1. Introduction

Aquilaria sinensis (Lour.) Spreng. belongs to Thymelaeaceae

Aquilaria. It is a rare medicinal plant endemic to China [

1], and it is mainly found in evergreen broad-leaved mixed forests in low-altitude mountains and hills, such as those in Guangdong, Hainan, Fujian, Yunnan, and Taiwan. Agarwood is often used in the production of drugs, as it has sedative, aphrodisiac, cardiotonic, antiemetic, anti-asthmatic, neuroregulatory, anti-inflammatory [

2], antibacterial, antitumor [

3], antidepressant [

4], antioxidant [

5], hypoglycemic, hypolipidemic, antipyretic, and analgesic effects, with additional therapeutic potential against diabetes [

6,

7] and Alzheimer’s disease. It is considered by the

Pharmacopoeia of the People’s Republic of China (2020 Edition) to be the only plant source of Chinese agarwood. Agarwood formation in

A. sinensis is a result of the host’s defensive response to mechanical damage, insect attack, or microbial invasion [

8,

9], and a healthy plant will not produce this product without such external damage or stimulation. Despite research having been carried out over the past 100 years, agarwood formation mechanisms are still controversial and have not yet been clarified. There are five main hypotheses: the pathological hypothesis [

10], the non-pathological hypothesis (physical and chemical injury induction hypothesis) [

11], the traumatic pathology hypothesis, the defense response induction hypothesis, and the elicitor induction hypothesis. These hypotheses represent the foundation for the study of the formation mechanisms of agarwood. However, these existing hypotheses have limitations. One limitation is that each hypothesis attempts to explain complex phenomena with a single dominant factor (e.g., fungi, oxidation, genes), but agarwood formation is fundamentally a result of synergistic interactions among multiple factors, including biological (fungi, insects), chemical (oxidation, enzyme catalysis), physical (damage, environmental stress), and genetic (gene expression) factors. Second, these studies overlook the temporal dynamics. Natural agarwood formation takes decades, but most existing research is based on short-term experiments (months to years), which fails to capture long-term processes, such as resin synthesis, oxidative polymerization, and microbial community succession. Third, there is a lack of strong interdisciplinary integration. Chemical analyses are often conducted in isolation from the ecological context (e.g., overlooking the role of symbiotic microorganisms), and biological research is insufficiently linked to the functions of specific compounds, resulting in a fragmented understanding of agarwood formation mechanisms. These problems deserve our further attention.

Many agarwood induction techniques have been widely examined. At present, methods for creating agarwood are divided into three categories. One is the physical trauma method [

12,

13], including the chiseling method, the chopping method, the fire stud method, the trunk burning method, the semi-trunk breaking method, full-trunk breaking method, or the branch breaking method; the second is the artificial inoculation induction method [

14,

15]; and the third is the chemical induction method. These induction methods greatly promote the efficiency of agarwood output. Of course, artificial induction technology for agarwood is still developing. Although the formation time of agarwood has been shortened to a certain extent and output efficiency has improved, the quality of the agarwood produced has not yet reached that of wild agarwood, and the induction technology needs to be improved further.

The authenticity of agarwood on the market is difficult to determine, and the quality is varied. Authentic agarwood has a special aroma and bitterness, the surface is uneven, and it contains more oily substances than its artificially induced counterpart [

16]. Counterfeit agarwood is mainly derived from heartwood, such as

Caesalpinia sappan,

Pinus massoniana, and

Dalbergia. Its surface color is different, and its texture is hard and heavy. Authentic agarwood has a strong, lasting aroma during combustion and leaves no black carbon residue afterwards [

17]. However, counterfeit agarwood produces an unpleasant odor during burning, and the burning ash leaves a black carbon residue [

18]. At present, the quality of agarwood is mainly determined using high-performance liquid chromatography (HPLC) by identifying the contents of the main indicator compounds of agarwood. For instance, agarotetrol is the main active ingredient of agarwood and can be used as a potential quality marker [

19]. In addition, agarwood contains more than 300 compounds. These include flavonoids, sesquiterpenes, and 2-(2-phenylethyl) chromones [

20], with the latter two displaying the widest range of pharmacological activities, and their contents and concentrations are often used as criteria for evaluating the quality of agarwood [

20,

21]. That being said, there are a variety of aromatic compounds and pharmacologically active ingredients in agarwood that are important factors for determining its quality [

22,

23].

