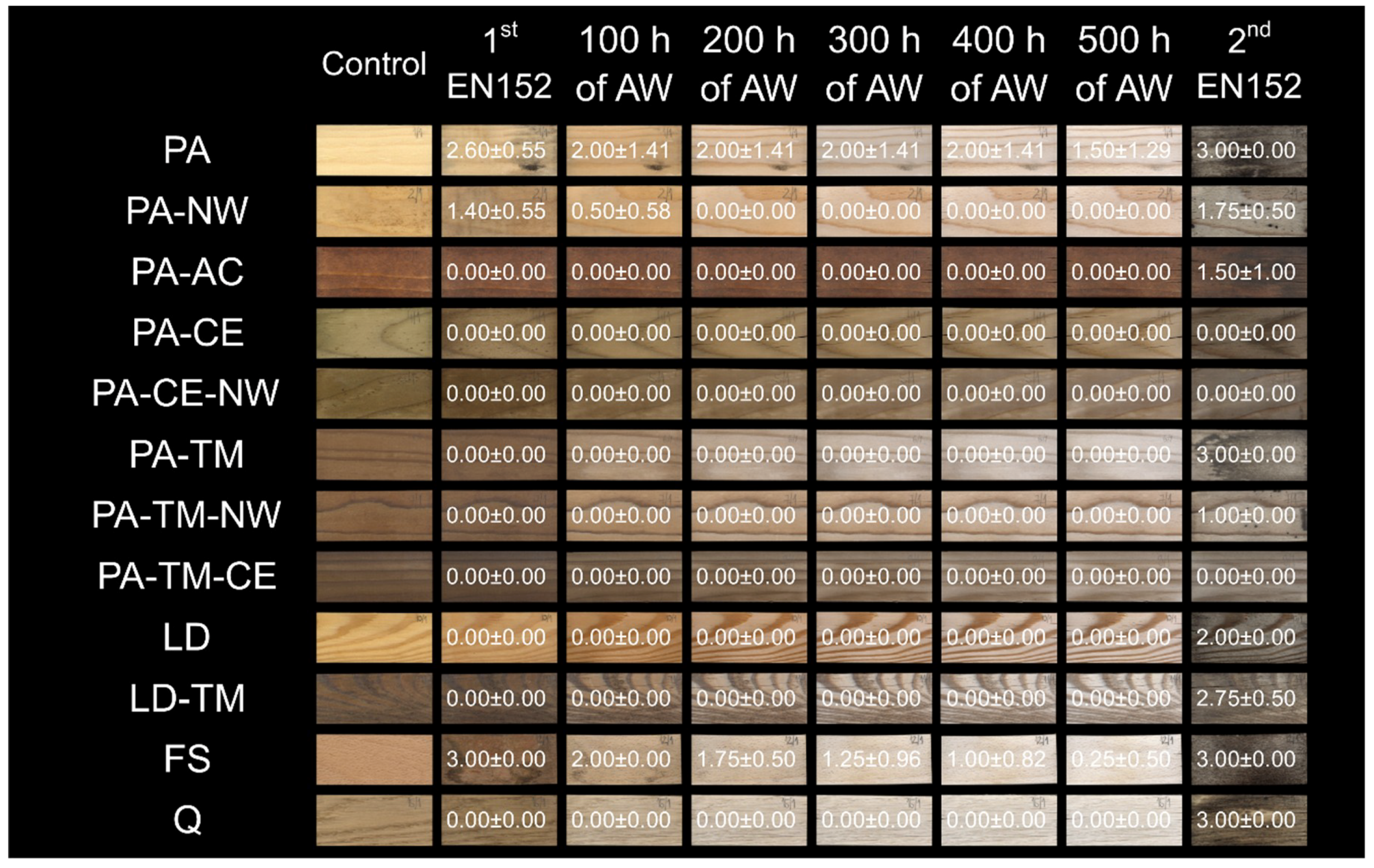

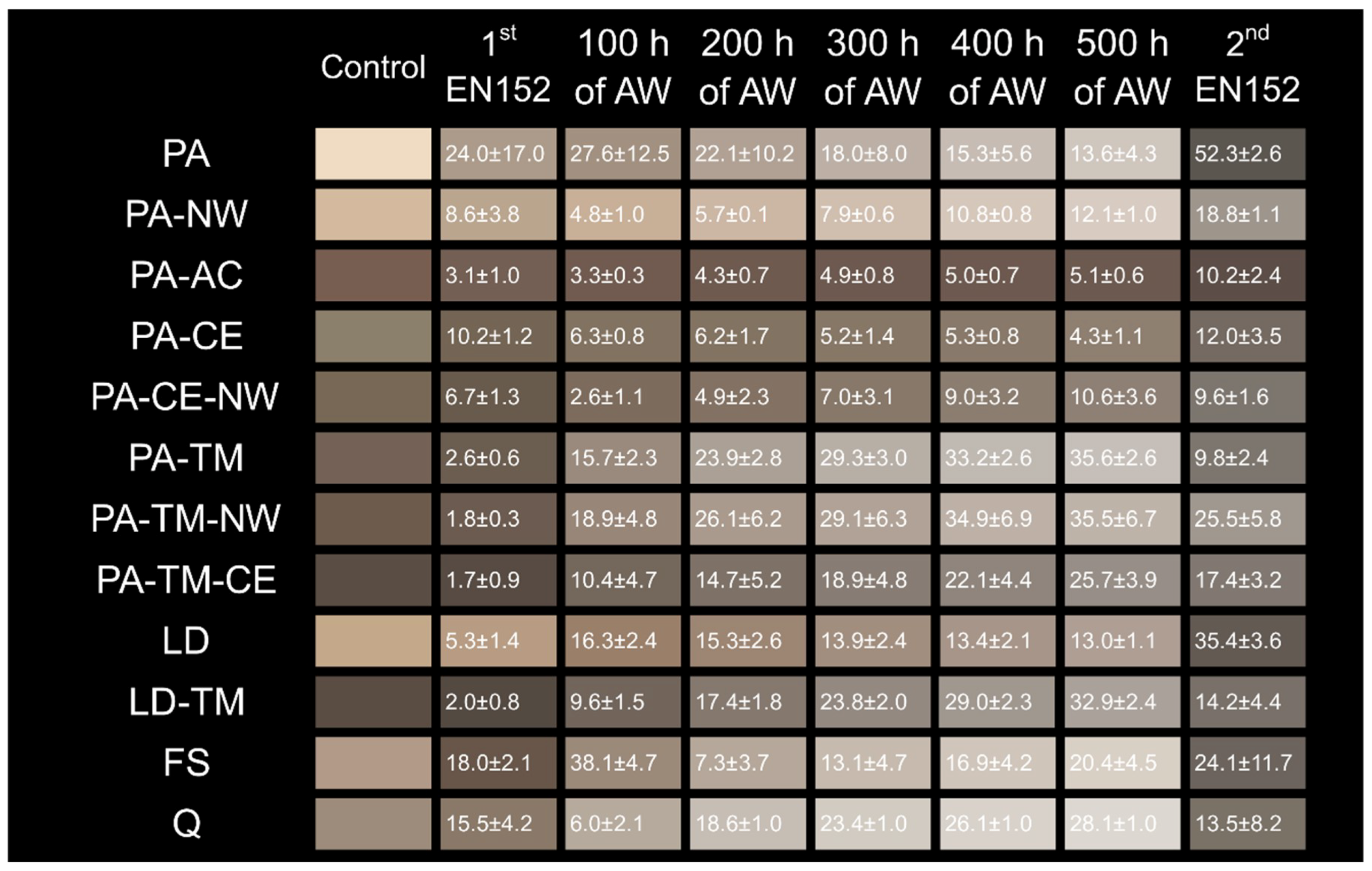

3.2. Influence of Blue Staining and Artificial Weathering Test on Colour Changes

3.3. Pearson’s Correlations Factors for Colour Change between In-Service and Laboratory Testing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Viitanen, H.; Toratti, T.; Makkonen, L.; Thelandersson, S.; Isaksson, T.; Früwald, E.; Jermer, J.; Englund, F.; Suttie, E. Modelling of service life and durability of wooden structures. In Proceedings of the 9th Nordic Symposium on Building Physics—NSB 2011, Tampere, Finland, 29 May–2 June 2011; Volume 2, pp. 925–932. [Google Scholar]

- Isaksson, T.; Thelandersson, S.; Brischke, C.; Jermer, J. Service Life of Wood in Outdoor above Ground Applications—Engineering Design Guidline; Report TVBK-3060; Division of Structural Engineering, Lund University: Lund, Sweden, 2011; Available online: http://www.kstr.lth.se/fileadmin/kstr/pdf_files/Guideline/TVBK3067.pdf (accessed on 29 November 2017).

- Burud, I.; Smeland, K.A.; Thiis, T.K.; Gobakken, L.R.; Sandak, A.; Sandak, J.; Liland, K.H. Modeling weather degradation of wooden facades using NIR hyperspectral imaging on thin wood samples. In Proceedings of the World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016; p. 8. [Google Scholar]

- Sandak, A.; Sandak, J. Prediction of service life—Does aesthetic matter? In Proceedings of the IRG Annual Meeting 2017, Ghent, Belgium, 4–8 June 2017.

- George, B.; Suttie, E.; Merlin, A.; Deglise, X. Photodegradation and photostabilisation of wood—The state of the art. Polym. Degrad. Stab. 2005, 88, 268–274. [Google Scholar] [CrossRef]

- Isaksson, T.; Brischke, C.; Thelandersson, S. Development of decay performance models for outdoor timber structures. Mater. Struct. 2013, 46, 1209–1225. [Google Scholar] [CrossRef]

- Zink, P.; Fengel, D. Studies on the Colouring Matter of Blue-stain Fungi. Part 1. General Characterization and the Associated Compounds. Holzforschung 1988, 42, 217–220. [Google Scholar] [CrossRef]

