Manufacturing Process and Performance Experiment of Natural Arc-Shaped Bamboo Laminated Lumber

Abstract

1. Introduction

2. Materials and Methods

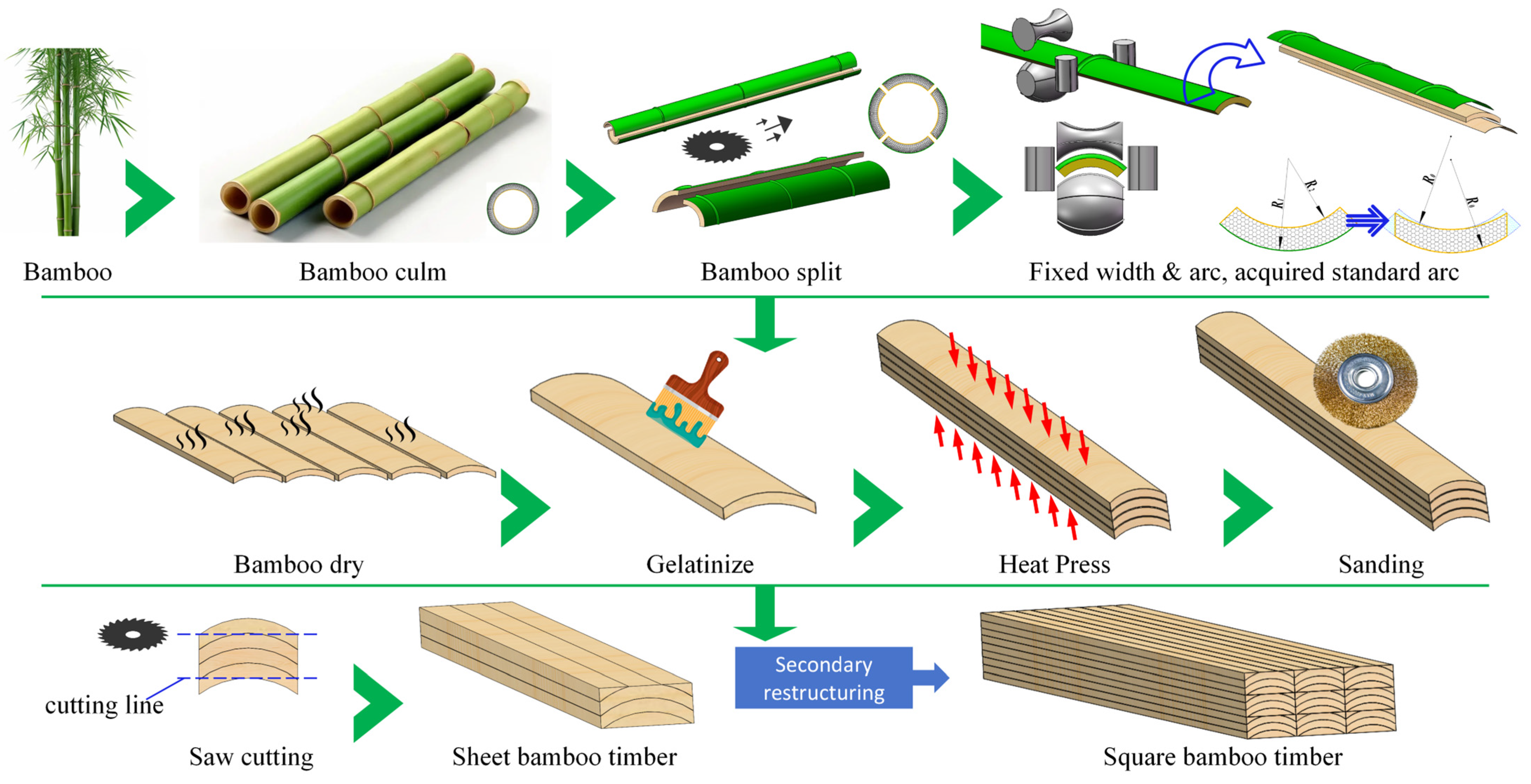

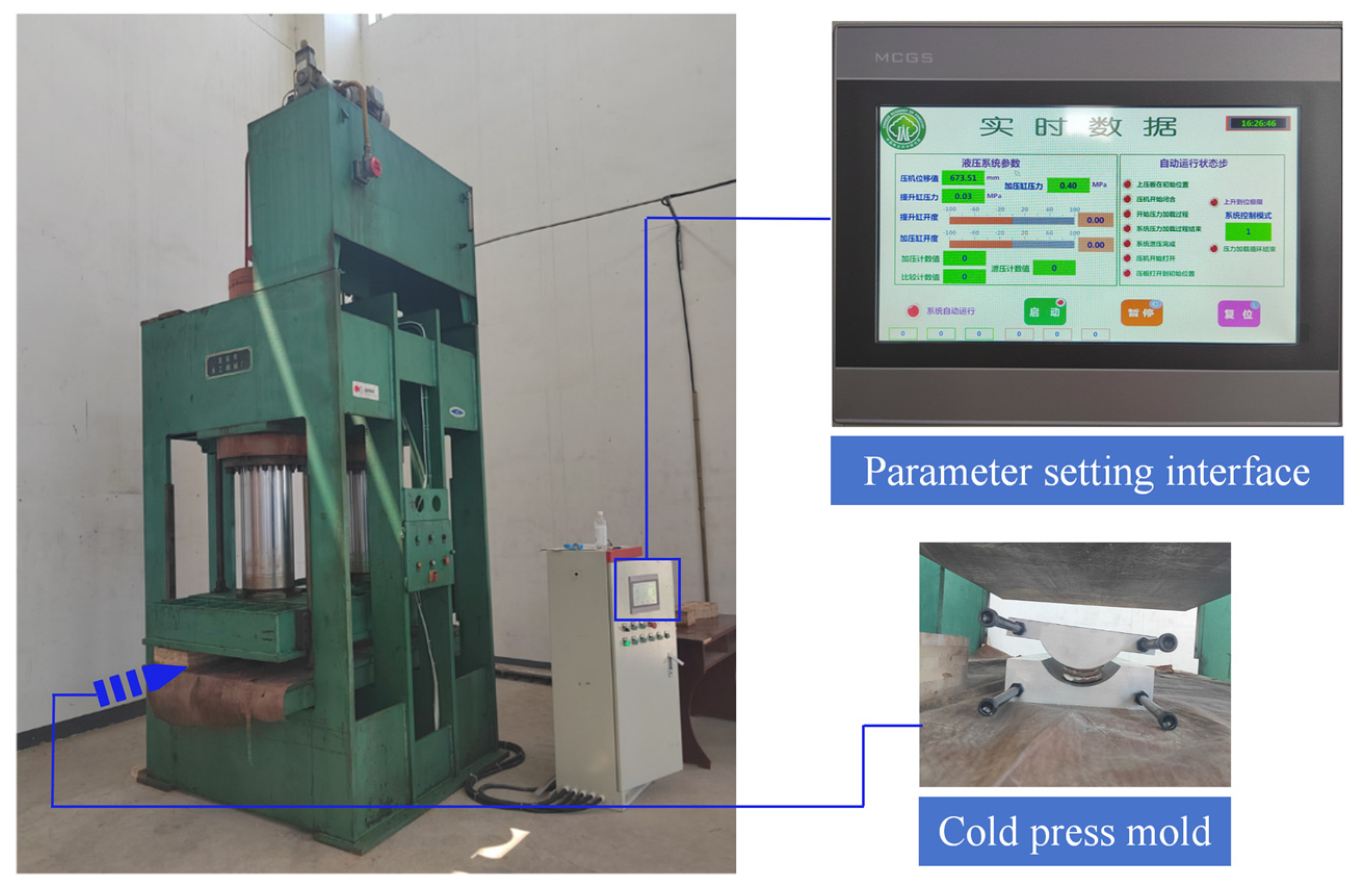

2.1. Novel Production Process for ABLL

