Accuracy of Measuring Methods of Pile Volume of Forest Harvesting Residues and Economic Impacts

Abstract

1. Introduction

2. Material and Methods

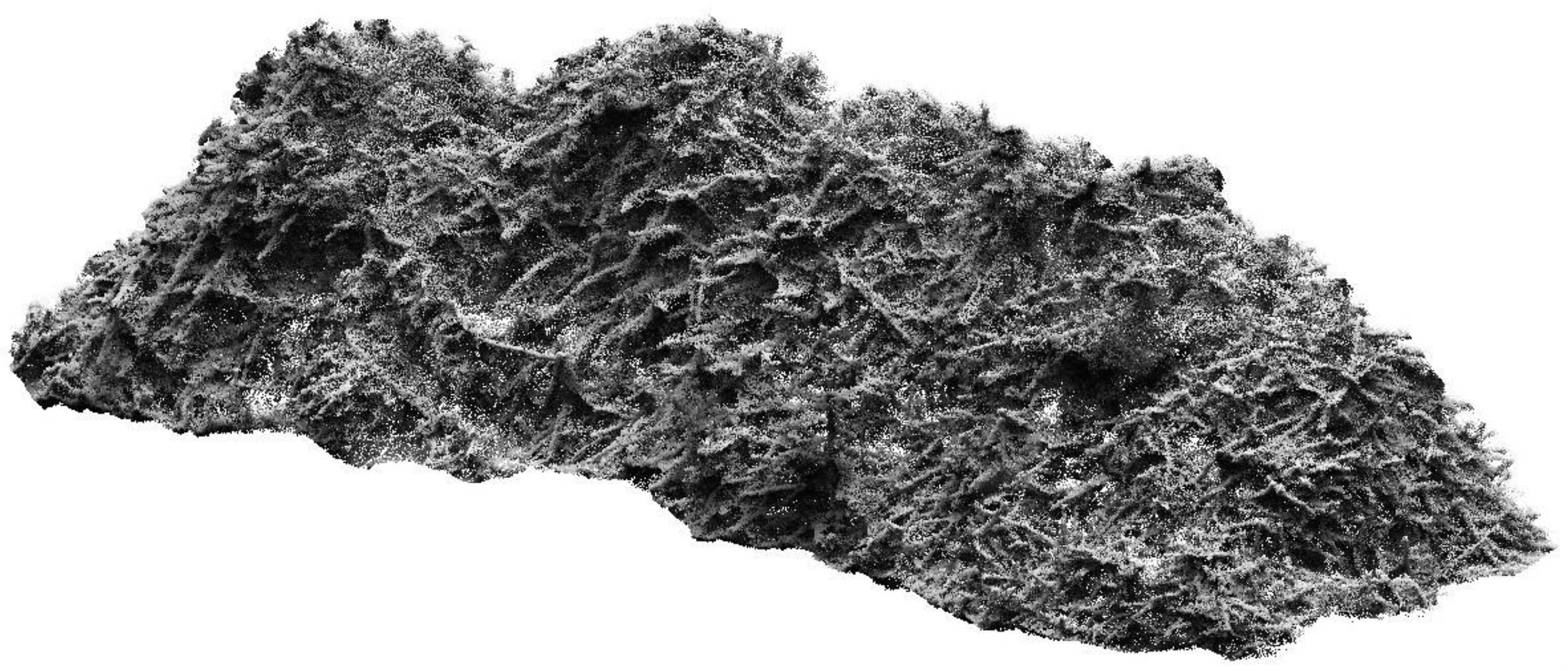

2.1. Characteristics of Sites and Identification of Logging Residues

2.2. Terrestrial 3D Laser Scanning Method

2.2.1. The Principle of 3D Modeling Technology and the Measurement Procedure

2.2.2. Data Processing and Output Evaluation

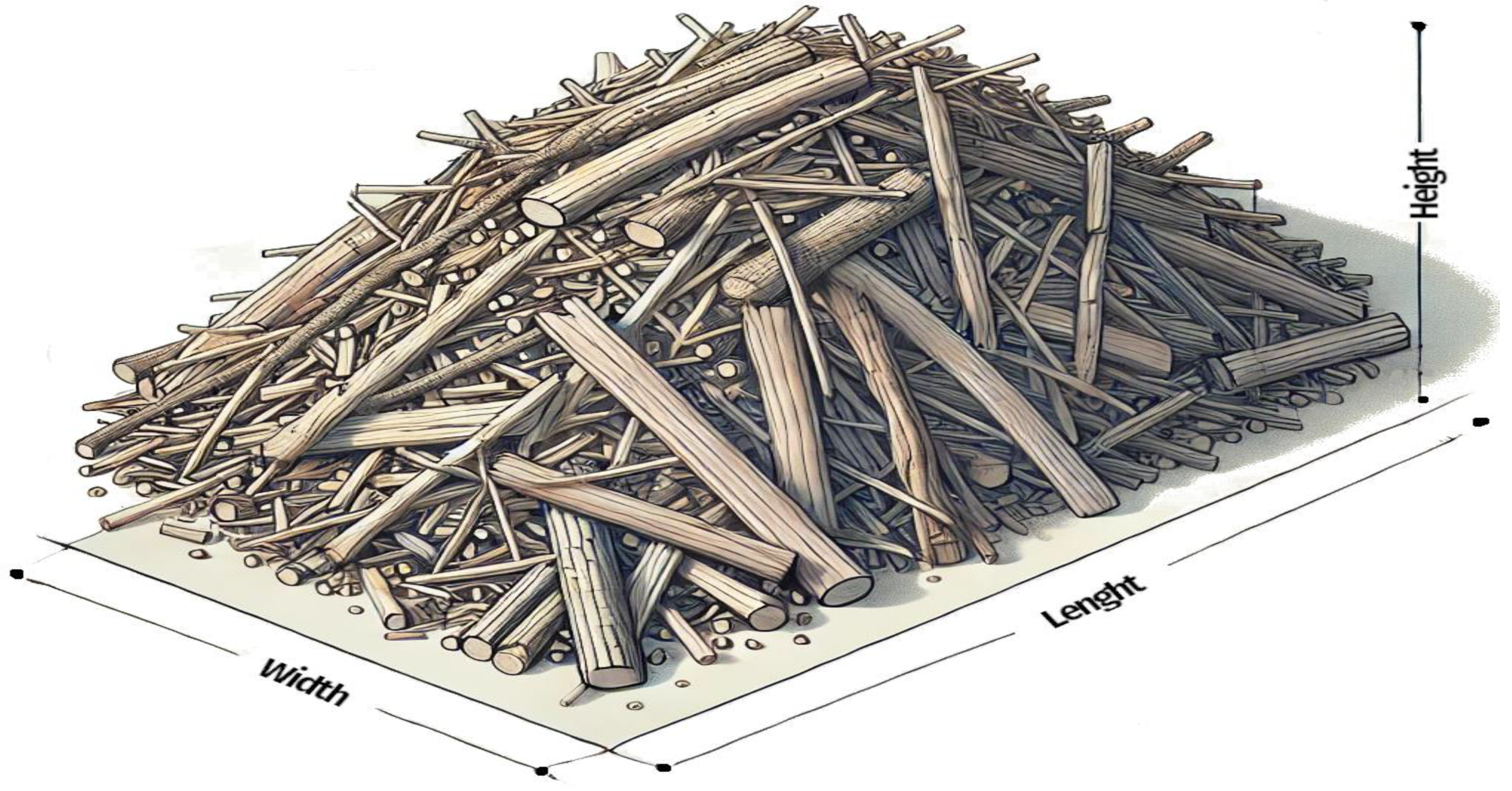

2.3. Manual Measurement Method

2.3.1. Determination of the Actual Volume of Wood Chips

2.3.2. Comparison of Methods and Calculation of Conversion Coefficients

2.3.3. Statistical Verification of Data Normality

2.3.4. Time Measurement Methodology

- -

- Field data collection: Time required to manually measure pile dimensions and perform 3D scanning;

- -

- Data processing: Time spent processing the 3D point cloud and manually calculated volume;

- -

- Volume calculation: Computation time required for each method.

