Effect of Impregnation with Maltodextrin and 1,3-Dimethylol-4,5-Dihydroxyethyleneurea on Poplar Wood

Abstract

1. Introduction

2. Experiment

2.1. Materials

2.2. Impregnation Treatment

2.3. Determination of Weight Percent Gain and Weight Leaching Ratio

2.4. Determination of Density and Dimensional Stability

2.5. Mechanical Tests

2.6. Morphological Analyses

2.7. Fourier-Transform Infrared Spectroscopy

2.8. X-ray Diffraction Analysis (XRD)

2.9. Statistical Analysis

3. Results and Discussion

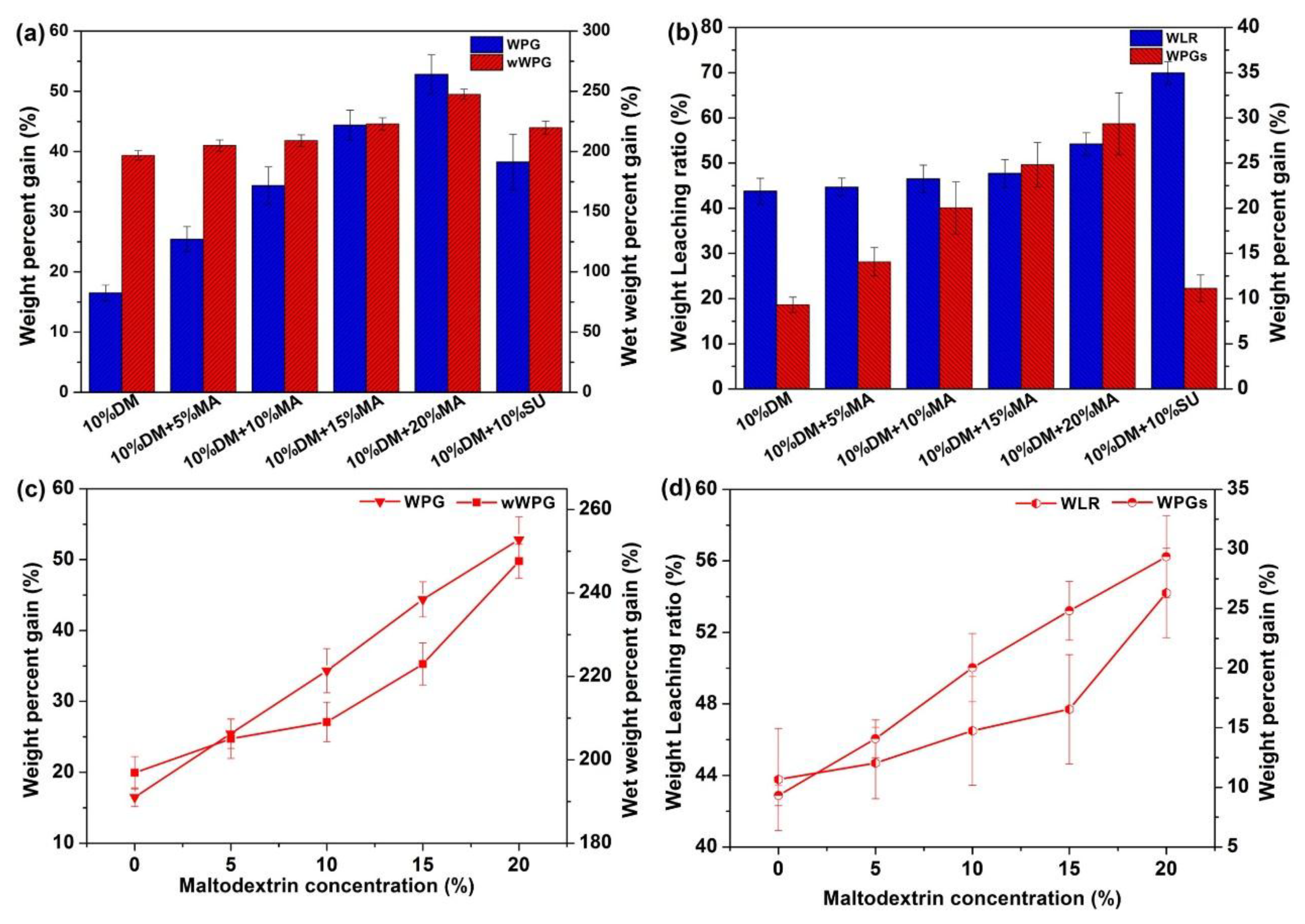

3.1. Effect of Modifier Concentration on Weight Percent Gain (WPG) and Weight Leaching Ratio (WLR)

3.2. Changes in Dimensional Stability after Treatment

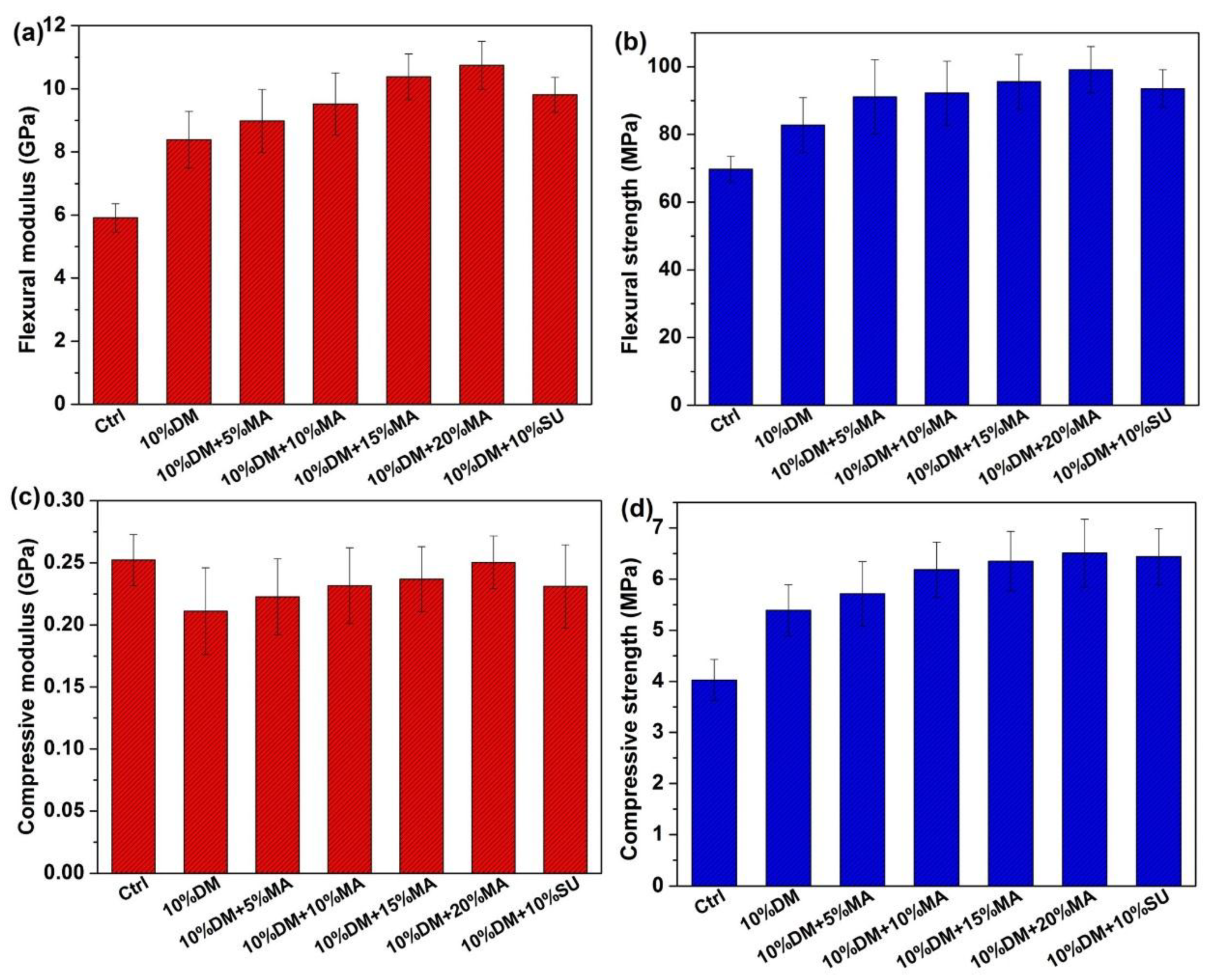

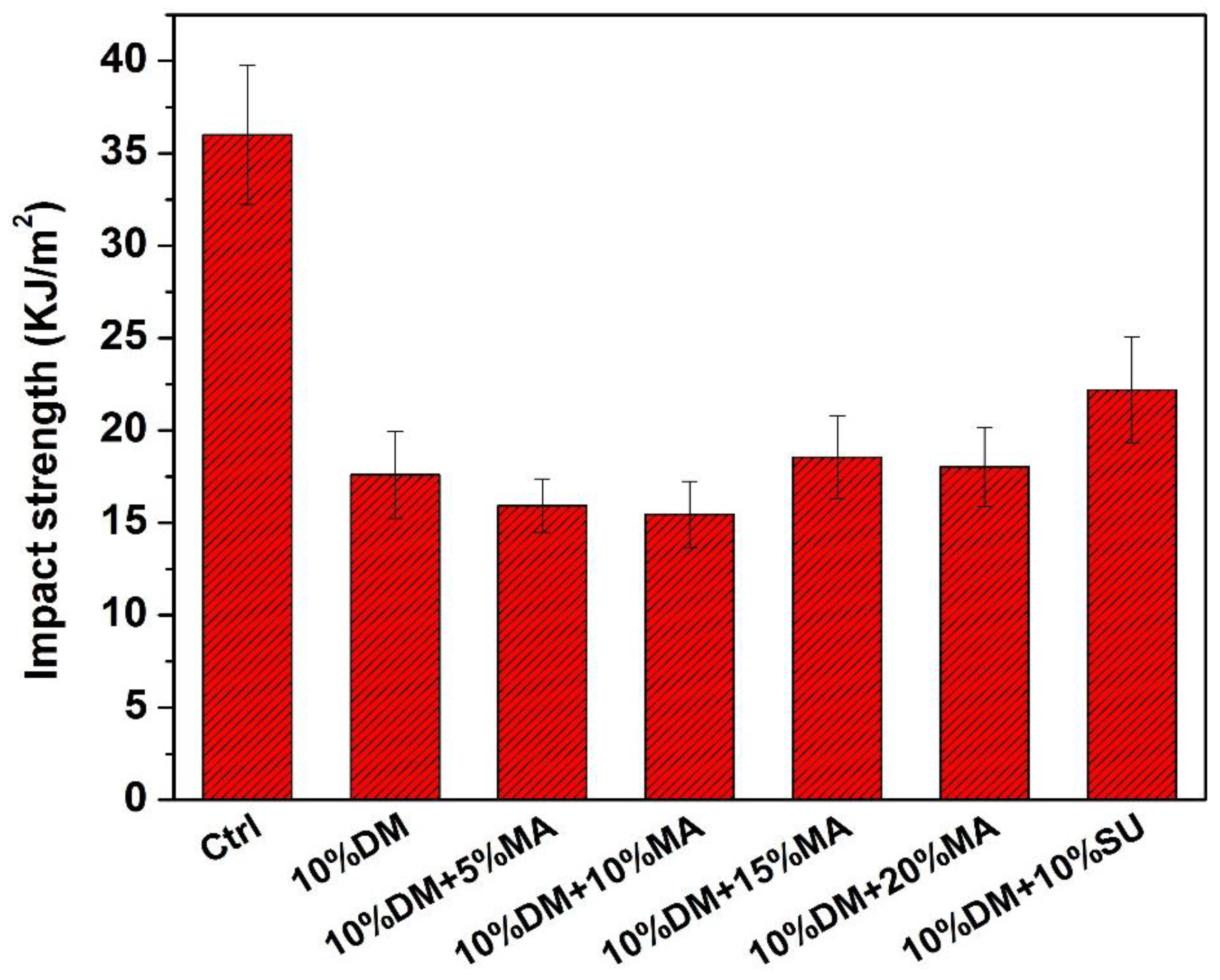

3.3. Determination of Mechanical Strength

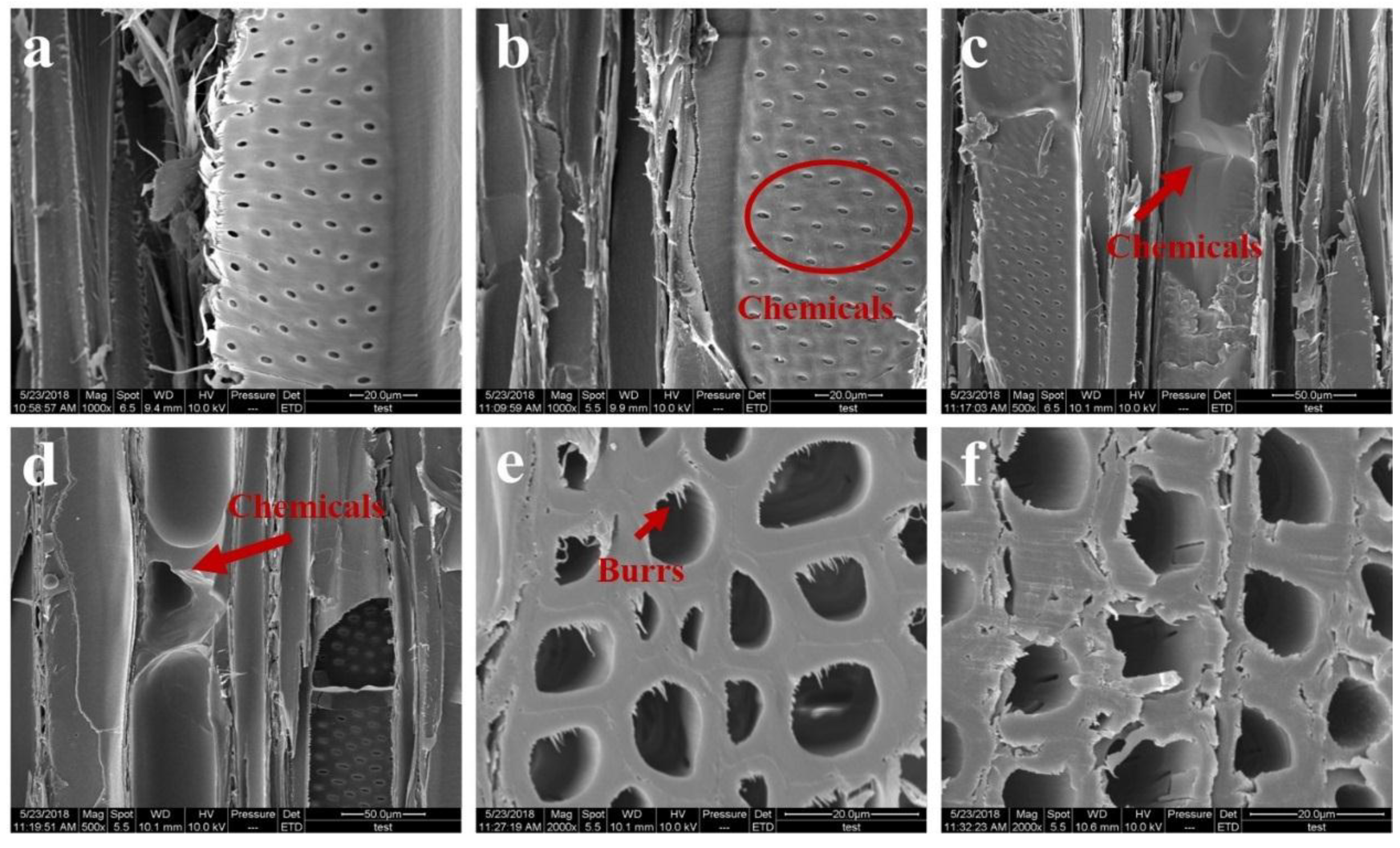

3.4. Morphological Analyses

