How the Scots Pine and Beech Aging Process Affects Wood

Abstract

1. Introduction

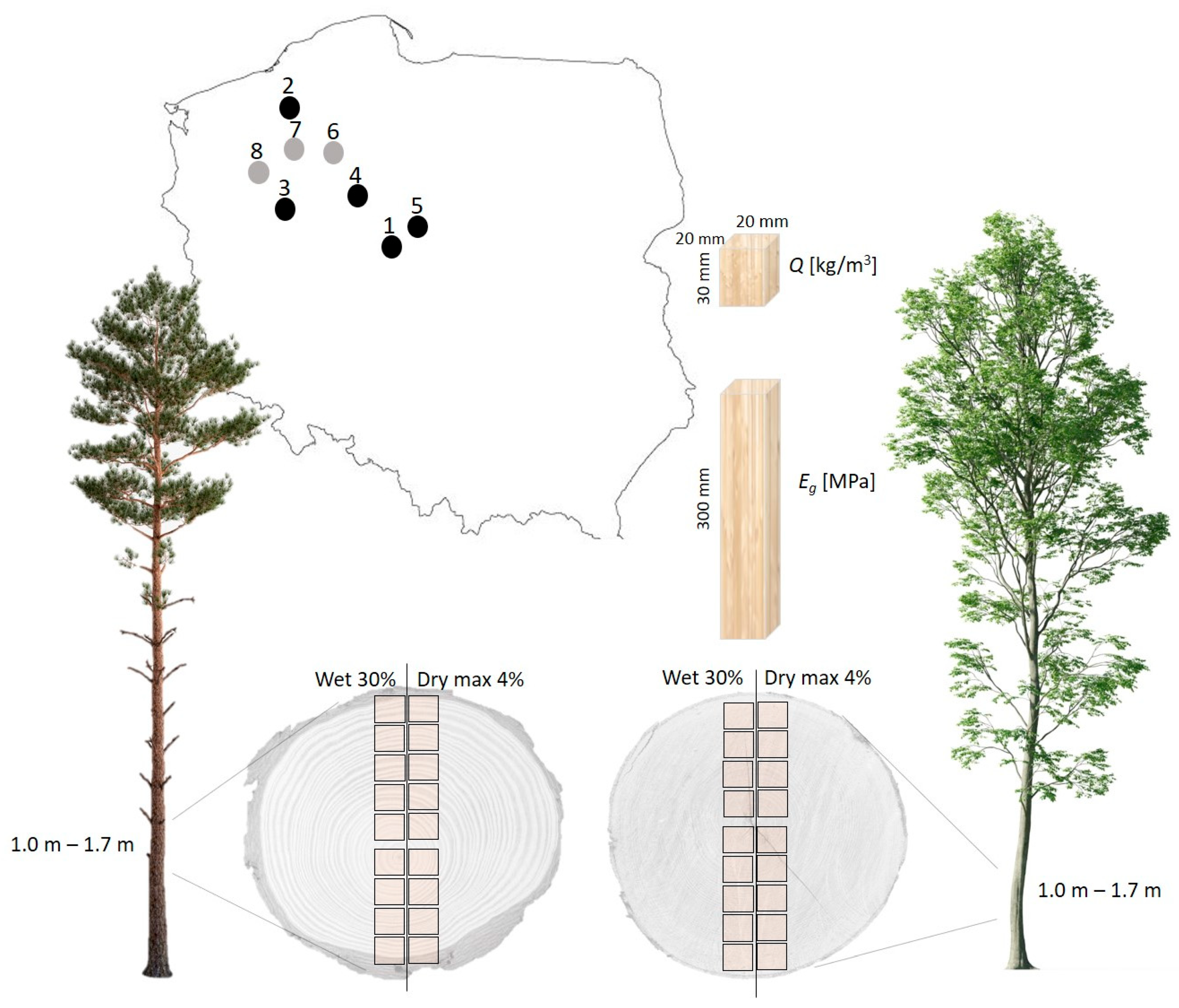

2. Materials and Methods

2.1. Wood Properties of Scots Pine and Beech

2.2. Wood Density of Scots Pine and Beech

- Q—basic density;

- m0—mass of dry wood [kg];

- Vmax—the volume of wet wood in the state of maximum moisture content [m3].

2.3. Modulus of Elasticity of Wood in Bending

- E—modulus of elasticity;

- Pi—load of a given range [N];

- P1—preload [N];

- l—support spacing [mm];

- b—width of the sample [mm];

- h—height of the sample [mm];

- fi—deflection value of the load of a given range [mm];

- f1—deflection value forced by preload [mm].

