An Integrated GIS–MILP Framework for Cost-Optimal Forest Biomass-to-Bioenergy Supply Chains: A Case Study in Queensland, Australia

Abstract

1. Introduction

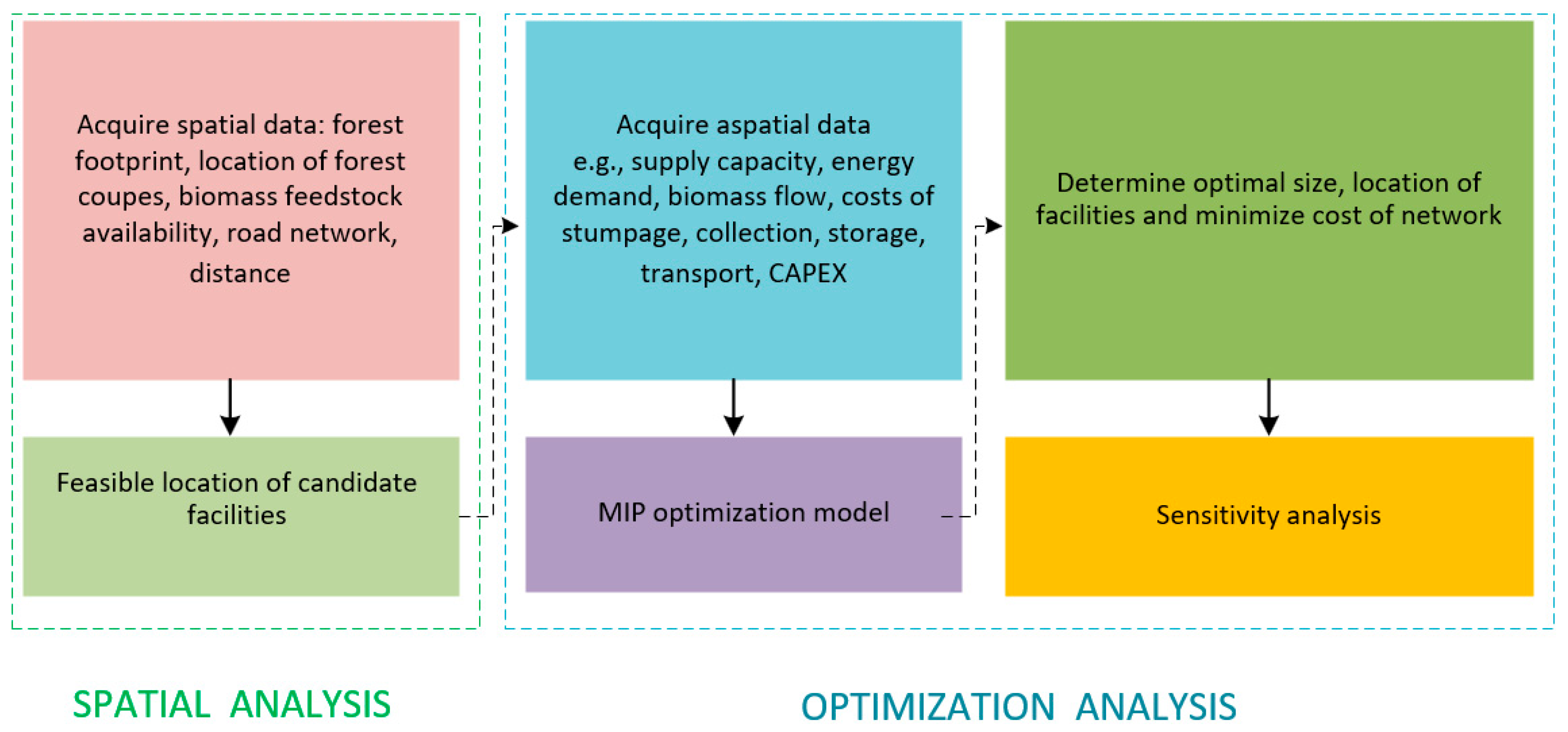

2. Materials and Methods

2.1. Case Study Description

2.2. Preceding GIS Analysis

2.3. Data Collection

2.3.1. Network Construction

2.3.2. Cost Parametrization

| Model Input | Notation | Value | Rationale/Source |

|---|---|---|---|

| Unit stumpage cost of biomass, assumed constant for different harvesting areas | cs | 10 AUD DMT−1 | (Personal communication) |

| Percentage storage interest rate of biomass | cm | 7% p.a. | Represents interest on delayed payment [38] |

| Unit collection of biomass in native forest (harvesting, chipping, forwarding) assumed constant for different harvesting areas | 69.23 AUD DMT−1 | [32]—Appendix A | |

| Unit collection cost of biomass in plantation forest (harvesting, chipping, forwarding), assumed constant for different harvesting areas | 38.37AUD DMT−1 | [32]—Appendix A | |

| Fixed transport cost | cf | 6.02 AUD DMT−1 | [32]—Appendix A |

| Variable transport cost | cv | 0.118 AUD DMT−1−km | [32]—Appendix A |

| Capacity-dependent installation cost of a facility j with capacity f | ck | 3,000,000 AUD MW−1 | [39,40,41] |

| Maximum transportation distance (km) | Dmax | 105 km | Economic break-even calculation (Equation (7)) [32,42] |

| Unit energy consumption cost | α | 0.005 AUD MJ−1 | [34,35] |

| Energy demand harvesting/forwarding | eh | 204.66 MJ DMT−1 | [43] |

| Energy demand transport | et | 2.38 MJ DMT−km | [44] |

| Unit environmental cost of CO2 emissions | β | 0.04 AUD kg−1 | Represents a carbon tax scenario [45] |

| GHG emissions harvesting/forwarding | gh | 39.66 kg CO2-eq DMT−1 | Calculated average for QLD [36,37] |

| GHG emissions transport | gt | 0.37 kg CO2-eq DMT−km | Calculated average for QLD [37] |

2.4. Optimization Model Formulation

2.4.1. Objective and Scope

2.4.2. Mathematical Structure

- I: set of forest biomass supply nodes, indexed by i;

- N ⊂ I: set of native forest origins, indexed by n;

- P ⊂ I: set of plantation forest origins, indexed by p;

- J: set of potential facility locations, indexed by j;

- F: set of discrete facility capacity levels, indexed by f.

