1. Introduction

Bamboo, a widely distributed plant in tropical and subtropical regions such as China, South America, and Southeast Asia, has served as a traditional industrial crop for millennia. Historically, its abundance and favorable mechanical properties made it a primary material for construction alongside wood. In modern engineering, its applications have expanded to include construction, furniture, decoration, and various structural applications. As a sustainable, low-carbon, and biodegradable material, bamboo exhibits significantly lower energy consumption and greater degradability than conventional industrial materials such as steel and cement, giving it prominent advantages for green economy applications [

1,

2]. These features underscore bamboo’s importance as a sustainable alternative in climate-conscious material science.

However, the inherent properties of bamboo, particularly its rapid nutrient uptake and high moisture content, also present significant processing challenges. During its rapid growth, bamboo absorbs water and essential mineral nutrients such as nitrogen and phosphorus from the soil, while sugars and starches are synthesized internally through photosynthesis. These characteristics, combined with its high moisture content, make bamboo highly susceptible to insect infestation and microbial decay, and can lead to dimensional instability, thereby compromising its quality and service life. Consequently, drying and chemical modification are essential pre-treatments to enhance its durability and dimensional stability.

Unfortunately, these processes are severely hampered by the inherently poor permeability of bamboo [

3,

4,

5]. Research indicates that the average penetration depth of untreated bamboo is only 431 μm, which is 3–5 times lower than that of typical wood [

5]. This limited permeability is intrinsically linked to bamboo’s unique anatomical structure, which features longitudinal transport tissues but relies predominantly on diffusion through cell wall micropores for transverse conduction [

6,

7,

8]. This greatly affects its penetration efficiency and uniformity, making it necessary to improve the permeability of bamboo. As a result, bamboo’s penetration efficiency and treatment uniformity are significantly compromised [

5,

9,

10].

A systematic understanding of bamboo permeability is therefore crucial for enabling targeted improvements in processing technologies [

11,

12,

13]. However, current studies on bamboo permeability are fragmented and often focused on isolated treatment techniques or single experimental methods [

14,

15]. This disparate approach has led to a lack of standardization, with evaluation indicators and testing techniques varying widely among researchers, thereby limiting comparability and preventing a unified perspective. Moreover, investigations have largely remained at the macroscopic level, with insufficient attention paid to the fundamental relationships between bamboo’s multi-scale microstructure, anatomical features, and fluid permeation behavior [

16,

17]. As a result, a coherent framework that effectively bridges scientific insights with practical industrial applications is still lacking [

18,

19].

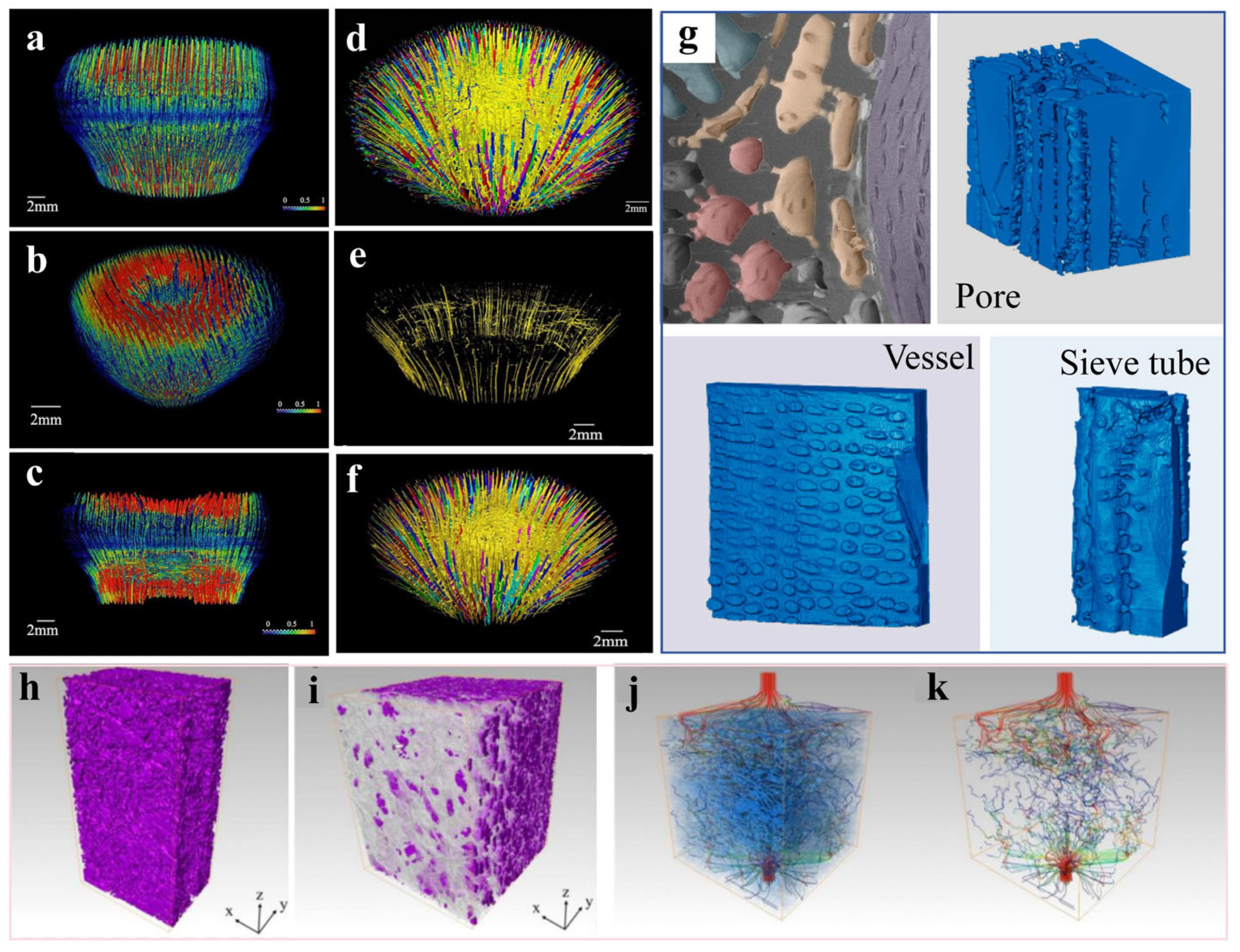

To address these identified gaps, this study employs a comprehensive literature review to systematically consolidate research on bamboo permeability from the past two decades. The review is structured around three core analytical dimensions: structural characteristics, permeation mechanisms, and performance evaluation alongside improvement strategies. Specifically, as shown in

Figure 1, this article first delineates the structural basis of bamboo permeability from the macro- to the micro-scale, establishing a foundation for classifying the underlying transport mechanisms. The review further examines current detection techniques, from direct measurement to advanced imaging, and categorizes modification strategies by their working principles and environmental impact. By integrating these multifaceted perspectives, this review aims to identify key scientific questions, highlight emerging research trends, and ultimately provide a comprehensive reference framework to guide future fundamental research and practical applications in bamboo processing.

2. Multiscale Structural Basis of Bamboo Permeability

2.1. Overview of Bamboo’s Conduction System

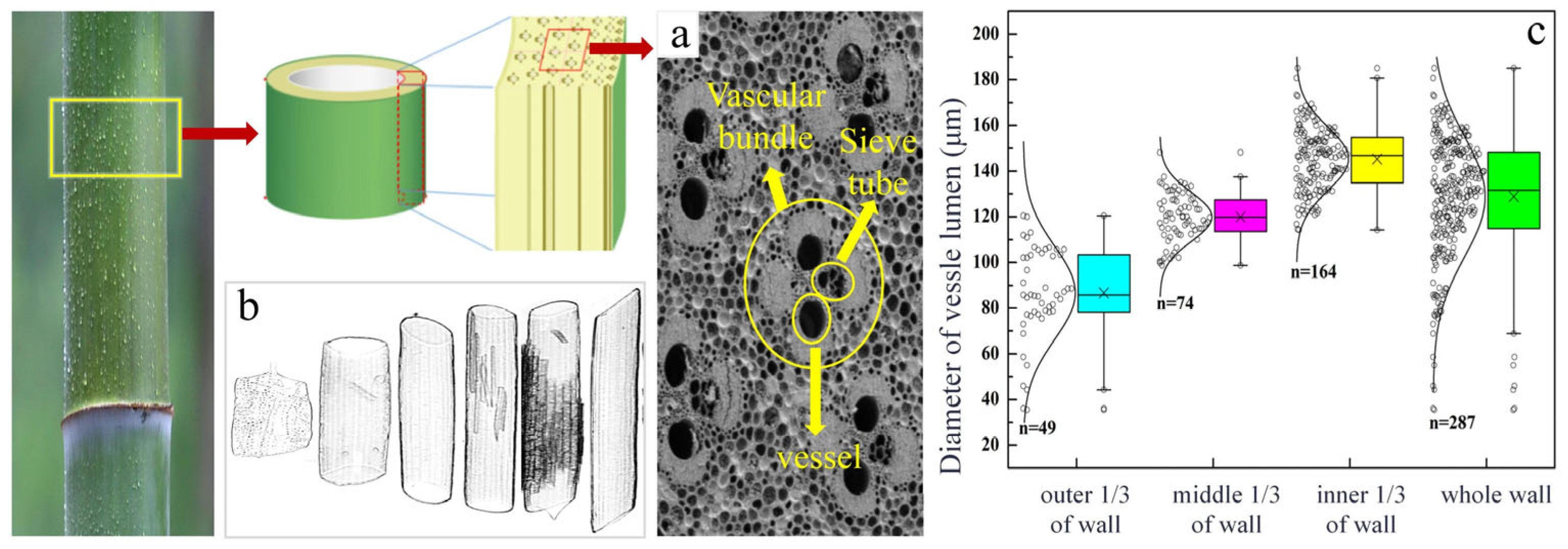

Liquid penetration in bamboo is a complex process. To better illustrate this process,

Figure 2 is provided to give a systematic understanding of bamboo’s permeation behavior. In general, longitudinal penetration is mainly governed by the conductive function of vascular bundles, while a smaller fraction of liquid relies on pit-mediated transport across cell walls for lateral movement. Furthermore, the presence of nodes complicates the longitudinal pathway [

16,

20]. As shown in

Figure 2A, liquid transport proceeds in a repeating sequence of internode–node–internode, forming a cyclical pattern along the culm axis. The penetration behavior of liquid in internodes and nodes differs owing to their distinct structural features. As shown in

Figure 2B, vascular bundles are distributed longitudinally within the internode and are embedded in a matrix of parenchyma cells. Each vascular bundle consists of conducting tissues and fibers (

Figure 2C,F). Liquid primarily flows longitudinally through the conducting elements, while lateral transfer occurs through pit structures on the vessel walls (

Figure 2D), allowing diffusion into adjacent parenchyma cells [

20]. Within parenchyma, both longitudinal and transverse transport are facilitated, as illustrated in

Figure 2D,E. The pits, located at cell interfaces, serve as pathways for material exchange. Specifically, substances diffuse across pit membranes, moving from regions of higher concentration to lower concentration.