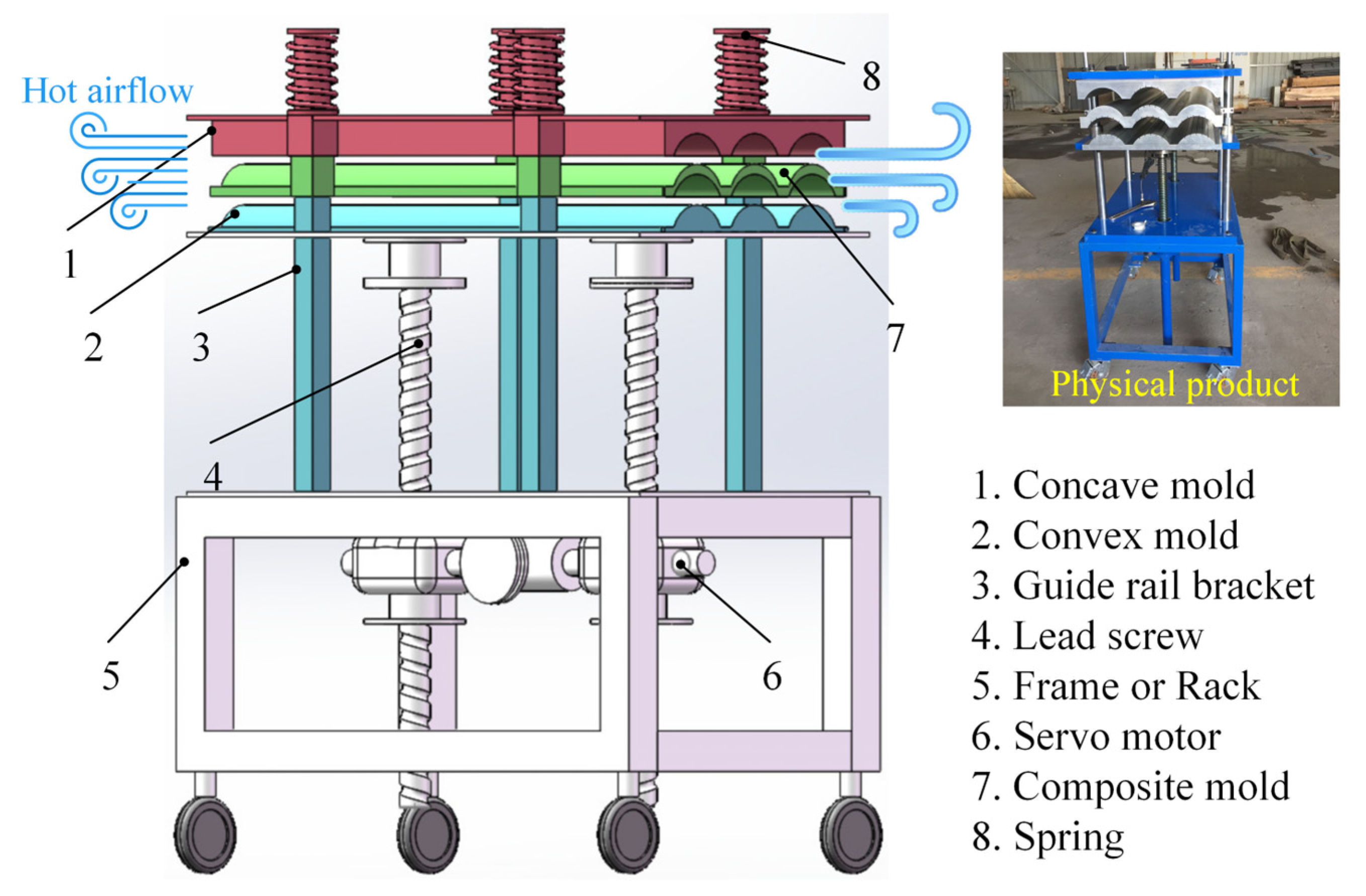

2.2. Design of the Prototype for the Experiment

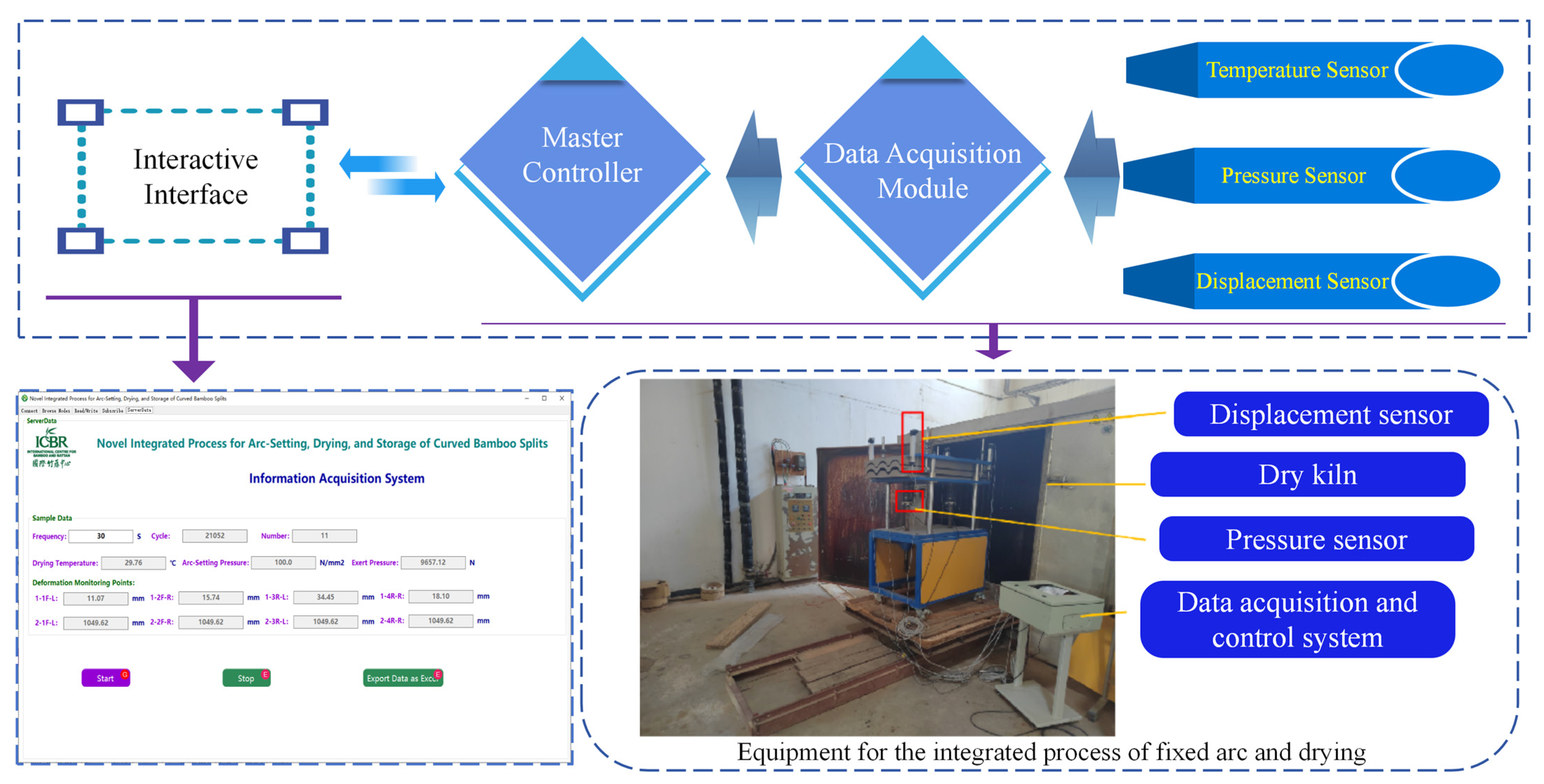

2.3. Design of the Information Acquisition and Control System

- (1)

- Real-time temperature acquisition in the drying kiln and associated data storage;

- (2)

- Real-time acquisition of the mold’s pre-stored release force and data storage;

- (3)

- Real-time gap measurement between concave and convex molds and data storage;

- (4)

- Real-time display of acquired parameters, system operation monitoring, and sampling frequency configuration.

