A Novel Chrono-Potentiometry (CP) Method for Determining the Moisture Content of Wood Above the Fibre Saturation Point (FSP)

Abstract

1. Introduction

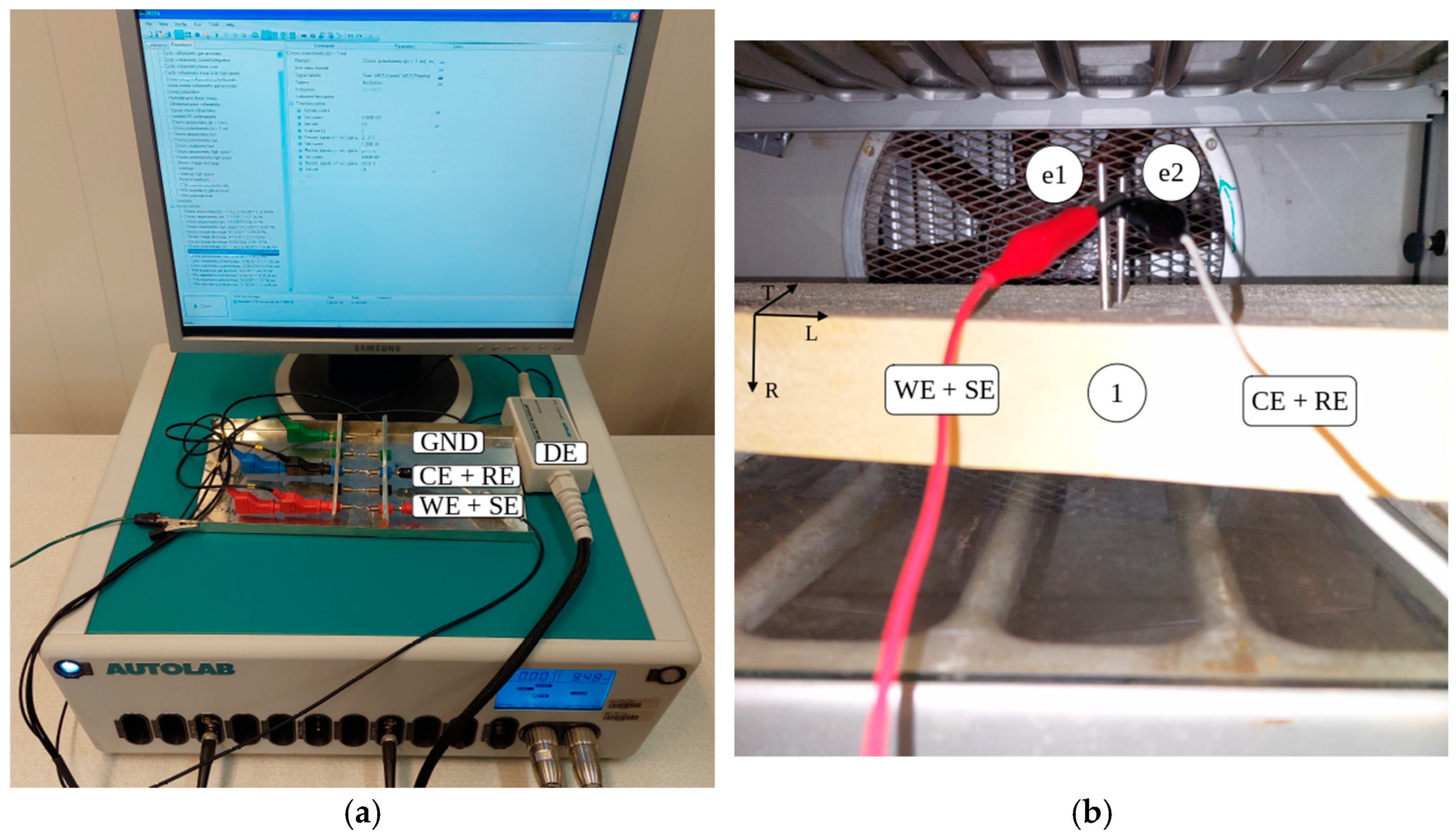

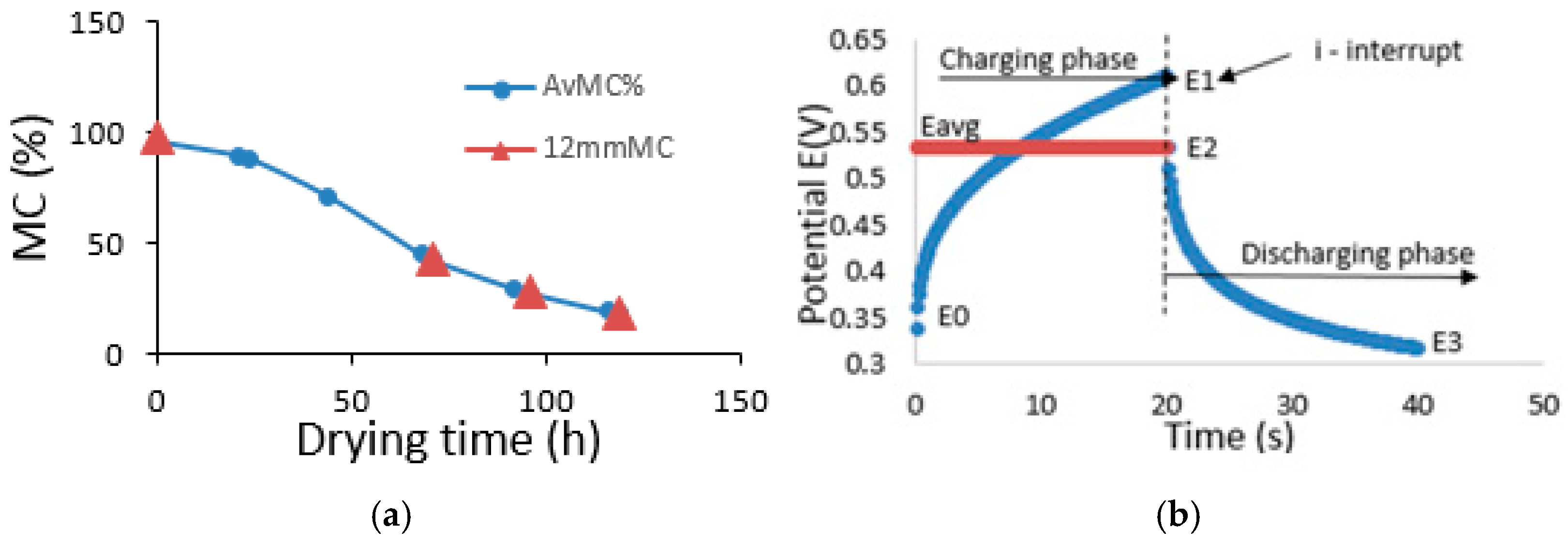

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. A Quality Assessment for the Wood Moisture Meter’s Calibration Model