2.4. Desorption Enhancement

2.5. Statistical Analyses

3. Results

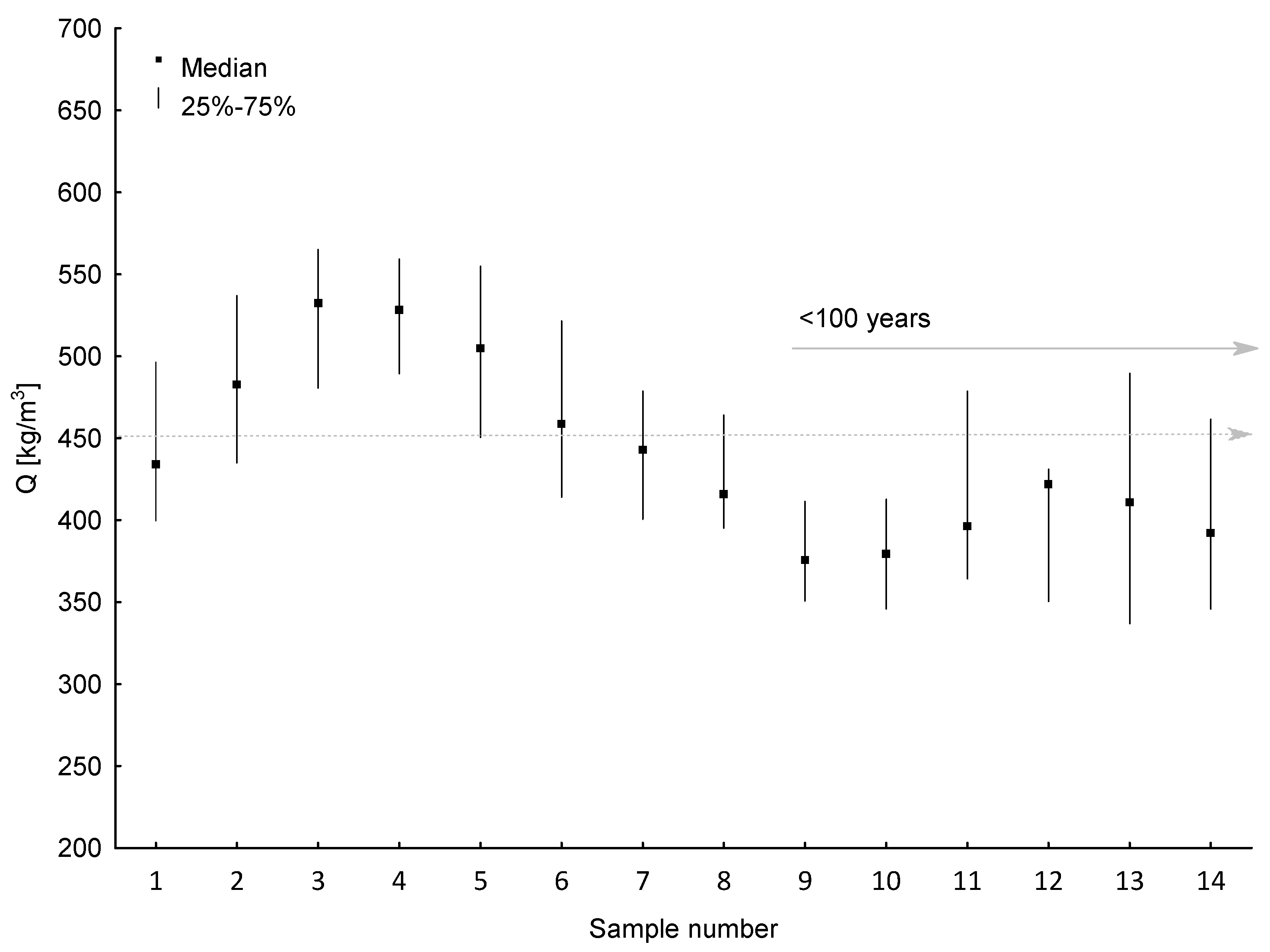

3.1. Wood Density of Beech Wood

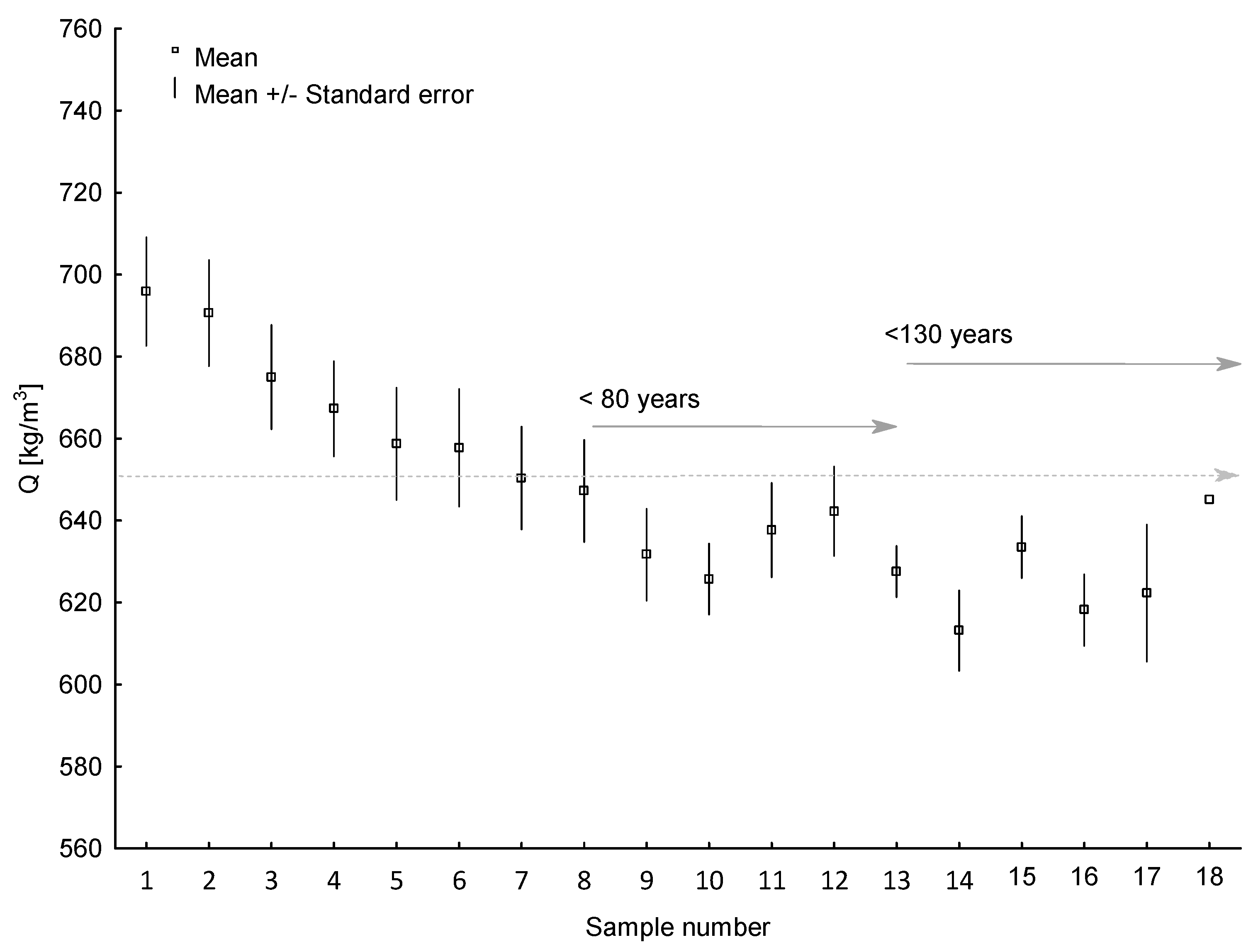

3.2. Wood Density of Scots Pine Wood

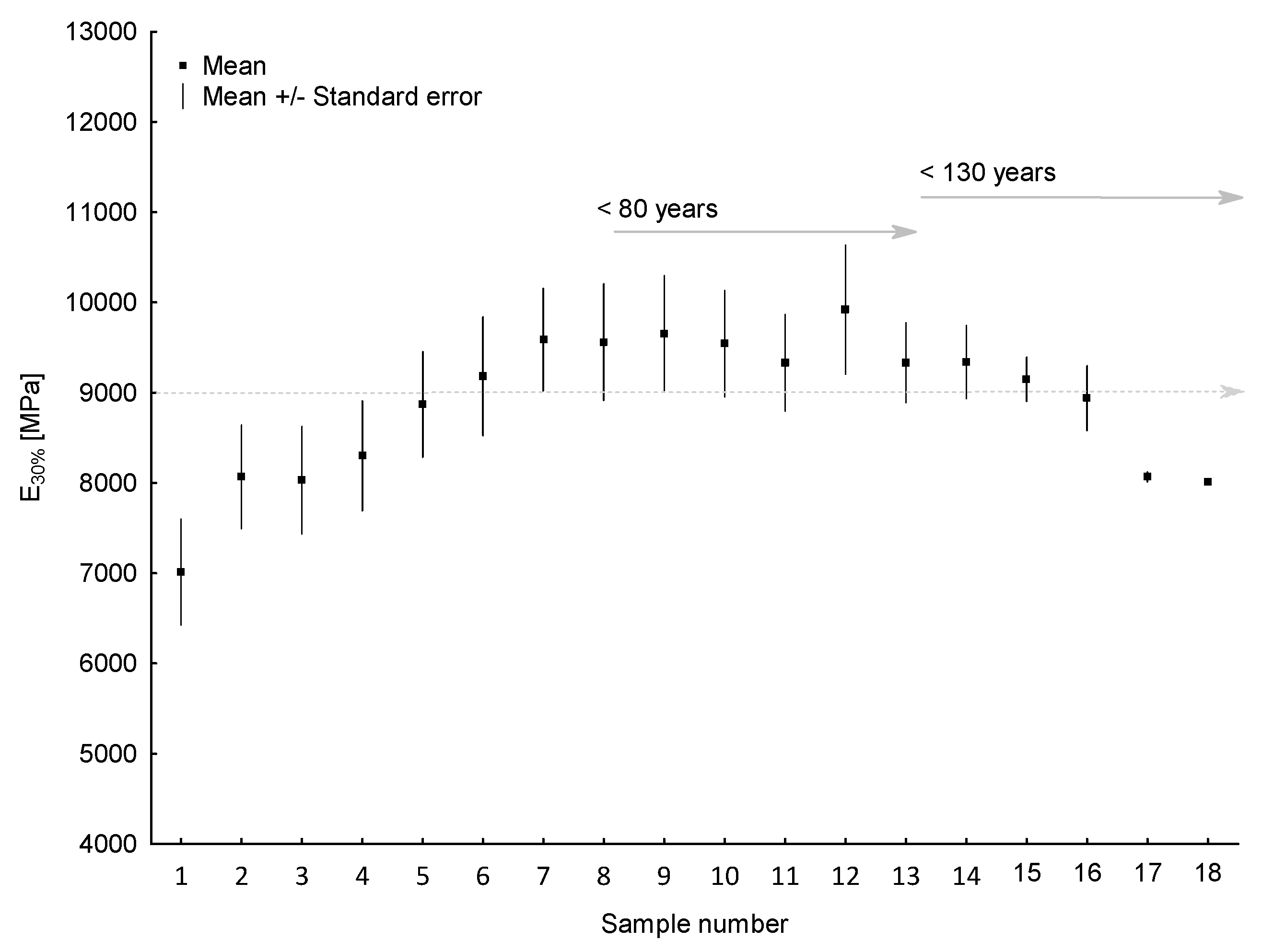

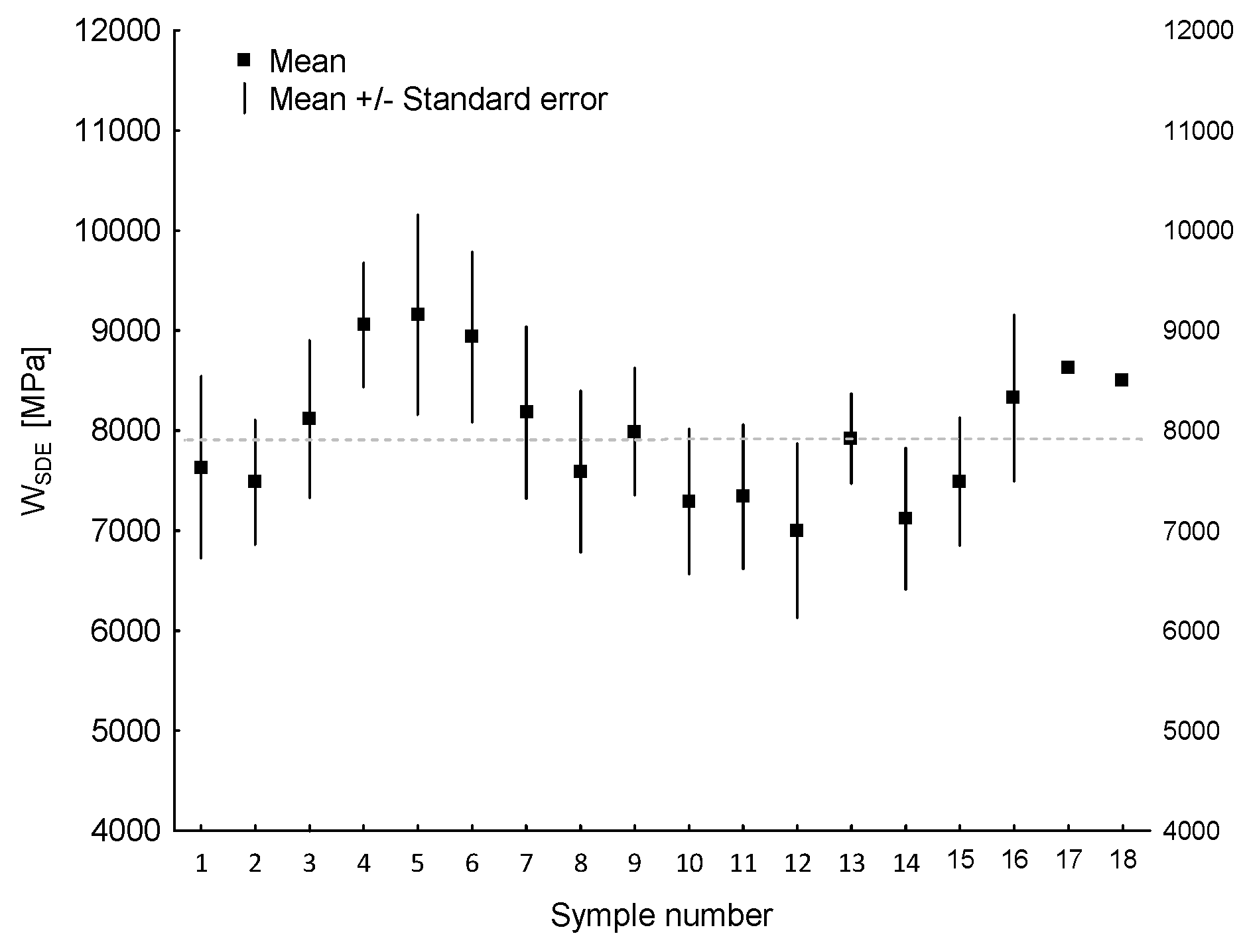

3.3. Modulus of Elasticity of Beech Wood in Bending

