Predicting Porosity in Raw Cork Using Near-Infrared Spectroscopy

Abstract

1. Introduction

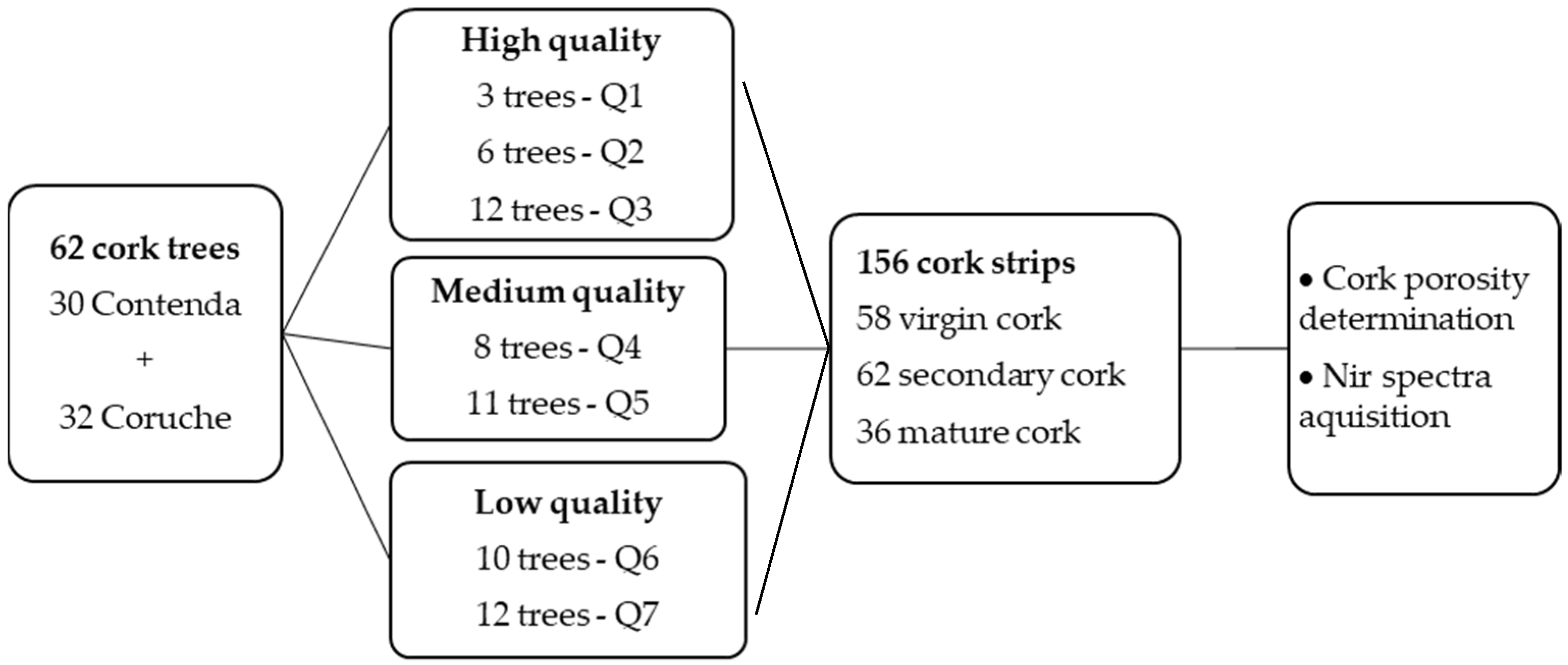

2. Materials

2.1. Cork Sampling and Preparation

2.2. Cork Porosity Measurements

3. Methods

3.1. Near-Infrared (NIR) Spectroscopy

3.2. Partial Least Square Regression (PLS-R)

4. Results and Discussion

4.1. Cork Porosity

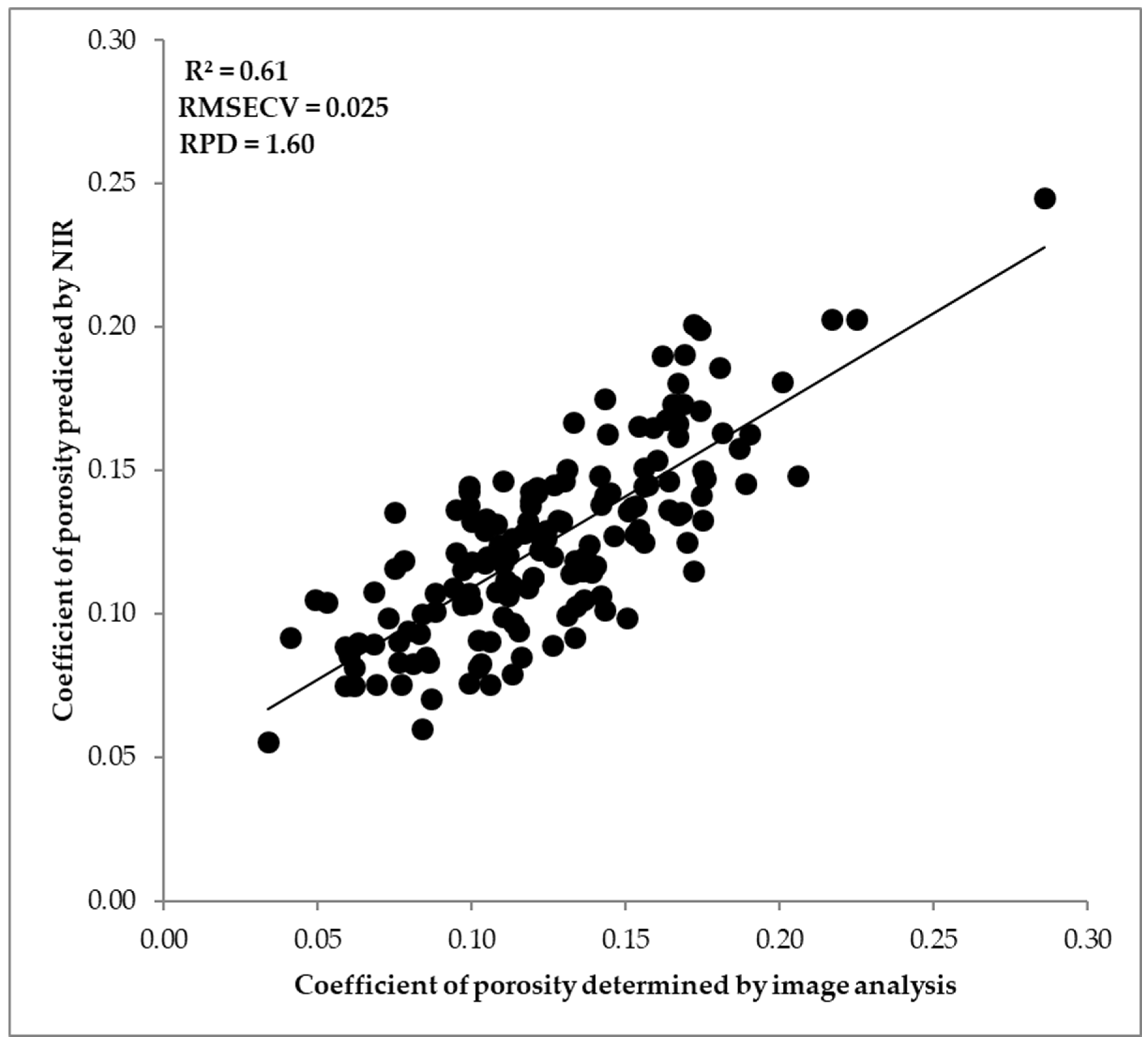