- C: Total cost of the network, a sum of stumpage, collection, storage and transportation, and opening a facility [AUD];

- Qi: Availability of biomass at harvesting area i [DMT yr−1];

- Dij: binary indicator = 1, if dij ≤ Dmax; 0 otherwise;

- dij: Distance from harvesting area i to bioenergy facility j [km];

- Dmax: Maximum transportation distance [km];

- cs: Stumpage cost [AUD DMT−1];

- , : Collection costs in native and plantation forests [AUD DMT−1];

- cm: Percentage storage interest rate of biomass [%];

- cf: Fixed transport cost [AUD DMT−1];

- cv: Variable transport cost [AUD DMT−km];

- ck: Facility installation cost of a facility j with capacity f [AUD MW−1];

- Bjf: Capacity of facility f, if any, built at location j [MW];

- θ: Biomass-to-capacity conversion factor [DMT yr−1 MW−1];

- E: Total energy capacity target [MW].

- Yij: Biomass transported from node i to facility j [DMT yr−1];

- Xjf: Binary, =1 if facility j is built with capacity f, 0 otherwise.

2.4.3. Constraints

2.5. Scenario Design

- (1)

- Supply-Push (Biomass supply-driven) Scenario: In this scenario, the objective was to minimize system cost while maximizing the utilization of available forest biomass. The model considered all pre-identified candidate sites and installed the minimum number of facilities required to process the biomass supply, subject to lower and upper bounds on facility capacity and a maximum transport distance. Here, the installed capacity emerged as a proxy for the total bioenergy potential of the forest resource, rather than being constrained by external demand.

- (2)

- Demand-Pull (Energy demand-driven) Scenario: In this scenario, the model was cost-minimizing but constrained to meet a predefined regional energy demand [24,46]. Facilities were again restricted by minimum/maximum capacity and maximum transport distance. However, unlike the supply-push case, the total installed capacity was defined by an exogenous demand parameter representing the target energy requirement of the study area, not by the biomass resource base (Equation (4)).

2.6. Technological Assumptions

- Incremental demand scaling: The model was run with increasing total bioenergy demand in 50 MW increments until the model returned an infeasible solution to analyze system behavior such supply chain scalability, identification of capacity constraints, and evaluation of economic trade-offs across different operational scales.

- Biomass storage losses: Decay during storage was considered negligible for the timeframe relevant to this strategic analysis and was therefore not explicitly modeled.

- Constant Biomass Supply: Seasonal variation in biomass availability was assumed to be negligible. This reflects the subtropical conditions of Queensland, where year-round harvesting operations of both native forests and plantations ensures a consistent biomass flow.

- Exclusion of Facility Operational Costs: The objective function focuses on strategic, capital-intensive decisions, namely facility installation and the collection-and-transport network. Recurring operational costs (e.g., labor, maintenance, consumables) were excluded. While this simplifies the Total Economic Analysis (TEA), it is a valid approach for strategic planning. The main implication is that the model identifies the lowest-capital solution; a full TEA including operational expenditures would be essential for a final investment decision.

- Emissions as an Output Metric, not a Constraint: GHG emissions from transportation and facility operations were calculated retrospectively from the optimized supply chain configurations. They were not integrated as a direct constraint or objective. This approach prioritizes cost minimization as a baseline, while enabling a clear post-analysis of cost–emission trade-offs. Future work may extend the model to multi-objective formulations that explicitly integrate climate objectives.

