1. Introduction

Various criteria are used during the selection of wood according to its intended application. In general, these features include timber availability, the wood’s anatomical features, its density, its strength, its seasoning properties, its natural durability and, in the case of preservative treatment, its freedom from defects, as well as its color and grain. Also, knowledge of its structural, physical, and mechanical properties is of key importance in determining the possible utilization of a given type of wood [

1,

2]. Such knowledge is even more crucial in species whose wood has multipurpose roles [

3].

In the technology of pulp production, the different anatomical structures of wood are considered, as well as their properties [

4,

5]. As fiber dimensions are among the basic characteristics of pulp, they have a significant impact on the structural and strength properties of the paper products. An analysis of fiber dimensions usually includes their length, diameter, fiber cell wall thickness, and lumen, and the interrelationships between these parameters [

6,

7]. Recognition of these relationships is an important element that determines the functional properties of the wood, and consequently, the possibility of using the wood of this species for pulp and paper purposes.

Black locust (

Robinia pseudoacacia L. (Fabaceae)) is one of circa 150 non-native tree species introduced to the forests of Europe [

8]. It originates from the eastern part of North America and was brought to the ‘old World’ as one of the first overseas tree species at the beginning of the 1600s [

9,

10,

11]. Eventually, it became the most common non-native broadleaved tree species on the continent and is now an important multipurpose species in many parts of Europe [

10,

11,

12]. On the other hand, black locust is considered one of the most invasive species [

13] as it reduces biodiversity by limiting the accessibility of light and by changing the microclimate and soil conditions.

As the observed climate changes are expected to favor the further expansion of black locust in both forested and non-forested areas of Europe [

14,

15], it is important to increase knowledge of the potential productivity of this species and the quality of its timber. It is also of great significance to compare the properties of wood from this non-native species with wood from local species.

The age and size of the tree are among the principal factors that significantly influence the majority of the structural, mechanical, and physical properties of black locust wood [

16,

17,

18,

19,

20]. The older the tree, the higher the usual value of its individual attributes. On the other hand, tree size affects wood features to lesser extent than age. In general, the best technical quality wood derives from the youngest trees. At the same time, research on the anatomical structure and the potential suitability of black locust wood for the pulp and paper industry is rather scarce [

21,

22,

23,

24].

As the properties of paper that is made from cellulose depend on the fiber morphology, morphological properties such as fiber length or width and cell wall thickness are very important factors in the selection of raw material for the paper and pulp industry [

22]. The presented study is a follow up of earlier research on the mechanical and structural features of the wood of black locust growing on oligotrophic sites in an area of Poland containing an abundance of this species [

17].

The particular objective of the paper was to investigate the influence of tree age and size (expressed by diameter) on the parameters and indices characterizing the shape and transverse dimensions of fibers in black locust wood as a part of an assessment of its suitability for use in pulp and paper production.

2. Materials and Methods

The material for the presented study was collected in southwestern Poland (51.5–51.7° N, 15.9–16.2° E), which is the area of the greatest abundance of black locust stands in Poland [

9,

25]. We selected three stands with a dominant share of black locust in the species composition (

Table 1). The age of these stands equaled 38 (II age class), 60 (III age class), and 71 (IV age class) years and was determined using the forest inventory database. In each stand, we chose three sample trees according to Hartig’s method. They represented three diameter classes within the given stands, and hereinafter, for the readers’ convenience, are referred to as follows: 1-thin specimens; 2-medium specimens; 3-thick specimens. From each tree, we prepared two 20 mm × 20 mm × 30 mm wood samples according to the PN-77/D-04227 standard [

26].