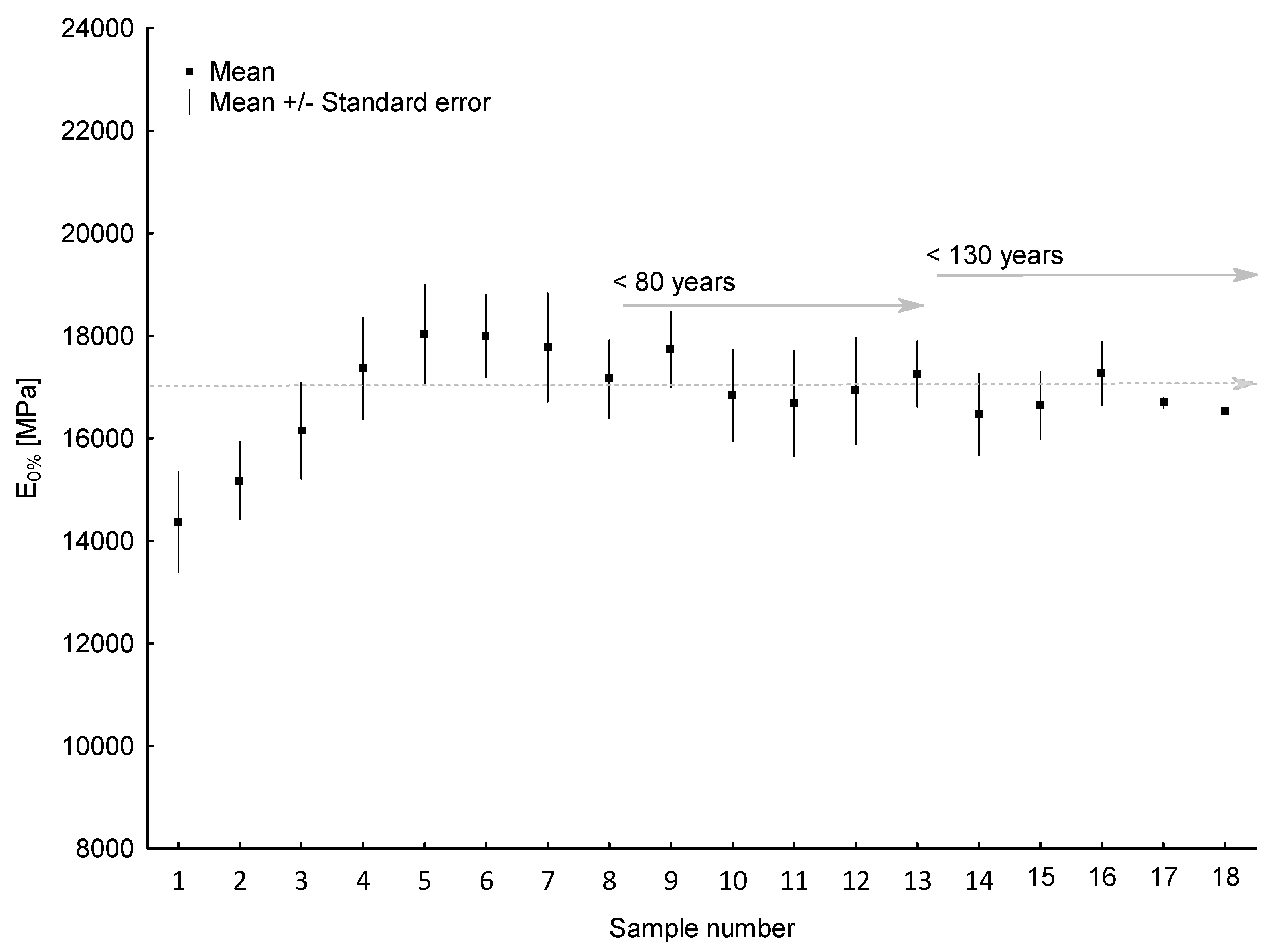

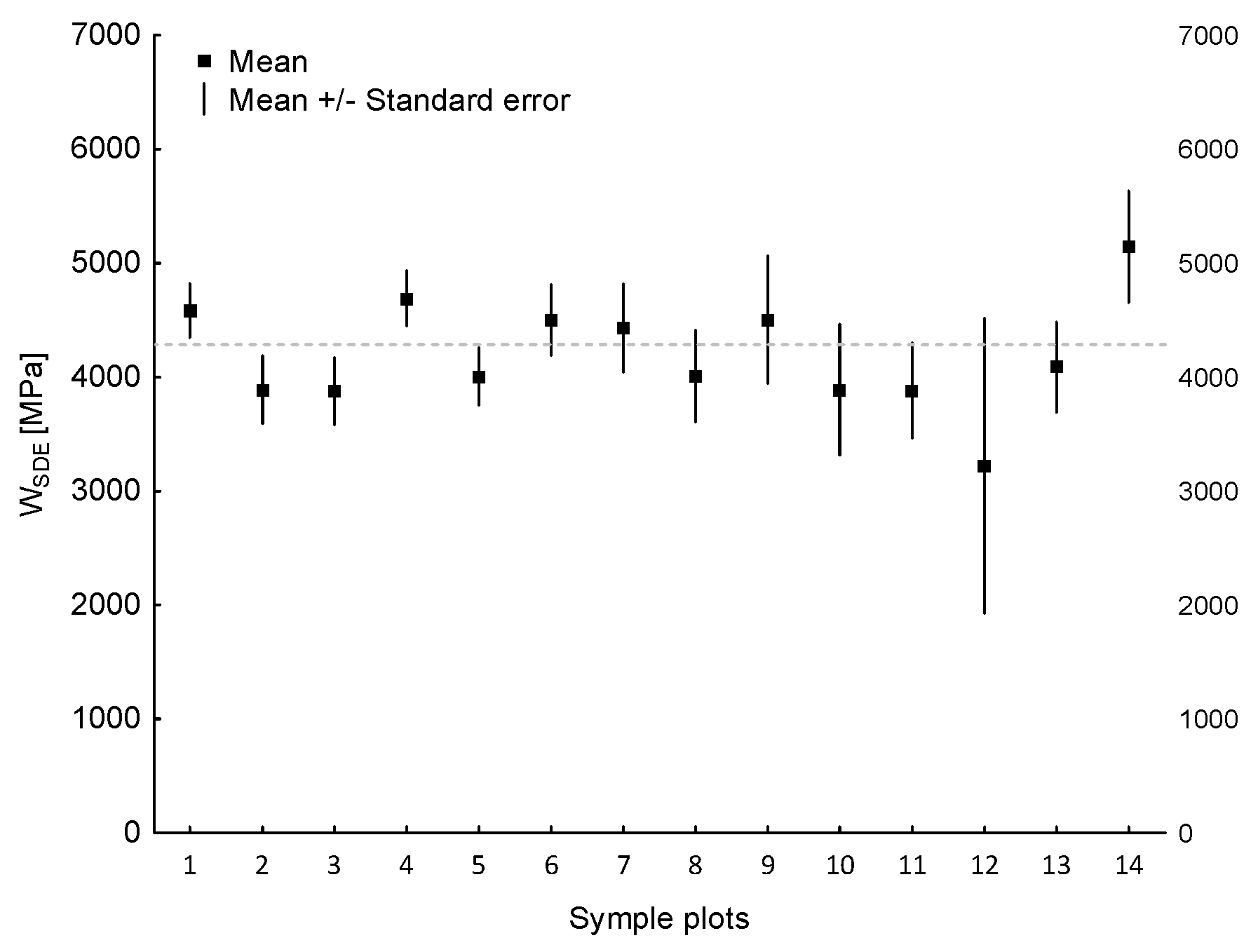

3.4. Modulus of Elasticity of Scots Pine Wood in Bending

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Savidge, R.A.; Barnett, J.R.; Napier, R. (Eds.) Cell and Molecular Biology of Wood Formation; BIOS Scientific: Oxford, UK, 2000. [Google Scholar]

- Zaehle, S. Effect of height on tree hydraulic conductance incompletely compensated by xylem tapering. Funct. Ecol. 2005, 19, 359–364. [Google Scholar] [CrossRef]

- Jelonek, T.; Pazdrowski, W.; Tomczak, A.; Grzywiński, W. Biomechanical stability of pines growing on former farmland in northern Poland. Wood Res. 2012, 57, 31–44. [Google Scholar]