A similar principle applies in nodes, yet the more intricate orientation of vascular bundles leads to greater complexity. As shown in

Figure 2G, when liquid encounters the node, part of it may pass directly through continuous vessels and reenter the next internode, while another portion may be redirected laterally, either inward toward the diaphragm or outward into the sheath ring [

21]. Thus, the connectivity of vascular bundles—particularly of conducting tissues—between internodes and nodes emerges as a critical factor governing longitudinal transport in bamboo. This connectivity has attracted considerable attention in recent studies.

In summary, from a structural perspective, liquid penetration in bamboo is primarily dependent on conducting tissues, including vessels and sieve tubes. Transfer occurs through perforation plates between end-to-end vessels, while pits mediate exchange between adjacent vessels or between vessels and other cells. At the macroscopic level, the difference in penetration efficiency between internodes and nodes further reflects the structural influence.

In addition, porosity, as a key parameter of bamboo’s porous architecture, plays a role distinct from that of vessels, sieve tubes, and pits, which provide direct flow pathways. Its influence lies in regulating the penetration rate and depth of liquid transport. Higher porosity generally indicates a larger void fraction and lower hydraulic resistance, thereby facilitating diffusion and retention of liquid within bamboo. Conversely, lower porosity restricts penetration: even when conductive pathways are present, insufficient pore volume may hinder infiltration and reduce transport efficiency.

The following section provides a systematic summary of current research related to these structural features and their effects on bamboo permeability.

2.2. Microscopic Conduits Networks

2.2.1. Vessels: The Main Arteries for Longitudinal Flow

Vessels are an important type of cells in the xylem of vascular bundles (

Figure 3a) [

19], which are mainly responsible transporting water and dissolved minerals. They are composed of several vessel elements connected end-to-end to form a continuous pipeline to transport water from the roots to other parts of bamboo. The diameter of a vessel has the most direct effect on its permeability, and its size varies from 10 μm to 200 μm, depending on the bamboo species and the sampling location (

Figure 3b,c) [

16,

20]. For example, the diameter of the vessels of

Gigantochloa scortechinii ranges from 114 μm to 137 μm [

19], whereas those of

Phyllostachys edulis (Moso bamboo) range from 35.6 μm to 185.1 μm, as shown in

Figure 3c [

20].

In addition, to overcome the complexity and low efficiency of traditional anatomical procedures for bamboo vessels, our team applied computer vision techniques to analyze the cross-sections of entire bamboo culms from top to bottom. Specially, a new detection model using the YOLO v7 algorithm were employed to analyze the axial and radial distribution characteristics of vessels in the entire cross-section of moso bamboo [

22]. The processes of vessel detection model construction are shown in

Figure 4a. The results showed that the number and area of the vessels gradually increased along the axial direction from the base to the top of the bamboo culm, as shown in

Figure 4b. This variation helped compensate for the increasing hydraulic resistance with height. Additionally, in the radial direction, the proportion of vessels area increased from the epidermis to the endodermis, with the rate of change transitioning from rapid to slow. The inflection point of this rate change was located at one-third of the bamboo culm’s thickness, which indicates that the structure of bamboo has been optimized to ensure efficient hydraulic transport.

2.2.2. Sieve Tubes: Channels for Organic Nutrient Transport

Sieve tubes are the key conductive tissue in the phloem of bamboo vascular bundles (

Figure 3a), and they are tightly connected through their intercellular sieve pores to form a continuous transport network. This elaborate structure is responsible for efficiently transporting organic nutrients synthesized through photosynthesis, such as sugars, to various parts of the bamboo. Sieve tubes range in diameter from approximately 0.02 mm to 0.22 mm, but their sizes and size distributions significantly vary across different culm sections. Specifically, the middle section of the bamboo culm contains larger and denser sieve tube cells, while the basal and apical sections have smaller and sparser cells. This distribution pattern correlates with the growth requirements of bamboo: the central section, where growth is vigorous and demands more nutrients, has a denser concentration of sieve tubes to facilitate efficient transport. Conversely, the basal and apical sections, with lower growth demands, have sparser sieve tube distributions. This indicates that sieve tubes play a crucial role in nutrient transport within bamboo, with their functions varying according to different plant sections [

23]. Sieve tubes also play a significant role in bamboo processing. Previous investigations have revealed that during tung oil heat treatment, tung oil rapidly penetrates bamboo through sieve tubes and fills the pits, thereby significantly reducing the water absorption and permeability of the resulting bamboo material [

24,

25,

26].

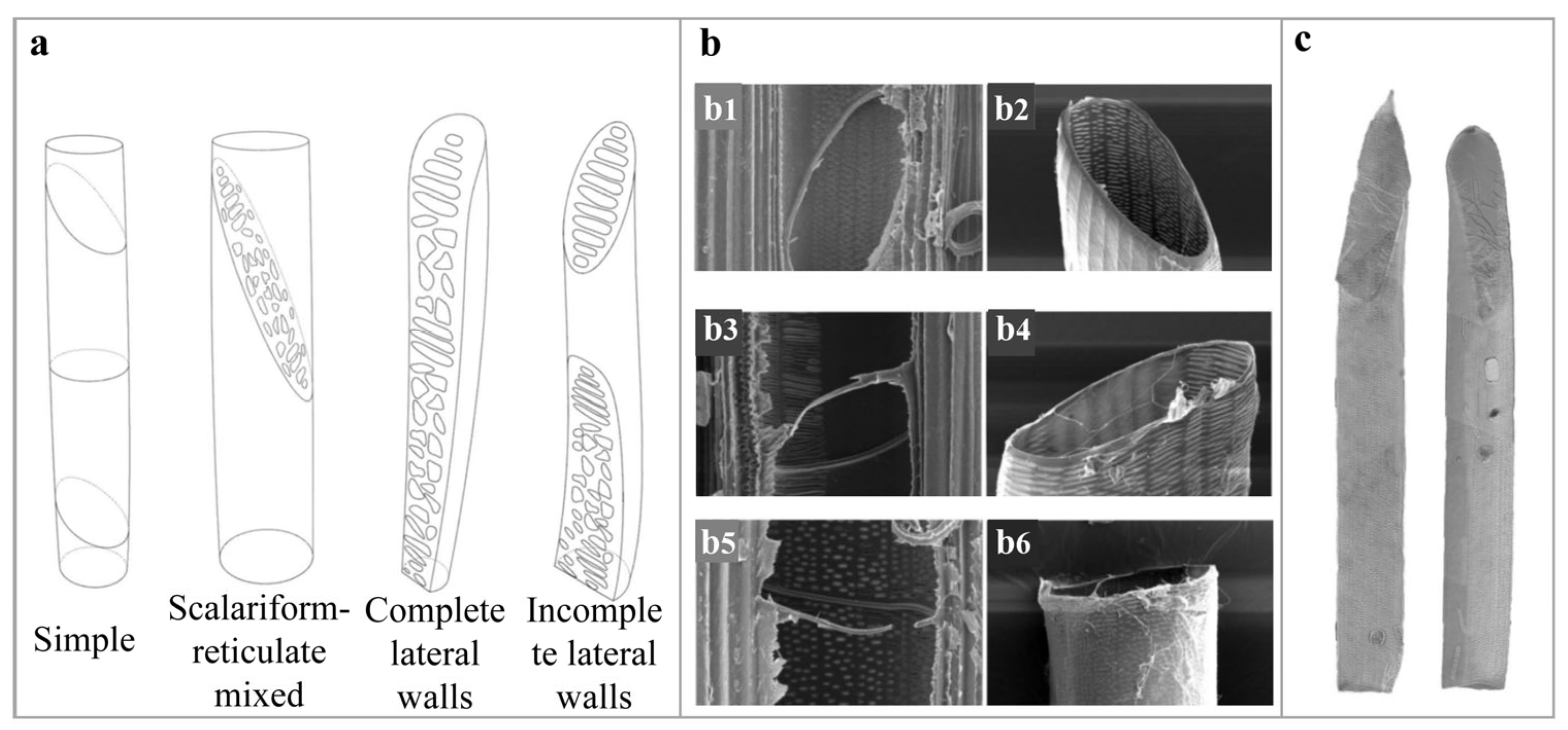

2.2.3. Perforation Plates: Gateways Between Vessel Elements

Perforation plates are specialized structures on the end walls of vessel cells and are responsible for connecting adjacent vessel cells to form longitudinal water transport channels. Perforation plates enable the efficient vertical transport of water and nutrients within bamboo [

19] and are categorized into four types: simple type, scalariform-reticulate mixed type, complete lateral wall type, and incomplete lateral wall type, as shown in

Figure 5. Among these, the simple perforation plates are the most evolved, and their flow resistance is small, while trapezoidal ones are primitive with a larger flow resistance. The evolution of perforation plates occurs from trapezoid to simple perforated plates to accommodate efficient water transport requirements [

16]. In bamboo culm, the main types are simple perforation plates (

Figure 5a) and scalariform-reticulate mixed perforation plates (

Figure 5b). The inclination angle of the perforation plate has a notable influence on the efficiency of water transport. Studies have demonstrated that a smaller inclination angle of the perforation plate within the range of 0° to 83° generates less resistance to water transportation, resulting in a higher transport efficiency [

23]. Furthermore, Luo et al. compared the patterns, inclination angles, and quantities of perforation plates across 12 distinct bamboo species and revealed significant variations among species with different types of underground stems [

23]. These previous results have shown that the structural characteristics of the perforation plates are closely related to the growth environment and physiological traits of bamboo species. The adaptability of different bamboo species in water and nutrient transport may lead to perforation plates with different morphologies and functions.