2.4. Assessment of Economic Aspects

3. Results

3.1. Analysis of Conversion Coefficients

3.2. Comparison of Potential Revenues

3.3. Time Consumption of the Applied Measurement Methods

4. Discussion

4.1. Quality of Wood Chips and Its Impact on Volume

4.2. The Effect of Moisture on the Weight and Volume of Wood Chips

4.3. Economic Impacts of Using Both Methods

4.4. Laser Scanning Limitations

4.5. Recommendations for Practice

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/LSU/?uri=oj%3AJOL_2018_328_R_0003 (accessed on 8 February 2025).

- Parikka, M. Global biomass fuel resources. Biomass Bioenergy 2004, 27, 613–620. [Google Scholar] [CrossRef]

- Zervos, A.; Lins, C.; Muth, J.; Smith, E. Re-Thinking 2050: A 100% Renewable Energy Vision for the European Union; European Renewable Energy Council (EREC): Brussels, Belgium, 2010. [Google Scholar]

- Brown, M.W. Evaluation of the Impact of Timber Truck Configuration and Tare Weight on Payload Efficiency: An Australian Case Study. Forests 2021, 12, 855. [Google Scholar] [CrossRef]

- Moskalik, T.; Tymendorf, Ł.; van der Saar, J.; Trzciński, G. Methods of Wood Volume Determining and Its Implications for Forest Transport. Sensors 2022, 22, 6028. [Google Scholar] [CrossRef] [PubMed]

- Clauser, N.M.; Felissia, F.E.; Area, M.C.; Vallejos, M.E. A framework for the design and analysis of integrated multi-product biorefineries from agricultural and forestry wastes. Renew. Sust. Energy Rev. 2021, 139, 110687. [Google Scholar] [CrossRef]

- Gałęzia, T. Energy balance and time-consumption of selected components in technological chain of forest biomass harvesting. Sylwan 2013, 157, 419–424. [Google Scholar]

- Han, S.-K.; Murphy, G. Trucking productivity and costing model for transportation of recovered wood waste in Oregon. For. Prod. J. 2011, 61, 552–560. [Google Scholar] [CrossRef]

- Sadowski, J.; Moskalik, T.; Zastocki, D.; Wrona, T. Selected Economic and Natural Aspects of Management of Logging Residues, Studies and Materials CEPL in Rogów. 2012, pp. 246–253. Available online: https://agro.icm.edu.pl/agro/element/bwmeta1.element.agro-7bbc38f4-d356-424b-b484-ba6619d7c6c8 (accessed on 8 February 2025).

- Jodłowski, K.; Moskalik, T.; Tomusiak, R.; Sarzyński, W. The Use of Photo-Optical Systems for Measurement of Stacked Wood. In Proceedings of the From Theory to Practice: Challenges for Forest Engineering, Warsaw, Poland, 4–7 September 2016; Department of Forest Utilization, Warsaw University of Life Sciences-SGGW: Warsaw, Poland, 2016; p. 306. [Google Scholar]

- Simanov, V.; Rozdíly v Evidovaném Objemu dříví. Lesnická práce. 2003. 2/3. [In Czech]. Available online: https://lesprace.cz/casopis-lesnicka-prace-archiv/rocnik-92-2013/lesnicka-prace-c-7-13/tezba-drivi (accessed on 8 February 2025).

