Experimental Study of Timber Composite Beam Elements Using Hardwood Mechanically Inserted and Welded Dowels

Abstract

1. Introduction

1.1. In General

1.2. Aim of the Study

2. Materials and Methods

2.1. In General

2.2. Assessment of Efficiency

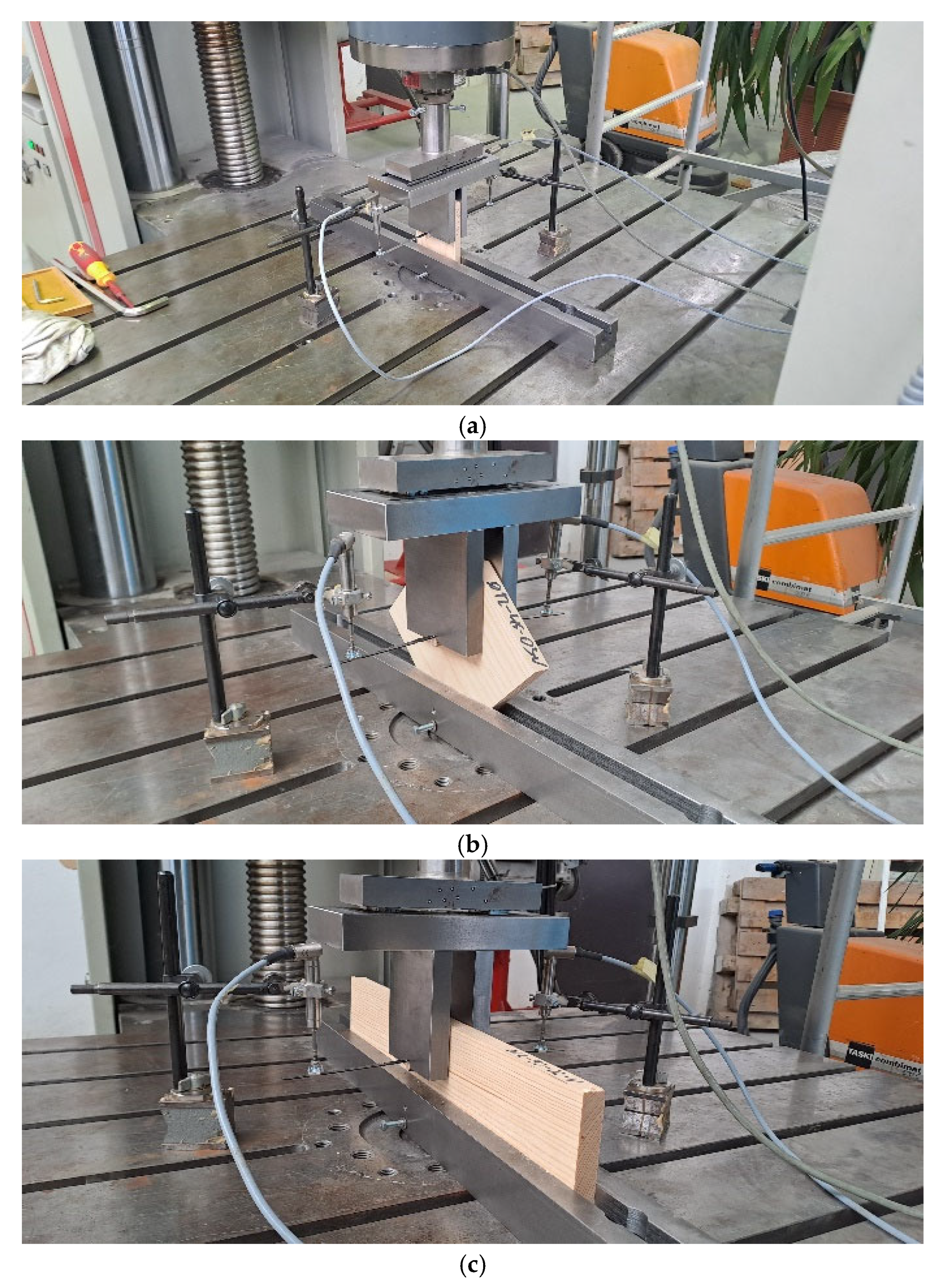