- Hernández, V.A.; Evans, P.D. Effects of UV radiation on melanization and growth of fungi isolated from weathered wood surfaces. In Proceedings of the IRG Annual Meeting 2015, Viña del Mar, Chile, 10–14 May 2015; pp. 1–12. [Google Scholar]

- Walther, T.; Reinsch, H.; Grosse, A.; Ostermann, K.; Deutsch, A.; Bley, T. Mathematical modeling of regulatory mechanisms in yeast colony development. J. Theor. Biol. 2004, 229, 327–338. [Google Scholar] [CrossRef] [PubMed]

- Van Den Bulcke, J.; Van Acker, J.; Stevens, M. Laboratory testing and computer simulation of blue stain growth on and in wood coatings. Int. Biodeterior. Biodegrad. 2007, 59, 137–147. [Google Scholar] [CrossRef]

- Humar, M.; Vek, V.; Bučar, B. Properties of blue-stained wood. Drv. Ind. 2008, 59, 75–79. [Google Scholar]

- Fojutowski, A. The influence of fungi causing blue—stain on absorptiveness of Scotch pine wood. In Proceedings of the IRG Annual Meeting 2005, Viña del Mar, Chile, 10–14 May 2005; pp. 1–5. [Google Scholar]

- Sharpe, P.R.; Dickinson, D.J. Blue stain in service on wood surface coatings. Part 1: The nutritional requirements of Aureobasidium pullulans. In Proceedings of the IRG Annual Meeting 1992, Harrogate, UK, 10–15 May 1992. [Google Scholar]

- Schmidt, O. Wood and Tree Fungi: Biology, Damage, Protection, and Use; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Ayadi, N.; Lejeune, F.; Charrier, F.; Charrier, B.; Merlin, A. Colour stability of heat-treated wood during artificial weathering. Holz als Roh- und Werkstoff 2003, 61, 221–226. [Google Scholar] [CrossRef]

- Hayoz, P.; Peter, W.; Rogez, D. A new innovative stabilization method for the protection of natural wood. Prog. Org. Coat. 2003, 48, 297–309. [Google Scholar] [CrossRef]

- Feist, W.C. Outdoor Wood Weathering and Protection; Rowell, R.M., Barbour, R.J., Eds.; American Chemical Society: Washington, DC, USA, 1990; pp. 263–298. [Google Scholar] [CrossRef]

- Kalnins, M.A. Surface Characteristics of Wood as They Affect Durability of Finishes; United States Department of Agriculture, Forest Products Laboratory: Madison, WI, USA, 1966; 60p.