3. Results

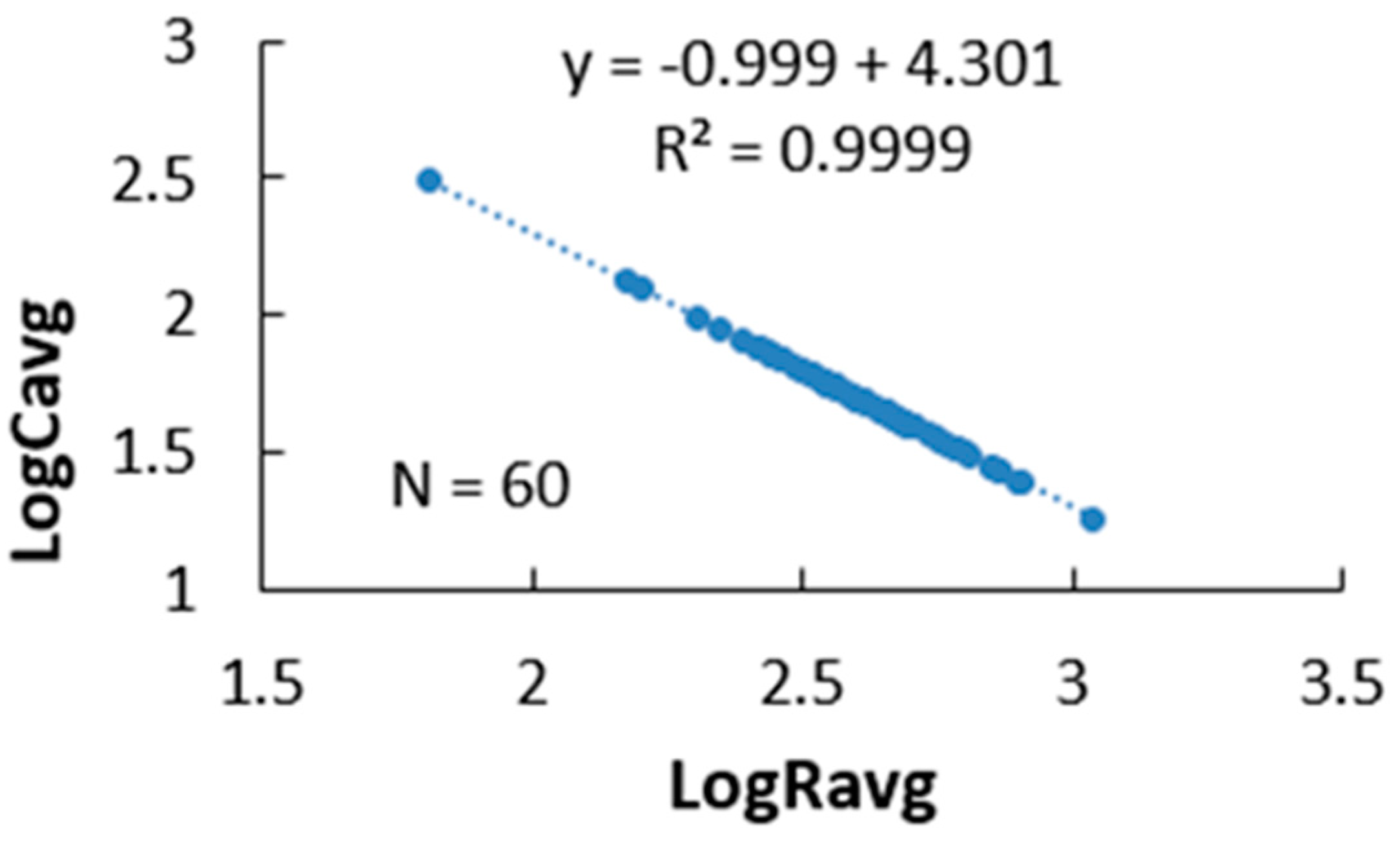

3.1. Average Charging Number, Cha(N)avg, in the Wood

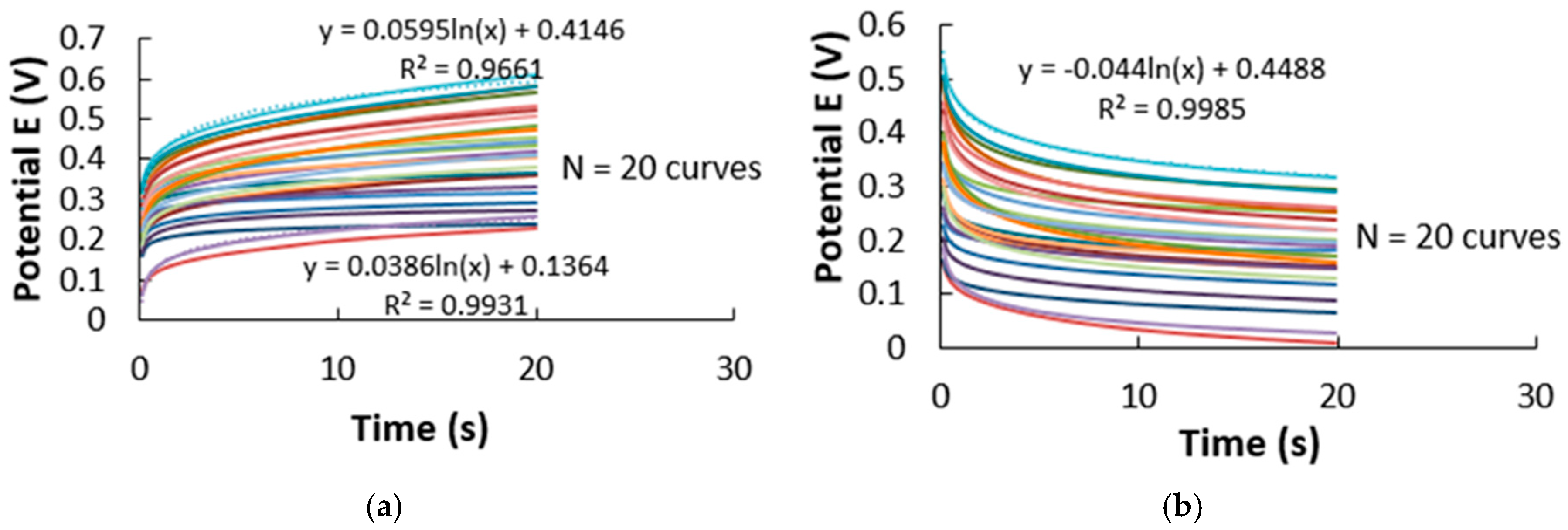

3.2. Selecting Measurement Data for the Moisture Meter’s Calibration Model

3.3. Calibration Models for Different Tree Species and a Determination of Electrical Chargeability, Cha(E), for Different Tree Species in Terms of the Galvanostatic Charging Mode

