Pilot Performance Testing of a Battery-Powered Salamander Micro-Skidder in Timber Harvesting

Abstract

1. Introduction

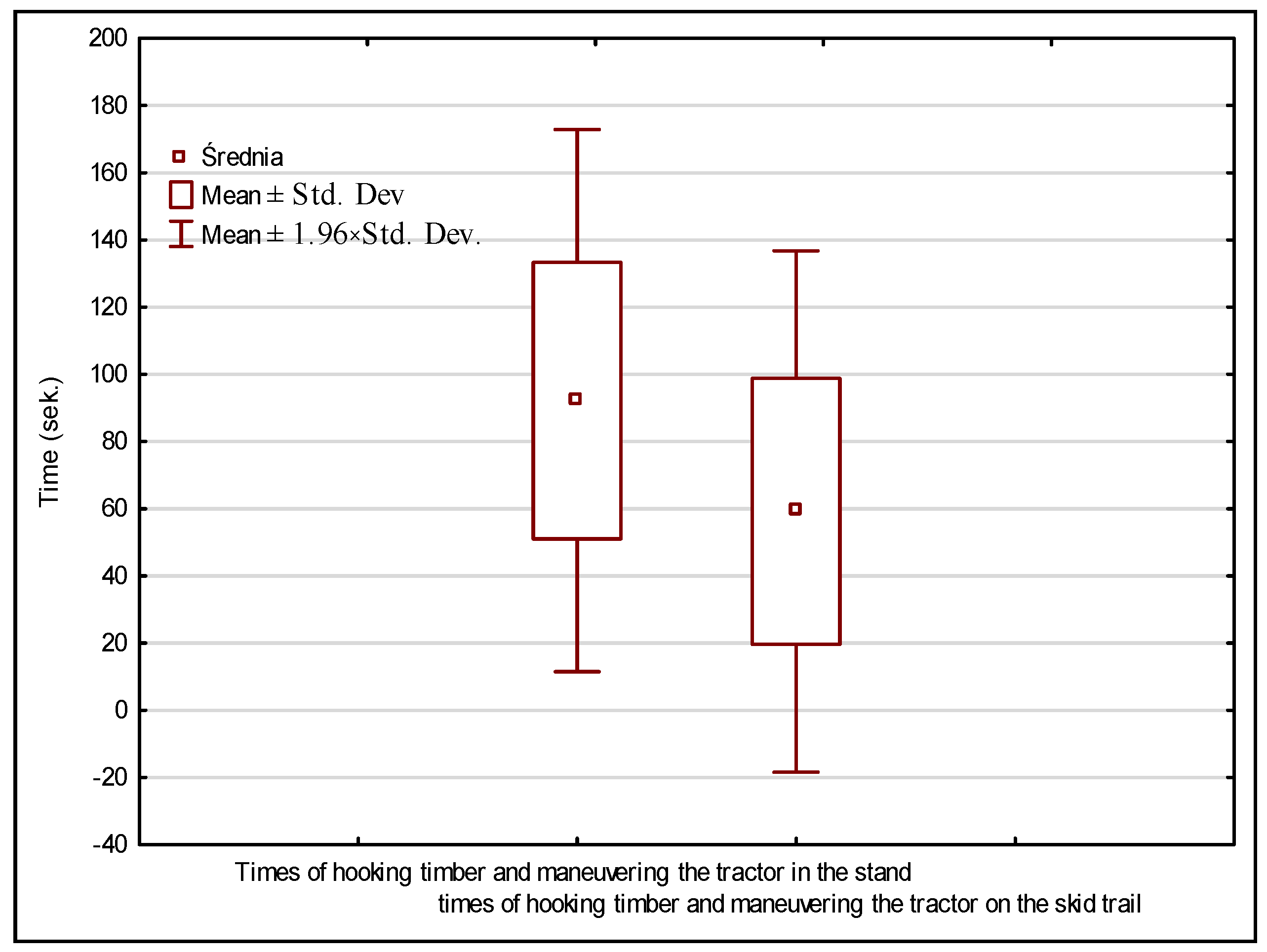

2. Materials and Methods

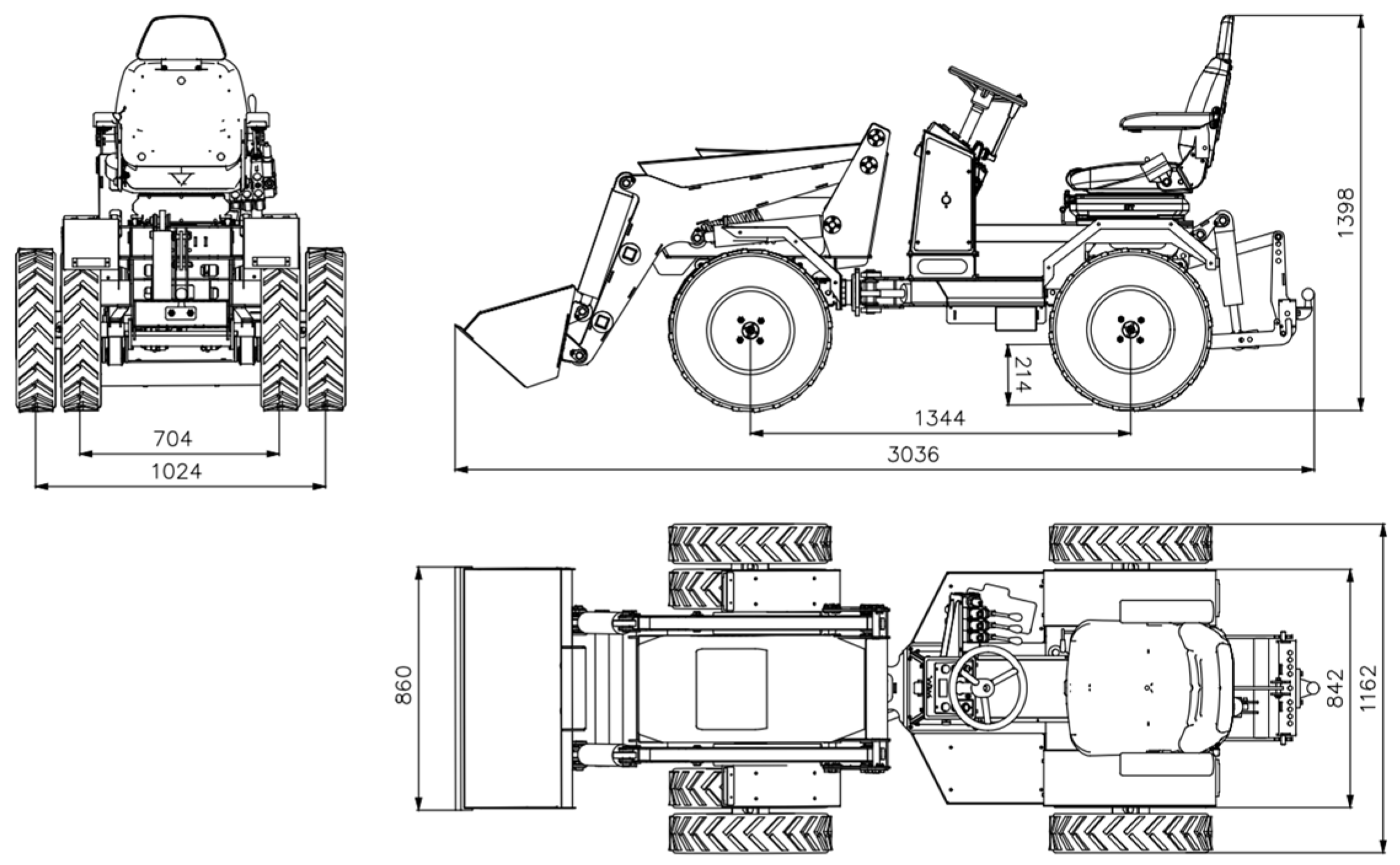

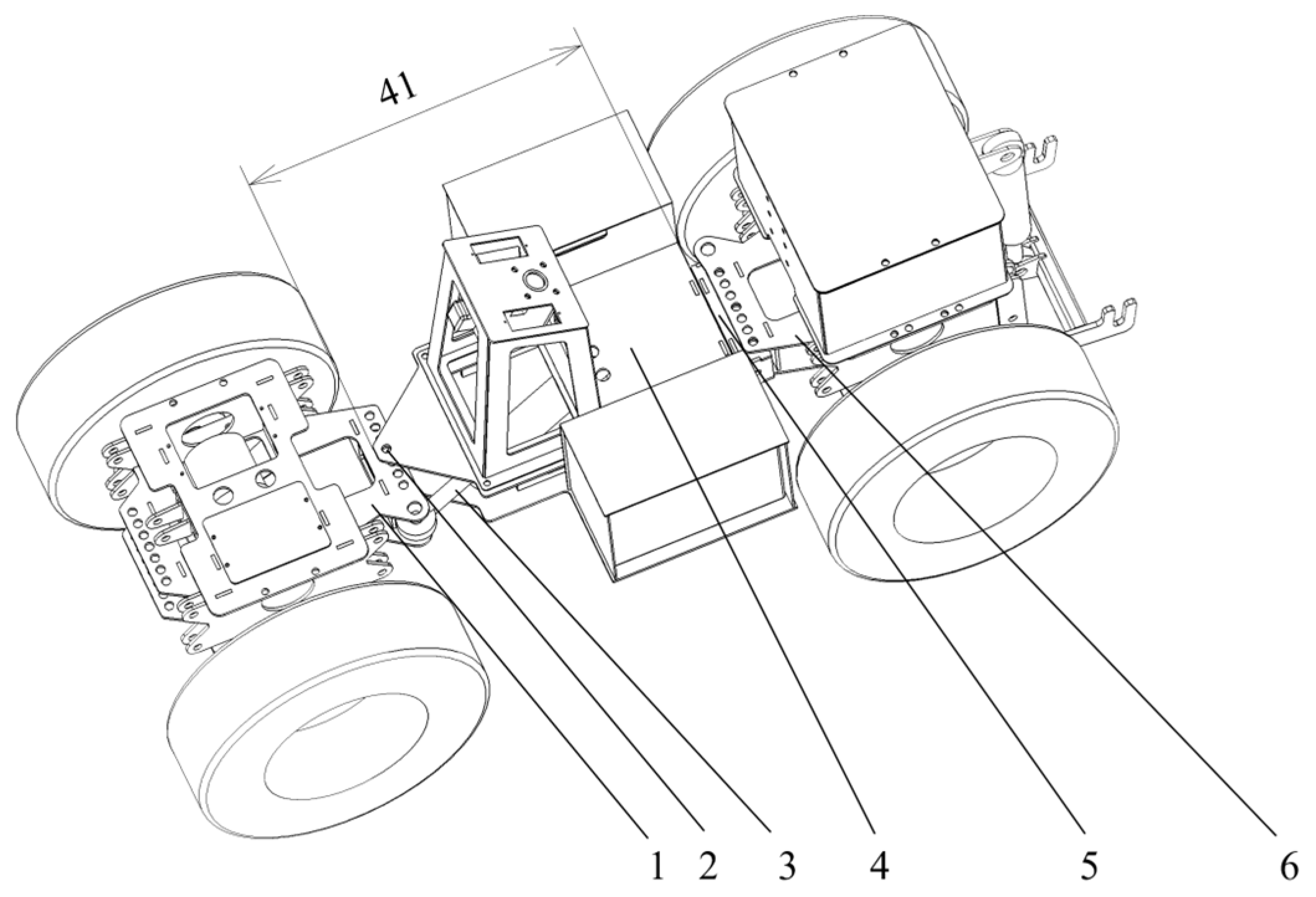

2.1. Salamander 600 Micro-Skidder

2.2. Field Measurements

2.3. Time Intensity of Timber Harvesting