- Jelonek, T. Biomechaniczna Stabilność Drzew a Wybrane Właściwości Fizyczne, Mechaniczne i Strukturalne Ksylemu Sosny Zwyczajnej (Pinus sylvestris L.) Wyrosłej w Warunkach Gruntów Porolnych i Leśnych; Rozprawy naukowe 455; Wydawnictwo Uniwersytetu Przyrodniczego: Poznań, Poland, 2013. [Google Scholar]

- Brutovská, E.; Sámelová, A.; Dušička, J.; Mičieta, K. Ageing of trees: Application of general ageing theories. Ageing Res. Rev. 2013, 12, 855–866. [Google Scholar] [CrossRef]

- Kollmann, F.F.P.; Wilfred, A.C.J. Principles of Wood Science and Technology: Solid Wood; Springer: Berlin/Heidelberg, Germany, 1968. [Google Scholar]

- Vacek, Z.; Prokůpková, A.; Vacek, S.; Cukor, J.; Bílek, L.; Gallo, J.; Bulušek, D. Silviculture as a tool to support stability and diversity of forests under climate change: Study from Krkonoše Mountains. Cent. Eur. For. J. 2020, 66, 116–129. [Google Scholar] [CrossRef]

- Vacek, Z.; Vacek, S.; Cukor, J. European forests under global climate change: Review of tree growth processes, crises and management strategies. J. Environ. Manag. 2023, 332, 117353. [Google Scholar] [CrossRef] [PubMed]

- Zeidler, A.; Borůvka, V.; Brabec, P.; Tomczak, K.; Bedřich, J.; Vacek, Z.; Cukor, J.; Vacek, S. The possibility of using non-native spruces for Norway Spruce wood replacement—A case study from the Czech Republic. Forests 2024, 15, 255. [Google Scholar] [CrossRef]

- Cukor, J.; Vacek, Z.; Vacek, S.; Linda, R.; Podrázský, V. Biomass productivity, forest stability, carbon balance, and soil transformation of agricultural land afforestation: A case study of suitability of native tree species in the submontane zone in Czechia. CATENA 2022, 210, 105893. [Google Scholar] [CrossRef]

- Borecki, T.; Orzechowski, M.; Stępień, E.; Wójcik, R. Expected impact of climate change on forest ecosystems and its consequences in forest management planning. Sylwan 2017, 161, 531–538. [Google Scholar]

- IPCC. Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Netherer, S.; Schopf, A. Potential effects of climate change on insect herbivores in European forests—General aspects and the pine processionary moth as specific example. For. Ecol. Manag. 2010, 259, 831–838. [Google Scholar] [CrossRef]

- Brzeziecki, B.; Keczyński, A.; Zajączkowski, J.; Drozdowski, S.; Gawron, L.; Buraczyk, W.; Bielak, K.; Szeligowski, H.; Dzwonkowski, M. Threatened tree species of the Białowieża National Park (the Strict Reserve). Sylwan 2012, 156, 252–261. [Google Scholar]

- Drozdowski, S.; Brzeziecki, B.; Żybura, H.; Żybura, B.; Gawron, L.; Buraczyk, W.; Zajączkowski, J.; Bolibok, L.; Szeligowski, H.; Bielak, K.; et al. Long–term dynamics of old–growth stands in the managed part of the Białowieża Forest: Increasing and declining tree species. Sylwan 2012, 156, 663–671. [Google Scholar]

- Wójkiewicz, B.; Cavers, S.; Wachowiak, W. Current approaches and perspectives in population genetics of Scots pine (Pinus sylvestris L.). For. Sci. 2016, 62, 343–354. [Google Scholar] [CrossRef]

- Brichta, J.; Vacek, S.; Vacek, Z.; Cukor, J.; Mikeska, M.; Bílek, L.; Šimůnek, V.; Gallo, J.; Brabec, P. Importance and Potential of Scots Pine (Pinus sylvestris L.) in 21 St Century. Cent. Eur. For. J. 2023, 69, 3–20. [Google Scholar]

- Statistical Office in Białystok. Statistical Yearbook of Forestry 2024; Statistical Office in Białystok: Białystok, Poland, 2024; p. 39. [Google Scholar]

- Vacek, S.; Vacek, Z.; Bílek, L.; Simon, J.; Remeš, J.; Hůnová, I.; Král, J.; Putalova, T.; Mikeska, M. Structure, regeneration and growth of Scots pine (Pinus sylvestris L.) stands with respect to changing climate and environmental pollution. Silva Fenn. 2016, 50, 1564. [Google Scholar] [CrossRef]

- Gao, Y.; Markkanen, T.; Aurela, M.; Mammarella, I.; Thum, T.; Tsuruta, A.; Yang, H.; Aalto, T. Response of water use efficiency to summer drought in a boreal Scots pine forest in Finland. Biogeosciences 2017, 14, 44094422. [Google Scholar] [CrossRef]

- Buras, A.; Schunk, C.; Zeiträg, C.; Herrmann, C.; Kaiser, L.; Lemme, H.; Menzel, A. Are Scots pine forest edges particularly prone to drought-induced mortality? Environ. Res. Let. 2018, 13, 025001. [Google Scholar] [CrossRef]

- Allen, C.D.; Breshears, D.D.; McDowell, N.G. On underestimation of global vulnerability to tree mortality and forest die-off from hotter drought in the Anthropocene. Ecosphere 2015, 6, 129. [Google Scholar] [CrossRef]

- Kharuk, V.I.; Im, S.T.; Dvinskaya, M.L. Decline of spruce (Picea abies) in forests of Belarus. Russ. J. Ecol. 2016, 47, 241–248. [Google Scholar] [CrossRef]

- Haberstroh, S.; Werner, C.; Grün, M.; Kreuzwieser, J.; Seifert, T.; Schindler, D.; Christen, A. Central European 2018 hot drought shifts scots pine forest to its tipping point. Plant Biol. 2022, 7, 1186–1197. [Google Scholar] [CrossRef]

- Mutlu, S.; Osma, E.; Ilhan, V.; Turkoglu, H.I.; Atici, O. Mistletoe (Viscum album) reduces the growth of the Scots pine by accumulating essential nutrient elements in its structure as a trap. Trees 2016, 30, 815–824. [Google Scholar] [CrossRef]

- Jelonek, T.; Tomczak, A.; Jakubowski, M.; Grzywiński, W.; Pazdrowski, W.; Remlein, A.; Jurkiewicz, E. An analysis of the quality and value of timber in pine tree stands representing selected ecotypes of this species in Poland. Ann. WULS SGGW For. Wood Technol. 2016, 95, 20–28. [Google Scholar]

- Tomczak, A.; Pazdrowski, W.; Jelonek, T.; Grzywiński, W. Jakość drewna sosny zwyczajnej (Pinus sylvestris L.). Część I. Charakterystyka wybranych cech i właściwości drewna wpływających na jego jakość. Sylwan 2009, 153, 363–372. [Google Scholar]

- Repola, J. Models for vertical wood density of Scots pine, Norway spruce and birch stems, and their application to determine average wood density. Silva Fenn. 2006, 40, 673–685. [Google Scholar] [CrossRef]