4. Discussion

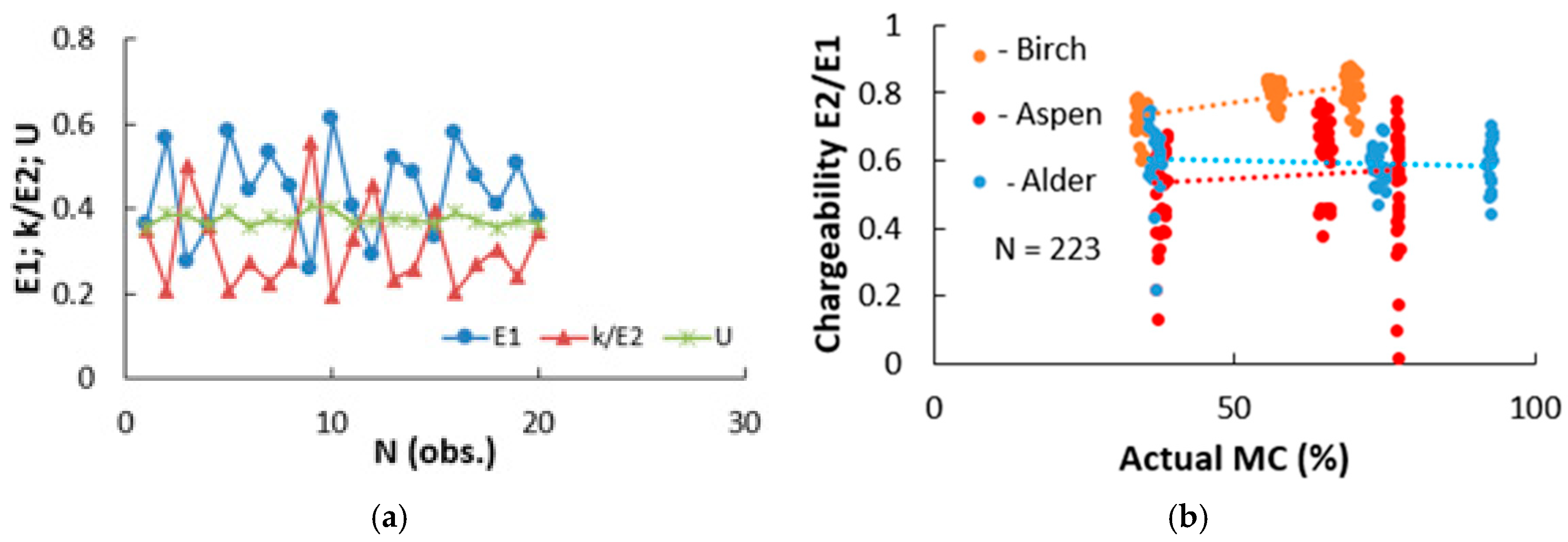

- For three hardwood species—birch (Betula spp.), aspen (Populus spp.), and black alder (Alnus glutinosa (L.) Gaertn)—rather surprisingly, it was found that the average electrical chargeability, Cha(E), in the wood was practically independent of the wood’s average MC in the region above the FSP (see Table 1 and Figure 6b). The actual density of the birch wood sample was 0.66 g/cm3. The actual density of the aspen wood was 0.53 g/cm3. The actual density of the alder wood sample was 0.46 g/cm3. On the other hand, the average electrical chargeability was found to be of the same order of magnitude as the basic density (i.e., the dry weight divided by the wet volume (above the FSP)) for the same wood species. If the hypothesis of an approximate numerical equivalence between the wood’s basic density and its average electrical chargeability is confirmed by further studies, then the possibility opens up that the wood’s chargeability can be used to predict the wood’s basic density in a non-destructive way, something that is similar to that of the use of a resistograph [26].