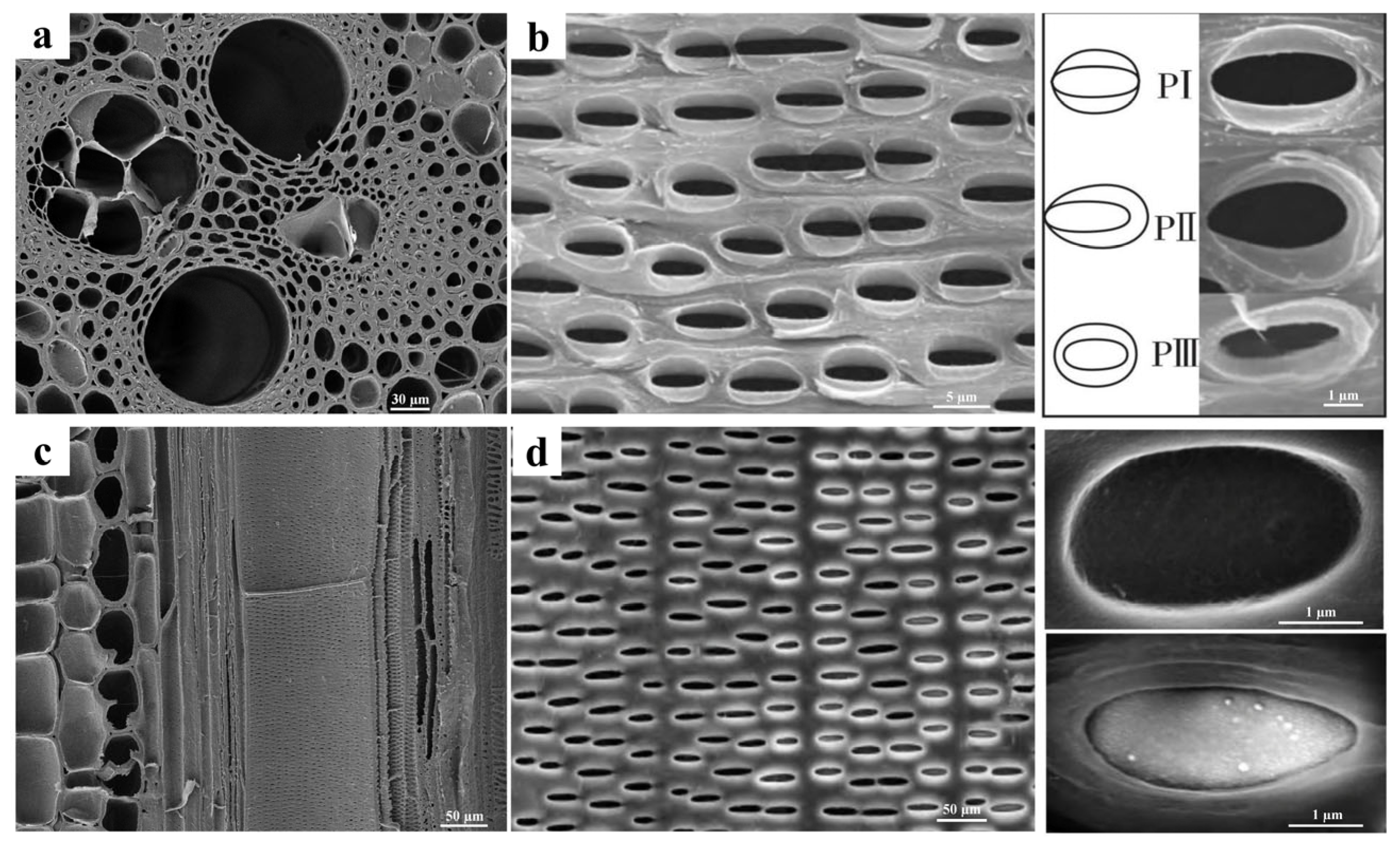

2.2.4. Pits: The Critical Pathways for Transverse Transport

Pits are pores or depressions on the cell walls of bamboo that have not undergone secondary thickening. They serve as important channels for material transport during the growth and development of bamboo and play a central role in transverse conduction and permeation between bamboo cells [

19]. They can be classified into three types based on their distribution: vessel pits, fiber cell pits, and parenchyma cell pits. Liu et al. discovered that the pit characteristics of vessel elements in moso bamboo notably affected bamboo’s permeability [

27]. This was primarily manifested in aspects including geometric morphology, distribution pattern, and state of the pit membranes, as well as the contents within the vessels, as illustrated in

Figure 6. (1) Pit classification: Pits are primarily categorized into simple pits and bordered pits based on their structure and characteristics, with bordered pits having a higher fluid flow resistance and lower permeability efficiency. (2) Pore distribution: The selective arrangement of pores on metaxylem vessels creates uneven transverse permeation paths for fluids within bamboo. (3) State of the pit membrane: The presence or absence of microfibrils covering the pit membrane also influences the fluid passage rate. (4) Contents within the vessels: Material deposits on the inner walls of the vessel can obstruct pores, thereby decreasing their permeability.

Current research on bamboo pits has primarily focused on three aspects: morphological characterization, microchemical analysis of pit membranes, and micromechanical behavior [

28]. A variety of advanced imaging and analytical techniques have been employed to explore these aspects, including optical microscopy, electron microscopy (e.g., focused ion beam–scanning electron microscopy (FIB–SEM) and transmission electron microscopy (TEM)), laser confocal microscopy, atomic force microscopy (AFM), and X-ray computed tomography (CT). In addition, histochemical staining, infrared (IR), ultraviolet (UV), and Raman spectroscopic analyses, as well as AFM-based nanomechanical mapping and nanoindentation techniques, have also been utilized to investigate the structural and functional properties of pits (

Figure 7).

Although the spatial resolution of optical microscopy is relatively limited, it offers distinct advantages for pit observation. As long as the section thickness allows light transmission, pits located at any depth within the slice can be visualized—without the need for the section plane to precisely intersect the pit. For example,

Figure 7a [

16] illustrates that all pits distributed within the slice thickness are observable in a single field of view, whereas

Figure 7b [

29] and

Figure 7c [

27] display only those pits exposed on the section surface.

Except for optical microscopy and X-ray CT, most other methods require that pits be directly exposed on the specimen surface for observation. This constraint poses a particular challenge for fiber cell pits, which are typically small and sparsely distributed, making them difficult to capture. In comparison, the resin-casting technique provides a significant advantage over conventional anatomical slicing, as it removes cellular contents that would otherwise obscure the view, thereby enabling direct three-dimensional visualization of pit geometry and interconnectivity (

Figure 7d [

27],

Figure 7e [

30],

Figure 7f [

31] and

Figure 7g [

32]).

2.3. Macroscopic Structures: The Role of Nodes

Bamboo nodes consist of three parts: the sheath scar, the diaphragm, and the node ridge [

33], with the detailed structural composition shown in

Figure 8 [

21,

34]. Ding et al. reconstructed the three-dimensional structure of the vascular bundles in bamboo nodes through consecutive longitudinal and transverse sections [

35]. Research has shown that most axial primary vascular bundles pass directly through the node, while those located on the outer perimeter of the culm wall bend slightly outward and have branching vascular bundles that extend into the sheath. The vascular bundles in the inner layers of the culm wall are thicker and bend inward significantly and form a complex network through branching at nodes, especially along the edge of the node diaphragm. Here, the branching secondary small vascular bundles wind repeatedly in the horizontal direction, extending from one side of the bamboo culm to the other. Du et al. [

36] proposed that the overall permeability of nodes was better than that of the internodes due to the presence of transverse vascular bundles in the bamboo nodes. However, quantitative research conducted by Shu et al. found that the presence of bamboo nodes significantly reduced the permeability of moso bamboo [

36]. This apparent contradiction highlights that the influence of nodes on bamboo permeability is complex and context-dependent. Factors such as species, the type and viscosity of the liquid, and the flow direction can all affect permeability measurements. These variations underscore the need for further systematic studies to clarify the role of nodes in bamboo’s transport properties.

There are also significant differences in the node structures of different bamboo species, which are mainly reflected in the arrangement and distribution of the vessels. Xiang et al. [

21] used micro-computed tomography (μCT) to conduct a three-dimensional visualization analysis of the node structures of two bamboo species (Indocalamus latifolius and Shibataea chinensis).

Figure 8 showed the μCT images and 3D reconstruction of these two bamboo nodes. It consisted of horizontal and longitudinal vessel bundles, with the fiber sheaths being short in the tangential direction and long in the radial direction. The number of vessels decreased and their size increased from the outer to the inner layers (

Figure 8a). Most longitudinal vessels directly penetrated the node, while the inner vessels entered the septum in a “Γ” shape and twisted horizontally (

Figure 7d). In contrast, the nodes of Shibataea chinensis had a greater number of vessels and a more complex system, with some vessels extending laterally from the main axis to the secondary axis, where they formed fiber cells at boundaries [

21].

2.4. Porosity and Pore Structure: The Overall Permeability Regulator

Bamboo contains abundant pores inside, including cell lumens, micropores on cell walls, and intercellular spaces, which serve as the main liquid infiltration channels [

37]. In terms of the pore morphology, the vessel cells in bamboo are cylindrical, while the fiber cells are long and fusiform with sharp ends [

38,

39,

40]. The parenchyma cells that form the basic tissue of the bamboo are shorter in length compared with vessel cells, approximately two-thirds of their length [

40]. In addition, the thick-walled cells that constitute the pith ring region have short and square columnar shapes [

41,

42,

43]. As bamboo ages, the cell walls gradually thicken, eventually transforming into stone cells and losing their ability to allow fluid permeation [

44,

45]. On the inner walls of these cellular pores, there are micropores (pits) of varying numbers and shapes, whose presence interconnects adjacent pores, thus forming the main channels for fluid and nutrient transport within bamboo [

46,

47].

In terms of porous material analysis, the permeability of bamboo is influenced by the pore size and by the porosity, pore connectivity, pore structure, and tortuosity [

48,

49,

50]. The porosity is a key indicator of porous materials and directly determines the permeability of the material, followed closely by pore size [

51,

52,

53]. He et al. [

43] found significant differences in porosity between moso bamboo and

Pinus sylvestris L. lumber (abbreviated as Scots pine), as shown in

Table 1. Moso bamboo had a lower porosity (47.58%) with a smaller mesopore diameter of approximately 32.4 mm, while the Scots pine had a higher porosity (67.16%) with a larger mesopore diameter of about 226.7 mm. These differences created significant variations in the pore area between the two porous wood materials. The study also indicated that the internal pore connectivity of moso bamboo was worse than that of Scots pine. Pore connectivity is used to describe the interconnectedness of pores and significantly affects the permeability and gas transport properties of bamboo. These different pore characteristics are why the permeability of moso bamboo is significantly lower than that of Scots pine.

In summary, the permeability of bamboo is fundamentally governed by its multiscale structure. From the macroscopic nodes to the microscopic pits, these structural features collectively determine the pathways and efficiency of liquid transport within the culm. Based on these structural characteristics, the following section systematically discusses the main physical mechanisms underlying liquid penetration in bamboo.

3. Underlying Physical Mechanism of Liquid Penetration

The penetration behavior of bamboo reflects the dynamic interaction between its microscopic structure and the penetrating liquid. As mentioned above, the anisotropic architecture and heterogeneous porous nature of bamboo result in permeability that primarily depends on the following three physical mechanisms, which may act synergistically or in competition.

3.1. Capillarity: The Primary Driving Force in Micro-Conduits

Capillary phenomena occur when a wetting liquid rises in a narrow tube or when a non-wetting liquid descends in a narrow tube due to interactions between the liquid’s surface tension and capillary tube walls [

54]. In bamboo, capillary action primarily occurs via the mesopores and micropores, such as those in vessel cells, sieve tube cells, and pit membranes. The size range of these pores is typically 2 nm to 100 nm [

55]. The rising or falling height of liquid due to capillary phenomena can be determined by Formula (1), which shows that a reduction in pore size increases the liquid height in bamboo. This is because smaller pores increase the van der Waals forces between the liquid and pore walls, thereby facilitating the ascent of a liquid [

56]. The properties of the liquid also impact the ascent height, with a higher liquid surface tension and a lower viscosity promoting its penetration into bamboo [

57].

where h represents the height of liquid rise in a capillary tube, γ denotes the surface tension,

stands for the density of the liquid, g indicates the gravitational acceleration, and r is the radius of the capillary tube.