- Feist, W.C.; Hon, D.N.-S. Chemistry of weathering and protection. Chem. Solid Wood 1984, 207, 401–451. [Google Scholar]

- Hon, D.N.-S. Weathering and photochemistry of wood. Wood Cell. Chem. 2001, 2, 512–546. [Google Scholar]

- Kielmann, B.C.; Mai, C. Natural weathering performance and the effect of light stabilizers in water-based coating formulations on resin-modified and dye-stained beech-wood. J. Coat. Technol. Res. 2016, 13, 1065–1074. [Google Scholar] [CrossRef]

- Cogulet, A.; Blanchet, P.; Landry, V. The Multifactorial Aspect of Wood Weathering: A Review Based on a Holistic Approach of Wood Degradation Protected by Clear Coating. BioResources 2018, 13, 2116–2138. [Google Scholar] [CrossRef]

- Williams, R.S. Weathering of Wood. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Pánek, M.; Oberhofnerová, E.; Zeidler, A.; Šedivka, P. Efficacy of Hydrophobic Coatings in Protecting Oak Wood Surfaces during Accelerated Weathering. Coatings 2017, 7, 172. [Google Scholar] [CrossRef]

- Herrera, R.; Sandak, J.; Robles, E.; Krystofiak, T.; Labidi, J. Weathering Resistance of Thermally Modified Wood Finished with Coatings of Diverse Formulations. Prog. Org. Coat. 2018, 119, 145–154. [Google Scholar] [CrossRef]

- Pandey, K.K. A note on the influence of extractives on the photo-discoloration and photodegradation of wood. Polym. Degrad. Stab. 2005, 87, 375–379. [Google Scholar] [CrossRef]

- Oberhofnerová, E.; Pánek, M.; García-Cimarras, A. The Effect of Natural Weathering on Untreated Wood Surface. Maderas Cienc. Tecnol. 2017, 19, 173–184. [Google Scholar] [CrossRef]

- Ugovšek, A.; Šubic, B.; Starman, J.; Rep, G.; Humar, M.; Lesar, B.; Thaler, N.; Brischke, C.; Meyer-Veltrup, L.; Jones, D.; et al. Short-Term Performance of Wooden Windows and Facade Elements Made of Thermally Modified and Non-Modified Norway Spruce in Different Natural Environments. Wood Mater. Sci. Eng. 2018, 1–6. [Google Scholar] [CrossRef]

- Forsthuber, B.; Grüll, G. Prediction of Wood Surface Discoloration for Applications in the Field of Architecture. Wood Sci. Technol. 2018, 52, 1093–1111. [Google Scholar] [CrossRef]

- Srinivas, K.; Pandey, K.K. Photodegradation of thermally modified wood. J. Photochem. Photobiol. B Biol. 2012, 117, 140–145. [Google Scholar] [CrossRef] [PubMed]

- Rüther, P.; Jelle, B.P. Colour changes of wood and wood-based materials due to natural and artificial weathering. Wood Mater. Sci. Eng. 2013, 8, 13–25. [Google Scholar] [CrossRef]

- Pánek, M.; Reinprecht, L. Effect of vegetable oils on the colour stability of four tropical woods during natural and artificial weathering. J. Wood Sci. 2016, 62, 74–84. [Google Scholar] [CrossRef]

- Teacă, C.-A.; Roşu, D.; Bodîrlău, R.; Roşu, L. Structural Changes in Wood under Artificial UV Light Irradiation Determined by FTIR Spectroscopy and Color Measurements—A Brief Review. BioResources 2013, 8, 1478–1507. [Google Scholar] [CrossRef]

- Agresti, G.; Bonifazi, G.; Calienno, L.; Capobianco, G.; Lo Monaco, A.; Pelosi, C.; Picchio, R.; Serranti, S. Surface Investigation of Photo-Degraded Wood by Colour Monitoring, Infrared Spectroscopy, and Hyperspectral Imaging. J. Spectrosc. 2013, 2013, 380536. [Google Scholar] [CrossRef]

- Pandey, K.K. Study of the Effect of Photo-Irradiation on the Surface Chemistry of Wood. Polym. Degrad. Stab. 2005, 90, 9–20. [Google Scholar] [CrossRef]

- Rep, G.; Pohleven, F. Wood modification—A promising method for wood preservation. Drv. Ind. 2001, 52, 71–76. [Google Scholar]

- Rep, G.; Pohleven, F.; Bučar, B. Characteristics of thermally modified wood in vacuum. In Proceedings of the IRG Annual Meeting 2004, Ljubljana, Slovenia, 6–10 June 2004; p. 9. [Google Scholar]

- Humar, M.; Pohleven, F. Solution for Wood Preservation. European Patent EP 1791682 (B1), 3 September 2008. [Google Scholar]

- Thelandersson, S.; Isaksson, T.; Suttie, E.; Frühwald, E.; Toratti, T.; Grüll, G.; Viitanen, H.; Jermer, J. Quantitative design guideline for wood outdoors above ground applications. In Proceedings of the IRG Annual Meeting 2011, Queenstown, New Zealand, 8–12 May 2011; International research group on wood protection: Stockholm, Sweden, 2011; p. 19. Available online: http://lup.lub.lu.se/search/ws/files/5572865/2154681.pdf (accessed on 26 May 2018).