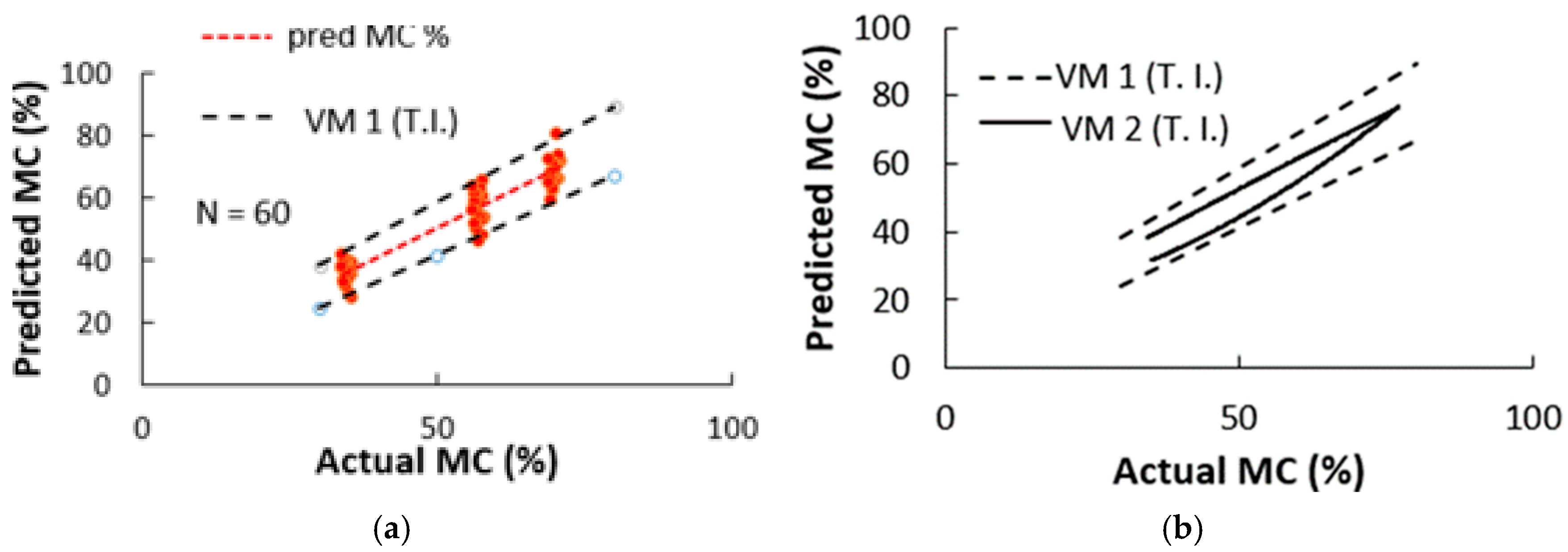

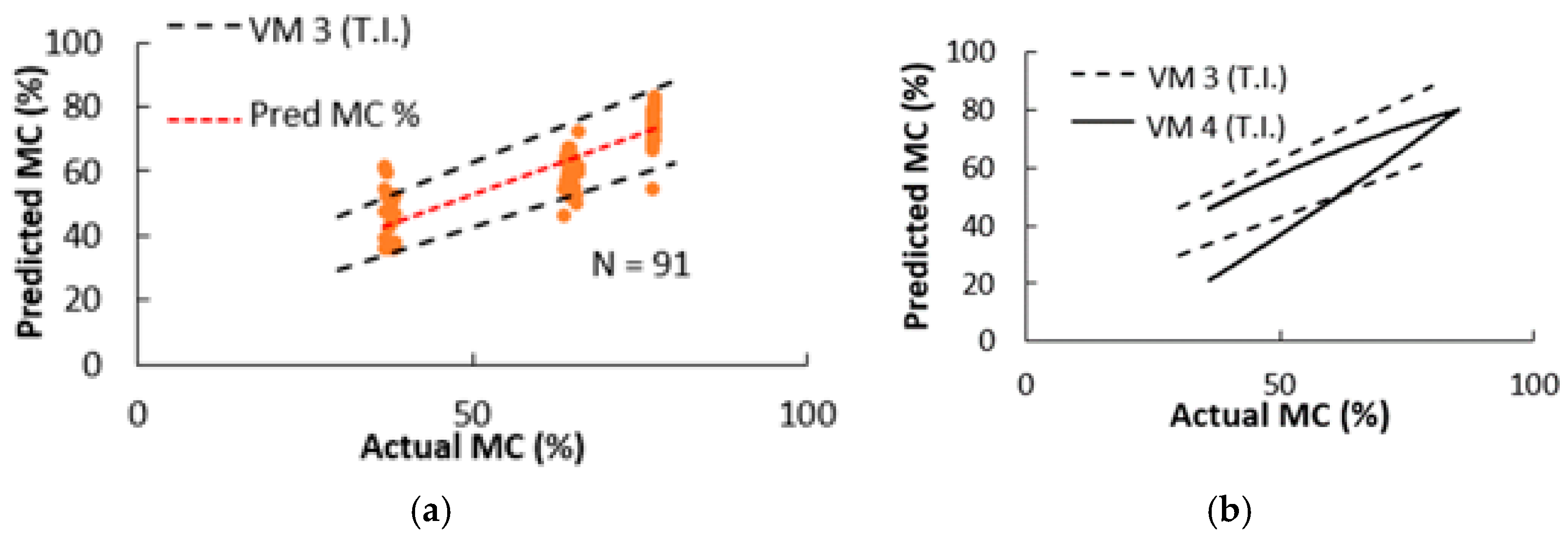

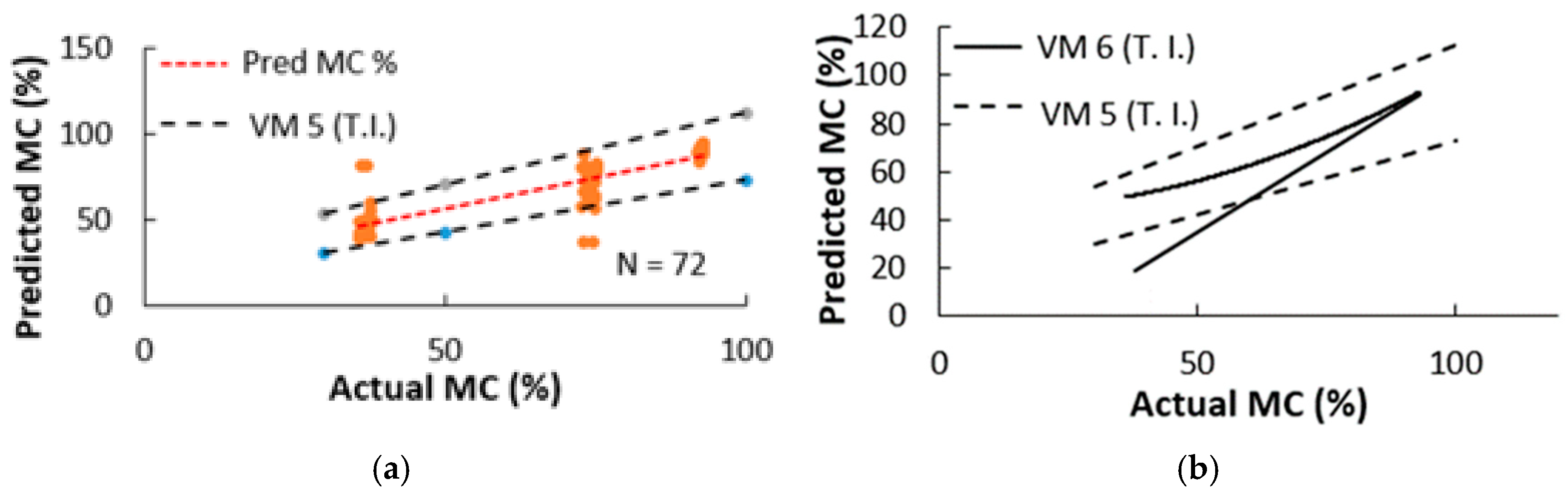

- For three hardwood species—birch (Betula spp.), aspen (Populus spp.), and black alder (Alnus glutinosa (L.) Gaertn)—it was found that the electrical resistance, R, of the wood as determined by the CP method was suitable for the prediction of the wood’s average MC using the R-model (see Figure 7a, Figure 8a and Figure 9a and Table 2).

- For the three hardwood species, it was found that the CP-determined auxiliary variable U (E1;E2) (see Equation (9)) was suitable for predicting the average wood MC using the U-model, with a prediction accuracy about five times better than the one that involved the R-model (see Figure 7b, Figure 8b and Figure 9b and Table 2).

- Comparing the tolerance intervals (T.I.s) of the R-model (VM 1, VM 3, VM 5) and U-model (VM 2, VM4, VM6) single measurements shown in Figure 7b, Figure 8b and Figure 9b, similar trends as in the paper by Tamme (2021) [8] were observed. Namely, the T.I. of the R-model expanded with increasing wood MC, while the T.I. of the U-model concentrated at a single point with increasing wood MC.

- Table 2 shows that the standard error (SE) of the U-model is smaller than the SE of the R-model for all three tree species modelled in this paper.

- When comparing the RMSE of the validation model of the NIR method [27] and the SE of the validation model of the CP method, the RMSE of the NIR method was between 11.29 and 11.38 MC%, depending on the used model. This is of the same order of magnitude as the SE of the R-model of the CP method (see