- Knyaz, V.A.; Maksimov, A.A. Photogrammetric Technique for Timber Stack Volume Contol. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2014, 40, 157–162. [Google Scholar]

- Siekański, P.; Magda, K.; Malowany, K.; Rutkiewicz, J.; Styk, A.; Krzesłowski, J.; Kowaluk, T.; Zagórski, A. On-Line Laser Triangulation Scanner for Wood Logs Surface Geometry Measurement. Sensors 2019, 19, 1074. [Google Scholar] [CrossRef]

- Zemánek, T.; Cibulka, M.; Pelikán, P.; Skoupil, J. The use of terrestrial laser scanning for determining the driver’s field of vision. Sensors 2017, 17, 2098. [Google Scholar] [CrossRef]

- Zvěřina, L.; Cibulka, M.; Staněk, L.; Ulrich, R. Analysis of Field View from Tractor and Trailer Units Using the Method of Terrestrial Laser Scanning. Forests 2022, 13, 1383. [Google Scholar] [CrossRef]

- Kupčák, V. Dendromass Potential for Energy in the Conditions of Forest-Timber Branch of the Czech Republic and the Forestry. Intercathedra. 2009. sv. 25, č. 1, s. 68--72. ISSN 1640-3622. Available online: https://1library.net/article/v%C3%A1clav-kup%C4%8D%C3%A1k-intercathedra-annual-scientific-bulletin-economic-departme.zg33e08q (accessed on 8 February 2025).

- Staněk, L.; Zvěřina, L.; Ulrich, R.; Pavlíková, E.A. A Unique Grubbing Head Prototype forEnvironmentally Friendly and Sustainable Stump Removal. Forests 2022, 13, 1515. [Google Scholar] [CrossRef]

- Staněk, L.; Hamřík, T.; Košulič, O. Effect of age structure and management typeon epigeic arthropods in commercial oak forests. Zpráv. Lesn. Výzk. 2020, 65, 265–27533. [Google Scholar]

- Korboulewsky, N.; Bilger, I.; Bessaad, A. How to Evaluate Downed Fine Woody Debris Including Logging Residues? Forests 2021, 12, 881. [Google Scholar] [CrossRef]

- Wojnar, T. ; Doporučená Pravidla pro měření a Třídění dříví v České Republice; Lesnická Práce: Kostelec nad Černými lesy., Czech Republic, 2007; ISBN 978-80-87154-01-4. [Google Scholar]

- Janák, K. Differences in Round Woodmeasurements Usingelectronic 2D and 3Dsystems and Standardmanual Method. Drv. Industija. 2007, 53, 127–133. [Google Scholar]

- Plankenbühler, T.; Kolb, S.; Grümer, F.; Müller, D.; Karl, J. Image-based model for assessment of wood chip quality and mixture ratios. Processes 2020, 8, 728. [Google Scholar] [CrossRef]

- Schön, C.; Kuptz, D.; Mack, R.; Zelinski, V.; Loewen, A.; Hartmann, H. Influence of wood chip quality on emission behaviour in small-scale wood chip boilers. Biomass Convers. Biorefinery 2019, 9, 71–82. [Google Scholar] [CrossRef]

- Spinelli, R.; Eliasson, L.; Han, H.S. A critical review of comminution technology and operational logistics of wood chips. Curr. For. Rep. 2020, 6, 210–219. [Google Scholar] [CrossRef]

- Wataniyakul, P.; Boonnoun, A.T.P.; Quitain, M.; Sasaki, T.; Kida, N.; Laosiripojana, A. Shotipruk. Preparation of hydrothermal carbon as catalyst support for conversion of biomass to 5-hydroxymethylfurfural. Catal. Commun. 2018, 104, 41–47. [Google Scholar] [CrossRef]

- Borz, S.A.; Morocho Toaza, J.M.; Forkuo, G.O.; Marcu, M.V. Potential of Measure App in Estimating Log Biometrics: A Comparison with Conventional Log Measurement. Forests 2022, 13, 1028. [Google Scholar] [CrossRef]

- Houshfar, E.; Løvås, T.; Skreiberg, Ø. Experimental investigation on NOx reduction by primary measures in biomass combustion: Straw, peat, sewage sludge, forest residues and wood pellets. Energies 2012, 5, 270–290. [Google Scholar] [CrossRef]

