Design and Experiment of the Mold for the Production Process of Natural Arc-Shaped Bamboo Laminated Lumber

Abstract

1. Introduction

2. Materials and Methods

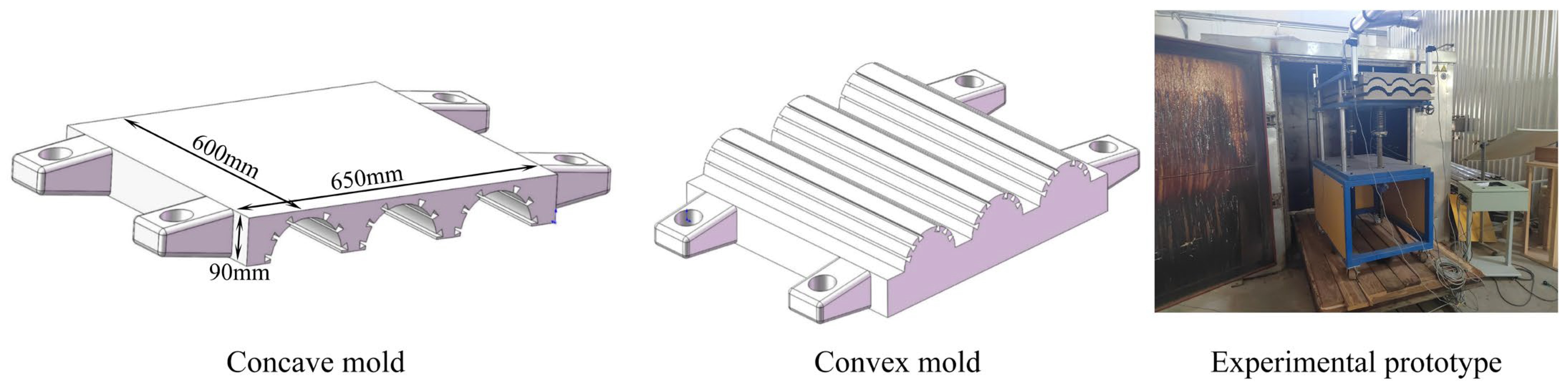

2.1. The Mold of Arc-Shaped Bamboo Split

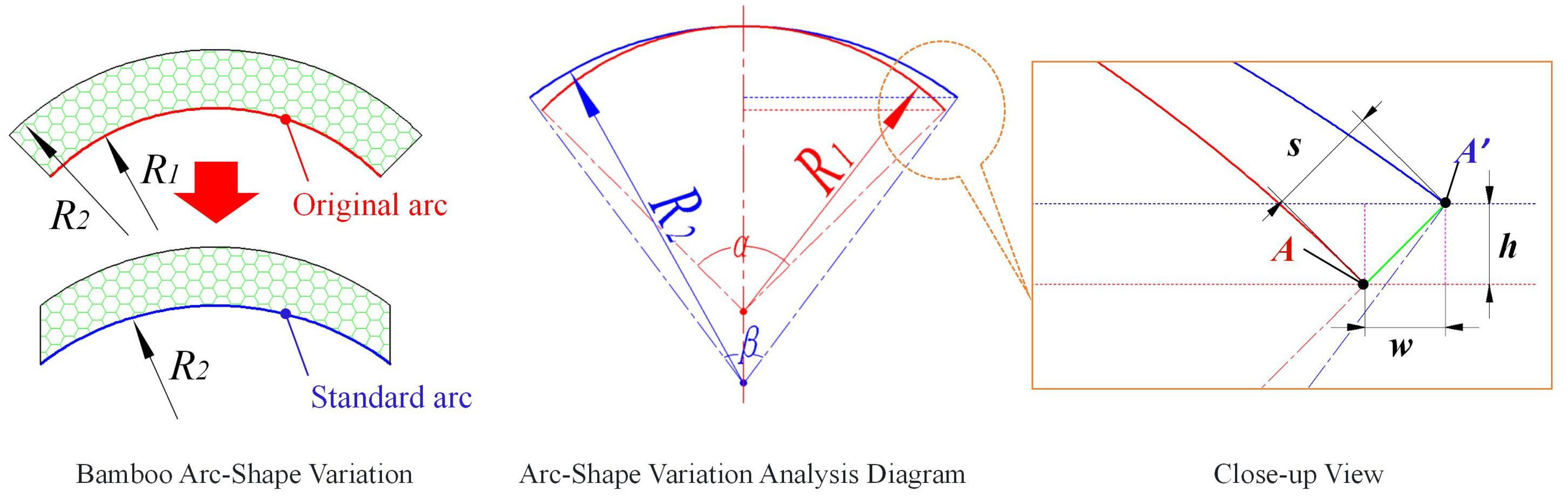

2.1.1. The Fixed-Arc Model of Arc-Shaped Bamboo Split Mold

2.1.2. Materials Tested

2.1.3. Experimental Platform

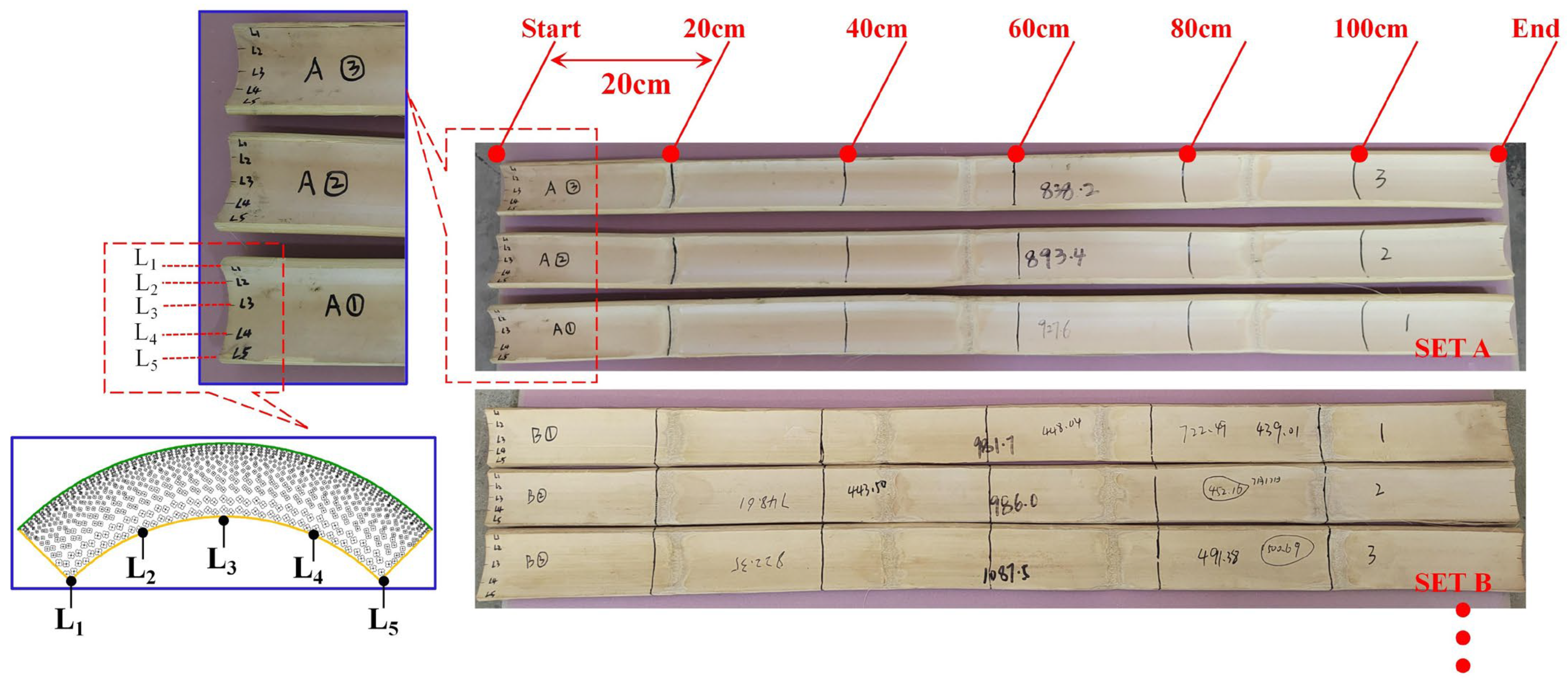

2.2. Experimental Scheme

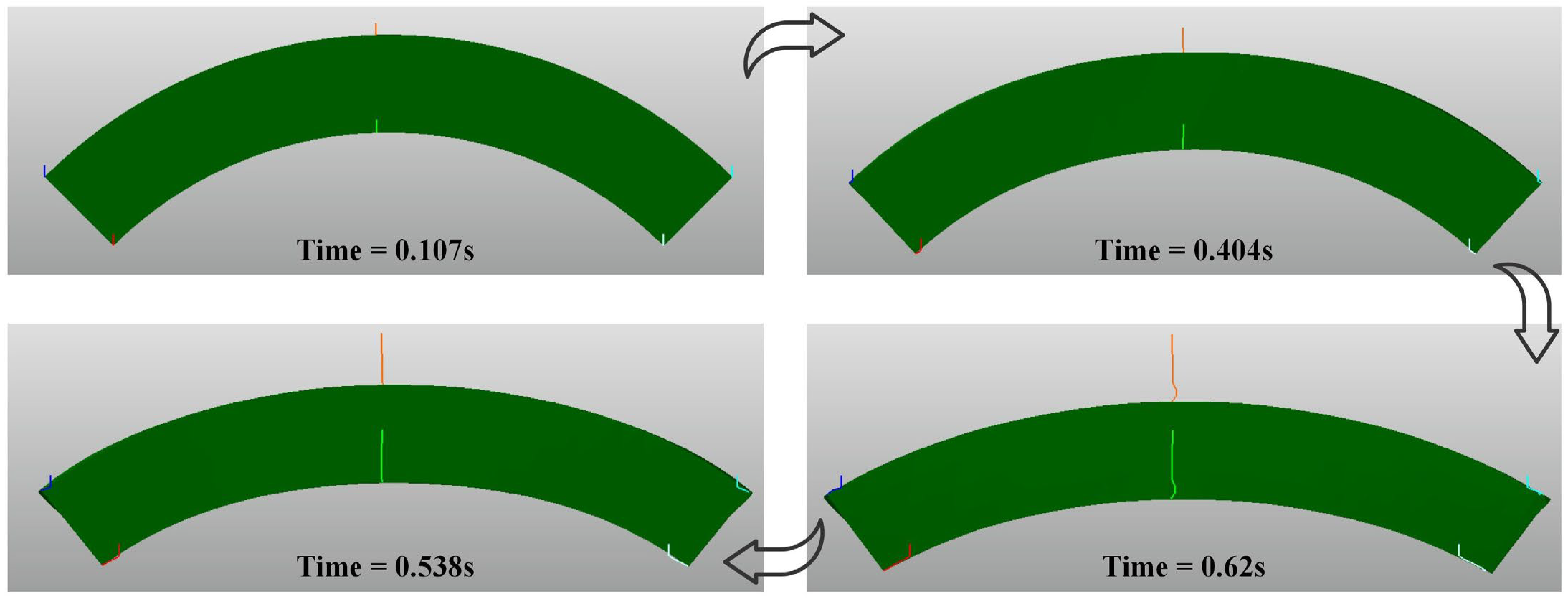

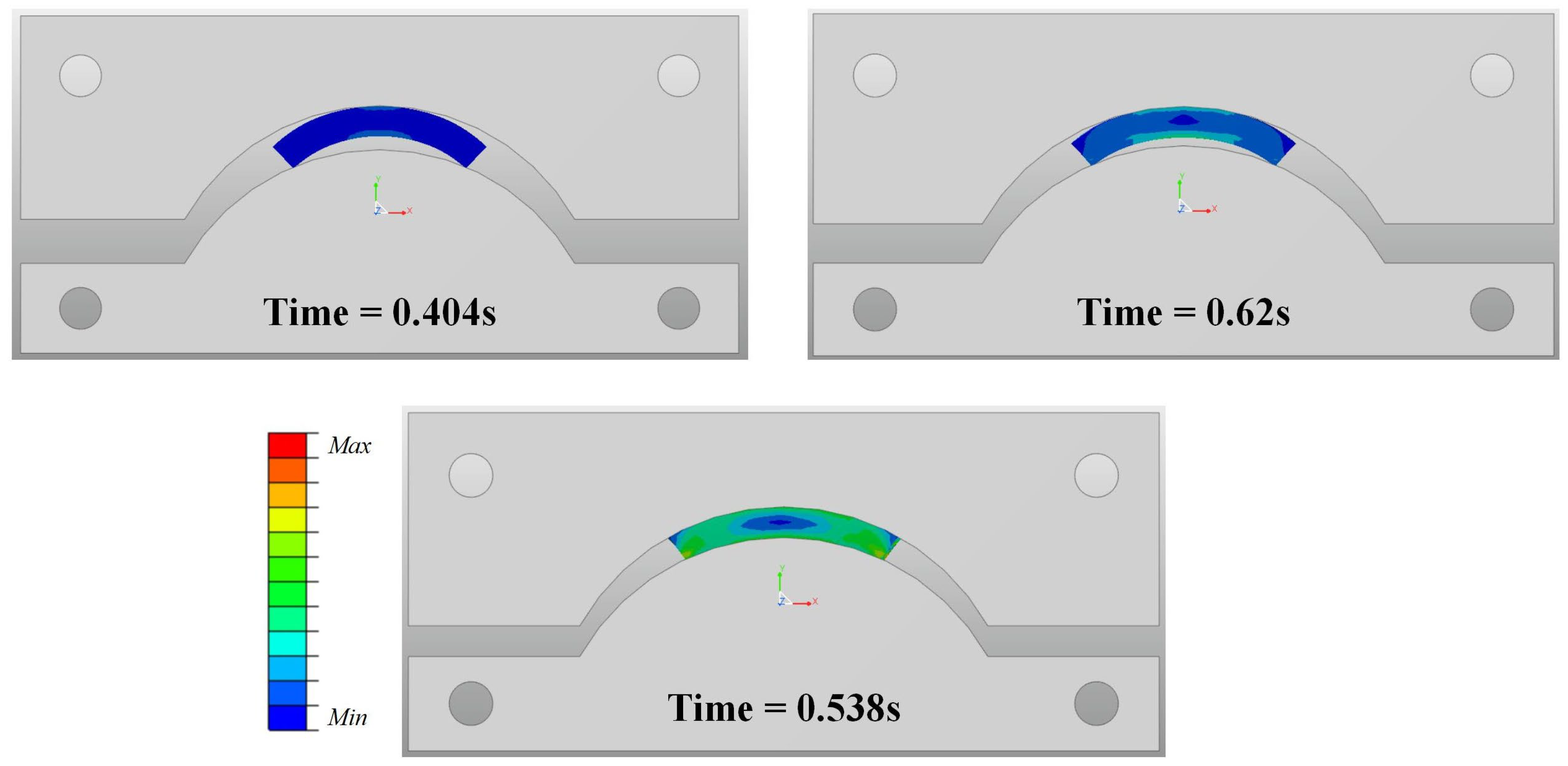

2.3. Virtual Simulation

3. Results and Discussion

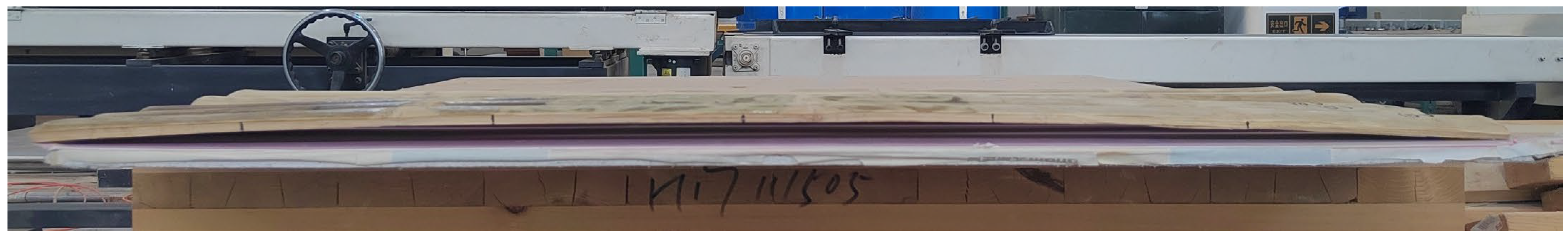

3.1. Analysis of the Fixed-Arc Process

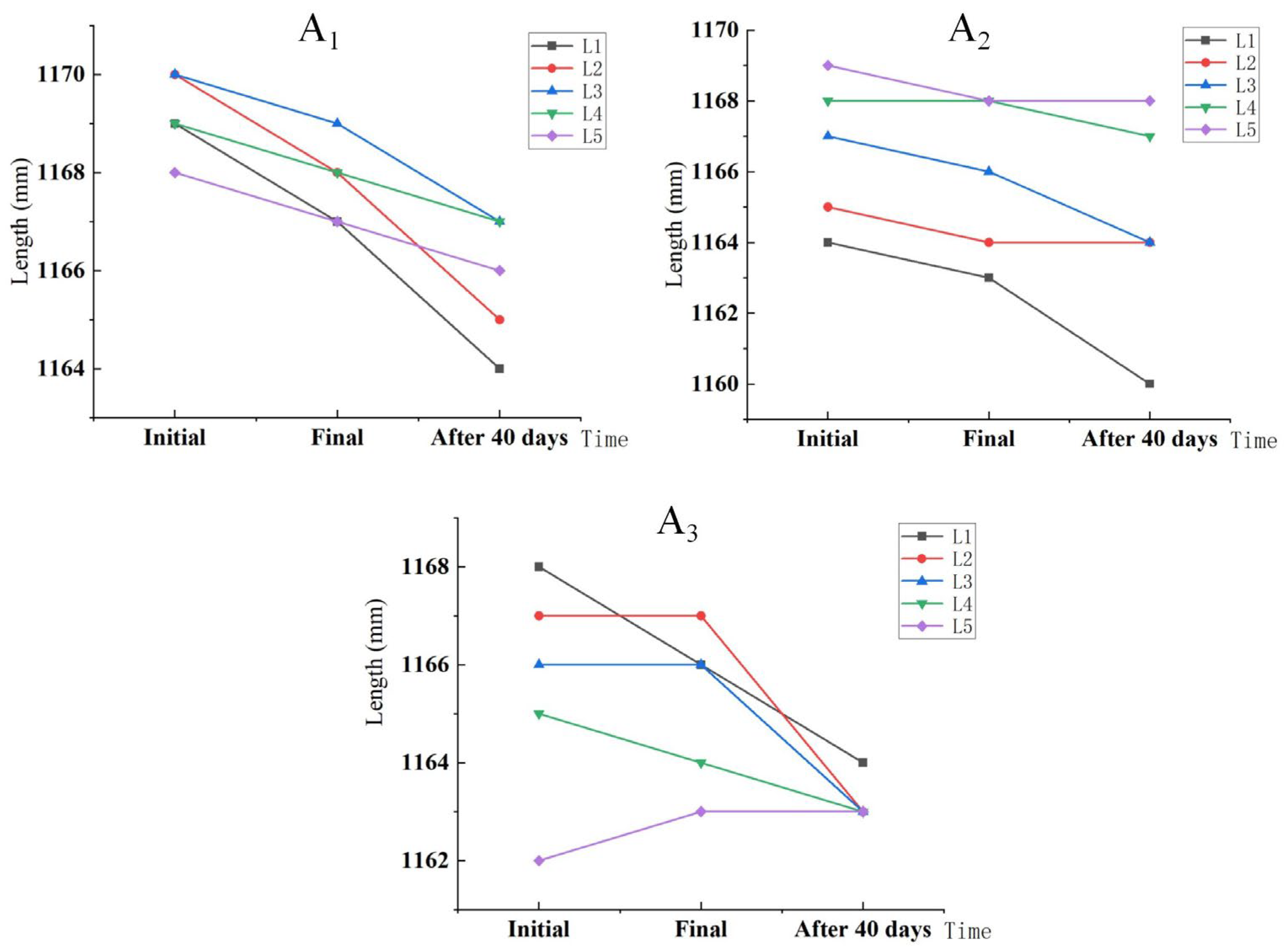

