Improving the Physical Characteristics and Durability of Wood Through a Combined Modification Process Using Thermal Treatment and Wax Impregnation in One Step

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Modification Method

2.3. Test Methods

3. Results and Discussion

3.1. Wax Uptake and Mass Loss

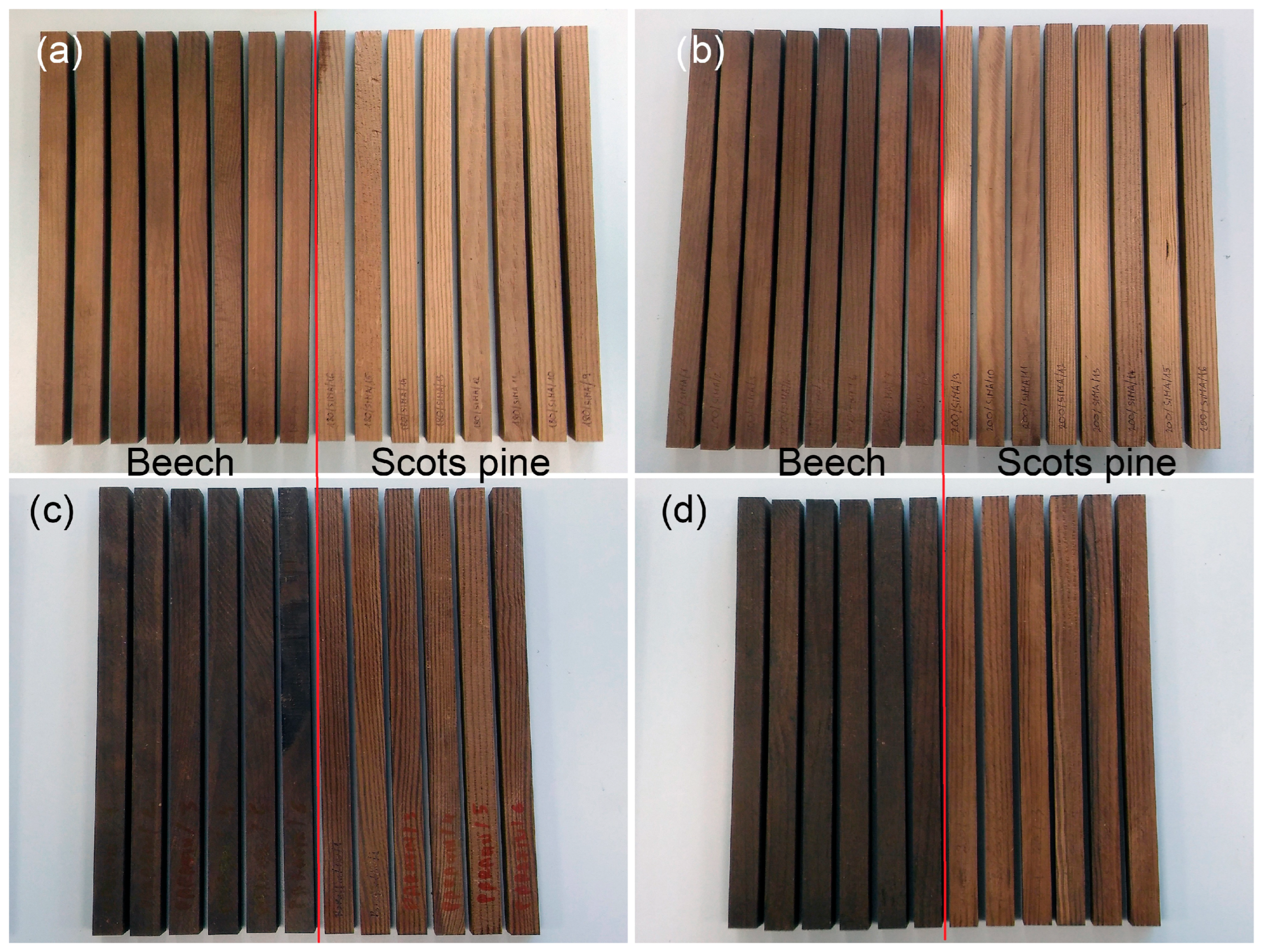

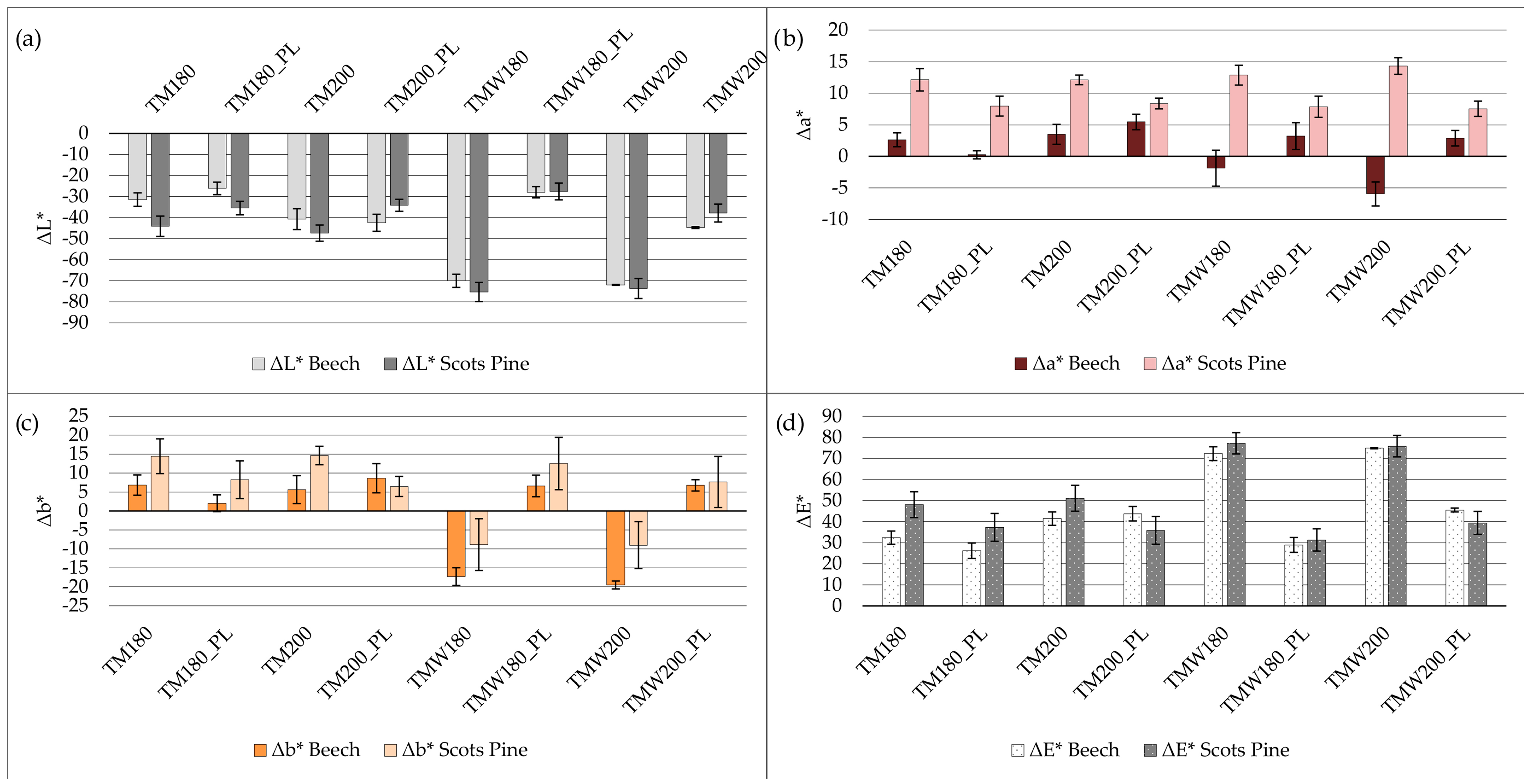

3.2. Color Change

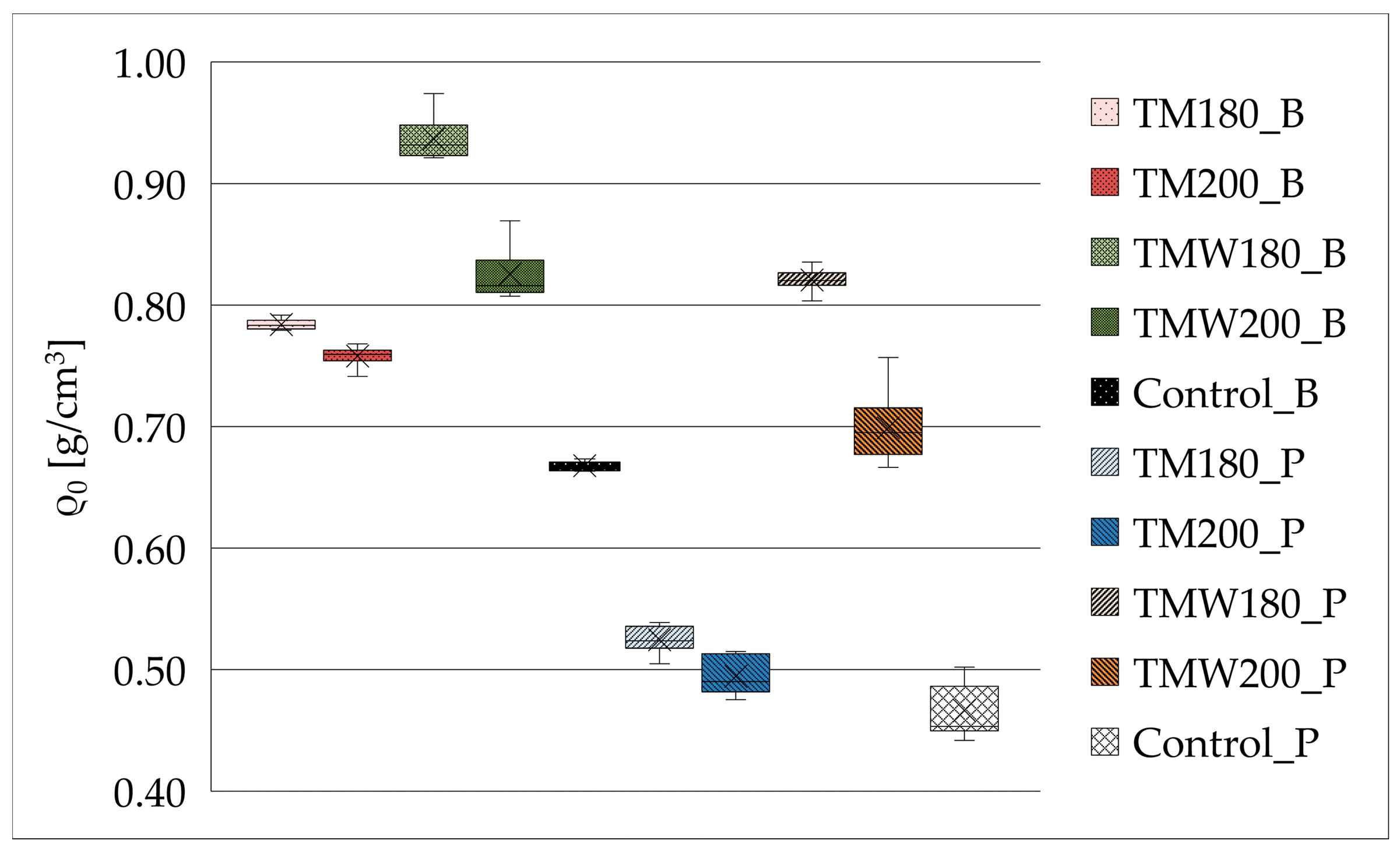

3.3. Ovendry Density

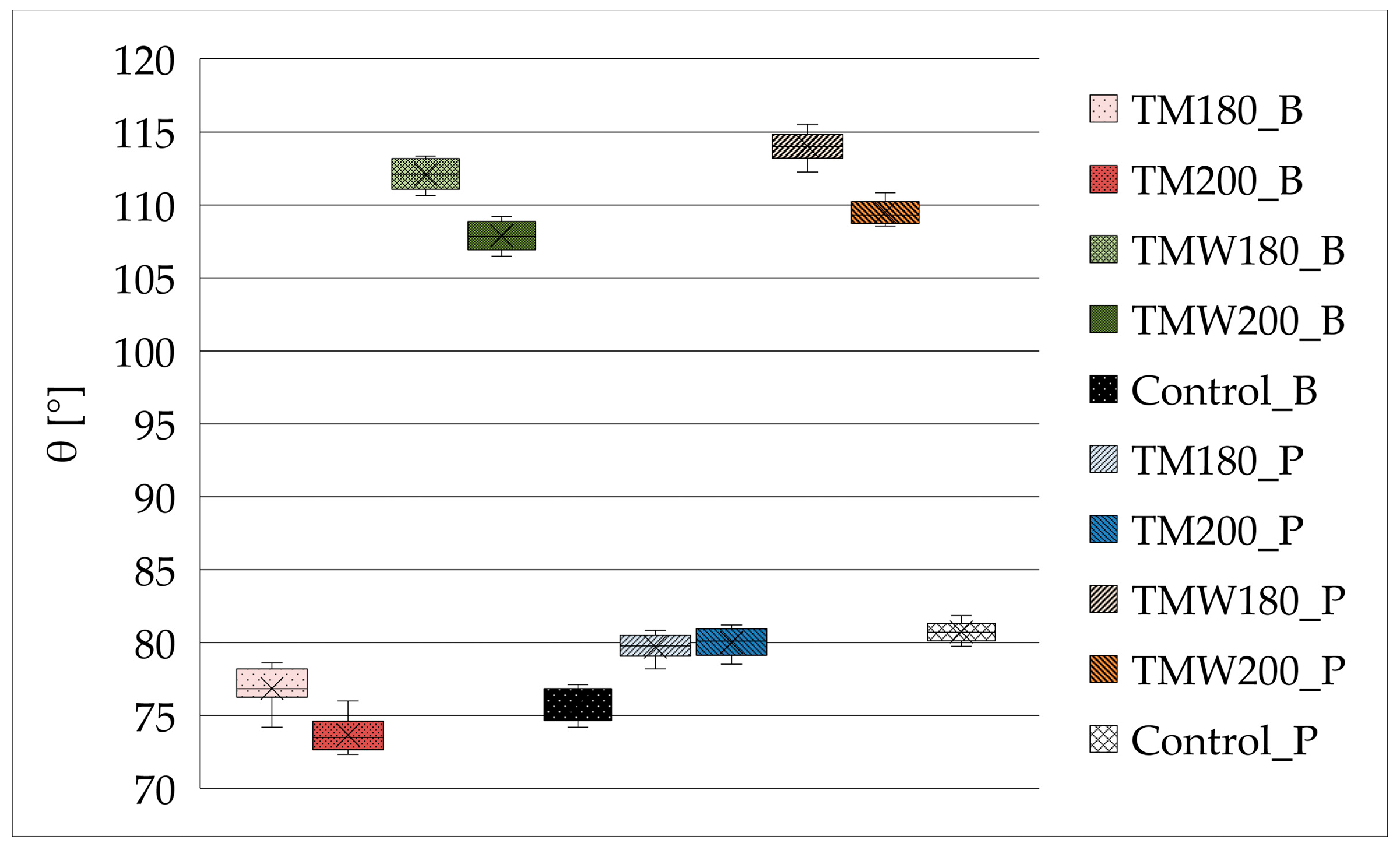

