Parameters of Medium-Size Wood Deliveries Depending on the Season, Moisture Content and Assortment of the Load

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of Medium-Sized Wood Assortments and Determination of Load Volume

- S2a—one-sided curvature up to 8 cm/1, with length over 1 m up to 10 cm along the entire length and unacceptable soft rot;

2.2. Determination of the Moisture Content of the Wood Transports

2.3. Determination of Load Mass and Density

2.4. Statistical Analyses

3. Results

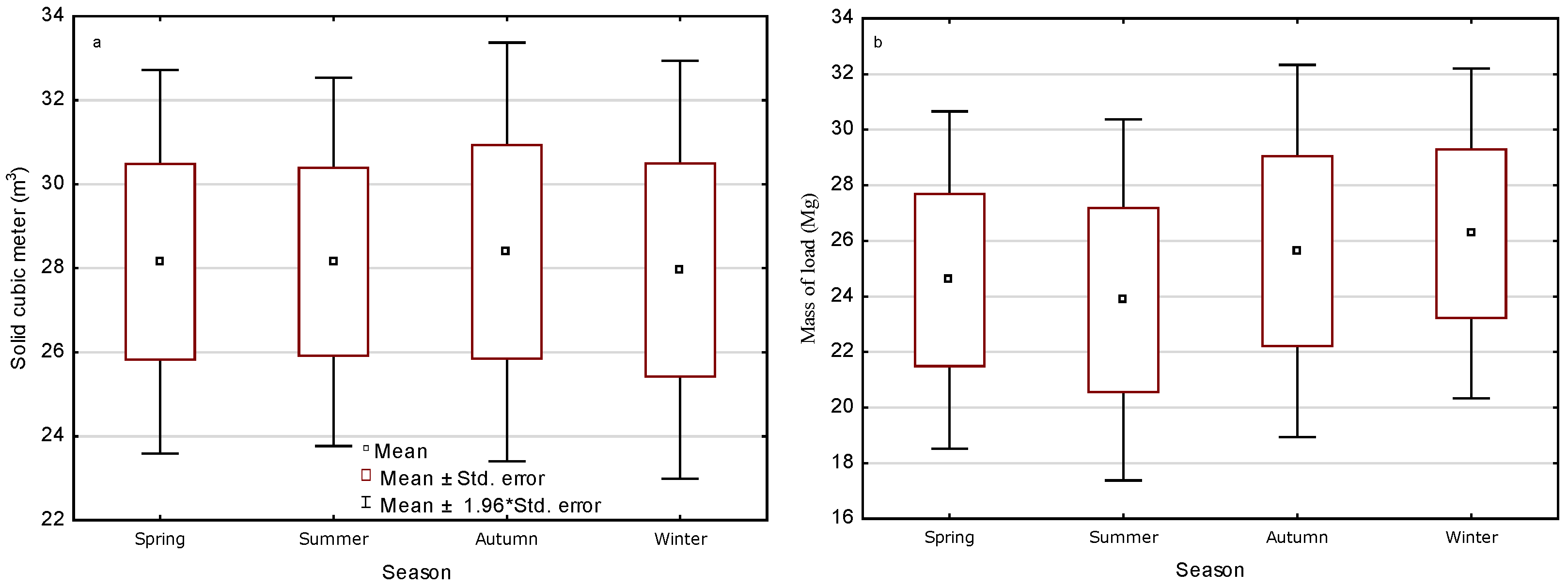

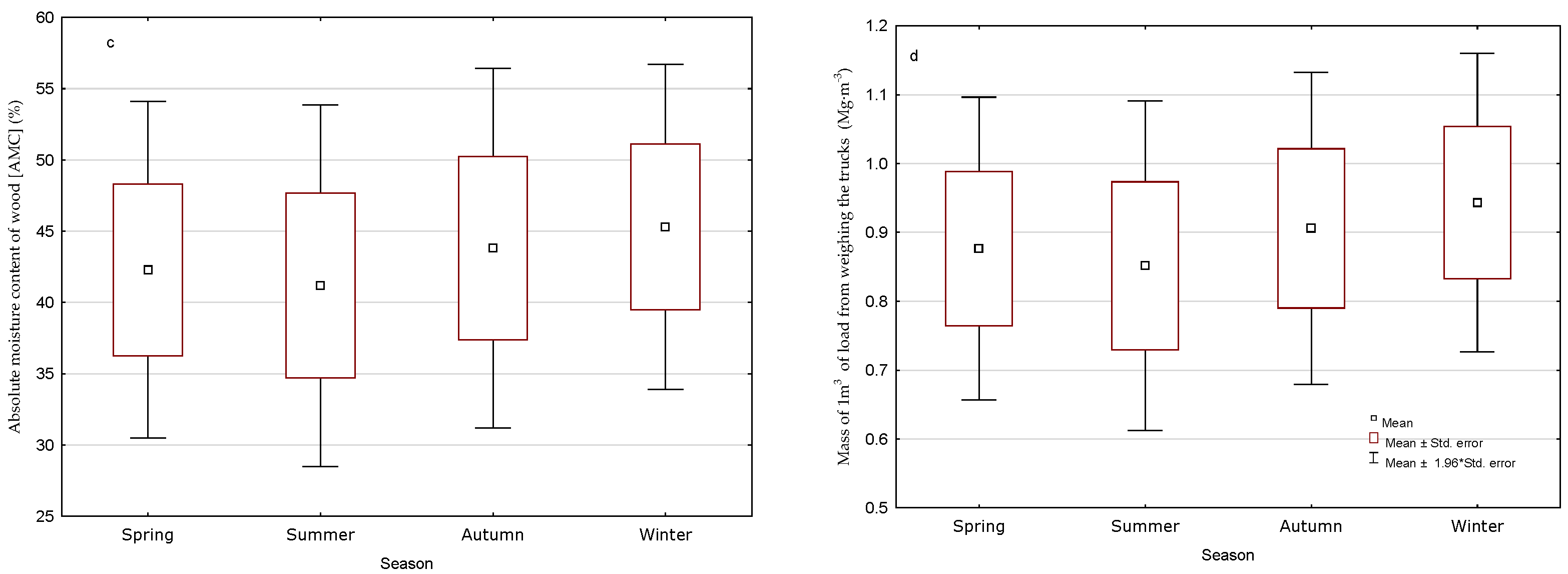

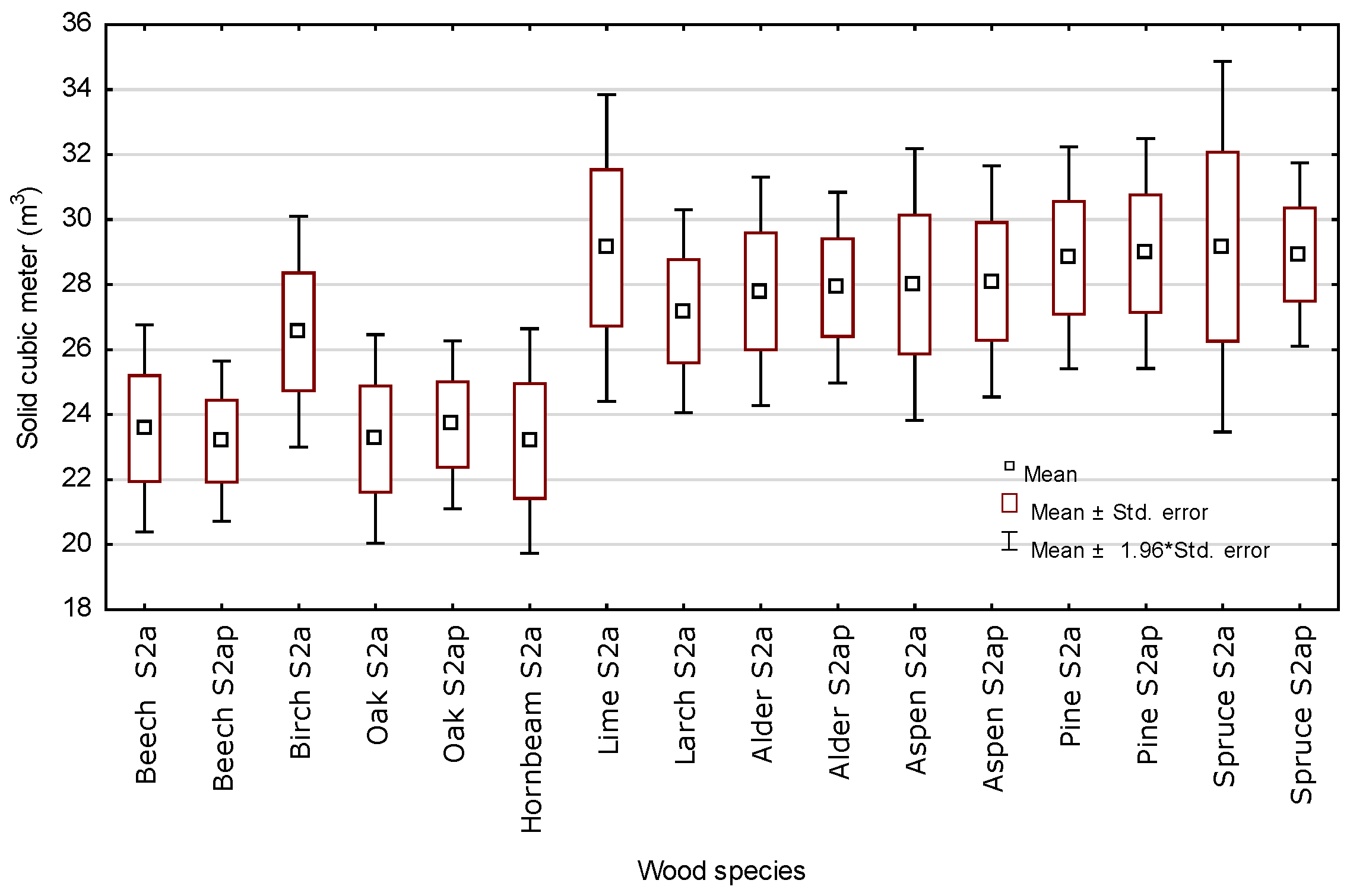

3.1. Volume of Transported Wood in Solid Cubic Meter (m3) Depending on the Species and Assortment of Wood and Season of the Year