3.2. The Length of Bamboo Split

3.3. Wall Thickness of Bamboo Splits

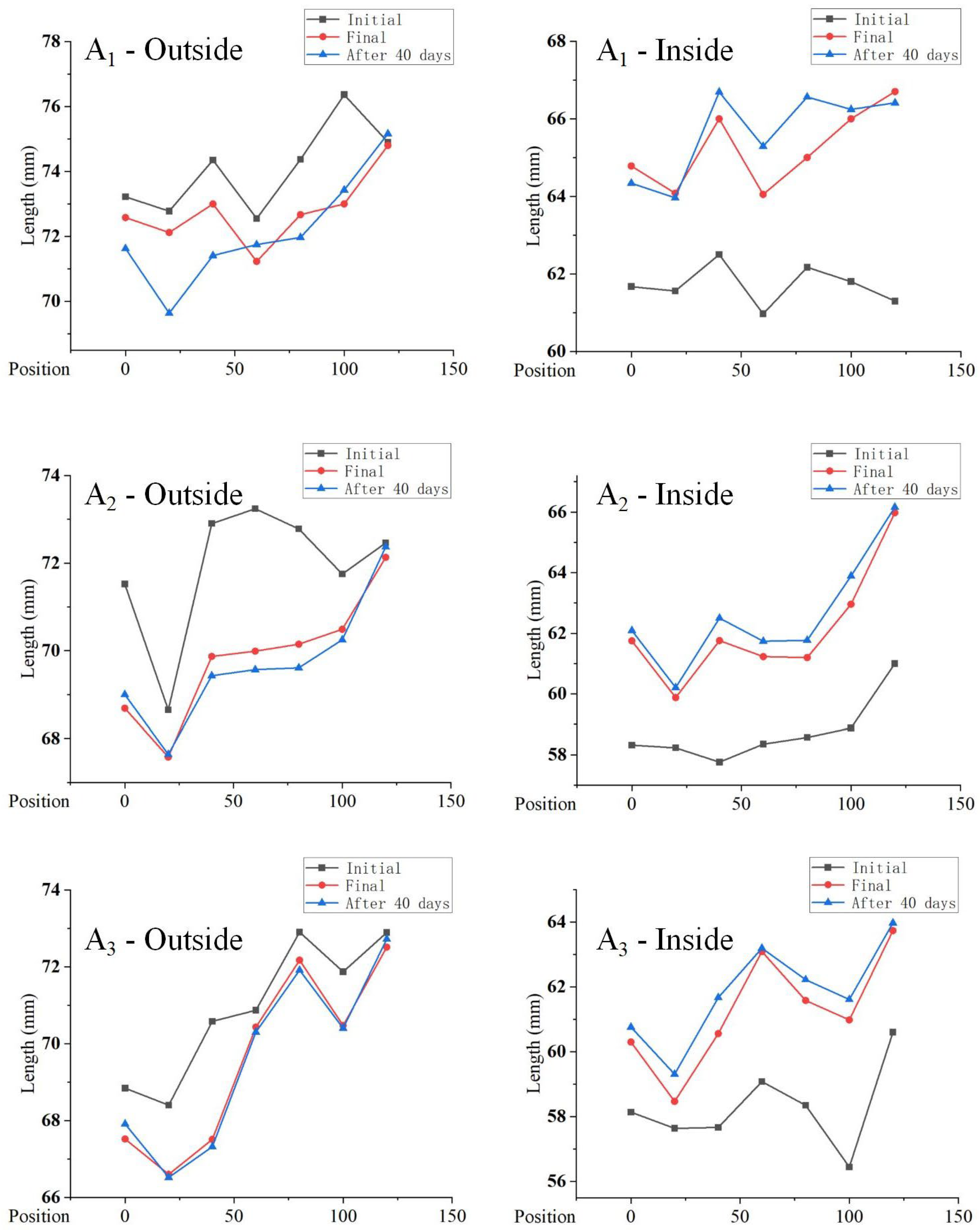

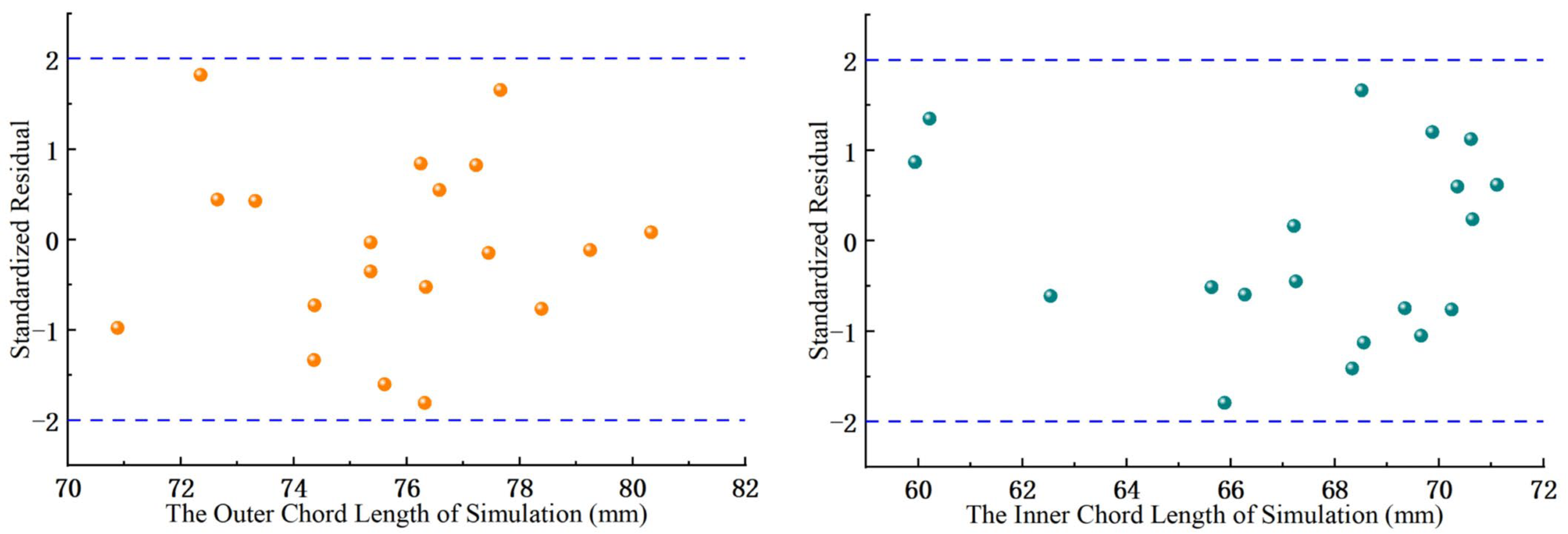

3.4. Inner/Outer Chord Lengths of Bamboo Splits

3.5. The Moisture Content of Bamboo Split

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, M.; Ye, L.; Semple, K.; Ma, J.; Zhang, J.; Weng, Y.; Yan, H.; Fei, B.; Dai, C. A new protocol for rapid assessment of bond durability of bio-based pipes: Bamboo winding composite pipe as a case study. Eur. J. Wood Wood Prod. 2022, 80, 947–959. [Google Scholar] [CrossRef]

- Yuan, J.; Fang, C.; Chen, Q.; Fei, B. Observing bamboo dimensional change caused by humidity. Constr. Build. Mater. 2021, 309, 124988. [Google Scholar] [CrossRef]