Sesquiterpenes are important compounds in agarwood and have been widely studied. Sesquiterpene biosynthesis in agarwood involves two pathways—one is the MVA pathway that starts in the cytoplasm and the other is the MEP pathway that starts in the plastid [

24,

25]. In the MVA pathway, AACT is the primary enzyme acting in the initial stage. HMGS and HMGR are the key enzymes responsible for the conversion of acetyl-CoA to mevalonate in the second and third stages. MVK and PMK cause phosphorylation. In the final stage, MVD acts as the rate-limiting enzyme during the synthesis of the terpenoid precursor IPP in the MVA synthesis pathway. These enzymes have been identified as homologous genes [

26]. In the MEP pathway, DXS is the primary rate-limiting enzyme in terpenoid biosynthesis, and DXR, MCT, CMK, MDS, and HDR also play important regulatory roles. The general precursor of terpenoid synthesis is formed via these two pathways, and then the monoterpene precursor, GPP, the sesquiterpene precursor, FPP, and the diterpene and tetraterpene terpenoid precursor, GGPP [

27], are synthesized by GPPS [

28], FPS, GGPPS, and other enzymes. Finally, the terpenoid synthase TPS reacts with these terpenoid precursors through a series of modification reactions to further generate terpenols, aldehydes, acids, esters, and other derivatives [

29,

30].

The purpose of this study is to explore the dominant strains and wood-eating insects that promote the formation of agarwood in A. sinensis and to examine its induction through physical damage, fungi, wood-eating insects, and fungal infections combined with insect damage. The content of agarotetrol in the samples under different treatments was used to identify the best way to promote and improve the efficiency and quality of agarwood formation in A. sinensis using the ‘insect + fungus’ method. At the same time, a transcriptome analysis of agarwood samples under different treatments was carried out in order to explore the mechanisms of agarwood induction by insects combined with fungi, to find the key genes and transcriptional regulators of the sesquiterpene synthesis pathway of agarwood, to provide experience and reference for the future development and promotion of stable, efficient, environmentally friendly, and sustainable artificial induction methods of agarwood in A. sinensis, and to offer a theoretical basis for exploring the formation mechanism of agarwood.

2. Materials and Methods

2.1. Experimental Material

The A. sinensis plants used in this study were located in Naban River Nature Reserve, Xishuangbanna Dai Autonomous Prefecture, Yunnan Province. The trees were in good condition. The fungi used were all from the laboratory of fungal preservation of the Institute of Forest Protection, Yunnan Academy of Forestry and Grassland Sciences. Odontotermes formosanus was collected from the base of A. sinensis; Tomicus yunnanensis and Cerambycidae sp. were collected from Huanglishan, Chengjiang City, Yuxi City; and Scleroderma guani Xiao et Wu was purchased from the Beijing Glinghong Biological Science and Technology Development Center.

2.2. Screening of Fungi and Insects

We collected agarwood tissue from the base of the

Aquilaria tree and removed surface soil and debris using a soft brush. We then disinfected the samples with 75% alcohol for 2 min and transferred them into a 10%–20% sodium hypochlorite solution for 10–20 min under gentle shaking. The samples were rinsed 3–5 times with sterile distilled water for 1–2 min each and cut into small wood chips (5 mm in length and 1 mm in width) and then rinsed 2–3 times with sterile water. The sterilized samples were placed on potato dextrose agar (PDA) medium and incubated at 25 °C in the dark. Colony isolation was performed until pure fungal strains were obtained. The core workflow for fungal sequencing identification involves the following steps. Fungal DNA was extracted using a QIAGEN DNeasy Plant Mini Kit (Wuhan Sevier Biotechnology Co., Ltd., Wuhan, China) and assessed for purity and integrity through agarose gel electrophoresis. A PCR protocol targeting the ITS regions was performed with specific primers (ITS1/ITS4) (

Supplementary Materials, Table S1) under an annealing temperature of 50–60 °C, followed by electrophoretic verification of amplified products. Purified PCR amplicons were sequenced using Sanger sequencing. Downstream analysis included BLAST alignment against the NCBI database, with taxonomic classification determined based on sequence similarity thresholds (≥98% for species-level, ≥95% for genus-level). For ambiguous species, multi-locus phylogenetic analysis supplemented by morphological characterization was employed to ensure reliable identification. By consulting the literature, we identified fungi reported to induce agarwood formation in

