1. Introduction

Technology has played an important role in enabling more efficient use of the timber available in a wider range of uses [

1]. For as long as humans have used wood, technology has enabled better recovery, utilisation and new products from timber. Technology has also allowed wood resources previously thought unsuitable for processing and manufacture to be adapted and remade into products that meet market needs [

2]. Technology advances have enabled the use of resources previously considered low-grade or waste. Examples include the reconditioning of sawn hardwood eucalyptus timber; production of glue-laminated products from undersized pieces of timber previously deemed waste; and the manufacture of particle board and Masonite from sawdust waste [

3].

Global and Australian demand for wood products grew between 2019 and 2022, across all segments, but particularly wood-based panels, paper and paperboard, sawn wood and miscellaneous forest products [

4,

5]. At the same time, the supply of traditional wood sources from native forests has been declining, with more wood coming from plantations, non-forest trees and non-conventional harvesting models aimed at improving health of native forests [

6]. Compared to traditional resources, tree species from these sources often differ in their physical and mechanical properties, as well as in size and appearance. To maintain profitability and meet the increasing demand for wood products requires innovative processing options that recover more product from smaller logs. Product manufacturers need to innovate and adapt to changing raw material inputs and changing market preferences. This requires a whole of value chain view of the potential to grow, process and use new products [

6].

Around the world, the production of wood from native forests is declining due to conversion of forests to other uses, overharvesting in accessible areas and environmental and regulatory constraints. This is very apparent in Australia, with the native forest log harvest declining by 48% between 2012 and 2023 and by 29%, from 3.5 million to 2.5 million, between 2022 and 2023 [

7]. The reduction in available supply and quality has seen timber processors receiving and using lower quality grades of timber, including smaller-diameter logs and unconventional resources, including plantation-grown logs originally managed for pulpwood.

Timber product value chains extend from the growth and production of raw material through to the sale and use of manufactured products. These chains are similar to agricultural products, with a reliance on climatic and landscape characteristics and management inputs for biological production, machinery for harvest, transport, primary and secondary processing and further manufacturing, transport, marketing and sale downstream in the value chain. In marketing, sale and use, particularly for commodity and construction products, wood products are similar to steel, concrete or other construction materials.

While much research has been conducted into innovation in the wood products sector [

8,

9,

10,

11,

12,

13,

14,

15,

16], little of this research has been focused on the Australian context and most of it has examined manufacturing technology and processes [

17,

18,

19]. Less of this literature has focused on the application of business and managerial frameworks in the application of innovation in wood science and technology.

De Klerk and Ghaffariyan [

20] examined the application of the entrepreneurial method in developing circular economy approaches to the use of wood waste, noting that “The linear, scientific view that espouses causal thinking to identify, evaluate and exploit opportunities does not reflect the actions of successful serial entrepreneurs”. This suggests that the success of businesses can only be partially evaluated and understood through technical and process orientations and requires perspectives from business and enterprise orientations to create useful insights to foster improvements in business and sector performance.

This research utilises this resource-based view of firms, innovation theory and competency theory. The aims of this study are to extend an existing set of case studies from previous post-graduate research [

21] to further develop approaches to innovation in the timber processing sector, as well as to test to what extent business- or market-oriented theory and practice can add value to the broader sector in a time of change. To these ends, this case study examined the innovation stance of a medium-scale domestic timber mill using existing frameworks and case studies. Outcomes of this case study include assessment of how firm resources enable innovation at the mill, as well as the timber manufacturing sector more generally as it responds to changing supply, market, social license and regulatory conditions.

While this case study is a limited contribution to knowledge in itself, it demonstrates how an existing set of case studies can be further built upon over time and adds weight to existing research suggesting that the wood processing sector stands to gain from further applying business theory and concepts within enterprises in the sector.

1.1. Theoretical Framework

Within business-related disciplines, innovation has been examined through a range of theoretical lenses. Design and analysis of this case study draws on a number of theoretical frameworks, particularly the Resource-Based View (RBV), core competencies, dynamic, capabilities, innovation theory and innovation systems.

1.2. Competitive Advantage and Drivers of Innovation

Generally, innovation literature defines the measure of success in innovation in terms of competitive advantage. This assumes that the purpose of such activities is aligned with the core principles of growth-oriented businesses, being profitability, market share and business growth. Madhani [

22] examined in detail the history of this concept as core to RBV in particular. Technological innovation is one way that firms are supposed to be able to achieve competitive advantage.