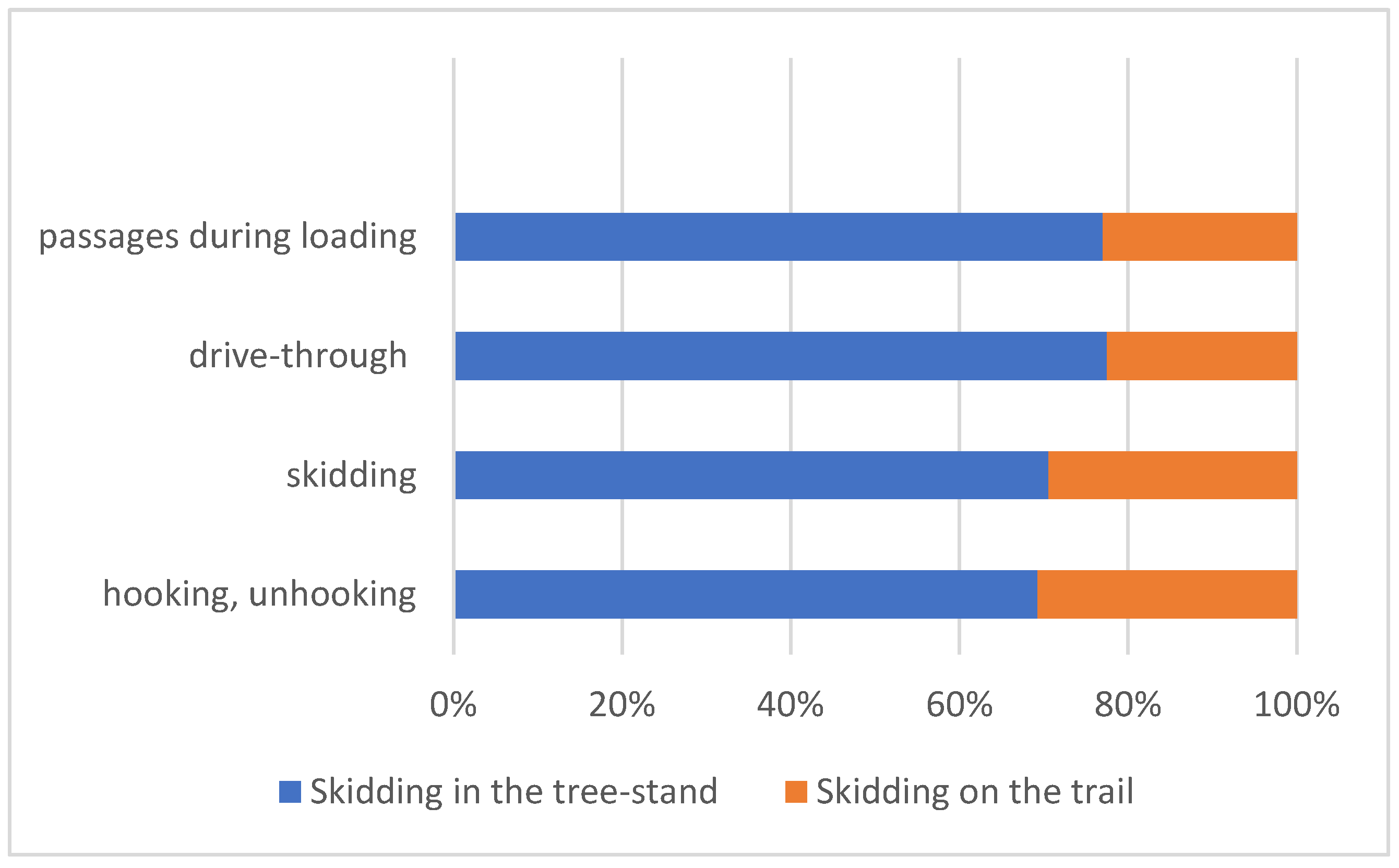

- (a)

- Hooking, unhooking (supportive time)—from the moment the operator grasps the hauling rope until it is hooked or unhooked from the timber to be harvested;

- (b)

- Passages during loading (supportive time)—the act of hooking and unhooking the load, from the moment the operator moves forwards until he stops;

- (c)

- Skidding (work time)—from the time the skidder starts to move from the loading spot until it stops at the next timber loading spot in the forest stand or after the timber has been detached at the landing;

- (d)

- Drive-through (supportive time)—from the start of the unloaded skidder until the skidder has arrived at the next loading point.