A. sinensis. The obtained fungi were analyzed, and then the agarwood test was carried out using the fungal treatment induction method, as shown in

Section 2.3. The induced agarwood samples were analyzed using GC-MS to detect whether they contained chemical components similar to the main components of agarwood, and strains with the ability to induce agarwood formation in

A. sinensis were determined.

We disinfected the insects by immersing them in 3% hydrogen peroxide for 1–2 min. Then, we immediately rinsed them 3–5 times with sterile distilled water to thoroughly remove any residual disinfectant. The insects were transferred to a Petri dish for observation of their survival condition. Based on literature findings, the most appropriate insects for inducing agarwood in

A. sinensis were selected. Subsequently, insect analysis was carried out using the insect boring treatment, as described in

Section 2.3. After 7~15 days, the survival and feeding activity of the insects in the tree were observed to assess their potential to promote agarwood formation.

2.3. Processing and Sampling of A. sinensis

The experiment employed a randomized complete block design with six treatments and three temporal replicates. Thirty-six healthy 8-year-old A. sinensis trees with comparable growth status (DBH 15 ± 2 cm, height 4 ± 0.5 m) were randomly assigned to six treatment groups (n = 6 trees per group): cold drilling treatment, fungal induction treatment, PDA treatment, insect boring treatment, insects combined with fungi treatment, and untreated control. All mechanical interventions were performed by trained technicians using sterilized tools. Between-tree contamination was prevented using disposable gloves and surface-disinfected equipment (75% ethanol). Treatments were applied during morning hours (08:00–10:00) to minimize circadian rhythm effects. The cold drilling treatment used a puncher positioned 50 cm from the ground at an inclination angle of 45°. From the base to the apex of the trees, each trunk was drilled in four directions—east, south, west, and north—with an average of 4 holes, a pore size of 1 cm, hole spacing of 7 cm, a depth of 3–4 cm, and row spacing of 15 cm, with a total of 9 rows. The fungal induction treatment was based on the cold drilling treatment. A 5 mm sterilized puncher was used to punch holes in the activated fungal PDA plate; a fungal block was placed in the pre-made hole using a sterile bamboo stick, and then the holes were sealed from first to last using parafilm. The PDA treatment involved inserting sterile PDA blocks into the hole using the same process as in the fungal induction method, which was based on the cold drilling treatment. For the insect boring treatment, based on the cold drilling treatment, sterile tweezers were used to insert the insect into the hole, and then the hole was covered with parafilm from the base to the apex of the trees and pricked with a needle to allow for gas flow. For the treatment involving insects combined with fungi, based on the cold drilling treatment, insects were held with tweezers, dipped into a beaker containing fungal suspension for 5~10 s, and quickly placed in the hole, which was then sealed. For the blank treatment, the above induction techniques were not required, and the trees were left to grow naturally. Systematic destructive sampling was conducted at 2, 4, and 6 months post-induction, with 2 trees per treatment group sampled at each time point. Using an autoclaved coring tool (150 mm diameter, 200 mm maximum depth), three vertical sampling zones were established along the trunk: lower (0–50 cm above ground), middle (50–100 cm), and upper (100–150 cm). Within each vertical zone, three equidistant horizontal quadrants (120° apart, aligned with the original treatment orientations of east, south, west, and north) were sampled, maintaining a 2 cm buffer from treatment hole edges to avoid boundary effects. Each tree yielded 9 standardized core samples (3 vertical zones × 3 horizontal quadrants) with ≥15 cm spacing between adjacent sampling points. For artificially treated groups, samples were specifically collected from the reactive interface between induced resinous tissue and healthy xylem, identified by in situ dark pigmentation. Untreated controls were equivalently sampled from healthy xylem in non-manipulated trunk regions. Samples were immediately flash-frozen in liquid nitrogen and stored at −80 °C.

