Abstract

Due to increasing environmental concerns and the scarcity of high-quality hardwood resources, enhancing wood properties—such as strength, surface smoothness, and impact resistance—has become essential, especially for veneer-based products. Wood densification is a promising method for such improvements, typically involving mechanical, thermo-mechanical, or hygrothermal-mechanical processes. However, most prior studies examined only one densification parameter at a time. This study systematically investigates the combined effects of equilibrium moisture content (EMC), pressing temperature, and pressure on birch veneer densification. Birch veneers were densified radially using four temperatures (90–210 °C), three pressures (1.8–5.4 MPa), and three EMC levels (5%–20%) for a fixed pressing time of 8 min, resulting in 36 unique combinations. Results showed that higher pressing pressure and higher initial EMC consistently led to greater veneer densification. Optimal outcomes were achieved under two distinct conditions: (1) 90 °C with high EMC and high pressure, and (2) 210 °C with the same high EMC and high pressure. Intermediate temperatures (130–170 °C) were less effective. Temperatures above 200 °C were found critical due to lignin softening beyond its glass transition temperature. These findings highlight the interactive role of key parameters and provide practical guidance for upgrading low-quality veneers into high-performance engineered wood products in a sustainable and resource-efficient manner.

1. Introduction

With the growing global demand for sustainable construction materials and increasing pressure on forest resources, improving the properties of wood has become essential. Natural wood often exhibits limitations such as low strength, dimensional instability, and surface irregularities, especially in fast-growing or low-density species. Enhancing these properties is crucial for expanding the usability of underutilized species and improving the performance of high-grade woods. By compressing the cellular structure of wood under heat and pressure, densification significantly increases density, strength, surface hardness, and dimensional stability of wood, making it a viable alternative to tropical hardwoods and synthetic materials.

Wood densification is a widely studied technique aimed at improving the physical and mechanical properties of low-density wood species, making them viable alternatives to traditional high-density species in structural and decorative applications [1,2,3]. The efficiency and quality of densification, however, are strongly dependent on several factors, including temperature, pressing pressure, and the wood’s initial equilibrium moisture content (EMC) [3,4,5].

One of the key mechanisms in the densification process is the softening of the wood cell wall components—primarily lignin and hemicellulose—when subjected to heat. Lignin, in particular, exhibits a glass transition temperature that varies depending on moisture content, becoming thermo-plastically active and allowing for permanent deformation of the wood structure [5]. At elevated temperatures, such as those above 200 °C, this thermal softening dominates the deformation behavior, often compensating for reduced plasticization by moisture. Through the application of heat (typically between 150 °C and 170 °C), pressure, and steam, wood can be compacted to significantly improve its density and strength [6]. Also, several studies have confirmed that higher pressing temperatures during densification improved compressibility and stability. For instance, Bekhta and Niemz [7] found that heating spruce wood at 200 °C in densification improved dimensional stability, although they noted reductions in bending strength and modulus of elasticity (MoE) at excessive temperatures. Similarly, Fang et al. [3] reported improved dimensional stability in the 180–220 °C densification temperature range, with no set recovery observed at 220 °C.

Alongside temperature, pressing pressure significantly affects densification outcomes. Higher pressures promote greater cell wall collapse and compaction, leading to higher final densities and improved mechanical performance. For example, Huang W. [8] applied pressures up to 20 MPa to basswood blocks and observed tensile strength increasing from 5 to 10 MPa, followed by a decrease beyond 10 MPa. Bekhta et al. [9] found that increasing pressing pressure from 4 to 12 MPa reduced surface roughness. Navi and Girardet [10] demonstrated that densification under high pressures significantly improved the shear strength and Brinell hardness of spruce, pine, and beech samples.

Studies by Kutnar et al. [11] and Rautkari et al. [12] emphasized the importance of high initial EMC or steam-assisted densification in improving compressibility and structural stability.

Scharf et al. [13] investigated the hardness of surface-densified wood and emphasized that density profiles and test parameters significantly influence hardness results, highlighting the need for standardized testing methods or profile-based evaluation.

In our earlier research, it was found that densification of face veneers significantly improved the bending strength, load-carrying capacity, screw withdrawal resistance, surface hardness, and material efficiency of aspen and black alder plywood [14,15]. However, there remains a need to define optimal wood densification process conditions based on a systematic evaluation of densification parameters. Most of the research has focused on densification at higher temperatures and on solid softwood, which results in a less homogeneous final outcome due to variations in compression properties across grain directions, and differences in the densities of earlywood and latewood. The aim of this study is to gain insight into the combined effects of densification process parameters through optimization using lower pressures, lower temperatures, and shorter densification cycle durations.