- Humar, M.; Kržišnik, D.; Lesar, B.; Thaler, N.; Ugovšek, A.; Zupančič, K.; Žlahtič, M. Thermal modification of wax-impregnated wood to enhance its physical, mechanical, and biological properties. Holzforschung 2017, 71, 57–64. [Google Scholar] [CrossRef]

- Johansson, P.; Ekstrand-Tobin, A.; Svensson, T.; Bok, G. Laboratory study to determine the critical moisture level for mould growth on building materials. Int. Biodeterior. Biodegrad. 2012, 73, 23–32. [Google Scholar] [CrossRef]

- CEN. European Standard EN 152. Wood Preservatives. Determination of the protective effectiveness of a preservative treatment against blue stain in wood in service. Laboratory method. In Proceedings of the B/515, Brussels, Belgium, 2012; BSI: London, UK, 2012; Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030212121 (accessed on 12 October 2014).

- Raspor, P.; Smole-Možina, S.; Podjavoršek, J.; Pohleven, F.; Gogala, N.; V Nekrep, F.; Rogelj, I.; Hacin, J. ZIM: Zbirka Industrijskih Mikroorganizmov. Katalog Biokultur; Biotehniška fakulteta, Katedra za Biotehnologijo: Ljubljana, Slovenia, 1995. [Google Scholar]

- CEN. Paints and varnishes—Methods of exposure to laboratory light sources—Part 1: General guidance. In Proceedings of ISO/TC 35/SC 9 General Test Methods for Paints and Varnishes, Brussels, Belgium, 2013; BSI: London, UK, 2013; Available online: https://www.iso.org/obp/ui/#iso:std:iso:16474:-1:ed-1:v1:en (accessed on 12 October 2014).

- CIE, Colourimetry—Part 4: CIE 1976 L*a*b* Colour Space. 2007. Available online: http://www.cie.co.at/publications/colorimetry-part-4-cie-1976-lab-colour-space (accessed on 12 October 2014).

- Humar, M.; Kržišnik, D.; Lesar, B.; Ugovšek, A.; Rep, G.; Šubic, B.; Thaler, N.; Žlahtič, M. Performance of window, door, decking and façade elements made of thermally modified spruce wood on model house in Ljubljana. In Proceedings of the 27th International Conference on Wood Science and Technology (ICWST) Implementation of Wood Science in Woodworking Sector, Zagreb, Croatia, 13–14 October 2016; pp. 75–82. [Google Scholar]

- Yildiz, S.; Gümüşkaya, E. The effects of thermal modification on crystalline structure of cellulose in soft and hardwood. Build. Environ. 2007, 42, 62–67. [Google Scholar] [CrossRef]

- Yildiz, S.; Tomak, E.D.; Yildiz, U.C.; Ustaomer, D. Effect of artificial weathering on the properties of heat treated wood. Polym. Degrad. Stab. 2013, 98, 1419–1427. [Google Scholar] [CrossRef]

- Deka, M.; Humar, M.; Rep, G.; Kričej, B.; Šentjurc, M.; Petrič, M. Effects of UV light irradiation on colour stability of thermally modified, copper ethanolamine treated and non-modified wood: EPR and DRIFT spectroscopic studies. Wood Sci. Technol. 2008, 42, 5–20. [Google Scholar] [CrossRef]

- CEN. EN 350–Durability of wood and wood-based products. Testing and classification of the durability to biological agents of wood and wood-based materials. In Proceedings of the B/515, October, 2016; BSI: London, UK, 2016. [Google Scholar]

- Thaler, N.; Lesar, B.; Humar, M. Performance of Copper-Ethanolamine-impregnated Scots Pine Wood during Exposure to Terrestrial Microorganisms. Bioresources 2013, 8, 3299–3308. [Google Scholar] [CrossRef]

- Schmolz, E.; Brüders, N.; Daum, R.; Lamprecht, I. Thermoanalytical investigations on paper covers of social wasps. Thermochim. Acta 2000, 361, 121–129. Available online: https://ac.els-cdn.com/S0040603100005530/1-s2.0-S0040603100005530-main.pdf?_tid=ad8fc58b-6cd3-4df1-b1a0-34deaf292e7c&acdnat=1520343132_d977f0f4bb497addb1bfa7223354e1e9 (accessed on 6 March 2018). [CrossRef]

- Mokrzycki, W.S.; Tatol, M. Colour difference Delta E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Kamdem, D.P.; Grelier, S. Surface Roughness and Colour Change of Copper Amine and UV Absorber-Treated Red Maple (Acer rubrum) Exposed to Artificial Ultraviolet Ligh. Holzforschung 2002, 56, 473–478. Available online: https://www.degruyter.com/downloadpdf/j/hfsg.2002.56.issue-5/hf.2002.073/hf.2002.073.pdf (accessed on 22 November 2017). [CrossRef]

- Landry, V.; Blanchet, P. Weathering resistance of opaque PVDF-acrylic coatings applied on wood substrates. Prog. Org. Coat. 2012, 75, 494–501. [Google Scholar] [CrossRef]

- Hernández, V.A.; Evans, P.D. Technical Note: Melanization of the wood-staining fungus Aureobasidium pullulans in response to UV radiation. Wood Fiber Sci. 2015, 47, 120–124. [Google Scholar]

- Hernández, V.A. Role of Non-Decay Fungi on the Weathering of Wood. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, September 2012. [Google Scholar]

- Evans, P.D.; Thay, P.D.; Schmalzl, K.J. Degradation of wood surfaces during natural weathering. Effects on lignin and cellulose and on the adhesion of acrylic latex primers. Wood Sci. Technol. 1996, 30, 411–422. [Google Scholar] [CrossRef]

- Schoeman, M.; Dickinson, D.J. Growth of Aureobasidium pullulans on lignin breakdown products at weathered wood surfaces. Mycologist 1997, 11, 168–172. [Google Scholar] [CrossRef]

- Evans, P.D. Wood Products: Weathering. Encycl. Mater. Sci. Technol. 2001, 9716–9721. [Google Scholar] [CrossRef]