Table 2). We note here that the RMSE and SE are numerically very close quantities because their definition formulas differ only by one degree of freedom. If we compare the RMSE of the validation model of the microwave method [28] and the SE of the validation model of the CP method, the microwave method has an RMSE = 1.9 MC%. However, the CP method (U-model) validation model has an SE = 1.95 MC % (see Table 2). Thus, the RMSEs (SEs) of the microwave and CP methods were practically equal. Unfortunately, in the articles on the NIR method [27] and the microwave method [28], there are no comparative data on the single-measurement tolerance interval (T.I.) of practical interest.

- For the calibration models, repeat measurements were carried out on the CP cycles under the typical indoor conditions of a kiln [13], but when it came to the CP measurement procedure, this fact had no effect on reliability (e.g., faulty measurements, random measurement noise, etc). Consequently, the CP measurement procedure can be used in practice as a possible method for the MC monitoring of wood in a kiln.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Brischke, C.; Rapp, A.O. Influence of wood moisture content and wood temperature on fungal decay in the field: Observations in different micro-climates. Wood Sci. Technol. 2008, 42, 663–677. [Google Scholar] [CrossRef]

- Brookhuis Micro-Electronics BV. Moisture Measuring Manual; Version 1.4; Brookhuis Micro-Electronics BV: Almelo, The Netherlands, 2009; p. 27. [Google Scholar]