- Tomczak, A.; Jelonek, T.; Zoń, L. Porównanie wybranych właściwości fizycznych drewna młodocianego i dojrzałego sosny zwyczajnej (Pinus sylvestris L.) z drzewostanów rębnych. Sylwan 2010, 154, 809–817. [Google Scholar]

- Wąsik, R.; Michalec, K.; Barszcz, A.; Mudryk, K. Variability of selected macrostructure features, density and compression strength along the grain of “taborz” scots pine wood (Pinus sylvestris L.). Wood 2020, 63, 205. [Google Scholar] [CrossRef]

- Gurau, L.; Cioncia, M.; Mansfield-Williams, H.; Sawyer, G.; Zeleniuc, O. Comparison of the mechanical properties of branch and stem wood for three species. Wood Fiber Sci. 2008, 40, 647–656. [Google Scholar]

- Lindström, H.; Reale, M.; Grekin, M. Using non-destructive testing to assess modulus of elasticity of Pinus sylvestris trees. Scand. J. For. Res. 2009, 24, 247–257. [Google Scholar] [CrossRef]

- Meier, E. WOOD! Identifying and Using Hundreds of Woods Worldwide; The Wood Database: Auckland, New Zealand, 2021. [Google Scholar]

- Hanewinkel, M.; Cullmann, D.A.; Schelhaas, M.J.; Nabuurs, G.J.; Zimmermann, N.E. Climate Change May Cause Severe Loss in the Economic Value of European Forest Land. Nat. Clim. Change 2013, 3, 203–207. [Google Scholar] [CrossRef]

- Gryc, V.; Vavrčík, H.; Gomola, Š. Selected properties of European beech (Fagus sylvatica L.). J. For. Sci. 2008, 54, 418–425. [Google Scholar] [CrossRef]

- BMLFUW. Holzeinschlagsmeldung Über Das Kalenderjahr 2020; BMLFUW: Vienna, Austria, 2021. [Google Scholar]

- Vrška, T.; Adam, D.; Hort, L.; Kolař, T. European beech (Fagus sylvatica L.) and silver fir (Abies alba Mill.) rotation in the Carpathians—A development cycle or a linear trend induced by man? For. Ecol. Manag. 2009, 258, 347–356. [Google Scholar]

- Pramreiter, M.; Grabner, M. The Utilization of European Beech Wood (Fagus sylvatica L.) in Europe. Forests 2023, 14, 1419. [Google Scholar] [CrossRef]

- Dudiak, M. Density of beech (Fagus sylvatica L.) wood through a cross-section of the trunk. Acta Facultatis Xylologiae Zvolen 2023, 65, 5–11. [Google Scholar]

- Wagenführ, R. Holzatlas; Fachbuchverlag: Lepzig, Germany, 2000; pp. 361–362. [Google Scholar]

- Geoffrey, D. Wood and Fibre Morphology. In Pulp and Paper Chemistry and Technology; De Gruyter: Stockholm, Sweden, 2009; Volume 1, p. 320. [Google Scholar]

- Bectaş, I.; Güller, C.; Baştürk, M.A. Principal mechanical properties of eastern beech wood (Fagus orientalis Lipsky) naturally grown in Andirin Northeastern Mediterranean Region of Turkey. Turk. J. Agric. For. 2002, 26, 147–154. [Google Scholar]

- Mišíková, O. The hardness and density of beech wood from necrotic wounds and opposite wood. In Proceedings of the 5th International Symposium Wood Structure of Properties ’06, Sliač-Sielnica, Slovakia, 3–6 September 2006; Arbora Publishers: Zvolen, Slovakia, 2006; pp. 309–311. [Google Scholar]

- Tarasiuk, S.; Jednoralski, G. Zmienność, jakość hodowlana i właściwości fizyczno–mechaniczne drewna trzech pochodzeń buka. Sylwan 2005, 3, 42–49. [Google Scholar]

- Aicher, S.; Hirsch, M.; Christian, Z. Hybrid cross-laminated timber plates with beech wood cross-layers. Constr. Build. Mater. 2016, 124, 1007–1018. [Google Scholar] [CrossRef]

- Brunetti, M.; Nocetti, M.; Pizzo, B.; Negro, F.; Aminti, G.; Burato, P.; Cremonini, C.; Zanuttini, R. Comparison of different bonding parameters in the production of beech and combined beech-spruce CLT by standard and optimized tests methods. Constr. Build. Mater. 2020, 265, 120168. [Google Scholar] [CrossRef]

- Hematabadi, H.; Madhoushi, M.; Khazaeian, A.; Ebrahimi, G. Structural performance of hybrid poplar-beech cross-laminated-timber (CLT). J. Build. Eng. 2021, 44, 102959. [Google Scholar] [CrossRef]

- Sciomenta, M.; Spera, L.; Bedon, C.; Rinaldi, V.; Fragiacomo, M.; Romagnoli, M. Mechanical characterization of novel homogeneous beech and hybrid beech-corsican pine thin cross-laminated timber panels. Constr. Build. Mater. 2021, 271, 121589. [Google Scholar] [CrossRef]

- Aicher, S.; Ohnesorge, D. Shear strength of glued laminated timber made from european beech timber. Eur. J. Wood Wood Prod. 2011, 69, 143–154. [Google Scholar] [CrossRef]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Ehrhart, T.; Steiger, R.; Lehmann, M.; Frangi, A. European beech (Fagus sylvatica L.) glued laminated timber: Lamination strength grading, production and mechanical properties. Eur. J. Wood Wood Prod. 2020, 78, 971–984. [Google Scholar] [CrossRef]

- Jauk, G.; Nöstler, M.; Fingerlos, B.; Zeman, R.; Gruber, B.; Pfeffer, C. BSP-Special 2021; Holzkurier: Vienna, Austria, 2021. [Google Scholar]

- Stepinac, M.; Rajčić, V.; Hunger, F.; van de Kuilen, J.W.G. Glued-in rods in beech laminated veneer lumber. Eur. J. Wood Wood Prod. 2016, 74, 463–466. [Google Scholar] [CrossRef]

- Benthien, J.T.; Riegler, M.; Engehausen, N.; Nopens, M. Specific dimensional change behavior of laminated beech veneer lumber (baubuche) in terms of moisture absorption and desorption. Fibers 2020, 8, 47. [Google Scholar] [CrossRef]

- Grönquist, P.; Weibel, G.; Leyder, C.; Frangi, A. Calibration of electrical resistance to moisture content for beech laminated veneer lumber “BauBuche S” and “BauBuche Q”. Forests 2021, 12, 635. [Google Scholar] [CrossRef]

- Zimmermann, M.; Raßbach, H. A study of the deformation behaviour of veneers resulting from water storage (A methodological approach for determining the swelling characteristic using the example of European beech veneer). Eur. J. Wood Wood Prod. 2018, 76, 1677–1683. [Google Scholar] [CrossRef]

- Fabbri, A.; Minghini, F.; Tullini, N. Monotonic and cyclic pull-pull tests on dowel-nut connector in laminated veneer lumber made of European beech wood. Constr. Build. Mater. 2022, 359, 129461. [Google Scholar] [CrossRef]