This study investigates the effects of temperature, pressure, and EMC on the densification behavior of hardwood veneers, with a focus on density changes, compression ratios, and set recovery. By systematically analyzing these parameters across a range of processing conditions, we aim to identify optimal densification regimes suitable for industrial-scale production, promoting enhanced dimensional stability and reduced energy consumption.

2. Materials and Methods

2.1. Wood Materials

Logs of silver birch (Betula pendula Roth) were used in this study. The logs were freshly felled in September 2022 from Käru, Rapla County, Estonia, by the State Forest Management Centre (RMK). The logs, with a nominal length of 3 m and an average diameter of 24 cm, were visually sorted to select those with fewer knots and no signs of decay for the veneer production process.

2.2. Veneer Preparation

The selected logs were submerged in a soaking tank filled with water maintained at 40 °C for a duration of 48 h. Prior to the peeling, the logs were debarked, and log parameters, including core temperature, moisture content (MC), length, and annual ring width, were carefully documented.

The peeling process was conducted using an industrial-scale laboratory lathe (model 3HV66, Raute Oyj, Lahti, Finland). During peeling, the logs were processed at a speed of 60 m/min with a knife angle set to 21° and a compression rate of 10%. The logs were rotary peeled to a veneer with nominal thickness of 3.2 mm.

Once peeled, the veneers were cut into sheets (900 × 450 mm2) subsequently dried in a laboratory-scale veneer dryer (Raute Oyj, Lahti, Finland) at 170 °C for 420 s. After drying, the veneers were conditioned in a controlled environment at 25 °C and 20% relative humidity (RH) at the Laboratory of Wood Technology, Tallinn University of Technology, Tallinn, Estonia. This step ensured a final MC of 5%, optimal for gluing applications.

Defect-free veneers were selected after conditioning and trimmed into smaller specimens with dimensions of 140 × 60 mm2.

To account for positional effects within the log, veneers were categorized based on their location in the tree: sapwood and heartwood.

2.3. Densification Parameters

In this study, four pressing temperatures were selected for veneer densification process: 90 °C, 130 °C, 170 °C, and 210 °C. The lowest temperature, 90 °C, was chosen to observe the influence of equilibrium moisture content (EMC) on densification while keeping energy consumption minimal. The 130 °C hot-pressing temperature setting served as an industrial reference point, as it is commonly used in plywood production. A higher temperature of 170 °C was included to maintain a consistent 40 °C interval for trend analysis across the temperature range. Lastly, 210 °C was selected based on findings in the literature [16,17] suggesting that temperatures above 200 °C can reduce set recovery after densification due to chemical changes in lignin.

Three EMC levels were used: 5%, 12%, and 20%. The 5% EMC condition was achieved by conditioning samples at 20% RH and 25 °C and reflects standard industry preparation for birch veneers. The 12% EMC condition, representing typical service moisture levels, was obtained at 65% RH and 20 °C. Meanwhile, the high 20% EMC was created under 90% RH and 30 °C, chosen because increased moisture content lowers the glass transition temperature of lignin, improving plasticization during densification Although these values were targeted during conditioning, the actual EMC of each sample was verified post-densification using oven-dry weight measurements.

To study the role of pressing pressure in combination with wood MC and pressing temperature, three levels were applied: 1.8 MPa, 3.6 MPa, and 5.4 MPa. The 1.8 MPa pressure corresponds to standard industrial conditions for birch plywood pressing. A mid-range pressure of 3.6 MPa approaches the yield point of birch in radial compression. The highest pressure, 5.4 MPa, was designed to initiate plastic deformation within the wood structure. According to simulations by Aimene et al. [18], transverse compression of wood perpendicular to the grain reaches the plastic region near 6 MPa at 20 °C, supporting the choice of this upper pressure level. The pressing duration in this study was 8 min.

2.4. Standards and Methods of Analysis

In wood densification studies, the densification ratio and compression ratio are key parameters for evaluation of the efficiency of densification treatments and to quantify the extent of material compaction.

2.4.1. Densification Ratio

The densification ratio (DR) is defined as the percentage increase in density as a result of the densification process. It is calculated by comparing the initial and final densities of the material. Formula (1), for calculating the densification ratio, is given as:

where:

- DR = Densification ratio (%);

- Df = Final density after densification (kg/m3);

- Di = Initial density before densification (kg/m3).

A higher densification ratio indicates a greater increase in density, which is typically associated with improved mechanical properties such as hardness, bending strength, and surface wear resistance.

2.4.2. Compression Ratio

The compression ratio (CR) measures the reduction in thickness of the material due to applied pressing pressure during densification. It is an essential parameter for understanding the compaction behavior of wood and is expressed as a percentage decrease in thickness relative to the initial thickness. Formula (2), for calculating the compression ratio, is:

where:

- CR = Compression ratio (%);

- ti = Initial thickness before densification (mm);

- tf = Final thickness after densification (mm).