2.4. Experimental Materials and Scheme

3. Results and Discussion

3.1. The Products of the Experiment

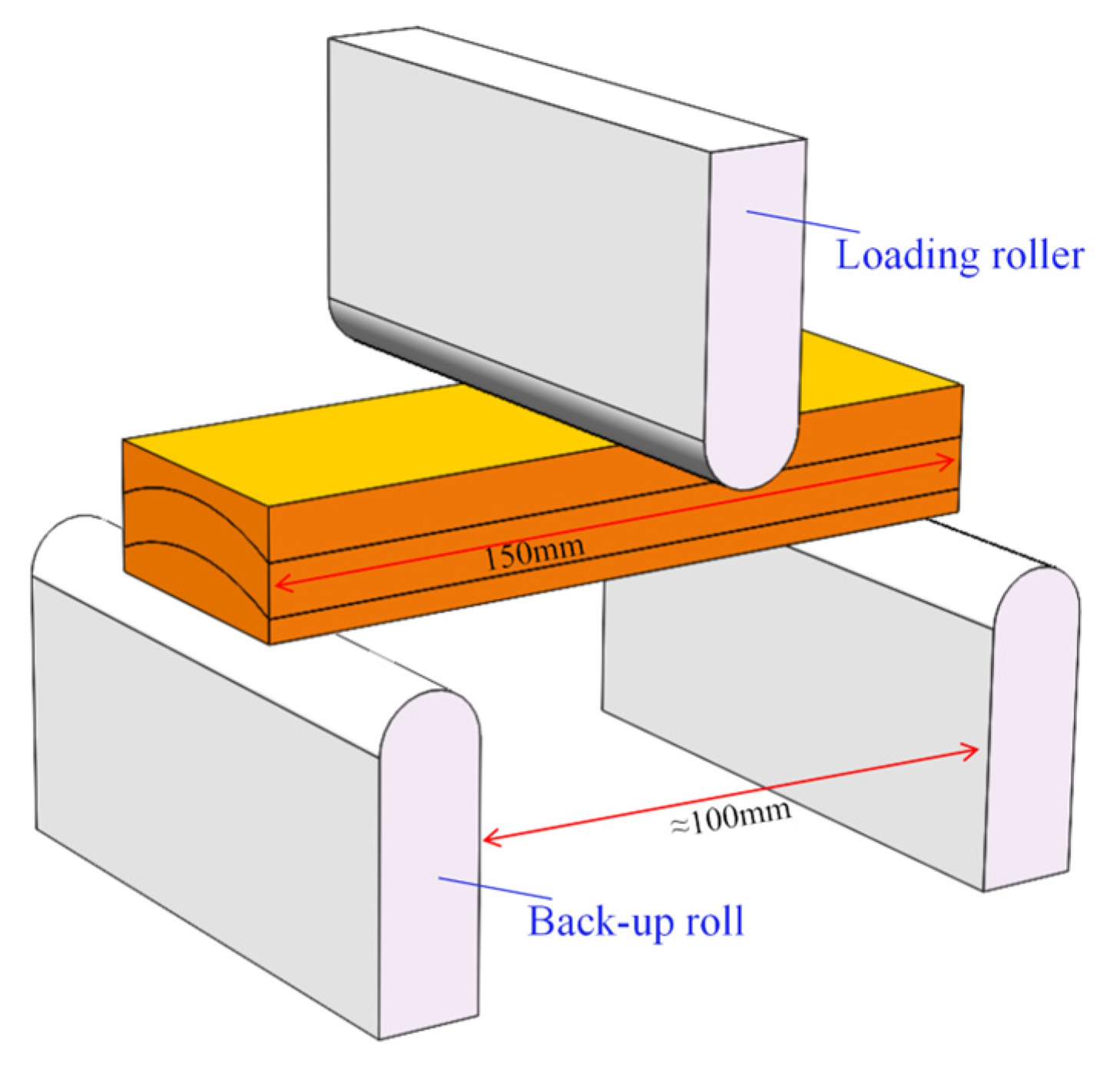

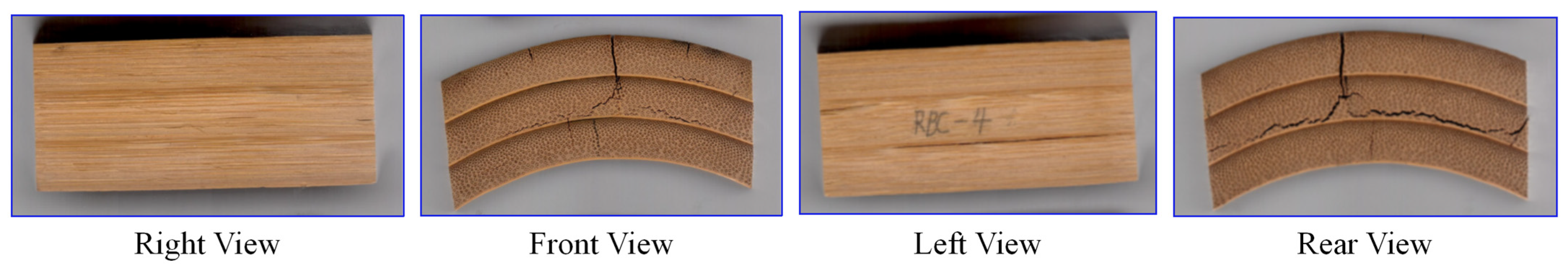

3.2. The Experimental Effect on Bonding Quality

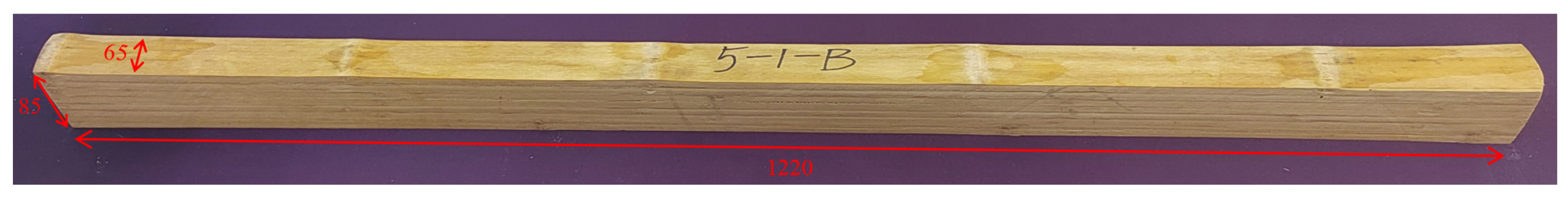

3.3. The Material Utilization Rate of ABLL

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Q.; Fei, B.; Qi, J.; Zhang, S.; Huang, X.; Jiang, Y.; Xie, J.; Jia, S. Effect of moisture content on bamboo’s mode I interlaminar fracture toughness: The competition between promoting and impeding crack growth. Constr. Build. Mater. 2022, 341, 127822. [Google Scholar] [CrossRef]

- Ma, Y.; Luan, Y.; Chen, L.; Huang, B.; Luo, X.; Miao, H.; Fang, C. A Novel Bamboo–Wood Composite Utilizing High-Utilization, Easy-to-Manufacture Bamboo Units: Optimization of Mechanical Properties and Bonding Performance. Forests 2024, 15, 716. [Google Scholar] [CrossRef]

- Arya, S.; Kumar, R.; Chauhan, S. Preparation and characterization of woven jute fabric layered composite by using bamboo fiber reinforced polymers as resin matrix. Constr. Build. Mater. 2024, 411, 134343. [Google Scholar] [CrossRef]

- Huang, B.; Chen, L.; Wang, X.; Ma, X.; Liu, H.; Zhang, X.; Sun, F.; Fei, B.; Fang, C. Eco-friendly, high-utilization, and easy-manufacturing bamboo units for engineered bamboo products Processing and mechanical characterization. Compos. Part B Eng. 2023, 267, 111073. [Google Scholar] [CrossRef]

