A Genetic Algorithm for Forest Logging Trucks Routing and Scheduling Problem

Abstract

1. Introduction

2. Literature Review

2.1. Overveiw of the FRSP

2.2. Overview of Genetic Algorithms in Routing and Scheduling Studies

- Based on theoretical analysis, a GA-based heuristic is proposed for solving large-sized instances;

- A novel hybrid encoding method combining integer encoding has been developed, allowing for efficient and flexible problem representation;

- By evaluating the proposed GA against the well-known commercial optimization solver CPLEX, it is demonstrated that the algorithm is a viable alternative for complex FRSP scenarios.

3. Problem Statement and Formulation

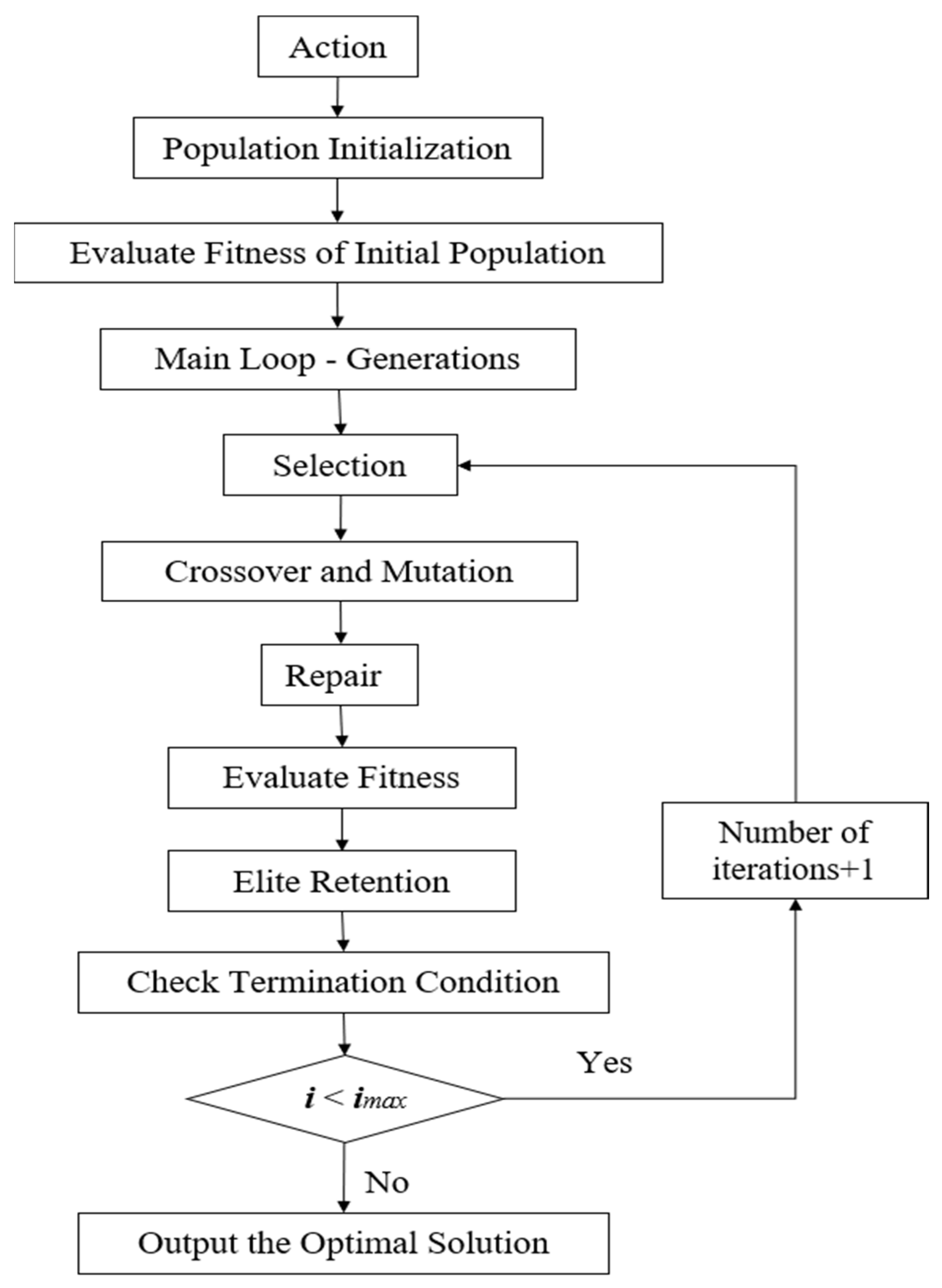

4. Genetic Algorithm Design

4.1. Encoding Representation

4.2. Decoding Representation

4.3. Initial Population Generation

| Algorithm 1: Initial Population Generation |

| Input: Parameters of the GA, pop_size, path_length |

| Output: Initial solutions to the GA |

| For i = 1, …, pop_size, do: |

| Call generate_path() to construct a feasible path. |

| Call generate_base_assignment(path) to determine the corresponding base assignment for the generated path. |