The compression ratio provides valuable information about the deformation characteristics of the wood material under varying pressure and moisture content conditions.

2.4.3. Effect of Moisture Content on Compression and Densification

To account for variations in initial EMC, the adjusted compression ratio is sometimes used. This approach standardizes the final thickness measurements by conditioning the samples at a controlled relative humidity (RH) and temperature after densification, ensuring consistency in comparative analysis. The adjusted compression ratio is given by Formula (3):

where:

- CRadjusted = Adjusted compression ratio (%);

- ti = Initial thickness before densification (mm);

- tf,adjusted = Final thickness after conditioning at standard RH (65%) and temperature (20 °C) (mm).

Conditioned veneer samples were measured for length, width, thickness, and weight using calipers and a balance to precisely determine the initial thickness and density of the wood material at 65% RH and 20 °C. Thickness measurements were also taken right before densification for each equilibrium moisture content (EMC) for different samples. The measurement points were first marked, and thickness was measured at those points to eliminate differences in thickness at different locations.

2.4.4. Densification Process

To precisely control pressure cycle, the pressure, deformation, time intervals, and pressure cycles were monitored. The non-densified veneers underwent uniaxial compression using a 50 kN universal testing machine (Zwick/Roell Z050, ZwickRoell GmbH, Ulm, Germany), and hot-pressing plates were prepared with a custom-designed controlled heating system. This system also included a cooling system using free-running cold tap water at around 10 °C.

The densification cycle was applied as follows: first, the plates were heated to the target densification temperature, then a preload of 5 N was applied, followed by the increase in pressure until the target values and continuing the densification process for 8 min. During the cooling phase, heating was turned off, and tap water was introduced to cool the plates. The temperature was reduced below 40 °C and maintained under load at the same pressure for 5 min. After this, the sample was removed, and length, width, and thickness were measured again from the marked points.

The densified samples were then conditioned at 65% RH and 20 °C. Thickness measurements for each densified sample were taken under these conditions to eliminate the effect of different EMCs and thickness variations that could introduce errors in the densification ratio for both thickness and density.

Specimen dimensions were measured following European Standard EN325:2012 [19] after conditioning at 20 ± 2 °C and 65 ± 5% RH. Thickness measurements adhered to EN315:2002 [20], while density determinations were conducted as per EN323:2002 [21]. All density measurements were taken after conditioning specimens at a RH of 65 ± 5% and a temperature of 20 ± 2 °C. The moisture contents of samples were measured according EN13183-1 [22].

3. Results and Discussion

3.1. Density and Densification Ratio

The densification process led to notable increases in density across all combinations of temperature, pressure, and EMC. Table 1 summarizes the density results before and after densification. The highest final density, 1028 kg/m3, was achieved at 90 °C, 5.4 MPa, and 20% EMC, closely followed by 954 kg/m3 at 210 °C and 5.4 MPa with the same EMC. A previous study [2] reported that the density of densified wood is influenced by the applied pressure and temperature during the densification process, as well as the wood species used. Similar trends were observed in our study. For instance, in the referenced literature, using birch veneer with an initial EMC of 5%, a densification temperature of 200 °C, and pressing pressure of 12 MPa, a final density of 963 kg/m3 was achieved. In comparison, our study, using birch veneer and the initial EMC (5%) but with a temperature of 210 °C and a lower pressing pressure of 5.4 MPa resulted in a final density of 941 kg/m3. This demonstrates that our results are quite comparable despite the significantly lower applied pressure. In contrast, the lowest final density, 565 kg/m3, occurred at 170 °C, 1.8 MPa, and 5% EMC. These results suggest that high EMC combined with elevated pressure significantly enhances wood plasticization and compressibility, particularly at 90 °C and 210 °C. Even at low temperatures, high EMC can sufficiently soften the wood matrix for effective densification.

Table 1.

Initial and final densities of veneer samples before and right after densification; values in parentheses show the standard deviations.