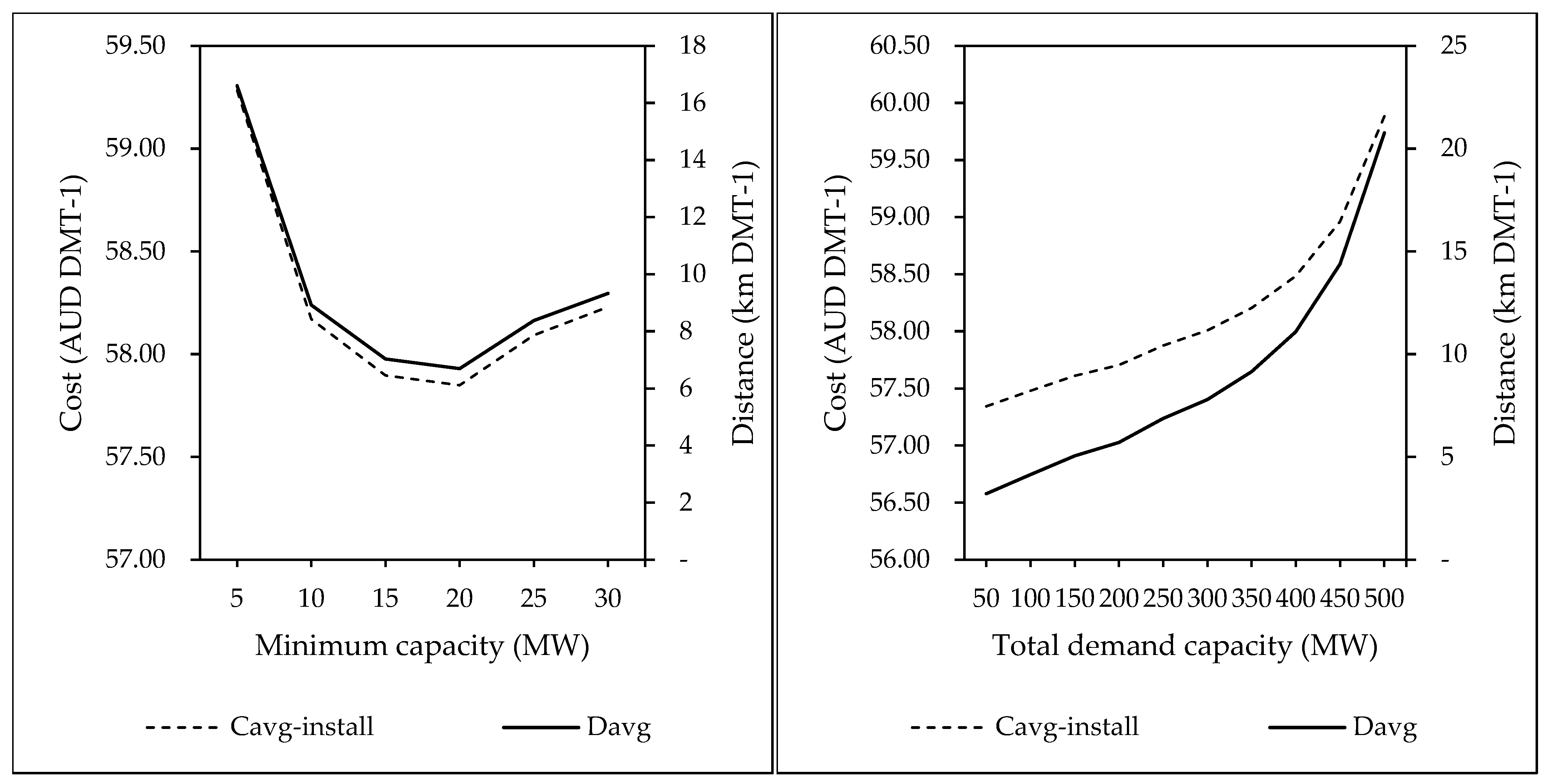

2.7. Sensitivity Analysis

3. Results

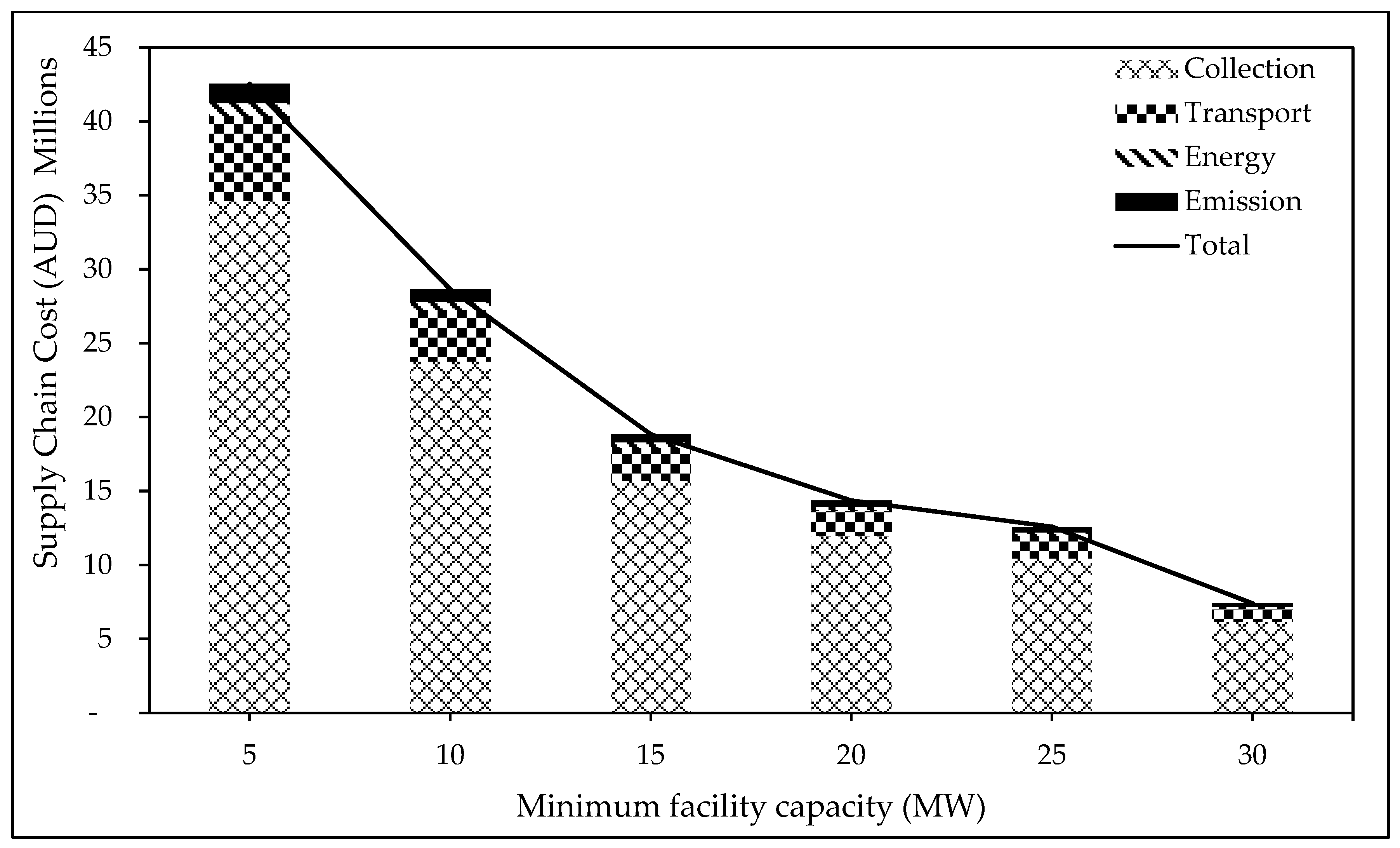

3.1. Supply-Push Scenario (Biomass-Driven)

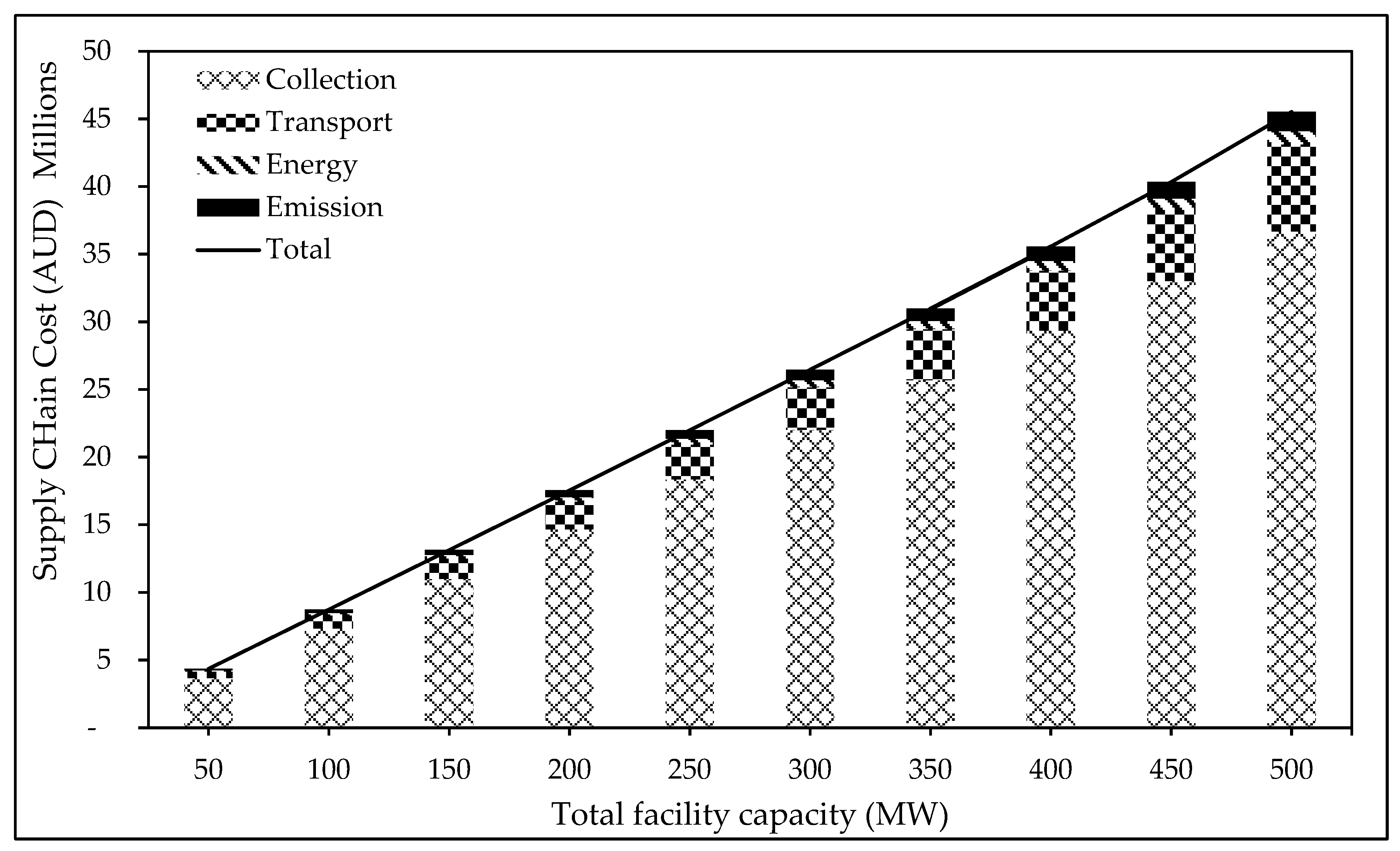

3.2. Demand-Pull Scenario (Energy-Driven)

3.3. Operational Cost Trends

3.4. Sensitivity Analysis

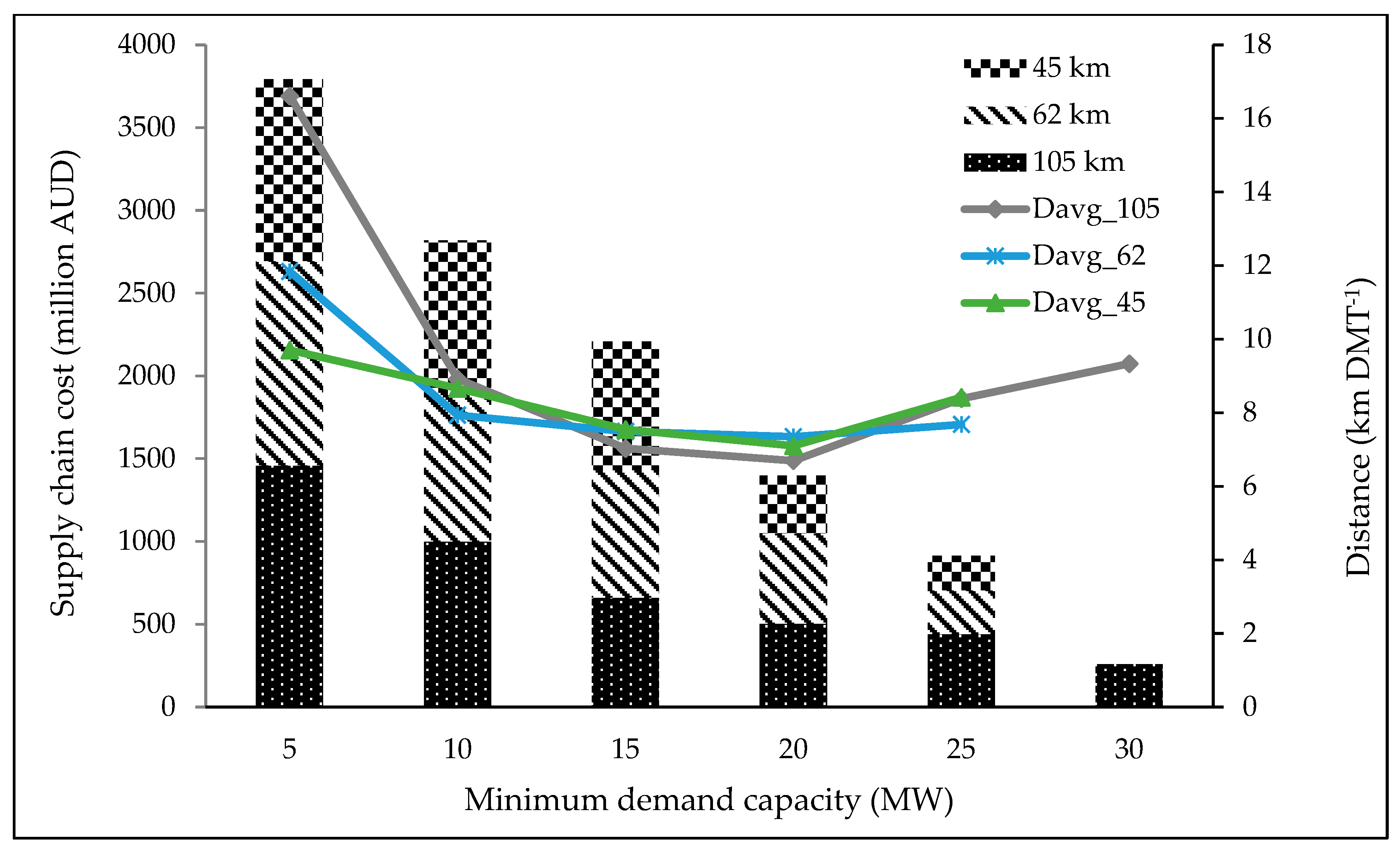

3.4.1. Impact of Maximum Transport Distance

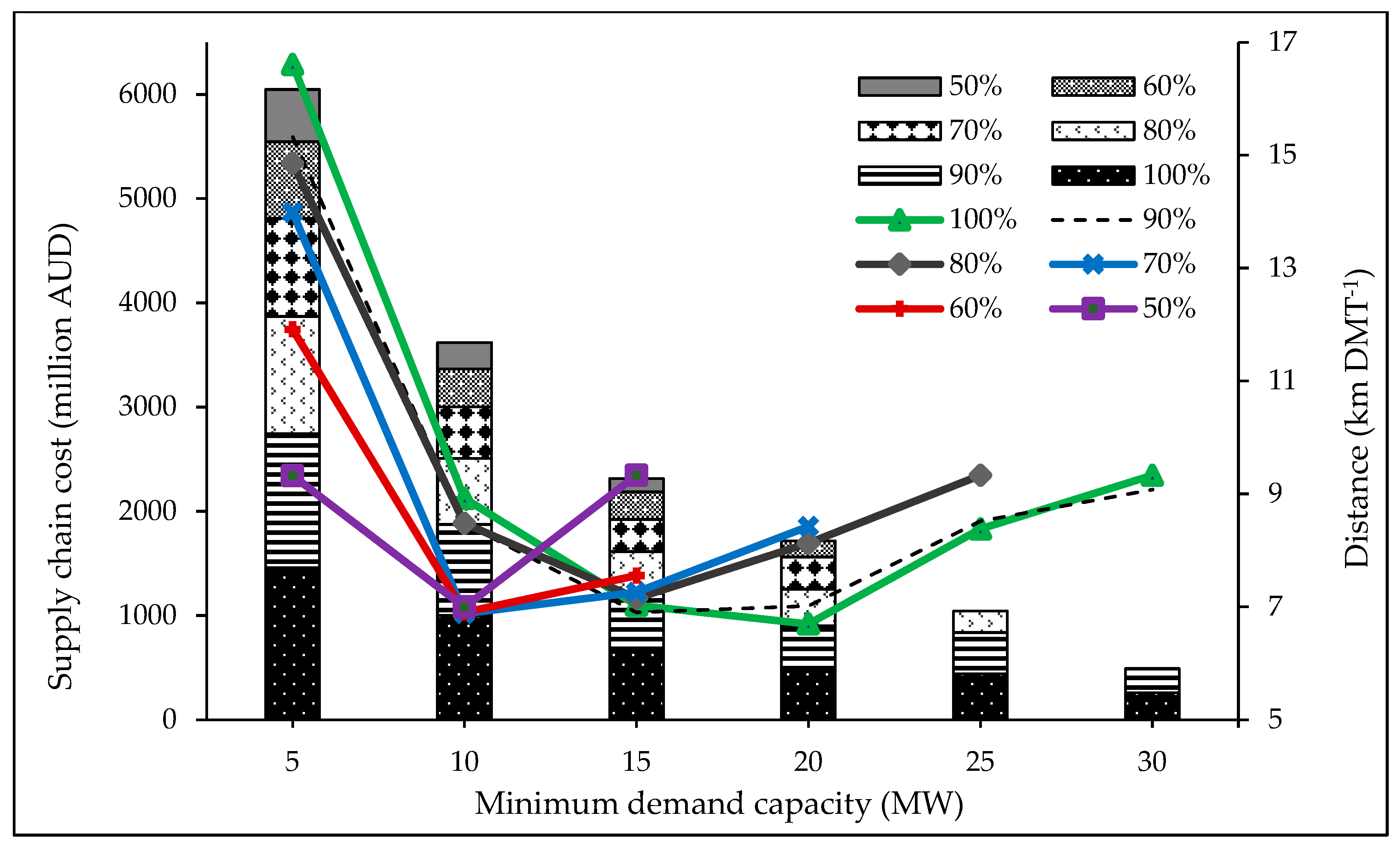

3.4.2. Impact of Biomass Availability

4. Discussion

4.1. Novelty and Contributions of the Framework

4.2. Scenario Insights

4.3. Strategic and Policy Implications

4.4. Limitations and Future Research

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA Bioenergy. Answers to Ten Frequently Asked Questions about Bioenergy, Carbon Sinks and Their Role in Global Climate Change; IEA Bioenergy: Graz, Austria, 2001. [Google Scholar]

- Szulecka, J. Towards Sustainable Wood-Based Energy: Evaluation and Strategies for Mainstreaming Sustainability in the Sector. Sustainability 2019, 11, 493. [Google Scholar] [CrossRef]

- KPMG. Bioenergy State of the Nation Report; Bioenergy Australia: Canberra, Australia, 2018. [Google Scholar]

- Australian Government. Australian Energy Update 2018; Department of the Environment and Energy: Canberra, Australia, 2018. [Google Scholar]