That technological innovation is driven by either by technology push or demand pull is a well-accepted principle in relevant theories and literature, with much debate over which is more effective [

23]. Technology push describes technological development which enables new products or innovations, while demand pull involves clear market signals from buyers and users [

24]. In the context of innovation in timber processing, Bull [

21] proposed a third driver of innovation in the form of a resource push, where available resources are the critical factor driving innovation. This is a concept that has key potence for the wood products sector where the resource characteristics significantly determine the range of possible products.

1.3. The Resource-Based View (RBV) of the Firm: The Theoretical Basis for This Study

The characteristics of a firm, its resources—financial, physical, tacit and explicit—are recognised in the business literature and research as major factors in determining the success of business activities [

25]. The availability of these resources is critical to ensuring competitiveness and ability to innovate to sustain competitiveness. The RBV theory assesses these resources in terms of value, rarity, ability for them to be imitated and the extent to which they can be substituted by other resources.

Brumagim’s [

26] hierarchy of resources discerns four different levels of tangible resources; chiefly, production, administrative, organizational and strategic resources. From this, he characterised examples of the types of resources that might fall under each of these categories, including human, innovation and reputational resources as categories of intangible resources. Barney [

25] defined the degree of competitive advantage generated by resources in terms of whether they are valuable, rare, imperfectly imitable and non-substitutable. The RBV theory has gone on to become one of the heavily cited theories in business and management studies, with various additions and variations [

27].

Mekić and Mekić [

28] provide one of the few critiques of the notion of competitive advantage. Focusing on Porter [

29] and Barney [

25], they noted that several authors have observed the need for the underlying assumptions of competitive advantage to evolve with changes such as globalization, digitalization and deregulation. Denning [

30] proposed that competitive advantage is obsolete, with businesses competing with others outside of their own industry or product lines. Klein [

31] pointed out that while competitive advantage is widely accepted as central to concepts of business strategy, it is poorly defined, at worst tautological. The author also saw the concept as problematic in terms of assumed causality between competitive advantage and strategic success. He suggested that modalities of competition are poorly expressed as theories and that business and management fads could indicate deeper cultural evolution of what is meant by competition.

Knowledge-keeping at a firm can be further categorised as tacit or explicit. Explicit knowledge refers to formally encoded and stored information, while tacit knowledge is that held informally, usually by individual staff members. Explicit knowledge might be held in documents, databases or file storage systems at a firm and could include readily verifiable data such as market size, number of competitors and wider statistically-derived data. Tacit knowledge is likely held in the minds and memories of staff-members and could include information about how they individually approach different tasks, as well as anecdotal information and evidence from colleagues or contacts in the marketplace around them [

19].

While the RBV has often been used as a lens to understand competitive advantage in an adversarial relationship with other entities and among firms, more recent research has examined the RBV in terms of inter-organizational collaboration. This growing body of work has sought to apply the RBV to business ecosystems and the exchange of information and resources for a greater overall gain and a wider distribution of value and benefit [

32].

The RBV theory has been extended to understand how non-technological resources are required to ensure the success of technological innovation. Relevant studies have looked particularly at the role of entrepreneurial orientation [

33], entrepreneurial networking [

34] and non-technological innovation [

35].

Outcomes other than competitive advantage have been considered as the goal of applying the resource-based view. Such outcomes examined as desirable outcomes of the application of the RBV include sustainable growth [

34], improved environment, sustainability and governance (ESG) [

36] and green enterprise or environmental performance [

33]. This diversity of new theories developed around the RBV are not new, with a range of different perspectives, dimensions and alternative theories associated with the notion of defining how business can gain competitive advantage. Some of these, such as core competencies and dynamic capability, are examined here.

1.4. Core Competencies

Core competencies are the critical elements influencing firm competitiveness, with these further described as the ability to deliver better value by coordinating technology and skills within a firm [

37]. A previous literature review [

38] examined the breadth of approaches to defining core competencies, with different types of businesses demanding different interpretations depending on the nature of their activities. It was concluded that core competencies are the integration of knowledge, human capital and financial and non-financial capital of the organizations and the source of competitive advantage for a firm. However, this does not account for firm culture as a source of advantage, with further research thought to be required to explore this aspect.

1.5. Dynamic Capabilities

The internal characteristics of a firm can also be drivers of success in rapidly changing business environments. The emphasis of this theory is that the speed with which a firm can respond to a crisis is reflected in its ability to generate abnormal returns. It calls on firms to align their particular competencies and resource base to rapid changes in the market environment to win competitive advantage, measured in revenue disproportionately higher than competitors.

Such competencies and resources include a range of intangible factors like knowledge and information gathering as well as physical resources and assets [

39]. This idea has been further expanded to a framework of resources and dynamic capabilities that surpasses classical theories of business and competitive advantage, particularly regarding the matter of innovation [

40].