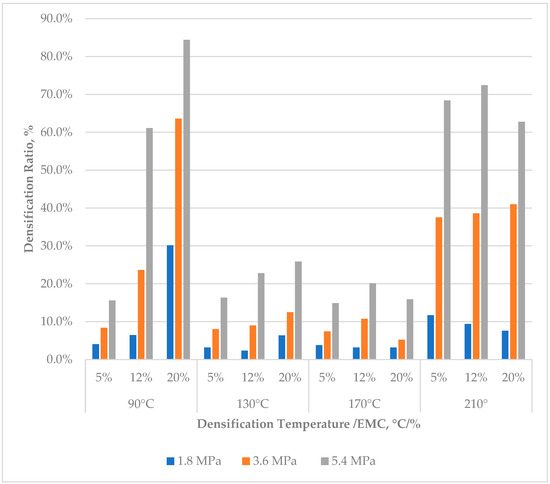

The densification ratio showed a clear dependence on temperature, pressure, and EMC (Figure 1). At 90 °C, the highest ratio of 84.4% was obtained at 5.4 MPa and 20% EMC. Densification tests were conducted using saturated steam at temperatures ranging from 140 °C to 220 °C, and pressures between 4.5 and 9 MPa on aspen and hybrid poplar achieved compression ratios approaching 100% [3], which is higher than the results obtained in this study, likely due to the lower initial density of aspen compared to the birch used in this study. Lower values were seen at intermediate temperatures like 130 °C and 170 °C, except for 5.4 MPa and 5% EMC at 130 °C. For instance, at 130 °C and 12% EMC, the ratio dropped to 22.8%, while at 90 °C and the same pressure and EMC, it reached 61.1%. However, at 210 °C, the densification ratio increased again, reaching 72.4% under 5.4 MPa and 12% EMC, even though wood moisture content is almost entirely lost (e.g., from 11.6% to 0.2% at 3.6 MPa) (see Table 2). This can be attributed to the fact that this temperature exceeds the lignin glass transition point, allowing for structural rearrangement of the wood matrix despite the low moisture content, leading to high densification levels. Thus, despite excessive moisture loss, the structural softening at high temperatures compensates for the reduction in compressibility. These variations are strongly influenced by the change in EMC during pressing, Table 2 and Figure 1 show that the relationship between pressure and densification is not entirely linear across all temperatures and EMC levels. However, at the same temperature and EMC, higher pressure results in greater densification. The same trend applies to increasing EMC at constant pressing pressure and temperature. The difference in final veneer densities between 210 °C and 90 °C may result from moisture loss at higher temperatures. The veneer samples densified at 210 °C are almost completely dry, while those at 90 °C retain some moisture. For instance, under the condition of 90 °C, 5.4 MPa, and an initial EMC of 20%, the final EMC after densification was still 16.6%, indicating that a significant amount of moisture remained in the veneer post-compression.

Figure 1.

Densification ratios of veneer samples.

Table 2.

Initial and final EMC of veneer samples right before and right after densification.

Error bars are not included in Figure 1, Figure 2, Figure 3 and Figure 4 due to significant variability introduced by the use of three different logs, each with distinct average densities: 520 kg/m3 for Log 1, 634 kg/m3 for Log 2, and 538 kg/m3 for Log 3. While the standard deviation appears high when calculated using the overall dataset, this variation primarily reflects the natural density differences between logs rather than inconsistency in the densification process itself. For instance, under the condition of 90 °C, 5.4 MPa, and 20% EMC in Figure 1, the densification ratio showed a standard deviation of 30.4% when all logs were averaged. However, when calculated within individual logs, the deviation for the same condition dropped significantly to just 4.6%. Similar trends are observed across Figure 2, Figure 3 and Figure 4. Therefore, including error bars based on the total dataset might give a misleading impression of process instability, whereas the actual variation lies in the inherent biological differences between logs. To avoid misinterpretation and preserve clarity, error bars are omitted from these figures. The focus is instead on illustrating general trends across pressing parameters.

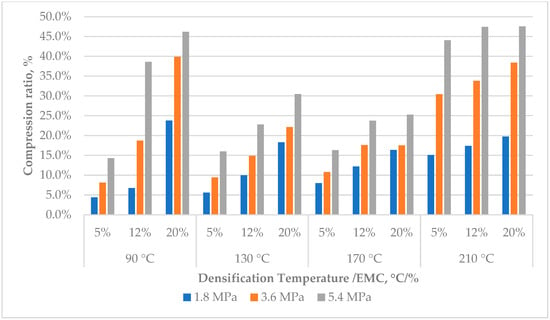

Figure 2.

Compression ratios after densification calculated before and after densification.

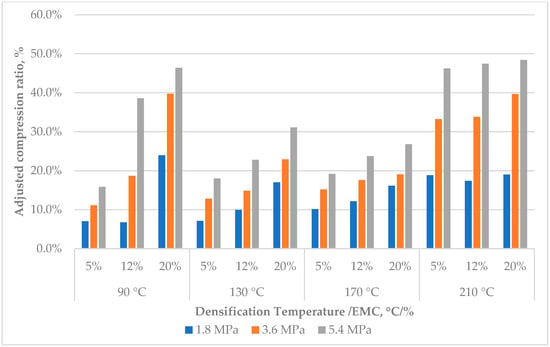

Figure 3.

Adjusted compression ratio taken for all samples’ initial thickness at 20 °C and 65%RH.