- Dauletbek, A.; Li, H.; Lorenzo, R.; Corbi, I.; Corbi, O.; Ashraf, M. A review of basic mechanical behavior of laminated bamboo lumber. J. Renew. Mater. 2022, 10, 273. [Google Scholar] [CrossRef]

- Reynolds, T.P.; Sharma, B.; Serrano, E.; Gustafsson, P.-J.; Ramage, M.H. Fracture of laminated bamboo and the influence of preservative treatments. Compos. B Eng. 2019, 174, 107017. [Google Scholar] [CrossRef]

- Wang, X.; Chen, X.; Shang, L.; Chen, L.; Huang, B.; Ma, X.; Fei, B.; Liu, H.; Fang, C. A straightforward and efficient gradient pressure method for bamboo flattening: Strain and multi-scale deformation. Compos. Part B Eng. 2024, 272, 111232. [Google Scholar] [CrossRef]

- Fang, C.-H.; Jiang, Z.-H.; Sun, Z.-J.; Liu, H.-R.; Zhang, X.-B.; Zhang, R.; Fei, B.-H. An overview on bamboo culm flattening. Constr. Build. Mater. 2018, 171, 65–74. [Google Scholar] [CrossRef]

- Yuan, T.; Wang, X.; Liu, X.; Lou, Z.; Mao, S.; Li, Y. Bamboo flattening technology enables efficient and value-added utilization of bamboo in the manufacture of furniture and engineered composites. Compos. Part B Eng. 2022, 242, 110097. [Google Scholar] [CrossRef]

- State Forestry Administration Beijing Forestry Machinery Research Institute. Arc-Shaped Bamboo Original State Recombinant Material and its Manufacturing Method. CN1970254B, 7 November 2006. [Google Scholar]

- Fu, W.S.; Zhou, J.B. Study on industrial manufacturing technology of Natural Arc-bamboo Laminated Lumber. Wood Process. Mach. 2010, 6, 7–11. [Google Scholar]

- Li, W.; Zhang, Z.; Cheng, F.; Fu, W. The processing method and utilization ratio of arch bamboo pieces. For. Grassl. Mach. 2009, 20, 1–6. [Google Scholar]

- Liu, J.; Fu, W.; Zhou, J. Research on original re-combined arc bamboo board material. For. Grassl. Mach. 2010, 21, 26–29. [Google Scholar]

- Zhang, Z.; Li, W.; Peng, X.; Li, W.; Zhang, J. Development of Bamboo Shaping and Curve Milling Equipment. For. Mach. Woodwork. Equip. 2011, 39, 18–22. [Google Scholar]

- Zhou, J. Study on Adhesives Strength of A-BROS and Developing of Arc Bamboo Fine-Milling Machine. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2015. [Google Scholar]

- Chen, L.; Fang, C.; Liu, H.; Ma, X.; Fei, B. Study Progress on the Forming Technology of Curved Bamboo. China For. Prod. Ind. 2021, 58, 40–44. [Google Scholar]

- Yan, W.; Zhou, J.; Zhang, B.; Fu, W.; Chen, Z.; Ma, C.; Ningxia, Y. Development design and mechanical properties of arc bamboo. Wood Res. 2017, 62, 365–372. [Google Scholar]

- Chen, L.; Huang, B.; Su, Q.; Wang, X.; Fang, C.; Zhang, X.; Chen, Q.; Yuan, J.; Fei, B. In-situ dynamic observation on the gluing process of Moso bamboo cells. Ind. Crops Prod. 2023, 204, 9. [Google Scholar] [CrossRef]

- Chen, L.; Luo, X.; Huang, B.; Ma, Y.; Fang, C.; Liu, H.; Fei, B. Properties and bonding interface characteristics of an innovative bamboo flattening and grooving unit (BFGU) for laminated bamboo lumber. Colloids Surf. A Physicochem. Eng. Asp. 2023, 676, 132185. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, J.; Wang, X.; Huang, B.; Ma, X.; Fang, C.; Zhang, X.; Sun, F.; Fei, B. Effect of bamboo pith ring on the stability of the gluing interface. Ind. Crops Prod. 2022, 187, 11. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, J.; Wang, X.; Huang, B.; Ma, X.; Fang, C.; Zhang, X.; Sun, F.; Fei, B. Fine gluing of bamboo skin and bamboo pith ring based on sanding. Ind. Crops Prod. 2022, 188, 12. [Google Scholar] [CrossRef]

- Hu, G. Study on Dynamic Viscoelasticities of Heat-Treated Bamboo. Master’s Thesis, Zhejiang A&F University, Hangzhou, China, 2012. [Google Scholar]

- Huang, M.; Zhang, W.; Zhang, X.; Yu, W.; Li, W.; Dai, C.; Wang, S. Dynamic mechanical analysis of moso bamboo timber. J. Nanjing For. Univ. 2016, 40, 123–128. [Google Scholar]