Capillary action is a significant driving force for liquid penetration in bamboo materials. In plant physiology, bamboo absorbs water from the soil and transports it to various parts of the plant body to meet the needs of plant growth via capillary action. Scientists have also developed new methods for sewage and seawater purification by exploiting capillary action in bamboo. Xu et al. designed a bamboo-based solar seawater evaporator with highly efficient filtration and purification functions by leveraging capillary action in bamboo and using the special pore structure at bamboo nodes [

22].

3.2. Diffusion: Governing Lateral Mass Transfer

Diffusion is the spontaneous migration of substances from regions with a high concentration to regions with a low concentration [

58,

59]. This process follows Fick’s Law [

60,

61], which states that the diffusion flux is proportional to the concentration gradient, as shown in Formula (2). The microscopic mechanisms of diffusion include molecular diffusion and convective diffusion, with molecular diffusion being the result of random molecular movements, while convective diffusion is the migration of substances driven by the flow of fluid [

60]. The latter mainly occurs via the vessels and pits of bamboo. Vessels, as the main conducting channels, are responsible for the long-distance transport of water and nutrients, while pits play a crucial role in lateral penetration. The geometric morphology, distribution pattern, and membrane structure of pits directly influence the diffusion efficiency of bamboo, with temperature also exerting a significant impact. Sun et al. [

62] discovered that the moisture diffusion coefficient during the drying process of bamboo was closely related to temperature. As the drying temperature increased, the moisture diffusion coefficient gradually increased, indicating that higher temperatures accelerated the migration rate of moisture [

62].

where

F is the diffusion flux (diffusion rate per unit area);

D is the diffusion coefficient;

dc/

dx is the concentration gradient.

3.3. Viscous Resistance: The Key Impediment to Fluid Flow

Viscous resistance is the force acting against an object moving in a viscous fluid. When an object is immersed in a viscous fluid and moves, a velocity gradient forms between the fluid layers near the object’s surface, and internal frictional forces arise between these layers. This resistance, directly generated by the fluid’s viscosity, is referred to as viscous resistance [

63]. During the penetration process of bamboo, viscous resistance is primarily manifested as the resistance encountered by a fluid when passing through vessels and pits.

Viscous resistance negatively impacts the penetration efficiency of liquids in bamboo, and differences in viscous resistance at different parts within bamboo may create uneven penetration. This resistance is influenced by various factors such as fluid viscosity, the size of vessels and pits, and the temperature of the fluid. By reducing the fluid viscosity or increasing the size of vessels and pits, the viscous resistance can be decreased, thereby improving the permeability of bamboo. Su’s study (2022) found that heating rosin solution decreased its viscosity, which increased its permeation depth in round bamboo culm [

64].

3.4. Synergistic Effects: Towards a Composite Transport Model

Capillary action, diffusion, and viscous resistance work synergistically to influence liquid penetration into bamboo, with capillary action dominating the entry of a liquid into bamboo [

57,

58,

59,

65]. The liquid forms capillary flow by moving along the microscale channels created by the vessels and pits in bamboo due to surface tension, thereby entering the bamboo interior, after which the liquid achieves a lateral uniform distribution through diffusion via cell lumens and pit membranes [

66]. In other words, capillary action is responsible for the initial entry of the liquid, while diffusion is responsible for its lateral distribution. The two mechanisms together form a composite longitudinal capillary rise/lateral diffusion flow mode. The viscous resistance varies with the viscosity of the liquid, which affects its flow rate. Synergistically regulating the relationships among the three factors (capillary action, diffusion, and viscous resistance) can significantly improve the penetration efficiency and uniformity of a liquid in bamboo, thereby providing a scientific basis for bamboo processing and functional utilization [

5,

6].

4. Detection and Evaluation Techniques for Bamboo Permeability

4.1. Direct Methods for Quantifying and Visualizing Penetration

4.1.1. Weight Gain Rate for Macro Quantification

The weight gain rate (WGR) is the most commonly used and intuitive method to measure the penetration efficiency of agents in bamboo materials [

28,

29,

64]. It refers to the rate of change in weight of bamboo before and after absorbing agents such as preservatives or flame retardants. A higher weight gain rate indicates a greater penetration of the agent, suggesting a more thorough internal treatment of the bamboo material. Li found that the penetration efficiency of furfuryl alcohol resin in bamboo was much lower than that in woods under the same impregnation conditions through weight gain rate measurements [

67]. Specifically, the weight gain rates of poplar, fir, and bamboo were 60%, 85%, and 32%, respectively, after one vacuum pressure impregnation. Su et al. [

61] calculated that the weight gain rate of rosin solution in round bamboo culm was only around 12%. Sun et al. [

61] quantitatively investigated the effects of pretreatment methods, bamboo structure, liquid type, liquid concentration, and moisture content on the liquid permeability of Dendrocalamus giganteus by calculating the weight gain rate [

68,

69]. Due to its advantages of being quick and quantitative, the weight gain rate is used in almost all studies on the permeability of bamboo materials [

70,

71]. However, the weight gain rate has limitations as a measure of bamboo permeability, such as its inability to assess the depth and uniformity of penetration, which are also crucial for the modification effect. Therefore, more visualization methods need to be combined with the weight gain rate to analyze the permeability performance of bamboo materials.

4.1.2. Microscopic and Spectroscopic Visualization

Observation methods can be used to directly observe the distribution of a liquid inside bamboo or to trace the distribution of specific elements or functional groups in a liquid to analyze liquid penetration. Microscopy (utilizing optical microscopes and electron microscopes), energy dispersive analysis, and spectroscopic analysis are frequently employed.

- (1)

Light/electron microscopy

Bright-field microscopy is a commonly used optical microscopy technique based on the principles of geometrical optics that is often employed to observe the distribution of a dye solution in bamboo cells. Scanning electron microscopy (SEM) is the most commonly utilized form of electron microscopy. Its fundamental principle involves scanning the surface of a sample with an electron beam and subsequently capturing the reflected or scattered electron signals to construct an image. SEM can be used to precisely observe particle size, shape, distribution, and surface texture from the micrometer to submicrometer scale. Su et al. used SEM to observe that rosin formed a dense and continuous film on the end surface of the bamboo, but no rosin was observed inside the bamboo [

64]. Instead, they observed the penetration of rosin inside the bamboo using the fluorescence lifetime method. He et al. employed scanning electron microscopy to demonstrate that calcium-alginate-assisted in situ mineralization enabled uniform deposition of hydroxyapatite (HAP) particles both inside and outside bamboo cells (

Figure 9) [

72]. This may have been related to the particle size and distribution within the liquid solute [

73,

74,

75]. Solutes with large particles were more easily observed when they aggregated in a clump-like manner on the cell wall, whereas solutes with small particles tended to form a film on the wall and were difficult to observe [

76,

77,

78].

- (2)

Element/Functional Group Tracing

The distribution of a modifying agent in bamboo is commonly tracked by monitoring its characteristic elements or functional groups. Energy-dispersive spectrometry (EDS) is commonly employed to analyze the elemental composition and distribution on the surface of bamboo [

73]. It operates based on the principle of X-ray energy dispersion, where an electron beam bombards the sample surface, exciting characteristic X-rays whose energies are directly related to the identity of an element, thus enabling the determination of the element distribution of a material [

74,

79,

80]. Ren et al. [

75] used EDS to study the content of tracer ions (phosphorus and aluminum ions) inside round bamboo and analyzed the penetration pattern and distribution of the chemical agent under different treatment conditions. He et al. also used EDS to observe O, P, and Ca atoms in Bamboo-CaAlg-HAP and then formed an element map, as shown in

Figure 9b–e [

72]. Fourier-transform infrared (FTIR) spectroscopy is also utilized to qualitatively and quantitatively analyze the distribution of chemical modification agents by detecting changes in the functional groups of bamboo [

77,

78,

81]. Wang et al. [

81] employed FTIR spectroscopy to investigate the distribution and fixation mechanism of copper azole preservatives in bamboo. The results indicated that the intensity of the characteristic peak of lignin near 1510 cm

−1 significantly increased after treatment, suggesting the involvement of phenolic hydroxyl groups of lignin in the formation of copper-lignin complexes, as shown in

Figure 10. Additionally, the stretching vibration peaks of the carboxyl group and acyloxy bond (C=O) in hemicellulose shifted, confirming interactions between copper azole agents and hemicellulose. Liu et al. [

82] showed that the intensity of the 1736 cm

−1 band, linked to xylan’s C=O stretching, increased sharply and shifted slightly to 1711 cm

−1 post-treatment. This indicated the infusion of furfuryl alcohol resin into bamboo parenchymal cell walls due to peak superposition, while weaker peaks at 1037 cm

−1 (C-O in cellulose/hemicellulose) and 897 cm

−1 suggested the acid hydrolysis of hemicelluloses during furfurylation (

Figure 10F,G).

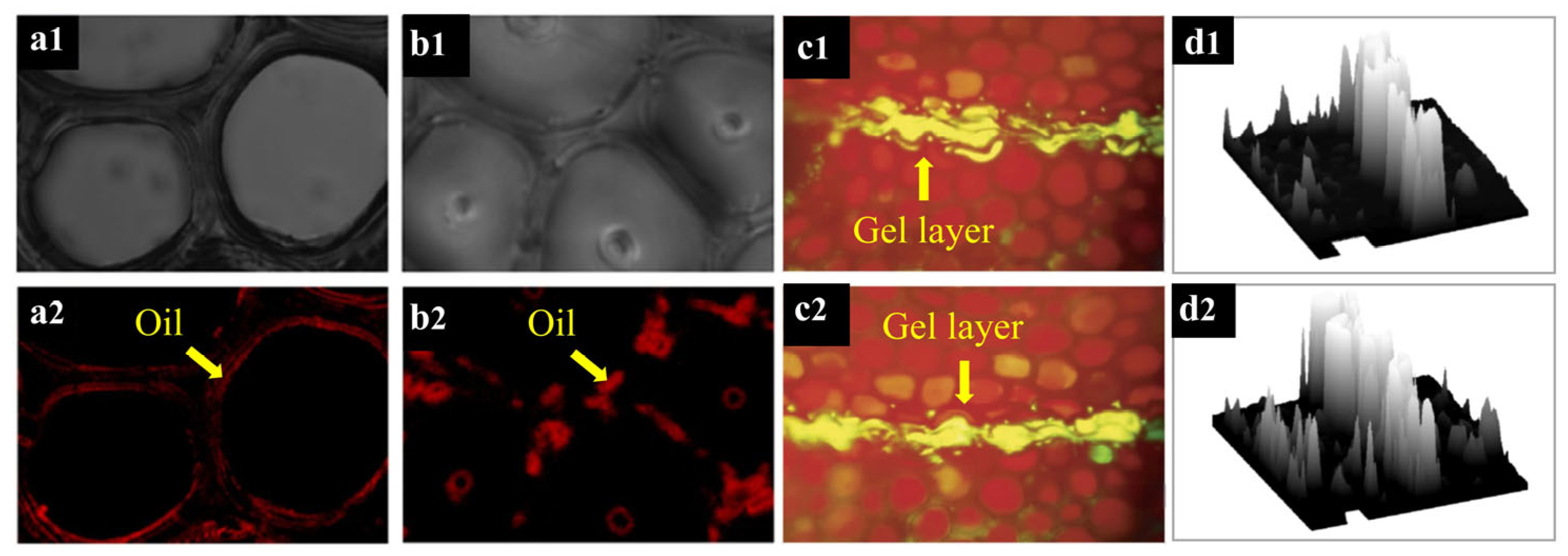

- (3)

Fluorescence Tracking and Confocal Imaging

Fluorescence analysis is based on the emission of light by fluorescent substances upon specific light excitation. It can be used to track the penetration and distribution of modification agents in bamboo through the intensity and distribution of fluorescence signals. Confocal laser scanning microscopy (CLSM) is commonly used to detect fluorescence and capture images. Nile Red was used as the fluorescent agent to label tung oil, and the samples were excited at 633 nm to avoid the auto-fluorescence of bamboo. The CLSM images (

Figure 11) indicated that tung oil was distributed throughout the cell walls of bamboo samples after oil heat treatment [

28,

83].