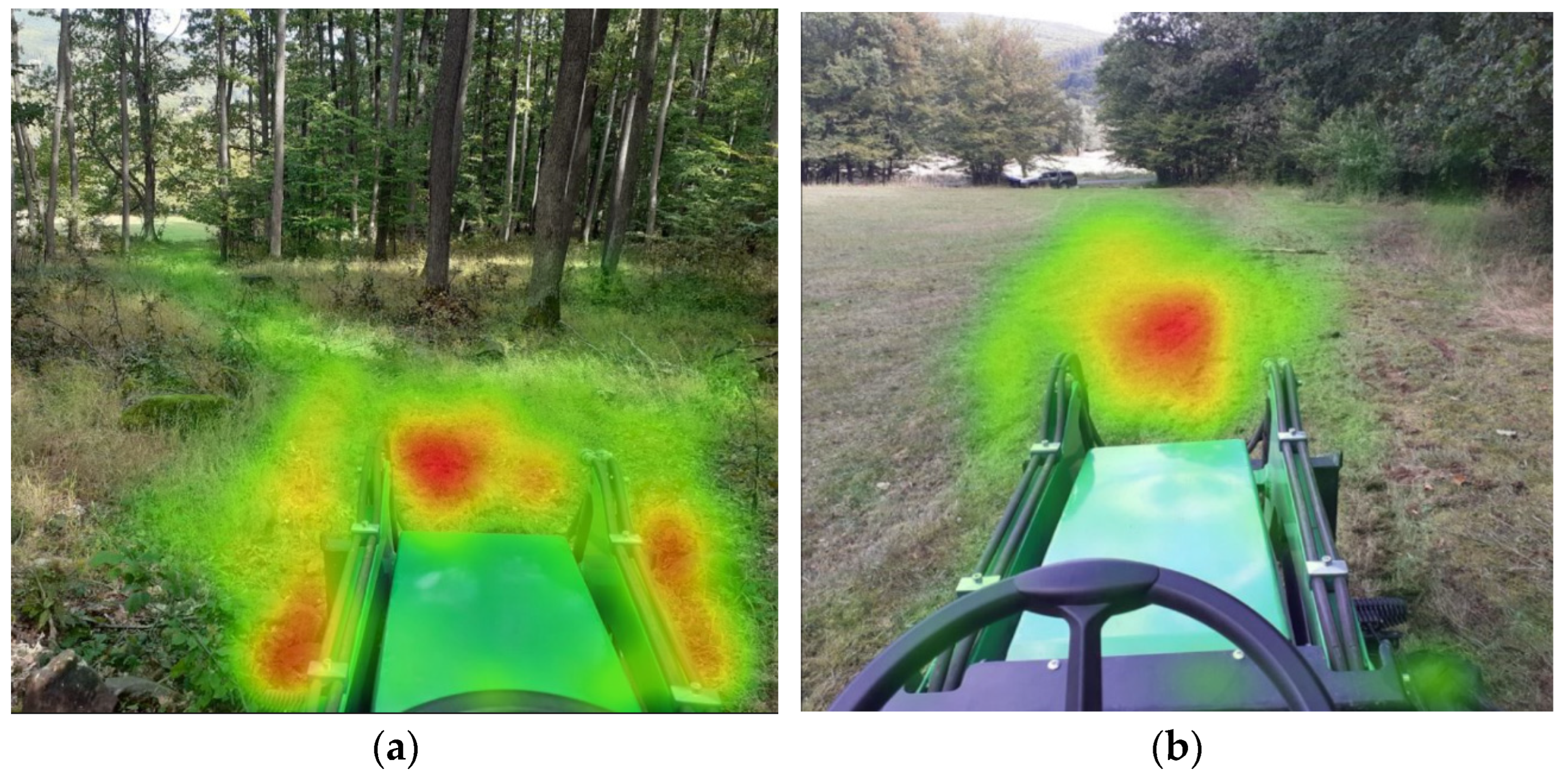

2.4. Analysis of the Operator’s Vision Scene

2.5. Skidder Wheel Slip

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EU | European Union |

| ATV | All-terrain vehicle |

| SSF | Small-scale forestry |

References

- Forest Information System. Available online: https://forest.eea.europa.eu/topics/forest-management/harvest (accessed on 17 March 2025).

- Weiss, G.; Živojinović, I.; Wolfslehner, B. Who owns the forests and how are they managed? In Key Questions on Forests in the EU; Mauser, H., Ed.; European Forest Institute: Joensuu, Finland, 2021; pp. 12–16. [Google Scholar]

- European Forest Owners. European Forest Owners. Available online: https://www.cepf-eu.org/about-us/european-forest-owners (accessed on 16 February 2025).