More recently, this theory has been applied to the context of open innovation (OI) to examine how collaboration with partners in an innovation ecosystem can enhance innovation and adaptability to crises [

41]. The authors make much of the notion of coopetition; that is, collaborative business activity that achieves mutual benefit while remaining, in traditional business terminology, a competitor specifically with the collaborator, as well as the market more broadly.

1.6. Firm Resources and Sustained Competitive Advantage in Wood Processing

Sustained competitive advantage has traditionally been seen as the primary goal of RBV-based analyses [

42]. The notion assumes that a firm is in a directly competitive market and that the goal of the business is successfully compete for market share and greater shares of revenue [

25].

The RBV has been identified as relevant to the wood products sector, particularly in understanding the factors for success in wood product commercialisation, with specific market dynamics and pressures to innovate [

43]. Other studies have examined the technological, economic and supply and demand pressures that drive innovation in the forest products sector. For example, in addition to reduced supply, rising manufacturing and labour costs were identified, though not examined in detail, as significant drivers of innovation in timber manufacturing in developed countries [

44].

With a declining supply of traditional resources and rising costs, wood product processing firms that can innovate will be more viable and resilient to future shocks. How innovation can be structured and promoted is an important question for these businesses. A number of ways of fostering innovation in timber processing have been identified. Nybakk et al. [

10] found that emerging market situations, changes in company strategy and innovation champions all had the potential to drive innovation in different situations.

In their study of new product development (NPD) in the digital transformation era, Barrane et al. [

15] discovered that complexity and technological developments drove companies to look beyond their own corporate structure to develop new products. They observed organizations working together to develop industry clusters that leveraged multi-stakeholder relationships to develop advanced products.

A Finish study examined matters of environmental sustainability as a driver of innovation and used a business ecosystem approach in the analysis of network-based collaboration, learning and end-user involvement in novel wood construction approaches [

45]. This approach reflected Leavengood and Bull’s [

44] identification of collaboration as a way to drive innovation. They particularly examine the concept of innovation systems (ISs) as a critical way to characterise and optimise innovation in timber processing. They examine two different types of ISs, regional innovation systems (RISs) and sectoral innovation systems (SISs), as models to characterise and coordinate innovation efforts.

2. Materials and Methods

This research seeks to develop a case study of a timber manufacturing business, Radial Timber Australia (RTA) based in Yarram, Victoria, Australia. RTA has successfully innovated in the past and is currently undertaking a step-change innovation to respond to a range of market shocks and resource supply signals. It is designed to add to the body of non-technical research into innovation within the timber manufacturing industry. In particular, it draws its method and structure from an existing set of wood processing case studies [

21].

The development of a spindleless lathe line at RTA builds on a history of successful innovation at the mill, particularly in developing technology to utilise undersize logs to produce high-quality solid-wood building products. This enabled low-grade resources previously considered waste to be processed for high-value products. RTA is a small-size business (less than 100 employees), with an average of around 40 people employed between RTA and Radial Timber Sales (RTS).

This investment in the new lathe technology is designed to use even smaller logs in the production of veneers. In the first instance, the team hopes to manufacture and market products to supply proximate markets to those they already service. Their current product set is largely appearance grade products for external use such as cladding, fencing and screening.

Before recent timber supply disruptions, the business processed approximately 35,000 m3 of timber per year; this has dropped to less than 17,500 m3. With the new innovation, it is estimated that they may be able to process an additional 10,000 m3 per annum.

2.1. Case Study Design

Based on this analysis, this research drew on existing frameworks [

46,

47] to examine the innovation capacity of this firm. These frameworks and the method developed and used for this research align with methods previously used examine innovation in the timber processing industry in Australia [

21]. In this way, it is intended to subscribe to widely established and accepted case study development practices and to build on the body of knowledge regarding innovation in the Australian timber industry specifically. Questions and the subsequent results were specifically designed to emulate and build upon that previous research.

Scholz and Tietje [

48] developed a system for designing qualitative research by defining a range of relevant dimensions, assigning each a limited set of options to classify the research approach under each dimension. The approach helps clarify a design approach to a specific enquiry.

Table 1 below demonstrates the authors’ system of dimensions and classifications and how these were applied specifically to this research enquiry.

The firm which is the subject of this research, Radial Timbers Australia (RTA), is a timber mill situated in the east of the Gippsland region. In response to declining native timber supply, the mill has established its own eucalypt plantation resource. The installation of a spindleless lathe is an innovation that will enable the firm to produce engineered wood products from small-diameter logs from early-stage plantation thinning.