Guan et al. [

72] explored the advantages of the fluorescence tracing method for characterizing the adhesive layer distribution at the gluing interface of bamboo. They used toluidine blue as a fluorescent stain for the adhesive, and the staining effect was observed with a fluorescence microscope (

Figure 11(c1,c2)). The penetration depth of the adhesive inside bamboo was visually observed through 3D grayscale images (

Figure 11(d1,d2)). This indicated that the fluorescence tracing method, as a non-destructive detection technique, can be used to visually observe the distribution of an adhesive inside bamboo by labeling the adhesive with a fluorescent staining agent and combining it with image analysis.

4.2. Indirect Methods for Characterizing Permeability-Related Structures

Indirect methods for testing permeability involve measuring the permeability of bamboo by assessing its pore structure and porosity or reconstructing the 3D structure of its vascular tissues.

4.2.1. Porosity Measurement

Mercury intrusion porosimetry (MIP) and gas adsorption methods are often employed to characterize the pore characteristics of bamboo [

84,

85,

86]. MIP is suitable for measuring macropores, with its range spanning several nanometers to several hundred micrometers, which encompasses structures such as vessels and cell lumens in bamboo [

42,

66,

87,

88]. He et al. [

43] employed MIP to analyze the pore structure of bamboo before and after alkali solution treatment and revealed that the internal pore volume of modified bamboo bundles increased. The number of pores with a diameter of approximately 40 nm within the cell walls increased, as did the pore diameters. The higher pore volume increased the penetration volume of fluid within the bamboo bundles, while the larger pore diameters improved the fluid penetration efficiency inside them [

89,

90].

The gas adsorption methods employed included nitrogen adsorption method and carbon dioxide adsorption. Gas adsorption methods are more suitable for measuring mesopores (2–50 nm) and micropores (<2 nm) [

91,

92,

93]. In bamboo, this generally includes micropores on the pit membranes, as well as micropores within cell lumens and on cell walls. Carbon dioxide and nitrogen are two common gases used in this testing method. Cao et al. [

55] analyzed the cell wall pore structures in six bamboo and two plantation wood species using CO

2 and N

2 adsorption and found that bamboo species had lower cell wall porosities (2.6%–3.8%) than wood (4.0%–5.1%). Tissue-specific pore characteristics were found, in which the Moso bamboo parenchyma cells showed a higher pore volume and porosity than fibers.

4.2.2. Three-Dimensional Structural Reconstruction

Micro-computed tomography (Micro-CT) is a non-destructive testing method based on X-rays that can generate high-resolution three-dimensional images of bamboo through scanning and reconstruction techniques. These images clearly display detailed information such as the cellular structure, fiber distribution, pore distribution, and cell wall thickness of bamboo [

93,

94]. Li et al. [

95,

96,

97]. and da Rocha Rodrigue et al. [

98] employed Micro-CT to perform a three-dimensional reconstruction of the vascular bundles at bamboo nodes, which indicated that the conducting tissues were interwoven with each other to form a complex three-dimensional network. Specifically, they performed a three-dimensional reconstruction of the conducting tissues at bamboo joints, as illustrated in

Figure 12a–f, which shows the structure from different angles. Additionally, conducting tissues in the node septum were reconstructed and classified into three types based on their volume and connectivity: the largest conducting tissues, interconnected conducting tissues, and non-interconnected conducting tissues, as depicted in

Figure 12a–f. This provided an important structural foundation for understanding the liquid transport characteristics at bamboo nodes. Furthermore, in the oil-immersion resistance and water resistance tests of bamboo fiber meal boxes conducted by Chen et al. [

99], they used Micro-CT to reconstruct the pore structure of bamboo fiber plates. The seepage of oil through the connected pores in the thickness direction of bamboo was simulated (

Figure 12j,k).

In addition, Focused ion beam–scanning electron microscopy (FIB-SEM) represents an advanced in situ imaging technique that enables nanoscale three-dimensional (3D) reconstruction of biological tissues. Unlike traditional sectioning or resin-casting methods, which often introduce deformation and uncertainty in cell position, FIB-SEM combines precise ion-beam milling with high-resolution SEM imaging to serially section samples and acquire sequential images for 3D reconstruction. This approach provides direct structural information on internal cellular architectures, allowing the visualization of fine details such as pit morphology and cell wall interfaces.

Li et al. successfully applied FIB-SEM to visualize the ultrastructure of the vascular parenchyma complex (VPCs) and small vessels (SVs) as shown in

Figure 12g [

100]. The reconstructed 3D models revealed remarkable heterogeneity in cellular morphology and pit distribution. Cells adjacent to small tracheids exhibited elongated lumina with high length-to-width ratios and fewer pits, while those near metaxylem vessels had lower shape factors and larger pits. These structural gradients indicate a transition from tracheid-like to vessel-like cells, suggesting a functional adaptation to directional water transport. Compared with conventional SEM or micro-casting approaches, FIB-SEM offers higher spatial resolution and minimizes artifacts caused by sample preparation, making it a powerful tool for understanding micro–nano scale transport pathways in bamboo vascular systems.

4.3. Comparison of Various Detection and Evaluation Techniques for Bamboo Permeability

To provide a clearer comparison,

Table 2 summarizes the main observation and detection techniques used to study bamboo permeability. These methods differ greatly in their working principles, spatial resolution, and characterization depth. For instance, macroscopic measurements such as weight gain rate offer rapid quantitative evaluation, while microscopic and spectroscopic approaches reveal structural or chemical details at the micro–nano scale. Fluorescence and 3D reconstruction techniques further enable visualization of flow pathways within the hierarchical structure. Overall, each method has its own advantages and limitations, and a combined application is often required for comprehensive permeability analysis.

These complementary techniques together provide a multiscale understanding of bamboo permeability, ranging from macro-level liquid uptake to nano-scale pore structure evolution. Integrating different characterization methods can thus help establish a more complete structure–permeability relationship.

5. Enhancement Strategies for Improving Bamboo Permeability

As mentioned above, the capillary action of vessels in bamboo is mainly responsible for liquid conduction in the longitudinal direction, while it solely depends on the osmotic effect of pit apertures in cell walls for material transfer in the transverse direction [

101,

102]. Consequently, bamboo has a relatively low permeability efficiency, which restricts the absorption capacity of bamboo for treatment agents and also affects the uniformity and depth of modification. Therefore, enhancing the permeability of bamboo can improve bamboo’s processing efficiency and optimize its modification effects [

103,

104]. Various methods have been applied to improve the permeability of bamboo, which can be classified into one of three main categories: chemical methods, physical methods, and biological methods [

105,

106,

107].

5.1. Chemical Modification: Altering Composition and Porosity

Chemical modification of bamboo changes the chemical composition or properties of bamboo, thereby changing its permeability. This mainly includes acid modification, alkali modification, and ethanol extraction. Among these, acid modification changes the chemical structure and surface properties of bamboo through acid treatment or acidification reactions. For instance, succinic acid modification of bamboo fibers increases the number of carboxyl and ester groups through esterification reactions, which makes the surface rougher and more porous, thereby enhancing the adsorption [

108,

109,

110]. Hydrochloric acid treatment mainly hydrolyzes hemicelluloses and lignin in bamboo, thereby damaging the cell walls and creating more pores [

111,

112,

113]. In addition, acidic substances promote the rearrangement and cross-linking of lignocellulose, thereby further improving the permeability [

108]. Similarly, alkali treatment also degrades some hemicelluloses and lignin, which exposes cellulose and forms permeation channels. However, the difference is that an alkali solution causes cellulose to swell, thereby enlarging the gaps in the cell walls and directly increasing the porosity. Li et al. treated bamboo using NaOH solutions with different concentrations (1%–10%), and the results indicated that the porosity was significantly improved, and the liquid penetration rate increased by 2–3 times [

102].

Ethanol extraction also improves the permeability of bamboo. Rao et al. [

114] extracted bamboo using ethanol and analyzed the effects of the ethanol concentration, water bath time, and temperature on the resulting permeability. The results showed that the penetration lengths of all treated bamboo samples were higher than those of the untreated samples, with an increase of 25%–78%. This was because ethanol extracted tyloses in the vessels and blockages in the pits [

34] and opened channels for dye molecules to enter bamboo. The temperature had the greatest impact on the treatment effect, with a higher temperature accelerating the diffusion of ethanol inside the bamboo and thereby strengthening the extraction effect.

5.2. Physical Modification: Disrupting Structural Barriers

Improving the permeability of bamboo through physical methods involves treating bamboo to alter its internal structure and pore characteristics, thereby enhancing the penetration of liquids or gases [

115,

116,

117]. Common physical methods include heat treatment, microwave treatment, ultrasonic treatment, and vacuum freeze-drying treatment [

118,

119,

120,

121]. Rao et al. [

114] compared the effects of two heat treatment methods (i.e., high-temperature steaming and high-temperature boiling) on the permeability of bamboo. The results showed that high-temperature boiling was overall more effective than steaming, but compared with chemical treatment, both effects were worse. Pang et al. reported that the microwave treatment increased the pore volume and pore size of bamboo, which improved its permeability [

115,

116]. This was because the vapor pressure generated by the microwaves impacted the weak cells of bamboo, such as the ray parenchyma cells and the pitted membrane, thus destroying their cell structures. Similarly, during ultrasonic treatment, cavitation produced shock waves that destroyed the microstructure. Yong et al. used the ultrasonic effect to modify the transverse permeability of bamboo, and SEM showed that the depth of the pits increased by 50%–100% after treatment [

9]. Vacuum freeze-drying treatment destroyed the cells of bamboo through freezing and sublimation, thereby increasing its porosity and permeability. Xu et al. employed vacuum freeze-drying to treat bamboo, and the results indicated that the porosity increased from 48.54% to 73.48%, with the mesopore diameter expanding from 44.3 nm to 101.5 nm [

42]. There was also an approximate 7.5% increase in copper over time, demonstrating a significant improvement in the fluid diffusion efficiency [

42].

