An Accelerated Test Method for Evaluating the Performance of Wood Pole Fumigants

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Accelerant Percolation Through Dazomet Crystals

2.3. Dazomet Crystal Measurements

2.4. Wood Substrate Preparation and Treatment

2.5. Test Sites and Field Sites

2.6. Sampling and Sample Preparation

2.7. MITC Analysis

3. Results and Discussion

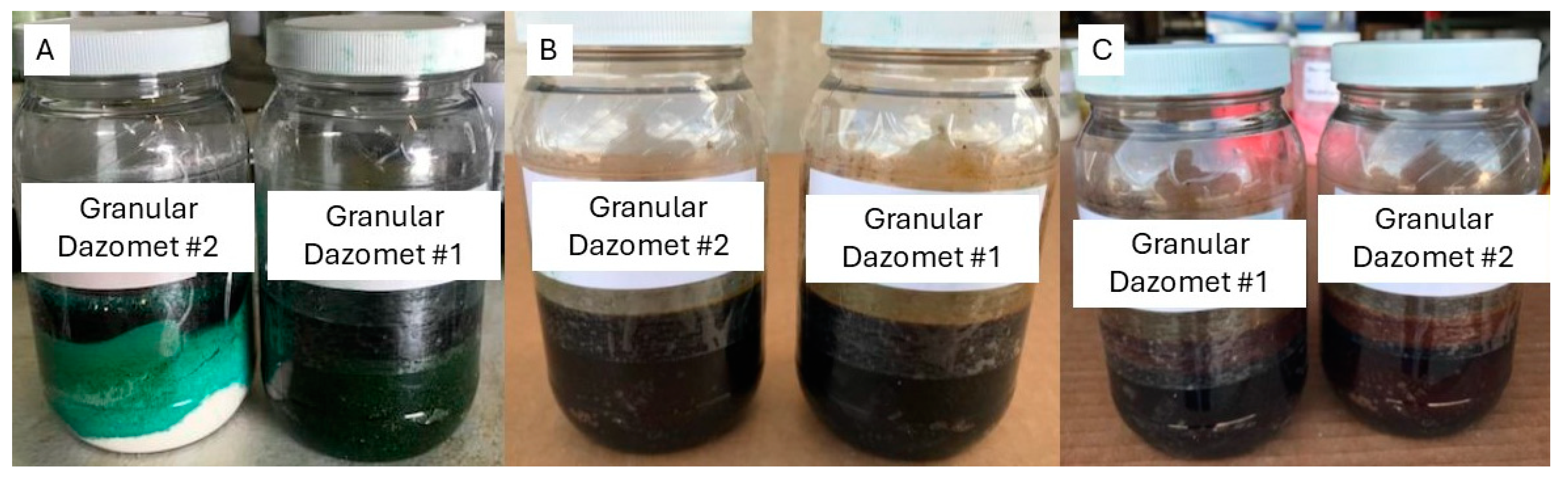

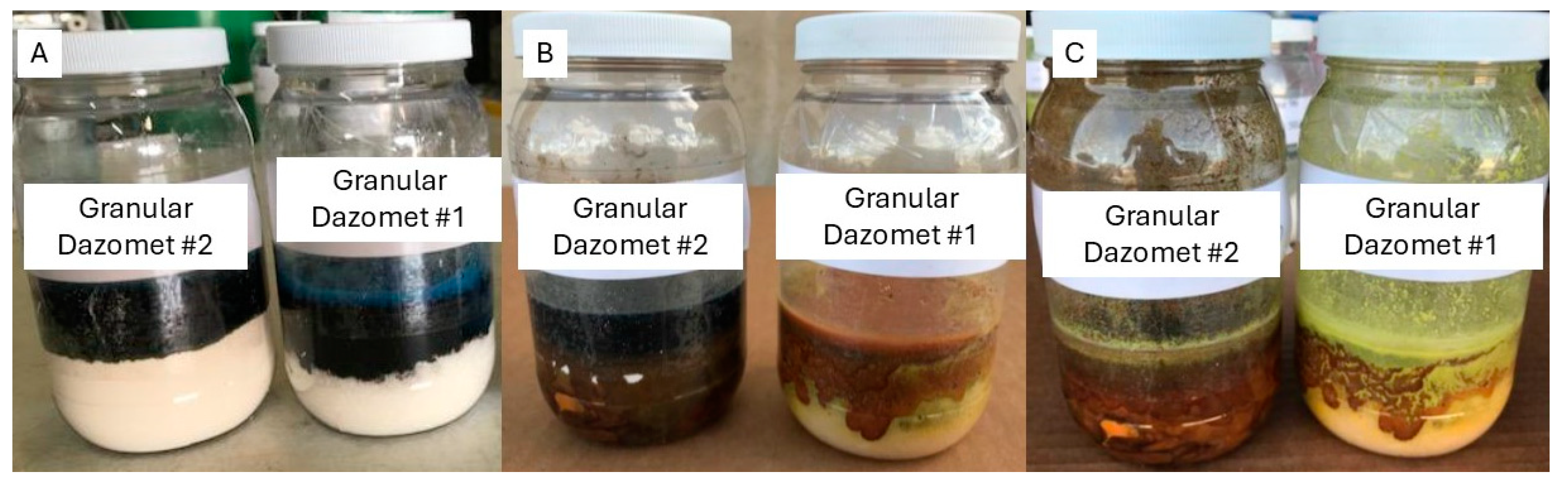

3.1. Accelerant Penetration Through Granular Dazomet Formulas

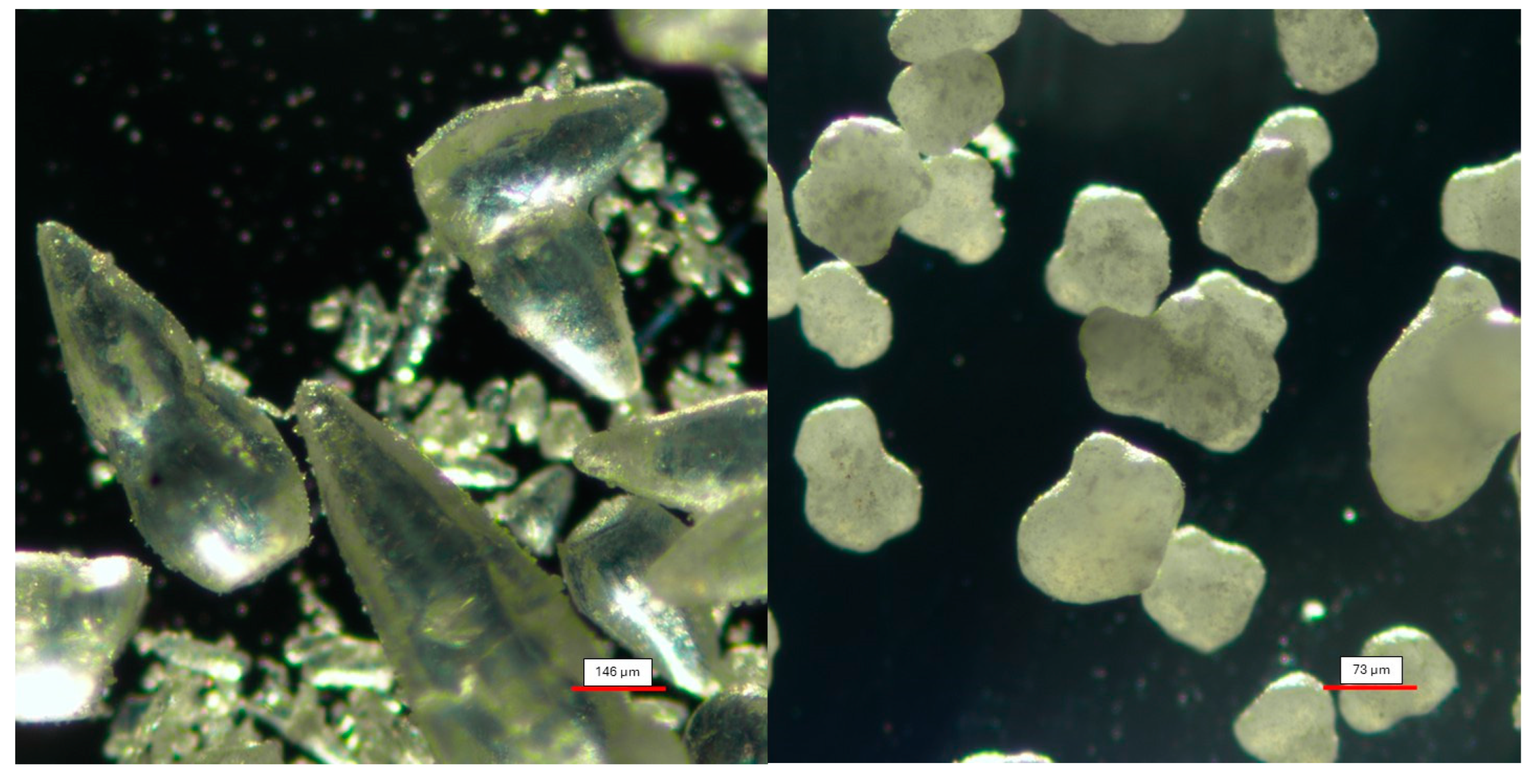

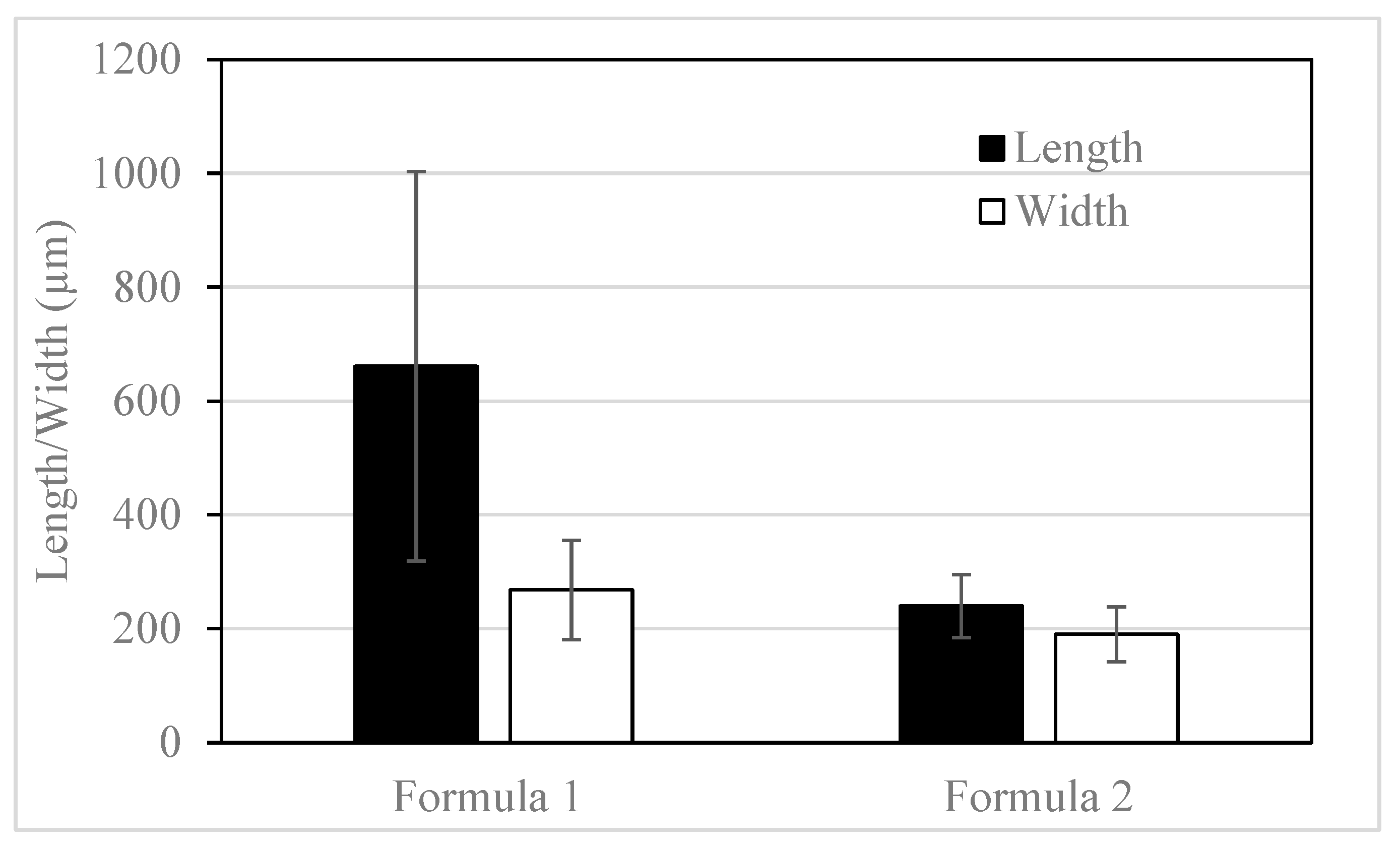