At the scale of the mill, this approach is innovative in the sense that it will use resource that was previously considered waste, or low-value, using relatively novel technology to extend the suite of products into a new product class. It represents innovation at the national industry scale in that the development leverages recent research concerning the use of small-diameter logs from forest resources and the use of spindleless lathes particularly. At the time of publication, the lathe is thought to be only the second installed in the national context enabling the use of underutilised resources and manufacture of new products.

Principles of case study research were used in developing the case study on RTA, with the goal of data collection to (1) describe the setting and context and (2) classify the type of case study (typology development), as well as (3) theory development and (4) limited theory testing. The primary goal is understanding the setting through in-depth, multi-dimensional investigation. Case studies can be used to derive evidence and conclusions from a limited set of data and observations. They aim to link decisions or actions cause and effect, sometimes testing the difference between intended and actual outcomes. In this way, case studies are particularly suited to real world events that have already occurred, with a limited set of data and limited ability to control variables in the way that they would be a for controlled experiments or studies [

49].

2.2. Methods

2.2.1. Interviewee Selection

To inform this case study, interviews were undertaken with individuals who have previous and ongoing experience in the operations of RTA, including three internal personnel and one consultant external to the business. These were selected on the basis of their experience in previous and current innovation efforts at the business. The method for this limited set of interviews was designed to gain first-person insight into how innovation occurs at RTA. Interviewees were selected, including the managing director, sales manager, the mill manager and a mechanical engineer with whom RTA has maintained a long-standing professional engagement, from an external business specializing in timber milling equipment.

2.2.2. Interview Design

The interview was semi-structured with 18 questions, which could be adapted or omitted depending on the particular interview and interviewee. The aim of semi-structured interviews is to create a more conversational tone, allowing the interview to go into areas that the researcher might not have anticipated and for interviewees to communicate points which they feel are important [

50].

The questions were based on the RBV as set forward by Barney [

25] as reflected in

Table 2 with examples of each resource as proposed by Madhani [

21]. In order to ground this work in a broader research context, questions were developed from Madhani’s examples with reference to Bull’s [

24] work. The intention here was to ensure that this limited case study was able to be related to a body of research and that previously developed research pathways could be continued.

The specific questions outlined in

Table 3 were developed with reference to Bull’s [

24] results, essentially seeking to arrive at the types of questions that would result in that range of answers. While the author of that paper was not able to provide the original questions leading to that research output, she was able to provide feedback to ensure the questions were sufficiently aligned to result in a comparable data set and results. Emerging themes and codes are related in the table to reflect how responses to specific questions translated into specific codes and the results below.

2.2.3. Interview Interpretation

Interviews were held online on Zoom between November 2023 and October 2024 and were recorded in MP4 format. Audio recordings were converted to text using the transcription function included in Microsoft Word. Transcriptions were visually scanned by the primary researcher for unusual phrasing or anomalous statements and, where these were identified, compared to the audio to ensure accuracy. Coding and analysis of interviews was conducted on the software platform NVivo Version 15.

Interpretation of NVivo outputs was combined with direct personal insights made through the interview process. Initial codes were developed inductively through a line-by-line reading of the transcripts. Patterns were identified based on recurring concepts and participant language. These codes were iteratively refined into broader themes through team discussions and comparison across interviews with reference to the results of Bull’s [

21] work.

4. Discussion

Overall, RTA can be seen to be well placed to innovate with a range approaches that make it somewhat unique to businesses examined in previous case studies. These differences can be further examined and understood in the context of the wider body of literature on innovation. These broader perspectives on innovation from outside of the Australian timber industry yield some interesting insights into how such concepts can add value to further consideration of innovation in the sector locally.

The firm’s strategy remains to stay small and to share intellectual property around process and product innovation to support similar innovation at regional scale elsewhere. Such questions of broader market characteristics and demand may be more relevant at an industry scale. Such a strategic approach is at odds with conventional business theory, which assumes that the natural objective of business is to accumulate market share and deliver growing profits. Such alternative mindsets may be represented in the literature elsewhere but were not apparent in the research undertaken for this study. The notion of market strategies with natural limitations applied to them may be worth further exploration, potentially under novel theoretical areas such as post-commodity, sustainability or regionally sufficient market strategies. Given the contested nature of forestry in Australia and elsewhere around the world, such shifts in perspective may help to temper perceptions of the industry as an endlessly voracious growth-machine.