- Bacescu, N.M.; Cadei, A.; Moskalik, T.; Wiśniewski, M.; Talbot, B.; Grigolato, S. Efficiency Assessment of Fully Mechanized Harvesting System through the Use of Fleet Management System. Sustainability 2022, 14, 16751. [Google Scholar] [CrossRef]

- Frutig, F.; Fahrni, F.; Stettler, A.; Egger, A. Mechanisierte Holzernte in Hanglagen. Wald Holz 2007, 4, 47–52. [Google Scholar]

- Visser, R.; Obi, O.F. Automation and robotics in forest harvesting operations: Identifying near-term Oopportunities. Croat. J. For. Eng. 2021, 42, 13–24. [Google Scholar] [CrossRef]

- Dvořák, J.; Bystrický, R.; Hošková, P.; Hrib, M.; Jarkovská, M.; Kováč, J.; Krilek, J.; Natov, P.; Natovová, L. The Use of Harvester Technology in Production Forests; Folia Forestalia Bohemica. Lesnická Práce: Kostelec nad Černými lesy, Czech Republic, 2011; p. 156. [Google Scholar]

- Kulak, D.; Sowa, J.M.; Szewczyk, G.; Stańczykiewicz, A. The accessibility of post-fire areas for mechanized thinning operations. Forests 2020, 11, 471. [Google Scholar] [CrossRef]

- Russel, F.; Mortimer, D. A Review of Small-Scale Harvesting Systems in Use Worldwide and Their Potential Application in Irish Forestry; COFORD: Dublin, Ireland, 2005; 48p. [Google Scholar]

- Lindroos, O.; Lidestav, G.; Nordfjell, T. Swedish non-industrial private forest owners: A survey of self-employment and equipment investments. Small-Scale For. Econ. Manag. Policy 2005, 4, 409–426. [Google Scholar] [CrossRef]

- Neruda, J.; Simanov, V.; Klvač, R.; Skoupý, A.; Kadlec, J.; Zemanek, T.; Nevrkla, P. Technika a Technologie v Lesnictví: Učební Text Pro Předměty Technika a Technologie v Lesnictví, Základní Procesy Těžby a Dopravy Dříví, Technika a Technologie Lesnej Těžby a Technika a Technologie Dopravy Dříví, 2nd ed.; Mendel University in Brno: Brno, Czech Republic, 2022; p. 272. [Google Scholar]

- Zelená Správa. Správa o Lesnom Hospodárstve v Slovenskej Republike za Rok 2023. Bratislava, 19. November 2024, 78p. Available online: https://www.mpsr.sk/zelena-sprava-2024/123---19415/ (accessed on 16 February 2025).

- Moskalik, T.; Borz, S.A.; Dvořák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdiņš, A.; Styranivsky, O. Timber harvesting methods in eastern European countries: A review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Kärhä, K.; Rönkkö, E.; Gumse, S. Productivity and cutting costs of thinning harvesters. Int. J. For. Eng. 2004, 2, 43–56. [Google Scholar] [CrossRef]

- Mederski, P.S. A comparison of harvesting productivity and costs in thinning operations with and without midfield. For. Ecol. Manag. 2006, 224, 286–296. [Google Scholar] [CrossRef]

- Maksymiak, M.; Grieger, A. Analiza wydajności pracy miniforwadera Vimek 606 TT w trakcie zrywki w drzewostanie trzebieżowym. Tech. Rol. Ogrod. Leśna 2008, 5, 5–7. [Google Scholar]

- Stempski, W.; Pilarek, Z. Charakterystyka zrywki drewna miniforwarderem VIMEK 606 D. Tech. Rol. Ogrod. Leśna 2012, 3, 26–28. [Google Scholar]

- Stringer, J. Moving logs–small scale logging for woodland owners. Ky. Woodl. Mag. 2013, 2, 1–4. [Google Scholar]

- Zimelis, A.; Lazdiņš, A.; Spalva, G. Comparison of productivity of Vimek harvester in birch plantation and young coniferous stands. Res. Rural Dev. 2017, 1, 107–112. [Google Scholar] [CrossRef]

- Halbroock, J.M. Productivity and Cost Analysis of Three Small-Scale Harvest Systems for Fuel Reduction Within the Wildland Urban Intermix of North-Central Idaho. Master’s Thesis, University of Idaho, Moscow, ID, USA, 2005. [Google Scholar]

- Savelli, S.; Cavalli, R.; Baldini, S.; Picchio, R. Small scale mechanization of thinning in artificial coniferous plantation. Croat. J. For. Eng. 2010, 1, 11–21. [Google Scholar]

- Tylek, P. Mikrociągniki typu ATV w leśnictwie. Przegląd Tech. Rol. I Leśnej 2000, 10, 19–21. [Google Scholar]

- Edlund, B.; Lindroos, O.; Nordfjell, T. The effect of rollover protection systems and trailers on quad bike stability. Int. J. For. Eng. 2020, 31, 95–105. [Google Scholar] [CrossRef]

- Kincl, Z. Time study of an all-terrain vehicle (ATV) with a forwarding trailer in the Eagle Mountains in the Czech Republic. J. For. Sci. 2022, 2, 72–82. [Google Scholar] [CrossRef]

- Stańczykiewicz, A.; Kulak, D.; Leszczyński, K.; Szewczyk, G.; Kozicki, P. Effectiveness and injury risk during timber forwarding with a quad bike in early thinning. Forests 2021, 12, 1626. [Google Scholar] [CrossRef]

- Hedderick, D.B. Small Woodlot Harvesting. A Guide for Landowners, Land Managers and Forest Products Operators; Working Woodlot Initiative; Maryland Department of Natural Resources: Wye Mills, MD, USA, 2008; p. 56. [Google Scholar]

- Vaughan, D.; Mackes, K. Characteristics of Colorado forestry contractors and their role in current forest health issues. For. Prod. J. 2015, 5–6, 217–225. [Google Scholar] [CrossRef]

- Yuma, P.J.; Maxson, R.T.; Brown, D. All-terrain vehicles and children: History, injury burden, and prevention strategies. J. Pediatr. Health Care 2006, 20, 67–70. [Google Scholar] [CrossRef]