4.2. PLS-R Modeling and Cork Porosity Prediction

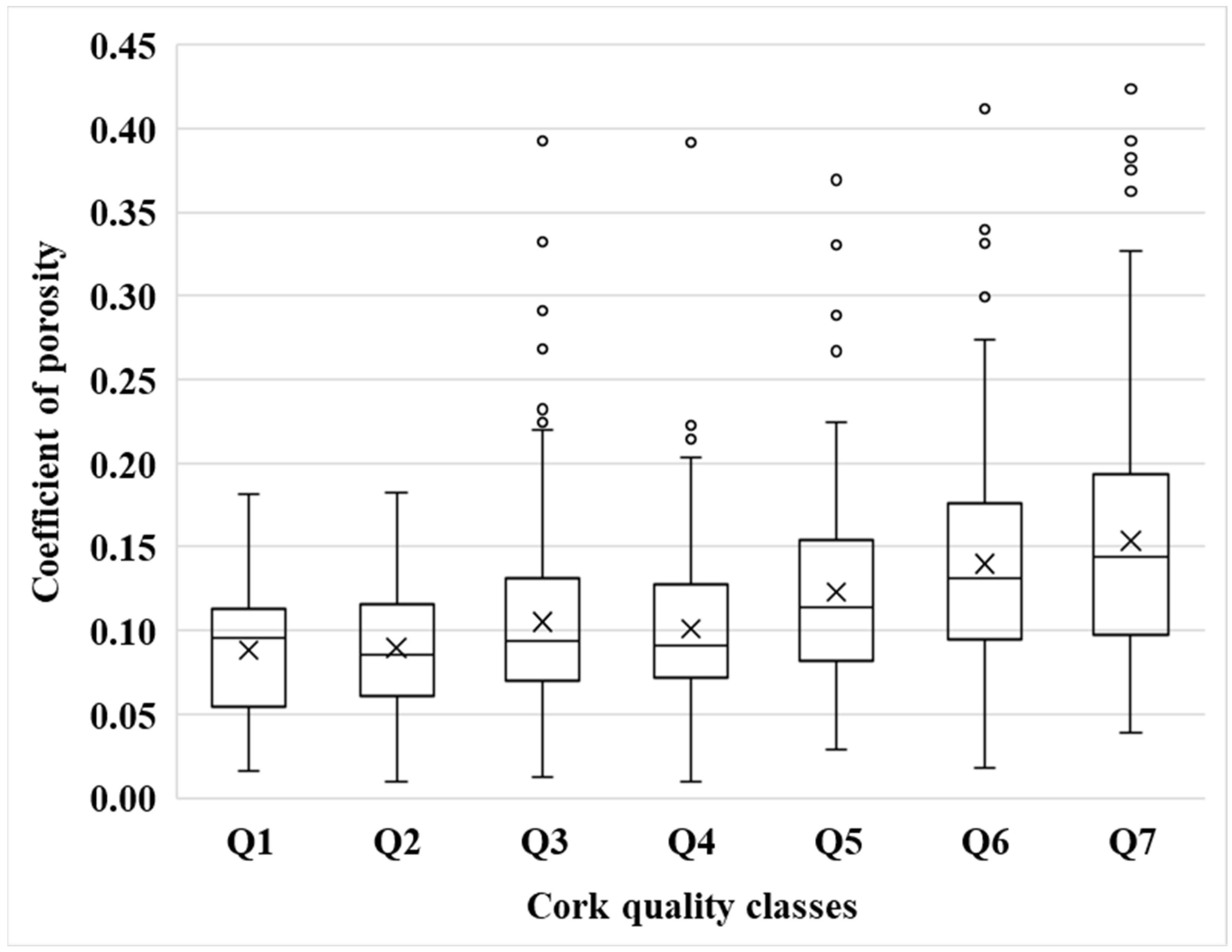

4.3. NIR-Predicted Cork Porosity in Secondary Cork Visual Quality Classes

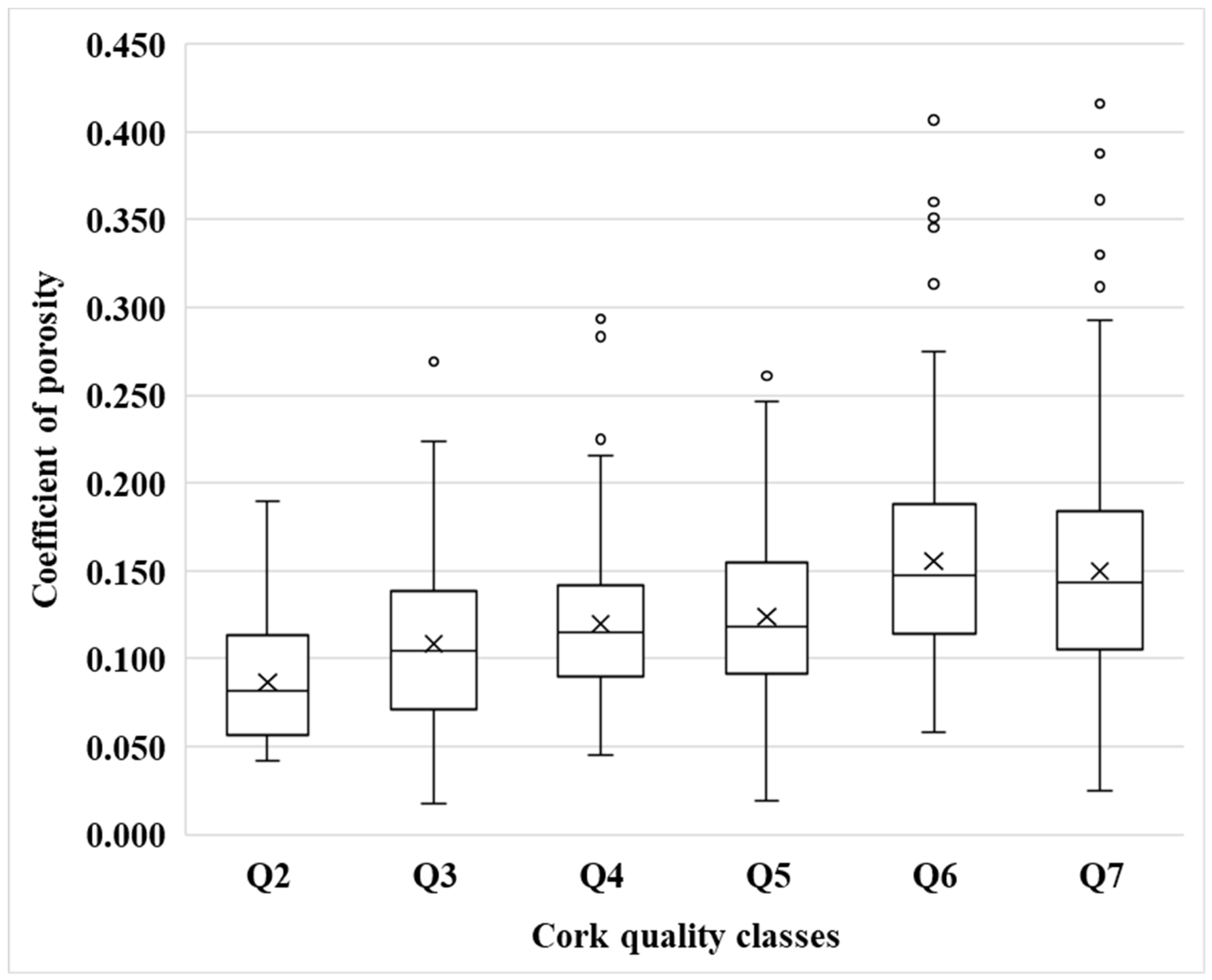

4.4. NIR-Predicted Cork Porosity in Mature Cork Visual Quality Classes

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pereira, H.; Tomé, M. Non-wood products: Cork Oak. In Encyclopedia of Forest Sciences; Burley, J., Evans, J., Youngquist, J.A., Eds.; Elsevier: Oxford, UK, 2004; pp. 613–620. [Google Scholar]

- Pereira, H. The Rationale behind Cork Properties: A Review of Structure and Chemistry. Bioresources 2015, 10, 6207–6229. [Google Scholar] [CrossRef]

- Costa, A.; Nunes, L.C.; Spiecker, H.; Graça, J. Insights into the Responsiveness of Cork Oak (Quercus suber L.) to Bark Harvesting. Econ. Bot. 2015, 69, 171–184. [Google Scholar] [CrossRef]

- Faias, S.P.; Paulo, J.A.; Tomé, M. Inter-tree competition analysis in undebarked cork oak plantations as a support tool for management in Portugal. New For. 2020, 51, 489–505. [Google Scholar] [CrossRef]

- Graça, J.; Pereira, H. The periderm development in Quercus suber. Iawa J. 2004, 25, 325–335. [Google Scholar] [CrossRef]