While previous research framed the topic of innovation in terms of whether the private sector or public entities such as universities are better placed to successfully innovate [

24], the circumstances at the firm studied represent a more complex model of how public-sector and private interests interact. While the firm is privately owned, it is worth noting that a portion of its capital is derived from a successful business spun out of the Commonwealth Scientific and Industrial Research Organisation (CSIRO), the Australian government scientific research entity. The business actively pursues grants and support from government programs at all three levels of government and the proprietor actively monitors and engages with academic, government and industry-funded research. This approach has helped to access funding and new information to which the firm would otherwise not have had access. These approaches increase access to novel knowledge, practices and concepts, reduce financial risk, increase financial capacity and increase the rate and scope of innovation. The way this firm develops and shares knowledge and utilises resources made available from public and industry institutions is an approach that does have precedent in practice and research globally.

Previous research [

24,

43] found mixed correlation between the level of technology knowledge and successful innovation. Among the firms examined in that study, there was a high correlation established between successful innovation and high levels of technology knowledge. However, less successful innovations demonstrated low, medium and high levels of technology knowledge, suggesting that while high levels of technology knowledge were a component of successful innovation, they are not a guarantee. The same research also found a relatively high correlation of successful innovations to medium or high levels of commercialisation knowledge, with all unsuccessful innovations having low–medium levels and limbo innovations having medium or low–medium levels of commercialisation knowledge. Examples from North America demonstrated a mixed correlation between commercialisation knowledge and successful innovation. Findings from that paper also found a relatively high correlation of successful innovations to firms with high levels of marketplace knowledge, more firms with successful innovations held knowledge in both tacit and explicit forms than those with knowledge primarily held in one or other form. Unsuccessful innovations had low or medium levels of marketplace knowledge, with a mix of explicit and tacit knowledge.

4.1. Other Innovation Frameworks

This approach, where the business interacts with and draws on public, academic and industry institutional resources, is an example of an innovation system or regional innovation system [

51,

52,

53]. This conceptual framing not only captures the activity and actors involved in innovation at the firm, but recognises the value of external agencies, businesses and organizations can provide.

Importantly, this ties the notion of successful innovation not just to how firms interact with the knowledge, power and financial resource structures around them, but to questions of social licence, policy and regulation, which are of critical importance to forestry and wood manufacturing. This more complex perspective is essential in the local context, where proactively engaging with these questions forms an essential consideration not just to innovation, but to the success or otherwise of the timber industry generally. Where supply-side resource shortages lead to reduced competitive pressure to fill unmet demand, such frameworks could be of significant value to the wider timber manufacturing sector as it adapts to changing market and societal conditions. Concepts such as OI, ISs and coopetition could hold important and untapped value for businesses making these transitions [

54].

4.2. Resource Push

In innovation studies, there is a broader question of whether technology push or market pull is most effective in facilitating successful innovation [

23,

24,

55]. There has been much debate as to which of these factors has the most influence on the success or otherwise of an innovation, to which an additional factor suggested is that of available resources or a resource push [

43]. While this term appears to have not gained currency in the broader discourse, others have included resources within the notion of a technology push [

56], and the effect of available resource in shaping the direction of timber manufacturing innovation has been well explored elsewhere [

9,

57,

58].

In the instance of this case study, it seems that the concurrent factors of the development of cost-effective spindleless lathe technology, the reduction of available native timber resources and the excess of small-diameter plantation logs represent drivers for innovation at RTA. The market context to these technology and resource pushes is a significant domestic and global market pull for hardwood timber products domestically and timber panels globally [

4,

7]. While this study is not sufficient to discern whether one factor is more effective than another, it could be posited that the alignment of all three is promising for the success of this innovation.

All those things are, you know, the market side was looked after. Everything was going really good until the Victorian Forestry Plan. Until like that that’s the thing you can’t plan for is the master plan. You know, the idea was always clear we’d do plantations. But you know we would have continued on for another 10 years and it would have been the time would have been right. So, with the VFP we just had to, you know, change our market, our whole sort of business structure and supply structure and everything.

That sort of stuff, it does excite me where you’ve actually now got the resource, you know, how can you maximise that resource in every part of it?—Radial Group Managing Director

The introduction of civil society and regulatory factors into this perspective provides a means to further examine and contextualise questions of how a resource push is influenced by civil society and regulation in addition to other factors. An interesting line of enquiry might be to examine whether increased consideration of low-value products and by-products reflects a resource vacuum caused by other factors. Further, it raises interesting questions as to how forestry and timber processing firms, as well as industry at large, engage with the connected and interrelated questions of resource supply and public policy in meeting the needs and expectations of the public, society and consumers at large.