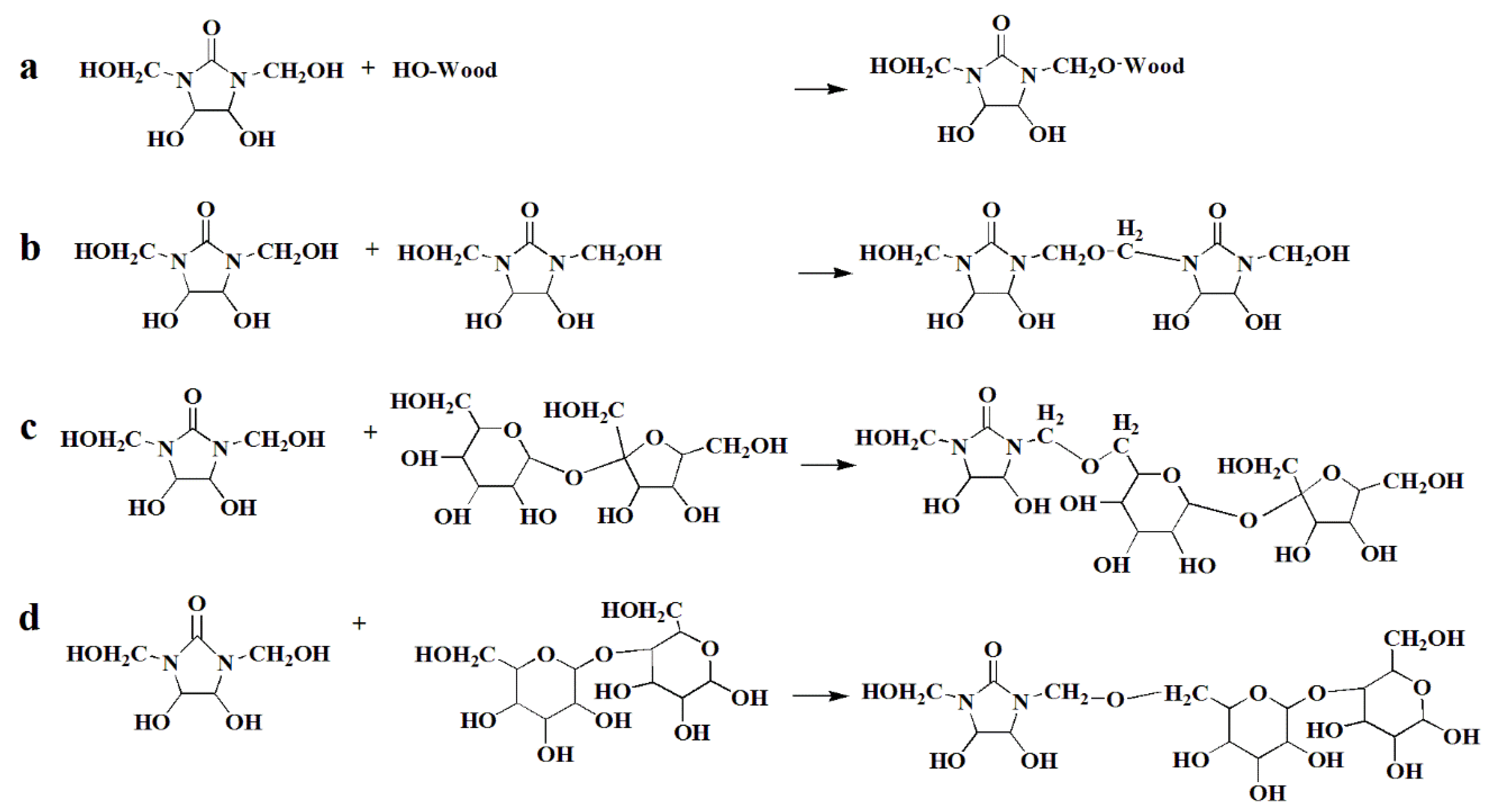

3.5. Fourier-Transform Infrared Spectroscopy

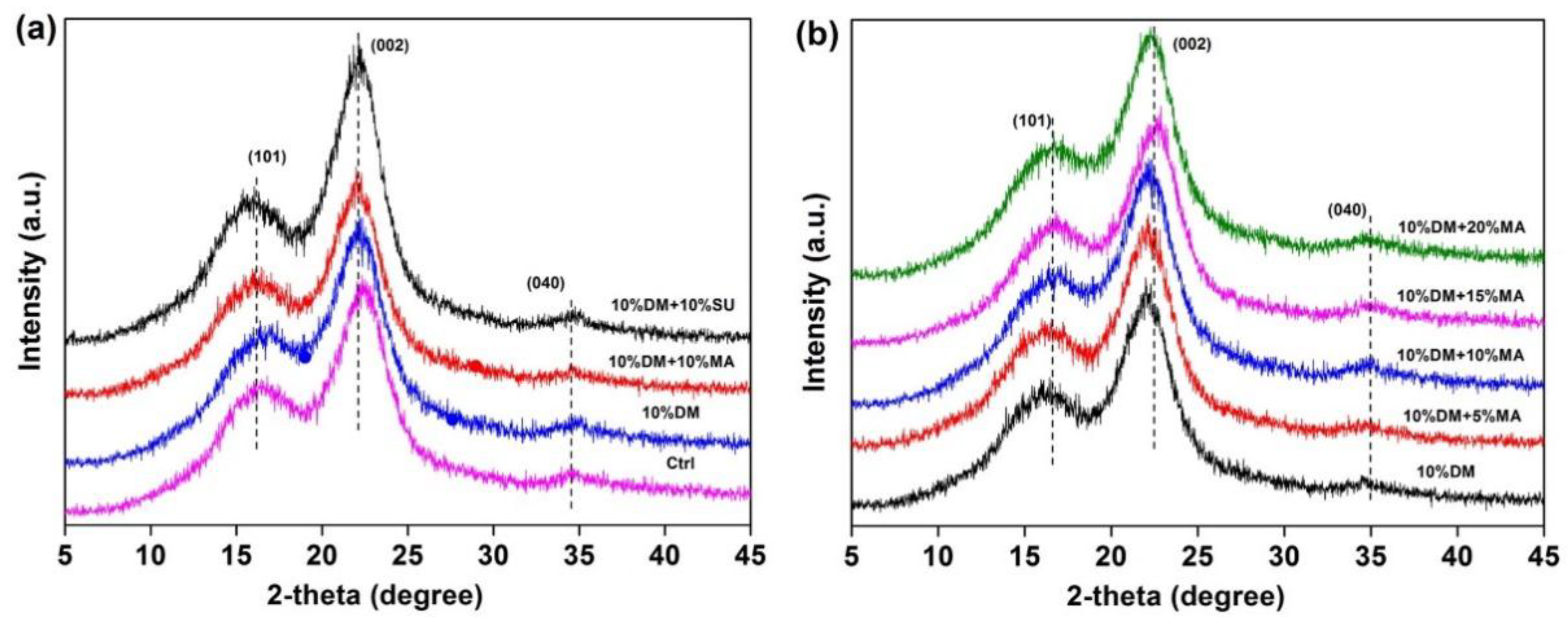

3.6. XRD Analyses

4. Conclusions

- (1)

- Before and after leaching, the WPG and WLR of the poplar wood improved, with up to 52.81% increase in MA concentration; however, WLR also increased from 43.78% to 54.20%. The wood treated with 10% MA concentration obtained an ASE with a maximum rate of 57.05%, which is lower than the ASE (63.55%) obtained when the wood was treated with SU at the same concentration. Simultaneously, the dry density, air density, and basic density of the wood increased by more than 40%;

- (2)

- In addition, the flexural strength, flexural modulus, and compressive strength perpendicular to the grain direction increased with an increase in MA concentration, reaching 42.13%, 81.68%, and 61.54%, respectively; however, the compressive modulus was slightly reduced, and the impact strength decreased by 57.05%;