- Charisi, S.; Thiis, T.K.; Stefansson, P.; Burud, I. Prediction model of microclimatic surface conditions on building façades. Build. Environ. 2018, 128, 46–54. [Google Scholar] [CrossRef]

| Wood Species | Treatment | |||||||

|---|---|---|---|---|---|---|---|---|

| Norway Spruce (Picea abies) | European Larch (Larix decidua) | European Beech (Fagus sylvatica) | English Oak (Quercus robur) | Thermal Modification | Impregnation with Suspension of NATURAL Wax | Copper-Ethanolamine Impregnation | Water Borne Acrylic Surface Coating | |

| Abbreviation | PA | LD | FS | Q | TM | NW | CE | AC |

| PA | × | |||||||

| PA-NW | × | × | ||||||

| PA-AC | × | × | ||||||

| PA-CE | × | × | ||||||

| PA-CE-NW | × | × | × | |||||

| PA-TM | × | × | ||||||

| PA-TM-NW | × | × | × | |||||

| PA-TM-CE | × | × | × | |||||

| LD | × | |||||||

| LD-TM | × | × | ||||||

| FS | × | |||||||

| Q | × | |||||||

| Material | Exposure Direction | 1st Evaluation | 2nd Evaluation | 3rd Evaluation | 4th Evaluation | 5th Evaluation | 6th Evaluation |

|---|---|---|---|---|---|---|---|

| 29 November 2013 | 7 January 2014 | 18 March 2014 | 5 June 2014 | 7 October 2014 | 3 July 2015 | ||

| PA | north | 0.18 ± 0.60 | 1.09 ± 1.22 | 2.73 ± 1.10 | 3.18 ± 0.98 | 3.14 ± 1.46 | 3.00 ± 0.89 |

| south | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.20 ± 0.45 | 0.20 ± 0.45 | 0.20 ± 0.45 | |

| east | 0.00 ± 0.00 | 1.57 ± 0.79 | 1.86 ± 1.07 | 2.14 ± 1.07 | 2.29 ± 0.95 | - | |

| west | 0.00 ± 0.00 | 1.67 ± 0.71 | 2.44 ± 0.73 | 2.67 ± 0.71 | 3.50 ± 0.58 | 2.25 ± 0.46 | |

| decking | 1.79 ± 1.31 | 2.50 ± 1.16 | - | - | - | - | |

| PA-NW | north | 0.36 ± 0.81 | 0.73 ± 0.79 | 1.00 ± 1.10 | 1.36 ± 1.43 | 1.73 ± 1.35 | 2.73 ± 1.01 |

| south | 0.80 ± 1.10 | 2.00 ± 0.71 | 3.20 ± 0.45 | 3.60 ± 0.55 | 3.40 ± 0.55 | 3.40 ± 0.55 | |

| east | 0.00 ± 0.00 | 1.75 ± 0.46 | 2.00 ± 0.00 | 2.00 ± 0.00 | 2.00 ± 0.00 | 1.75 ± 0.46 | |

| west | 0.73 ± 0.79 | 1.91 ± 0.83 | 3.36 ± 0.50 | 3.64 ± 0.50 | 2.33 ± 2.08 | - | |

| decking | 1.36 ± 1.60 | 2.14 ± 1.03 | - | - | - | - | |

| PA-AC | north | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | - |

| south | 0.00 ± 0.00 | 0.40 ± 0.89 | 0.40 ± 0.89 | 0.40 ± 0.89 | 0.00 ± 0.00 | - | |

| east | 0.00 ± 0.00 | 0.71 ± 0.49 | 0.71 ± 0.49 | 0.29 ± 0.49 | 0.14 ± 0.38 | - | |

| west | 0.00 ± 0.00 | 0.73 ± 1.10 | 1.27 ± 1.62 | 1.27 ± 1.62 | 1.27 ± 1.62 | 1.00 ± 1.18 | |

| decking | 0.00 ± 0.00 | 0.43 ± 0.65 | 0.36 ± 0.50 | 0.50 ± 0.65 | 0.00 ± 0.00 | 0.00 ± 0.00 | |

| PA-CE | north | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.83 ± 0.98 |

| south | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | |

| east | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | |

| west | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.78 ± 0.83 | |

| decking | 0.00 ± 0.00 | 0.00 ± 0.00 | - | - | - | - | |

| PA-CE-NW | north | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| south | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.20 ± 0.45 | 0.20 ± 0.45 | 1.00 ± 1.00 | 3.00 ± 0.00 | |

| east | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.56 ± 0.88 | 0.56 ± 0.88 | 0.00 ± 0.00 | 0.00 ± 0.00 | |

| west | 0.00 ± 0.00 | 0.08 ± 0.28 | 0.23 ± 0.60 | 0.00 ± 0.00 | 0.00 ± 0.00 | 2.31 ± 0.48 | |

| decking | 0.00 ± 0.00 | 0.00 ± 0.00 | - | - | - | - | |

| PA-TM | north | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 1.67 ± 0.82 | 2.80 ± 0.45 | 3.00 ± 0.00 |

| south | 0.00 ± 0.00 | 0.40 ± 0.55 | 1.60 ± 1.14 | 1.80 ± 0.84 | 2.00 ± 0.71 | 2.00 ± 0.71 | |

| east | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.83 ± 0.39 | 1.50 ± 0.52 | 2.18 ± 0.40 | |

| west | 0.00 ± 0.00 | 0.36 ± 0.67 | 0.64 ± 0.81 | 0.91 ± 0.94 | 1.40 ± 0.84 | 2.67 ± 0.50 | |

| decking | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | - | - | |

| PA-TM-NW | north | 0.00 ± 0.00 | 0.83 ± 0.75 | 1.50 ± 0.84 | 1.50 ± 0.84 | 1.50 ± 0.84 | 0.50 ± 0.84 |