| Combine the generated path and base assignment into a solution matrix. |

| [[path], [base_assignment]]. |

| Add the solution matrix to the population pool. |

| Output Initial Population: |

| Return the initial population pool population containing pop_size solutions. |

4.4. Selection Mechanism

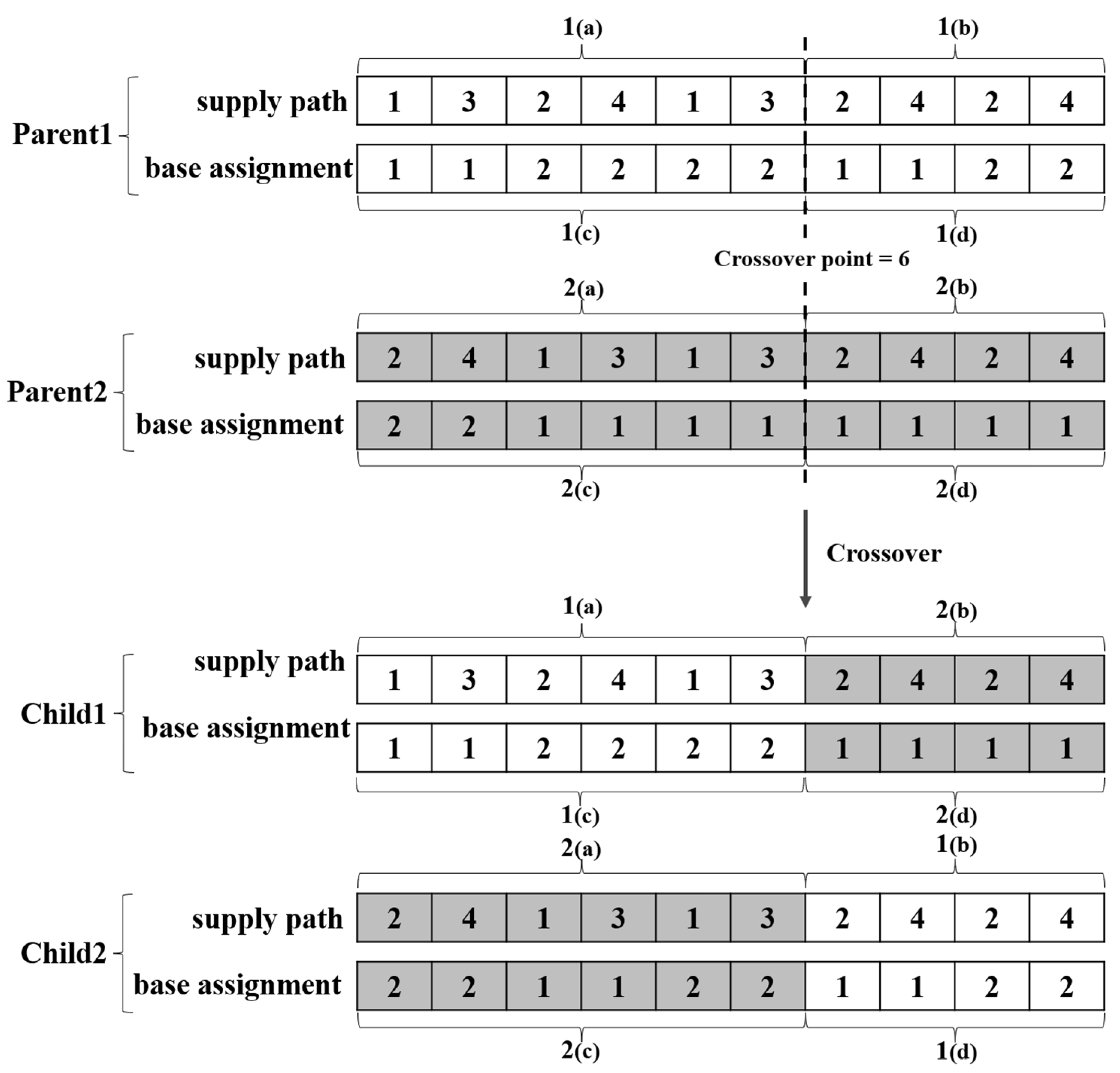

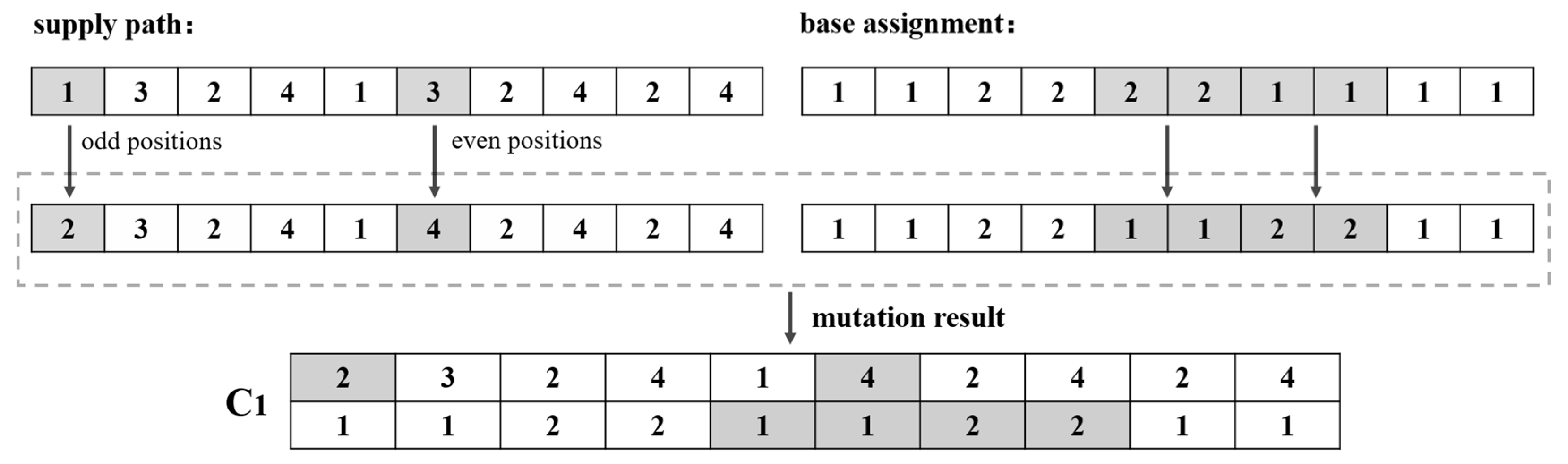

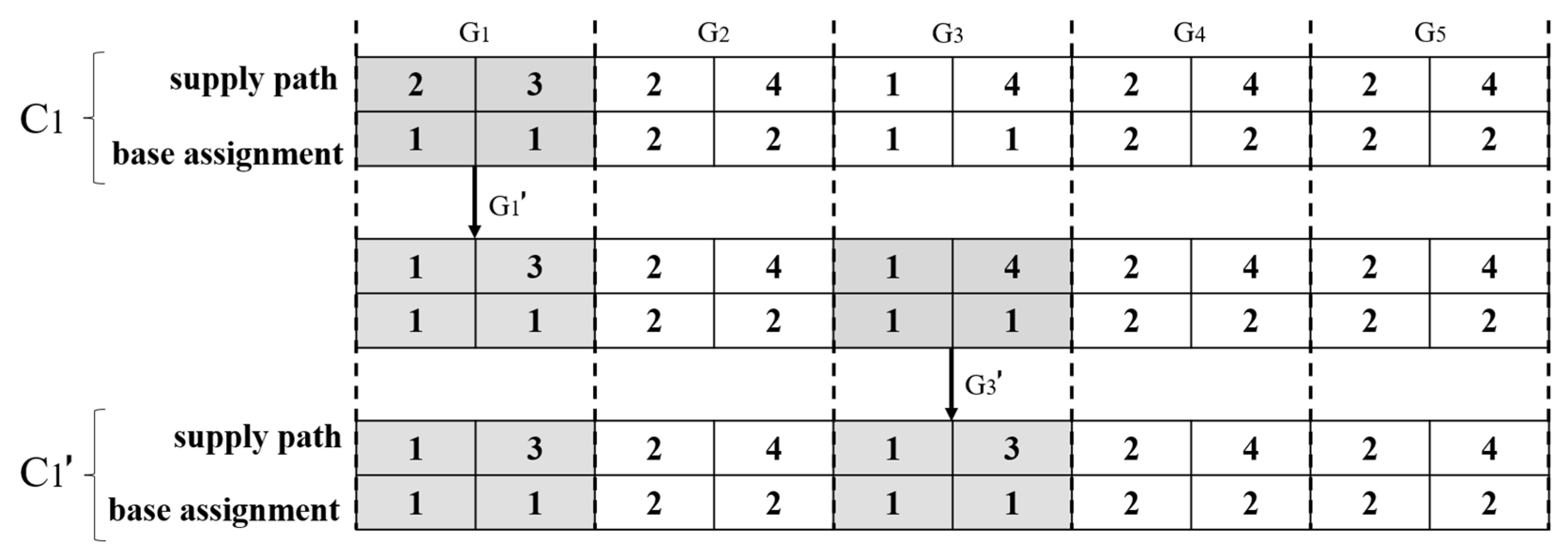

4.5. Crossover, Mutation and Repair

- The path part’s odd indices mutate to a random integer between 1 and F (representing a harvest area).