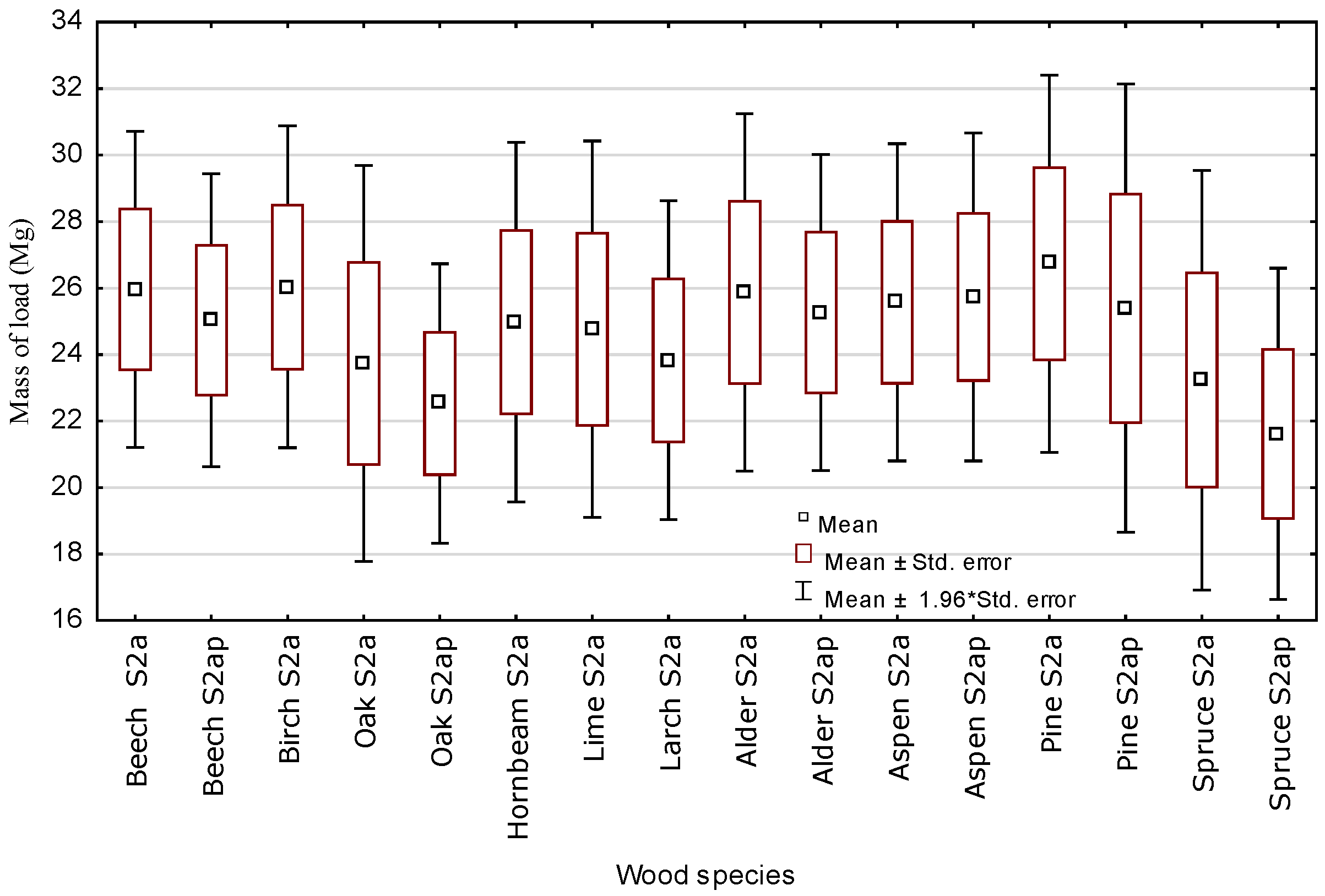

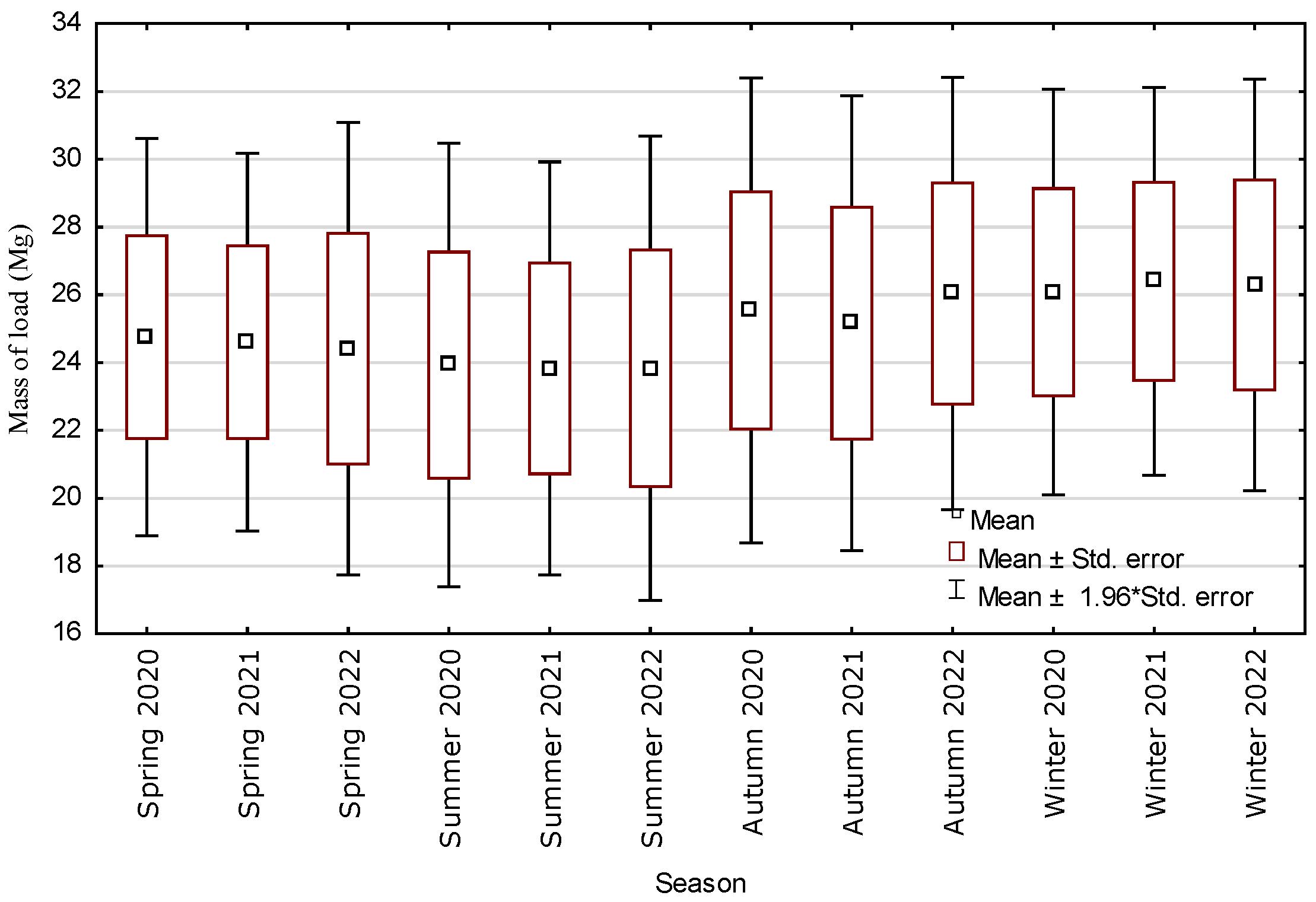

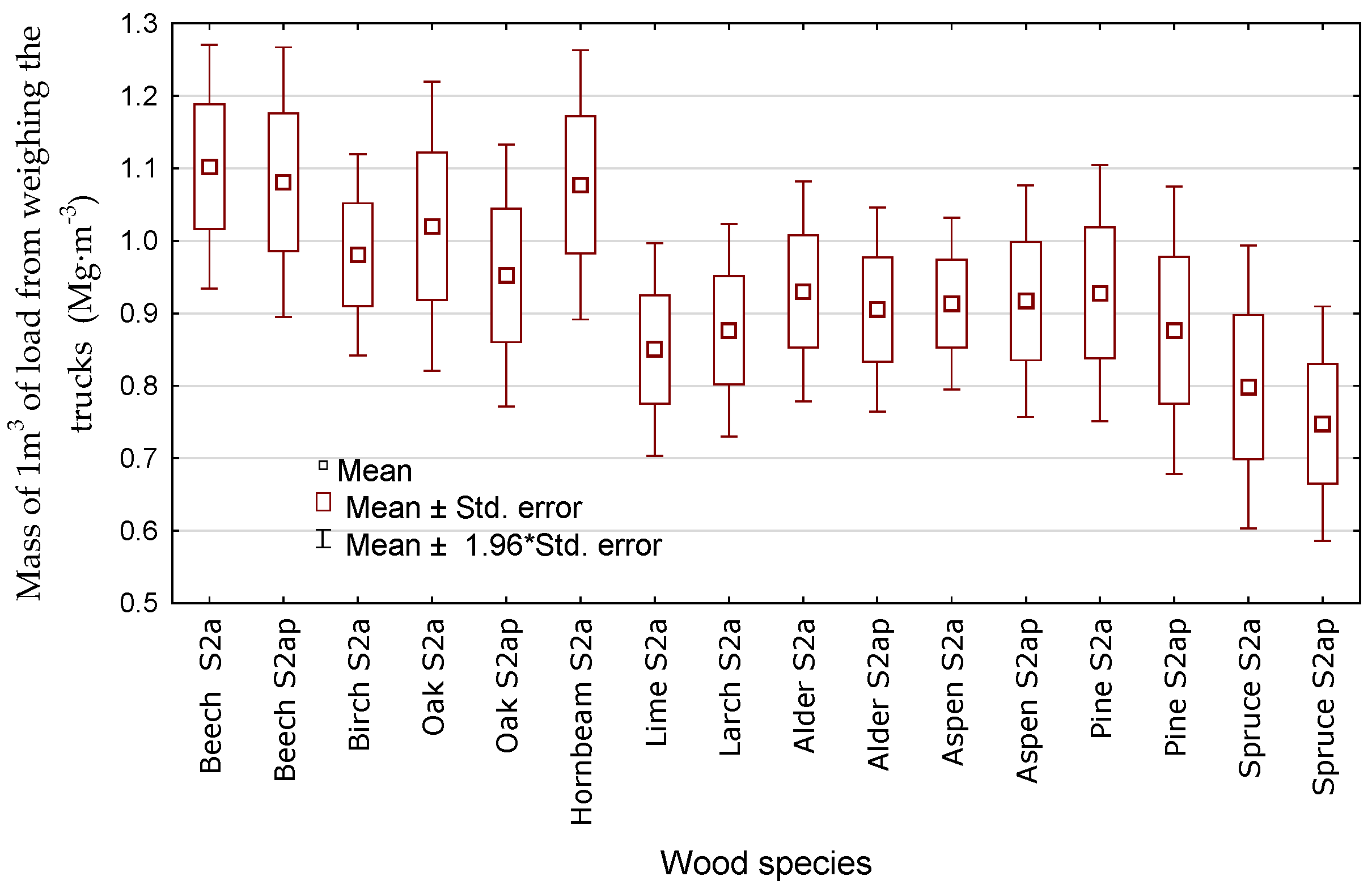

3.2. Load Mass (Mg) Depending on Tree Species, Wood Assortment and Season

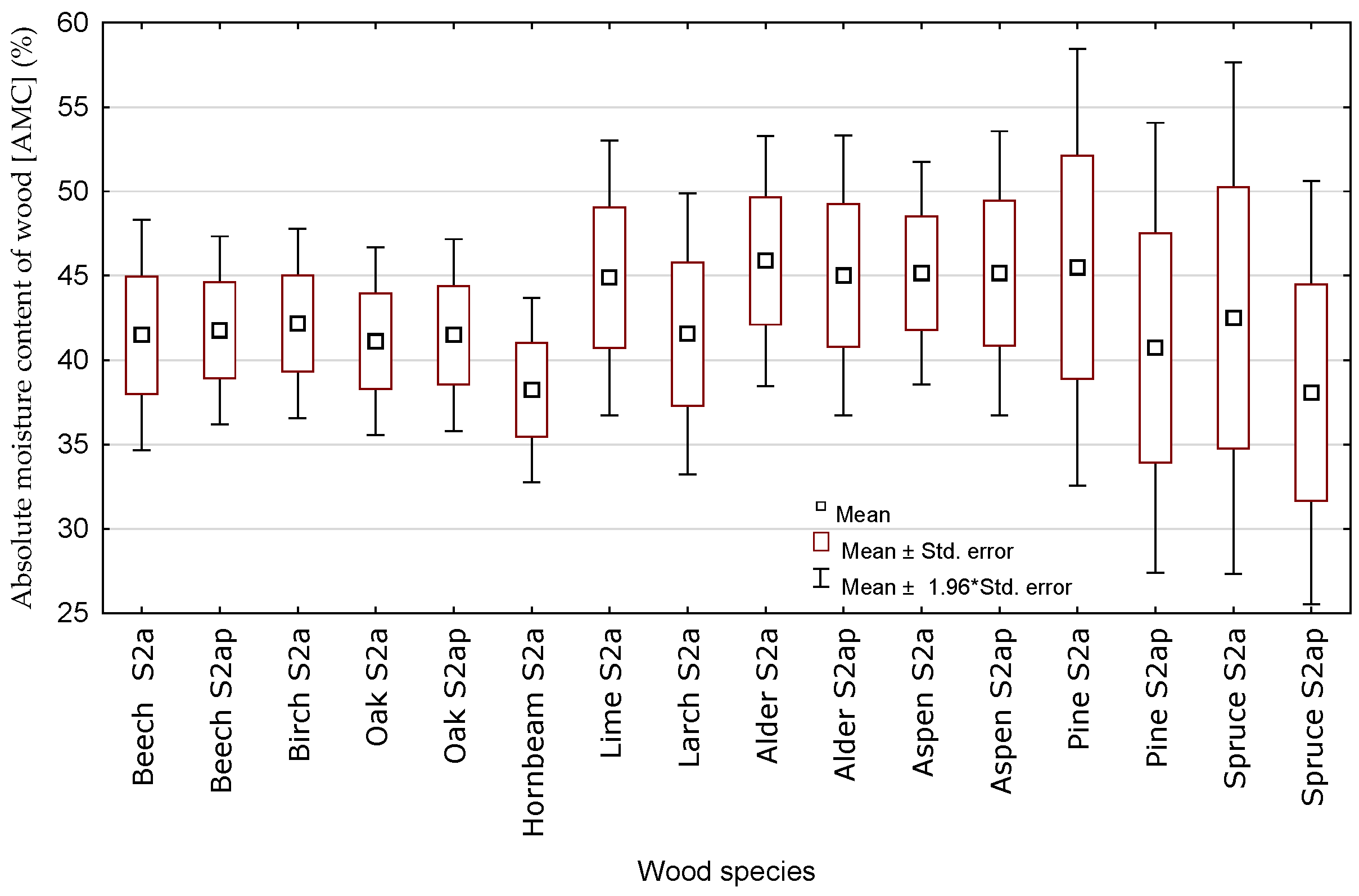

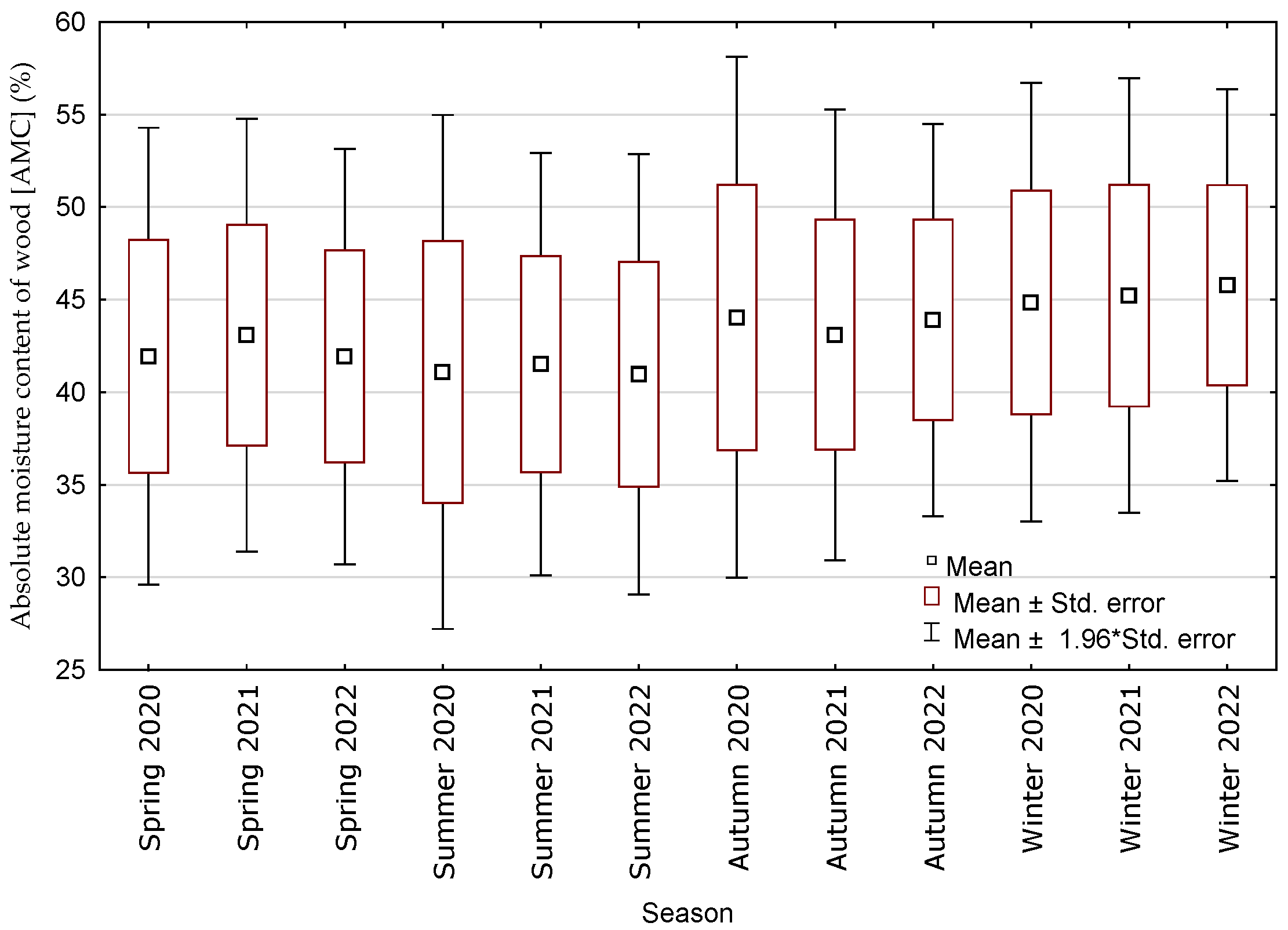

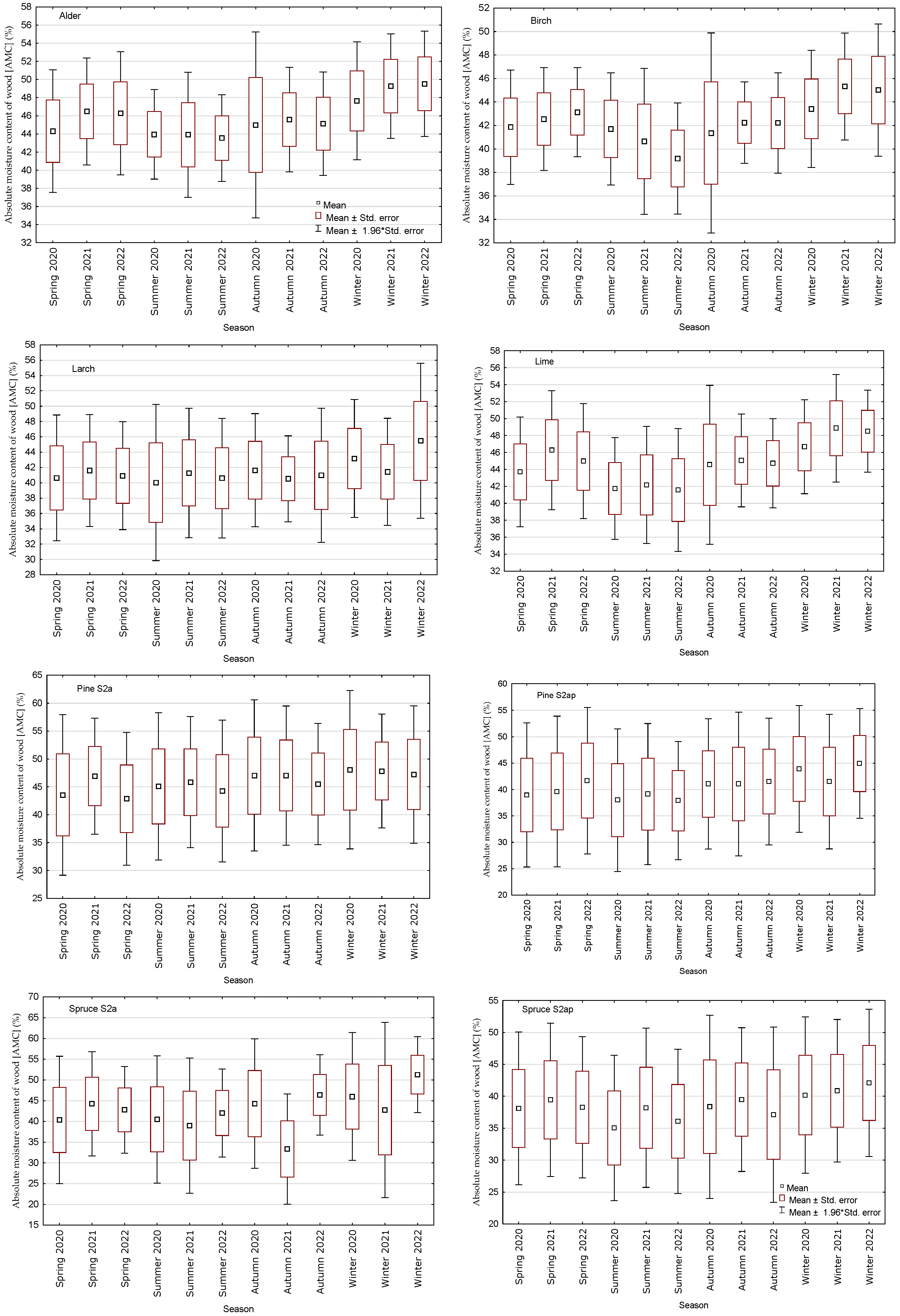

3.3. Absolute Moisture Content of Wood (AMC) Depending on Species, Wood Assortment and Delivery Season

4. Discussion

- Resulting from different weather conditions in temperate climates in northern Poland, where there is usually high relative humidity of the air in autumn and winter, and lower in spring and summer [39].

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Greulich, F. Transportation networks in forest harvesting: Early development of the theory. In Proceedings of the International Seminar on New Roles of Plantation Forestry Requiring Appropriate Tending and Harvesting Operations, Tokyo, Japan, 29 September–5 October 2002; Yoshimura, T., Ed.; pp. 57–65. Available online: http://faculty.washington.edu/greulich/Documents/IUFRO2002Paper.pdf (accessed on 4 May 2025).