As indicated in the literature, competitive advantage, with consequent market share and revenue growth, have traditionally been the default assumption of business studies [

27,

59]. More recent literature examines other strategic goals observed in businesses and how these shape innovation [

41,

45].

A critical question for innovating businesses, then, is whether profit and growth motives are more effective at driving innovation. This raises the question of what measures of success might be appropriate if growth and market share are not, and whether these can or should be measured beyond the boundary of an individual firm.

Where the Australian forestry and associated manufacturing industries have been recognised to historically focus on innovation in technology and mechanization [

60], there is also a question around how expanding research and associated strategic lenses could support industry adaptation and innovation. Such expansion could consider, on the one hand, the practices of business and marketing disciplines, and on the other, the social attitudes and shifts towards corporate citizenship in the era of social and environmental challenges like dangerous climate change and biodiversity loss.

In accelerating and expanding the relevant literature and knowledge available to wood product industries, similarities with other primary industries like agriculture, forestry and mining and associated secondary and tertiary industries could be drawn. Other parallels may be drawn to additional industries also. Drawing these similarities may widen the body of available literature and knowledge able to be brought to bear in seeking to drive innovation and opportunities for forestry. However, this approach is somewhat limited in defining and addressing the gap between wood product sectors and those with more extensive existing bodies in terms of business and innovation knowledge and research.

All these aspects point to the need to develop more sophisticated approaches to understanding forestry, its place in society, the economy and the environment and how forestry can innovate to meet the needs of a growing global economy in the context of a range of pressures and resource constraints.

4.3. Resource Push in the Context of Declining Resource Availability

The concept of what is constitutes a “resource” is complex, as changes in technology development and market conditions can lead to a change the perception and definition of whether something is considered waste or not [

61,

62]. In the instance of this case study, the small diameter logs which are the feedstock for the spindleless lathe were previously a waste material, thinned and left on the plantation floor. The introduction of a firewood processor manufacturing solid fuel from these logs necessitated a reclassification of this material from waste to low-value resource. The innovation under consideration here enables this resource to be utilised for a higher use again, with reclassification from a low-value resource to a high-value resource. This raises interesting questions around how a resource is characterised as waste, a by-product or a low-grade or high-grade resource. These considerations are also relevant to the current interest in the circular economy and the bioeconomy.

It also points to an implied imperative in forestry to ensure that resources are utilised for their highest and best use. In the current context, this will involve not only upgrading conversion and subsequent outputs, but also connecting how each resource is grown, harvested and processed with customer needs. It has been argued that this requires much better integration of the different stages of the timber value chain [

6].

Resource limitations and unmet market demand are one dimension of the timber supply and manufacturing sector. Environmental drivers for efficient resource use and waste utilisation along with advances in technology development add importance to traditional business imperatives, such as efficient and time-effective manufacturing. These are all factors that are relevant in assessing different timber manufacturing optimisation pathways. The outcomes against these different pathways can then be assessed for feasibility and profitability as options analysis [

63].