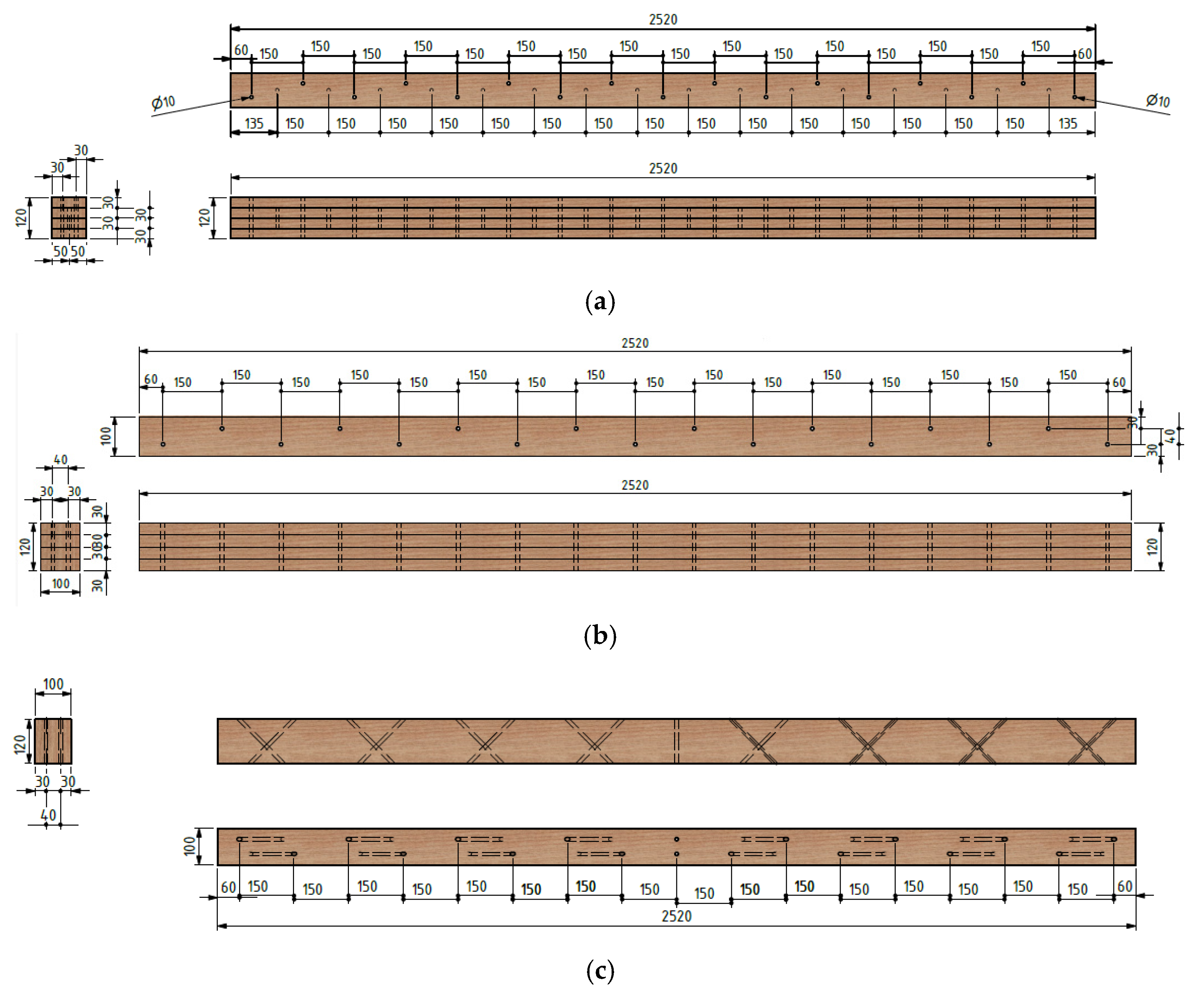

2.3. Determination of Wooden Dowels Embedment Strength

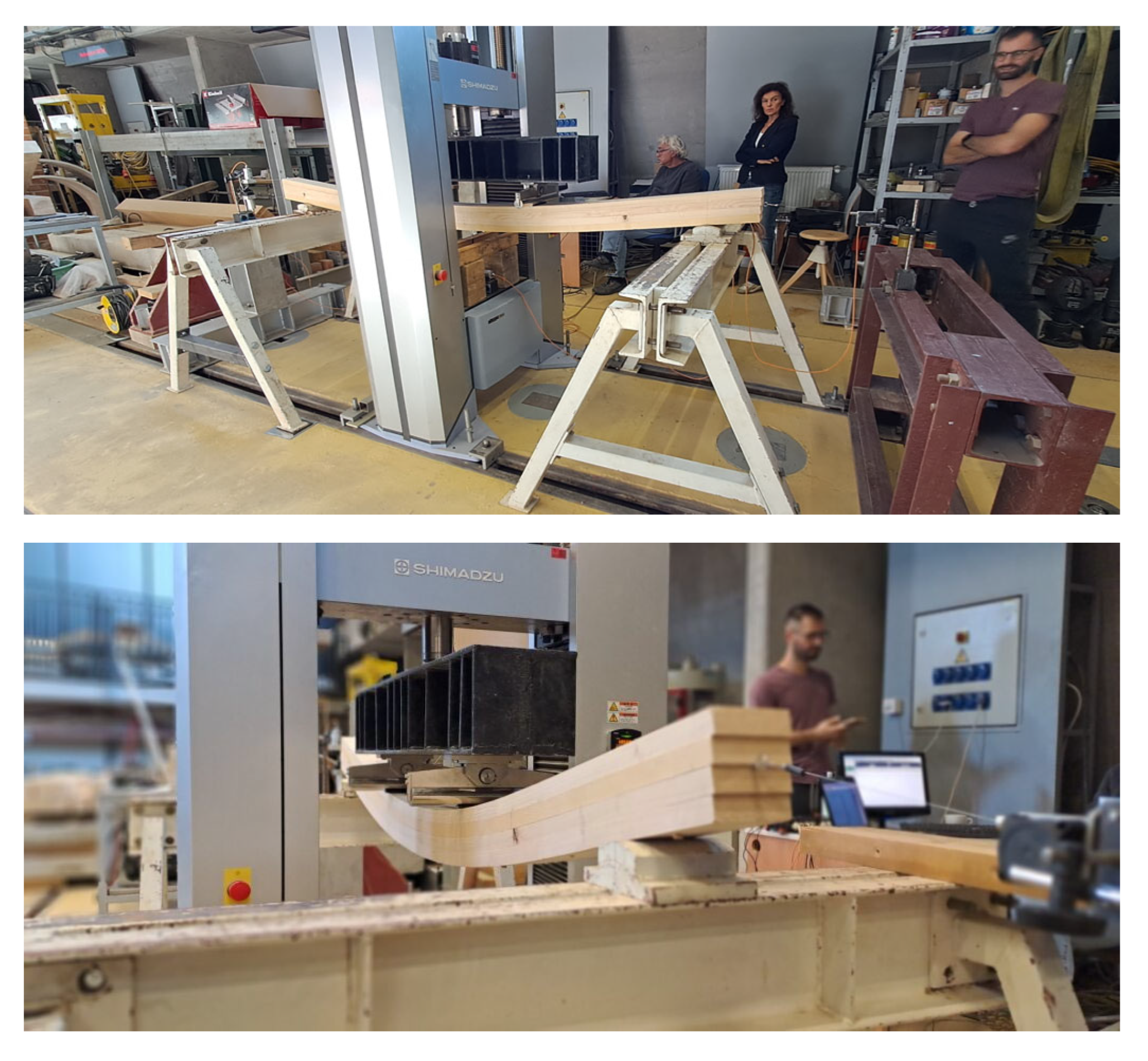

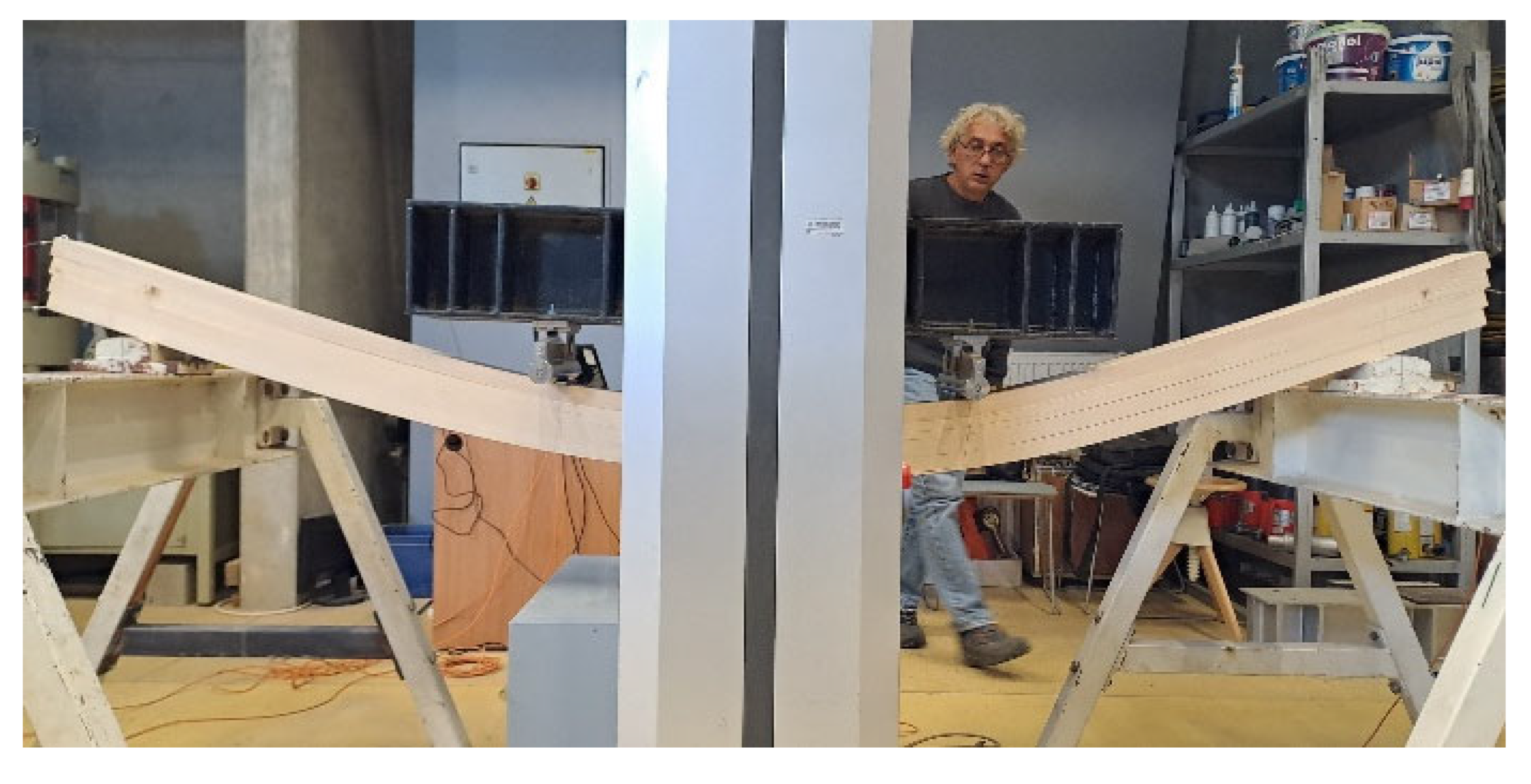

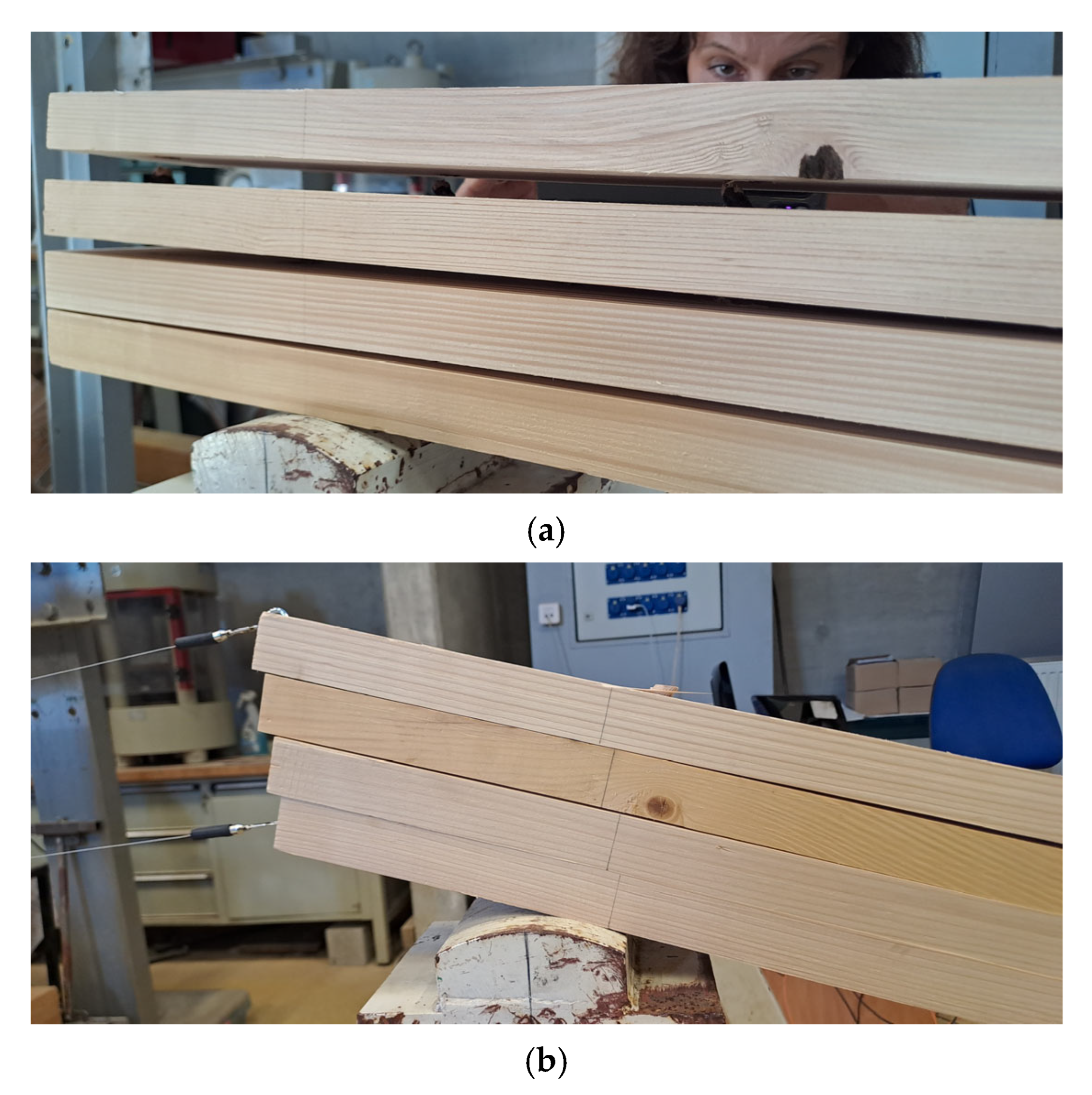