- Pereira, H.; Lopes, F.; Graca, J. The evaluation of the quality of cork planks by image analysis. Holzforschung 1996, 50, 111–115. [Google Scholar] [CrossRef]

- Pereira, H. Cork: Biology Production and Uses; Elsevier Science B.V.: Amsterdam, The Netherlands, 2007; pp. 7–31. [Google Scholar]

- Fortes, M.A.; Rosa, M.E.; Pereira, H. A Cortiça; IST Press: Lisboa, Portugal, 2004. [Google Scholar]

- Prades, C.; García-Olmo, J.; Romero-Prieto, T.; de Ceca, J.L.G.; López-Luque, R. Methodology for cork plank characterization (Quercus suber L.) by near-infrared spectroscopy and image analysis. Meas. Sci. Technol. 2010, 21, 065602. [Google Scholar] [CrossRef]

- Demertzi, M.; Paulo, J.A.; Faias, S.P.; Arroja, L.; Dias, A.C. Evaluating the carbon footprint of the cork sector with a dynamic approach including biogenic carbon flows. Int. J. Life Cycle Assess. 2018, 23, 1448–1459. [Google Scholar] [CrossRef]

- Lagorce-Tachon, A.; Karbowiak, T.; Loupiac, C.; Gaudry, A.; Ott, F.; Alba-Simionesco, C.; Gougeon, R.D.; Alcantara, V.; Mannes, D.; Kaestner, A.; et al. The cork viewed from the inside. J. Food Eng. 2015, 149, 214–221. [Google Scholar] [CrossRef]

- Hor, Y.L.; Federici, J.F.; Wample, R.L. Nondestructive evaluation of cork enclosures using terahertz/millimeter wave spectroscopy and imaging. Appl. Opt. 2008, 47, 72–78. [Google Scholar] [CrossRef]

- Sánchez-González, M.; García-Olmo, J.; Prades, C. Correlation between porosity of cork planks before and after boiling using near infrared spectroscopy. Eur. J. Wood Wood Prod. 2016, 74, 509–517. [Google Scholar] [CrossRef]

- Inácio, V.; Martins, M.T.; Graça, J.; Morais-Cecílio, L. Cork Oak Young and Traumatic Periderms Show PCD Typical Chromatin Patterns but Different Chromatin-Modifying Genes Expression. Front. Plant Sci. 2018, 9, 1194. [Google Scholar] [CrossRef]

- Brunetti, A.; Cesareo, R.; Golosio, B.; Luciano, P.; Ruggero, A. Cork quality estimation by using Compton tomography. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. At. 2002, 196, 161–168. [Google Scholar] [CrossRef]

- Oliveira, V.; Van den Bulcke, J.; Van Acker, J.; de Schryver, T.; Pereira, H. Cork structural discontinuities studied with X-ray microtomography. Holzforschung 2016, 70, 87–94. [Google Scholar] [CrossRef]

- Gonzalez-Adrados, J.R.; Lopes, F.; Pereira, H. Quality grading of cork planks with classification models based on defect characterisation. Holz Als Roh-Und Werkst. 2000, 58, 39–45. [Google Scholar] [CrossRef]

- Prades, C.; Gómez-Sánchez, I.; García-Olmo, J.; González-Adrados, J.R. Discriminant Analysis of Geographical Origin of Cork Planks and Stoppers by Near Infrared Spectroscopy. J. Wood Chem. Technol. 2012, 32, 54–70. [Google Scholar] [CrossRef]

- Pérez-Terrazas, D.; González-Adrados, J.R.; Sánchez-González, M. Qualitative and quantitative assessment of cork anomalies using near infrared spectroscopy (NIRS). Food Packag. Shelf Life 2020, 24, 100490. [Google Scholar] [CrossRef]

- Prades, C.; Gómez-Sánchez, I.; García-Olmo, J.; González-Hernández, F.; González-Adrados, J.R. Application of VIS/NIR spectroscopy for estimating chemical, physical and mechanical properties of cork stoppers. Wood Sci. Technol. 2014, 48, 811–830. [Google Scholar] [CrossRef]