3.2. Crystal Size and Morphology of the Two Dazomet Formulations

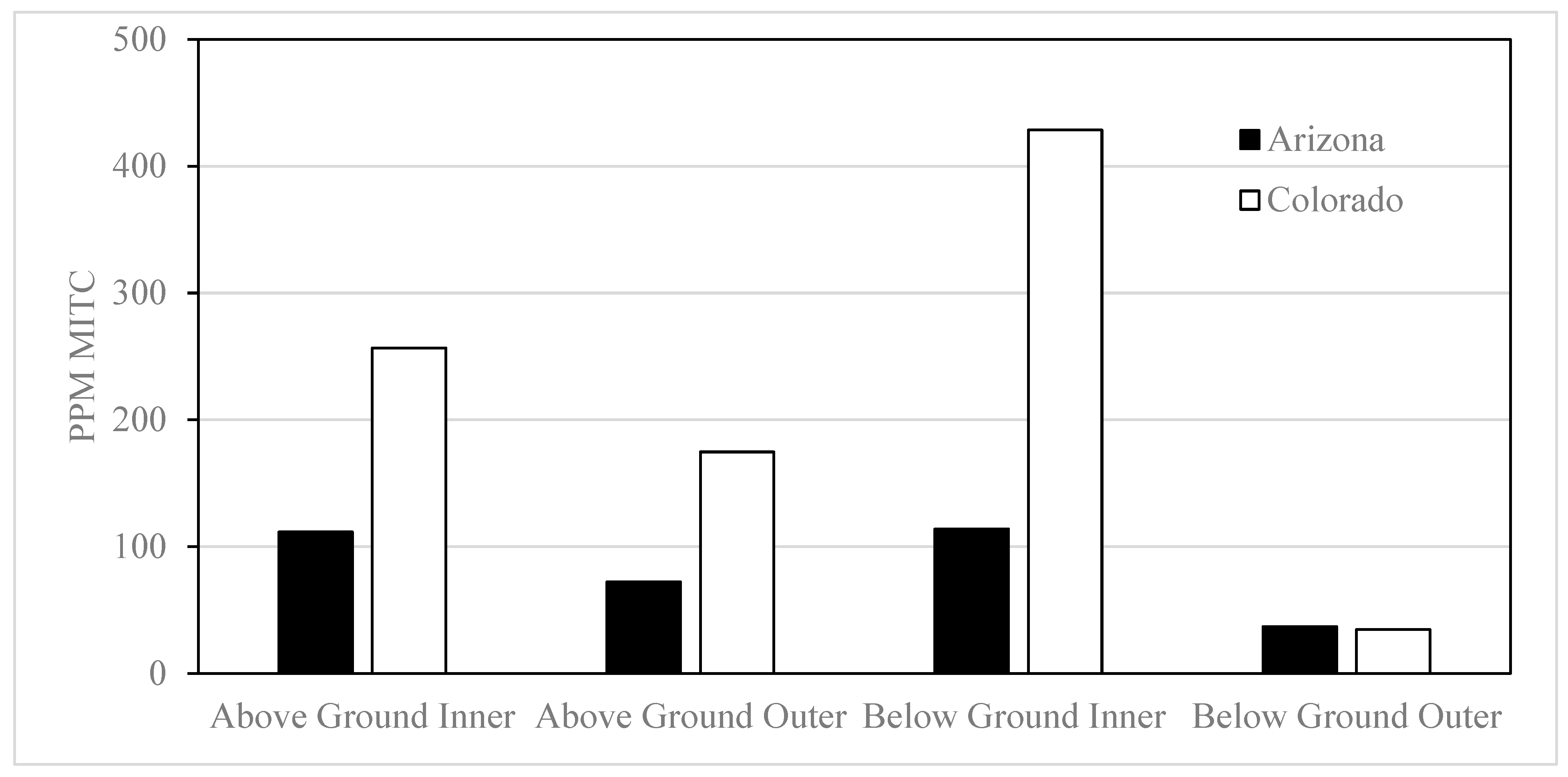

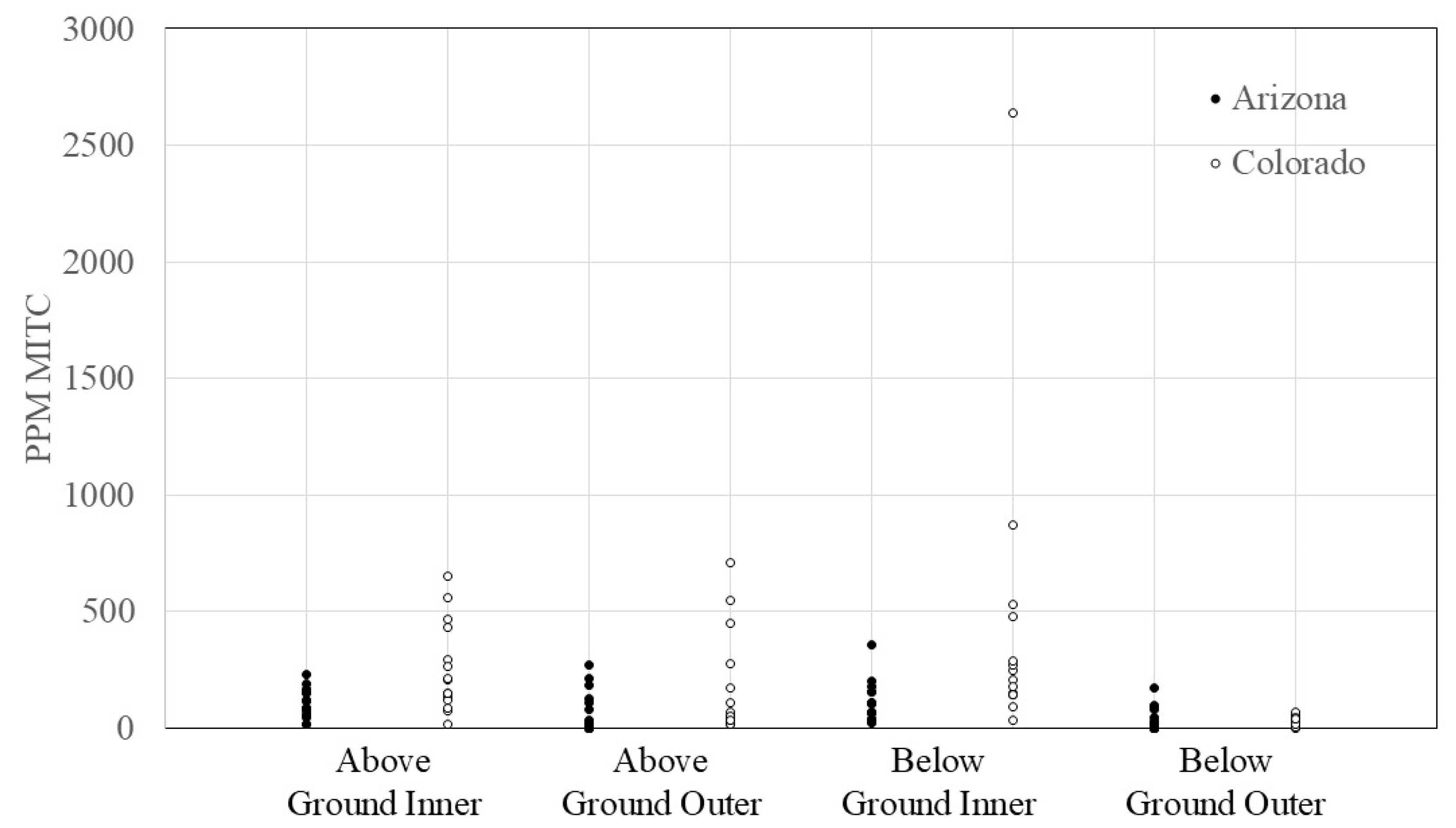

3.3. Methylisothiocyanate Production in Wood Mesocosms

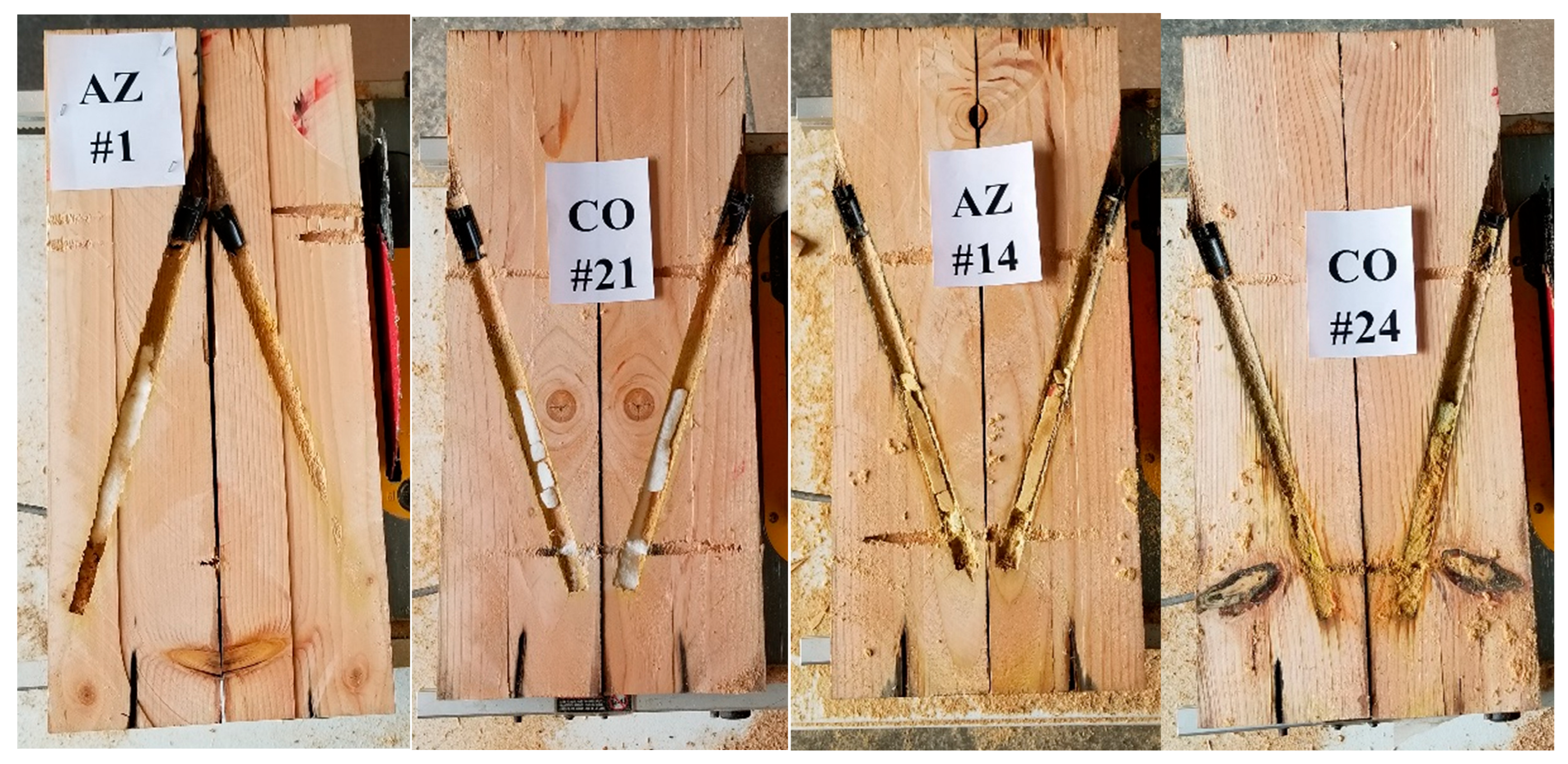

3.4. Condition of Granular Dazomet After the Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morrell, J.J. Wood Pole Maintenance Manual: 2012 Edition (Research Contribution 51); Forest Research Laboratory, Oregon State University: Corvallis, OR, USA, 2012. [Google Scholar]

- Graham, R.D.; Mothershead, J.S. Inspecting and Treating Western Redcedar and Douglas Fir Poles in Service; Forest Products Research Laboratory, Oregon State University: Corvallis, OR, USA, 1967. [Google Scholar]

- Morrell, J.J. Estimated Service Life of Wood Poles (Technical Bulletin No. 16-U-101); North American Wood Pole Council: Alpharetta, GA, USA, 2016. [Google Scholar]

- Graham, R.D. Improving the Performance of Wood Poles. Proc. Am. Wood Preserv. Assoc. 1983, 79, 222–229. [Google Scholar]

- Graham, R. Preventing and Stopping Internal Decay of Douglas-fir Poles. Holzforschung 1973, 27, 168–173. [Google Scholar] [CrossRef]