- Fawcett, V.J.; Tsang, B.; Taheri, A.; Belton, K.; Widder, S.L. A review on all-terrain vehicle safety. Safety 2016, 2, 15. [Google Scholar] [CrossRef]

- Lagerstrom, E.A.; Hibiske, S.; Gilkey, D.; Rosecrance, J. Case Study: The development of safety tip sheets for ATV use in ranching. Safety 2015, 1, 84–93. [Google Scholar] [CrossRef]

- Sennblad, G. Small Scale Forestry in the Forest; The Swedish University of Agricultural Sciences: Garpenberg, Sweden, 1993. [Google Scholar]

- Nordfjell, T. Small off road vehicles for thinning (mini-forwarders, mini-skidders, SKOGIS, ATV, snow mobiles). Small Scale For. 1990, 1, 13–22. [Google Scholar]

- Nordfjell, T. Studies of Mobility and Load Capacity of Small Terrain Vehicles; Research Notes No 265; The Swedish University of Agricultural Sciences, Faculty of Forestry: Garpenberg, Sweden, 1994. [Google Scholar]

- Hutchison, I. Mechanised minimal-impact extraction systems. Q. J. For. 1995, 1, 27–32. [Google Scholar]

- Krilek, J.; Ivanič, F. Konštrukčný Návrh Hnacieho Vývozného Vozíka za Malotraktor; Brno University of Technology: Brno, Czech Republic, 2024; pp. 50–59. [Google Scholar]

- Krilek, J.; Petrenec, S.; Hanes, J. Trojdielny rám traktora: úžitkový vzor č. 9769. Vestník ÚPV SR č. 10/2023. Banská Bystrica: Úrad priemyselného vlastníctva Slovenskej republiky, 2023. 6 s. Available online: https://wbr.indprop.gov.sk/WebRegistre/UzitkovyVzor/Detail/75-2022 (accessed on 5 April 2025).

- Björheden, R. An international nomenclature for forest work study. Forest work study nomenclature. In Proceedings of the IUFRO 1995, XX World Congress „Caring for the Forest: Research in a Changing World”, Tampere, Finland, 6–12 September 1995. [Google Scholar]

- Szewczyk, G.; Sowa, J.M. The accuracy of measurements in a time study of harvester operations. N. Z. J. For. Sci. 2017, 47, 24. [Google Scholar] [CrossRef]

- Granka, L.; Feusner, M.; Lorigo, L. Eye monitoring in online search. In Passive Eye Monitoring; Hammoud, R.I., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 347–372. [Google Scholar] [CrossRef]

- dos Santos, R.O.J.; de Oliveira, J.H.C.; Rocha, J.B.; Giraldi, J.M.E. Eye tracking in neuromarketing: A research agenda for marketing studies. Int. J. Psychol. 2015, 7, 32–42. [Google Scholar] [CrossRef]

- Zoz, F.M.; Grisso, R.D. Traction and Tractor Performance. ASAE Disting. Lect. Ser. Tract. Des. 2003, 27, 24–25. [Google Scholar]

- Kormanek, M.; Gołąb, J. Analysis of Surface Deformation and Physical and Mechanical Parameters of Soils on Selected Skid Trails in the Gorce National Park. Forests 2021, 12, 797. [Google Scholar] [CrossRef]

- Kormanek, M.; Dvořák, J. Use of Impact Penetrometer to Determine Changes in Soil Compactness after Entracon Sioux EH30 Timber Harvesting. Croat. J. For. Eng. 2022, 43, 13. [Google Scholar] [CrossRef]

- Tuschner, J. How to Properly Ballast a Tractor: Increase Traction & Reduce Fuel. 2020. Available online: https://www.farm-equipment.com/articles/18076-how-to-properly-ballast-a-tractor-increase-traction-and-reduce-fuel (accessed on 16 February 2025).

- Giedra, K.; Janulevičius, A. Tractor ballasting in field transport work. Transport 2005, 4, 146–153. [Google Scholar] [CrossRef]

- Leszczyński, K.; Stańczykiewicz, A.; Kulak, D.; Szewczyk, G.; Tylek, P. Estimation of Productivity and Costs of Using a Track Mini-Harvester with a Stroke Head for the First Commercial Thinning of a Scots Pine Stand. Forests 2021, 12, 870. [Google Scholar] [CrossRef]

- Bulgakov, V.; Ivanovs, S. Mathematical Simulation of Oscillations of Towed Agricultural Aggregates. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 28–29 May 2009. [Google Scholar]

- Biris, S.S.; Ungureanu, N.; Murad, E.; Manea, M.; Vladut, V.; Atanasov, A. Theoretical study of the dynamics of all-terrain vehicles (ATV). In Proceedings of the Research People and Actual Tasks on Multidisciplinary Sciences, Lozenec, Bulgary, 8–10 June 2011. [Google Scholar]

- Kühmaier, M.; Stampfer, K. Development of a multi-attribute spatial decision support system in selecting timber harvesting systems. Croat. J. For. Eng. 2010, 2, 75–88. [Google Scholar]

- Đuka, A.; Poršinsky, T.; Pentek, T.; Pandur, Z.; Janeš, D.; Papa, I. Soil measurements in the context of planning harvesting operations and variable climatic conditions. South-East Eur. For. 2018, 1, 61–71. [Google Scholar] [CrossRef]

