Co-Pelletization of Lavender Waste and Pine-Wood for Sustainable Fuel Pellet Production

Abstract

1. Introduction

2. Materials and Methods

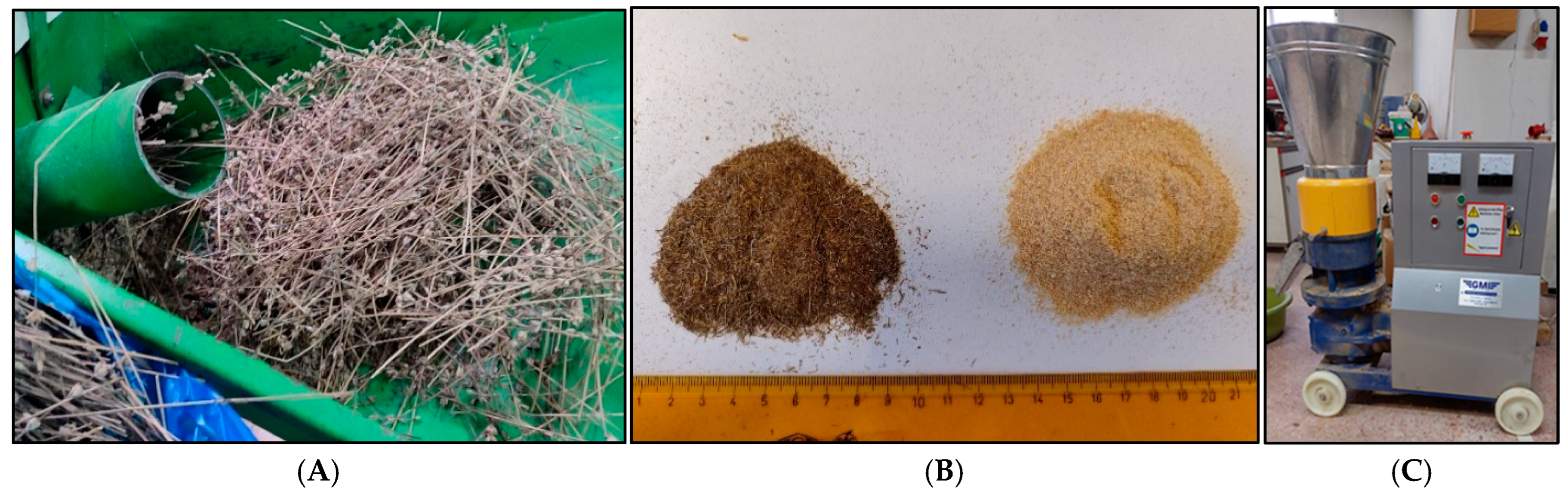

2.1. Feedstock Material Processing and Characterization

2.2. Feedstock Mixture Preparation—Pellet Production

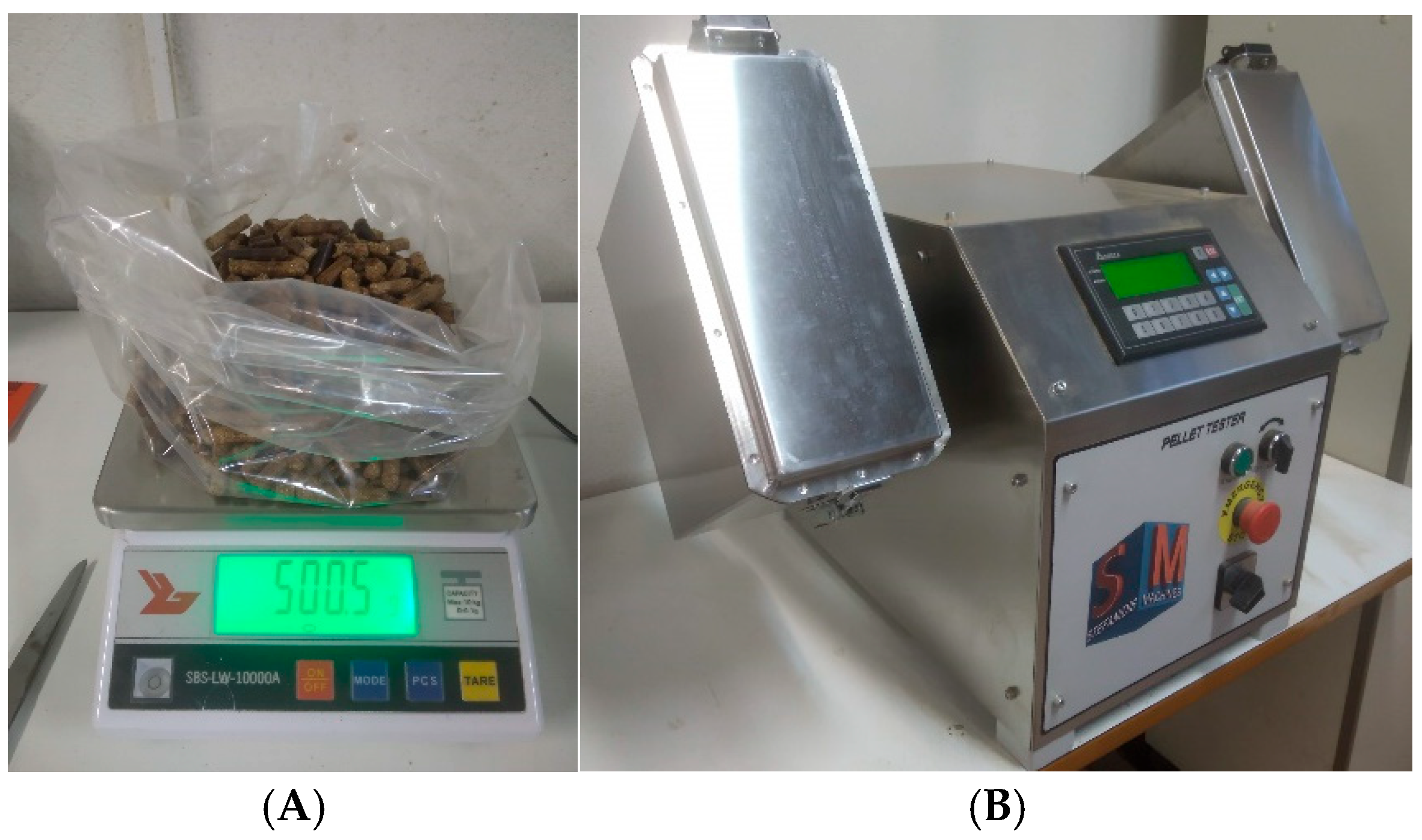

2.3. Characterization of Pellets

2.4. Statistical Analysis

3. Results

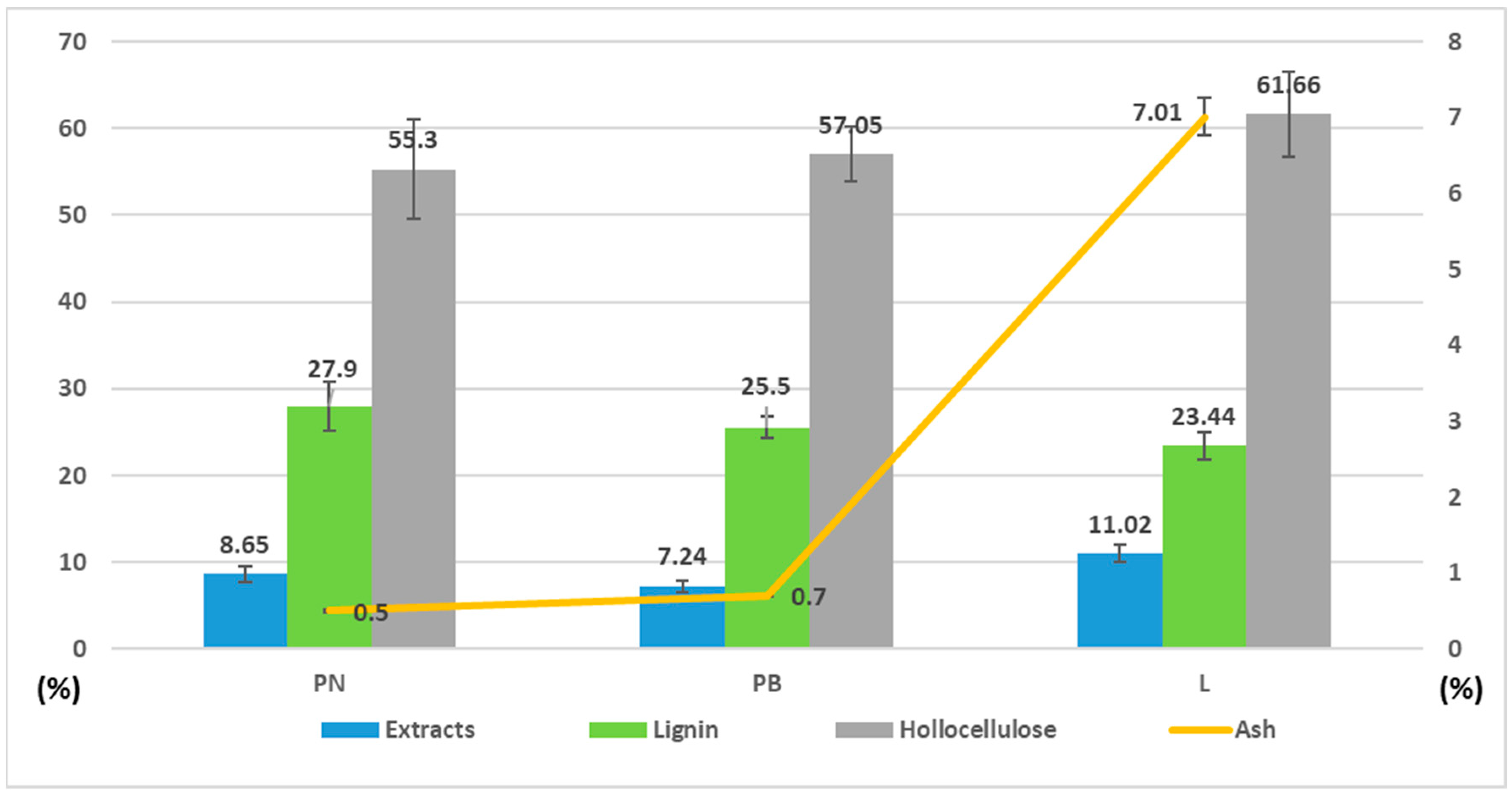

3.1. Raw Material Characterization

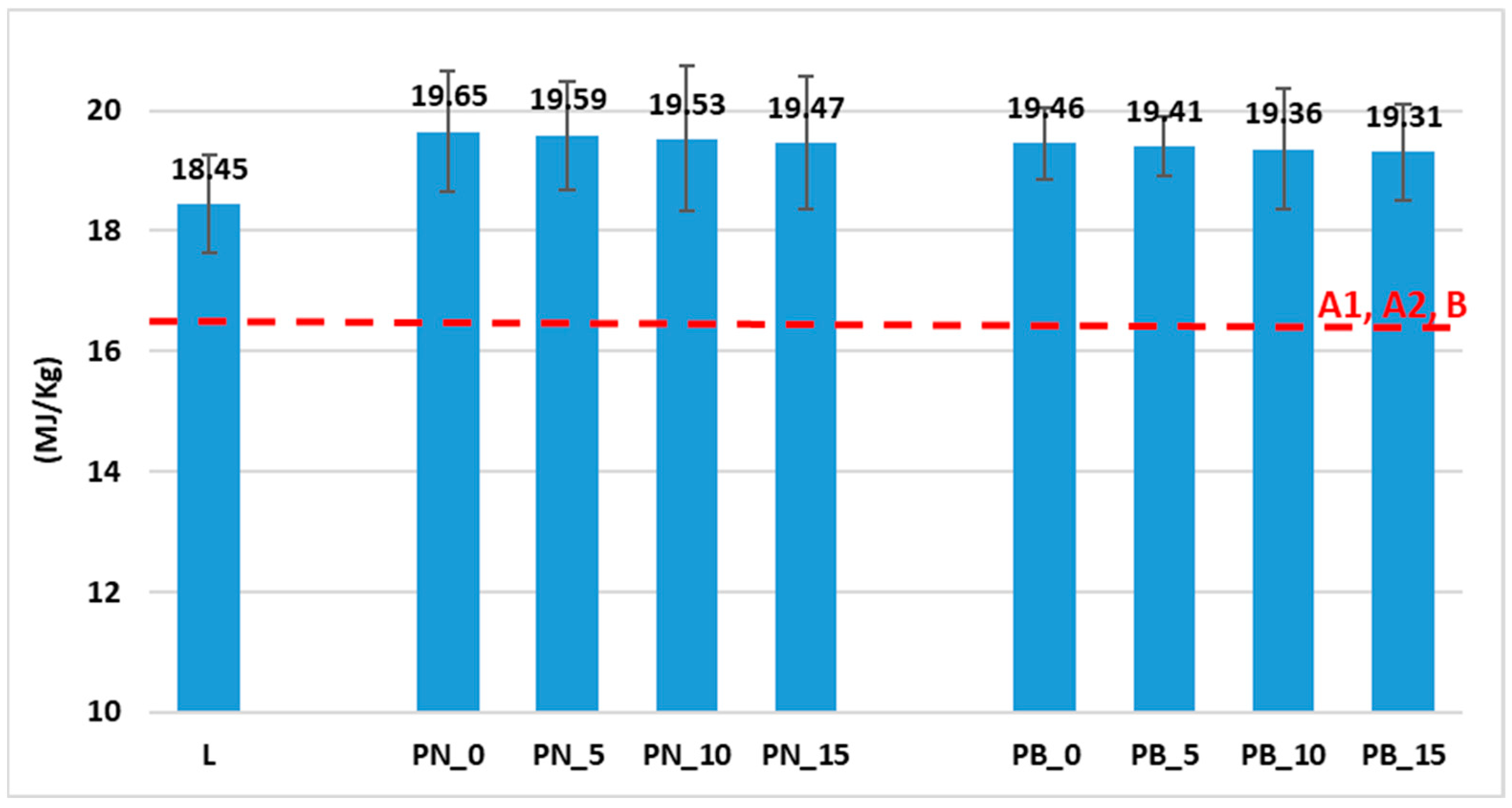

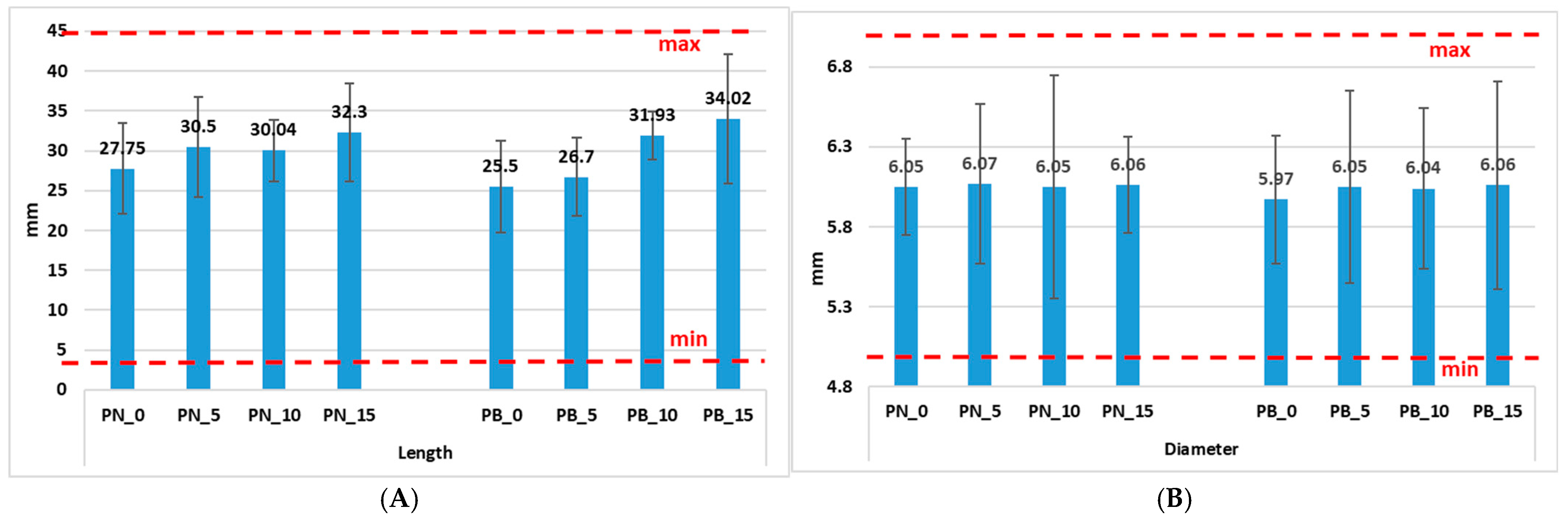

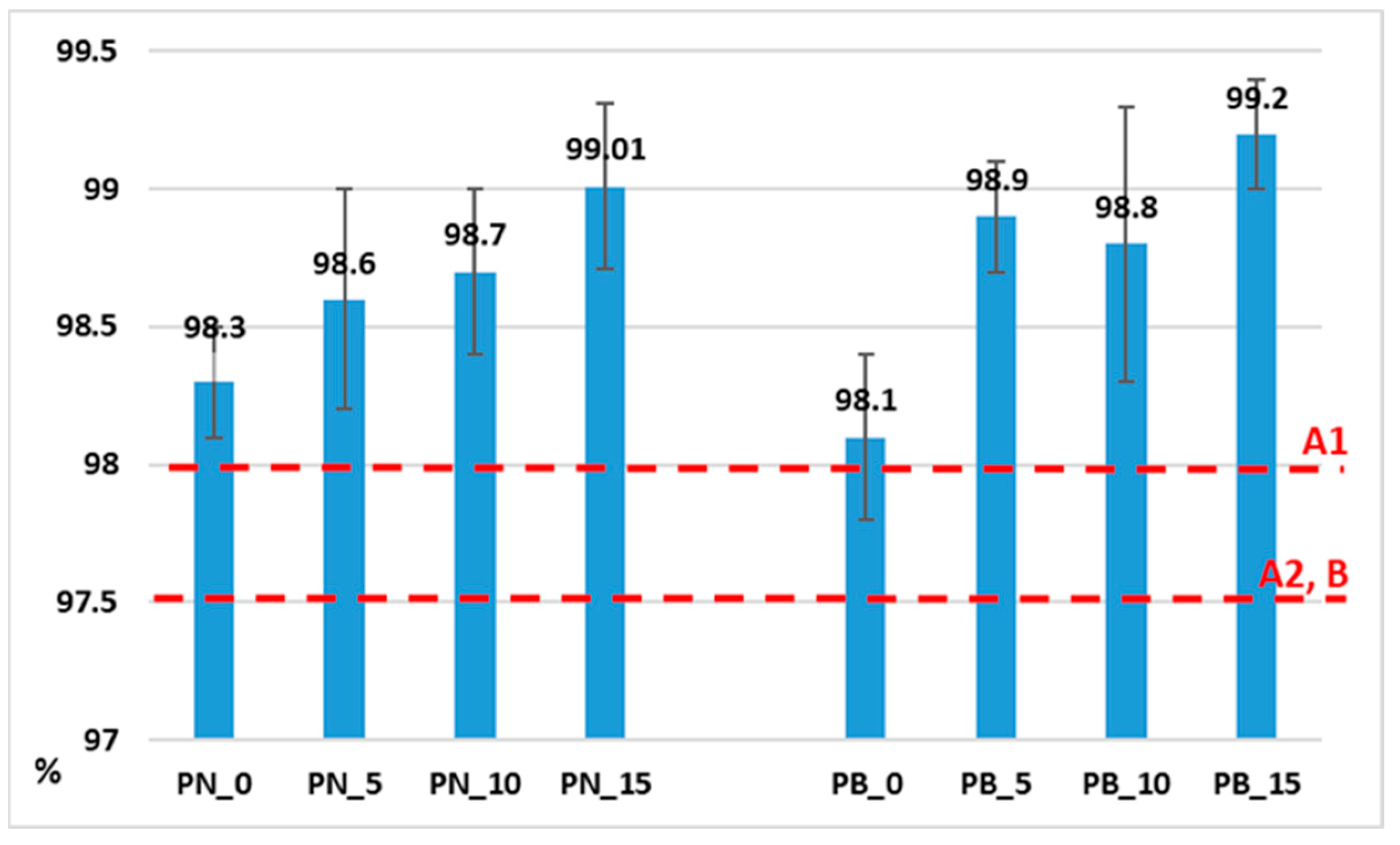

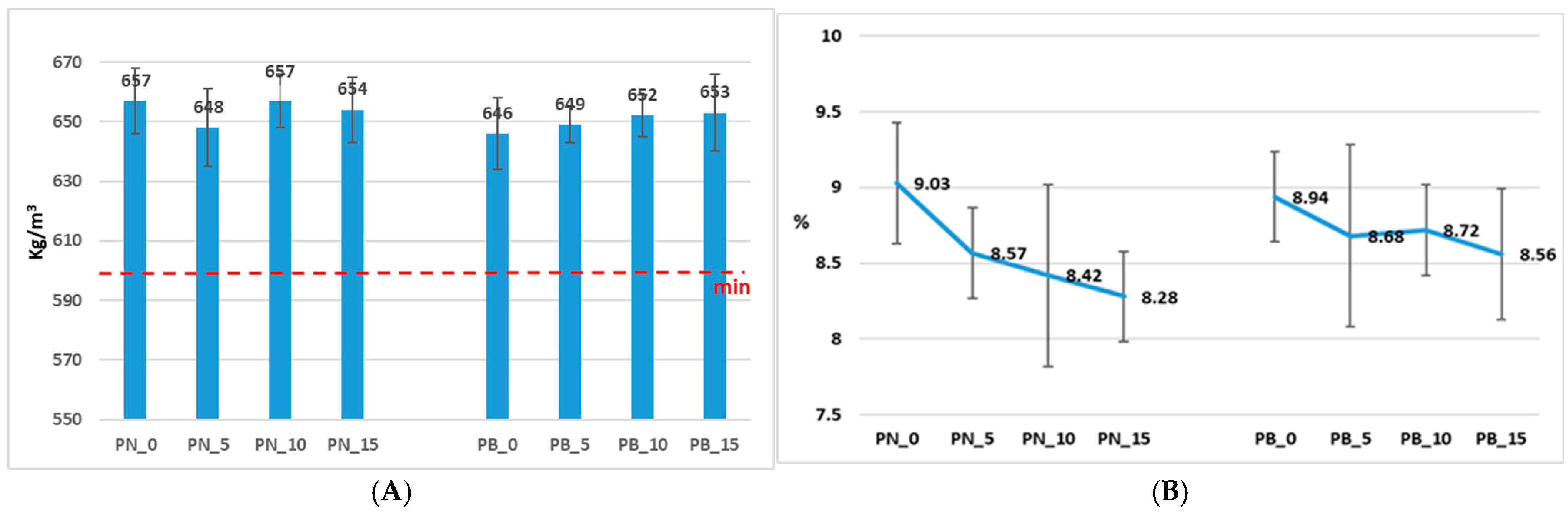

3.2. Pellet Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adam, K.; Lavender Production, Products, Markets, and Entertainment Farms. ATTRA-National Sustainable Agriculture Information Service. 