- Morrell, J.; Corden, M. Controlling wood deterioration with fumigants—A review. For. Prod. J. 1986, 36, 26–34. [Google Scholar]

- Eslyn, W.E.; Highley, T.L. Efficacy of Various Fumigants in the Eradication of Decay Fungi Implanted in Douglas-fir Timbers. Phytopathology 1985, 75, 588–592. [Google Scholar] [CrossRef]

- Zahora, A.R.; Humphrey, P.E.; Morrell, J.J. Preliminary modelling of methylisothiocyanate movement through Douglas fir transmission poles. In Proceedings of the IRG Annual Meeting, IRG/WP/3466, Madrid, Spain, 24–29 April 1988; p. 12. [Google Scholar]

- Highley, T.L. Movement and Persistence of Dazomet and Pelleted Methylisothiocyanate in Wrapped Douglas-fir and Southern Pine Timbers. In Proceedings of the IRG Annual Meeting, IRG/WP/1496-91, Kyoto, Japan, 20–24 May 1991; p. 5. [Google Scholar]

- Forsyth, P.G. Decomposition of Basamid in Douglas-Fir Heartwood; Oregon State University: Corvallis, OR, USA, 1993. [Google Scholar]

- Konkler, M.J.; Cappellazzi, J.; Love, C.S.; Freitag, C.; Morrell, J.J. Performance of Internal Remedial Treatments on Douglas-Fir Poles: A Large-Scale Field Trial. For. Prod. J. 2019, 69, 289–304. [Google Scholar] [CrossRef]

- Forsyth, P.; Morrell, J.; Chen, H. Rates of MITC release from Basamid® applied with selected additives to Douglas-fir poles. For. Prod. J. 1998, 48, 40–43. [Google Scholar]

- Love, C.S.; Freitag, C.; Morrell, J.J. Effect of Copper on Long-Term Performance of Dazomet as an Internal Remedial Treatment in Douglas-Fir Poles. For. Prod. J. 2010, 60, 194–199. [Google Scholar] [CrossRef]

- Forsyth, P.; Morrell, J. The effect of selected additives and conditions on the decomposition of Basamid in Douglas-fir Heartwood. In Proceedings of the IRG Annual Meeting, IRG/WP/3698-92, Harrogate, UK, 10–15 May 1992; p. 11. [Google Scholar]

- Morrell, J.; Freitag, C.; Rhatigan, R.; Love, C.S.; Mankowski, M. Oregon State University Cooperative Pole Research Program 20th Annual Report; Oregon State University: Corvallis, OR, USA, 2001; p. 108. [Google Scholar]

| Granular Dazomet Formula | Dazomet Dose (g) | Accelerant | Accelerant Dose (g) |

|---|---|---|---|

| 1 | 70 | None | 0 |

| 1 | 70 | Copper naphthenate 1% as metal in mineral spirits | 14 |

| 1 | 60 | 33% sodium N-methyldithiocarbamate | 20 |

| 1 | 60 | Water-based solution of copper ethanolamine (2.5% as copper) and DOT (6.25%) | 20 |

| 1 | 60 | Runny paste 16.83% DOT, Cu(OH)2 2.08% as metal | 20 |

| 1 | 40 | Copper naphthenate 1% as metal in mineral spirits | 40 |

| 1 | 40 | Water-based solution of copper ethanolamine (2.5% as copper) and DOT (6.25%) | 40 |

| 1 | 40 | Runny paste 16.83% DOT, Cu(OH)2 2.08% as metal | 40 |

| 2 | 60 | None | 0 |

| 2 | 60 | Copper naphthenate 1% as metal in mineral spirits | 20 |

| 2 | 60 | Water-based solution of copper ethanolamine (2.5% as copper) and DOT (6.25%) | 20 |

| 2 | 60 | Runny paste 16.83% DOT, Cu(OH)2 2.08% as metal | 20 |

| 2 | 40 | Copper naphthenate 1% as metal in mineral spirits | 40 |

| 2 | 40 | Water-based solution of copper ethanolamine (2.5% as copper) and DOT (6.25%) | 40 |

| 2 | 40 | Runny paste 16.83% DOT, Cu(OH)2 2.08% as metal | 40 |

| Formula | Dazomet Dose (g) | Accelerant | Accelerant Dose (g) | Arizona MITC (ppm) | Colorado MITC (ppm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Above Ground | Below Ground | Above Ground | Below Ground | ||||||||