- The path part’s even indices mutate to a random integer between F and F + P (representing a plant).

- The base assignment part mutates to a random integer between 1 and B.

- Create deep copies of the initial supply and demand.

- For each pair of indices in the path, check if the supply from the harvest area meets the demand from the plant for the required materials.

- If a match is found, update the supply and demand accordingly and add the indices to the repaired path and base assignment.

- If no match is found, randomly select new indices for the harvest area and plant until a match is found.

5. Numerical Experiments

5.1. Performance Evaluation on GA

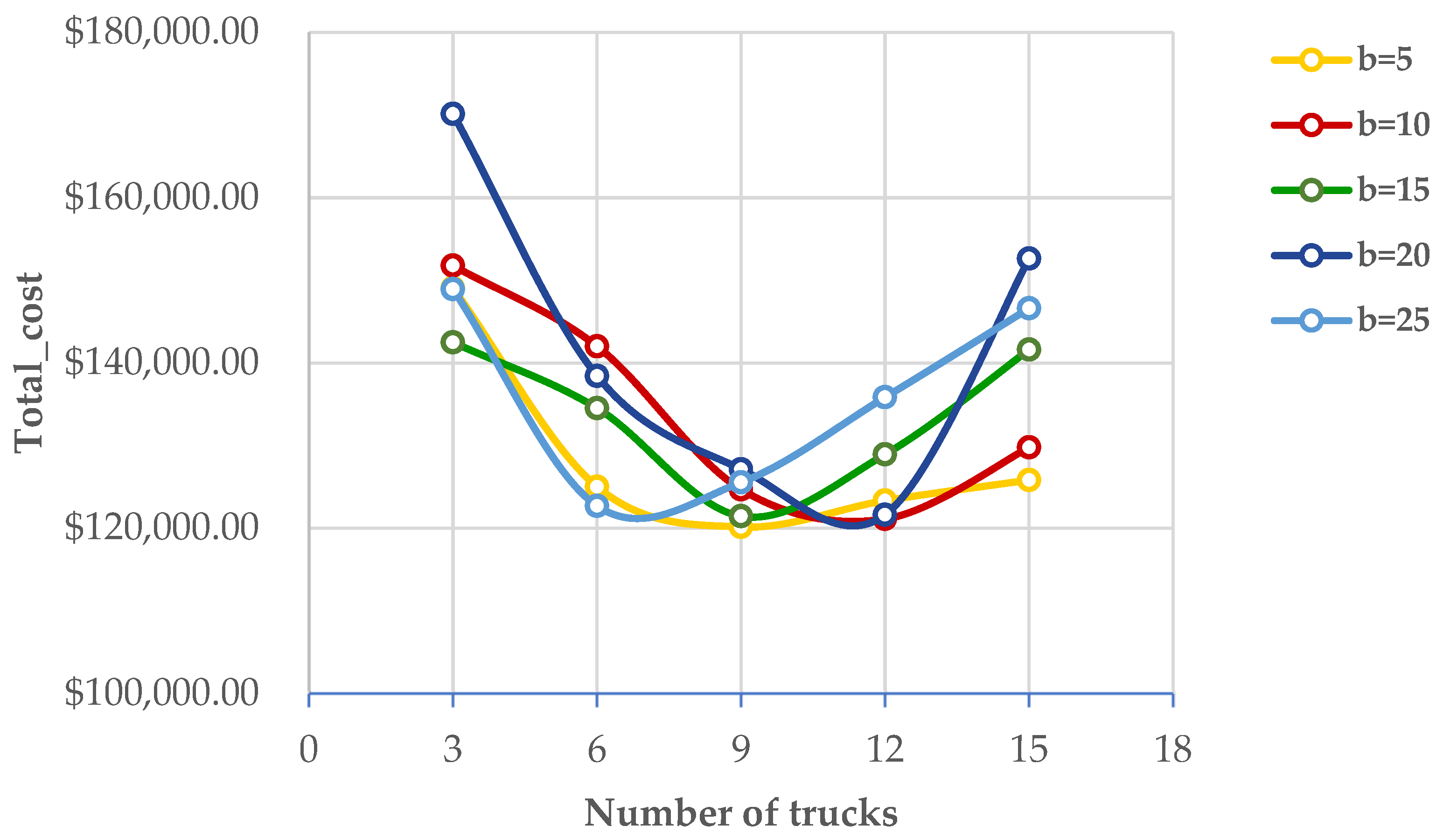

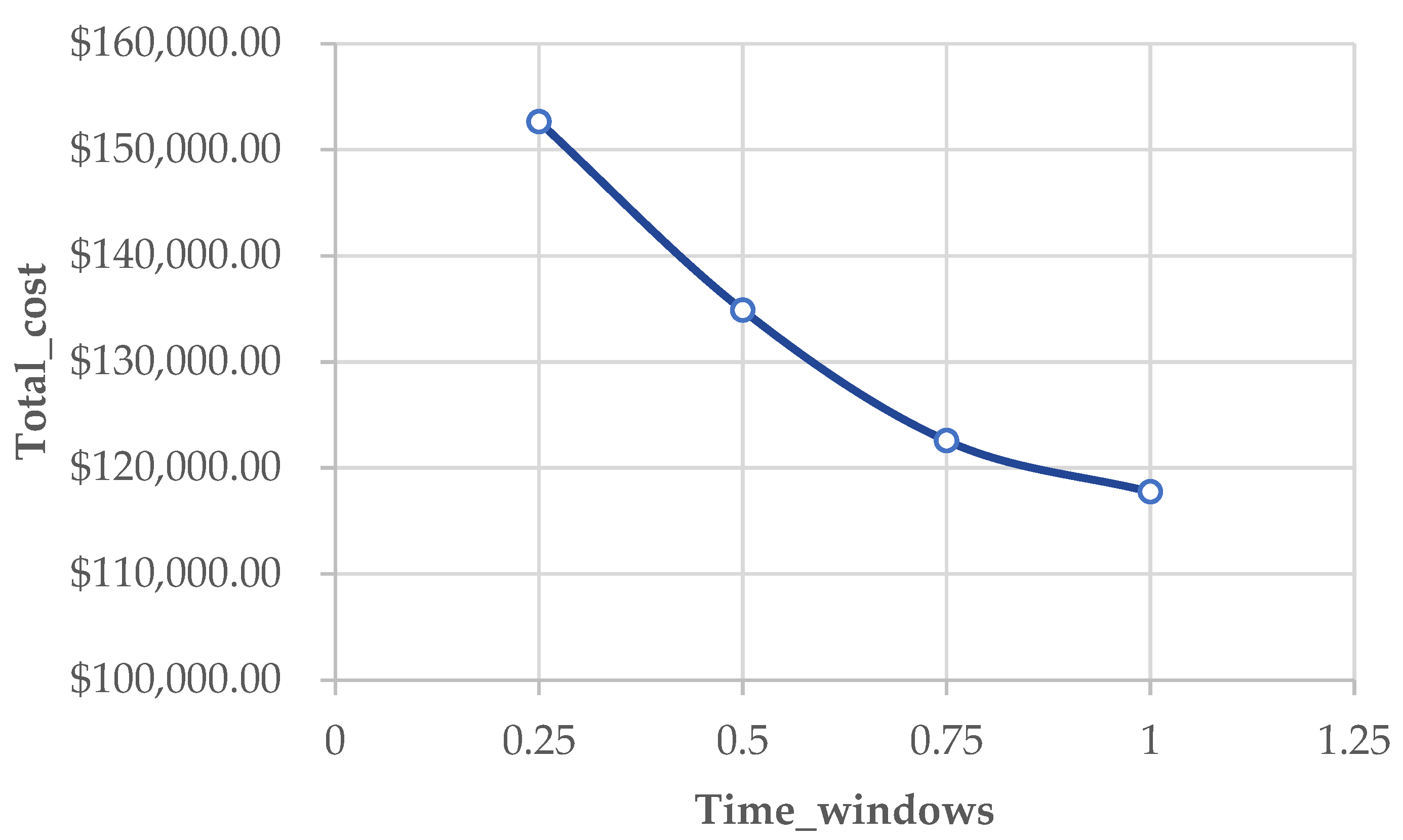

5.2. Sensitivity Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Notations and Parameters

| Sets | |

| B | set of regional bases b. |

| C | set of available trucks c. |

| Cb | set of trucks c that belongs to the regional base b. |

| F | set of harvest areas f. |

| Fm | set of harvest areas f that offer raw material m. |

| If | set of shifts i in f. |

| Lp | set of shifts l in p. |

| M | set of raw materials m. |

| P | set of plants p. |

| Pm | set of plants p that demand raw material m. |

| Δf,p | set of pairs (i, l) with i ∈ If and l ∈ Lp such that l is allowed to be used after shift i. |

| Πp,f | set of pair (i, l) with l ∈ Lp and i ∈ If such that i is allowed to be used after shift l. |