2006. Available online: https://www.agri4africa.com/wp-content/uploads/2020/09/Lavender-Production-Products-Markets-and-Entertainment-Farms.pdf (accessed on 20 March 2025).

- Holubcik, M.; Durcansky, P.; Jandacka, J.; Najser, J.; Klacko, A. Novel Design for Rotary Burner for Low-Quality Pellets. Appl. Sci. 2023, 13, 3053. [Google Scholar] [CrossRef]

- European Parliament. The EU’s Energy Dependence: Facts and Figures. 2023. Available online: https://www.europarl.europa.eu/news/en/headlines/economy (accessed on 14 September 2023).

- European Commission. REPowerEU: Joint European Action for more Affordable, Secure and Sustainable Energy. 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52022DC0108 (accessed on 15 September 2023).

- Kovacs, E.; Hoaghia, M.-A.; Senila, L.; Scurtu, D.A.; Varaticeanu, C.; Roman, C.; Dumitras, D.E. Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy. Agronomy 2022, 12, 1320. [Google Scholar] [CrossRef]

- Mandley, S.J.; Wicke, B.; Junginger, M.; van Vuuren, D.P.; Daioglou, V. The implications of geopolitical, socioeconomic, and regulatory constraints on European bioenergy imports and associated greenhouse gas emissions to 2050. Biofuels Bioprod. Biorefin. 2022, 16, 1551–1567. [Google Scholar] [CrossRef]

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast). Available online: https://eur-lex.europa.eu/eli/dir/2018/2001/oj/eng (accessed on 17 August 2025).