3.4. Water Contact Angle

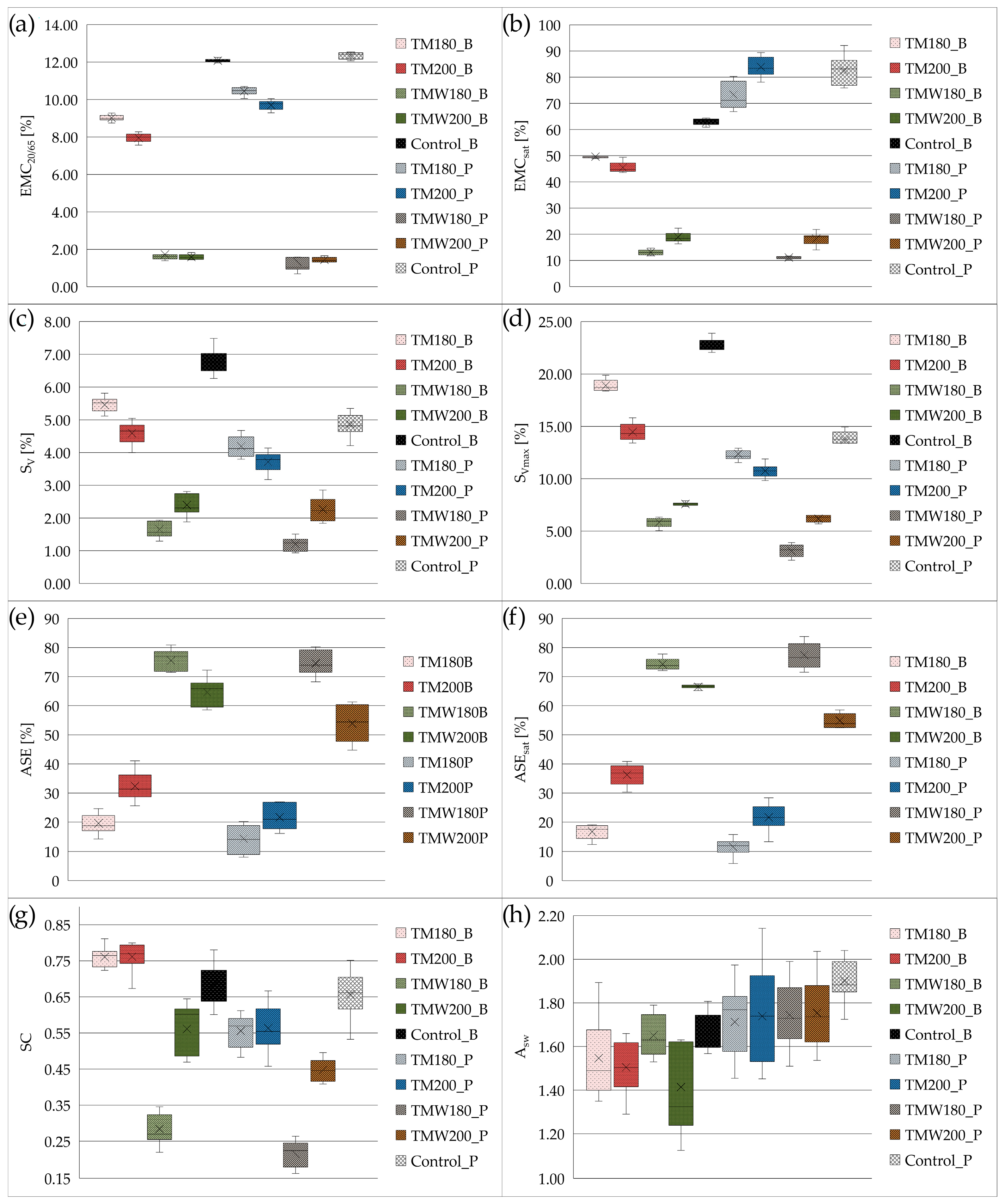

3.5. Wood–Water Relations

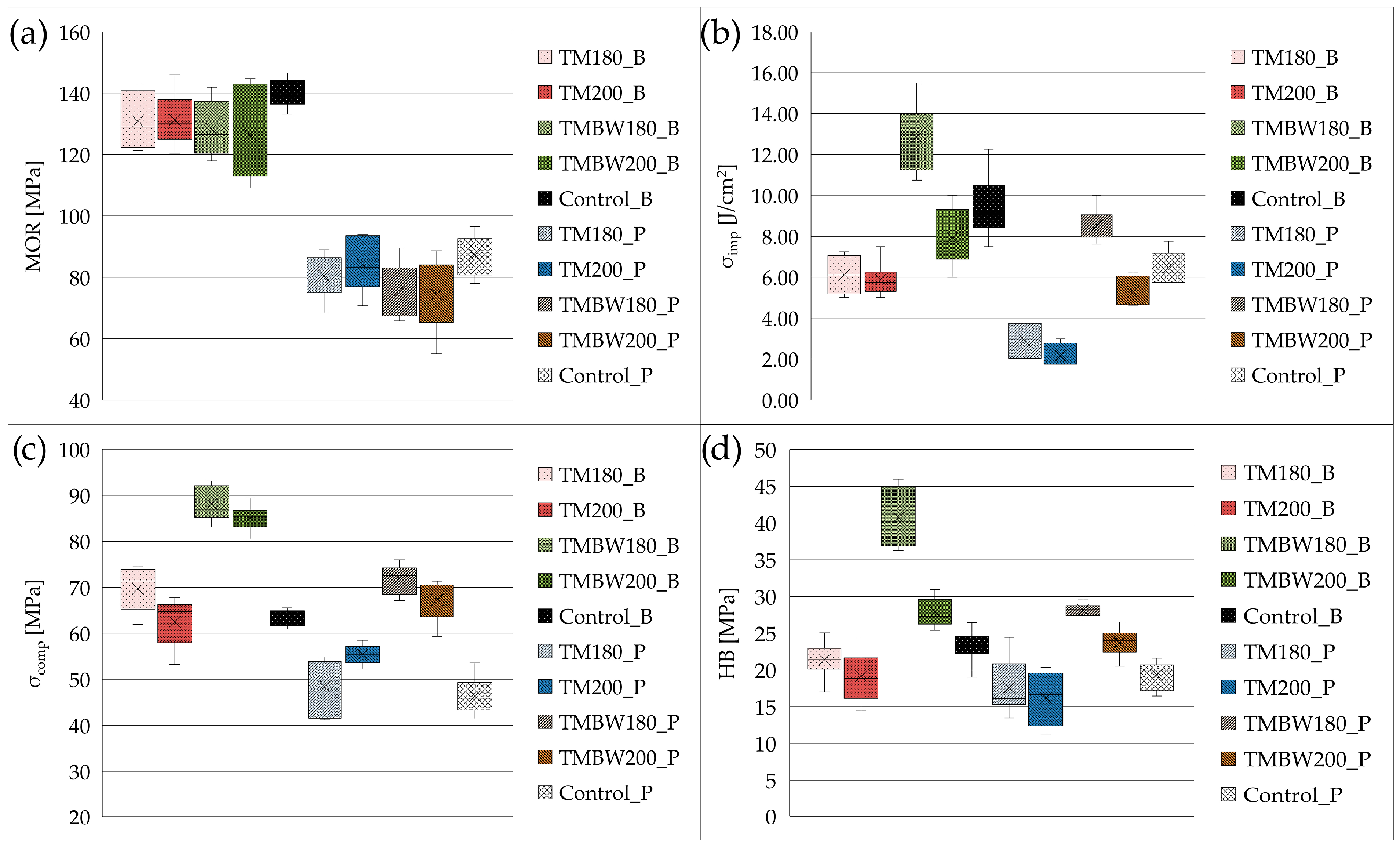

3.6. Mechanical Properties

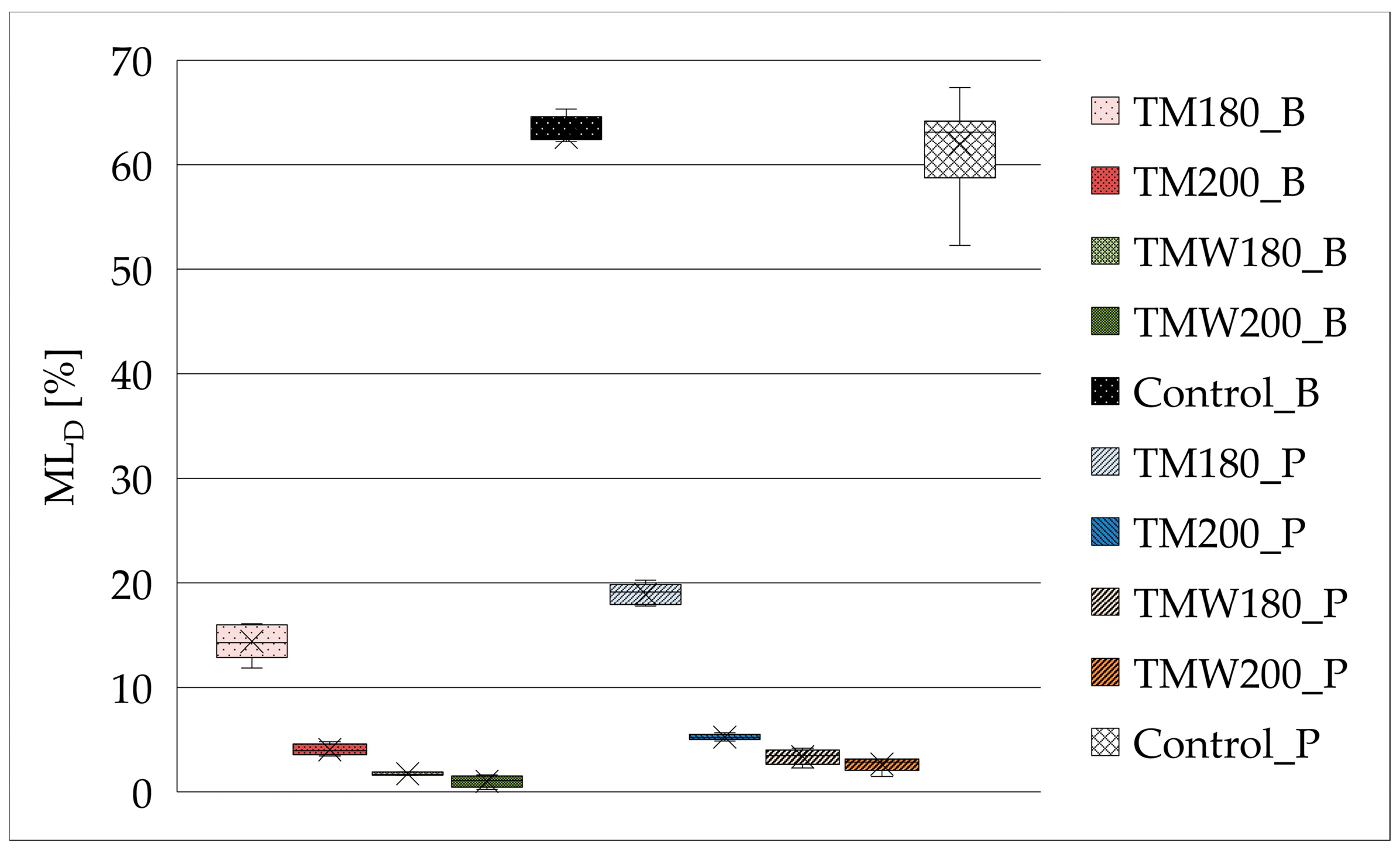

3.7. Durability

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Salman, S.; Pétrissans, A.; Thévenon, M.F.; Dumarçay, S.; Gérardin, P. Decay and Termite Resistance of Pine Blocks Impregnated with Different Additives and Subjected to Heat Treatment. Eur. J. Wood Prod. 2016, 74, 37–42. [Google Scholar] [CrossRef]