| Ωb,f | set of all shifts i ∈ If that can be reached from b. |

| Vc | set of loading capacity of vehicle C. |

| Parameters | |

| CBFb,f | cost (in USD per traveled kilometer) between nodes b and f. |

| CFPf,p | cost (in USD per traveled kilometer) between nodes f and p. |

| CloseFf | closing time for harvest area f. |

| ClosePp | closing time for plant p. |

| CPBp,b | cost (in USD per traveled kilometer) between nodes p and b. |

| CPFp,f | cost (in USD per traveled kilometer) between nodes p and f. |

| DBFb,f | distance between nodes b and f. |

| DEMp,m | demand (in full truckloads) of material m at plant p. |

| DFPf,p | distance between nodes f and p. |

| DPBp,b | distance between nodes p and b. |

| DPFp,f | distance between nodes p and f. |

| EAWb | maximum ending time for truck departure from base b. |

| EFIf,i | ending time for a shift i of f. |

| EPLp,l | ending time for a shift l of p. |

| limNT | number of allowed trips per truck. |

| Loadf | loading time at harvest area f. |

| LRTc | time limit for route performed by c. |

| OFf,m | supply (in full truckloads) of material m at harvest area f. |

| OpeningFf | opening time for harvest area f. |

| OpeningPp | opening time for plant p. |

| SAWb | minimum starting time for truck departure from base b. |

| SBFb,f | average speed to cross the path between nodes b and f. |

| SFIf,i | starting time for a shift i of f. |

| SFPf,p | average speed to cross the path between nodes f and p. |

| SPBp,b | average speed to cross the path between nodes p and b. |

| SPFp,f | average speed to cross the path between nodes p and f. |

| SPLp,l | starting time for a shift l of p. |

| TBFb,f | required time to travel between nodes b and f. |

| TFPf,p | required time to travel between nodes f and p. |

| TPFp,f | required time to travel between nodes p and f. |

| TPBp,b | required time to travel between nodes p and b. |

| Unloadp | unloading time at plant p. |

| WTFf | maximum waiting time for harvest area f. |

| WTPp | maximum waiting time for plant p. |

| Binary variables | |

| xc,f,i,m | takes value 1 if the truck c departs from its regional base to the harvest area f for loading raw material m in shift i. |

| xc,f,i,p,l,m | takes value 1 if the truck c leaves the harvest area f at the end of shift i to unload raw material m at the plant p during shift l. |

| xc,p,l,f,i,m | takes value 1 if the truck c leaves the plant p at the end of shift l to load raw material m at the harvest area f during shift i. |

| xc,p,l | takes value 1 if the truck c leaves the plant p at the end of shift l and returns to its regional base. |

| Continuous variables | |

| TCOST | total transportation costs. |

| TIMEc,b | total working time of truck c. |

References

- Akay, A.O.; Demir, M. A Scenario-Based Analysis of Forest Product Transportation Using a Hybrid Fuzzy Multi-Criteria Decision-Making Method. Forests 2022, 13, 730. [Google Scholar] [CrossRef]

- Weintraub, A.; Navon, D. A Forest Management Planning Model Integrating Silvicultural and Transportation Activities. Manag. Sci. 1976, 22, 1299–1309. [Google Scholar] [CrossRef]

- Weintraub, A.; Barahona, F.; Epstein, R. A Column Generation Algorithm for Solving General Forest Planning Problems with Adjacency Constraints. For. Sci. 1994, 40, 142–161. [Google Scholar] [CrossRef]

- Weintraub, A.; Epstein, R.; Morales, R.; Seron, J.; Traverso, P. A truck scheduling system improves efficiency in the forest industries. Interfaces 1996, 26, 1–12. [Google Scholar] [CrossRef]

- Arthur, J.L.; Dykstra, D.P. Timber Harvest Planning—A Combined Optimization/Simulation Model. Environ. Manag. 1980, 4, 491–498. [Google Scholar] [CrossRef]

- Bordón, M.R.; Montagna, J.M.; Corsano, G. An exact mathematical formulation for the optimal log transportation. For. Policy Econ. 2018, 95, 115–122. [Google Scholar] [CrossRef]

- dos Santos, P.A.V.H.; da Silva, A.C.L.; Arce, J.E.; Augustynczik, A.L.D. A Mathematical Model for the Integrated Optimization of Harvest and Transport Scheduling of Forest Products. Forests 2019, 10, 1110. [Google Scholar] [CrossRef]

- Melchiori, L.; Nasini, G.; Montagna, J.M.; Corsano, G. Resources synchronization in a full truckload pickup and delivery problem: An exact approach. Comput. Oper. Res. 2023, 151, 106–118. [Google Scholar] [CrossRef]

- Melchiori, L.; Nasini, G.; Montagna, J.M.; Corsano, G. A mathematical modeling for simultaneous routing and scheduling of logging trucks in the forest supply chain. For. Policy Econ. 2022, 136, 102–693. [Google Scholar] [CrossRef]

- Schneeweiss, C. Distributed Decision Making; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Palmgren, M.; Rönnqvist, M.; Värbrand, P.; Palmgren, M.; Ro, M. A solution approach for log truck scheduling based on composite pricing and branch bound. Int. Trans. Oper. Res. 2003, 10, 15. [Google Scholar] [CrossRef]

- El Hachemi, N.; Gendreau, M.; Rousseau, L.M. A hybrid constraint programming approach to the log-truck scheduling problem. Ann. Oper. Res. 2011, 184, 163–178. [Google Scholar] [CrossRef]