- European Commission. Communication from the Commission to the European Parliament (2024), the Council, the European Economic and Social Committee and the Committee of the Regions ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality. 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52021DC0550 (accessed on 17 August 2025).

- Wikipedia, Binomial Nomenclature. Available online: https://en.wikipedia.org/wiki/Binomial_nomenclature#Authority (accessed on 10 September 2025).

- Gallotte, P.; Fremondière, G.; Gallois, P.; Bernier, J.P.B.; Buchwalder, A.; Walton, A.; Piasentin, J.; Fopa-Fomeju, B. Lavandula angustifolia Mill. and Lavandula x Intermedia Emeric Ex Loisel: Lavender and Lavandin. In Medicinal, Aromatic and Stimulant Plants; Novak, J., Blüthner, W.-D., Eds.; Handbook of Plant Breeding; Springer International Publishing: Cham, Switzerland, 2020; pp. 303–311. [Google Scholar]

- Wells, R.; Truong, F.; Adal, A.M.; Sarker, L.S.; Mahmoud, S.S. Lavandula Essential Oils: A Current Review of Applications in Medicinal, Food, and Cosmetic Industries of Lavender. Nat. Prod. Commun. 2018, 13, 1934578X1801301038. [Google Scholar] [CrossRef]

- Peter, K.V. Handbook of Herbs and Spices; Woodhead Publishing: Sawston, UK, 2004; Volume 2. [Google Scholar]

- Muntean, L.S.; Tămaș, M.; Muntean, S.; Muntean, L.; Duda, M.M.; Vârban, D.I.; Florian, S. Treatise of Cultivated and Spontaneous Medicinal Plants; Risoprint: Cluj-Napoca, Romania, 2016. [Google Scholar]

- Gökdoğan, O. Determination of input-output energy and economic analysis of lavender production in Turkey. Int. J. Agric. Biol. Eng. 2016, 9, 154–161. [Google Scholar] [CrossRef]