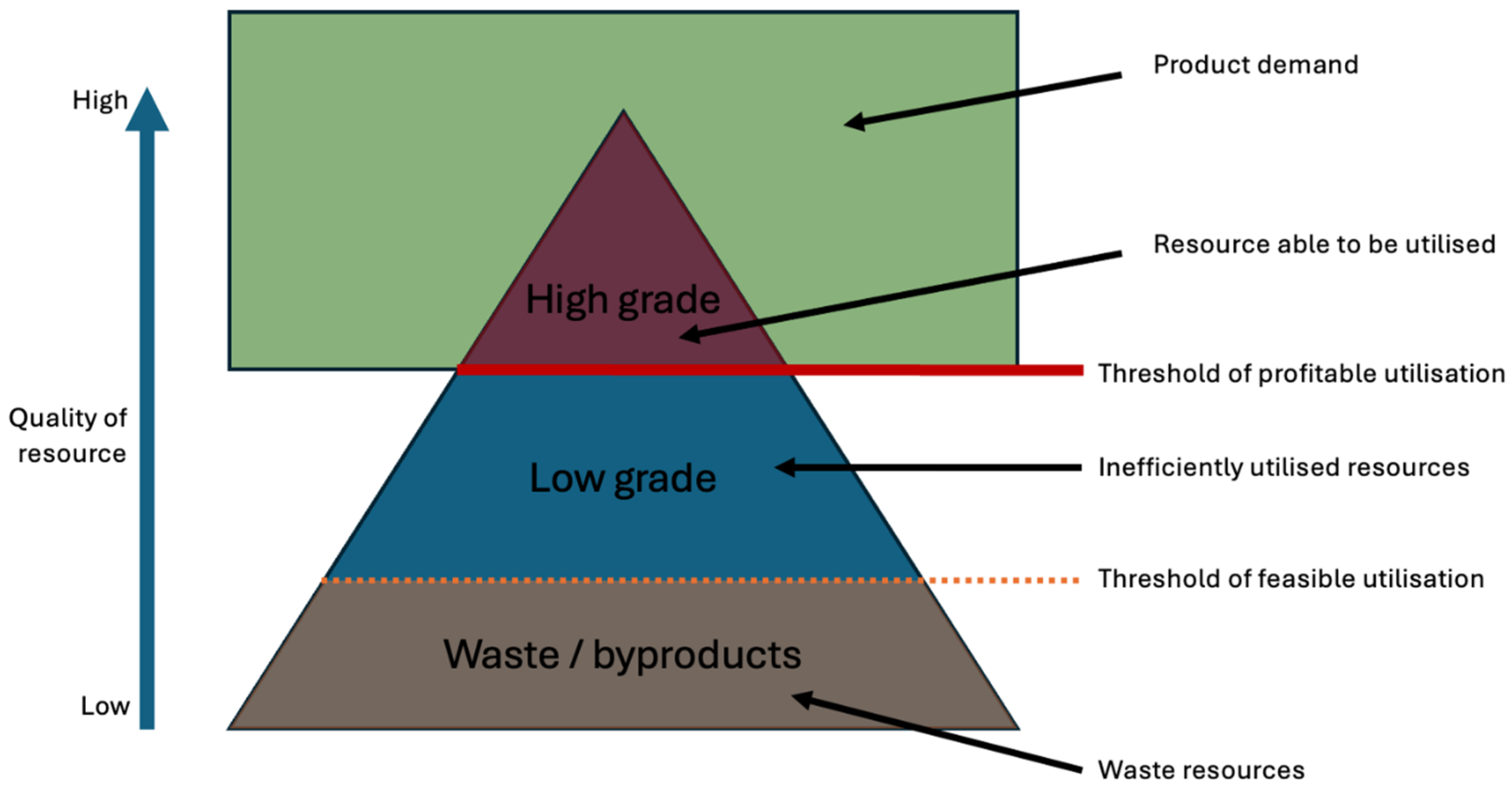

A coarse model for the process of resource reclassification and optimisation as undertaken at RTA can be seen in

Figure 1. The purple triangle represents resources that can be manufactured and supplied to market as timber products, with the green rectangle around the triangle representing a notional unmet demand. The sections below the red line represent wood resources that are grown and harvested but currently unable to be manufactured into wood products for reasons such as limitations related to technological capability or cost. Thus, the red line is the threshold of profitable utilization, or the point at which technology and cost factors make profitable the production of wood products that can meet market demand from resources within the existing resource value chain. The orange dotted line represents the threshold of feasible utilisation, a frontier where what was previously seen as waste can now technically be converted from waste into feedstock for useful wood products. The blue section represents material that could be converted into products that will be able to meet unmet market demand as technology and market factors shift sufficiently. The grey section, below the threshold of feasible utilisation, represents waste or uneconomic byproducts for which there is neither technical nor profitable utilisation possible.

With regards to this case study, small-diameter logs sit in the blue section, where the advent of low-cost spindleless lathe technology enables the inclusion of this material above the threshold of technically feasible utilisation. It will be the task of product and market development to ensure that the outputs manufactured meet the needs of the market and the profit imperative of the business. Regarding waste byproducts, efforts are afoot at the mill to convert wood offcuts and sawdust into energy to feed both the heat and electricity needs of the mill.

In this way, technology, market demand and resource availability are crucially interrelated in decision-making for the manufacturing of wood products. As such, the concept of resource push and its related business and marketing theories of technology push and market pull may be a useful lens to help define and drive innovation and optimization in the timber processing industry. Applying this approach to timber manufacturing should help to meet the needs of the global economy for sustainably produced resources. In the context of dwindling forest resource availability and increasing demand, these theories form a potential framework for research development, technology selection and the optimisation of the manufacture of wood products for contemporary market conditions.

4.4. Designing Current Research Methods with Reference to Previous Research Outputs

The intention to design this research to develop further the previous efforts of Bull’s [

24] extensive set of case studies was largely successful, although this was limited by the lack of access to the foundational unpublished research design elements such as the questions and interpretation categories. This research attempted to continue a tradition of research and build on a particular approach that was developed almost 20 years earlier. The time requirement to maintain storage of academic research materials is only seven years.