- Kubík, P.; Šebek, F.; Krejčí, P.; Brabec, M.; Tippner, J.; Dvořáček, O.; Lechowicz, D.; Frybort, S. Linear woodcutting of European beech: Experiments and computations. Wood Sci. Technol. 2023, 57, 51–74. [Google Scholar] [CrossRef]

- Rohumaa, A.; Viguier, J.; Girardon, S.; Krebs, M.; Denaud, L. Lathe check development and properties: Effect of log soaking temperature, compression rate, cutting radius and cutting speed during peeling process of European Beech (Fagus sylvatica L.) veneer. Eur. J. Wood Wood Prod. 2018, 76, 1653–1661. [Google Scholar] [CrossRef]

- Hering, S.; Keunecke, D.; Niemz, P. Moisture-dependent orthotropic elasticity of beech wood. Wood Sci. Technol. 2012, 46, 927–938. [Google Scholar] [CrossRef]

- Hering, S.; Niemz, P. Moisture-dependent, viscoelastic creep of European Beech wood in longitudinal direction. Eur. J. Wood Wood Prod. 2012, 70, 667–670. [Google Scholar] [CrossRef]

- Ozyhar, T.; Hering, S.; Niemz, P. Moisture-dependent elastic and strength anisotropy of European Beech wood in tension. J. Mater. Sci. 2012, 47, 6141–6150. [Google Scholar] [CrossRef]

- Kraft, G. Beiträge zur Lehre von den Durchforstungen, Schlagstellungen und Lichtungshieben; Klindworth: Hannover, Germany, 1884; pp. 85–130. [Google Scholar]

- Van Laar, A.; Akça, A. Forest Mensuration; Springer: Dordrecht, The Netherlands, 2007; pp. 95–147. [Google Scholar]

- ISO 13910:2014; Timber Structures. Strength Graded Timber. Test Methods for Structural Properties. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 13061-2:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens. Part 2: Determination of Density for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- PN-EN 380:1998; Timber Structures—Test Methods—General Principles for Static Load Testing. European Committee for Standardization: Brussels, Belgium, 1998.

- PN-EN 408:2004; Konstrukcje Drewniane—Drewno Konstrukcyjne Lite i Klejone Warstwowo—Oznaczanie Niektórych Właściwości Fizycznych i Mechanicznych. Polski Komitet Normalizacyjny: Warsaw, Poland, 2004.

- ASTM D143-94; Standard Test Methods for Small Clear Specimens of Timber. ASTM International: West Conshohocken, PA, USA, 2000.

- Jeronimidis, G.; Barnett, J.R. (Eds.) Wood Quality and Its Biological Basis; Sheffield Biological Sciences Series, Wood Quality and Its Biological Basis; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Record, S.J. The Mechanical Properties of Wood. Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber Testing; Hardpress Publications: Madrid, Spain, 2022. [Google Scholar]

- Mäkelä, H. Wood properties of Scots pine (Pinus sylvestris) and Norway spruce (Picea abies) in relation to age, site, and genetic factors. Scand. J. For. Res. 2000. [Google Scholar]

- Verma, S.K.; Kuroda, T. Wood properties of Beech (Fagus sylvatica L.) and their suitability for various applications. Wood Sci. Technol. 2008, 42, 391–404. [Google Scholar]

- U.S. Forest Service. Wood Quality of Beech and Pine Trees from the Northeastern United States; U.S. Forest Service Research Paper; U.S. Forest Service: Amboy, WA, USA, 1999.

- Zobel, B.J.; Van Buijtenen, J.P. Wood Variation: Its Causes and Control; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Kiseleva, A.V.; Snegireva, S.N.; Platonov, A.D. Formation of pine wood density depending on the parameters of annual ring and latitudinal zoning. In Proceedings of the October 2021 IOP Conference Series Earth and Environmental Science, Voronezh, Russia, 9–10 September 2021; Volume 875, p. 012035. [Google Scholar] [CrossRef]

- Plomion, C.; Leprovost, G.; Stokes, A. Wood formation in trees. Plant Physiol. 2001, 127, 1513–1523. [Google Scholar] [CrossRef]

- Mencuccini, M.; Grace, J.; Fioravanti, M. Biomechanical and hydraulic determinants of tree structure in Scots pine: Anatomical characteristics. Tree Physiol. 1997, 17, 105–113. [Google Scholar] [CrossRef]

- Fujimoto, T. Evaluation of the age dependent variation of wood properties based on the eigenvalue distribution of near infrared spectra. Chem. Int. Lab. Syst. 2022, 225, 104576. [Google Scholar] [CrossRef]

- Konofalska, E.; Kozakiewicz, P.; Buraczyk, W.; Szeligowski, H.; Lachowicz, H. The technical quality of the wood of Scots pine (Pinus sylvestris L.) of diverse genetic origin. Forests 2021, 12, 619. [Google Scholar] [CrossRef]

- Witkowska, J.; Lachowicz, H. Variability of conventional wood density of Scots pine (Pinus sylvestris L.) depending on the selected factors. Sylwan 2013, 157, 336–347. [Google Scholar]

- Auty, D.; Achim, A.; Macdonald, E.; Cameron, A.D.; Gardiner, B.A. Models for predicting wood density variation in Scots pine. For. Int. J. For. Res. 2014, 87, 449–458. [Google Scholar] [CrossRef]

- Frühwald, A.; Ressel, J.B.; Bernasconi, A. Hochwertiges Brettschnichtholz aus Buchenholz; Abschulssbericht: Hamburg, Germany, 2003; p. 181. [Google Scholar]

- Klement, I.; Vilkovský, P.; Vilkovská, T. Change in selected mechanical properties of beech wood at the contact drying. Materials 2022, 15, 7433. [Google Scholar] [CrossRef]

- Gustafsson, S.-I. The Strength Properties of Swedish Oak and Beech. Drewno. Pr. Nauk. Donies. Komunik. 2010, 53, 183. [Google Scholar]

- Wood Handbook: Wood as an Engineering Material; Centennial edition; General Technical Report FPL; GTR-190; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; Chapter 5; pp. 5.1–5.46.

- Wood Handbook: Wood as an Engineering Material; United States Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010.

- Wood Handbook, Wood as an Engineering Material; USDA Forest Products Lab: Madison, WI, USA, 1999.