- (3)

- Morphological analysis proved that chemical agents were attached to the cell lumen. FTIR spectroscopy also revealed that MA could inhibit cellulose hydrolysis and cross-linking between DM and the cell wall polymer. Crystallographic analysis showed that with an increase in MA concentration, the crystallinity of the cellulose crystallization zone was slightly reduced.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wacker, J.P. Chapter 17: Use of wood in buildings and bridges. In Wood Handbook: Wood as an Engineering Material; General Technical Report FPL GTR-190; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; Volume 190, pp. 1–13. [Google Scholar]

- Schneider, M.H.; Witt, A.E. History of wood polymer composite commercialization. For. Prod. J. 2004, 54, 19–24. [Google Scholar]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- González-Peña, M.M.; Hale, M.D.C. Rapid assessment of physical properties and chemical composition of thermally modified wood by mid-infrared spectroscopy. Wood Sci. Technol. 2011, 45, 83–102. [Google Scholar] [CrossRef]

- Militz, H. Treatment of timber with water soluble dimethylol resins to improve their dimensional stability and durability. Wood Sci. Technol. 1993, 27, 347–355. [Google Scholar] [CrossRef]

- Xie, Y.; Krause, A.; Militz, H.; Mai, C. Coating performance of finishes on wood modified with an N-methylol compound. Prog. Org. Coat. 2006, 57, 291–300. [Google Scholar] [CrossRef]

- Xie, Y.; Krause, A.; Mai, C.; Militz, H.; Richter, K.; Urban, K.; Evans, P.D. Weathering of wood modified with the N-methylol compound 1,3-dimethylol-4,5-dihydroxyethyleneurea. Polym. Degrad. Stab. 2005, 89, 189–199. [Google Scholar] [CrossRef]

- Xie, Y.; Krause, A.; Militz, H.; Mai, C. Weathering of uncoated and coated wood treated with methylated 1,3-dimethylol-4,5-dihydroxyethyleneurea (mDMDHEU). Holz als Roh-und Werkstoff 2008, 66, 455. [Google Scholar] [CrossRef]

- Krause, A.; Wepner, F.; Xie, Y.; Militz, H. Wood protection with dimethyloldihydroxy-ethyleneurea and its derivatives. In ACS Symposium Series; Oxford University Press: Oxford, UK, 2008; Volume 982, pp. 356–371. [Google Scholar]

- Scheiding, W.; Kruse, K.; Plaschkies, K.; Weiß, B. Thermally Modified Wood for Playground Toys: Investigations on 13 Industrially Manufactured Products. In Proceedings of the 2nd European Conference on Wood Modification, Göttingen, Germany, 6–7 October 2005. [Google Scholar]

- Hoa, T.T.P.; Thanh, N.D.; Loan, N.T. Effects of mDMDHEU treatment on mold and fungal resistance of Canarium album wood. In Proceedings of the IAWS—VFU Workshop Proceeding, Hanoi, Vietnam; 2015. [Google Scholar]