- Díaz-Maroto, M.C.; Alarcón, M.; Díaz-Maroto, I.J.; Pérez-Coello, M.S.; Soriano, A. Rapid and non-invasive estimation of total polyphenol content and antioxidant activity of natural corks by NIR spectroscopy and multivariate analysis. Food Packag. Shelf Life 2023, 38, 101099. [Google Scholar] [CrossRef]

- Paulo, J.A.; Santos, D.I. Virgin cork colour and porosity as predictors for secondary cork industrial quality. Ind. Crops Prod. 2023, 205, 117513. [Google Scholar] [CrossRef]

- Conzen, J. Multivariate Calibration. In A Practical Guide for the Method Development in the Analytical Chemistry; Bruker Optik GmbH: Ettlingen, Germany, 2006; p. 116. [Google Scholar]

- Alves, A.; Hevia, A.; Simoes, R.; Majada, J.; Alia, R.; Rodrigues, J. Improving spatial synchronization between X-ray and near-infrared spectra information to predict wood density profiles. Wood Sci. Technol. 2020, 54, 1151–1164. [Google Scholar] [CrossRef]

- Rinnan, Å.; van den Berg, F.; Engelsen, S.B. Review of the most common pre-processing techniques for near-infrared spectra. Trac-Trends Anal. Chem. 2009, 28, 1201–1222. [Google Scholar] [CrossRef]

- Gómez-Sánchez, I.; de Ceca, J.L.G.; García-Olmo, J.; Lara-Buil, L.; López-Luque, R.; Prades, C. Application of image analysis and NIRS technology to the evaluation of the porosity of planks, sheets and cork stoppers, and its relation with the industrial quality. Maderas-Cienc. Y Tecnol. 2013, 15, 293–309. [Google Scholar] [CrossRef]

- Oliveira, V.; Knapic, S.; Pereira, H. Natural variability of surface of porosity of wine cork stoppers of different commercial classes. J. Int. Des Sci. Vigne Vin 2012, 46, 331–340. [Google Scholar] [CrossRef]

- Costa, A.; Pereira, H. Influence of vision systems, black and white, colored and visual digitalization, in natural cork stopper quality estimation. J. Sci. Food Agric. 2007, 87, 2222–2228. [Google Scholar] [CrossRef]

- Costa, A.; Pereira, H. Quality characterization of wine cork stoppers using computer vision. OENO One 2025, 39, 209–218. [Google Scholar] [CrossRef]

| With Insect Galleries | Without Insect Galleries | |||||||

|---|---|---|---|---|---|---|---|---|

| Cork Type | Virgin | Secondary | Mature | Total | Virgin | Secondary | Mature | Total |

| Average | 0.125 | 0.119 | 0.136 | 0.125 | 0.114 | 0.115 | 0.128 | 0.118 |

| Min. | 0.049 | 0.034 | 0.083 | 0.034 | 0.043 | 0.034 | 0.083 | 0.034 |

| Max. | 0.286 | 0.225 | 0.217 | 0.286 | 0.213 | 0.224 | 0.213 | 0.224 |

| STD | 0.04 | 0.04 | 0.03 | 0.04 | 0.04 | 0.04 | 0.03 | 0.04 |

| CoeVar (%) | 33.9 | 34.3 | 21.7 | 31.7 | 33.3 | 34.0 | 22.2 | 31.4 |

| CI | (0.114; 0.136) | (0.109; 0.129) | (0.129; 0.143) | (0.119; 0.131) | (0.104; 0.124) | (0.105; 0.125) | (0.121; 0.135) | (0.112; 0.123) |

| Model | Preprocessing Treatment and Wavenumber Range (cm−1) | n | Cross-Validation | ||||

|---|---|---|---|---|---|---|---|

| R2 | RMSECV | RPD | Rk | OL | |||

| CPVwith galleries | 1stDerVN 9500–6100; 4600–4250 | 58 | 0.53 | 0.029 | 1.45 | 4 | 0 |

| CPV | 1stDerMSC 6100–5450 | 58 | 0.48 | 0.027 | 1.39 | 4 | 0 |

| CPSwith galleries | 1stDerMSC 9500–5450; 4600–4424 | 62 | 0.61 | 0.025 | 1.60 | 5 | 0 |