- Yu, W.; Jiang, Z.; Ye, K. Characteristics research of bamboo and its development. World For. Res. 2002, 15, 50–55. [Google Scholar]

- Miao, H.; Gao, R.; Wang, G.; Ma, X.; Fang, C.; Liu, H. Design and Experiment of the Mold for the Production Process of Natural Arc-Shaped Bamboo Laminated Lumber. Forests 2025, 16, 1452. [Google Scholar] [CrossRef]

- Correal, J.F.; Ramirez, F. Adhesive bond performance in glue line shear and bending for glued laminated guadua bamboo. J. Trop. For. Sci. 2010, 4, 433–439. [Google Scholar]

- GB/T 1927.4-2021; Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens—Part 4: Determination of Moisture Content. Standards Press of China: Beijing, China, 2021.

- Zhang, W.; Jiang, Z.; Wang, G.; Cheng, H.; Zhang, D. Radial compression mechanical properties of bamboo-culm by ring stiffness. J. Beijing For. Univ. 2013, 35, 119–122. [Google Scholar]

- Yang, F. Processing Technology of Bamboo Scrimper and OSB Composite and Its Performance Prediction. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2014. [Google Scholar]

- GB/T 20241-2021; Laminated Veneer Lumber. Standards Press of China: Beijing, China, 2022.

- Huang, B.; Fang, C.; Chen, L.; Miao, H.; Ma, X.; Liu, H.; Fei, B. Analysis of the use rate of equal arc-shaped bamboo splits. Constr. Build. Mater. 2021, 302, 124273. [Google Scholar] [CrossRef]

- ISO 12578:2016; Timber Structures—Glued Laminated Timber—Component Performance Requirements. International Organization for Standardization: Geneva, Switzerland, 2016.

- LY/T 1815-2009; Non-Structural Glued Laminated Bamboo. Standards Press of China: Beijing, China, 2009.

- Nkeuwa, W.N.; Zhang, J.; Semple, K.E.; Chen, M.; Xia, Y.; Dai, C. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. B Eng. 2022, 235, 109776. [Google Scholar] [CrossRef]

- Azadeh, A.; de Sá, A.D.; Kadivar, M.; Gauss, C.; Junior, H.S. The effect of densification on physical and mechanical properties of bamboo Dendrocalamus asper. Eur. J. Wood Prod. 2022, 80, 877–888. [Google Scholar] [CrossRef]

- Brito, F.M.S.; Paes, J.B.; da Silva Oliveira, J.T.; Arantes, M.D.C.; Vidaurre, G.B.; Brocco, V.F. Physico-mechanical characterization of heat-treated glued laminated bamboo. Constr. Build. Mater. 2018, 190, 719–727. [Google Scholar] [CrossRef]

- Serrano, E.; Enquist, B. Contact-free measurement and non-linear finite element analyses of strain distribution along wood adhesive bonds. Holzforschung 2005, 59, 641–646. [Google Scholar] [CrossRef]

- Müller, U.; Sretenovic, A.; Vincenti, A.; Gindl, W. Direct measurement of strain distribution along a wood bond line. Part 1: Shear strain concentration in a lap joint specimen by means of electronic speckle pattern interferometry. Holzforschung 2005, 59, 300–306. [Google Scholar] [CrossRef]

- Maulana, S.; Gumelar, Y.; Fatrawana, A.; Maulana, M.I.; Hidayat, W.; Sumardi, I.; Wistara, N.J.; Lee, S.H.; Kim, N.H.; Febrianto, F. Destructive and Non-destructive Tests of Bamboo Oriented Strand Board under Various Shelling Ratios and Resin Contents. J. Korean Wood Sci. Technol. 2019, 47, 519–532. [Google Scholar] [CrossRef]

- Kelkar, B.; Shukla, S.; Paul, B.; Arya, S. Effect of softening duration on physical, mechanical and microstructural properties of flattened densified Bambusa bambos. J. Build. Eng. 2023, 74, 106821. [Google Scholar] [CrossRef]

- Wang, X.; Su, N.; Chen, X.; Fei, B.; Ma, X.; Liu, H.; Miao, H.; Fang, C. Impact of temperature on mechanical properties and dimensional stability in a novel gradient pressure bamboo flattening technique. Constr. Build. Mater. 2024, 427, 136258. [Google Scholar] [CrossRef]

- Kadivar, M.; Gauss, C.; Stanislas, T.T.; Ahrar, A.J.; Charca, S.; Savastano, H., Jr. Effect of bamboo species and pre-treatment method on physical and mechanical properties of bamboo processed by flattening-densification. Mater. Chem. Phys. 2022, 291, 126746. [Google Scholar] [CrossRef]

- Mirmehdi, M. The Effects of Bamboo Species and Adhesive Type on Mechanical Properties of Laminated Bamboo Lumber (LBL). Ph.D. Thesis, Federa University of Lavras, Lavras, Brazil, 2016. [Google Scholar]

- LY/T 1072-2022; Bamboo Parallel Sliver Lumber. Standards Press of China: Beijing, China, 2022.