- Lis-Balchin, M. Lavender: The Genus Lavandula; Taylor and Francis: London, UK, 2002. [Google Scholar]

- Giray, F.H. An Analysis of World Lavender Oil Markets and Lessons for Turkey. J. Essent. Oil Bear. Plants. 2018, 21, 1612–1623. [Google Scholar] [CrossRef]

- Vijulie, I.; Lequeux-Dincă, A.-I.; Preda, M.; Mareci, A.; Matei, E. Could Lavender Farming Go from a Niche Crop to a Suitable Solution for Romanian Small Farms? Land 2022, 11, 662. [Google Scholar] [CrossRef]

- Lesage-Meessen, L.; Bou, M.; Ginies, C.; Chevret, D.; Navarro, D.; Drula, E.; Bonnin, E.; del Río, J.C.; Odinot, E.; Bisotto, A.; et al. Lavender- and Lavandin-Distilled Straws: An Untapped Feedstock with Great Potential for the Production of High-Added Value Compounds and Fungal Enzymes. Biotechnol. Biofuels 2018, 11, 217. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Couroutzidou, C.; Kampragkou, P. Utilization of Lavender Waste in Traditional Mortars. In Conservation and Restoration of Historic Mortars and Masonry Structures; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- Koutsianitis, D.; Ninikas, K.; Mitani, A.; Ntalos, G.; Miltiadis, N.; Vasilios, A.; Taghiyari, H.R.; Papadopoulos, A.N. Thermal Transmittance, Dimensional Stability, and Mechanical Properties of a Three-Layer Laminated Wood Made from Fir and Meranti and Its Potential Application for Wood-Frame Windows. Coatings 2021, 11, 304. [Google Scholar] [CrossRef]

- Kamperidou, V. Quality Analysis of Commercially Available Wood Pellets and Correlations between Pellets Characteristics. Energies 2022, 15, 2865. [Google Scholar] [CrossRef]

- Mitani, A.; Barboutis, I. Assessment of colour changes and hygroscopic properties of beech (Fagus sylvatica) wood after thermal modification. In Proceedings of the 23rd International Scientific Conference: Wood is Good—With Knowledge and Technology to a Competitive Forestry and Wood Technology Sector, Zagreb, Croatia, 12 October 2012; Proceedings 2012. pp. 111–118. [Google Scholar]

- Flach, B.; Bolla, S. European Union: EUWood Pellet Annual; European Union: Maastricht, The Netherlands, 2022; p. E42022-0049. [Google Scholar]

- Kamperidou, V. Chemical and Structural Characterization of Poplar and Black Pine Wood exposed to Short Thermal Modification. Drv. Ind. 2021, 72, 155–167. [Google Scholar] [CrossRef]

- Moreira, B.R.D.A.; Viana, R.D.S.; Cruz, V.H.; Magalhães, A.C.; Miasaki, C.T.; Figueiredo, P.A.M.D.; Lisboa, L.A.M.; Ramos, S.B.; Sánchez, D.E.J.; Teixeira Filho, M.C.M.; et al. Second-Generation Lignocellulosic Supportive Material Improves Atomic Ratios of C:O and H:O and Thermomechanical Behavior of Hybrid Non-Woody Pellets. Molecules 2020, 25, 4219. [Google Scholar] [CrossRef]

- Mašán, V.; Burg, P.; Soucek, J.; Slaný, V.; Vaštík, L. Energy Potential of Urban Green Waste and the Possibility of Its Pelletization. Sustainability 2023, 15, 16489. [Google Scholar] [CrossRef]

- Duca, D.; Riva, G.; Foppa Pedretti, E.; Toscano, G. Wood pellet quality with respect to EN 14961-2 standard and certifications. Fuel 2014, 135, 9–14. [Google Scholar] [CrossRef]

- Siyal, A.A.; Liu, Y.; Mao, X.; Siyal, Z.A.; Ran, C.; Ao, W.; Fu, J.; Zhou, C.; Wang, L.; Li, X.; et al. Co-pelletization of sewage sludge, furfural residue and corn stalk: Characteristics and quality analysis of pellets. Biomass Bioenergy 2021, 150, 106121. [Google Scholar] [CrossRef]

- Pyrovolos, A.; Kamperidou, V. Utilization of aromatic plants residual biomass after distillation mixed with wood in solid biofuels production. Renew. Energy 2025, 248, 123198. [Google Scholar] [CrossRef]

- European Pellet Council (EPC). Part 3: Pellet Quality Requirements. In ENplus Handbook, 3rd ed.; European Pellet Council (EPC): Brussels, Belgium, 2015. [Google Scholar]

- Kamperidou, V.; Terzopoulou, P.; Barboutis, I. Marginal lands providing tree-crop biomass as feedstock for solid biofuels. BioFPR 2021, 15, 1395–1405. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization–A review. BioResources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Żabiński, A.; Sadowska, U.; Wcislo, G. Options of use of waste biomass from herbal production for energy purposes. Agric. Eng. 2015, 19, 139–145. [Google Scholar]

- Tumuluru, J.S. Pelleting of pine and switchgrass blends: Effect of process variables and blend ratio on the pellet quality and energy consumption. Energies 2019, 12, 1198. [Google Scholar] [CrossRef]

- Chakyrova, D.; Doseva, N. Analysis of the energy recovery possibilities of energy from lavender straws after a steam distillation process. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1032, 012023. [Google Scholar] [CrossRef]

- Philippou, I. Chemistry and Chemical Technology of Wood; Giahoudi-Giapouli Publications: Thessaloniki, Greece, 2014; 357p. [Google Scholar]

- European Pellet Council (EPC). ENplus Handbook; Part 3: Pellet Quality Requirements; Version 3.0; European Pellet Council (EPC): Ixelles, Belgium, 2015. [Google Scholar]

- ASTM D1107-21; Standard Test Method for Ethanol-Toluene Solubility of Wood. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D1106-96; Standard Test Method for Acid-Insoluble Lignin in Wood. ASTM: West Conshohocken, PA, USA, 2017.