- Chen, L.; Huang, B.; Wang, X.; Fang, C.; Zhang, X.; Fei, B. Study on gluing characteristics of bamboo pith ring. Ind. Crops Prod. 2022, 178, 114624. [Google Scholar] [CrossRef]

- Fang, C.-H.; Jiang, Z.-H.; Sun, Z.-J.; Liu, H.-R.; Zhang, X.-B.; Zhang, R.; Fei, B.-H. An overview on bamboo culm flattening. Constr. Build. Mater. 2018, 171, 65–74. [Google Scholar] [CrossRef]

- Huang, B.; Fang, C.; Chen, L.; Miao, H.; Ma, X.; Liu, H.; Fei, B. Analysis of the use rate of equal arc-shaped bamboo splits. Constr. Build. Mater. 2021, 302, 124273. [Google Scholar] [CrossRef]

- Wang, X.; Su, N.; Chen, X.; Fei, B.; Ma, X.; Liu, H.; Miao, H.; Fang, C. Impact of temperature on mechanical properties and dimensional stability in a novel gradient pressure bamboo flattening technique. Constr. Build. Mater. 2024, 427, 136258. [Google Scholar] [CrossRef]

- Huang, B.; Chen, L.; Wang, X.; Ma, X.; Liu, H.; Zhang, X.; Sun, F.; Fei, B.; Fang, C. Eco-friendly, high-utilization, and easy-manufacturing bamboo units for engineered bamboo products Processing and mechanical characterization. Compos. Part B Eng. 2023, 267, 111073. [Google Scholar] [CrossRef]

- Huang, B.; Fang, C.; Chen, L.; Wang, X.; Ma, X.; Liu, H.; Zhang, X.; Sun, F.; Fei, B. A novel ecological, highly-utilizable manufacturing technology for standard bamboo units and its deformation laws. Ind. Crops Prod. 2022, 183, 115008. [Google Scholar] [CrossRef]