2.4. Behavior Investigation of Dowel-Laminated Timber Beams

3. Results

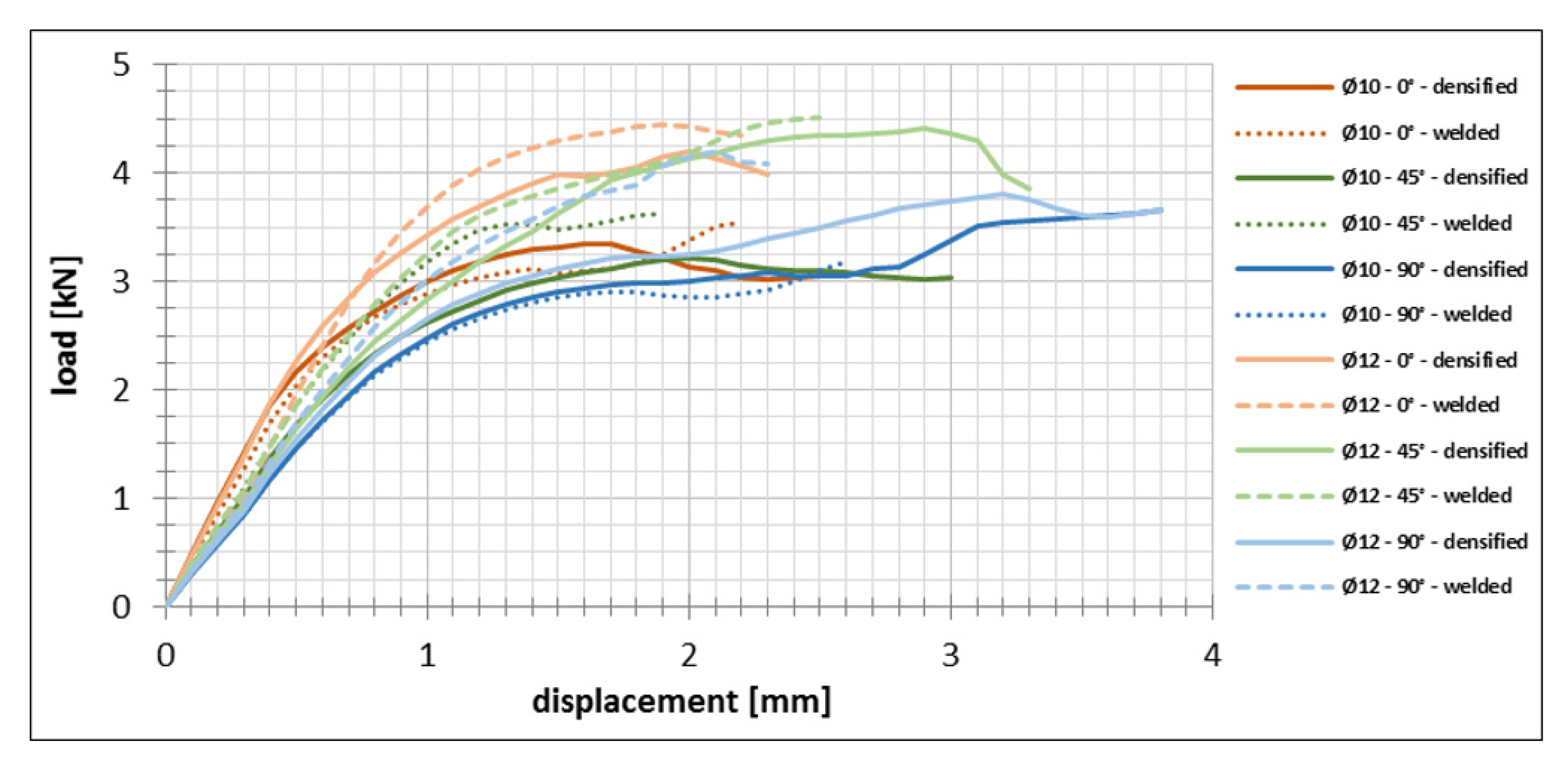

3.1. Wooden Dowels Embedment Strength

where k90 = 1.35 + 0.015 × d for softwoods,

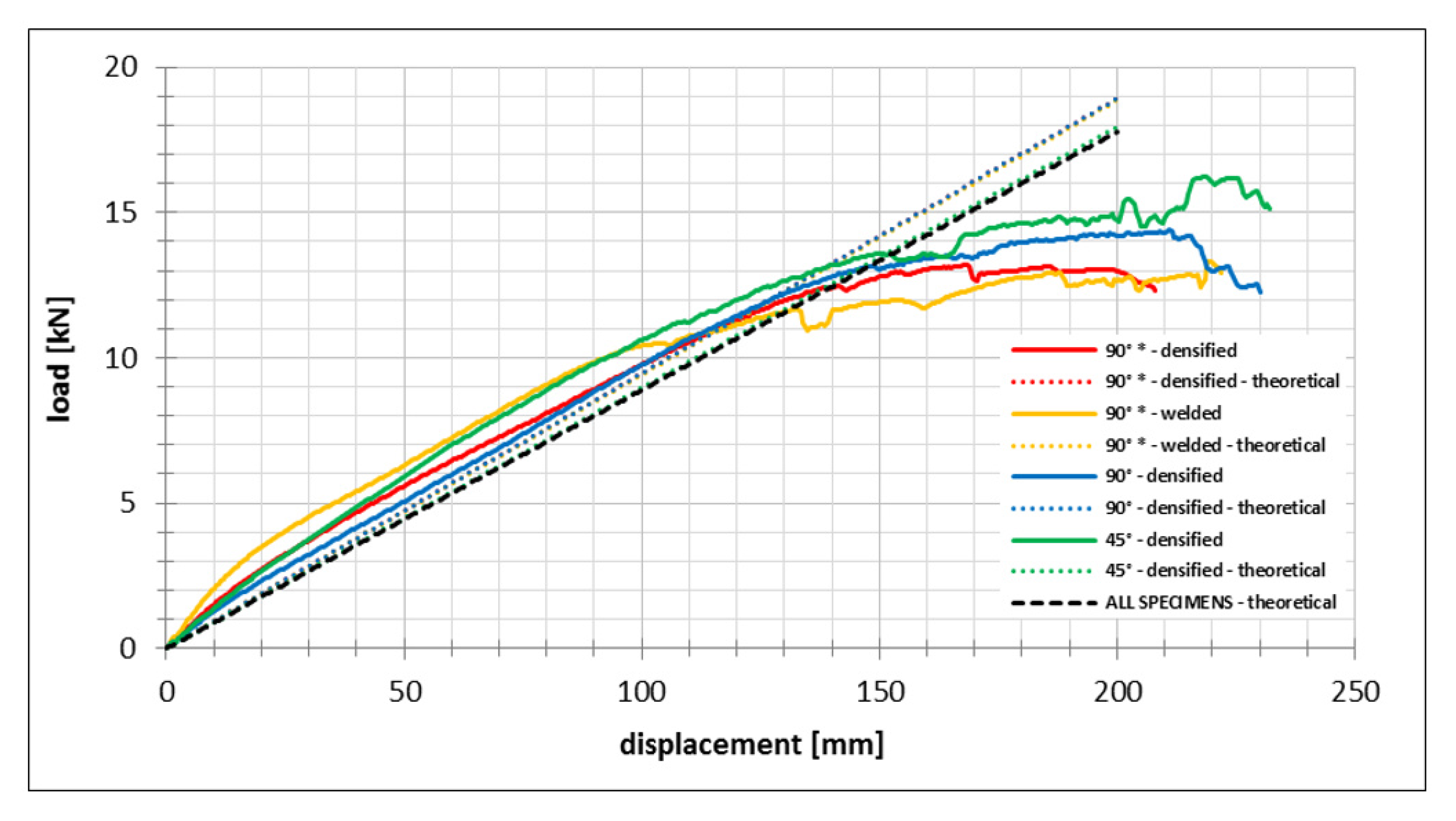

3.2. Behavior of Dowel-Laminated Timber Beams

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, L.; Kutnar, A.; Sandak, J.; Šušteršič, I.; Sandberg, D. Adhesive-and Metal-Free Assembly Techniques for Prefabricated Multi-Layer Engineered Wood Products: A Review on Wooden Connectors. Forests 2023, 14, 311. [Google Scholar] [CrossRef]

- Sotayo, A.; Bradley, D.; Bather, M.; Sareh, P.; Oudjene, M.; El-Houjeyri, I.; Harte, A.M.; Mehra, S.; O’Ceallaigh, C.; Haller, P.; et al. Review of state of the art of dowel laminated timber members and densified wood materials as sustainable engineered wood products for construction and building applications. Dev. Built Environ. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Puettmann, M.E.; Wilson, J.B. Gate-to-gate life-cycle inventory of glued-laminated timbers production. Wood Fiber Sci. 2005, 37, 99–113. [Google Scholar]