- Moskalik, T.; SarzyĹ, W.; Zastocki, D. Efficiency of slash bundling in mature coniferous stands. Sci. Res. Essays 2013, 8, 1478–1486. [Google Scholar] [CrossRef]

- Olsson, B.A.; Hannrup, B.; Jönsson, M.; Larsolle, A.; Nordström, M.; Mörtberg, U.; Rudolphi, J.; Strömgren, M. A decision support model for individual tree stump harvesting options based on criteria for economic return and environmental protection. Scand. J. For. Res. 2017, 32, 246–259. [Google Scholar] [CrossRef]

- Hagan, J.M.; Grove, S.L. Coarse woody debris: Humans (and nature competing for trees. J. For. 1999, 97, 6–11. [Google Scholar] [CrossRef]

| Site Pile No. | Volume of Biomass (m3) | Coefficients | |||

|---|---|---|---|---|---|

| Scanner ZEB Horizon VS | Manual Measurement * VM | Wood Chips (LCM) VR | kS | kM | |

| 1.1 | 388.90 | 496 | 135 | 0.35 | 0.27 |

| 1.2 | 952.08 | 1455 | 355 | 0.37 | 0.24 |

| 1.3 | 306.25 | 479 | 110 | 0.36 | 0.23 |

| 1.4 | 142.11 | 220 | 55 | 0.39 | 0.25 |

| 1.5 | 419.24 | 662 | 145 | 0.35 | 0.22 |

| 1.6 | 267.67 | 405 | 100 | 0.37 | 0.25 |

| 1.7 | 119.45 | 172 | 45 | 0.38 | 0.26 |

| 1.8 | 918.73 | 1493 | 335 | 0.36 | 0.22 |

| 2.1 | 2390.15 | 3832 | 840 | 0.35 | 0.22 |

| 3.1 | 438.08 | 704 | 160 | 0.37 | 0.23 |

| 3.2 | 1066.08 | 1624 | 400 | 0.38 | 0.25 |

| 3.3 | 1398.54 | 1861 | 470 | 0.34 | 0.25 |

| Mean Value | 0.3629 | 0.2411 | |||

| Standart Deviation | 0.0152 | 0.0171 | |||

| Site | Scanner ZEB Horizon | Manual Measurement | Wood Chips | |||

|---|---|---|---|---|---|---|

| VS (m3) | RS (EUR) | VM (m3) | RM (EUR) | VR (LCM) | Revenues R (EUR) | |

| Žďárná | 3514.43 | 29,873 | 5382 | 45,747 | 1 280 | 10,880 |

| Brodek | 2390.15 | 20,316 | 3832 | 32,572 | 840 | 7140 |

| Boskovice | 2902.70 | 24,673 | 4189 | 35,607 | 1030 | 8755 |

| Total | 8807.28 | 74,862 | 13,403 | 113,926 | 3150 | 26,755 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zvěřina, L.; Cibulka, M.; Ulrich, R.; Badal, T.; Kupčák, V. Accuracy of Measuring Methods of Pile Volume of Forest Harvesting Residues and Economic Impacts. Forests 2025, 16, 498. https://doi.org/10.3390/f16030498

Zvěřina L, Cibulka M, Ulrich R, Badal T, Kupčák V. Accuracy of Measuring Methods of Pile Volume of Forest Harvesting Residues and Economic Impacts. Forests. 2025; 16(3):498. https://doi.org/10.3390/f16030498

Chicago/Turabian StyleZvěřina, Ladislav, Miloš Cibulka, Radomír Ulrich, Tomáš Badal, and Václav Kupčák. 2025. "Accuracy of Measuring Methods of Pile Volume of Forest Harvesting Residues and Economic Impacts" Forests 16, no. 3: 498. https://doi.org/10.3390/f16030498

APA StyleZvěřina, L., Cibulka, M., Ulrich, R., Badal, T., & Kupčák, V. (2025). Accuracy of Measuring Methods of Pile Volume of Forest Harvesting Residues and Economic Impacts. Forests, 16(3), 498. https://doi.org/10.3390/f16030498