- Huang, B.; Jia, H.; Fei, B.; Chen, L.; Fang, C.; Liu, H.; Zhang, X.; Ma, X.; Sun, F. Study on the correlation between the puncture impact performance of arc-shaped bamboo splits and bamboo ages. Ind. Crops Prod. 2022, 186, 115252. [Google Scholar] [CrossRef]

- State Forestry Administration Beijing Forestry Machinery Research Institute. Arc-Shaped Bamboo Original State Recombinant Material Its Manufacturing Method. CN1970254B, 7 November 2006. [Google Scholar]

- Fu, W.; Zhou, J. Study on industrial manufacturing technology of Natural Arc-bamboo Laminated Lumber. For. Grassl. Mach. 2010, 21, 1–5+9. [Google Scholar]

- Li, W.; Zhang, Z.; Cheng, F.; Fu, W. The processing method and utilization ratio of arch bamboo pieces. For. Grassl. Mach. 2009, 20, 1–6. [Google Scholar]

- Zhang, Z.; Li, W.; Peng, X.; Li, W.; Zhang, J. Development of Bamboo Shaping and Curve Milling Equipment. For. Mach. Woodwork. Equip. 2011, 39, 18–22. [Google Scholar]

- Sun, W. Study on Microwave Softening Flattening Without Nicked Technology of Curved Bamboo Strips. Master’s Thesis, Nanjing Forestry University, Nanjing, China, 2023. [Google Scholar]

- Xiao, X. Development of Curved Bamboo Strip Softening Equipment and Study on Flattening Proc. Master’s Thesis, Nanjing Forestry University, Nanjing, China, 2023. [Google Scholar]

- Li, W.; Zhang, Z.; Li, W. Change in Radius of Moso Arc Spawlate during Drying, J. Bamboo Res. 2010, 29, 45–49. [Google Scholar]