- Venkatarama-Reddy, B.V. Sustainable building technologies. Curr. Sci. 2024, 87, 899–907. [Google Scholar]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Niu, Y.; Rasi, K.; Hughes, M.; Halme, M.; Fink, G. Prolonging life cycles of construction materials and combating climate change by cascading: The case of reusing timber in Finland. Resour. Conserv. Recycl. 2021, 170, 105555. [Google Scholar] [CrossRef]

- Derikvand, M.; Hosseinzadeh, S.; Fink, G. Mechanical Properties of Dowel Laminated Timber Beams with Connectors Made of Salvaged Wooden Materials. J. Archit. Eng. 2021, 27, 04021035. [Google Scholar] [CrossRef]

- Derikvand, M.; Fink, G. Potential of reusing salvaged wooden materials in fabricating structural dowel laminated timber. In Proceedings of the World Conference on Timber Engineering 2023—WCTE 2023, Oslo, Norway, 19–22 June 2023; pp. 1–6. [Google Scholar]

- Aloisio, A.; Wang, Y.; Crocetti, R.; Nyrud, A.Q.; Tomasi, R. Mechanical performance of pure-wood moment-resisting ridge joints with plywood gussets and wooden dowels. Eng. Struct. 2025, 334, 120271. [Google Scholar] [CrossRef]

- O’Ceallaigh, C.; Conway, M.; Mehra, S.; Harte, A.M. Numerical investigation of reinforcement of timber elements in compression perpendicular to the grain using densified wood dowels. Constr. Build. Mater. 2021, 288, 122990. [Google Scholar] [CrossRef]

- Conway, M.; Mehra, S.; Harte, A.M.; O’Ceallaigh, C. Densified wood dowel reinforcement of timber perpendicular to the grain: A pilot study. J. Struct. Integr. Maint. 2021, 6, 177–186. [Google Scholar] [CrossRef]

- O’Ceallaigh, C.; Harte, A.M.; McGetrick, P.J. Numerical examination of the behaviour of dowel laminated timber elements utilising compressed wood dowels. In Proceedings of the World Conference on Timber Engineering 2023—WCTE 2023, Oslo, Norway, 19–22 June 2023; pp. 1–9. [Google Scholar]

- Xu, B.-H.; Zhang, S.-D.; Zhao, Y.-H.; Bouchaïr, A.; Zhang, B. Mechanical Properties of Adhesive-Free Cross-Laminated Timber. J. Struct. Eng. 2022, 148, 04022135. [Google Scholar] [CrossRef]

- Bruzzone, G.; Godoy, D.; Quagliotti, S.; Arrejuria, S.; Böthig, S.; Moya, L. Experimental Investigation on Dowel Laminated Timber Made of Uruguayan Fast-Grown Species. Forests 2023, 14, 2215. [Google Scholar] [CrossRef]

- El-Houjeyri, I.; Thi, V.-D.; Oudjene, M.; Khelifa, M.; Rogaume, Y.; Sotayo, A.; Guan, Z. Experimental investigations on adhesive free laminated oak timber beams and timber-to-timber joints assembled using thermo-mechanically compressed wood dowels. Constr. Build. Mater. 2019, 222, 288–299. [Google Scholar] [CrossRef]

- Teodorescu, I.; Pereira, B.; Aquino, C.D.; Branco, J.M. Experimental evaluation of dowel-type timber joints with wooden dowels. Proc. Inst. Civ. Eng. Struct. Build. 2020, 173, 927–938. [Google Scholar] [CrossRef]

- Khan, I.U.; Subhani, M.; Ghabraie, K.; Ashraf, M. Exploring and refining testing approaches for hardwood dowels under axial and flexural loading: An experimental and numerical study. Wood Mater. Sci. Eng. 2025, 1–23. [Google Scholar] [CrossRef]

- Tomasi, R.; De Santis, Y.; Aloisio, A.; Crocetti, R.; Sæby, V.H.; Nyrud, A.Q. Experimental and analytical investigation on timber connections with beech, birch and laminated densified wooden dowels. Constr. Build. Mater. 2025, 494, 14269. [Google Scholar] [CrossRef]

- Župčić, I.; Vlaović, Z.; Domljan, D.; Grbac, I. Influence of Various Wood Species and Cross-Sections on Strength of a Dowel Welding Joint. Drv. Ind. 2014, 65, 121–127. [Google Scholar] [CrossRef]

- Gedara, A.K.A.; Chianella, I.; Endrino, J.L.; Zhang, Q. Adhesiveless bonding of wood—A review with a focus on wood welding. BioResources 2021, 16, 6448–6470. [Google Scholar] [CrossRef]

- Bocquet, J.F.; Pizzi, A.; Despres, A.; Mansouri, H.R.; Resch, L.; Michel, D.; Letort, F. Wood joints and laminated wood beams assembled by mechanically–welded wood dowels. J. Adhes. Sci. Technol. 2007, 21, 301–317. [Google Scholar] [CrossRef]

- O’Loinsigh, C.; Oudjene, M.; Ait–Aider, H.; Fanning, P.; Pizzi, A.; Shotton, E.; Meghlat, E.-M. Experimental study of timber-to-timber composite beam using welded-through wood dowels. Constr. Build. Mater. 2012, 36, 245–250. [Google Scholar] [CrossRef]

- EN 1995-1-1:2004+AC:2006+A1:2008; Eurocode 5: Design of Timber Structures. CEN: Bruxelles, Belgium, 2008.