- Devlin, G.J.; McDonnell, K.; Ward, S. Timber haulage routing in Ireland: An analysis using GIS and GPS. J. Transp. Geogr. 2008, 16, 63–72. [Google Scholar] [CrossRef]

- Devlin, G.J.; McDonnell, K.M. Assessing real time GPS asset tracking for timber haulage. Open Transp. J. 2009, 3, 78–86. [Google Scholar] [CrossRef]

- McDonald, T.P.; Haridass, K.; Valenzuela, J. Mileage savings from optimization of coordinated trucking. In Proceedings of the 2010 COFE: 33rd Annual Meeting of the Council on Forest Engineering; Auburn, AL, USA, 6–9 June 2010, Mitchell, D., Gallagher, T., Eds.; Available online: https://research.fs.usda.gov/treesearch/41837 (accessed on 4 May 2025).

- Acuna, M.; Mirowski, L.; Ghaffariyan, M.R.; Brown, M. Optimizing transport efficiency and costs in Australian wood chipping operations. Biomass Bioenergy 2012, 46, 291–300. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Acuna, M.; Brown, M. Analysing the effect of five operational factors on forest residue supply chain costs: A case study in Western Australia. Biomass Bioenergy 2013, 59, 486–493. [Google Scholar] [CrossRef]

- Trzciński, G.; Moskalik, T.; Wojtan, R. Total weight and axle loads of truck units in the transport of timber depending on the timber cargo. Forests 2018, 9, 164. [Google Scholar] [CrossRef]