- Simonsen, J. Lack of Dimensional Stability in Cross-Linked Wood-Polymer Composites. Holzforschung 1998, 52, 102–104. [Google Scholar] [CrossRef]

- Homan, W.J.; Jorissen, A.J.M. Wood modification developments. Heron 2004, 49, 360–369. [Google Scholar]

- Stick, R.V. Carbohydrates: The sweet molecules of life. Carbohydr. Res. 2001, 337, 381. [Google Scholar]

- Wyman, C.E.; Dale, B.E.; Elander, R.T.; Holtzapple, M.; Ladisch, M.R.; Lee, Y.Y.; Mitchinson, C.; Saddler, J.N. Comparative sugar recovery and fermentation data following pretreatment of poplar wood by leading technologies. Biotechnol. Prog. 2009, 25, 333–339. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Xiao, Z.; Sui, S.; Wang, Q.; Xie, Y. Esterification of wood with citric acid: The catalytic effects of sodium hypophosphite (SHP). Holzforschung 2014, 68, 427–433. [Google Scholar] [CrossRef]

- He, X.; Xiao, Z.; Feng, X.; Sui, S.; Wang, Q.; Xie, Y. Modification of poplar wood with glucose crosslinked with citric acid and 1,3-dimethylol-4,5-dihydroxy ethyleneurea. Holzforschung 2016, 70, 47–53. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, Z.; Zhang, Q.; Huang, Z.; Xie, Y. Mechanical properties of the Fast-growing Planted Wood chemically modified with sucrose and N-methylol resin. J. Northeast For. Univ. 2017, 45, 44–48. [Google Scholar]

- Xiao, Z.; Yuan, P.; Wang, Q.; Guo, Y.; Feng, X.; Xie, Y. Coating and weathering performance of wood modified with a mixing solution of sucrose and DMDHEU. J. For. Eng. 2016, 1, 18–24. [Google Scholar]

- Zhang, Z.; Tu, D.; Guan, L.; Yun, H.; Liao, L. Drying schedule of Chinese White Poplar Lumber Impregnated with Modified Urea-Formaldehyde Resin. China Wood Ind. 2014, 28, 42–44. [Google Scholar]

- Zhang, X.; Wang, R.; Wang, W.; Wang, W.; Li, L.; Chu, Y.; Tian, Q. Study on Cross-Linking reaction of Maltodextrin with Formaldehyde. Guangzhou Chem. Ind. 2018, 46, 58–60. [Google Scholar]

- Qin, J.; Li, X.; Shao, Y.; Shi, K.; Zhao, X.; Feng, T. Optimization of delignification process for efficient preparation of transparent wood with high strength and high transmittance. Vacuum 2018, 158, 158–165. [Google Scholar] [CrossRef]

- Zhao, Y.; Gu, Z. Study on Stability of Maltdextrin. J. Chin. Cereals Oils Assoc. 2008, 23, 96–101. [Google Scholar]

- Xie, Y.; Xiao, Z.; Grüneberg, T.; Militz, H.; Hill, C.A.; Steuernagel, L.; Mai, C. Effects of chemical modification of wood particles with glutaraldehyde and 1,3-dimethylol-4,5-dihydroxyethyleneurea on properties of the resulting polypropylene composites. Compos. Sci. Technol. 2010, 70, 2003–2011. [Google Scholar] [CrossRef]

- Xie, Y.; Fu, Q.; Wang, Q.; Xiao, Z.; Militz, H. Effects of chemical modification on the mechanical properties of wood. Eur. J. Wood Wood Prod. 2013, 71, 401–416. [Google Scholar] [CrossRef]

- Winandy, J.E.; Rowell, R.M. Chemistry of wood strength. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2012; pp. 428–471. [Google Scholar]

- Xiao, Z.; Xie, Y.; Militz, H.; Mai, C. Effect of glutaraldehyde on water related properties of solid wood. Holzforschung 2010, 64, 483–488. [Google Scholar] [CrossRef]

- Larnøy, E.; Militz, H.; Eikenes, M. Uptake of chitosan based impregnation solutions with varying viscosities in four different European wood species. Holz als Roh-und Werkstoff 2005, 63, 456–462. [Google Scholar] [CrossRef]

- Bi, Z.; Lang, Q.; Pu, J. Chemical Modification of Fast-Grown Poplar by Urea Formaldehyde and Polyacrylic Resin. Wood Fiber Sci. 2014, 46, 573–580. [Google Scholar]

- Rautkari, L.; Laine, K.; Laflin, N.; Hughes, M. Surface modification of Scots pine: The effect of process parameters on the through thickness density profile. J. Mater. Sci. 2011, 46, 4780–4786. [Google Scholar] [CrossRef]

- Higgins, H.G.; Stewart, C.M.; Harrington, K.J. Infrared spectra of cellulose and related polysaccharides. J. Polym. Sci. 1961, 51, 59–84. [Google Scholar] [CrossRef]

- Faix, O.; Grünwald, C.; Beinhoff, O. Determination of phenolic hydroxyl group content of milled wood lignins (MWL’s) from different botanical origins using selective aminolysis, FTIR, 1H-NMR, and UV spectroscopy. Holzforschung 1992, 46, 425–432. [Google Scholar] [CrossRef]