- Pandey, K.K.; Vinoth Kumar, S.; Srinivas, K. Inhibition of Leaching of Water Soluble Extractives of Pterocarpus Marsupium by Heat Treatment. Eur. J. Wood Prod. 2016, 74, 223–229. [Google Scholar] [CrossRef]

- Broda, M.; Popescu, C.-M.; Poszwa, K.; Roszyk, E. How Thermal Treatment Affects the Chemical Composition and the Physical, Mechanical and Swelling Properties of Scots Pine Juvenile and Mature Wood. Wood Sci. Technol. 2024, 58, 1153–1180. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Olek, W.; Weres, J. Effects of Heat Treatment on Thermal Properties of European Beech Wood. Eur. J. Wood Prod. 2020, 78, 425–431. [Google Scholar] [CrossRef]

- Ali, M.R.; Abdullah, U.H.; Ashaari, Z.; Hamid, N.H.; Hua, L.S. Hydrothermal Modification of Wood: A Review. Polymers 2021, 13, 2612. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood Modification by Heat Treatment: A Review. BioResources 2008, 4, 370–404. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-1-351-02822-6. [Google Scholar]

- Scholz, G.; Krause, A.; Militz, H. Volltränkung modifizierten Holzes mit Wachs. Eur. J. Wood Prod. 2012, 70, 91–98. [Google Scholar] [CrossRef]

- Popescu, C.; Jones, D.; Kržišnik, D.; Humar, M. Determination of the Effectiveness of a Combined Thermal/Chemical Wood Modification by the Use of FT–IR Spectroscopy and Chemometric Methods. J. Mol. Struct. 2020, 1200, 127133. [Google Scholar] [CrossRef]

- Kuka, E.; Cirule, D.; Andersone, I.; Andersons, B.; Kurnosova, N.; Verovkins, A.; Puke, M. Environmental Performance of Combined Treated Wood. Wood Mater. Sci. Eng. 2023, 18, 88–96. [Google Scholar] [CrossRef]

- Kamperidou, V.; Ratajczak, I.; Perdoch, W.; Mazela, B. Impact of thermal modification combined with silicon compounds treatment on wood structure. Wood Res. 2022, 67, 773–784. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, X.; Chen, Z.; Dong, H.; Tan, Y.; Bai, X. Properties and Durability of Wood Impregnated with High Melting Point Polyethylene Wax for Outdoor Use. J. Wood Chem. Technol. 2022, 42, 342–351. [Google Scholar] [CrossRef]

- Waßmann, O.; Ahmed, S.I.-U. Tribological Properties and Related Effects of Compressed, Thermally Modified and Wax-Impregnated Wood. Eur. J. Wood Prod. 2024, 82, 2155–2168. [Google Scholar] [CrossRef]

- Soares, A.K.; Cademartori, P.H.G.D.; Evtyugin, D.V.; Zanatta, P.; Gatto, D.A. Eficiência Do Tratamento Combinado de Impregnação e Termorretificação Nas Propriedades Da Madeira de Pinus. Matéria 2018, 23, e12242. [Google Scholar] [CrossRef]

- Kačík, F.; Kubovský, I.; Bouček, J.; Hrčka, R.; Gaff, M.; Kačíková, D. Colour and Chemical Changes of Black Locust Wood during Heat Treatment. Forests 2022, 14, 73. [Google Scholar] [CrossRef]

- Reinprecht, L.; Repák, M. The Impact of Paraffin-Thermal Modification of Beech Wood on Its Biological, Physical and Mechanical Properties. Forests 2019, 10, 1102. [Google Scholar] [CrossRef]

- Lee, S.H.; Ashaari, Z.; Lum, W.C.; Abdul Halip, J.; Ang, A.F.; Tan, L.P.; Chin, K.L.; Md Tahir, P. Thermal Treatment of Wood Using Vegetable Oils: A Review. Constr. Build. Mater. 2018, 181, 408–419. [Google Scholar] [CrossRef]

- Candelier, K.; Dibdiakova, J. A Review on Life Cycle Assessments of Thermally Modified Wood. Holzforschung 2021, 75, 199–224. [Google Scholar] [CrossRef]

- Acosta, A.P.; Diaz, R.H.; Amico, S.C.; Beltrame, R.; Barbosa, K.T.; Delucis, R.A.; Gatto, D.A. Effect of the Temperature of the Heat Treatment of Pine Wood on Subsequent in situ Polymerization with Poly(Methyl Methacrylate). Biofuels Bioprod. Biorefining 2023, 17, 499–509. [Google Scholar] [CrossRef]

- He, Z.; Wang, Z.; Qu, L.; Qian, J.; Yi, S. Modeling and Simulation of Heat-Mass Transfer and Its Application in Wood Thermal Modification. Results Phys. 2019, 13, 102213. [Google Scholar] [CrossRef]

- Tang, J.; Zhan, T.; Li, Z.; Jiang, J.; Lyu, J. Optimization of Dimensional Stability and Mechanical Performance of Thermally Modified Wood Using Cyclic-Gradient Thermal Treatment. Constr. Build. Mater. 2025, 458, 139596. [Google Scholar] [CrossRef]

- Mandraveli, E.; Mitani, A.; Terzopoulou, P.; Koutsianitis, D. Oil Heat Treatment of Wood—A Comprehensive Analysis of Physical, Chemical, and Mechanical Modifications. Materials 2024, 17, 2394. [Google Scholar] [CrossRef] [PubMed]

- Dubey, M.K.; Pang, S.; Walker, J. Oil Uptake by Wood during Heat-Treatment and Post-Treatment Cooling, and Effects on Wood Dimensional Stability. Eur. J. Wood Prod. 2012, 70, 183–190. [Google Scholar] [CrossRef]