- Pearson, R.G.; Gilmore, R.C. Effect of fast growth on the mechanical properties of loblolly pine. For. Prod. J. 1980, 30, 47–54. [Google Scholar]

- Machado, J.; Cruz, H. Within stem variation of maritime pine timber mechanical. Eur. J. Wood Wood Prod. 2005, 63, 154–159. [Google Scholar] [CrossRef]

- Olivar, J.; Rathgeber, C.; Bravo, F. Climate change, tree-ring width and wood density of pines in mediterranean environments. IAWA J. 2015, 36, 257–269. [Google Scholar] [CrossRef]

- Diaconu, D.; Wassenberg, M.; Spiecker, H. Variability of European beech wood density as influenced by interactions between tree-ring growth and aspect. For. Ecosyst. 2016, 3, 6. [Google Scholar] [CrossRef]

- Teskey, R.O.; Hinckley, T.M. Moisture: Effects of Water Stress on Trees. In Stress Physiology and Forest Productivity; Hennessey, T.C., Dougherty, P.M., Kossuth, S.V., Johnson, J.D., Eds.; Springer: Dordrecht, The Netherlands, 1986. [Google Scholar] [CrossRef]

- Polle, A.; Chen, S.L.; Eckert, C.; Harfouche, A. Engineering Drought resistance in forest trees. Front. Plant Sci. 2019, 8, 1875. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Barigah, T.S.; Charrier, O.; Douris, M.; Bonhomme, M.; Herbette, S.; Améglio, T.; Fichot, R.; Brignolas, F.; Cochard, H. Water stress-induced xylem hydraulic failure is a causal factor of tree mortality in beech and poplar. Ann Bot. 2013, 112, 1431–1437. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Bréda, N. Modelling variability of wood density in beech as affected by ring age, radial growth and climate. Trees—Struct. Funct. 2004, 18, 264–276. [Google Scholar]

- van der Maaten, E.; van der Maaten-Theunissen, M.; Spiecker, H. Temporally resolved intra-annual wood density variations in European beech (Fagus sylvatica L.) as affected by climate and aspect. Ann. For. Res. 2012, 55, 113–124. [Google Scholar]

- Hématy, K.; Höfte, H. Cellulose and cell elongation. The expanding cell. Plant. Cell Monogr. 2007, 6, 33–56. [Google Scholar]

- Krauss, A. Ultrastrukturalne uwarunkowania wybranych właściwości mechanicznych drewna sosny i świerku. Rozpr. Nauk. UP Pozn. 2010, 406, 1–115. [Google Scholar]

- Astley, R.J.; Harrington, J.J.; Stol, K.A. Mechanical Modelling of Wood Microstructure, an Engineering approach. IPENZ Trans. 1997, 24, 1. [Google Scholar]

- Schniewind, A.P. Horizontal specifi c gravity variation in tree stems in relations to their support function. For. Sci. 1962, 8, 111–118. [Google Scholar]

- Sperry, J.S.; Hacke, U.G.; Pittermann, J. Size and function in conifer tracheids and angiosperm vessels. Am. J. Bot. 2006, 93, 1490–1500. [Google Scholar] [CrossRef]

| Plot | Tree Number | Height [m] | DBH [cm] | Average Age of Samples | Class of the Stand | GPS |

|---|---|---|---|---|---|---|

| (WGS-84) | ||||||

| 1/S | 1 | 31.0 | 51.5 | 182 | II | N: 52.5770, E: 18.1748 |

| 2 | 30.2 | 50.0 | ||||

| 3 | 28.8 | 48.5 | ||||

| 2/S | 1 | 29.2 | 50.5 | 156 | II | N: 54.2320, E: 16.8884 |

| 2 | 28.5 | 48.5 | ||||

| 3 | 27.0 | 46.0 | ||||

| 3/S | 1 | 29.4 | 49.5 | 162 | II | N: 52.4989, E: 15.9889 |

| 2 | 28.2 | 48.5 | ||||

| 3 | 26.8 | 47.0 | ||||

| 4/S | 1 | 30.5 | 52.5 | 167 | II | N: 52.5358, E: 17.1044 |

| 2 | 29.2 | 50.5 | ||||

| 3 | 27.5 | 48.5 | ||||

| 5/S | 1 | 32.0 | 49.5 | 151 | II | N: 52.6228, E: 17.5698 |

| 2 | 31.2 | 48.5 | ||||

| 3 | 29.6 | 47.0 | ||||

| 6/B | 1 | 32.5 | 66.5 | 170 | II | N: 53.3108, E: 17.1767 |

| 2 | 31.2 | 64.0 | ||||

| 3 | 29.0 | 62.5 | ||||

| 7/B | 1 | 30.6 | 59.5 | 184 | II | N: 53.99078, E: 16.8472 |

| 2 | 29.5 | 58.0 | ||||

| 3 | 27.8 | 56.6 | ||||

| 8/B | 1 | 35.0 | 72.0 | 165 | II | N: 53.4181, E:16.1911 |

| 2 | 33.8 | 70.5 | ||||

| 3 | 32.1 | 68.0 |

| Q [kg/m3] | ||||||

|---|---|---|---|---|---|---|

| Mean | Confidence | Standard Deviation | Minimum | Maximum | ||

| −95% | 95% | |||||

| Total | 652.71 | 646.04 | 659.38 | 52.67 | 524.28 | 792.5 |

| Q [kg/m3] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | Confidence | Standard Deviation | Minimum | Maximum | Q 25 | Median | Q 75 | ||

| −95% | 95% | ||||||||

| Total | 491.41 | 485.8 | 497.03 | 72.28 | 319.33 | 884.81 | 434.16 | 487.66 | 542.02 |

| Modulus of Elasticity | E [MPa] | |||||

|---|---|---|---|---|---|---|

| Mean | Confidence | Standard Deviation | Minimum | Maximum | ||

| −95% | 95% | |||||

| E0% | 16,842 | 16,377 | 17,307 | 3663 | 4150 | 26,133 |

| E30% | 8926 | 8614 | 9237 | 2460 | 2903 | 15,728 |

| Modulus of Elasticity | E [MPa] | |||||

|---|---|---|---|---|---|---|

| Mean | Confidence | Standard Deviation | Minimum | Maximum | ||

| −95% | 95% | |||||

| E0% | 9447.37 | 9132.68 | 9762.06 | 3273.15 | 1770.37 | 16,278.11 |

| E30% | 5412.77 | 5254.21 | 5571.39 | 1649.51 | 859.44 | 9033.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jelonek, T.; Klimek, K.; Naskrent, B.; Tomczak, A.; Jakubowski, M.; Kuźmiński, R.; Szwed, T.; Kopaczyk, J.; Grabowski, D.; Szaban, J. How the Scots Pine and Beech Aging Process Affects Wood. Forests 2025, 16, 772. https://doi.org/10.3390/f16050772

Jelonek T, Klimek K, Naskrent B, Tomczak A, Jakubowski M, Kuźmiński R, Szwed T, Kopaczyk J, Grabowski D, Szaban J. How the Scots Pine and Beech Aging Process Affects Wood. Forests. 2025; 16(5):772. https://doi.org/10.3390/f16050772

Chicago/Turabian StyleJelonek, Tomasz, Katarzyna Klimek, Bartłomiej Naskrent, Arkadiusz Tomczak, Marcin Jakubowski, Robert Kuźmiński, Tomasz Szwed, Joanna Kopaczyk, Daniel Grabowski, and Jarosław Szaban. 2025. "How the Scots Pine and Beech Aging Process Affects Wood" Forests 16, no. 5: 772. https://doi.org/10.3390/f16050772

APA StyleJelonek, T., Klimek, K., Naskrent, B., Tomczak, A., Jakubowski, M., Kuźmiński, R., Szwed, T., Kopaczyk, J., Grabowski, D., & Szaban, J. (2025). How the Scots Pine and Beech Aging Process Affects Wood. Forests, 16(5), 772. https://doi.org/10.3390/f16050772