- GB/T 26899-2022; Structural Glued Laminated Timber. Standards Press of China: Beijing, China, 2022.

- ISO 22156:2021; Bamboo Structures—Bamboo Culms—Structural Design. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 7567:2024; Bamboo Structures—Glued Laminated Bamboo—Product Specifications. International Organization for Standardization: Geneva, Switzerland, 2024.

| Parameter | Value |

|---|---|

| Maximum loading capacity | 10 t |

| Length | 1200 mm |

| Width | 800 mm |

| Height | Determined by pressing layers |

| Stroke of mold | 75 mm |

| Layers of mold | 2 |

| Parameters | Value |

|---|---|

| Adhesive application amount | 200 g/m2 (single-sided application) |

| Curing time | ≤10 min (20 °C, air humidity: 65%, bamboo moisture content: 12%) |

| Pressurization time | 45 min |

| Ambient temperature | 30 ± 5 °C |

| Ambient humidity | 40% ± 10% |

| Pressurization pressure | 0.8 ± 2 MPa |

| Post-pressurization placement time | At least 2 h of placement in a 20 °C environment after pressurization |

| Parameter | Mean Value | Standard Deviation (SD) | Variance (s2) |

|---|---|---|---|

| Peel length of the right view | 0 mm | 0 | 0 |

| Length of the right view | 148.6 mm | 3.8 | 14.46 |

| Peel length of the front view | 0 mm | 0 | 0 |

| Length of the front view | 148.9 mm | 2.73 | 10.32 |

| Peel length of the left view | 21.8 mm | 1.32 | 8.33 |

| Length of the left view | 148.6 mm | 3.64 | 11.26 |

| Peel length of the rear view | 0 mm | 0 | 0 |

| Length of the rear view | 148.9 mm | 2.93 | 9.65 |

| Peel rate | 3.67% |

| Specimen Number | Oven-Dry Weight (g) | Initial Weight (g) | Initial Moisture Content (%) | Weight After Node Removal and Sanding (g) | Weight After Arc-Setting and Drying (g) | Moisture Content After Arc-Setting and Drying (%) | Oven-Dry Weight After Arc-Setting and Drying (g) | Weight of Edge- Sawing Trimmings (g) | Finished Product Weight (g) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 483.26 | 705.32 | 45.9 | 641.51 | 562.88 | 16.5 | 470 | 908.12 | 3774.29 |

| 2 | 530.25 | 758.12 | 43 | 695.05 | 615.98 | 16.2 | 516.19 | ||

| 3 | 519.61 | 727.98 | 40.1 | 670.98 | 602.9 | 16.0 | 506.44 | ||

| 4 | 367.05 | 543.74 | 48.1 | 499.67 | 427.58 | 16.5 | 357.03 | ||

| 5 | 407.78 | 617.68 | 51.4 | 556.48 | 476.35 | 16.8 | 396.32 | ||

| 6 | 516.3 | 821.21 | 59.1 | 742.78 | 603.43 | 16.8 | 502.05 | ||

| 7 | 521.17 | 916.4 | 75.8 | 846.32 | 616.12 | 18.2 | 503.99 | ||

| 8 | 518.17 | 834.92 | 61.1 | 761.21 | 610.84 | 17.8 | 502.11 | ||

| SD | 61.50 | 120.64 | 11.75 | 111.92 | 72.68 | 0.77 | 59.60 | ||

| s2 | 3309.76 | 12,734.24 | 120.75 | 10,959.96 | 4621.56 | 0.52 | 3107.70 | ||

| SUM | 3863.59 | 3754.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Gao, R.; Miao, H.; Wang, Y.; Fang, C.; Liu, H. Manufacturing Process and Performance Experiment of Natural Arc-Shaped Bamboo Laminated Lumber. Forests 2025, 16, 1699. https://doi.org/10.3390/f16111699

Wang G, Gao R, Miao H, Wang Y, Fang C, Liu H. Manufacturing Process and Performance Experiment of Natural Arc-Shaped Bamboo Laminated Lumber. Forests. 2025; 16(11):1699. https://doi.org/10.3390/f16111699

Chicago/Turabian StyleWang, Guofu, Rui Gao, Hu Miao, Yong Wang, Changhua Fang, and Huanrong Liu. 2025. "Manufacturing Process and Performance Experiment of Natural Arc-Shaped Bamboo Laminated Lumber" Forests 16, no. 11: 1699. https://doi.org/10.3390/f16111699

APA StyleWang, G., Gao, R., Miao, H., Wang, Y., Fang, C., & Liu, H. (2025). Manufacturing Process and Performance Experiment of Natural Arc-Shaped Bamboo Laminated Lumber. Forests, 16(11), 1699. https://doi.org/10.3390/f16111699