- Humar, M.; Kržišnik, D.; Lesar, B.; Thaler, N.; Ugovšek, A.; Zupančič, K.; Žlahtič, M. Thermal Modification of Wax-Impregnated Wood to Enhance Its Physical, Mechanical, and Biological Properties. Holzforschung 2017, 71, 57–64. [Google Scholar] [CrossRef]

- Wu, G.; Shah, D.U.; Janeček, E.-R.; Burridge, H.C.; Reynolds, T.P.S.; Fleming, P.H.; Linden, P.F.; Ramage, M.H.; Scherman, O.A. Predicting the Pore-Filling Ratio in Lumen-Impregnated Wood. Wood Sci. Technol. 2017, 51, 1277–1290. [Google Scholar] [CrossRef]

- Plötze, M.; Niemz, P. Porosity and Pore Size Distribution of Different Wood Types as Determined by Mercury Intrusion Porosimetry. Eur. J. Wood Prod. 2011, 69, 649–657. [Google Scholar] [CrossRef]

- Bak, M.; Molnár, F.; Rákosa, R.; Németh, Z.; Németh, R. Dimensional Stabilization of Wood by Microporous Silica Aerogel Using In-Situ Polymerization. Wood Sci. Technol. 2022, 56, 1353–1375. [Google Scholar] [CrossRef]

- ISO 13061-2; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests. International Organization for Standardization: Geneve, Switzerland, 2014.

- ISO 13061-1; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests. International Organization for Standardization: Geneve, Switzerland, 2014.

- ISO 13061-13; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 13: Determination of Radial and Tangential Shrinkage. International Organization for Standardization: Geneve, Switzerland, 2024.

- ISO 13061-14; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 14: Determination of Volumetric Shrinkage. International Organization for Standardization: Geneve, Switzerland, 2024.

- ISO 13061-15; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 15: Determination of Radial and Tangential Swelling. International Organization for Standardization: Geneve, Switzerland, 2025.

- ISO 13061-16; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 16: Determination of Volumetric Swelling. International Organization for Standardization: Geneve, Switzerland, 2025.

- Wagenführ, R.; Wagenführ, A. Holzatlas, 7th ed.; Carl Hanser Verlag GmbH & Co., KG: München, Germany, 2021; ISBN 978-3-446-46838-2. [Google Scholar]

- EN 350:2016; Durability of Wood and Wood-Based Products. Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials. European Committee for Standardization: Brussels, Belgium, 2016.

- Mahmoud Kia, M.; Tarmian, A.; Karimi, A.N.; Gholamiyan, H.; Abdulkhani, A.; Mastri Farahani, M.R. The Efficiency of Pistacia Atlantica Gum for Increasing Resistance of Rapeseed Oil-Heat Treated Wood to Fungal Attacks. Maderas Cienc. Tecnol. 2020, 22, 457–466. [Google Scholar] [CrossRef]

- Bessala, L.F.B.; Gao, J.; He, Z.; Wang, Z.; Yi, S. Effects of Heat Treatment on Color, Dimensional Stability, Hygroscopicity and Chemical Structure of Afrormosia and Newtonia Wood: A Comparative Study of Air and Palm Oil Medium. Polymers 2023, 15, 774. [Google Scholar] [CrossRef]

- Suri, I.F.; Kim, J.H.; Purusatama, B.D.; Yang, G.U.; Prasetia, D.; Lee, S.H.; Hidayat, W.; Febrianto, F.; Park, B.H.; Kim, N.H. Comparison of the Color and Weight Change in Paulownia Tomentosa and Pinus Koraiensis Wood Heat-Treated in Hot Oil and Hot Air. BioResources 2021, 16, 5574–5585. [Google Scholar] [CrossRef]

- Awoyemi, L.; Cooper, P.A.; Ung, T.Y. In-Treatment Cooling during Thermal Modification of Wood in Soy Oil Medium: Soy Oil Uptake, Wettability, Water Uptake and Swelling Properties. Eur. J. Wood Prod. 2009, 67, 465–470. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Bayani, S.; Militz, H.; Papadopoulos, A.N. Heat Treatment of Pine Wood: Possible Effect of Impregnation with Silver Nanosuspension. Forests 2020, 11, 466. [Google Scholar] [CrossRef]

- Esteves, B.; Graça, J.; Pereira, H. Extractive Composition and Summative Chemical Analysis of Thermally Treated Eucalypt Wood. Holzforschung 2008, 62, 344–351. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Militz, H. Chemical Changes in Hydrothermal Treated Wood: FTIR Analysis of Combined Hydrothermal and Dry Heat-Treated Wood. Holz als Roh und Werkstoff 2005, 63, 102–111. [Google Scholar] [CrossRef]

- Hakkou, M.; Pétrissans, M.; Zoulalian, A.; Gérardin, P. Investigation of Wood Wettability Changes during Heat Treatment on the Basis of Chemical Analysis. Polym. Degrad. Stab. 2005, 89, 1–5. [Google Scholar] [CrossRef]

- Bayani, S.; Taghiyari, H.R.; Papadopoulos, A.N. Physical and Mechanical Properties of Thermally-Modified Beech Wood Impregnated with Silver Nano-Suspension and Their Relationship with the Crystallinity of Cellulose. Polymers 2019, 11, 1538. [Google Scholar] [CrossRef]

- Candelier, K.; Hannouz, S.; Elaieb, M.; Collet, R.; Dumarçay, S.; Pétrissans, A.; Gérardin, P.; Pétrissans, M. Utilization of Temperature Kinetics as a Method to Predict Treatment Intensity and Corresponding Treated Wood Quality: Durability and Mechanical Properties of Thermally Modified Wood. Maderas. Cienc. Tecnol. 2015, 17, 253–262. [Google Scholar] [CrossRef]

- Timar, M.C.; Varodi, A.M.; Hacibektasoglu, M.; Campean, M. Color and FTIR Analysis of Chemical Changes in Beech Wood (Fagus sylvatica L.) after Light Steaming and Heat Treatment in Two Different Environments. BioResources 2016, 11, 8325–8343. [Google Scholar] [CrossRef]

- Poncsák, S.; Kocaefe, D.; Bouazara, M.; Pichette, A. Effect of High Temperature Treatment on the Mechanical Properties of Birch (Betula papyrifera). Wood Sci. Technol. 2006, 40, 647–663. [Google Scholar] [CrossRef]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H. Heat-Induced Colour Changes of Pine (Pinus pinaster) and Eucalypt (Eucalyptus globulus) Wood. Wood Sci. Technol. 2008, 42, 369–384. [Google Scholar] [CrossRef]

- Kamperidou, V.; Barmpoutis, P. Correlation between the changes of colour and mechanical properties of thermally-modified scots pine (Pinus sylvestris L.) wood. Pro Ligno 2015, 11, 360–365. [Google Scholar]