- Kormanek, M.; Dvořák, J.; Tylek, P.; Jankovský, M.; Nuhlíček, O.; Mateusiak, Ł. Impact of MHT9002HV Tracked Harvester on Forest Soil after Logging in Steeply Sloping Terrain. Forests 2023, 14, 977. [Google Scholar] [CrossRef]

- Alexandrovich, Y.K. The Issue of Evaluation of stability of skidders. World Appl. Sci. J. 2013, 7, 971–979. [Google Scholar] [CrossRef]

- Rainoldi, M.; Neuhofer, B.; Jooss, M. Mobile Eyetracking of Museum Learning Experiences. In Information and Communication Technologies in Tourism; Stangl, B., Pesonen, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 473–485. [Google Scholar]

- Szewczyk, G.; Spinelli, R.; Maganotti, N.; Tylek, P.; Sowa, J.M.; Rudy, P.; Gaj-Gielarowiec, D. The mental workload of harvester operators working in steep terrain conditions. Silva Fenn. 2020, 54, 1–18. [Google Scholar] [CrossRef]

- Szewczyk, G.; Spinelli, R.; Magagnotti, N.; Mitka, B.; Tylek, P.; Kulak, D.; Adamski, K. Perception of the Harvester Operator’s Working Environment in Windthrow Stands. Forests 2021, 12, 168. [Google Scholar] [CrossRef]

- Duchowski, A.T. Eye Tracking Methodology: Theory and Practice, 2nd ed.; Springer: London, UK, 2007; 336p. [Google Scholar]

- Renshaw, J.A.; Finlay, J.E.; Tyfa, D.; Ward, R.D. Regressions re-visited: A new definition for the visual display paradigm. In Proceedings of the CHI: Conference on human factors in computing systems, Vienna, Austria, 24–29 April 2004. [Google Scholar]

- Holmqvist, K.; Nyström, M.; Andersson, R.; Dewhurst, R.; Jarodzka, H.; Van de Weijer, J. Eyetracking: A Comprehensive Guide to Methods and Measures; Oxford University Press: Oxford, UK, 2011; p. 560. [Google Scholar]

| Specification | Value |

|---|---|

| Tractive force [kN] | 6 |

| Weight [kg] | 650 |

| Load capacity of front loader [kg] | 200 |

| Load capacity of the three-point hitch [kg] | 250 |

| No. of speeds | 2 |

| Maximum speed [km/h−1] | 15 |

| Tyres | 5.00 × 12 |

| Service life [h] (depending on operation type) | >4 |

| Vanguard lithium battery [V/kWh] | 48/5 |

| Battery charging speed | The charging time is 5 h, as the tractor is equipped with a 1 kW charger. With a higher charger power input, the charging time decreases, e.g., a 2 kW charger would reduce the charging time to 2.5 h. The charging time also depends on the type of charging station used. |

| Advantages over a traditional combustion engine | Lower operating costs, less maintenance, zero emissions, quiet operation and instant power. |

| Total Area [ha] | Age [years] | Species | Share [%] | Growing Stock [m3 · ha−1] |

|---|---|---|---|---|

| 18.28 | 110 | English oak (Quercus robur) | 40 | 327 |

| Common hornbeam (Carpinus betulus) | 30 | |||

| European beech (Fagus sylvatica) | 20 | |||

| Red oak (Quercus rubra) | 10 |

| Sampling frequency | 50–100 Hz (with respect to eye movement trackers, the sampling frequency means the number of identified locations of fixation points per 1 second. This frequency determines the quality of the results and the accuracy of the measurements taken) |