| south | 0.00 ± 0.00 | 0.40 ± 0.55 | 0.80 ± 0.45 | 1.00 ± 0.00 | - | - | |

| east | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.83 ± 0.41 | 1.00 ± 0.00 | 1.17 ± 0.41 | 0.33 ± 0.52 | |

| west | 0.00 ± 0.00 | 1.00 ± 0.00 | 1.00 ± 0.00 | 1.30 ± 0.48 | - | - | |

| decking | 0.14 ± 0.53 | 0.14 ± 0.53 | - | - | - | - | |

| PA-TM-CE | north | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| south | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | |

| east | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | |

| west | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.40 ± 0.84 | |

| decking | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | - | |

| LD | north | 0.00 ± 0.00 | 0.36 ± 0.92 | 1.00 ± 1.10 | 2.82 ± 0.40 | 3.27 ± 0.65 | 3.67 ± 0.82 |

| south | 0.00 ± 0.00 | 1.00 ± 0.71 | 1.00 ± 0.71 | 0.80 ± 0.84 | - | - | |

| east | 0.00 ± 0.00 | 1.29 ± 0.49 | 2.00 ± 0.00 | 2.00 ± 0.00 | 2.86 ± 0.38 | 3.00 ± 0.58 | |

| west | 0.00 ± 0.00 | 0.33 ± 0.59 | 2.00 ± 0.69 | 2.56 ± 0.70 | 3.22 ± 0.81 | 4.00 ± 0.00 | |

| decking | 0.70 ± 0.82 | 1.00 ± 0.00 | - | - | - | - | |

| LD-TM | north | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 1.27 ± 0.79 |

| south | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | |

| east | 0.00 ± 0.00 | 0.14 ± 0.38 | 0.57 ± 0.53 | 0.71 ± 0.76 | 0.86 ± 0.69 | 2.00 ± 1.00 | |

| west | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.45 ± 0.52 | 0.90 ± 0.32 | 0.80 ± 0.45 | 2.17 ± 0.41 | |

| decking | 0.00 ± 0.00 | 0.00 ± 0.00 | - | - | - | - | |

| FS | north | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.09 ± 0.30 | 0.45 ± 0.52 | 1.80 ± 0.92 |

| south | 0.80 ± 1.10 | 2.20 ± 0.45 | 3.20 ± 0.45 | 3.20 ± 0.45 | - | - | |

| east | 0.00 ± 0.00 | 2.57 ± 0.79 | 2.86 ± 0.38 | 3.71 ± 0.49 | 3.71 ± 0.49 | 3.00 ± 0.00 | |

| west | 0.00 ± 0.00 | 2.64 ± 0.50 | 3.64 ± 0.50 | 4.00 ± 0.00 | 4.00 ± 0.00 | 4.00 ± 0.00 | |

| decking | 1.00 ± 0.00 | 1.29 ± 0.47 | - | - | - | - | |

| Q | north | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.20 ± 0.45 | 0.80 ± 0.45 | 1.00 ± 0.71 | 3.40 ± 0.55 |

| south | 0.00 ± 0.00 | 1.00 ± 0.00 | 2.00 ± 0.00 | 2.40 ± 0.55 | 2.33 ± 0.58 | - | |

| east | 0.00 ± 0.00 | 0.00 ± 0.00 | 3.00 ± 0.82 | 3.14 ± 0.90 | 0.00 ± 0.00 | - | |

| decking | 0.00 ± 0.00 | 3.38 ± 0.81 | - | - | - | - |

| December 2013 | March 2014 | May 2014 | August 2014 | October 2014 | April 2015 | October 2015 | October 2016 | October 2016 | May 2017 | October 2017 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| North | 1st EN152 | 0.2532 | 0.3795 | 0.3051 | 0.5954 * | 0.4108 | 0.2575 | 0.3622 | 0.5125 | 0.4533 | 0.5986 * | 0.6380 * |

| 100 h of AW | 0.0838 | 0.1350 | 0.1040 | 0.2742 | 0.2710 | 0.3420 | 0.4173 | 0.5228 | 0.4278 | 0.4829 | 0.4105 | |

| 200 h of AW | 0.4715 | 0.5256 | 0.4837 | 0.2042 | 0.3276 | 0.4210 | 0.2751 | 0.2082 | 0.2813 | 0.2566 | 0.1982 | |

| 300 h of AW | 0.5005 | 0.5124 | 0.5061 | 0.0507 | 0.2503 | 0.1669 | 0.0308 | −0.0357 | 0.0241 | 0.0288 | −0.0299 | |

| 400 h of AW | 0.4499 | 0.4402 | 0.4747 | −0.0303 | 0.1948 | 0.0340 | −0.0809 | −0.1663 | −0.1129 | −0.1085 | −0.1532 | |

| 500 h of AW | 0.4377 | 0.4193 | 0.4641 | −0.0697 | 0.1709 | −0.0456 | −0.1422 | −0.2292 | −0.1820 | −0.1724 | −0.2220 | |

| 2nd EN152 | 0.1468 | 0.2683 | 0.2106 | 0.6746 * | 0.4468 | 0.8077 ** | 0.7820 ** | 0.8716 *** | 0.8840 *** | 0.8622 *** | 0.7754 ** | |

| South | 1st EN152 | −0.1013 | −0.1073 | 0.1510 | 0.0445 | 0.0439 | 0.0772 | 0.1256 | 0.1228 | 0.1306 | 0.2097 | |

| 100 h of AW | 0.2786 | 0.3490 | 0.5295 | 0.5555 | 0.4627 | 0.4225 | 0.3873 | 0.2317 | 0.1564 | 0.1929 | ||

| 200 h of AW | 0.5735 | 0.5999 * | −0.0073 | 0.0354 | −0.2184 | −0.2998 | −0.2910 | −0.3103 | −0.3887 | −0.4064 | ||

| 300 h of AW | 0.6487 * | 0.5906 * | −0.1047 | −0.0331 | −0.2384 | −0.3832 | −0.3564 | −0.4190 | −0.4867 | −0.5196 | ||