- Evans, P.D.; Michell, A.J.; Schmalzl, K.J. Studies of the degradation and protection of wood surfaces. Wood Sci. Technol. 1992, 26, 151–163. [Google Scholar] [CrossRef]

- Yuan, J.; Hu, Y.; Li, L.; Cheng, F. The mechanical strength change of wood modified with DMDHEU. BioResources 2013, 8, 1076–1088. [Google Scholar] [CrossRef]

- Wada, M.; Okano, T.; Sugiyama, J. Allomorphs of native crystalline cellulose I evaluated by two equatoriald-spacings. J. Wood Sci. 2001, 47, 124–128. [Google Scholar] [CrossRef]

- Segal, L.G.; Creely, J.J.; Martin, A.E., Jr.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Jiang, Z. Analysis of the microfibrilla angles & crystallinity index of daemonorops margaritae with X-ray diffractometry and the effects of γ-ray irradiation. Spectrosc. Spectr. Anal. 2010, 30, 1404–1407. [Google Scholar]

- Ma, X.-X.; Wang, C.-G.; Zhang, S.-Y. Analysis of Microfibrilla Angles and Crystallinity Index of Grapevine. Chin. J. Spectrosc. Lab. 2012, 4, 51. [Google Scholar]

- Bhuiyan, M.T.R.; Hirai, N.; Sobue, N. Changes of crystallinity in wood cellulose by heat treatment under dried and moist conditions. J. Wood Sci. 2000, 46, 431–436. [Google Scholar] [CrossRef]

- Zhang, R.H.; He, Z.C.; Wang, H.W.; You, F.; Li, K.N. Study on self-tuning tyre friction control for developing main-servo loop integrated chassis control system. IEEE Access 2017, 5, 6649–6660. [Google Scholar] [CrossRef]

- Sun, X.J.; Zhang, H.; Meng, W.J.; Zhang, R.H.; Li, K.L.; Peng, T. Primary resonance analysis and vibration suppression for the harmonically excited nonlinear suspension system using a pair of symmetric viscoelastic buffers. Nonlinear Dyn. 2018, 4, 1–23. [Google Scholar] [CrossRef]

- Xiong, H.Y.; Zhu, X.L.; Zhang, R.H. Energy Recovery Strategy Numerical Simulation for Dual Axle Drive Pure Electric Vehicle Based on Motor Loss Model and Big Data Calculation. Complexity 2018, 2018, 1–14. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Li, H.; Ma, Y.; Zhang, R. High selective production of 5-hydroxymethylfurfural from fructose by sulfonic acid functionalized SBA-15 catalyst. Compos. Part B Eng. 2019, 156, 88–94. [Google Scholar] [CrossRef]

| Method | WPG (%) | wWPG (%) | WLR (%) | WPGs (%) |

|---|---|---|---|---|

| 10% DM | 16.50 ± 1.32 | 196.92 ± 3.88 | 43.78 ± 2.86 | 9.32 ± 0.84 |

| 10% DM + 5% MA | 25.45 ± 2.08 *,b | 205.04 ± 4.69 *,b | 44.69 ± 1.99 *,b | 14.08 ± 1.58 *,b |

| 10% DM + 10% MA | 34.34 ± 3.11 *,b,c | 209.06 ± 4.76 *,b,c | 46.49 ± 3.04 *,b,c | 20.05 ± 2.87 *,b,c |

| 10% DM + 15% MA | 44.39 ± 2.49 *,b,c,d | 222.97 ± 5.05 *,b,c,d | 47.70 ± 3.06 *,b,c,d | 24.82 ± 2.46 *,b,c,d |

| 10% DM + 20% MA | 52.81 ± 3.22 *,b,c,d,e | 247.61 ± 4.09 *,b,c,d,e | 54.20 ± 2.49 *,b,c,d,e | 29.35 ± 3.43 *,b,c,d,e |

| 10% DM + 10% SU | 38.26 ± 4.62 *,b,c,d,e,f | 219.79 ± 5.45 *,b,c,d,e,f | 69.94 ± 2.51 *,b,c,d,e,f | 11.15 ± 1.47 *,b,c,d,e,f |

| Method | Swelling (%) | Shrinkage (%) | ASE (%) | |

|---|---|---|---|---|

| R | T | |||

| Ctrl | 4.15 ± 0.42 | 4.38 ± 0.88 | 8.97 ± 0.64 | — |

| 10% DM | 3.29 ± 0.27 *,a | 2.44 ± 0.74 *,a | 5.12 ± 0.57 *,a | 52.45 ± 2.88 |

| 10% DM + 5% MA | 3.19 ± 0.41 *,a,b | 1.97 ± 0.39 *,a,b | 4.94 ± 0.56 *,a,b | 56.66 ± 3.24 *,b |

| 10% DM + 10% MA | 3.40 ± 0.38 *,a,b,c | 2.11 ± 0.69 *,a,b,c | 5.05 ± 0.47 *,a,b,**,c | 57.04 ± 5.26 *,b,**,c |

| 10% DM + 15% MA | 3.90 ± 0.28 *,a,b,c,d | 2.18 ± 0.18 *,a,b,c,d | 5.46 ± 0.47 *,a,b,c,d | 57.05 ± 3.66 *,b,c |

| 10% DM + 20% MA | 4.01 ± 0.32 *,a,b,c,d,e | 2.26 ± 0.24 *,a,b,c,d,e | 5.48 ± 0.82 *,a,b,c,d,**,e | 53.33 ± 3.78 *,b,c,d,e |