- Uwizeyimana, P.; Perrin, M.; Eyma, F. Moisture monitoring in glulam timber structures with embedded resistive sensors: Study of influence parameters. Wood Sci. Technol. 2020, 54, 1463–1478. [Google Scholar] [CrossRef]

- Skaar, C. Some factors involved in the electrical determination of moisture gradients in wood. For. Prod. J. 1964, 14, 239–243. [Google Scholar]

- Tamme, V.; Muiste, P.; Kask, R.; Tamme, H. Experimental study of electrode effects of resistance type electrodes for monitoring wood drying process above fiber saturation point. For. Stud. 2012, 56, 42–55. [Google Scholar]

- Berga, S.C.; Gil, R.G.; Anton, A.E.; Muñoz, A.R. Novel Wood Resistance Measurement Method Reducing the Initial Transient Instabilities Arising in DC Methods Due to Polarization Effects. Electronics 2019, 8, 1253. [Google Scholar] [CrossRef]

- Suarez, S.; Sandhacker, M.; Logar, L.; Riegler, M.; Arminger, B.; Konnerth, J.; Kindl-Altmutter, W.; Tran, A. Non-invasive method to measure bulk electrical resistivity of spruce wood—Influence of moisture content and anatomical direction. Wood Mater. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Tamme, V.; Tamme, H.; Miidla, P.; Muiste, P. Novel polarization-type moisture meter for determining moisture content of wood above fibre saturation point. Eur. J. Wood Wood Prod. 2021, 79, 1577–1587. [Google Scholar] [CrossRef]

- Tamme, V.; Jänes, A.; Romann, T.; Tamme, H.; Muiste, P.; Kangur, A. Investigation and modeling of the electrical charging effect in birch wood above the fiber saturation point (FSP). For. Stud. 2022, 77, 21–37. [Google Scholar] [CrossRef]

- Eco Chemie, Metrohm Autolab B.V. Available online: https://www.metrohm.com/en/applications/ (accessed on 23 January 2025).