2.4. Volatile Detection

The samples treated with fungi in February, April, and June were selected. Grinding was performed using a grinder, and 5 g of samples was accurately weighed for each treatment and sent to Yunnan Tongchuang Detection Technology Co., Ltd. (Kunming, China) for GC-MS detection. Splitless injection was used, and the solvent delay time was 4.0 min. The mass spectrometry conditions were as follows: electron bombardment (EI) ion source; the electron energy was 70 eV; the interface temperature was 280 °C; the ion source temperature was 230 °C; the quadrupole temperature was 150 °C; standard tuning mode was used; the electron multiplication voltage was 1718 V; and the mass scanning range was 40–800

m/

z. Using a data analysis workstation, combined with the NIST 20 version mass spectrometry database and the related literature, the chromatographic peaks of the sample were analyzed [

31,

32], and the total ion flow diagram was obtained. The relative content of the chemical composition of the sample was determined using the peak area normalization method.

2.5. Determination of Agarotetrol Content

In accordance with the method [

33] of Li et al., the content of agarotetrol in the sample was determined. The reference solution was prepared as follows: a total of 2 mg of the agarotetrol reference standard was weighed and placed in a 100 mL volumetric flask, and an appropriate amount of HPLC-grade anhydrous ethanol was added for dissolution. The mixture was then shaken to obtain the 20 μg/mL agarotetrol reference solution. The preparation of sample solution was as follows: 0.10 g of agarwood sample was placed in a 25 mL conical flask, 10 mL of methanol was added, and the total mass was weighed and shaken well. Ultrasonic extraction (power 250 W; frequency 35 kHz) was performed for 60 min; then, the flask was cooled, replenished to initial mass with methanol, and filtered. The filtrate was collected, and 2.5 mL of the filtrate was withdrawn with a sterile syringe (Yunnan Sanxin Medtec Co., Ltd., Kunming, China) and passed through a 0.45 μm membrane filter into the HPLC vial. For the negative control solution (‘Chinese medicinal agarwood control’), the method was the same as that used for the sample solution’s preparation. The chromatographic conditions were as follows. For high-performance liquid chromatography (Thermo UltiMate 3000, Thermo Fisher Scientific, Waltham, MA, USA), a liquid chromatography column (Thermo Fisher Scientific, Waltham, MA, USA) was used, where the column length was 250 mm, the inner diameter was 4.6 mm, and the particle size was 5 μm. Acetonitrile (FISHER) was used as mobile phase A, 0.1% formic acid aqueous solution (Ron Reagent Company, Shanghai, China) was used as mobile phase B, and gradient elution was performed according to the specified time (

Table 1), where the flow rate was 0.7 mL per minute and the column temperature was 30 °C. The detection wavelength was 252 nm. The control solution, sample solution, and the reference solution were placed on the injection plate according to the number, and 10 μL of each solution was injected according to the procedure. The content was then quantified, and the chromatogram was obtained.

2.6. Transcriptome Sequencing

According to the analysis of the chemical composition of agarwood samples and the content of agarotetrol, samples with better induction effects and blank treatments were selected for sequencing. Sequencing was repeated three times on each sample. The samples were numbered (

Supplementary Materials, Table S2) and sent to Wuhan Bena Technology Co., Ltd. (Wuhan, China) for transcriptome sequencing, including RNA extraction, quality control, and library construction. Raw sequencing data were processed by removing reads with >5% ambiguous bases (N), reads where >50% of bases had Phred quality scores ≤ 5, adapter-contaminated reads, and PCR duplicates. The transcriptome sequencing data were deposited in the NCBI Sequence Read Archive (SRA) under BioProject accession number PRJNA1232343, with release scheduled for 1 March 2026.

2.7. Transcript Assembly and Annotation

Clean reads were assembled using Trinity v2.11.0 [

34]. Subsequently, CD-HIT v4.8.1 [

35] was used for clustering (95% similarity threshold) to remove redundant transcripts and obtain unigenes. Functional annotation of unigenes was then performed against the Nr, Pfam, Uniprot, KEGG, GO, and KOG/COG databases.

2.8. Differential Expression Analysis and Functional Enrichment

RSEM was used to quantify unigene expression levels and generate read counts for each sample. Differential expression analysis was performed using DESeq2 (v1.26.0) [

36], with a significance threshold of padj < 0.01. When fewer than 10 differentially expressed unigenes (DEGs) were identified, the threshold was relaxed to an unadjusted

p-value < 0.05. Functional enrichment analysis of GO terms and KEGG pathways was then conducted using the R (v4.1.2) package clusterProfiler. Significant enrichments were determined by comparing DEGs against the whole transcriptome background, with parameters set as pAdjustMethod = ‘BH’ (Benjamini–Hochberg) and pvalueCutoff = 0.05.