In this regard, this broader research arc could be characterised as intermittent, discontinuous and longitudinal. The guidelines and methods for academic research are not designed to facilitate this approach, as demonstrated by the lack of access to the constituent elements of previous research. Intermittent longitudinal research could be supported by a long-term, extensive, strategic research agenda and guidelines or conditions that might assist and provide the means for a longer-term research program.

4.5. How Do Firm Resources Enable Competitive Advantage

The functional link between firm-based resources and competitive advantage has been well established [

64,

65,

66]. This has even been specifically shown for the forest products industry [

67,

68]. Some researchers have even gone as far as to suggest that firms with strong links outside of their own corporate footprint perform even better in terms of competitive advantage than those who do not participate in networks of resources, information and innovation. Hinterhuber [

69] developed a model to predict future firm performance on the basis of current resources and capabilities that supports the conclusion that this firm is well placed to capitalise on its strength in its performance regarding the RBV.

Recent analysis shows [

70,

71] how a resource-based theory (RBT) approach can underlie a firm’s success in pursuing strategic goals. Further, the authors show how RBT and RBV can determine the strategic value of goals other than competitive advantage, with findings that suggest that, for firms, prioritising the “private provision of public goods” or CSR (corporate social responsibility) in fact increases competitive advantage.

4.6. Research at the Nexus of Science/Engineering and Business

Research like this is made complicated by the fact that it applies business concepts and principles in a technical or scientific context. Outputs from business- or market-oriented approaches and methods are often not generally considered scientific in that they are not verifiable. However, these practices have been shown to deliver value where they are applied in the commercial sector. This interdisciplinary tension complicates efforts to work in this area, with differences in technical outlook and worldviews as well as differences in resulting cultural expressions.

However, the tendency to focus on technical and production aspects of wood resource production and manufacturing is recognised as a gap, or oversight, in the wood processing sector, where a tendency to focus on production or technical aspects of the industry may diminish the capability of industries and businesses to withstand challenging conditions and make full use of emerging opportunities. This research did not seek to address or overcome these tensions in any substantial fashion, but they were recognised in the course of research and are recognised in the broader literature. Overcoming this gap may be of strategic interest to the wood products sector.

5. Conclusions

This research adds incrementally to the existing body of knowledge on innovation in timber processing. While not as extensive as Bull’s [

24] original research, it demonstrates that designing research with reference to previous studies and efforts both extends the existing body of knowledge, as well as grounding current developments to a body of previous research.

5.1. Limitations

Key limitations of this research include the fact that the innovation in question is yet to be fully realized; the limited generalizability of a single case study; the small sample size; potential biases of interviewees, particularly regency bias; lack of performance data; and the unique capital position of the business.

In forming conclusions from this research, it must be noted that, at this stage, the selection of new products is yet to be determined and the success of any new products manufactured by this enterprise is yet to be determined. That said, there are a range of factors studied that can potentially lead to the successful innovation and commercialisation of laminated veneer lumber (LVL) products at RTA.

5.2. Synthesis

While limited, this research demonstrates that using business-oriented lenses can help to understand what enables innovation. In this case, resources outside of a business’s corporate footprint were drawn upon to effectively draw on external research and build capital, knowledge and internal systems to pursue competitive advantage or other strategic goals.

Viewed in the context of relevant literature and research, the firm’s resources are such that commercialisation of products developed from the spindleless lathe might be expected to succeed. The firm has ready access to capital from other businesses in the group. The amount of capital is disproportionate to Bull’s proxy measure using business size to assess capital availability. This shelters innovation efforts at the firm to some extent from immediate commercial necessities, enabling the long research, development, lead-in and commissioning periods required to upgrade the plant equipment and systems required to undertake this type of step-change in manufacturing capability.

A number of successful innovations in the history of the firm have been the result of interactions between numerous personnel in different companies within the group and also with institutions and sources of information and resources outside of the firm. Internal information exchange is explicitly supported and encouraged by the proprietor. In some instances, forums for communication have been systematized for better communication, supporting knowledge sharing and iterative communication. These elements effectively strengthen factors important for innovation.

The firm has established market access to customers in niche markets with a strong reputation based on qualitative factors such as local manufacturing and highly efficient resource conversion, which sets it in good stead to access markets and pricing structures outside of mainstream commodity timber product markets.

This investigation shows that RTA is well-placed to innovate, undertaking the development of products derived from commissioning the spindleless lathe and commercialising them. The firm has high capital resources, very high knowledge of technology, medium–high market knowledge and high, though tacit, knowledge of the marketplace. These factors would suggest that the firm is well positioned to successfully commercialise LVL products manufactured with the spindleless lathe.