- Feutron Klimasimulation GmbH. Available online: https://www.feutron.de/en/weathering-chamber/ (accessed on 22 January 2025).

- Nitrocellulose Laquer. Available online: https://www.madinter.com/en/nitorlackr-nitrocellulose-lacquer-vintage-clear-gloss-spray.html (accessed on 22 January 2025).

- Tamme, H.; Kask, R.; Muiste, P.; Tamme, V. An experimental determination of the critical diffusion coefficient and critical relative humidity (RH) of drying air when optimizing the drying of three hardwood species (Birch, Aspen, and Black Alder). For. Stud. 2023, 79, 3–20. [Google Scholar] [CrossRef]

- EN 13183-2:2005; Moisture Content of a Piece of Sawn Timber—Part 2: Estimation by Electrical Resistance Method. iTeh Standards: San Francisco, CA, USA, 2005; p. 6.

- Gann Mess-u Regeltechnik GmbH. Available online: http://www.gann.de (accessed on 22 January 2025).

- ISO 3130:1975; Wood—Determination of Moisture Content for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 1975; p. 2.

- Kretchetov, I.V. Kiln Drying; Wood Industry: Moscow, Russia, 1972; p. 440. (In Russian) [Google Scholar]

- Eco Chemie. Metrohm Autolab B.V. Available online: https://www.metrohm.com/en_nl/products/electrochemistry/modular-line.html (accessed on 24 January 2025).

- ISO 3534-1:1993; Statistics—Vocabulary and Symbols—Part 1: Propability and General Statistical Terms. International Organization of Standartization: Geneva, Switzerland, 1993; p. 46.

- R-Projekt. The R Project for Statistical Computing. Available online: http://www.r-project.org (accessed on 24 January 2025).

- ISO/IEC GUIDE 98-3:2008(E); Uncertainty of Measurement—Part 3: Guide to the Expression of Uncertainty in Measurement (GUM:1995). International Organisation for Standardization: Geneva, Switzerland, 2008; p. 120.

- Laaneots, R.; Mathiesen, O. An Introduction to Metrology; TUT Press: Tallinn, Estonia, 2006; p. 271. [Google Scholar]

- Rozema, P. Dos and Don’ts in Respect to Moisture Measurement. The Future of Quality Control for Wood & Wood Products. In Proceedings of the Final Conference of COST Action E 53, Edinburgh, UK, 4–7 May 2010; p. 9. [Google Scholar]

- Tamme, H.; Kask, R.; Muiste, P.; Tamme, V. Comparative testing of two alternating current methods for determining wood moisture content in kiln conditions. For. Stud. 2021, 74, 72–87. [Google Scholar] [CrossRef]

- Tamme, H. Development of Control and Optimization Methods for Wood Drying. Ph.D. Thesis, Estonian University of Life Sciences, Tartu, Estonia, 2023; p. 181. [Google Scholar]

- Gendvilas, V.; Downes, G.M.; Lausberg, M.; Harrington, J.-J.; Lee, D.J. Predicting Wood Density Using Resistance Drilling: The Effect of Varying Feed Speed and RPM. Forests 2024, 15, 579. [Google Scholar] [CrossRef]

- Amaral, E.A.; Baliza, L.F.; dos Santos, L.M.; Shashiki, A.T.; Trugilho, P.F.; Hein, P.R.G. Hydromechanical behavior of wood during drying studied by NIR spectroscopy and image analysis. Holzforschung 2023, 77, 618–628. [Google Scholar] [CrossRef]

- Afif, O.; Franceschelli, L.; Iaccheri, E.; Trovarello, S.; Di Florio DiRenzo, A.; Ragni, L.; Costanzo, A.; Tartagni, M. A Versatile, Machine-Learning-Enhanced RFSpectral Sensor for Developing aTrunk Hydration Monitoring System in Smart Agriculture. Sensors 2024, 24, 6199. [Google Scholar] [CrossRef] [PubMed]

| Measured Actual MC (%) | Measured Electrical. Resistance (kΩ) | Measured Electrical Chargeability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Moisture Group Obs. No. | Avg MC% | Range, MC% | St. Dev. MC% | Var. Coef. (%) | Avg (kΩ) | Range, (kΩ) | St. Dev. (kΩ) | Var. Coef. (%) | Avg | Range | St. Dev. | Var. Coef. (%) |