- Chen, Y.; Fan, Y.; Gao, J.; Stark, N.M. The Effect of Heat Treatment on the Chemical and Color Change of Black Locust (Robinia pseudoacacia) Wood Flour. BioResources 2012, 7, 1157–1170. [Google Scholar] [CrossRef]

- Gierlinger, N.; Jacques, D.; Grabner, M.; Wimmer, R.; Schwanninger, M.; Rozenberg, P.; Pâques, L.E. Colour of Larch Heartwood and Relationships to Extractives and Brown-Rot Decay Resistance. Trees Struct. Funct. 2004, 18, 102–108. [Google Scholar] [CrossRef]

- Cademartori, P.H.G.D.; Mattos, B.D.; Missio, A.L.; Gatto, D.A. Colour Responses of Two Fast-Growing Hardwoods to Two-Step Steam-Heat Treatments. Mat. Res. 2014, 17, 487–493. [Google Scholar] [CrossRef]

- Dudiak, M.; Dzurenda, L. Changes in the Physical and Chemical Properties of Alder Wood in the Process of Thermal Treatment with Saturated Water Steam. Coatings 2021, 11, 898. [Google Scholar] [CrossRef]

- Taraborelli, C.; Monteoliva, S.; Keil, G.; Spavento, E. Effect of Heat Treatment on Hardness, Density and Color of Populus x canadensis ‘I-214’ Wood. For. Syst. 2022, 31, e023. [Google Scholar] [CrossRef]

- Sedlar, T.; Šefc, B.; Stojnić, S.; Jarc, A.; Perić, I.; Sinković, T. Hardness of Thermally Modified Beech Wood and Hornbeam Wood. J. For. Soc. Croat. Sumar. List. Hrvat. Sumar. Drus. 2019, 143, 425–433. [Google Scholar] [CrossRef]

- Herrera-Builes, J.F.; Sepúlveda-Villarroel, V.; Osorio, J.A.; Salvo-Sepúlveda, L.; Ananías, R.A. Effect of Thermal Modification Treatment on Some Physical and Mechanical Properties of Pinus Oocarpa Wood. Forests 2021, 12, 249. [Google Scholar] [CrossRef]

- Englund, F.; Bryne, L.E.; Ernstsson, M.; Lausmaa, J.; Wålinder, M. Spectroscopic studies of surface chemical composition and wettability of modified wood. Wood Mater. Sci. Eng. 2009, 4, 80–85. [Google Scholar] [CrossRef]

- Miklečić, J.; Lončarić, A.; Veseličić, N.; Jirouš-Rajković, V. Influence of Wood Surface Preparation on Roughness, Wettability and Coating Adhesion of Unmodified and Thermally Modified Wood. Drv. Ind. 2022, 73, 261–269. [Google Scholar] [CrossRef]

- Gindl, M.; Reiterer, A.; Sinn, G.; Stanzl-Tschegg, S.E. Effects of surface ageing on wettability, surface chemistry, and adhesion of wood. Holz als Roh und Werkstoff 2004, 62, 273–280. [Google Scholar] [CrossRef]

- Kamusewitz, H.; Possart, W.; Paul, D. The Relation between Young’s Equilibrium Contact Angle and the Hysteresis on Rough Paraffin Wax Surfaces. Colloids Surf. A Physicochem. Eng. Asp. 1999, 156, 271–279. [Google Scholar] [CrossRef]

- Qin, C.; Zhao, Z.; Piao, X.; Wang, Z.; Jin, C. Facile Preparation of Bamboo with Improved Hydrophobicity, Dimensional Stability and Mold Resistance by Paraffin/Tung Oil Modification. J. Mater. Res. Technol. 2024, 33, 8132–8141. [Google Scholar] [CrossRef]

- Wu, B.; Song, K. Enhancing the Water Resistance and Dimensional Stability of Wood through Microwave Treatment and Impregnation with Oxidised Paraffin Emulsion. Wood Mater. Sci. Eng. 2025, 1–14. [Google Scholar] [CrossRef]

- EN 335:2013; Durability of Wood and Wood-Based Products. Use Classes: Definitions, Application to Solid Wood and Wood-Based Products. European Committee for Standardization: Brussels, Belgium, 2013.

- Hill, C.; Altgen, M.; Rautkari, L. Thermal Modification of Wood—A Review: Chemical Changes and Hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Zhang, J.-W.; Liu, H.-H.; Yang, L.; Han, T.-Q.; Yin, Q. Effect of Moderate Temperature Thermal Modification Combined with Wax Impregnation on Wood Properties. Appl. Sci. 2020, 10, 8231. [Google Scholar] [CrossRef]

- Borrega, M.; Kärenlampi, P.P. Hygroscopicity of Heat-Treated Norway Spruce (Picea abies) Wood. Eur. J. Wood Prod. 2010, 68, 233–235. [Google Scholar] [CrossRef]

- Repellin, V.; Guyonnet, R. Evaluation of Heat-Treated Wood Swelling by Differential Scanning Calorimetry in Relation to Chemical Composition. Holzforschung 2005, 59, 28–34. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Cao, J.; Wang, W. Improved Water Repellency and Dimensional Stability of Wood via Impregnation with an Epoxidized Linseed Oil and Carnauba Wax Complex Emulsion. Forests 2020, 11, 271. [Google Scholar] [CrossRef]

- Kocaefe, D.; Huang, X.; Kocaefe, Y. Dimensional Stabilization of Wood. Curr. For. Rep. 2015, 1, 151–161. [Google Scholar] [CrossRef]

- Deka, M.; Saikia, C.N. Chemical Modification of Wood with Thermosetting Resin: Effect on Dimensional Stability and Strength Property. Bioresour. Technol. 2000, 73, 179–181. [Google Scholar] [CrossRef]

- Bytner, O.; Laskowska, A.; Drożdżek, M.; Kozakiewicz, P.; Zawadzki, J. Evaluation of the Dimensional Stability of Black Poplar Wood Modified Thermally in Nitrogen Atmosphere. Materials 2021, 14, 1491. [Google Scholar] [CrossRef] [PubMed]

- Thybring, E.E.; Fredriksson, M. Wood Modification as a Tool to Understand Moisture in Wood. Forests 2021, 12, 372. [Google Scholar] [CrossRef]

- He, Z.; Qu, L.; Wang, Z.; Qian, J.; Yi, S. Effects of Zinc Chloride–Silicone Oil Treatment on Wood Dimensional Stability, Chemical Components, Thermal Decomposition and Its Mechanism. Sci. Rep. 2019, 9, 1601. [Google Scholar] [CrossRef]