2.9. Construction of a Co-Expression Network

Based on the FPKM values of differentially expressed genes (DEGs) and transcription factor (TF) genes involved in sesquiterpene biosynthesis, Pearson correlation coefficients were calculated using R. Significant co-expression pairs were defined as those with an absolute correlation ≥ 0.9 and a permutation test

p-value < 0.05 (10,000 iterations) [

37]. The co-expression network was visualized using Cytoscape (v3.10.3) [

38]. Betweenness centrality (BC) values of genes were computed with the CytoNCA plugin to identify hub genes.

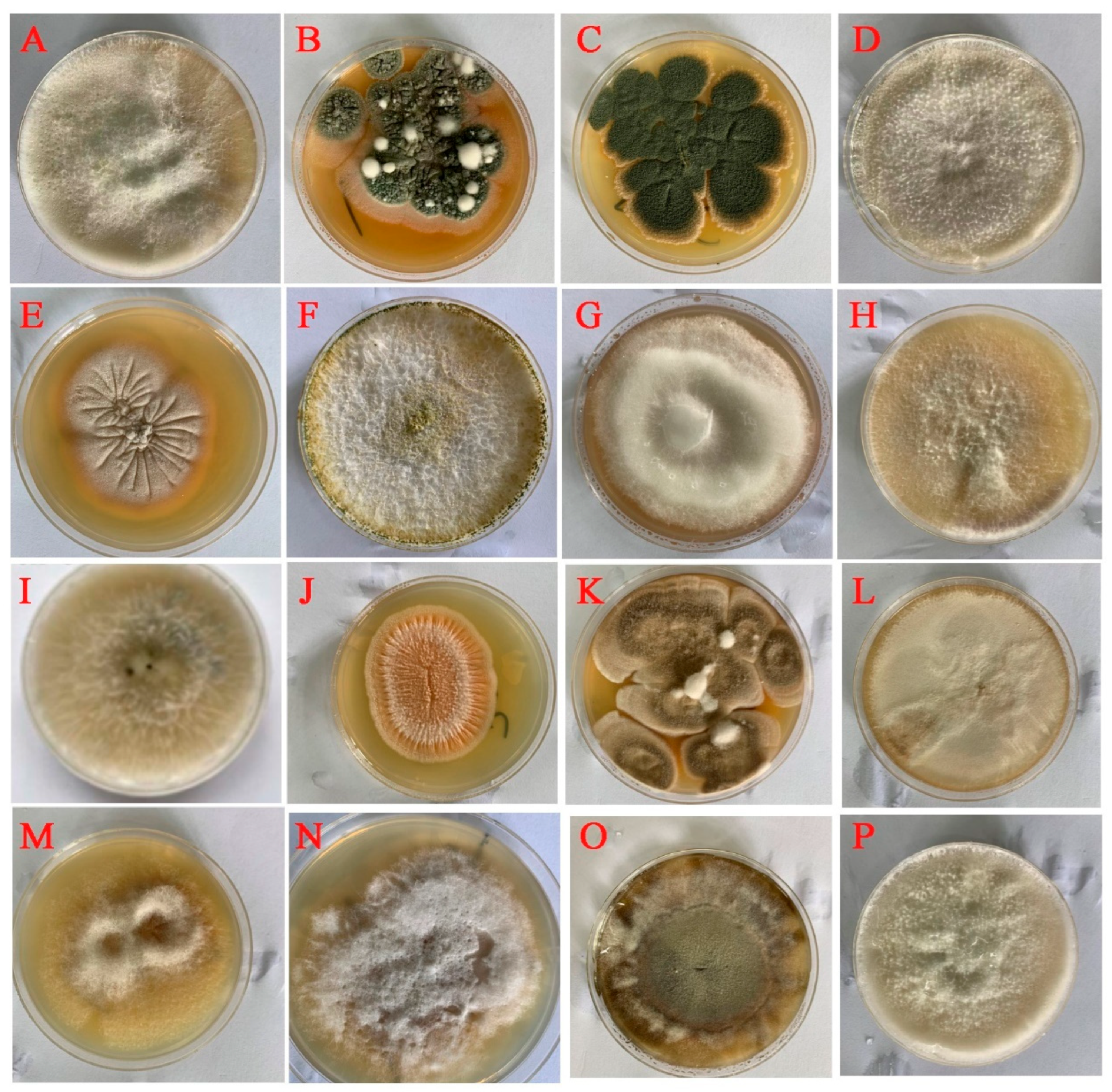

4. Discussion

This study analyzed 16 potential agarwood-inducing fungal strains. Samples treated with these strains contained terpenoids resembling characteristic agarwood components: (-)-β-elemene, β-eudesmol, alloaromadendrene, camphor, humulene, naphthalene, and 1-tetradecene. Fusarium solani, Penicillium chrysogenum, Fusarium equiseti, and Phaeoacremonium alvesi exhibited elevated agarotetrol levels. Quantifying alcohol-soluble extracts, 2-(2-phenylethyl) chromones, and other biomarkers could validate their efficacy as dominant induction strains. Nadezhdiella cantori larvae demonstrated ideal biotic induction by forming feeding galleries within A. sinensis xylem. Although termites are documented consumers of A. sinensis, their exclusion was necessitated by obligate eusociality requiring intact colonies for survival, coupled with destructive feeding behavior that causes structural collapse when tree defenses are compromised.

When

A. sinensis experiences physical/chemical/fungal stress, it activates defense responses producing antibacterial sesquiterpenes and chromones [

41]. Prior transcriptomics identified 26 sesquiterpene biosynthetic genes in mechanically injured xylem [

42]. Our study revealed that April treatments induced significant transcriptional reprogramming with consistent pathway enrichment versus BMZ controls; upregulated genes in isoflavonoid/flavonoid/sesquiterpenoid biosynthesis potentially drive sesquiterpene production, while downregulated photosynthesis/light-harvesting/circadian genes reflect adaptive stress responses [

43,

44]. This dynamic equilibrium enhances stress tolerance during agarwood formation [

45,

46,

47,