| 10% DM + 10% SU | 3.63 ± 0.36 *,a,b,c,d,e,f | 2.26 ± 0.23 *,a,b,c,d,e | 5.47 ± 0.81 *,a,b,c,d,**,e,f | 63.55 ± 6.12 *,b,c,d,e,f |

| Method | Density (g/cm3) | Improvement in Density (%) | ||||

|---|---|---|---|---|---|---|

| Dry | Air | Basic | Dry | Air | Basic | |

| Ctrl | 0.40 | 0.42 | 0.35 | — | — | — |

| 10% DM | 0.45 | 0.47 | 0.41 | 11.40 | 11.39 | 17.53 |

| 10% DM + 5% MA | 0.47 | 0.50 | 0.44 | 18.22 | 18.57 | 26.65 |

| 10% DM + 10% MA | 0.52 | 0.54 | 0.48 | 28.35 | 28.45 | 38.33 |

| 10% DM + 15% MA | 0.53 | 0.55 | 0.49 | 31.53 | 31.15 | 39.89 |

| 10% DM + 20% MA | 0.57 | 0.60 | 0.52 | 42.00 | 41.26 | 49.10 |

| 10% DM + 10% SU | 0.51 | 0.53 | 0.48 | 26.70 | 26.79 | 37.49 |

| Method | I (GPa) | II (MPa) | III (GPa) | IV (MPa) | V (kJ/m2) |

|---|---|---|---|---|---|

| Ctrl | 5.91 ± 0.44 | 69.75 ± 3.82 | 0.25 ± 0.02 | 4.03 ± 0.40 | 35.99 ± 3.75 |

| 10% DM | 8.38 ± 0.89 *,a | 82.81 ± 8.07 *,a | 0.21 ± 0.03 *,a | 5.39 ± 0.49 *,a | 17.59 ± 2.37 *,a |

| 10% DM + 5% MA | 8.98 ± 0.99 *,a,b | 91.12 ± 10.99 *,a,b | 0.22 ± 0.03 *,a,**,b | 5.71 ± 0.63 *,a,b | 15.93 ± 1.47 *,a,b |

| 10% DM + 10% MA | 9.52 ± 0.98 *,a,b,c | 92.25 ± 9.43 *,a,b,c | 0.23 ± 0.02 *,a,b,**,c | 6.18 ± 0.54 *,a,b,c | 15.46 ± 1.79 *,a,b,**,c |

| 10% DM + 15% MA | 10.38 ± 0.72 *,a,b,c,d | 95.58 ± 8.08 *,a,b,c,d | 0.24 ± 0.02 *,a,b,c,d | 6.35 ± 0.59 *,a,b,c,d | 18.56 ± 2.25 *,a,b,c,d |

| 10% DM + 20% MA | 10.74 ± 0.76 *,a,b,c,d,**,e | 99.14 ± 6.84 *,a,b,c,d,e | 0.25 ± 0.02 *,a,b,c,d,e | 6.51 ± 0.66 *,a,b,c,d,e | 18.02 ± 2.14 *,a,b,c,d,e |

| 10% DM + 10% SU | 9.81 ± 0.55 *,a,b,c,d,e,f | 93.56 ± 5.58 *,a,b,c,d,e,f | 0.23 ± 0.03 *,a,b,c,e,f,**,d | 6.44 ± 0.55 *,a,b,c,d,e,f | 22.19 ± 2.86 *,a,b,c,d,e,f |

| Method | Peak Position at 2θ | Cr (%) | D002 (nm) |

|---|---|---|---|

| Ctrl | 22.237 | 56.71 | 3.9944 |

| 10% DM | 22.002 | 55.07 | 4.0366 |

| 10% DM + 5% MA | 22.063 | 48.79 | 4.0255 |

| 10% DM + 10% MA | 21.985 | 44.51 | 4.0446 |

| 10% DM + 15% MA | 22.861 | 45.40 | 3.8868 |

| 10% DM + 20% MA | 22.835 | 45.03 | 3.8911 |

| 10% DM + 10% SU | 22.480 | 40.72 | 3.9517 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, M.; Fu, Z.; Cai, Y.; Li, Z.; Xu, C.; Xu, C.; Li, S. Effect of Impregnation with Maltodextrin and 1,3-Dimethylol-4,5-Dihydroxyethyleneurea on Poplar Wood. Forests 2018, 9, 676. https://doi.org/10.3390/f9110676

Cai M, Fu Z, Cai Y, Li Z, Xu C, Xu C, Li S. Effect of Impregnation with Maltodextrin and 1,3-Dimethylol-4,5-Dihydroxyethyleneurea on Poplar Wood. Forests. 2018; 9(11):676. https://doi.org/10.3390/f9110676

Chicago/Turabian StyleCai, Mingzhen, Zongying Fu, Yingchun Cai, Zhengdong Li, Can Xu, Cong Xu, and Shuai Li. 2018. "Effect of Impregnation with Maltodextrin and 1,3-Dimethylol-4,5-Dihydroxyethyleneurea on Poplar Wood" Forests 9, no. 11: 676. https://doi.org/10.3390/f9110676

APA StyleCai, M., Fu, Z., Cai, Y., Li, Z., Xu, C., Xu, C., & Li, S. (2018). Effect of Impregnation with Maltodextrin and 1,3-Dimethylol-4,5-Dihydroxyethyleneurea on Poplar Wood. Forests, 9(11), 676. https://doi.org/10.3390/f9110676