- Li, W.; Zhang, Z.; Li, W. Drying Characteristics of Bamboo Are Plate. Chin. J. Wood Sci. Technol. 2010, 24, 10–12. [Google Scholar]

- Zhou, J. Study on Adhesive Strength of A-BROS and Developing of Arc Bamboo Fine-Milling Machine. Master’s Thesis, Chinese Academy of Forestry, Beijing, China, 2015. [Google Scholar]

- Huang, B.; Chen, L.; Fang, C.; Wang, X.; Ma, X.; Liu, H.; Zhang, X.; Sun, F.; Fei, B. Multi-scale mechanical characterization of an ecological, strong and novel bamboo unit—An in-situ flexural characterization. Constr. Build. Mater. 2022, 342, 128061. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Chen, L.; Su, N.; Liu, L.; Luan, Y.; Ma, X.; Fei, B.; Fang, C. Impact of the natural structure of cortex and pith ring on water loss and deformation in bamboo processing. Constr. Build. Mater. 2024, 411, 134396. [Google Scholar] [CrossRef]

- Yang, X.M.; Chai, Y.; Liu, H.R.; Sun, Z.J.; Jiang, Z.H. Study on size classification of bamboo stem round bamboo. J. For. Eng. 2019, 4, 53–58. [Google Scholar]

- GB/T 1927.4-2021; Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens—Part 4: Determination of Moisture Content. Standards Press of China: Beijing, China, 2021.

- Lu, H. Study on the Poisson’s Ratio and Its Variation Pattern of Bamboo. Master’s Thesis, Zhejiang A&F University, Hangzhou, China, 2022. [Google Scholar]

- Zhang, Y.; Wang, B.; Wang, C. Contribution Rate of phyllostachys heterocycle to basic density compressive strength parallel to grain. J. Northeast For. Univ. 2022, 50, 105–108. [Google Scholar]

- Wang, X.; Chen, X.; Huang, B.; Chen, L.; Fang, C.; Ma, X.; Fei, B. Gradient changes in fiber bundle content and mechanical properties lead to asymmetric bending of bamboo. Constr. Build. Mater. 2023, 395, 132328. [Google Scholar] [CrossRef]

- Placet, V.; Passard, J.; Perré, P. Viscoelastic properties of wood across the grain measured under water-saturated conditions up to 135 °C: Evidence of thermal degradation. J. Mater. Sci. 2008, 43, 3210–3217. [Google Scholar] [CrossRef]

- Kadivar, M.; Gauss, C.; Tomazello-Filho, M.; Ahrar, A.J.; Ghavami, K.; Savastano, H. Optimization of thermo-mechanical densification of bamboo. Constr. Build. Mater. 2021, 298, 123860. [Google Scholar] [CrossRef]

- Kelkar, B.; Shukla, S.; Paul, B.; Arya, S. Effect of softening duration on physical, mechanical and microstructural properties of flattened densified Bambusa bambos. J. Build. Eng. 2023, 74, 106821. [Google Scholar] [CrossRef]

- Chen, Q.; Fei, B.; Qi, J.; Zhang, S.; Huang, X.; Jiang, Y.; Xie, J.; Jia, S. Effect of moisture content on bamboo’s mode I interlaminar fracture toughness: The competition between promoting and impeding crack growth. Constr. Build. Mater. 2022, 341, 127822. [Google Scholar] [CrossRef]

- Parkkeeree, T.; Matan, N.; Kyokong, B. Flattening of half tubular bamboo culms and fixation of bamboo boards. J. Trop. For. Sci. 2014, 26, 101–114. [Google Scholar]

- GB/T 38071-2019; Structural Laminated Bamboo Sliver Curtain Lumber. Standards Press of China: Beijing, China, 2019.

- LY/T 1072-2022; Bamboo Parallel Sliver Lumber. Standards Press of China: Beijing, China, 2022.

- ISO 22157:2019; Bamboo Structures—Determination of Physical and Mechanical Properties of Bamboo Culms—Test Methods. International Organization for Standardization: Geneva, Switzerland, 2019.

- GB/T 26899-2022; Structural Glued Laminated Timber. Standards Press of China: Beijing, China, 2022.

- ISO 22156:2021; Bamboo Structures—Bamboo Culms—Structural Design. International Organization for Standardization: Geneva, Switzerland, 2021.

- Brito, F.M.S.; Paes, J.B.; da Silva Oliveira, J.T.; Arantes, M.D.C.; Vidaurre, G.B.; Brocco, V.F. Physico-mechanical characterization of heat-treated glued laminated bamboo. Constr. Build. Mater. 2018, 190, 719–727. [Google Scholar] [CrossRef]

- Azadeh, A.; de Sá, A.D.; Kadivar, M.; Gauss, C.; Junior, H.S. The effect of densification on physical and mechanical properties of bamboo Dendrocalamus asper. Eur. J. Wood Prod. 2022, 80, 877–888. [Google Scholar] [CrossRef]

- Dixon, P.G.; Semple, K.E.; Kutnar, A.; Kamke, F.A.; Smith, G.D.; Gibson, L.J. Comparison of the flexural behavior of natural and thermo-hydromechanically densified Moso bamboo. Eur. J. Wood Wood Prod. 2016, 74, 633–642. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Wang, M.; Li, X.; Du, F.; Jin, J. A review on ring rolling technology. Proc. Inst. Mech. Engineers. Part B J. Eng. Manuf. 2019, 233, 663–691. [Google Scholar]