- ABARES. Australia’s State of the Forests Report 2018; Australian Government Department of Agriculture and Water Resources: Canberra, Australia, 2018. [Google Scholar]

- Berndes, G.; Abts, B.; Asikainen, A.; Cowie, A.; Dale, V.; Egnell, G.; Lindner, M.; Marelli, L.; Paré, D.; Pingoud, K.; et al. Forest Biomass, Carbon Neutrality and Climate Change Mitigation; European Forest Institute: Joensuu, Finland, 2016. [Google Scholar]

- Acuna, M.; Sessions, J.; Zamora, R.; Boston, K.; Brown, M.; Ghaffariyan, M.R. Methods to Manage and Optimize Forest Biomass Supply Chains: A Review. Curr. For. Rep. 2019, 5, 124–141. [Google Scholar] [CrossRef]

- Shi, X.; Elmore, A.; Li, X.; Gorence, N.J.; Jin, H.; Zhang, X.; Wang, F. Using Spatial Information Technologies to Select Sites for Biomass Power Plants: A Case Study in Guangdong Province, China. Biomass Bioenergy 2008, 32, 35–43. [Google Scholar] [CrossRef]

- Hock, B.K.; Blomqvist, L.; Hall, P.; Jack, M.; Möller, B.; Wakelin, S.J. Understanding Forest-Derived Biomass Supply with GIS Modelling. J. Spat. Sci. 2012, 57, 213–232. [Google Scholar] [CrossRef]

- Acuna, M. Timber and Biomass Transport Optimization: A Review of Planning Issues, Solution Techniques and Decision Support Tools. Croat. J. For. Eng. 2017, 38, 279–290. [Google Scholar]

- Murphy, H.T.; O’Connell, D.A.; Raison, R.J.; Warden, A.C.; Booth, T.H.; Herr, A.; Braid, A.L.; Crawford, D.F.; Hayward, J.A.; Jovanovic, T.; et al. Biomass Production for Sustainable Aviation Fuels: A Regional Case Study in Queensland. Renew. Sustain. Energy Rev. 2015, 44, 738–750. [Google Scholar] [CrossRef]

- Sahoo, K.; Hawkins, G.L.; Yao, X.A.; Samples, K.; Mani, S. GIS-Based Biomass Assessment and Supply Logistics System for a Sustainable Biorefinery: A Case Study with Cotton Stalks in the Southeastern US. Appl. Energy 2016, 182, 260–273. [Google Scholar] [CrossRef]

- Delivand, M.K.; Cammerino, A.R.B.; Garofalo, P.; Monteleone, M. Optimal Locations of Bioenergy Facilities, Biomass Spatial Availability, Logistics Costs and GHG (Greenhouse Gas) Emissions: A Case Study on Electricity Productions in South Italy. J. Clean Prod. 2015, 99, 129–139. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.; Johnson, M.; Watkins, D.; Froese, R.; Wang, J. Decision Support System Integrating GIS with Simulation and Optimisation for a Biofuel Supply Chain. Renew. Energy 2016, 85, 740–748. [Google Scholar] [CrossRef]

- Acuna, M.; Sánchez-García, S.; Canga, E. An Optimization Approach to Assess the Impact of Drying and Dry Matter Losses of Eucalyptus Globulus Roundwood and Biomass on Supply Chains Costs and GHG Emissions. Forests 2022, 13, 701. [Google Scholar] [CrossRef]

- Perpiña, C.; Martínez-Llario, J.C.; Pérez-Navarro, Á. Multicriteria Assessment in GIS Environments for Siting Biomass Plants. Land Use Policy 2013, 31, 326–335. [Google Scholar] [CrossRef]

- Voivontas, D.; Assimacopoulos, D.; Koukios, E.G. Assessment of Biomass Potential for Power Production: A GIS Based Method. Biomass Bioenergy 2001, 20, 101–112. [Google Scholar] [CrossRef]

- Panichelli, L.; Gnansounou, E. GIS-Based Approach for Defining Bioenergy Facilities Location: A Case Study in Northern Spain Based on Marginal Delivery Costs and Resources Competition between Facilities. Biomass Bioenergy 2008, 32, 289–300. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.M.; Sutherland, J.W. A GIS-Based Method for Identifying the Optimal Location for a Facility to Convert Forest Biomass to Biofuel. Biomass Bioenergy 2011, 35, 3951–3961. [Google Scholar] [CrossRef]

- Woo, H.; Acuna, M.; Moroni, M.; Taskhiri, M.S.; Turner, P. Optimizing the Location of Biomass Energy Facilities by Integrating Multi-Criteria Analysis (MCA) and Geographical Information Systems (GIS). Forests 2018, 9, 585. [Google Scholar] [CrossRef]

- Xing, J.; Sun, S.; Huang, Q.; Chen, Z.; Zhou, Z. Application of Geoinformatics in Forest Planning and Management. Forests 2024, 15, 439. [Google Scholar] [CrossRef]

- Costanza, L.; Maldera, F.; Garofalo, S.; Pietro; Vivaldi, G.A.; Camposeo, S. Ecological Optima Show the Potential Diffusion of Minor Tree Crops in Xylella Fastidiosa Subsp. Pauca-Infected Areas through a GIS-Based Approach. Front. Agron. 2024, 6, 1421627. [Google Scholar] [CrossRef]

- Ezzati, S.; Mohammadi, J. A Decision Support Model for Planning of Spatial Large Extent Biomass to Bioenergy Procurement Network. Bioresour. Technol. Rep. 2024, 27, 101886. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, J.; Liu, S.; Zhang, S.; Sutherland, J.W. Integrating GIS with Optimization Method for a Biofuel Feedstock Supply Chain. Biomass Bioenergy 2017, 98, 194–205. [Google Scholar] [CrossRef]

- Van Holsbeeck, S.; Srivastava, S.K. Feasibility of Locating Biomass-to-Bioenergy Conversion Facilities Using Spatial Information Technologies: A Case Study on Forest Biomass in Queensland, Australia. Biomass Bioenergy 2020, 139, 105620. [Google Scholar] [CrossRef]