5.3. Biological Modification: Enzymatic and Biomimetic Approaches

Biological modification methods use enzymolysis or biomimetic methods to act on the cell wall components of bamboo to optimize pore structures and increase liquid permeation channels [

121,

122,

123]. For example, cellulase, hemicellulose enzymes, or laccase can be used to selectively degrade lignin or hemicelluloses in the cell wall of bamboo, thereby disrupting its dense structure and increasing its porosity [

124,

125,

126]. In addition, biomimetic methods have also been frequently applied in recent years. Liu et al. [

103] mimicked the biological adhesion mechanism of mussel adhesive proteins by immersing bamboo in Tris-HCl buffer solution containing dopamine. Liu et al. [

103] mimicked the biological adhesion mechanism of mussel adhesive proteins by immersing bamboo in Tris-HCl buffer solution containing dopamine [

103]. Dopamine spontaneously polymerized into polydopamine under alkaline conditions to form a uniform coating on the surface of bamboo. The polydopamine coating exhibited excellent adhesion and was rich with active groups such as amino groups and phenolic hydroxyl groups that enhanced the loading capacity of subsequent agents.

Overall, chemical treatments exhibit the most pronounced effects on enhancing bamboo porosity and permeability; however, physical modification methods may be preferable for applications that require chemical-free processing or where residual chemicals could pose environmental or health concerns. Physical approaches are generally more environmentally friendly and can also achieve substantial improvements in permeability, although they are often limited by high energy consumption—particularly in heat-based treatments requiring significant electrical or thermal input. Therefore, developing low-energy physical modification techniques is an important direction for future research. In comparison, biological treatments remain relatively underexplored and often yield unstable results, requiring further investigation and optimization.

6. Discussion

This review integrates current knowledge on the structural basis, permeation mechanisms, detection techniques, and enhancement strategies related to bamboo permeability. The findings collectively show that bamboo’s complex anatomical structure—including vessels, sieve tubes, perforation plates, pits, and nodes—jointly shapes its inherently anisotropic permeability. While longitudinal permeation is mainly controlled by capillary effects along continuous vessels, transverse permeation is strongly restricted by pit structure, cell wall thickness, and the organizational arrangement of vascular bundles. Therefore, understanding permeability requires a multiscale view that spans from cell-level microstructure to culm-level fluid pathways.

At the same time, existing detection and evaluation techniques reveal important differences in how permeability can be quantified. Direct methods, such as weight gain tests and fluorescence tracing, intuitively reflect fluid transport behavior but lack spatial resolution. In contrast, Micro-CT and microscopy provide structural insight but do not directly capture dynamic flow. These complementary advantages highlight the need for integrated evaluation approaches that combine structural imaging with transport measurements.

Finally, current enhancement strategies differ significantly in mechanism, efficiency, and environmental impact. Chemical treatments are effective but may introduce ecological concerns. Physical methods improve permeability by modifying internal structures but are often energy-intensive. Biological treatments are more sustainable but require improved stability and controllability. Thus, permeability improvement is not only a technical challenge but also a balance among performance, cost, and sustainability.

7. Key Scientific Challenges and Future Outlook

Despite substantial progress in understanding the structural mechanisms, detection techniques, and enhancement strategies related to bamboo permeability, several limitations and challenges remain. First, the quantitative relationships between structural parameters (e.g., vessel diameter, pit density, and porosity) and actual permeation performance are still insufficiently characterized. Current studies have primarily provided qualitative descriptions, which limits the ability to predict treatment uniformity and efficiency. Second, multiscale coupling analyses are still lacking; most investigations focus on either microscopic imaging or macroscopic flow behavior, but few have integrated high-resolution structural characterization (such as SEM and Micro-CT) with permeability testing and fluid–structure modeling to establish structure–function correlations. Third, a considerable gap remains between laboratory-scale findings and industrial-scale applications. Many studies isolate variables under controlled conditions, without fully accounting for the natural heterogeneity and structural anisotropy of bamboo, which significantly influence large-scale processing. For example, the regulatory role of nodes in industrial impregnation systems remains underexplored. Finally, while chemical treatments often achieve the most pronounced permeability enhancement, they may introduce environmental or health risks, whereas physical methods, although more environmentally friendly, are typically energy-intensive. Therefore, developing low-energy, scalable, and environmentally sustainable permeability enhancement strategies remains a key challenge for future research.

To address these limitations, future research should focus on establishing robust quantitative relationships between bamboo microstructure and permeation performance by integrating high-resolution 3D characterization (e.g., SEM, Micro-CT, FIB-SEM) with controlled permeability testing and data-driven modeling. Machine learning and digital recognition techniques (such as YOLO-based structural identification and LS-SVM-based permeability prediction), combined with multiscale fluid–structure simulations, can help identify key structural predictors and enable predictive, performance-oriented processing design. Meanwhile, bridging laboratory research with industrial applications requires the development of standardized permeability evaluation protocols that consider treatment depth, uniformity, and culm-scale heterogeneity, as well as real-time structural feedback control during drying and impregnation. In addition, environmentally conscious modification strategies—such as enzyme-assisted or dopamine-based surface treatments, or coupling mild chemical activation with low-energy physical assistance (e.g., ultrasound or microwave)—offer promising pathways to enhance permeability while minimizing environmental and energy burdens. Furthermore, the establishment of open-source databases linking microstructural parameters with permeability indices will support data-driven material design and scalable engineering translation. By uniting multiscale structural insight, intelligent characterization, and sustainable process innovation, bamboo permeability enhancement can advance from fundamental research toward practical, controllable, and industrially viable applications.

8. Conclusions

This review provides a comprehensive overview of bamboo permeability from structural mechanisms to detection methods and enhancement strategies. By synthesizing research progress across multiple scales, it clarifies how anatomical features influence fluid transport, highlights the strengths and limitations of existing measurement approaches, and compares the effectiveness and sustainability of current modification techniques. In addition, the key scientific challenges and future directions discussed here will help guide research toward more quantitative, application-oriented, and environmentally responsible approaches. Overall, this review offers foundational knowledge and practical insights that support both scientific development and industrial utilization of bamboo as a sustainable engineering material.

Author Contributions

Conceptualization, N.S. and C.F.; methodology, N.S.; software, Q.Y. and W.S.; investigation, Q.Y., Y.L. and W.S.; writing—original draft preparation, N.S.; writing—review and editing, C.F. and H.X.; visualization, Q.Y.; supervision, H.X.; funding acquisition, N.S. and H.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Youth Foundation of China, grant number 32301679, and Natural Science Research of Jiangsu Higher Education Institutions of China, grant number 23KJB220004, and the Postgraduate Research & Practice Innovation Program of Jiangsu-Province, grant number KYCX23_1183.

Data Availability Statement

This study did not generate any new data. All data supporting the findings of this work are available in the cited references.

Acknowledgments

The authors gratefully acknowledge the valuable guidance and support provided by Rong Liu from Southwest Forestry University in the preparation of this manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shi, M.; Lin, Z.; Liu, H.; Ma, X.; Lian, J.; Wang, X. Flattened bamboo for replacing plastic products–An eco-friendly material to manufacture clothes hangers. BioResources 2025, 20, 5467–5486. [Google Scholar] [CrossRef]

- Lin, Z.; Shi, M.; Liu, H.; Zhang, X.; Lian, J.; Wang, X. Study on hot-press drying process for the flatten-bamboo slice. Dry. Technol. 2025, 43, 1354–1366. [Google Scholar] [CrossRef]

- Huang, P.; Latif, E.; Chang, W.S.; Ansell, M.P.; Lawrence, M. Water vapour diffusion resistance factor of Phyllostachys edulis (Moso bamboo). Constr. Build. Mater. 2017, 141, 216–221. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W.J. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Lv, C.Y.; Zhang, C.J.; Zhou, X.J.; He, M.Y.; Yu, L.L.; Tang, Z.Z. Effect of different pre-preatments on the Permeability of Glue-Laminated Bamboo. Wood Res. 2021, 66, 353–364. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Yang, X.; Ji, H.; Zhong, T.H.; Wang, G. A comparative study of the microstructure and water permeability between flattened bamboo and bamboo culm. J. Wood Sci. 2019, 65, 64. [Google Scholar] [CrossRef]

- Yong, C.; Chang, X.; Guan, M. Effect of ultrasonic wall-breaking on bambootransverse permeability. J. Bamboo Res. 2013, 32, 33–36. (In Chinese) [Google Scholar]

- Montaño, C.D.; van Dam, J. Potential of Bamboo for Renewable Energy: Main Issues and Technology Options; International Bamboo Rattan Organisation: Beijing, China, 2021. [Google Scholar]

- Guan, M.; Huang, Z. Direct strain distribution and finite-element-analysis simulation of the bonding interface of bamboo laminated lumber with ultrasound-treated bamboo strips. BioResources 2022, 17, 890–907. [Google Scholar] [CrossRef]

- Ebissa, D.T.; Tesfaye, T.; Worku, D.; Wood, D. Characterization and optimization of the properties of untreated high land bamboo fibres. Heliyon 2022, 8, e09856. [Google Scholar] [CrossRef]

- Cheng, P.; Zhong, T.; Long, J.; Shi, J.J.; Xia, C.L.; Chen, H. Green manufacturing of bamboo self-bonding composites with superior mechanical and electromagnetic interference shielding performance. Eur. J. Wood Wood Prod. 2025, 83, 163. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Su, N.; Fang, C. High-performance engineered bamboo units with customizable radius based on pressure-drying technology: Multi-scale mechanical properties. Constr. Build. Mater. 2024, 457, 139472. [Google Scholar] [CrossRef]

- Zuo, S.; Li, T.; Chen, T.; Li, J.; Liu, X. Degradation of oil paint coating based on wood under the combined effect of UV light and heat. Forests 2025, 16, 22. [Google Scholar] [CrossRef]

- Zhang, C.; Guo, H.; Zhou, X.J.; Yu, L.L.; Li, H.; Yang, Z.B. Effects of different boron-based flame retardants on the combustibility of bamboo filaments. Wood Res. 2022, 67, 221–230. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, J.; Wang, T.; Feng, X.; Liu, X. Research on volatile allergenic substances in chinese lacquer: An integrated analysis of their composition, detection, Mechanisms, and Prevention. Polymers 2025, 17, 1722. [Google Scholar] [CrossRef]

- Luo, J.J.; Lian, C.P.; Liu, R.; Zhang, S.Q.; Yang, F.; Fei, B.H. Comparison of metaxylem vessels and pits in four sympodial bamboo species. Sci. Rep. 2019, 9, 10876. [Google Scholar] [CrossRef]

- Tao, X.; Fang, X.; Wu, S.; Shao, C.; Xu, W. Facile synthesis of high-performance bamboo-based polymer composites with better dimensional stability and enhanced thermal conductivity. Wood Sci. Technol. 2025, 59, 97. [Google Scholar] [CrossRef]