| 400 h of AW | 0.6298 * | 0.5395 | −0.1745 | −0.0882 | −0.2370 | −0.4036 | −0.3652 | −0.4380 | −0.4883 | −0.5261 | ||

| 500 h of AW | 0.6380 * | 0.5296 | −0.1764 | −0.0916 | −0.2198 | −0.4034 | −0.3659 | −0.4557 | −0.5006 | −0.5423 | ||

| 2nd EN152 | 0.0098 | 0.2104 | 0.5323 | 0.4462 | 0.3585 | 0.3909 | 0.3806 | 0.3858 | 0.3425 | 0.3813 | ||

| East | 1st EN152 | 0.2084 | 0.1446 | 0.2478 | 0.3850 | 0.4875 | 0.6086 * | 0.7382 ** | 0.7495 ** | 0.6927 * | 0.6772 * | 0.6768 * |

| 100 h of AW | −0.1115 | 0.1531 | 0.1129 | 0.1671 | 0.3753 | 0.4782 | 0.4860 | 0.4502 | 0.2683 | 0.2952 | 0.3039 | |

| 200 h of AW | 0.3524 | 0.0036 | 0.2001 | 0.3383 | 0.4179 | 0.2532 | 0.1461 | 0.0963 | 0.0719 | 0.0009 | −0.0056 | |

| 300 h of AW | 0.3784 | 0.0574 | 0.1631 | 0.2989 | 0.3400 | 0.1196 | −0.0361 | −0.0889 | −0.1648 | −0.2186 | −0.2331 | |

| 400 h of AW | 0.3202 | 0.0647 | 0.1190 | 0.2242 | 0.2541 | 0.0146 | −0.1564 | −0.1986 | −0.3007 | −0.3362 | −0.3545 | |

| 500 h of AW | 0.3105 | 0.0938 | 0.1219 | 0.2204 | 0.2247 | −0.0255 | −0.2096 | −0.2513 | −0.3697 | −0.3977 | −0.4172 | |

| 2nd EN152 | −0.0328 | 0.0421 | 0.1845 | 0.3122 | 0.4960 | 0.6795 * | 0.7399 ** | 0.7440 ** | 0.7077 * | 0.6954 * | 0.7081 * | |

| West | 1st EN152 | 0.0362 | −0.2075 | 0.5939 | 0.5767 | 0.6030 * | 0.6915 * | 0.7063 * | 0.6259 * | 0.6614 * | 0.6732 * | |

| 100 h of AW | 0.0559 | 0.0595 | 0.3951 | 0.5087 | 0.5758 | 0.5787 | 0.5088 | 0.3588 | 0.4068 | 0.4027 | ||

| 200 h of AW | 0.5974 | 0.7549 ** | 0.2914 | 0.3615 | 0.2721 | 0.1887 | 0.0770 | 0.0542 | 0.0030 | 0.0179 | ||

| 300 h of AW | 0.6130 * | 0.7152 * | 0.1806 | 0.2708 | 0.1692 | 0.0518 | −0.0928 | −0.1549 | −0.1975 | −0.2008 | ||

| 400 h of AW | 0.5754 | 0.6723 * | 0.1106 | 0.2141 | 0.1030 | −0.0326 | −0.1841 | −0.2628 | −0.2999 | −0.3098 | ||

| 500 h of AW | 0.5557 | 0.6147 * | 0.0556 | 0.1630 | 0.0576 | −0.0792 | −0.2359 | −0.3209 | −0.3525 | −0.3685 | ||

| 2nd EN152 | 0.1333 | 0.2183 | 0.4793 | 0.5378 | 0.6494 * | 0.7102 * | 0.7152 * | 0.7255* | 0.7227 * | 0.7533 ** | ||

| Decking | 1st EN152 | 0.6605 * | 0.6882 * | 0.5994 * | 0.5102 | 0.4812 | 0.6223 * | 0.6000 * | 0.6865 * | 0.6686 * | 0.6978 * | |

| 100 h of AW | 0.4234 | 0.4539 | 0.1997 | 0.1391 | 0.1052 | 0.2182 | 0.1943 | 0.3051 | 0.2716 | 0.3101 | ||

| 200 h of AW | 0.2149 | 0.0812 | −0.2044 | −0.2799 | −0.3676 | −0.3100 | −0.3345 | −0.3031 | −0.3180 | −0.2944 | ||

| 300 h of AW | 0.0447 | −0.0419 | −0.3443 | −0.3986 | −0.4915 | −0.4749 | −0.5086 | −0.4884 | −0.4987 | −0.4800 | ||

| 400 h of AW | −0.0568 | −0.1314 | −0.3935 | −0.4171 | −0.5091 | −0.5248 | −0.5618 | −0.5569 | −0.5644 | −0.5525 | ||

| 500 h of AW | −0.1110 | −0.1624 | −0.4270 | −0.4432 | −0.5274 | −0.5538 | −0.5950 * | −0.5917 * | −0.5986 * | −0.5897 * | ||

| 2nd EN152 | 0.7716 ** | 0.6711 * | 0.5101 | 0.4251 | 0.4002 | 0.5374 | 0.5155 | 0.5883 * | 0.5632 | 0.5897 * |

| PA | North | South | East | West | Decking | AW | PA-TM-NW | North | South | East | West | Decking | AW |

| North | 1.0000 | North | 1.0000 | ||||||||||

| South | 0.7852 ** | 1.0000 | South | 0.5413 | 1.0000 | ||||||||

| East | 0.9474 **** | 0.7579 * | 1.0000 | East | 0.6711 * | 0.9185 *** | 1.0000 | ||||||

| West | 0.9621 **** | 0.8020 ** | 0.9812 **** | 1.0000 | West | 0.5053 | 0.2718 | 0.3918 | 1.0000 | ||||

| Decking | 0.9246 *** | 0.8600 ** | 0.9035 *** | 0.9234 *** | 1.0000 | Decking | 0.3724 | 0.4759 | 0.7005 * | 0.1609 | 1.0000 | ||