- Queensland Government. Forest Products Pocket Facts—2017; Queensland Government Department of Agriculture and Fisheries: Brisbane, Australia, 2017. [Google Scholar]

- Queensland Government. Queensland Forest & Timber Industry: An Overview; Queensland Government Department of Agriculture and Fisheries: Brisbane, Australia, 2016. [Google Scholar]

- ABARES. Australian Forest and Wood Products Statistics; March to June Quarter 2020; ABARES: Canberra, Australia, 2020. [Google Scholar]

- Lock, P.; Whittle, L. Future Opportunities for Using Forest and Sawmill Residues in Australia; Australian Government Department of Agriculture and Water Resources: Canberra, Australia, 2018. [Google Scholar]

- Albioma Tuan Biomass. Available online: https://www.albioma.com/pt/unidad/australia/tuan-biomass/ (accessed on 5 May 2020).

- Geoscience Australia. Bioregional Assessment Source Dataset; GEODATA TOPO 20K Series 3; Geoscience, Australia: Canberra, Australia, 2006. [Google Scholar]

- Van Holsbeeck, S.; Ezzati, S.; Röser, D.; Brown, M. A Two-Stage DSS to Evaluate Optimal Locations for Bioenergy Facilities. Forests 2020, 11, 968. [Google Scholar] [CrossRef]

- NHVR Common Heavy Freight Vehicle Configurations; National Heavy Vehicle Regulator: Brisbane, Australia, 2019.

- Cummins, J.; Skennar, C.; Cassidy, M.; Palmer, G.; Capill, L. Using Small Hardwood Logs to Produce Liquid Fuels and Electricity. Aust. For. 2016, 79, 189–195. [Google Scholar] [CrossRef]

- Pearman, G.I. Overheads of Truck Transport in Australia: Implications for Biomass as Feedstock for Bio-Energy. Aust. J. Multi-Discip. Eng. 2018, 14, 34–41. [Google Scholar] [CrossRef]

- England, J.R.; May, B.; Raison, R.J.; Paul, K.I. Cradle-to-Gate Inventory of Wood Production from Australian Softwood Plantations and Native Hardwood Forests: Carbon Sequestration and Greenhouse Gas Emissions. For. Ecol. Manag. 2013, 302, 295–307. [Google Scholar] [CrossRef]

- Farine, D.R.; O’Connell, D.A.; Raison, R.J.; May, B.M.; O’Connor, M.H.; Crawford, D.F.; Herr, A.; Taylor, J.A.; Jovanovic, T.; Campbell, P.K.; et al. An Assessment of Biomass for Bioelectricity and Biofuel, and for Greenhouse Gas Emission Reduction in Australia. GCB Bioenergy 2012, 4, 148–175. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Acuna, M.; Brown, M. Analysing the Effect of Five Operational Factors on Forest Residue Supply Chain Costs: A Case Study in Western Australia. Biomass Bioenergy 2013, 59, 486–493. [Google Scholar] [CrossRef]

- CEFC. The Australian Bioenergy and Energy from Waste Market; Clean Energy Finance Corporation: Sydney, Australia, 2015. [Google Scholar]

- Sönnichsen, N. Average Installation Cost for Bioenergy Plants Worldwide from 2010 to 2018 (in U.S. Dollars per Kilowatt)*. Available online: https://www.statista.com/statistics/799356/global-bioenergy-installation-cost-per-kilowatt/ (accessed on 21 June 2020).

- Stucley, C.R.; Schuck, S.M.; Larsen, P.L.; Turvey, N.D.; Marino, B.E. Biomass Energy Production in Australia: Status, Costs and Opportunities for Major Technologies; Australian Government Rural Industries Research and Development Corporation: Canberra, Australia, 2008. [Google Scholar]

- Rodriguez, L.C.; May, B.; Herr, A.; O’Connell, D. Biomass Assessment and Small Scale Biomass Fired Electricity Generation in the Green Triangle, Australia. Biomass Bioenergy 2011, 35, 2589–2599. [Google Scholar] [CrossRef]

- May, B.; England, J.R.; Raison, R.J.; Paul, K.I. Cradle-to-Gate Inventory of Wood Production from Australian Softwood Plantations and Native Hardwood Forests: Embodied Energy, Water Use and Other Inputs. For. Ecol. Manag. 2012, 264, 37–50. [Google Scholar] [CrossRef]

- Pandur, Z.; Šušnjar, M.; Zorić, M.; Nevečerel, H.; Horvat, D. Energy Return on Investment (EROI) of Different Wood Products. In Precious Forests—Precious Earth; IntechOpen: London, UK, 2015; pp. 165–184. [Google Scholar]

- Polglase, P.J.; Reeson, A.; Hawkins, C.S.; Paul, K.I.; Siggins, A.W.; Turner, J.; Crawford, D.F.; Jovanovic, T.; Hobbs, T.J.; Opie, K.; et al. Potential for Forest Carbon Plantings to Offset Greenhouse Emissions in Australia: Economics and Constraints to Implementation. Clim. Change 2013, 121, 161–175. [Google Scholar] [CrossRef]

- Freppaz, D.; Minciardi, R.; Robba, M.; Rovatti, M.; Sacile, R.; Taramasso, A. Optimizing Forest Biomass Exploitation for Energy Supply at a Regional Level. Biomass Bioenergy 2004, 26, 15–25. [Google Scholar] [CrossRef]

- Nord-Larsen, T.; Talbot, B. Assessment of Forest-Fuel Resources in Denmark: Technical and Economic Availability. Biomass Bioenergy 2004, 27, 97–109. [Google Scholar] [CrossRef]

- Frombo, F.; Minciardi, R.; Robba, M.; Rosso, F.; Sacile, R. Planning Woody Biomass Logistics for Energy Production: A Strategic Decision Model. Biomass Bioenergy 2009, 33, 372–383. [Google Scholar] [CrossRef]

- IndustryEdge. Australian Hardwood Chip Export Volume & Price Forecasts and Stumpage and Harvest Cost Review; IndustryEdge Pty Ltd.: Geelong West, Australia, 2013. [Google Scholar]