- Gutkowski, R.; Brown, K.; Shigidi, A.; Natterer, J. Laboratory tests of composite wood-concrete beams. Constr. Build. Mater. 2008, 22, 1059–1066. [Google Scholar] [CrossRef]

- EN 1380:2009; Timber Structures—Test Methods—Load Bearing Nails, Screws, Dowels and Bolts. CEN: Bruxelles, Belgium, 2009.

- ISO 3129:2019; Wood—Sampling Methods and General Requirements for Physical and Mechanical Testing of Small Clear Wood Specimens. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 13061:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1—Determination of Moisture Content for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- EN 384:2016+A2:2022; Structural Timber—Determination of Characteristic Values of Mechanical Properties and Density. CEN: Bruxelles, Belgium, 2022.

- EN 408:2010+A1:2012; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. CEN: Bruxelles, Belgium, 2012.

- EN 338:2016; Structural Timber—Strength Classes. CEN: Bruxelles, Belgium, 2016.

| Type of Specimen | Dimensions of the Lamellae That Makes Specimen | |||

|---|---|---|---|---|

| Dowel Diameter [mm] | Force Angle [°] | Length [mm] | Heigh [mm] | Thickness [mm] |

| 10 | 0 | 100 | 140 | 15 |

| 45 | 140 (198) | 140 | 15 | |

| 90 | 400 | 100 | 15 | |

| 12 | 0 | 100 | 168 | 18 |

| 45 | 168 (238) | 168 | 18 | |

| 90 | 480 | 100 | 18 | |

| Type of Specimen | Theoretical Data/Tested Data | |||

|---|---|---|---|---|

| Dowel Diameter [mm] | Force Angle [°] | Dowel Installation Type | fh,α,mean [N/mm2] | Kser,mean [N/mm] |

| 10 | 0 | pressed | 29.52/22.27 | 3479/4789 |

| welded | 31.75/23.62 | 3881/4260 | ||

| 45 | pressed | 27.72/21.37 | 4423/3389 | |

| welded | 33.39/24.11 | 5846/3698 | ||

| 90 | pressed | 21.20/24.34 | 3888/2949 | |

| welded | 21.44/21.21 | 3956/2927 | ||

| 12 | 0 | pressed | 26.34/19.46 | 3639/4674 |

| welded | 26.09/20.59 | 3588/3797 | ||

| 45 | pressed | 22.31/20.45 | 3901/3285 | |

| welded | 22.46/20.8 | 3941/3741 | ||

| 90 | pressed | 16.74/17.58 | 3489/3106 | |

| welded | 18.92/19.44 | 4190/3393 | ||

| Type of Specimen | Tested Data | Theoretical Data | |||

|---|---|---|---|---|---|

| Kser,mean [N/mm] | Fmax [kN] | EImean [Nmm2 × 1010] | Kser,mean [N/mm] | EImean [Nmm2 × 1010] | |

| 90°*-pressed | 4342 | 13.32 | 4.045 | 3836 | 3.384/3.180 |

| 90°*-welded | 4309 | 13.31 | 4.853 | 3836 | 3.371/3.180 |

| 90°-pressed | 4342 | 14.38 | 3.783 | 3836 | 3.384/3.180 |

| 45°-pressed | 3907 | 16.21 | 4.197 | 3836 | 3.209/3.180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbalić, J.; Zadravec, B.; Perković, N.; Rajčić, V. Experimental Study of Timber Composite Beam Elements Using Hardwood Mechanically Inserted and Welded Dowels. Forests 2025, 16, 1748. https://doi.org/10.3390/f16111748

Barbalić J, Zadravec B, Perković N, Rajčić V. Experimental Study of Timber Composite Beam Elements Using Hardwood Mechanically Inserted and Welded Dowels. Forests. 2025; 16(11):1748. https://doi.org/10.3390/f16111748

Chicago/Turabian StyleBarbalić, Jure, Bruno Zadravec, Nikola Perković, and Vlatka Rajčić. 2025. "Experimental Study of Timber Composite Beam Elements Using Hardwood Mechanically Inserted and Welded Dowels" Forests 16, no. 11: 1748. https://doi.org/10.3390/f16111748

APA StyleBarbalić, J., Zadravec, B., Perković, N., & Rajčić, V. (2025). Experimental Study of Timber Composite Beam Elements Using Hardwood Mechanically Inserted and Welded Dowels. Forests, 16(11), 1748. https://doi.org/10.3390/f16111748