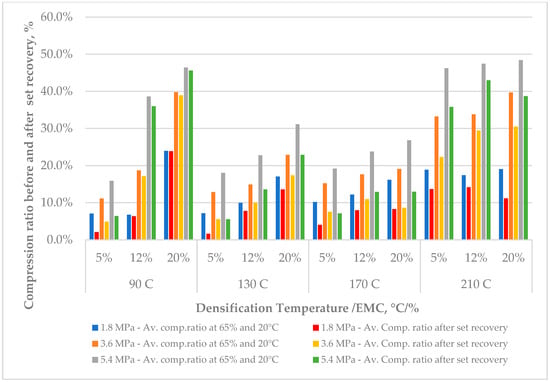

Figure 4.

Compression ratios of densified samples before and after set recovery.

These results confirm that combining high pressing pressure with increased EMC and moderate to high temperatures enhances densification. Higher initial moisture contributes to greater densification efficiency at lower temperatures, whereas excessive moisture loss reduces compressibility. For example, at 130 °C and 5.4 MPa with 12% EMC, the densification ratio was 22.8%, while at 90 °C under the same conditions, it was 61.1%. At 210 °C, densification ratios increased again, especially under higher pressures, reaching 72.4% at 5.4 MPa and 12% EMC. This is attributed to thermal softening of lignin [5] and hemicellulose, facilitating deformation under low EMC. Notably, densification at 90 °C and 5.4 MPa also yielded strong results, especially at high EMC, with a ratio of 84.4%. This suggests that although extreme temperatures such as 210 °C can lead to higher densification even with moisture loss, the performance of veneers at 90 °C is significantly higher (p = 0.016), while allowing for more controlled changes in EMC.

Comparing 90 °C and 210 °C at different pressures, both achieved high final densities. However, considering industrial scalability, energy efficiency, and environmental sustainability, 90 °C appears more suitable. Lower energy consumption at this temperature makes it favorable for large-scale processes.

In summary, while high temperatures (e.g., 210 °C) can achieve substantial densification despite moisture loss, 90 °C offers a more balanced approach, ensuring effective densification with manageable moisture changes and lower energy use.

At atmospheric pressure and 90 °C, densification efficiency was relatively high, especially at low pressures, likely due to minimal moisture loss. EMC values before and after densification show only slight reductions, allowing the wood to retain plasticity and achieve higher final densities.

At 130 °C and 170 °C, densification efficiency dropped despite higher pressures. This may be due to substantial moisture loss, as seen in Table 2. For example, at 130 °C and 3.6 MPa, EMC decreased from 10.5% to 2.4%, and at 170 °C and 1.8 MPa, from 12% to 0.4%. This limits plasticization and reduces densification efficiency, resulting in lower final densities compared to 90 °C under similar conditions.

3.2. EMC Change During Pressing

The change in EMC during hot pressing offers critical insight into the moisture-dependent plasticization of wood. As shown in Table 2, at 90 °C, EMC remained relatively stable due to lower thermal heating energy used, allowing the wood to retain its moisture content and maintain high compressibility. In contrast, at 130 °C, EMC dropped from 10.5% to 2.4%, and at 170 °C, from 12% to 0.4%. This substantial moisture loss diminished the softening effect of water within the wood structure, reducing densification efficiency.

Notably, at 210 °C, despite a significant EMC decrease, veneer densification improved. This suggests that at elevated temperatures, thermal softening of lignin and hemicellulose can compensate for moisture loss. Therefore, densification at 210 °C may depend more on heat-induced plasticization than on moisture content.

3.3. Compression Ratio and Adjusted Values

The compression ratio was evaluated under varying conditions of temperature, pressure, and initial equilibrium moisture content (EMC). Results are summarized in Figure 2, which categorizes compression ratios by initial EMC, and Figure 3, which presents values adjusted for initial thickness at standardized conditions (65% RH, 20 °C) immediately after compression.

Compression ratio analysis confirmed a strong dependence on pressing pressure and EMC. At 90 °C pressing temperature, compression ratio values ranged from 4.4% at 1.8 MPa and 5% EMC to 46.2% at 5.4 MPa and 20% EMC. At 210 °C, the compression ratio peaked at 47.5% under 5.4 MPa pressure and 20% EMC, with a minimum of 15.1% at 1.8 MPa and 5% EMC. The enhanced densification at 210 °C is likely due to increased plasticity of the wood matrix above the lignin glass transition temperature, which promotes deformation under pressure. In a previous study [2], birch veneers with an initial EMC of 5% were densified at three temperatures (100 °C, 150 °C, and 200 °C) using pressure levels of 4, 8, and 12 MPa. The results demonstrated that densification temperature and pressure had statistically significant effects on veneer thickness and compression ratio (CR). It was observed that CR increased with both temperature and pressure, reaching a maximum of 40% at 200 °C and 8 MPa, while the lowest CR was 7% at 200 °C and 4 MPa. Notably, there was no significant change between 100 °C and 150 °C in terms of thickness reduction, but a substantial change was seen at 200 °C, attributed to the softening of wood at higher temperatures. These findings are in good agreement with our results, where CR values ranged from 8.1% (5% EMC, 90 °C, 3.6 MPa) to 44% (5% EMC, 210 °C, 5.4 MPa), confirming a similar trend in which higher temperature and pressure led to greater densification in birch veneer.