- Abasian, F.; Rönnqvist, M.; Ouhimmou, M. Forest Bioenergy Network Design under Market Uncertainty. Energy 2019, 188, 116038. [Google Scholar] [CrossRef]

- Razm, S.; Dolgui, A.; Hammami, R.; Brahimi, N.; Nickel, S.; Sahebi, H. A Two-Phase Sequential Approach to Design Bioenergy Supply Chains under Uncertainty and Social Concerns. Comput. Chem. Eng. 2021, 145, 107131. [Google Scholar] [CrossRef]

- Guilhermino, A.; Lourinho, G.; Brito, P.; Almeida, N. Assessment of the Use of Forest Biomass Residues for Bioenergy in Alto Alentejo, Portugal: Logistics, Economic and Financial Perspectives. Waste Biomass Valorization 2018, 9, 739–753. [Google Scholar] [CrossRef]

- Cambero, C.; Hans Alexandre, M.; Sowlati, T. Life Cycle Greenhouse Gas Analysis of Bioenergy Generation Alternatives Using Forest and Wood Residues in Remote Locations: A Case Study in British Columbia, Canada. Resour. Conserv. Recycl. 2015, 105, 59–72. [Google Scholar] [CrossRef]

- Tucker, S.N.; Tharumarajah, A.; May, B.; England, J.; Paul, K.; Hall, M.; Mitchell, P.; Rouwette, R.; Seo, S.; Syme, M. Life Cycle Inventory of Australian Forestry and Wood Products; Forest and Wood Products Research and Development Corporation: Melbourne, Australia, 2009. [Google Scholar]

- Cherubini, F.; Strømman, A.H. Life Cycle Assessment of Bioenergy Systems: State of the Art and Future Challenges. Bioresour. Technol. 2011, 102, 437–451. [Google Scholar] [CrossRef]

| Aspect | Supply-Push Scenario (Biomass-Driven) | Demand-Pull Scenario (Energy-Driven) |

|---|---|---|

| Primary driver | Maximize utilization of available forest biomass | Meet predefined regional energy demand |

| Installed capacity defined by | Total biomass resource available (DMT → MW) | Exogenous energy demand parameter (MW) |

| Objective | Minimize total cost while processing maximum feasible biomass | Minimize total cost while meeting specified demand |

| Number of facilities | Minimum required to utilize biomass within capacity and distance limits | Minimum required to satisfy demand within capacity and distance limits |

| Key constraints | Minimum/maximum facility capacity; maximum transport distance; biomass availability | Minimum/maximum facility capacity; maximum transport distance; energy demand target |

| Interpretation | Proxy for bioenergy potential of the forest resource | Proxy for system adequacy to meet regional energy needs |

| Policy relevance | Informs strategies to mobilize underutilized biomass resources | Informs strategies to align bioenergy with energy market demand |

| Model Input | Notation | Value | Sensitivity Range | Rationale/Source |

|---|---|---|---|---|

| Max. viable transport distance | Dmax | 105 km | 84–126 km (±20%) | Economic break-even calculation (Equation (7)) [32,42] |

| Biomass availability multiplier | Qi | 1 | 0.8–1.2 | Reflects uncertainty in yield, access, and market competition |

| Minimum Capacity (MW) | Total Capacity (MW) | Avg. Facility Size (MW) | Number of Facilities | Avg. Number of Nodes | Installation Cost (AUD) |

|---|---|---|---|---|---|

| 5 | 472 | 14 | 34 | 898 | 1,416,258,616 |

| 10 | 324 | 19 | 17 | 351 | 971,902,370 |

| 15 | 214 | 18 | 12 | 292 | 642,005,093 |

| 20 | 163 | 20 | 8 | 311 | 490,068,742 |

| 25 | 143 | 29 | 5 | 448 | 427,561,012 |

| 30 | 84 | 42 | 2 | 280 | 250,823,755 |

| Energy Capacity (MW) | Average Capacity (MW) | Optimal Number of Facilities | Avg. Number of Nodes | Installation Cost (AUD) |

|---|---|---|---|---|

| 50 | 5 | 10 | 67 | 150,000,000 |

| 100 | 10 | 10 | 144 | 300,000,000 |

| 150 | 13 | 12 | 183 | 450,000,000 |

| 200 | 13 | 16 | 188 | 600,000,000 |

| 250 | 15 | 17 | 237 | 750,000,000 |

| 300 | 14 | 21 | 269 | 900,000,000 |

| 350 | 15 | 23 | 315 | 1,050,000,000 |

| 400 | 16 | 25 | 458 | 1,200,000,000 |

| 450 | 14 | 32 | 709 | 1,350,000,000 |

| 500 | 12 | 41 | 972 | 1,500,000,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Holsbeeck, S.; Acuna, M.; Ezzati, S. An Integrated GIS–MILP Framework for Cost-Optimal Forest Biomass-to-Bioenergy Supply Chains: A Case Study in Queensland, Australia. Forests 2025, 16, 1467. https://doi.org/10.3390/f16091467

Van Holsbeeck S, Acuna M, Ezzati S. An Integrated GIS–MILP Framework for Cost-Optimal Forest Biomass-to-Bioenergy Supply Chains: A Case Study in Queensland, Australia. Forests. 2025; 16(9):1467. https://doi.org/10.3390/f16091467

Chicago/Turabian StyleVan Holsbeeck, Sam, Mauricio Acuna, and Sättar Ezzati. 2025. "An Integrated GIS–MILP Framework for Cost-Optimal Forest Biomass-to-Bioenergy Supply Chains: A Case Study in Queensland, Australia" Forests 16, no. 9: 1467. https://doi.org/10.3390/f16091467

APA StyleVan Holsbeeck, S., Acuna, M., & Ezzati, S. (2025). An Integrated GIS–MILP Framework for Cost-Optimal Forest Biomass-to-Bioenergy Supply Chains: A Case Study in Queensland, Australia. Forests, 16(9), 1467. https://doi.org/10.3390/f16091467