- Niu, S.; Na, W.; Cui, B.; Wang, C.; Wu, H.; Zhang, S. Effects of different ages and positions on fiber morphology and crystallinity of Phyllostachys edulis. Zhejiang Agric. For. Univ. 2023, 40, 446–452. (In Chinese) [Google Scholar]

- Liese, W. The Anatomy of Bamboo Culms; Brill: Berlin, Germany, 1998. [Google Scholar]

- Liu, R.; Zhang, S.; Semple, K.; Lian, C.; Chen, M.; Luo, J.; Yang, F.; Dai, C.; Fei, B. Precise microcasting revealing the connectivity of bamboo pore network. Ind. Crops Prod. 2021, 170, 113787. [Google Scholar] [CrossRef]

- Xiang, E.; Yang, S.; Cao, C.; Yang, Z.; Ying, Y.; Ren, D.; Zhang, K.; Cheng, H.; Wang, H. Visualizing complex anatomical structure in bamboo nodes based on x-ray microtomography. J. Renew. Mater. 2021, 9, 1531–1540. [Google Scholar] [CrossRef]

- Xu, H.C.; She, Y.; Tian, F.; Su, N.; Xu, X. Parabolic concave surface modified by carbonized micro-cone array on rattan enables multi-dimensional light harvest for bio-based solar evaporators. Chem. Eng. J. 2024, 481, 148680. [Google Scholar] [CrossRef]

- Luo, J.J. Comparative Anatomy of Bamboo Metaxylem Vessel Pits. Master’s Thesis, Chinese Academy of Forestry Sciences (CAFS), Beijing, China, 2020. [Google Scholar]

- Tang, T.; Chen, X.; Zhang, B.; Liu, X.; Fei, B. Research on the physico-mechanical properties of moso bamboo with thermal treatment in tung oil and its influencing factors. Materials 2019, 12, 599. [Google Scholar] [CrossRef] [PubMed]

- Tang, T.; Zhang, B.; Liu, X.; Wang, W.; Chen, X.; Fei, B. Synergistic effects of tung oil and heat treatment on physicochemical properties of bamboo materials. Sci. Rep. 2019, 9, 12824. (In Chinese) [Google Scholar] [CrossRef] [PubMed]

- Hao, X.; Wang, Q.; Wang, Y.; Han, X.; Yuan, C.; Cao, Y.; Lou, Z.; Li, Y. The effect of oil heat treatment on biological, mechanical and physical properties of bamboo. J. Wood Sci. 2021, 67, 26. [Google Scholar] [CrossRef]

- Liu, R.; Yang, S.; Li, H.; Zhai, Z.; Fei, B. Characteristics of pits in the vessel element of moso bamboo (Phyllostachys edulis (Carr.) J. Houz.). J. Nanjing For. Univ. 2017, 41, 163–168. (In Chinese) [Google Scholar]

- Lian, C.; Liu, R.; Zhang, S.; Yuan, J.; Luo, J.; Yang, F.; Fei, B. Ultrastructure of parenchyma cell wall in bamboo (Phyllostachys edulis) culms. Cellulose 2020, 27, 7321–7329. [Google Scholar] [CrossRef]

- Parameswaran, N.; Liese, W. On the fine structure of bamboo fibres. Wood Sci. Technol. 1976, 10, 231–246. [Google Scholar] [CrossRef]

- Pereira, L.; Flores-Borges, D.N.A.; Bittencourt, P.R.L.; Mayer, J.L.S.; Kiyota, E.; Araújo, P.; Jansen, S.; Freitas, R.O.; Oliveira, R.S.; Mazzafera, P. Infrared nanospectroscopy reveals the chemical nature of pit membranes in water-conducting cells of the plant xylem. Plant Physiol. 2018, 177, 1629–1638. [Google Scholar] [CrossRef]

- Ma, X.X.; Jiang, M.L.; Qin, D.C.; Liu, X.M.; Yu, Y. Macro- and micro-structure changes in bamboo after attack by various fungi. Sci. Silvae Sin. 2012, 33, 356–384. [Google Scholar]

- Schulte, P.J.; Hacke, U.G.; Schoonmaker, A.L. Pit membrane structure is highly variable and accounts for a major resistance to water flow through tracheid pits in stems and roots of two boreal conifer species. New Phytol. 2015, 208, 102–113. [Google Scholar] [CrossRef]

- Londoño, X. Characterization of the anatomy of Guadua angustifolia (Poaceae: Bambusoideae) culms. Bamboo Sci. Cult. J. Am. Bamboo Soc. 2002, 16, 18–31. [Google Scholar]

- Peng, G.; Jiang, Z.; Liu, X.; Fei, B.; Yang, S.; Qin, D.; Ren, H.; Yu, Y.; Xie, H. Detection of complex vascular system in bamboo node by X-ray μCT imaging technique. Holzforschung 2014, 68, 223–227. [Google Scholar] [CrossRef]

- Ding, Y.W.; Liese, W. The research on the anatomical structure of bamboo culms. J. Bamboo Res. 1995, 14, 24–32. (In Chinese) [Google Scholar]

- Du, C.; Shu, T.; Ye, B.; Wang, L. Dye Solution Permeability and Its Influencing Factors of Phyllostachys edulis Slivers. Zhejiang Lin Ye Ke Ji 2010, 30, 9–13. (In Chinese) [Google Scholar]

- Wei, X.; Wang, G.; Smith, L.M.; Jiang, H. The hygroscopicity of moso bamboo (Phyllostachys edulis) with a gradient fiber structure. J. Mater. Res. Technol. 2021, 15, 4309–4316. [Google Scholar] [CrossRef]

- Jang, E.-S.; Yuk, J.-H.; Kang, C.-W. An experimental study on change of gas permeability depending on pore structures in three species (hinoki, Douglas fir, and hemlock) of softwood. J. Wood Sci. 2020, 66, 78. [Google Scholar] [CrossRef]

- Chen, Q.; Fang, C.; Wang, G.; Ma, X.; Luo, J.J.; Chen, M.; Dai, C.; Fei, B. Water vapor sorption behavior of bamboo pertaining to its hierarchical structure. Sci. Rep. 2021, 11, 12714. [Google Scholar] [CrossRef]

- Feng, L.; Sun, C.; Bi, W.; Ren, Z.; Liu, X.; Jiang, Z.; Ma, J. The distribution and orientation of cell wall components of moso bamboo parenchyma. Spectrosc. Spectr. Anal. 2020, 40, 2957–2961. [Google Scholar]

- Chen, L.; Wang, X.; Huang, B.; Yuan, J.; Ma, X.; Fang, C.; Zhang, X.; Sun, F.; Fei, B. Observation of the fundamental properties of bamboo pith ring. Wood Sci. Technol. 2024, 58, 797–810. [Google Scholar] [CrossRef]

- Li, H.; He, S.; Zhang, Z.; Chen, Y.; Wu, Z.; Li, N. Research progress of microstructure and porous structure of bamboo. J. Bamboo Res. 2019, 38, 52–58. (In Chinese) [Google Scholar]

- Xu, J.; He, S.; Yu, H.; Zhao, S.; Chen, Y.; Ma, L. Effect of vacuum freeze-drying on enhancing liquid permeability of moso bamboo. BioResources 2018, 13, 4159–4174. [Google Scholar] [CrossRef]

- He, S.; Xu, J.; Wu, Z.; Bao, Y.; Yu, H. Compare of porous structure of moso bamboo and Pinus sylvestris L. Lumber J. Nanjing For. Univ. (Nat. Sci. Ed.) 2017, 41, 157–162. (In Chinese) [Google Scholar]

- Ellerby, D.; Ennos, A. Resistances to fluid flow of model xylem vessels with simple and scalariform perforation plates. J. Exp. Bot. 1998, 49, 979–985. [Google Scholar] [CrossRef]

- Zhang, J. Bonding Process and Performance of Structural Bamboo-Wood Laminates. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2022. [Google Scholar]

- Yao, X.; Huang, Y.; Zhang, S.; Yu, Y. Bamboo parenchymal cells: An untapped bio-based resource for sustainable material. J. Renew. Mater. 2025, 13, 1881–1898. [Google Scholar] [CrossRef]

- Garcia, L.M. Radial and Longitudinal Variation of the Mechanical Properties of bamboo. Bachelor’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2011. [Google Scholar]

- Lian, C.; Liu, R. Characterization of the pits in parenchyma cells of the moso bamboo [Phyllostachys edulis (Carr.) J. Houz.] culm. Holzforschung 2019, 73, 629–636. [Google Scholar] [CrossRef]

- Yang, W. Resin Transfer Molding (rtm) of Wood Strands. Master’s Thesis, Washington State University, Pullman, WA, USA, 2014. [Google Scholar]

- Ridgway, C.J.; Gane, P.A.C. Dynamic absorption into simulated porous structures. Colloids Surf. A Physicochem. Eng. Asp. 2002, 206, 217–239. [Google Scholar] [CrossRef]

- Huang, P.; Chang, W.S.; Ansell, M.P.; Chew, Y.M.J.; Shea, A. Porosity estimation of Phyllostachys edulis (Moso bamboo) by computed tomography and backscattered electron imaging. Wood Sci. Technol. 2017, 51, 11–27. [Google Scholar] [CrossRef]

- Akwada, D.R. Characterisation of Bamboo as a Candidate Composite Material for Structural Applications: A Case Study in Ghana. Ph.D. Thesis, University of Johannesburg, Johannesburg, South Africa, 2020. [Google Scholar]

- Brunton, S.L.; Noack, B.R.; Koumoutsakos, P. Machine learning for fluid mechanics. Annu. Rev. Fluid Mech. 2020, 52, 477–508. [Google Scholar] [CrossRef]

- Cao, M.; Ren, W.; Zhu, J.; Wang, H.; Guo, J.; Zhang, X.; Yu, Y. Cell wall pore structures of bamboo evaluated using gas adsorption methods. Holzforschung 2022, 76, 754–764. [Google Scholar] [CrossRef]

- Athanasiou, K.; Douros, S. Thought experiments in science education: The case of water movement in tracheophyte plants in the gravity conditions of moon. Aquademia 2024, 8, ep24006. [Google Scholar] [CrossRef]

- Adamson, A.W.; Gast, A.P. Physical Chemistry of Surfaces; Wiley: Hoboken, NJ, USA, 1997. [Google Scholar]

- Tiburtino, R.F.; Paes, J.B.; Vidaurre, G.B.; Arantes, M.D.C.; Rosa, R.A. Influence of diaphragm in the preservative treatment of two bamboo species by sap displacement method. Ciência Florest. 2016, 26, 925–938. [Google Scholar] [CrossRef]

- Yang, B.-K.; Li, R.-R.; Meng, Y.; Xu, Z.-Y. Research on texture features classification of multilayered wood flooring using global image structure method. Wood Mater. Sci. Eng. 2025, 1–13. [Google Scholar] [CrossRef]

- Matter, F.; Niederberger, M. The importance of the macroscopic geometry in gas−phase photocatalysis. Adv. Sci. 2022, 9, 2105363. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Tian, Y.; Qing, Y. A study of water movement during the process of hot-press drying of bamboo timber. J. Cent. South For. Univ. 2006, 26, 47–51. [Google Scholar]