| AW | 0.3143 | 0.2760 | 0.3523 | 0.3495 | 0.6308 | 1.0000 | AW | 0.6277 | 0.1450 | 0.6998 | 0.8033 | 0.6470 | 1.0000 |

| PA-NW | North | South | East | West | Decking | AW | PA-TM-CE | North | South | East | West | Decking | AW |

| North | 1.0000 | North | 1.0000 | ||||||||||

| South | 0.8407 ** | 1.0000 | South | −0.4673 | 1.0000 | ||||||||

| East | 0.8482 *** | 0.9844 **** | 1.0000 | East | 0.2749 | −0.0188 | 1.0000 | ||||||

| West | 0.8201 ** | 0.9928 **** | 0.9798 **** | 1.0000 | West | −0.0889 | −0.2488 | 0.5296 | 1.0000 | ||||

| Decking | 0.5652 | 0.7771 ** | 0.7121 | 0.8043 ** | 1.0000 | Decking | 0.4215 | -0.8985 *** | 0.3512 | 0.5073 | 1.0000 | ||

| AW | 0.4204 | 0.8643 * | 0.7957 * | 0.9158 * | 0.6876 | 1.0000 | AW | 0.5139 | 0.2543 | 0.6927 | −0.2958 | 0.3548 | 1.0000 |

| PA-AC | North | South | East | West | Decking | AW | LD | North | South | East | West | Decking | AW |

| North | 1.0000 | North | 1.0000 | ||||||||||

| South | 0.7681 ** | 1.0000 | South | 0.8302 ** | 1.0000 | ||||||||

| East | 0.7699 ** | 0.9249 *** | 1.0000 | East | 0.9782 **** | 0.8900 *** | 1.0000 | ||||||

| West | 0.8656 ** | 0.9435 **** | 0.9196 *** | 1.0000 | West | 0.9465 **** | 0.7199 * | 0.9278 *** | 1.0000 | ||||

| Decking | 0.8193 ** | 0.9583 **** | 0.8645 ** | 0.9603 **** | 1.0000 | Decking | 0.8970 *** | 0.8885 *** | 0.8945 *** | 0.8453 ** | 1.0000 | ||

| AW | −0.1464 | 0.8160 * | 0.7329 | 0.6814 | 0.6653 | 1.0000 | AW | 0.5908 | 0.3699 | 0.5754 | 0.6334 | 0.1141 | 1.0000 |

| PA-CE | North | South | East | West | Decking | AW | LD-TM | North | South | East | West | Decking | AW |

| North | 1.0000 | North | 1.0000 | ||||||||||

| South | 0.7422 * | 1.0000 | South | 0.3221 | 1.0000 | ||||||||

| East | 0.5899 | 0.3193 | 1.0000 | East | −0.2922 | −0.3275 | 1.0000 | ||||||

| West | 0.4870 | 0.1706 | 0.8410 ** | 1.0000 | West | −0.1847 | −0.4317 | −0.5800 | 1.0000 | ||||

| Decking | 0.6192 | 0.5841 | 0.7878 ** | 0.6476 * | 1.0000 | Decking | 0.5429 | 0.5844 | −0.2029 | −0.2184 | 1.0000 | ||

| AW | 0.3691 | 0.5695 | 0.7043 | −0.2040 | 0.1235 | 1.0000 | AW | 0.6665 | 0.0745 | 0.2824 | −0.6144 | 0.5873 | 1.0000 |

| PA-CE-NW | North | South | East | West | Decking | AW | FS | North | South | East | West | Decking | AW |

| North | 1.0000 | North | 1.0000 | ||||||||||

| South | 0.2818 | 1.0000 | South | 0.6038 | 1.0000 | ||||||||

| East | 0.4946 | 0.3070 | 1.0000 | East | 0.7403 ** | 0.9003 *** | 1.0000 | ||||||

| West | 0.4491 | 0.2511 | 0.7293* | 1.0000 | West | 0.7271 * | 0.9673 **** | 0.9678 **** | 1.0000 | ||||

| Decking | 0.0895 | 0.5894 | 0.0820 | −0.3457 | 1.0000 | Decking | 0.8100 ** | 0.7687** | 0.7618* | 0.8357 ** | 1.0000 | ||

| AW | 0.2101 | −0.0241 | 0.6212 | −0.3288 | 0.6704 | 1.0000 | AW | −0.2983 | −0.0857 | 0.2286 | −0.0450 | −0.4772 | 1.0000 |

| PA-TM | North | South | East | West | Decking | AW | Q | North | South | East | West | Decking | AW |

| North | 1.0000 | North | 1.0000 | ||||||||||

| South | −0.7545 * | 1.0000 | South | 0.5416 | 1.0000 | ||||||||

| East | 0.1603 | −0.0571 | 1.0000 | East | 0.0448 | 0.6575 * | 1.0000 | ||||||

| West | 0.2688 | −0.1126 | 0.7073 * | 1.0000 | West | 1.0000 | |||||||

| Decking | 0.3617 | −0.6223 | 0.5705 | 0.4952 | 1.0000 | Decking | 0.7403 * | 0.5233 | 0.3485 | 1.0000 | |||

| AW | −0.2530 | 0.4051 | 0.7702* | 0.4695 | 0.7050 | 1.0000 | AW | −0.3479 | −0.0395 | 0.4405 | 0.2566 | 1.0000 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests 2018, 9, 488. https://doi.org/10.3390/f9080488

Kržišnik D, Lesar B, Thaler N, Humar M. Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests. 2018; 9(8):488. https://doi.org/10.3390/f9080488

Chicago/Turabian StyleKržišnik, Davor, Boštjan Lesar, Nejc Thaler, and Miha Humar. 2018. "Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials" Forests 9, no. 8: 488. https://doi.org/10.3390/f9080488

APA StyleKržišnik, D., Lesar, B., Thaler, N., & Humar, M. (2018). Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests, 9(8), 488. https://doi.org/10.3390/f9080488