- Shaffer, R.M.; Stuart, W.B. A Checklist for Efficient Log Trucking. Virginia Cooperative Extension. 1998. USA. Available online: https://pdfs.semanticscholar.org/e6f8/f30602317d743b8c035bcdb27df9d99e52db.pdf (accessed on 4 May 2025).

- Sosa, A.; Klvac, R.; Coates, E.; Kent, T.; Devlin, G. Improving Log Loading Efficiency for Improved Sustainable Transport within the Irish Forest and Biomass Sectors. Sustainability 2015, 7, 3017–3030. [Google Scholar] [CrossRef]

- Hamsley, A.; Greene, W.G.; Siry, J.; Mendell, B. Improving timber trucking performance by reducing variability of log truck weights. South. J. Appl. For. 2007, 31, 12–16. [Google Scholar] [CrossRef]

- Brown, M. The Impact of Tare Weight on Transportation Efficiency in Australian Forest Operations. CRC for Forestry, Harvesting and Operations Bulletin 3, December 2008; University of the Sunshine Coast: Queenslan, Australia, 2008; Available online: https://research.usc.edu.au/esploro/outputs/workingPaper/The-impact-of-tare-weight-on/99450382202621 (accessed on 4 May 2025).

- Lukason, O.; Ukrainski, K.; Varblane, U. Economic benefit of maximum truck weight regulation change for Estonian forest sektor. Veokite täismassi regulatsiooni muutmise majanduslikud mõjud eesti metsatööstuse sektorile. Est. Discuss. Econ. Policy 2011, 19, 2. [Google Scholar] [CrossRef]

- Liimatainen, H.; Pöllänen, M.; Nykänen, L. Impacts of increasing maximum truck weight—Case Finland. Eur. Transp. Res. Rev. 2020, 12, 14. [Google Scholar] [CrossRef]

- Palander, T.; Kärhä, K. Potential traffic levels after increasing the maximum vehicle weight in environmentally efficient transportation system: The Case of Finland. J. Sustain. Dev. Energy Water Environ. Syst. 2017, 5, 417–429. [Google Scholar] [CrossRef]

- Wilson, S. Permissible Maximum Weights of Lorries in Europe. Available online: https://www.itf-oecd.org/permissible-maximum-weights-lorries-europe (accessed on 4 May 2025).

- Tymendorf, Ł.; Trzciński, G. Multi-Factorial Load Analysis of Pine Sawlogs in Transport to Sawmill. Forests 2020, 11, 366. [Google Scholar] [CrossRef]

- Statistical Yearbook of Forestry. Statistics Poland. Statistical Office in Białystok, Warsaw. 2024. Available online: https://stat.gov.pl/en/topics/statistical-yearbooks/statistical-yearbooks/statistical-yearbook-of-forestry-2024,12,7.html (accessed on 4 May 2025)(In Polish/English).