- Sun, Z.; Yang, Y.; Gu, L. Study on liquid permeability of dendroclamus giganteus under normal pressure. China For. Prod. Ind. 2005, 1, 17–19. (In Chinese) [Google Scholar]

- Putri, A.R.; Alam, N.; Adzkia, U.; Amin, Y.; Darmawan, I.W.; Karlinasari, L. Physical and mechanical properties of oriented flattened bamboo boards from Ater (Gigantochloa atter) and Betung (Dendrocalamus asper) bamboos. J. Sylva Lestari 2023, 11, 1–21. [Google Scholar] [CrossRef]

- Na, S.; Changhua, F.; Zixuan, Y.; Hui, Z.; Xianke, W.; Tong, T.; Shuqin, Z.; Benhua, F. Effects of rosin treatment on hygroscopicity, dimensional stability, and pore structure of round bamboo culm. Constr. Build. Mater. 2021, 287, 123037. [Google Scholar] [CrossRef]

- Amaral, L.M.D.; de Mello Innocentini, M.D.; Kadivar, M.; Savastano, H. An exploratory study on bamboo permeability for evaluation of treatability with chemical solutions. An exploratory study on bamboo permeability for evaluation of treatability with chemical solutions. Mater. Today Commun. 2024, 40, 109719. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Liu, R.; Lian, C.P.; Luo, J.J.; Yang, F.; Liu, X.M.; Fei, B.H. Intercellular pathways in internodal metaxylem vessels of moso bamboo Phyllostachys edulis. IAWA J. 2019, 40, 871–883. [Google Scholar] [CrossRef]

- Li, W.J.; Xie, G.J.; Ma, H.X.; Li, X.W. Effect of furfurylation on bamboo-scrimber composites. Materials 2023, 16, 2931. [Google Scholar] [CrossRef]

- Huang, X.; Hse, C.Y.; Shupe, T.F. Study of moso bamboo’s permeability and mechanical properties. Emerg. Mater. Res. 2015, 4, 130–138. [Google Scholar] [CrossRef]

- Yusof, N.M.; Hua, L.S.; Tahir, P.M. Effects of boric acid pretreatment on the properties of four selected Malaysian bamboo strips. Forests 2023, 14, 196. [Google Scholar] [CrossRef]

- Wang, G.; Wei, Y.; Wang, J.; Zhou, Z.; Chen, S.; Zhu, B. Assessment of the properties of interface-modified bamboo aggregates for sustainable concrete construction. J. Build. Eng. 2024, 94, 110069. [Google Scholar] [CrossRef]

- Huang, L.; Gu, W.; Lin, F.; Zheng, Y.; Zhang, W.; Ma, Z.; Bao, M.; Li, Y. Effect of paraffin impregnation modification on bamboo properties and microstructure. Forests 2023, 14, 1158. [Google Scholar] [CrossRef]

- He, L.; Bao, G.; Yu, X.; Zhang, X.; Jin, X.; Yu, Z.; He, Y.; Zhang, R.; Qin, D. A green and eco-friendly method to enhance Bamboo flame resistance via calcium alginate assisted in-situ mineralization of hydroxyapatite. Chem. Eng. J. 2024, 485, 149765. [Google Scholar] [CrossRef]

- Sakai, K.; Mitsuda, K.; Tanaka, K. TEM-EDS with breakthroughs in 3D wiring and high-speed processing. J. Low Temp. Phys. 2012, 167, 759–764. [Google Scholar] [CrossRef]

- Wang, X.; Che, L.; Huang, B.; Yuan, J.; Shang, L.; Zhang, S.; Chen, M.; Fang, C.; Fei, B. Quantitative characterization of bamboo cortex structure based on X-ray microtomography. Cellulose 2022, 29, 4335–4346. [Google Scholar] [CrossRef]

- Ren, Y.; Niu, M.; Zhang, C.; Xie, Y. Study on longitudinal liquid permeability of bamboo-culms by energy spectrum analysis. J. Harbin Univ. Commer. (Nat. Sci. Ed.) 2023, 39, 721–727. (In Chinese) [Google Scholar]

- Li, X.; Wei, Y.; Xu, J.; Xu, N.; He, Y. Quantitative visualization of lignocellulose components in transverse sections of moso bamboo based on FTIR macro-and micro-spectroscopy coupled with chemometrics. Biotechnol. Biofuels 2018, 11, 263. [Google Scholar] [CrossRef]

- Kostryukov, S.; Matyakubov, H.; Masterova, Y.; Kozlov, A.; Pryanichnikova, M.; Pynenkov, A.; Khluchina, N. Determination of lignin, cellulose, and hemicellulose in plant materials by FTIR spectroscopy. J. Anal. Chem. 2023, 78, 718–727. [Google Scholar] [CrossRef]

- Ramful, R.; Sunthar, T.P.; Marin, E.; Zhu, W.; Pezzotti, G. Investigating the effect of smoke treatment on hygroscopic characteristics of bamboo by FTIR and raman spectroscopy. Materials 2022, 15, 1544. [Google Scholar] [CrossRef]

- Ii, S. Nanoscale chemical analysis in various interfaces with energy dispersive X-ray spectroscopy and transmission electron microscopy. In XX-Ray Spectroscopy; InTech: Vukovar, Croatia, 2012; pp. 265–280. [Google Scholar]

- Wang, Q.; Liu, X.E.; Yang, S. Predicting density and moisture content of Populus xiangchengensis and Phyllostachys edulis using the X-ray computed tomography technique. For. Prod. J. 2020, 70, 193–199. [Google Scholar] [CrossRef]

- Wang, X.Q.; Ren, H.Q.; Zhao, R.J.; Cheng, Q.; Chen, Y.P. FTIR and XPS spectroscopic studies of photodegradation of moso bamboo (Phyllostachys pubescens Mazel). Spectrosc. Spectr. Anal. 2009, 29, 1864–1867. [Google Scholar]

- Liu, M.; Li, W.; Wang, H.; Zhang, X.; Yu, Y. The distribution of furfuryl alcohol (FA) resin in bamboo materials after surface furfurylation. Materials 2020, 13, 1157. [Google Scholar] [CrossRef]

- Guan, M.; Yong, C.; Zhao, J. Characterization on bamboo bonding interface by fluorescent track. J. Nanjing For. Univ. (Nat. Sci. Ed.) 2012, 36, 125–128. (In Chinese) [Google Scholar]

- Qi, X.; Zhang, S.; Wang, T.; Guo, S.; Ren, R. Effect of high-dispersible graphene on the strength and durability of cement mortars. Materials 2021, 14, 915. [Google Scholar] [CrossRef] [PubMed]

- Tao, X.; Wu, J.; Xu, W.; Shao, C. Bioinspired fluorine-free superhydrophobic wood: Binary micro-/nanostructure engineering for chemically stable and mechanically robust green materials. Prog. Org. Coat. 2025, 209, 109582. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, B. Recent progress in single and combined porosity-evaluation techniques for porous materials. Materials 2022, 15, 2981. [Google Scholar] [CrossRef] [PubMed]

- Huang, P. Hygrothermal Performance of Moso Bamboo-Based Building Material. Ph.D. Thesis, University of Bath, Bath, UK, 2017. [Google Scholar]

- Giesche, H. Mercury porosimetry: A general (practical) overview. Part. Part. Syst. Charact. 2006, 23, 9–19. [Google Scholar] [CrossRef]

- Das, M.; Chakrabarty, D. Thermogravimetric analysis and weathering study by water immersion of alkali-treated bamboo strips. BioResources 2008, 3, 1051–1062. [Google Scholar] [CrossRef]

- Chen, H.; Wu, J.; Shi, J.; Wang, G.; Zhang, W. Dimensional stability and mold resistance of bamboo slivers treated by alkali. BioResources 2022, 17, 2827–2848. [Google Scholar] [CrossRef]

- Ai, W.; Duval, H.; Pierre, F.; Perre, P. A novel device to measure gaseous permeability over a wide range of pressures: Characterisation of slip flow for Norway spruce, European beech, and wood-based materials. Holzforschung 2017, 71, 147–162. [Google Scholar] [CrossRef]

- Sun, Z.; Tian, Y. Study on the gas permeability of bamboo timber of dendrocalamus giganteus in the longitudinal direction. China For. Sci. Technol. 2006, 4, 37–40. (In Chinese) [Google Scholar]

- Zhao, J.; Li, L.; Lv, P.; Sun, Z.; Cai, Y. A comprehensive evaluation of axial gas permeability in wood using XCT imaging. Wood Sci. Technol. 2023, 57, 33–50. [Google Scholar] [CrossRef]

- Peng, G.Y.; Jiang, Z.H.; Liu, X.E.; Yu, Y.; Yang, S.M.; Deng, B.; Xiao, T.Q.; Wang, X.H. Measuring the density of wood and bamboo using computed tomography. Spectrosc. Spectr. Anal. 2012, 32, 1935–1938. [Google Scholar]

- Li, S.; Yang, S.; Shang, L.; Liu, X.; Ma, Q.; Tian, G. 3D visualization of bamboo node’s vascular bundle. Forests 2021, 12, 1799. [Google Scholar] [CrossRef]

- Li, S.; Yang, Q.; Wang, Y.; Shang, L.; Yang, S.; Liu, X.E.; Ma, Q.; Cao, Z. Three-dimensional visualization of the vascular bundle in a branched bamboo node. Front. Plant Sci. 2023, 14, 1256772. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Liu, C.; Wang, Y.; Shang, L.; Liu, X.E.; Wang, S.; Yang, S. Three-dimensional visualization of the conducting tissue in a bamboo culm base. Wood Sci. Technol. 2024, 58, 1585–1603. [Google Scholar] [CrossRef]

- Da Rocha Rodrigues, E.J.; Pinto Cucinelli Neto, R.; Diniz Lopes Alves, H.; Paciornik, S.; Santos de Sá, D.; Ghavami, K.; Ginoble Pandoli, O. An investigation of the fluid-holding cavities in a lignocellulose-based bamboo matrix via a combined X-ray microtomography and proton time-domain NMR approach. Cellulose 2023, 30, 4925–4940. [Google Scholar] [CrossRef]

- Chen, X.; Chen, F.; Jiang, H.; Wang, J.; Li, Y.X.; Wang, G. Replacing plastic with bamboo: Eco-friendly disposable tableware based on the separation of bamboo fibers and the reconstruction of their network structure. ACS Sustain. Chem. Eng. 2023, 11, 7407–7418. [Google Scholar] [CrossRef]

- Li, S.; Yang, Q.; Sun, X.; Shang, L.; Yang, S.; Jiang, Z. The behavior and mechanism of longitudinal liquid permeation in Moso bamboo (Phyllostachys edulis). Ind. Crops Prod. 2025, 232, 121255. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, X.; Yuan, C.; Lou, Z.; Li, Y. Effect of saturated steam heat treatment on physical and chemical properties of bamboo. Molecules 2020, 25, 1999. [Google Scholar] [CrossRef]