- Vacca, I.; Salani, M.; Bierlaire, M. Optimization of Operations in Container Terminals: Hierarchical vs. Integrated Approaches. In Proceedings of the 10th Swiss Transport Research Conference, Ascona, Switzerland, 1–3 September 2010. [Google Scholar]

- Murphy, G. Reducing trucks on the road through optimal route scheduling and shared log transport services. South. J. Appl. For. 2003, 27, 198–205. [Google Scholar] [CrossRef]

- Malladi, K.T.; Sowlati, T. Optimization of operational level transportation planning in forestry: A review. Int. J. For. Eng. 2017, 28, 198–210. [Google Scholar] [CrossRef]

- Audy, J.F.; Rönnqvist, M.; D’Amours, S.; Yahiaoui, A.E. Planning methods and decision support systems in vehicle routing problems for timber transportation: A review. Int. J. For. Eng. 2023, 34, 143–167. [Google Scholar] [CrossRef]

- Gronalt, M.; Hirsch, P. Log-Truck scheduling with a tabu search strategy. Metaheuristics 2007, 39, 65–88. [Google Scholar]

- Flisberg, P.; Lidén, B.; Rönnqvist, M. A hybrid method based on linear programming and tabu search for routing of logging trucks. Comput. Oper. Res. 2009, 36, 1122–1144. [Google Scholar] [CrossRef]

- Haridass, K.; Valenzuela, J.; Yucekaya, A.D.; McDonald, T. Scheduling a log transport system using simulated annealing. Inf. Sci. 2014, 264, 302–316. [Google Scholar] [CrossRef]

- Iksan, N.; Tufail, A.; Apong, R.A.; Hidayatullah, A.F. Optimizing Maritime Passenger Transfer in Rich Vehicle Routing Problem Using a Hybrid Genetic Algorithm. IEEE Access 2024, 12, 80153–80164. [Google Scholar] [CrossRef]

- Bordón, M.R.; Montagna, J.M.; Corsano, G. Mixed integer linear programming approaches for solving the raw material allocation, routing and scheduling problems in the forest industry. Int. J. Ind. Eng. Comput. 2020, 11, 525–548. [Google Scholar] [CrossRef]

- Savuran, H.; Karakaya, M. Route optimization method for unmanned air vehicle launched from a carrier. Lect. Notes Softw. Eng. 2015, 3, 279–284. [Google Scholar] [CrossRef]

- Peng, K.; Du, J.; Lu, F.; Sun, Q.; Dong, Y.; Zhou, P.; Hu, M. A Hybrid Genetic Algorithm on Routing and Scheduling for Vehicle-Assisted Multi-Drone Parcel Delivery. IEEE Access 2019, 7, 49191–49200. [Google Scholar] [CrossRef]

- Moon, I.; Lee, S.; Bae, H. Genetic algorithms for job shop scheduling problems with alternative routings. Int. J. Prod. Res. 2008, 46, 2695–2705. [Google Scholar] [CrossRef]

- Baniamerian, A.; Bashiri, M.; Zabihi, F. Two phase genetic algorithm for vehicle routing and scheduling problem with cross-docking and time windows considering customer satisfaction. J. Ind. Eng. Int. 2018, 14, 15–30. [Google Scholar] [CrossRef]

- Cheikh, M.; Ratli, M.; Mkaouar, O.; Jarboui, B. A variable neighborhood search algorithm for the vehicle routing problem with multiple trips. Electron. Notes Discret. Math. 2015, 47, 277–284. [Google Scholar] [CrossRef]

- Cao, Q.; Fu, C.; Li, H. Route Planning for Chain Restaurants With Improved Delivery Mode Using an Adaptive Genetic Algorithm. IEEE Access 2022, 10, 25645–25656. [Google Scholar] [CrossRef]

- Maroof, A.; Ayvaz, B.; Naeem, K. Logistics Optimization Using Hybrid Genetic Algorithm (HGA): A Solution to the Vehicle Routing Problem with Time Windows (VRPTW). IEEE Access 2024, 12, 36974–36989. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Q. A Hybrid Genetic Algorithm for Flexible Job Shop Scheduling Problem with Sequence-Dependent Setup Times and Job Lag Times. IEEE Access 2021, 9, 104864–104873. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems; University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- Derigs, U.; Pullmann, M.; Vogel, U.; Oberscheider, M.; Gronalt, M.; Hirsch, P. Multilevel Neighborhood Search for Solving Full Truckload Routing Problems Arising in Timber Transportation. Electron. Notes Discret. Math. 2012, 39, 281–288. [Google Scholar] [CrossRef]