| Birch (Betula spp.) | ||||||||||||

| 1. n = 20 | 69.5 | 2.35 | 0.72 | 1.04 | 73.5 | 38.9 | 8.78 | 11.9 | 0.81 | 0.191 | 0.052 | 6.42 |

| 2. n = 20 | 56.7 | 2.31 | 0.71 | 1.25 | 100.7 | 60.3 | 15.9 | 15.8 | 0.81 | 0.11 | 0.033 | 4.07 |

| 3. n = 20 | 34.4 | 1.98 | 0.61 | 1.77 | 215.4 | 15.6 | 37.7 | 17.5 | 0.72 | 0.19 | 0.049 | 6.81 |

| Aspen (Populus spp.) | ||||||||||||

| 1. n = 31 | 77.06 | 0.505 | 0.156 | 0.2 | 46.7 | 49.1 | 8.6 | 18.4 | 0.533 | 0.76 | 0.172 | 32.3 |

| 2. n = 30 | 64.9 | 2.25 | 0.67 | 1.03 | 70.4 | 54 | 12 | 17.05 | 0.638 | 0.389 | 0.105 | 16.46 |

| 3. n = 30 | 37.6 | 1.88 | 0.61 | 1.62 | 114.6 | 97.7 | 2.8 | 2.4 | 0.511 | 0.543 | 0.144 | 28.2 |

| Black alder (Alnus glutinosa (L.) Gaertn.) | ||||||||||||

| 1. n = 24 | 92.58 | 0.905 | 0.27 | 0.29 | 193 | 119 | 30.5 | 15.8 | 0.59 | 0.263 | 0.066 | 11.2 |

| 2. n = 24 | 74.02 | 2.56 | 0.84 | 1.13 | 324 | 192 | 47 | 14.5 | 0.58 | 0.227 | 0.052 | 8.97 |

| 3. n = 24 | 36.8 | 2.33 | 0.69 | 1.9 | 400 | 60 | 15.7 | 3.9 | 0.61 | 0.53 | 0.117 | 19.2 |

| Mod. No. Obs. No. Figure No. | Model Type | Equations for Calculating Single-Measurement Tolerance Interval (T.I.) (T.I. = yupper − ylower) | R2 | SE; p- Value | Focal Point on MC % | Calculated MC Range Where T.I. < 3.5% (Acc. [23]) |

|---|---|---|---|---|---|---|

| Birch (Betula spp.), | ||||||

| VM 1 n = 60 Figure 7a | R- model | yupper = 1.0169x + 7.757 ylower = 0.8544x − 1.294 | 0.912 | 4.576 <0.01 | ----- | >3.5 |

| VM 2 n = 60 Figure 7b | U- model | yupp = −0.0005x2 + 0.95x − 6.14 ylow = 0.0086x2 + 0.11x + 17.1 | 0.98 | 1.95 <0.01 | 77 | 69–83 |

| Aspen (Populus spp.) | ||||||

| VM 3 n = 91 Figure 8a | R- model | yupper = 0.8404x + 20.829 ylower = 0.6647x + 9.629 | 0.753 | 7.19 <0.01 | ------ | >3.5 |

| VM 4 n = 91 Figure 8b | U- model | yupp = −0.0039x2 + 1.17x + 8.97 ylow = 0.0033x2 + 0.82x − 12.8 | 0.971 | 2.79 <0.01 | 85 | 76–89 |

| Black alder (Alnus glutinosa (L.) Gaertn.) | ||||||

| VM 5 n = 72 Figure 9a | R- model | yupper = 0.839x + 28.335 ylower = 0.6125x + 11.895 | 0.67 | 10.91 <0.01 | ----- | >3.5 |

| VM 6 n = 72 Figure 9b | U- model | yupp = 0.0092x2 − 0.37x + 51.1 ylow = 1.3327x − 32.08 | 0.93 | 5.86 <0.01 | 93 | 92–110 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamme, V.; Tamme, H.; Muiste, P.; Kangur, A. A Novel Chrono-Potentiometry (CP) Method for Determining the Moisture Content of Wood Above the Fibre Saturation Point (FSP). Forests 2025, 16, 446. https://doi.org/10.3390/f16030446

Tamme V, Tamme H, Muiste P, Kangur A. A Novel Chrono-Potentiometry (CP) Method for Determining the Moisture Content of Wood Above the Fibre Saturation Point (FSP). Forests. 2025; 16(3):446. https://doi.org/10.3390/f16030446

Chicago/Turabian StyleTamme, Valdek, Hannes Tamme, Peeter Muiste, and Ahto Kangur. 2025. "A Novel Chrono-Potentiometry (CP) Method for Determining the Moisture Content of Wood Above the Fibre Saturation Point (FSP)" Forests 16, no. 3: 446. https://doi.org/10.3390/f16030446

APA StyleTamme, V., Tamme, H., Muiste, P., & Kangur, A. (2025). A Novel Chrono-Potentiometry (CP) Method for Determining the Moisture Content of Wood Above the Fibre Saturation Point (FSP). Forests, 16(3), 446. https://doi.org/10.3390/f16030446