- Bak, M.; Takács, D.; Rákosa, R.; Németh, Z.I.; Németh, R. One-Step Process for the Fabrication of Hydrophobic and Dimensional Stable Wood Using Functionalized Silica Nanoparticles. Forests 2023, 14, 651. [Google Scholar] [CrossRef]

- Gaff, M.; Kačík, F.; Gašparík, M. Impact of Thermal Modification on the Chemical Changes and Impact Bending Strength of European Oak and Norway Spruce Wood. Compos. Struct. 2019, 216, 80–88. [Google Scholar] [CrossRef]

- Hassan Vand, M.; Tippner, J. Impact Bending Strength of Thermally-Modified Timber. Holzforschung 2023, 77, 828–837. [Google Scholar] [CrossRef]

- Tomak, E.D.; Viitanen, H.; Yildiz, U.C.; Hughes, M. The Combined Effects of Boron and Oil Heat Treatment on the Properties of Beech and Scots Pine Wood. Part 2: Water Absorption, Compression Strength, Color Changes, and Decay Resistance. J. Mater. Sci. 2011, 46, 608–615. [Google Scholar] [CrossRef]

- Windeisen, E.; Bächle, H.; Zimmer, B.; Wegener, G. Relations between Chemical Changes and Mechanical Properties of Thermally Treated Wood 10th EWLP, Stockholm, Sweden, August 25–28, 2008. Holzforschung 2009, 63, 773–778. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Van Acker, J.; Tjeerdsma, B.F.; Kegel, E.V. Strength Properties of Thermally Modified Softwoods and Its Relation to Polymeric Structural Wood Constituents. Ann. For. Sci. 2007, 64, 679–690. [Google Scholar] [CrossRef]

- Kapidani, A.; Hajdini, D.; Beqo, S. The Effect of Heating Temperature on Static Hardness of Beech (Fagus sylvatica L.) Wood. Int. J. Curr. Eng. Technol. 2019, 9, 363–367. [Google Scholar] [CrossRef]

- Suri, I.F.; Purusatama, B.D.; Kim, J.H.; Yang, G.U.; Prasetia, D.; Kwon, G.J.; Hidayat, W.; Lee, S.H.; Febrianto, F.; Kim, N.H. Comparison of Physical and Mechanical Properties of Paulownia tomentosa and Pinus koraiensis Wood Heat-Treated in Oil and Air. Eur. J. Wood Prod. 2022, 80, 1389–1399. [Google Scholar] [CrossRef]

- Suri, I.F.; Purusatama, B.D.; Lee, S.H.; Kim, N.H.; Hidayat, W.; Ma’ruf, S.D.; Febrianto, F. Characteristic features of the oil-heat treated woods from tropical fast growing wood species. Wood Res. 2021, 66, 365–378. [Google Scholar] [CrossRef]

- Mohebby, B.; Kevily, H.; Kazemi-Najafi, S. Oleothermal Modification of Fir Wood with a Combination of Soybean Oil and Maleic Anhydride and Its Effects on Physico-Mechanical Properties of Treated Wood. Wood Sci. Technol. 2014, 48, 797–809. [Google Scholar] [CrossRef]

- Phuong, L.X.; Shida, S.; Saito, Y. Effects of Heat Treatment on Brittleness of Styrax Tonkinensis Wood. J. Wood Sci. 2007, 53, 181–186. [Google Scholar] [CrossRef]

- Candelier, K.; Thevenon, M.-F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of Wood Thermal Treatment and Its Effects on Decay Resistance: A Review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef]

- CEN/TS 15083-1; Durability of Wood and Wood-Based Products—Determination of the Natural Durability of Solid Wood against Wood-Destroying Fungi, Test Methods—Part 1: Basidiomycetes. European Committee for Standardization: Brussels, Belgium, 2005.

- Németh, R.; Tsalagkas, D.; Bak, M. Effect of Soil Contact on the Modulus of Elasticity of Beeswax-Impregnated Wood. BioResources 2015, 10, 1574–1586. [Google Scholar] [CrossRef]

- Lesar, B.; Humar, M. Use of Wax Emulsions for Improvement of Wood Durability and Sorption Properties. Eur. J. Wood Prod. 2011, 69, 231–238. [Google Scholar] [CrossRef]

| Modification Step/Parameters | Temperature [°C] | Duration [h] | Heating Rate [min/°C] | Wax Application Steps in TMW |

|---|---|---|---|---|

| Heating up phase | up to 80 | 8 | 8 | no |

| Immersion of laths into wax (only TMW) | 80 | - | 0 | immersion |

| Temperature increase-I | 80 → 100 | 3 | 9 | immersion |

| Drying phase | 100 | 12 | 0 | immersion |

| Temperature increase-II | 100 → 180/200 | 10.5/12 | 8 | immersion |

| Thermal modification phase | 180 or 200 | 5 | 0 | immersion |

| Cooling phase-I | down to 80 | 10/12 | 6 | impregnation |

| Cooling phase-II | down to room temperature | 2 | not controlled | no |

| WU [%] | ML [%] | PFR [%] | ||||

|---|---|---|---|---|---|---|

| Beech | Scots Pine | Beech | Scots Pine | Beech | Scots Pine | |

| TM180 | - | - | 3.77 a (0.78) | 3.50 a (0.19) | - | - |

| TM200 | - | - | 7.14 b (0.87) | 6.57 b (0.56) | - | - |

| TMW180 | 52.84 a (1.30) | 133.15 b (2.64) | 7.27 b (0.42) | 7.82 b (1.27) | 64.81 a (1.92) | 85.54 b (3.07) |

| TMW200 | 28.22 c (1.29) | 55.94 a (4.39) | 12.37 c (2.05) | 12.32 c (1.34) | 41.04 c (1.83) | 48.35 d (4.87) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bak, M. Improving the Physical Characteristics and Durability of Wood Through a Combined Modification Process Using Thermal Treatment and Wax Impregnation in One Step. Forests 2025, 16, 1317. https://doi.org/10.3390/f16081317

Bak M. Improving the Physical Characteristics and Durability of Wood Through a Combined Modification Process Using Thermal Treatment and Wax Impregnation in One Step. Forests. 2025; 16(8):1317. https://doi.org/10.3390/f16081317

Chicago/Turabian StyleBak, Miklós. 2025. "Improving the Physical Characteristics and Durability of Wood Through a Combined Modification Process Using Thermal Treatment and Wax Impregnation in One Step" Forests 16, no. 8: 1317. https://doi.org/10.3390/f16081317

APA StyleBak, M. (2025). Improving the Physical Characteristics and Durability of Wood Through a Combined Modification Process Using Thermal Treatment and Wax Impregnation in One Step. Forests, 16(8), 1317. https://doi.org/10.3390/f16081317