- Terzopoulou, P.; Kamperidou, V. Chemical characterization of Wood and Bark biomass of the invasive species of Tree-of-heaven (Ailanthus altissima (Mill.) Swingle), focusing on its chemical composition horizontal variability assessment. Wood Mater. Sci. Eng. 2021, 17, 469–477. [Google Scholar] [CrossRef]

- ASTM D1102; Standard Test Method for Ash in Wood. ASTM: West Conshohocken, PA, USA, 2021.

- Obidzinski, S.; Dołzynska, M.; Kowczyk-Sadowy, M.; Jadwisienczak, K.; Sobczak, P. Densification and fuel properties of onion husks. Energies 2019, 12, 4687. [Google Scholar] [CrossRef]

- ISO 18134-1; Solid Biofuels. Determination of Moisture Content. Part 1: Reference Method. ISO: Geneva, Switzerland, 2022.

- ISO 17829; Solid Biofuels. Determination of Length and Diameter of Pellets. ISO: Geneva, Switzerland, 2015.

- ISO 17831-1; Solid Biofuels. Determination of Mechanical Durability of Pellets and Briquettes. Part 1: Pellets. ISO: Geneva, Switzerland, 2015.

- ISO 17828; Solid Biofuels. Determination of Bulk Density. ISO: Geneva, Switzerland, 2015.

- Pulidori, E.; Gonzalez-Rivera, J.; Pelosi, C.; Ferrari, C.; Bernazzani, L.; Bramanti, E.; Tiné, M.R.; Duce, C. Thermochemical Evaluation of Different Waste Biomasses (Citrus Peels, Aromatic Herbs, and Poultry Feathers) towards Their Use for Energy Production. Thermo 2023, 3, 66–75. [Google Scholar] [CrossRef]

- Angelova, G.; Brazkova, M.; Stefanova, P.; Blazheva, D.; Vladev, V.; Petkova, N.; Slavov, A.; Denev, P.; Karashanova, D.; Zaharieva, R.; et al. Waste rose flower and lavender straw biomass—An innovative lignocellulose feedstock for mycelium bio-materials development using newly isolated ganoderma resinaceum GA1M. J. Fungi 2021, 7, 866. [Google Scholar] [CrossRef]

- Üner, B.; Karaman, I.; Tanriverdi, H.; Özdemir, D. Prediction of lignin and extractive content of Pinus nigra Arnold. var. Pallasiana tree using near infrared spectroscopy and multivariate calibration. J. Wood Chem. Technol. 2009, 29, 24–42. [Google Scholar] [CrossRef]

- Uçar, G.; Fengel, D. Variation in composition of extractives from wood of Pinus nigra varieties. Phytochemistry 1995, 38, 877–880. [Google Scholar] [CrossRef]

- Dias, A.; Carvalho, A.; Silva, M.E.; Lima-Brito, J.; Gaspar, M.J.; Alves, A.; Rodrigues, J.C.; Pereira, F.; Morais, J.; Lousada, J.L. Physical, chemical and mechanical wood properties of Pinus nigra growing in Portugal. Ann. For. Sci. 2020, 77, 72. [Google Scholar] [CrossRef]

- Üner, B.; Karaman, I.; Tanrıverdi, H.; Özdemir, D. Determination of lignin and extractive content of Turkish Pine (Pinus brutia Ten.) trees using near infrared spectroscopy and multivariate calibration. Wood Sci. Technol. 2011, 45, 121–134. [Google Scholar] [CrossRef]

- ISO 18125; Solid Biofuels. Determination of Calorific Value. ISO: Geneva, Switzerland, 2017.

- Trnka, J.; Kantová, N.; Holubčík, M.; Čaja, A.; Najser, T.; Najser, J. Comparison of energy properties of pellets from shells of different nut species. BioResources 2023, 18, 2137–2145. [Google Scholar] [CrossRef]

- Tian, B.; Li, X.; Lv, Y.; Xu, J.; Ma, W.; He, C.; Chen, Y.; Jian, S.; Wang, W.; Zhang, C.; et al. Effect of Rice Husk Ash on the Properties of Alkali-Activated Slag Pastes: Shrinkage, Hydration and Mechanical Property. Materials 2023, 16, 3148. [Google Scholar] [CrossRef]

- Kayo, C.; Tojo, S.; Iwaoka, M.; Matsumoto, T. Evaluation of Biomass Production and Utilization Systems. In Research Approachesto Sustainable Biomass Systems; Academic Press: Cambridge, MA, USA, 2014; pp. 309–346. [Google Scholar] [CrossRef]

- Sgarbossa, A.; Costa, C.; Menesatti, P.; Antonucci, F.; Pallottino, F.; Zanetti, M.; Grigolato, S.; Cavalli, R. Colorimetric patterns of wood pellets and their relations with quality and energy parameters. Fuel 2014, 137, 70–76. [Google Scholar] [CrossRef]