| b1 | b2 | f1 | f2 | m1 | m2 | |

| b1 | - | - | 45 | 32 | - | - |

| b2 | - | - | 10 | 70 | - | - |

| p1 | 99 | 32 | 14 | 82 | 2 | 0 |

| p2 | 10 | 67 | 36 | 54 | 0 | 3 |

| m1 | - | - | 2 | 3 | - | - |

| m2 | - | - | 0 | 0 | - | - |

| Total Cost_C | CPU_C | Total Cost_GA | CPU_GA | Total Cost Deviation (%) | Total Cost_LNS | CPU_LNS | Total Cost Deviation (%) | |

|---|---|---|---|---|---|---|---|---|

| I | 35,005 USD | 16.86 | 35,445 USD | 1.28 | 1.26 | 35,720 USD | 1.67 | 2.04 |

| II | 117,890 USD | 1800 | 119,130 USD | 2.56 | 1.05 | 121,670 USD | 2.81 | 3.21 |

| Run | Total Cost_GA | Total Cost_LNS |

|---|---|---|

| 1 | 35,445 USD | 35,720 USD |

| 2 | 35,445 USD | 35,720 USD |

| 3 | 35,445 USD | 35,815 USD |

| 4 | 35,560 USD | 35,900 USD |

| 5 | 35,600 USD | 35,900 USD |

| 6 | 35,615 USD | 35,980 USD |

| 7 | 35,650 USD | 36,005 USD |

| 8 | 35,650 USD | 36,010 USD |

| 9 | 35,720 USD | 36,055 USD |

| 10 | 35,815 USD | 36,140 USD |

| b-f-p | Total Cost_GA | Total Cost_LNS |

|---|---|---|

| 5-10-5 | 118,825 USD | 121,055 USD |

| 10-20-10 | 304,425 USD | 336,980 USD |

| 15-30-15 | 457,815 USD | 462,405 USD |

| 20-40-20 | 588,505 USD | 622,630 USD |

| 25-50-25 | 736,370 USD | 778,115 USD |

| b-f-p | CPU_GA(s) |

|---|---|

| 5-10-5 | 1.3682 |

| 10-20-10 | 4.0425 |

| 15-30-15 | 8.0023 |

| 20-40-20 | 14.4467 |

| 25-50-25 | 22.0584 |

| b | Nt | Total Cost (USD) | CPU_GA (s) |

|---|---|---|---|

| 3 | 149,085 | 0.8737 | |

| 6 | 125,015 | 1.3085 | |

| 5 | 9 | 120,170 | 2.0508 |

| 12 | 123,350 | 2.0311 | |

| 15 | 125,830 | 2.0542 | |

| 3 | 151,780 | 0.8647 | |

| 6 | 140,135 | 1.2247 | |

| 10 | 9 | 124,725 | 2.0696 |

| 12 | 121,120 | 2.0234 | |

| 15 | 129,805 | 2.0516 | |

| 3 | 142,495 | 0.9114 | |

| 6 | 134,540 | 1.1626 | |

| 15 | 9 | 121,475 | 2.1132 |

| 12 | 128,935 | 2.1276 | |

| 15 | 141,620 | 2.1317 | |

| 3 | 170,150 | 0.9375 | |

| 6 | 138,430 | 1.3014 | |

| 20 | 9 | 127,155 | 2.0961 |

| 12 | 121,635 | 2.1435 | |

| 15 | 152,635 | 2.0215 | |

| 3 | 148,925 | 0.8550 | |

| 6 | 122,705 | 1.3018 | |

| 25 | 9 | 125,565 | 2.0524 |

| 12 | 135,855 | 2.0816 | |

| 15 | 146,635 | 2.1168 |

| Max_Work_Time (h) | Total Cost (USD) | CPU_GA (s) |

|---|---|---|

| 3 | - | 2.3488 |

| 6 | 154,870 | 2.2032 |

| 9 | 122,570 | 2.0639 |

| 12 | 117,755 | 2.1402 |

| 15 | 116,315 | 2.1679 |

| Time_Windows (h) | Total Cost (USD) | CPU_GA (s) |

|---|---|---|

| 0.25 | 152,650 | 2.5427 |

| 0.5 | 134,870 | 2.2146 |

| 0.75 | 122,570 | 2.3577 |

| 1 | 117,755 | 2.1497 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, W.; Feng, X. A Genetic Algorithm for Forest Logging Trucks Routing and Scheduling Problem. Forests 2025, 16, 1440. https://doi.org/10.3390/f16091440

Deng W, Feng X. A Genetic Algorithm for Forest Logging Trucks Routing and Scheduling Problem. Forests. 2025; 16(9):1440. https://doi.org/10.3390/f16091440

Chicago/Turabian StyleDeng, Weijie, and Xin Feng. 2025. "A Genetic Algorithm for Forest Logging Trucks Routing and Scheduling Problem" Forests 16, no. 9: 1440. https://doi.org/10.3390/f16091440

APA StyleDeng, W., & Feng, X. (2025). A Genetic Algorithm for Forest Logging Trucks Routing and Scheduling Problem. Forests, 16(9), 1440. https://doi.org/10.3390/f16091440