| Eye Tracker | |

| Cameras (in glasses frames) | 4 |

| Scene camera FOV | 82° horizontally, 52° vertically |

| Scene camera parameters | h.264; 1920 × 1080 pixels; @25 fps |

| Field of view | 160° |

| Diagonal of scene camera FOV | 90°; 16:9 |

| Sound recording | Yes |

| Weight | 45 g |

| Battery | 120 min. |

| Recording Station | |

| Connection | HDMI, Micro USB and 3.5 mm Jack |

| Frequency | 2.4 GHz and 5 GHz band |

| Dimensions | 130 × 85 × 27 mm |

| Weight | 312 g |

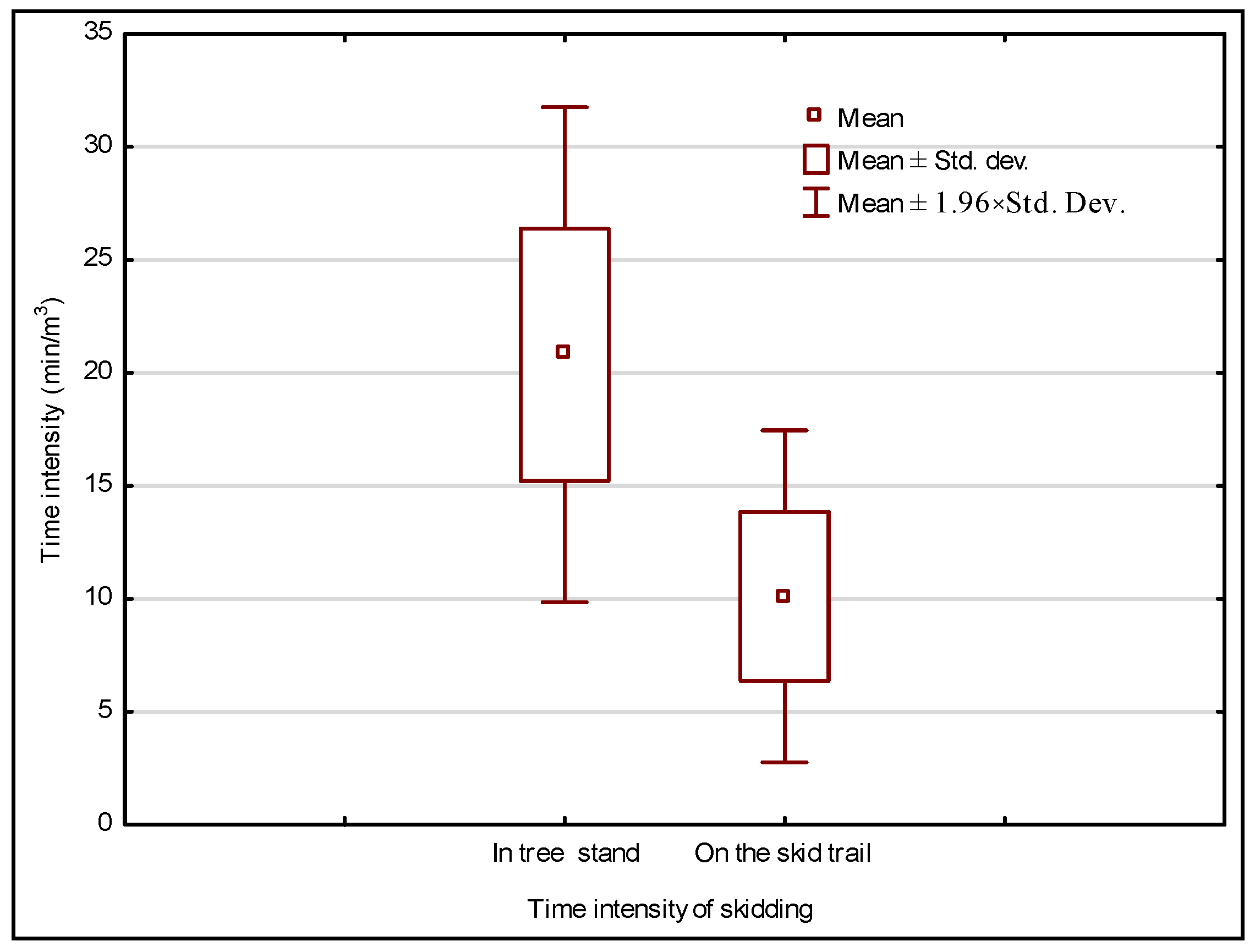

| Mean [min/m3] | Median [min/m3] | Minimum [min/m3] | Maximum [min/m3] | Std. Dev. | Variation Coefficient [%] | |

|---|---|---|---|---|---|---|

| Skidding of timber from the forest stand to the skid trail | 20.79 | 21.07 | 14.81 | 31.42 | 5.59 | 26.87 |

| Timber skidding on the skid trail | 10.11 | 10.54 | 5.09 | 15.69 | 3.75 | 37.07 |

| Fixation Time for AOI [ms] | Mean [ms] | Median [ms] | |||

|---|---|---|---|---|---|

| Forest Stand | Machine | Trail | |||

| Skidding in the forest stand | 250 | 240 | 290 | 260 | 250 |

| Skidding on the operational trail | 130 | 280 | 350 | 250 | 280 |

| Timber Harvesting | Mean [%] | Median [%] | Minimum [%] | Maximum [%] | Std. Dev. | Variation Coefficient [%] |

|---|---|---|---|---|---|---|

| From the forest stand to the skid trail | ||||||

| -front wheels | 23.1 | 21.07 | 14.8 | 38.3 | 11.9 | 51.5 |

| -rear wheels | 17.1 | 18.8 | 12.8 | 22.4 | 6.9 | 40.4 |

| On the skid trail | ||||||

| -front wheels | 14.4 | 15.4 | 11.1 | 21.7 | 6.7 | 46.5 |

| -rear wheels | 9.6 | 10.1 | 7.7 | 15.1 | 3.2 | 33.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szewczyk, G.; Krilek, J.; Tylek, P.; Hanes, J.; Petrenec, S.; Szczepańczyk, M.; Józefczyk, D. Pilot Performance Testing of a Battery-Powered Salamander Micro-Skidder in Timber Harvesting. Forests 2025, 16, 753. https://doi.org/10.3390/f16050753

Szewczyk G, Krilek J, Tylek P, Hanes J, Petrenec S, Szczepańczyk M, Józefczyk D. Pilot Performance Testing of a Battery-Powered Salamander Micro-Skidder in Timber Harvesting. Forests. 2025; 16(5):753. https://doi.org/10.3390/f16050753

Chicago/Turabian StyleSzewczyk, Grzegorz, Jozef Krilek, Paweł Tylek, Ján Hanes, Slavomír Petrenec, Miłosz Szczepańczyk, and Dominik Józefczyk. 2025. "Pilot Performance Testing of a Battery-Powered Salamander Micro-Skidder in Timber Harvesting" Forests 16, no. 5: 753. https://doi.org/10.3390/f16050753

APA StyleSzewczyk, G., Krilek, J., Tylek, P., Hanes, J., Petrenec, S., Szczepańczyk, M., & Józefczyk, D. (2025). Pilot Performance Testing of a Battery-Powered Salamander Micro-Skidder in Timber Harvesting. Forests, 16(5), 753. https://doi.org/10.3390/f16050753