- Soucya, J.; Kouba, A.; Migneault, S.; Riedl, B. The potential of paper mill sludge for wood–plastic composites. Ind. Crop. Prod. 2014, 54, 248–256. [Google Scholar] [CrossRef]

- Migneault, S.; Kouba, A.; Nadji, H.; Riedl, B.Y.; Zhang, T.; Deng, J. Medium-density fiberboard produced using pulp and paper sludge from different pulping processes. Wood Fiber Sci. 2010, 42, 292–303. [Google Scholar]

- García, R.; Gil, M.V.; Rubiera, F.; Pevida, C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel 2019, 251, 739–753. [Google Scholar] [CrossRef]

- López-Huertas, E.; Rubí-Villegas, J.; Sánchez-Moreno, L.; Nieto, R. Olive Pomace Extract Contains Low Molecular Weight Peptides and Possesses ACE Inhibitory Activity. Int. J. Mol. Sci. 2024, 25, 3962. [Google Scholar] [CrossRef] [PubMed]

- Papandrea, S.F.; Palma, A.; Carnevale, M.; Paris, E.; Vincenti, B.; Gallucci, F.; Proto, A.R. Characterization of Several Pellets from Agroforestry Residues: A Comparative Analysis of Physical and Energy Efficiency. Fire 2024, 7, 239. [Google Scholar] [CrossRef]

- Lehtikangas, P. Quality properties of pelletised sawdust, logging residues and bark. Biomass Bioenergy 2016, 20, 351–360. [Google Scholar] [CrossRef]

- Carroll, J.P.; Finnan, J. Physical and chemical properties of pellets from energy crops and cereal straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Mancera, C.; El Mansouri, N.-E.; Vilaseca, F.; Ferrando, F.; Salvado, J. The effect of lignin as a natural adhesive on the physico-chemical properties of Vitis Vinefera fiberboards. BioResources 2011, 6, 2851–2860. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to theircombustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Fernández, M.; Tapias, R.; Camacho, V.; Alaejos, J. Quality of the Pellets Obtained with Wood and Cutting Residues of Stone Pine (Pinus pinea L.). Forests 2023, 14, 1011. [Google Scholar] [CrossRef]

- Truzzi, E.; Chaouch, M.A.; Rossi, G.; Tagliazucchi, L.; Bertelli, D.; Benvenuti, S. Characterization and Valorization of the Agricultural Waste Obtained from Lavandula Steam Distillation for Its Reuse in the Food and Pharmaceutical Fields. Molecules 2022, 27, 1613. [Google Scholar] [CrossRef]

- Menon, D.; Menon, S. The lavender revolution: Sustainable farming and global economic implications. IJRA 2025, SP-8, 209–216. [Google Scholar] [CrossRef]

| Lavender Content | Pinus nigra L.—PN | Pinus brutia L.—PB |

|---|---|---|

| 0% | 0.5 | 0.7 |

| 5% | 0.82 | 1.01 |

| 10% | 1.15 | 1.33 |

| 15% | 1.47 | 1.64 |

| Correl. Coeffic. | Mechan. Durability | Ash | Lignin | Polysaccharides | Extracts | Lavender Percentage | |

|---|---|---|---|---|---|---|---|

| Pearson Correl. | Mechan. Durability | 1.000 | −0.664 | 0.829 | −0.645 | 0.907 | 0.792 |

| Ash | −0.664 | 1.000 | −0.387 | 0.316 | 0.575 | 0.629 | |

| Lignin | 0.829 | −0.387 | 1.000 | 0.127 | 0.296 | −0.177 | |

| Polysaccharides | −0.645 | 0.316 | 0.127 | 1.000 | 0.978 | 0.986 | |

| Extracts | 0.907 | 0.575 | 0.296 | 0.978 | 1.000 | 0.974 | |

| Lavender Percentage | 0.792 | 0.629 | −0.177 | 0.986 | 0.974 | 1.000 | |

| Sig. | Mech. Durability | - | 0.009 | 0.002 | 0.001 | 0.000 | 0.001 |

| Ash | 0.009 | - | 0.007 | 0.159 | 0.115 | 0.237 | |

| Lignin | 0.002 | 0.007 | - | 0.345 | 0.175 | 0.407 | |

| Polysaccharides | 0.001 | 0.015 | 0.045 | - | 0.000 | 0.000 | |

| Extractives | 0.000 | 0.115 | 0.075 | 0.000 | - | 0.000 | |

| Lavender Percentage | 0.001 | 0.237 | 0.017 | 0.000 | 0.000 | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamperidou, V.; Terzopoulou, P. Co-Pelletization of Lavender Waste and Pine-Wood for Sustainable Fuel Pellet Production. Forests 2025, 16, 1455. https://doi.org/10.3390/f16091455

Kamperidou V, Terzopoulou P. Co-Pelletization of Lavender Waste and Pine-Wood for Sustainable Fuel Pellet Production. Forests. 2025; 16(9):1455. https://doi.org/10.3390/f16091455

Chicago/Turabian StyleKamperidou, Vasiliki, and Paschalina Terzopoulou. 2025. "Co-Pelletization of Lavender Waste and Pine-Wood for Sustainable Fuel Pellet Production" Forests 16, no. 9: 1455. https://doi.org/10.3390/f16091455

APA StyleKamperidou, V., & Terzopoulou, P. (2025). Co-Pelletization of Lavender Waste and Pine-Wood for Sustainable Fuel Pellet Production. Forests, 16(9), 1455. https://doi.org/10.3390/f16091455