Initial EMC had a notable influence: higher EMC values (20%) consistently led to greater compression ratios, whereas lower EMC (5%) resulted in reduced compressibility. This reinforces the role of moisture as a plasticizer. In contrast, intermediate temperatures such as 130 °C and 170 °C were less effective due to excessive moisture loss, which limited the softening effect of water within the wood fibers.

When compression ratios were adjusted for standardized conditions (see Figure 3), slightly higher values were observed across all cases. The highest adjusted compression ratio was 48.4% at 210 °C and 5.4 MPa. These adjusted values were especially higher at elevated temperatures, emphasizing how post-densification conditions can affect the interpretation of compression efficiency.

3.4. Thickness Reduction and Set Recovery

Thickness measurements confirmed that densification consistently reduced veneer thickness. The most significant reduction occurred at 210 °C and 5.4 MPa, with a decrease from 3.39 mm to around 1.70 mm for high EMC samples. A similar reduction was seen at 90 °C and 5.4 MPa with 20% EMC, where thickness dropped from 3.39 mm to 1.86 mm.

In this study, set recovery was evaluated after densification by placing the samples into conditions of 65% relative humidity (RH) and 20 °C, which varied with densification parameters (see Figure 4). The lowest set recovery occurred at 90 °C, 20% EMC, and 1.8 MPa, indicating stable compaction and long-term thickness retention. In contrast, the highest set recovery was observed in veneer samples densified at 170 °C, 5.4 MPa, and 20% EMC, suggesting greater susceptibility to post-densification expansion.

When comparing veneers densified 90 °C and 210 °C at 5.4 MPa and 20% EMC, set recovery was lower at 90 °C, despite both achieving high compression ratios.

Due to the nature of the densification process and the equipment used, determining the immediate post-densification thickness was challenging. Since the densification process was conducted without mechanical stoppers, the samples were compressed freely until reaching their final thickness under the applied pressing temperature, EMC, and pressing pressure conditions.

Final densified veneer thicknesses measured after conditioning demonstrated that some degree of set recovery occurred across all pressing temperatures, EMC levels, and pressures. However, samples densified at lower temperatures and higher EMC—particularly at 90 °C, 20% EMC, and 1.8 MPa—exhibited the least recovery, retaining most of their compressed form. Conversely, higher set recovery at 130 °C and 170 °C and 5.4 MPa suggests greater sensitivity to humidity in those conditions.

These findings emphasize that pressing temperature, EMC, and pressure jointly influence the post-densification stability of veneers. Tao Li et al. [23] conducted a study to optimize parameters for Chinese fir wood densification, including densification temperature (140 °C, 155 °C, and 170 °C, which are comparable to our 130 °C and 170 °C), densification duration (10, 20, and 30 min), and post-densification heat treatment temperature (170 °C, 185 °C, and 200 °C). They reported that set recovery was significantly influenced by the densification temperature and heat treatment temperature, while the duration of densification had no significant effect—findings that are consistent with our results regarding the influence of temperature on set recovery. However, a key difference between their findings and ours is the direction of the effect: in our study, set recovery increased with higher densification temperature (from 130 °C to 170 °C), whereas Tao Li et al. observed a decrease in set recovery with increasing temperature. This discrepancy may be attributed to differences in the duration of densification and heat treatment parameters used in their study. Moreover, they did not report the pressing pressure applied during densification, nor did they investigate the influence of different EMC levels, both of which are critical factors considered in our research. Notably, they concluded that heat treatment was the most influential factor affecting set recovery, which could further explain the divergence in results. Densification at lower temperatures with adequate moisture levels can lead to more stable thickness retention after reconditioning, an important factor for industrial applications where long-term performance is essential.

3.5. Industrial Relevance and Optimization

From an industrial perspective, densification at 90 °C and 5.4 MPa with 20% EMC offers a favorable balance of higher compression ratio, low energy consumption, and superior thickness retention. Although veneer densification at 210 °C produced the highest compression ratios, it also involves greater energy demand and increased risk of thermal degradation and emissions, raising concerns over environmental and material sustainability.

The results confirmed that veneer densification process optimization requires careful combination of pressing temperature, pressure, and EMC parameters. High EMC enhances compressibility at lower temperatures, while high temperatures can offset moisture loss through thermal softening of wood polymers. Elevated pressure further amplifies densification efficiency. Understanding these interactions is crucial for developing energy-efficient and sustainable veneer densification processes.