| CPS | 1stDerMSC 9500–6100; 5450–4250 | 62 | 0.55 | 0.026 | 1.44 | 5 | 0 |

| CPMwith galleries | 1stDerVN 7500–6100; 5450–4600 | 36 | 0.63 | 0.018 | 1.64 | 2 | 0 |

| CPM | 1stDerMSC 9400–7500; 5450–4250 | 36 | 0.64 | 0.017 | 1.68 | 5 | 0 |

| Model | n | Cross-Validation 60% | Validation 40% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | RMSECV | RPD | Rk | OL | R2 | RMSEP | RPD | Rk | OL | ||

| CPwith galleries | 156 | 0.63 | 0.025 | 1.64 | 5 | 0 | 0.46 | 0.028 | 1.36 | 5 | 0 |

| CP | 156 | 0.51 | 0.025 | 1.42 | 5 | 0 | 0.52 | 0.026 | 1.45 | 5 | 0 |

| Coefficient of Porosity | |||||||

|---|---|---|---|---|---|---|---|

| Quality | Total spectra | Average | Min. | Max. | STD | CoeVar (%) | CI |

| Q1 | 33 | 0.088 | 0.016 | 0.182 | 0.039 | 43.9 | (0.075; 0.101) |

| Q2 | 66 | 0.090 | 0.010 | 0.182 | 0.041 | 45.5 | (0.080; 0.100) |

| Q3 | 162 | 0.105 | 0.013 | 0.393 | 0.057 | 54.2 | (0.096; 0.114) |

| Q4 | 126 | 0.101 | 0.010 | 0.392 | 0.050 | 49.0 | (0.093; 0.110) |

| Q5 | 147 | 0.123 | 0.029 | 0.369 | 0.057 | 46.2 | (0.114; 0.132) |

| Q6 | 167 | 0.140 | 0.018 | 0.412 | 0.063 | 45.3 | (0.130; 0.149) |

| Q7 | 193 | 0.154 | 0.039 | 0.424 | 0.074 | 47.9 | (0.143; 0.164) |

| Coefficient of Porosity | |||||||

|---|---|---|---|---|---|---|---|

| Quality | Total Spectra | Average | Min. | Max. | STD | CoeVar (%) | CI |

| Q1 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

| Q2 | 19 | 0.087 | 0.042 | 0.190 | 0.036 | 41.5 | (0.071; 0.103) |

| Q3 | 132 | 0.109 | 0.018 | 0.274 | 0.051 | 47.2 | (0.100; 0.117) |

| Q4 | 189 | 0.120 | 0.045 | 0.294 | 0.039 | 32.5 | (0.114; 0.126) |

| Q5 | 114 | 0.124 | 0.019 | 0.262 | 0.052 | 41.8 | (0.115; 0.134) |

| Q6 | 199 | 0.156 | 0.058 | 0.407 | 0.058 | 37.3 | (0.148; 0.164) |

| Q7 | 449 | 0.150 | 0.025 | 0.418 | 0.061 | 40.4 | (0.144; 0.156) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, A.; Paulo, J.A.; Santos, D.I.; Graça, J.; Rodrigues, J. Predicting Porosity in Raw Cork Using Near-Infrared Spectroscopy. Forests 2025, 16, 1737. https://doi.org/10.3390/f16111737

Alves A, Paulo JA, Santos DI, Graça J, Rodrigues J. Predicting Porosity in Raw Cork Using Near-Infrared Spectroscopy. Forests. 2025; 16(11):1737. https://doi.org/10.3390/f16111737

Chicago/Turabian StyleAlves, Ana, Joana Amaral Paulo, Diana I. Santos, José Graça, and José Rodrigues. 2025. "Predicting Porosity in Raw Cork Using Near-Infrared Spectroscopy" Forests 16, no. 11: 1737. https://doi.org/10.3390/f16111737

APA StyleAlves, A., Paulo, J. A., Santos, D. I., Graça, J., & Rodrigues, J. (2025). Predicting Porosity in Raw Cork Using Near-Infrared Spectroscopy. Forests, 16(11), 1737. https://doi.org/10.3390/f16111737