48]. Sesquiterpene biosynthesis correlated positively with MVA/MEP pathway enzymes and terpene synthases (TPS), particularly under fungal–insect co-induction (cjYB1Z4), suggesting enhanced sesquiterpenoid production and positioning this treatment as a key research model.

Transcriptional regulation [

49] of sesquiterpenoid biosynthesis involves AP2/ERF, WRKY, bZIP, and bHLH families [

50,

51,

52,

53]. bHLH member MYC directly activates

TPS promoters [

54], consistent with our observed bHLH upregulation. AP2/ERF and bZIP regulate terpenoid genes across plants [

55,

56,

57], exemplified by ORCA3-mediated

DXS activation in

Catharanthus roseus [

57]. WRKY proteins modulate stress responses and sesquiterpenoid synthesis, as shown by

GaWRKY1 activation and

WRKY44 repression of

TPS promoters [

52]. Our co-expression network indicates WRKY/AP2/bHLH/bZIP families exert dual (positive/negative) regulation on sesquiterpenoid biosynthesis, with

WRKY33,

ABF, and

WRKY2 showing high connectivity to synthase genes, suggesting pivotal regulatory roles requiring functional validation.

In conclusion, we propose that A. sinensis rapidly activates a protective mechanism upon injury by secreting resin containing compounds like sesquiterpenes and chromones. Under the dual ‘insect infestation + fungal invasion’ induction mode, genes associated with sesquiterpene and chromone biosynthesis exhibit significant upregulation, accelerating this process. Simultaneously, insect-bored tree tissues facilitate biochemical interactions between fungi and resin, triggering biochemical reactions that gradually transform resin into aromatic constituents (e.g., agarotetrol). This dual biological induction mechanism promotes agarwood formation and endows the product with distinctive aroma and medicinal properties. Our study addresses oversimplified induction methods by elucidating treatment-specific effects on agarwood formation. However, limitations exist, as molecular mechanisms require further characterization; although sesquiterpene/chromone biosynthesis genes showed significant upregulation, functional validation of key regulators (e.g., via gene knockout/overexpression) is needed to clarify precise roles. Additionally, environmental influences (temperature/humidity/light) were not quantified due to uncontrolled variables, and standardized production parameters await establishment. These unresolved issues warrant further investigation to advance fundamental understanding and practical applications.