Comparing the results at 90 °C and 210 °C, compression ratios achieved at 90 °C under 5.4 MPa closely approach those at 210 °C, especially at higher EMC levels (see Figure 3). However, the lower thermal load at hot pressing in 90 °C significantly reduces energy consumption, limits thermal degradation of wood, and minimizes emissions, offering a more sustainable and cost-effective solution for industrial-scale production.

It should also be noted that when comparing set recovery values at 90 °C and 210 °C, the moisture conditions during reconditioning differ significantly (see Table 2). At 210 °C, EMC drops to nearly zero, and reconditioning at 65% RH and 20 °C brings the EMC back up to approximately 12%, resulting in a large moisture change. In contrast, at 90 °C and 5.4 MPa with 20% initial EMC, the moisture loss is only around 1%, and the final EMC after densification remains at 16.5%. Reconditioning under the same conditions would therefore involve a much smaller moisture increase of only 4.5%. This distinction is important, as set recovery is influenced not only by mechanical compaction but also by the extent of moisture regain and should be interpreted with these moisture dynamics in mind.

4. Conclusions

This study explored the systematic investigation of the combined effects of pressing temperature, pressure, and equilibrium moisture content (EMC) on the densification performance of rotary-cut birch veneers. The densification process significantly influenced key physical properties, including final density, densification ratio, compression ratio, and set recovery. The following conclusions can be drawn based on the findings:

Increasing pressing pressures (up to 5.4 MPa) consistently improved final density and compression ratios of wood veneers, particularly when combined with higher initial EMC levels (12% and 20%). Veneers with 20% EMC achieved the highest densification ratios, especially at 90 °C and 210 °C. This confirms that sufficient moisture content enhances the plasticization of the wood matrix, leading to improved compaction.

At lower temperatures (90 °C), densification was highly efficient when paired with high EMC and pressure, resulting in final densities up to 1028 kg/m3 and densification ratios over 84%. At intermediate temperatures (130 °C and 170 °C), excessive moisture loss during pressing limited plastic deformation and reduced compaction. At 210 °C, despite near-total moisture loss, the thermal softening of lignin and hemicellulose enabled effective densification under higher pressure. However, to maintain moisture-assisted plasticization at high temperatures, pressing must be rapid. Quick loading allows compaction to occur before moisture escapes; otherwise, slower loading leads to EMC reduction and diminished compressibility.

The most stable thickness retention after reconditioning (65% RH, 20 °C) was observed at 90 °C with 20% initial EMC. Importantly, moisture conditions during reconditioning significantly affect set recovery outcomes. At 210 °C, the EMC after pressing drops to nearly zero, and reconditioning induces a ~12% moisture regain, leading to larger thickness recovery. In contrast, at 90 °C and 5.4 MPa with 20% initial EMC, the final EMC after densification is still 16.5%, and reconditioning involves only a 4.5% decrease, resulting in lower set recovery. This demonstrates that set recovery is influenced both by mechanical and hygroscopic changes, and must be interpreted within the context of actual moisture change during reconditioning.

Higher EMC values generally led to greater compression ratios. The maximum compression ratio of 47.5% was obtained at 210 °C, 5.4 MPa, and 20% EMC. When adjusted to standardized conditions (65% RH, 20 °C), compression ratios increased further, affirming the importance of both pressure and moisture in maximizing deformation and densification.

Although 210 °C provides high densification even with low residual moisture, the 90 °C condition under high EMC and pressure offers a better trade-off between performance, energy efficiency, and environmental impact. Lower-temperature processing reduces thermal degradation risks, minimizes emissions, and enables more stable dimensional retention after reconditioning, making it highly favorable for sustainable, large-scale wood veneer densification.

Author Contributions

Conceptualization, A.R. and T.A.; methodology, T.A.; validation, T.A., J.K. and A.R.; formal analysis, T.A.; investigation, T.A.; resources, J.K. and A.R.; data curation, T.A.; writing—original draft preparation, T.A.; writing—review and editing, J.K. and A.R.; visualization, T.A.; supervision, J.K. and A.R.; project administration, J.K. and A.R.; funding acquisition, J.K. and A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Estonian Research Council grant (PRG2213).