| Inner | Outer | Inner | Outer | Inner | Outer | Inner | Outer | ||||

| 1 | 70 | None | 0 | 46.5 | 0.0 | 156.4 | 0.0 | 18.2 | 19.0 | 34.4 | 0.0 |

| 1 | 70 | Copper naphthenate 1% as Cu in mineral spirits | 14 | 152.7 | 0.0 | 36.8 | 0.0 | 135.7 | 21.1 | 249.9 | 39.7 |

| 1 | 60 | 33% sodium N-methyldithiocarbamate | 20 | 119.9 | 0.0 | 107.2 | 0.0 | 296.2 | 15.3 | 274.3 | 8.4 |

| 1 | 60 | Copper ethanolamine (2.5% as Cu) and DOT (6.25%) | 20 | 113.0 | 270.5 | 156.1 | 12.0 | 655.5 | 707.5 | 2638.4 | 35.5 |

| 1 | 60 | Runny paste 16.83% DOT, Cu(OH)2 2.08% as Cu | 20 | 14.9 | 0.9 | 107.9 | 0.0 | 151.3 | 36.5 | 148.7 | 57.1 |

| 1 | 40 | Copper naphthenate 1% as Cu in mineral spirits | 40 | 158.2 | 12.5 | 23.4 | 22.4 | 267.8 | 279.3 | 532.5 | 21.3 |

| 1 | 40 | Copper ethanolamine (2.5% as copper) and DOT (6.25%) | 40 | 72.5 | 111.5 | 41.5 | 7.1 | 562.7 | 170.8 | 205.1 | 33.5 |

| 1 | 40 | Runny paste 16.83% DOT, Cu(OH)2 2.08% Cu | 40 | 88.1 | 0.0 | 63.4 | 0.0 | 75.8 | 51.7 | 143.4 | 27.5 |

| 2 | 60 | None | 0 | 17.4 | 17.5 | 27.9 | 0.0 | 210.2 | 44.7 | 91.2 | 28.4 |

| 2 | 60 | Copper naphthenate 1% as Cu in mineral spirits | 20 | 86.2 | 82.5 | 178.9 | 172.0 | 122.0 | 68.1 | 180.9 | 35.4 |

| 2 | 60 | Copper ethanolamine (2.5% as Cu) and DOT (6.25%) | 20 | 228.3 | 182.7 | 200.4 | 96.9 | 431.0 | 549.8 | 286.6 | 52.7 |

| 2 | 60 | Runny paste 16.83% DOT, Cu(OH)2 2.08% as Cul | 20 | 155.4 | 35.7 | 71.9 | 29.9 | 89.2 | 54.5 | 145.8 | 17.8 |

| 2 | 40 | Copper naphthenate 1% as Cu in mineral spirits | 40 | 167.8 | 27.7 | 360.5 | 78.2 | 215.9 | 450.9 | 480.9 | 70.5 |

| 2 | 40 | Copper ethanolamine (2.5% as Cu) and DOT (6.25%) | 40 | 59.5 | 126.5 | 71.3 | 43.4 | 465.0 | 112.5 | 871.4 | 48.3 |

| 2 | 40 | Runny paste 16.83% DOT, Cu(OH)2 2.08% as Cu | 40 | 192.0 | 215.0 | 104.1 | 92.2 | 151.6 | 37.6 | 145.5 | 42.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konkler, M.J.; Woods, T.L.; Gross, R.S.; Morrell, J.J.; Presley, G. An Accelerated Test Method for Evaluating the Performance of Wood Pole Fumigants. Forests 2025, 16, 572. https://doi.org/10.3390/f16040572

Konkler MJ, Woods TL, Gross RS, Morrell JJ, Presley G. An Accelerated Test Method for Evaluating the Performance of Wood Pole Fumigants. Forests. 2025; 16(4):572. https://doi.org/10.3390/f16040572

Chicago/Turabian StyleKonkler, Matthew J., Thomas L. Woods, Randy S. Gross, Jeffrey J. Morrell, and Gerald Presley. 2025. "An Accelerated Test Method for Evaluating the Performance of Wood Pole Fumigants" Forests 16, no. 4: 572. https://doi.org/10.3390/f16040572

APA StyleKonkler, M. J., Woods, T. L., Gross, R. S., Morrell, J. J., & Presley, G. (2025). An Accelerated Test Method for Evaluating the Performance of Wood Pole Fumigants. Forests, 16(4), 572. https://doi.org/10.3390/f16040572