- Kozakiewicz, P. Fizyka Drewna w Teorii i Zadaniach (Physic of Wood in Theory and Practice), 4th ed.; Changed; SGGW: Warsaw, Poland, 2012; Available online: https://www.researchgate.net/publication/326557330 (accessed on 4 May 2025). (In Polish)

- Sosa, A.; Acuna, M.; McDonnell, K.; Devlin, G. Controlling moisture content and truck configurations to model and optimise biomass supply chain logistics in Ireland. Appl. Energy 2015, 137, 338–351. [Google Scholar] [CrossRef]

- Koirala, A.; Kizhal, A.R.; Roth, B.E. Perceiving Major Problems in Forest Products Transportation by Trucks and Trailers: A Cross-sectional Survey. Eur. J. Forest Eng. 2017, 3, 23–34. [Google Scholar]

- Kozakiewicz, P.; Tymendorf, Ł.; Trzciński, G. Importance of the Moisture Content of Large-Sized Scots Pine (Pinus sylvestris L.) Roundwood in Its Road Transport. Forests 2021, 12, 879. [Google Scholar] [CrossRef]

- Owusu−Ababio, S.; Schmitt, R. Analysis of Data on Heavier Truck Weights. Transp. Res. Rec. J. Transp. Res. Board 2015, 2478, 82–92. [Google Scholar] [CrossRef]

- Trzciński, G.; Tymendorf, Ł. Axle load on roundwood truck transport unit in relation to load, set type, season and gross vehicle weight. Wood 2020, 65, 210. [Google Scholar] [CrossRef]

- Kärhä, K.; Seuri, M.; Mac Donagh, P.; Acuna, M.; Kanzian, C.; Petković, V.; Robert Renato, C.G.; Costa, L.H.; Cruz, R.C.; Krumov, T.; et al. Overview of Global Long-Distance Road Transportation of Industrial Roundwood. Croat. J. For. Eng. 2024, 45, 217–236. [Google Scholar] [CrossRef]

- PN-91D-95018; Round Wood. Medium-Sized Wood. Common Requirements and Tests. Polish Standardization Committee: Warsaw, Poland, 2002. (In Polish)

- PN-93/D-02002; Round Wood. Classification, Terminology and Symbols. Polish Standardization Committee: Warsaw, Poland, 2002. (In Polish)

- General Directorate of the State Forests. Zarządzenie nr 51 Dyrektora Generalnego Lasów Państwowych z dnia 30.09.2019 r. Regulation No. 51 of the General Director of the State Forests of 30.09.2019; General Directorate of the State Forests: Warsaw, Poland, 2019. Available online: http://drewno.zilp.lasy.gov.pl/drewno/Normy/1._podzia_terminologia_i_symbole_-_ujednolicono_wg_zarz_54-2020.pdf (accessed on 4 May 2025). (In Polish)

- PN-D-95000; Round Wood. Measurement, Volume Calculation and Hallmarking. Polish Standardization Committee: Warsaw, Poland, 2002. (In Polish)

- EN 13183-1:2002; Moisture Content of a Piece of Sawn Timber—Part 1: Determination by Oven Dry Method. Comité Européen de Normalisation (CEN): Brussels, Belgium, 2002. Available online: https://standards.iteh.ai/catalog/standards/cen/ebaf1b83-ed78-4bfe-838f-b02fef750459/en-13183-1-2002 (accessed on 4 May 2025).

- Murphy, K.R.; Myors, B. Statistical Power Analysis: A Simple and General Model for Traditional and Modern Hypothesis Tests, 2nd ed.; Lawrence Erlbaum Associates: London, UK, 2004; Available online: https://cdn.preterhuman.net/texts/unsorted2/Stock%20books%20030/K%20R%20Murphy,%20B%20Myors%20-%20Statistical%20Power%20Analysis.pdf (accessed on 2 May 2025).

- Dixon, P.M.; Garrett, K.A. Sampling ecological information: Choice of sample size, reconsidered. Ecol. Model. 1993, 68, 67–73. [Google Scholar] [CrossRef]

- McDonell, K.M.; Devlin, G.J.; Lyons, J.; Russell, F.; Mortimer, D. Assessment of GPS tracking devices and associated software suitable for real time monitoring of timber haulage trucks. In Annual Report; COFORD: Ireland, UK, 2008; Available online: https://www.coford.ie/media/coford/content/publications/projectreports/annualreports/2008-AR-E.pdf (accessed on 4 May 2025).

- Trzciński, G.; Tymendorf, Ł.; Kozakiewicz, P. Parameters of Trucks and Loads in the Transport of Scots Pine Wood Biomass Depending on the Season and Moisture Content of the Load. Forests 2021, 12, 223. [Google Scholar] [CrossRef]

- Kühmaier, M.; Erber, G. Research trends in European forest fuel supply chains: A review of the last ten years (2007–2016)—Part two: Comminution, transport & logistics. Croat. J. For. Eng. 2018, 39, 139–152. [Google Scholar]

- Millers, M.; Magaznieks, J. Scots Pine (Pinus sylvestris L.) Stem Wood and Bark Moisture and Density Influencing Factors. In Proceedings of the Research for Rural Development, Annual 18th International Scientific Conference Proceedings, Jelgava, Latvia, 16–18 May 2012; Volume 2, pp. 91–96. Available online: https://www2.llu.lv/research_conf/Proceedings/18th_volume2.pdf (accessed on 4 May 2025).

- Tomczak, A.; Jelonek, T. Green density of Scots pine (Pinus sylvestris L.) sapwood coming from selected stands north-western Poland. For. Lett. 2014, 107, 5–9. (In Polish) [Google Scholar]

- Tomczak, A.; Wesołowski, P.; Jelonek, T.; Jakubowski, M. Weight loss and green density changes of Scots pine pulpwood harvested and stored during the summer. Sylwan 2016, 160, 619–626. (In Polish) [Google Scholar]

- Tomczak, K.; Tomczak, A.; Jelonek, T. Effect of Natural Drying Methods on Moisture Content and Mass Change of Scots Pine Roundwood. Forests 2020, 11, 668. [Google Scholar] [CrossRef]

- Korzuchowski, K. Klimat Polski. In Climate of Poland, Edition I; Polish Scientific Publishers PWN: Warsaw, Poland, 2011. (In Polish) [Google Scholar]