- Kleiner, M.; Geiger, M.; Klaus, A. Manufacturing of Lightweight Components by Metal Forming. CIRP Ann. Manuf. Technol. 2003, 52, 521–542. [Google Scholar] [CrossRef]

- Kadivar, M.; Gauss, C.; Ghavami, K.; Savastano, H. Densification of bamboo: State of the art. Materials 2020, 13, 4346. [Google Scholar] [CrossRef] [PubMed]

- ISO 7567:2024; Bamboo Structures—Glued Laminated Bamboo—Product Specifications. International Organization for Standardization: Geneva, Switzerland, 2024.

| Parameter | Value |

|---|---|

| Young’s modulus of bamboo | 9.6 GPa |

| Poisson’s ratio of bamboo | 0.3 |

| Density of bamboo | 0.75 g/cm3 |

| Mesh Type | Shell 3 (Tria 3) |

| Nodes in total | 44,013 |

| The number of elements after division | 88,022 |

| Source of Variance | SS | df | MS | F | p-Value | F Crit |

|---|---|---|---|---|---|---|

| Between-group | 11.48 | 2 | 5.74 | 1.7 × 10−5 | 0.99 | 4.26 |

| Within-group | 3.05 × 106 | 9 | 338,518.8 | |||

| Cor Total | 3.05 × 106 | 11 |

| Source of Variance | SS | df | MS | F | p-Value | F Crit |

|---|---|---|---|---|---|---|

| Time | 9.511283 | 6 | 1.585214 | 43.29495 | 9.35 × 10−11 | 2.572712 |

| Position | 1.071461 | 2 | 0.53573 | 14.63173 | 0.000105 | 3.4668 |

| Interaction | 0.121028 | 12 | 0.010086 | 0.275457 | 0.987409 | 2.250362 |

| Internal | 0.7689 | 21 | 0.036614 | |||

| Cor Total | 11.47267 | 41 |

| Evaluation Indicator | Inner Chord Length (mm) | Outer Chord Length (mm) | ||||

|---|---|---|---|---|---|---|

| a-b | a-c | b-c | a-b | a-c | b-c | |

| RE | 8.46% | 1.92% | 7.16% | 2.07% | 5.89% | 7.91% |

| R2 | 0.78 | 0.89 | 0.79 | 0.93 | 0.82 | 0.71 |

| RMSE | 3.61 | 1.59 | 2.51 | 1.38 | 2.01 | 2.93 |

| Measurement Position | Inner Chord Length | Outer Chord Length | ||||

|---|---|---|---|---|---|---|

| Initial | Final | After 40 Days | Initial | Final | After 40 Days | |

| 0 | 3.10% | 3.81% | 2.75% | 3.35% | 3.67% | 2.90% |

| 20 | 3.52% | 4.28% | 2.33% | 3.57% | 4.80% | 4.03% |

| 40 | 2.62% | 3.93% | 2.95% | 4.66% | 4.55% | 4.23% |

| 60 | 1.69% | 0.89% | 1.57% | 2.27% | 2.28% | 2.81% |

| 80 | 1.21% | 1.86% | 1.89% | 3.59% | 3.34% | 4.16% |

| 100 | 3.58% | 2.04% | 2.51% | 4.54% | 3.99% | 3.62% |

| 120 | 1.77% | 1.97% | 2.07% | 0.58% | 2.37% | 2.05% |

| Specimen Position | Weight (g) | Moisture Content (%) | |||||

|---|---|---|---|---|---|---|---|

| Oven-Dry Weight | Initial State | Final State | After 40 Days | Initial State | Final State | After 40 Days | |

| A1 | 530.06 | 770.98 | 629.58 | 570.28 | 45.45 | 18.78 | 7.58 |

| A2 | 510.51 | 741.23 | 601.9 | 542.56 | 45.19 | 17.9 | 6.28 |

| A3 | 478.97 | 690.62 | 563.91 | 510.39 | 44.18 | 17.73 | 6.55 |

| CV | 0.0509 | 0.0553 | 0.0551 | 0.0554 | 0.0149 | 0.0311 | 0.1008 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, H.; Gao, R.; Wang, G.; Ma, X.; Fang, C.; Liu, H. Design and Experiment of the Mold for the Production Process of Natural Arc-Shaped Bamboo Laminated Lumber. Forests 2025, 16, 1452. https://doi.org/10.3390/f16091452

Miao H, Gao R, Wang G, Ma X, Fang C, Liu H. Design and Experiment of the Mold for the Production Process of Natural Arc-Shaped Bamboo Laminated Lumber. Forests. 2025; 16(9):1452. https://doi.org/10.3390/f16091452

Chicago/Turabian StyleMiao, Hu, Rui Gao, Guofu Wang, Xinxin Ma, Changhua Fang, and Huanrong Liu. 2025. "Design and Experiment of the Mold for the Production Process of Natural Arc-Shaped Bamboo Laminated Lumber" Forests 16, no. 9: 1452. https://doi.org/10.3390/f16091452

APA StyleMiao, H., Gao, R., Wang, G., Ma, X., Fang, C., & Liu, H. (2025). Design and Experiment of the Mold for the Production Process of Natural Arc-Shaped Bamboo Laminated Lumber. Forests, 16(9), 1452. https://doi.org/10.3390/f16091452