Informed Consent Statement

The authors declare the use of artificial intelligence (AI) in improving grammar in the writing process. During the preparation of this work, the authors used Google Scholar and ChatGPT in order to search for applicable literature and improve spelling and grammatical structure. After using these tools, the authors reviewed and edited the content as needed and take full responsibility for the content of the publication.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to acknowledge Estonian Research Council grant (PRG2213) for supporting this research. The authors acknowledge the use of ChatGPT-4 (OpenAI, Inc., San Francisco, CA, USA) for assistance with language editing. A literature search was conducted using Google Scholar and other academic databases, including Scopus and Web of Science, to identify relevant publications.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Ugovšek, A.; Kamke, F.A.; Sernek, M.; Kutnar, A. Bending performance of 3-layer beech (Fagus sylvativa L.) and Norway spruce (Picea abies (L.) Karst.) VTC composites bonded with phenol-formaldehyde adhesive and liquefied wood. Eur. J. Wood Wood Prod. 2013, 71, 507–514. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Sedliacik, J.; Novak, I.; Mamonova, M. Effects of short-term thermomechanical densification on the structure and properties of wood veneers. Wood Mater. Sci. Eng. 2017, 12, 40–54. [Google Scholar] [CrossRef]

- Fang, C.-H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. J. Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Kariz, M.; Kuzman, M.K.; Sernek, M.; Hughes, M.; Rautkari, L.; Kamke, F.A.; Kutnar, A. Influence of temperature of thermal treatment on surface densification of spruce. Eur. J. Wood Wood Prod. 2016, 75, 113–123. [Google Scholar] [CrossRef]

- Goring, D.A.I. Thermal Softening, Adhesive Properties and Glass Transitions in Lignin, Hemicellulose and Cellulose. In Consolidation of the Paper Web, Trans. of the IIIrd Fund. Res. Symp. Cambridge, 1965; Bolam, F., Ed.; Fundamental Research Committee (FRC): Manchester, UK, 1965; pp. 555–568. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A. Compression of wood under saturated steam, superheated steam, and transient conditions at 150 °C, 160 °C, and 170 °C. Wood Sci. Technol. 2012, 46, 73–88. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Huang, W.; Jin, Y.; Guo, Y.; Deng, J.; Yu, H.; He, B. Fabrication of High-Performance Densified Wood via High-Pressure Steam Treatment and Hot-Pressing. Polymers 2024, 16, 939. [Google Scholar] [CrossRef] [PubMed]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Mamonova, M.; Pinkowski, G.; Lis, B. Effect of thermomechanical densification on surface roughness of wood veneers. Wood Mater. Sci. Eng. 2014, 9, 233–245. [Google Scholar] [CrossRef]

- Navi, P.; Girardet, F. Effects of thermo-hydro-mechanical treatment on the structure and properties of wood. Holzforschung 2000, 54, 287–293. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A.; Sernek, M. Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci. Technol. 2009, 43, 57–68. [Google Scholar] [CrossRef]

- Rautkari, L.; Laine, K.; Laflin, N.; Hughes, M. Surface modification of Scots pine: The effect of process parameters on the through thickness density profile. J. Mater. Sci. 2011, 46, 4780–4786. [Google Scholar] [CrossRef]

- Scharf, A.; Neyses, B.; Sandberg, D. Hardness of surface-densified wood. Part 2: Prediction of the density profile by hardness measurements. Holzforschung 2022, 76, 515–524. [Google Scholar] [CrossRef]

- Kallakas, H.; Akkurt, T.; Scharf, A.; Mühls, F.; Rohumaa, A.; Kers, J. The Effect of Hardwood Veneer Densification on Plywood Density, Surface Hardness, and Screw Withdrawal Capacity. Forests 2024, 15, 1275. [Google Scholar] [CrossRef]

- Akkurt, T.; Rohumaa, A.; Kallakas, H.; Scharf, A.; Kers, J. Enhancing the bending strength, load-carrying capacity and material efficiency of aspen and black alder plywood through thermo-mechanical densification of face veneers. Constr. Build. Mater. 2024, 450, 138555. [Google Scholar] [CrossRef]

- Laine, K.; Rautkari, L.; Hughes, M.; Kutnar, A. Reducing the set-recovery of surface densified solid Scots pine wood by hydrothermal post-treatment. Eur. J. Wood Wood Prod. 2013, 71, 17–23. [Google Scholar] [CrossRef]

- Tu, D.; Su, X.; Zhang, T.; Fan, W.; Zhou, Q. Thermo-mechanical Densification of Populus tomentosa var. tomentosa with Low Moisture Content. BioResources 2014, 9, 3846–3856. [Google Scholar] [CrossRef]

- Aimene, Y.E.; Nairn, J.A. Simulation of transverse wood compression using a large-deformation, hyperelastic–plastic material model. Wood Sci. Technol. 2015, 49, 21–39. [Google Scholar] [CrossRef]

- EN 325; Wood-Based Panels—Determination of Dimensions of Test Pieces. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- EN 315; Plywood—Tolerances for Dimensions. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- EN 323; Wood-Based Panels—Determination of Density. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- EN 13183-1; Moisture Content of a Piece of Sawn Timber—Part 1: Determination by Oven Dry Method. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- Li, T.; Cai, J.-B.; Zhou, D.-G. Thermal densification of fir. Bioresources 2013, 8, 5279–5288. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).