- Wagenführ, R. Holzatlas. In Mit 890 Zum Teil Mehrfarbigen Bildern (Wooden Atlas. With 890 Partly Multicolored Pictures); VEB Fachbuchverlag Leipzig: Leipzig, Germany, 2007. (In German) [Google Scholar]

- Shmulsky, R.; Jones, P.D. Forest Products and Wood Science, 6th ed.; Wiley-Blackwell: Chichester, UK; Ames, IA, USA, 2011; ISBN 978-0-8138-2074-3. [Google Scholar]

- Erber, G.; Kanzian, C.; Stampfer, K. Modelling natural drying of European beech (Fagus sylvatica L.) logs for energy based on meteorological data. Scand. J. For. Res 2016, 31, 294–301. [Google Scholar] [CrossRef]

- Beardsell, M.G. Decreasing the Cost of Hauling Timber through Increased Payload. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 1986. Available online: https://vtechworks.lib.vt.edu/handle/10919/53617 (accessed on 4 May 2025).

| Year | 2020 | 2021 | 2022 | Total | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Season Wood species | Spring | Summer | Autumn | Winter | Spring | Summer | Autumn | Winter | Spring | Summer | Autumn | Winter | |

| Beech S2a | 3 | 2 | 20 | 2 | 42 | 43 | 23 | 30 | 14 | 4 | 16 | 12 | 211 |

| Beech S2ap | 6 | 5 | 3 | 0 | 16 | 14 | 5 | 10 | 22 | 11 | 11 | 26 | 129 |

| Birch S2a | 256 | 206 | 89 | 208 | 28 | 36 | 29 | 26 | 38 | 51 | 87 | 30 | 1084 |

| Oak S2a | 0 | 0 | 0 | 0 | 0 | 8 | 4 | 0 | 38 | 26 | 31 | 49 | 156 |

| Oak S2ap | 0 | 0 | 0 | 0 | 0 | 54 | 21 | 0 | 48 | 31 | 43 | 63 | 260 |

| Hornbeam S2a | 24 | 16 | 6 | 9 | 22 | 15 | 9 | 22 | 19 | 10 | 5 | 31 | 188 |

| Lime S2a | 77 | 87 | 128 | 43 | 137 | 115 | 52 | 86 | 76 | 79 | 74 | 103 | 1057 |

| Larch S2a | 23 | 36 | 29 | 37 | 129 | 88 | 15 | 31 | 23 | 29 | 61 | 41 | 542 |

| Alder S2a | 75 | 80 | 98 | 31 | 112 | 146 | 63 | 121 | 34 | 44 | 96 | 39 | 939 |

| Alder S2ap | 17 | 6 | 20 | 0 | 17 | 16 | 21 | 24 | 15 | 9 | 17 | 10 | 172 |

| Aspen S2a | 25 | 15 | 29 | 20 | 30 | 42 | 15 | 15 | 14 | 11 | 0 | 3 | 219 |

| Aspen S2ap | 5 | 12 | 11 | 4 | 7 | 11 | 16 | 23 | 6 | 13 | 7 | 17 | 132 |

| Pine S2a | 438 | 602 | 578 | 188 | 205 | 196 | 175 | 167 | 506 | 294 | 548 | 236 | 4133 |

| Pine S2ap | 118 | 90 | 174 | 95 | 112 | 99 | 87 | 113 | 77 | 83 | 88 | 83 | 1219 |

| Spruce S2a | 154 | 220 | 219 | 67 | 19 | 23 | 22 | 24 | 74 | 160 | 53 | 27 | 1062 |

| Spruce S2ap | 84 | 388 | 193 | 81 | 242 | 278 | 140 | 140 | 223 | 179 | 63 | 88 | 2099 |

| Total | 1305 | 1765 | 1597 | 785 | 1118 | 1184 | 697 | 832 | 1227 | 1034 | 1200 | 858 | 13,602 |

| Measure | Mean | SD | Min | Max | Q1 | Median | Q3 |

|---|---|---|---|---|---|---|---|

| Mass of load (Mg) | 24.95 | 3.36 | 13.92 | 38.20 | 22.66 | 25.02 | 27.24 |

| Solid cubic meter (m3) | 28.18 | 2.40 | 19.00 | 51.29 | 27.90 | 28.00 | 29.00 |

| Mass of 1 m3 of load from weighing the trucks (M1 m3) (Mg·m−3) | 0.89 | 0.12 | 0.49 | 1.46 | 0.81 | 0.90 | 0.97 |

| Absolute moisture content of wood (AMC) (%) | 42.91 | 6.41 | 15.64 | 66.79 | 39.52 | 43.38 | 47.06 |

| Measure | Solid Cubic Meter (m3) | Mass of Load (Mg) | Absolute Moisture Content of Wood (%) | Wood Species | Season Year | Mass of 1 m3 of Load (Mg·m−3) |

|---|---|---|---|---|---|---|

| Solid cubic meter (m3) | x | 0.2382 | - | 0.4442 | - | −0.3283 |

| Mass of load (Mg) | 0.2382 | x | 0.4894 | −0.2673 | 0.2086 | 0.7843 |

| Absolute moisture content of wood (%) | - | 0.4894 | x | −0.1537 | 0.1969 | 0.4320 |

| Wood species | 0.4442 | −0.2673 | −0.1537 | x | −0.0427 | −0.5382 |

| Season year | - | 0.2086 | 0.1969 | −0.0427 | x | 0.2159 |

| Mass of 1 m3 of load (Mg·m−3) | −0.3283 | 0.7843 | 0.4320 | −0.5382 | 0.2159 | x |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trzciński, G.; Tymendorf, Ł. Parameters of Medium-Size Wood Deliveries Depending on the Season, Moisture Content and Assortment of the Load. Forests 2025, 16, 897. https://doi.org/10.3390/f16060897

Trzciński G, Tymendorf Ł. Parameters of Medium-Size Wood Deliveries Depending on the Season, Moisture Content and Assortment of the Load. Forests. 2025; 16(6):897. https://doi.org/10.3390/f16060897

Chicago/Turabian StyleTrzciński, Grzegorz, and Łukasz Tymendorf. 2025. "Parameters of Medium-Size Wood Deliveries Depending on the Season, Moisture Content and Assortment of the Load" Forests 16, no. 6: 897. https://doi.org/10.3390/f16060897

APA StyleTrzciński, G., & Tymendorf, Ł. (2025). Parameters of Medium-Size Wood Deliveries Depending on the Season, Moisture Content and Assortment of the Load. Forests, 16(6), 897. https://doi.org/10.3390/f16060897