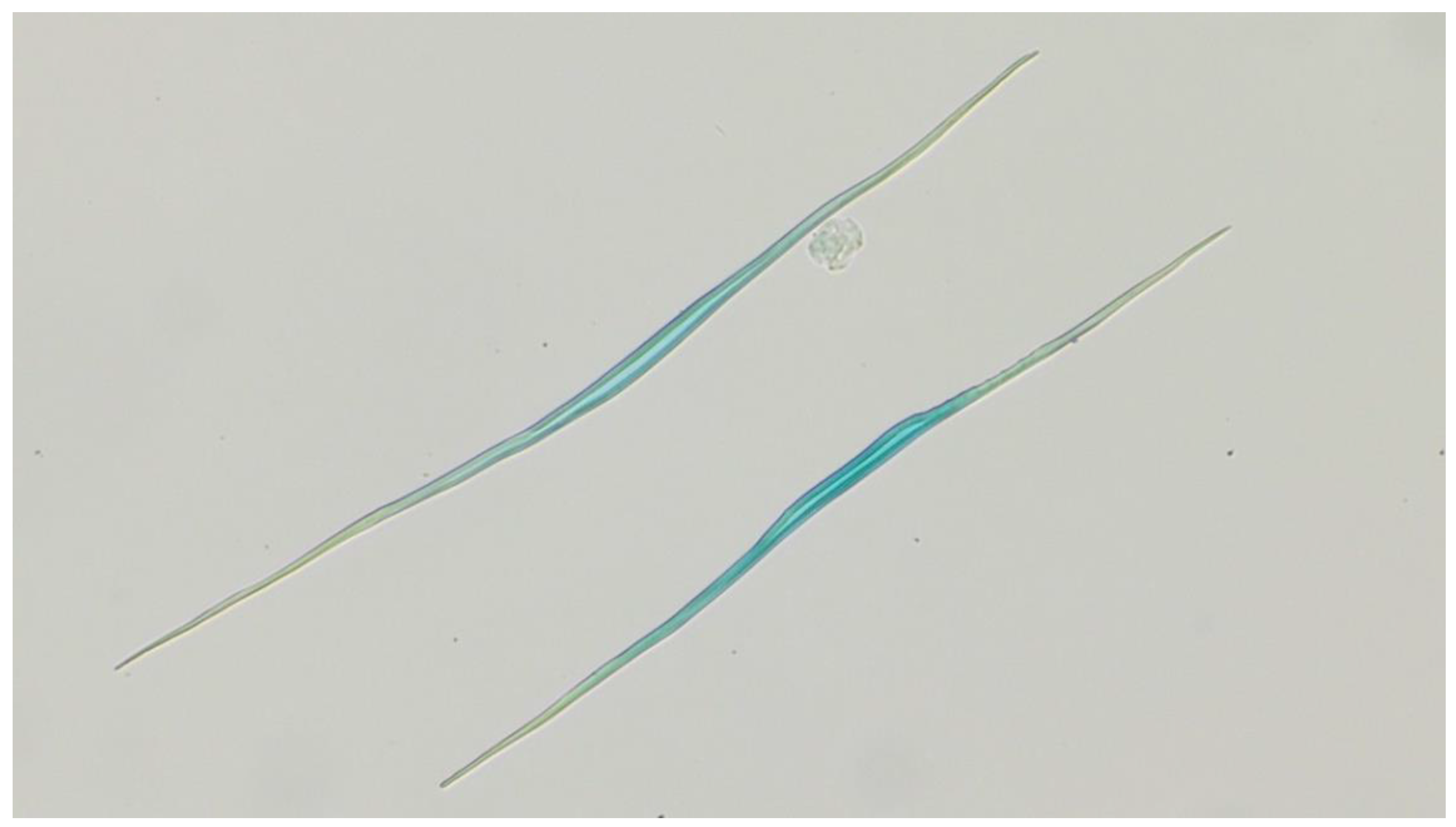

The samples were cut tangentially using Leica SM 2000 R sliding microtome. The obtained scrapings were placed in the 2 mL Eppendorf tubes and immersed in a maceration mixture consisting of hydrogen peroxide (30%) and glacial acetic acid (99.5%) in a 1:1 ratio. Maceration took place in a Memmert 30 incubator at 60 °C and lasted for 24 h. After that, the samples were rinsed three times with distilled water and left there for 7 days in order to further rinse the residual maceration mixture. Next, the samples were flooded with Etzold dye for a period of 24 h to stain the tested fibers blue, which facilitated subsequent microscopic observations. Later, the samples were rinsed with a 1:1 mixture of distilled water and glycerol to remove unbound dye. Other cell types (i.e., parenchyma, vessels), which constituted a negligible fraction of the produced substance, were excluded. Then, we prepared the microscope samples for fiber analyses using Olympus SZH10 Research stereo binocular, a 1:1 mixture of distilled water and glycerol, 25 mm × 75 mm subslides, and 24 mm × 40 mm coverslips, as well as an anatomical needle. The slides were placed under OLYMPUS PROVIS AX70 microscope with OLYMPUS UC90 camera and images of individual fibers were taken using cellSens Standard software (

www.olympus-lifescience.com, accessed on 30 November 2024). We collected 15 libriform fibers from each sample tested (

Figure 1).

The obtained images served as the basic material for the measurement of fibers’ dimensional parameters, which were later used to calculate the coefficients characterizing the fiber shape [

27,

28,

29]. Measurements of length, width, and lumen were made using ImageJ 1.8.0 software (LOCI, University of Wisconsin) (

https://imagej.nih.gov/, accessed on 30 November 2024). The resulting values were then recorded in an Excel spreadsheet.

The magnification was determined by the size of the individual fibers. In the majority of cases, images for length measurements were taken using 2× and 4× lenses, while for width and fiber lumen measurements, the best quality was obtained using 20× and 40× lenses. In total, anatomical studies were carried out on 510 fibers.

The analyses included those attributes that have a decisive influence on the use of wood in the pulp and paper industry [

27,

28,

29,

30,

31,

32]. We measured fiber length (L [mm]) and transverse dimensions, namely, diameter (D [mm]), lumen (d [mm]), and wall thickness (G [mm]). Based on those parameters, the following characteristics of the fibers’ proportions and shape were calculated:

This ratio should be as high as possible, no less than 40. The longer the fibers (L) and the higher the slenderness ratio (S), the better the paper strength [

33].

This index has a significant effect on the susceptibility of fibers to felting in the papermaking process and on the strength properties of paper products. The lower its value, the greater the suitability of the raw material for papermaking purposes [

31]. This index decreases with decreasing wall thickness (G). It is, therefore, lower for thin-walled fibers.

The rigidity index has an inversely proportional effect on the breaking stress. The higher its values (resulting from thicker fiber walls), the lower the strength values.

This index shows an inversely proportional tendency in relation to the deformation (flattening) of the fiber during the drying process [

30]. The smaller the index, the greater the tendency toward flattening.

The greater the lumen (d) or the smaller the fiber diameter (D), the higher the bendability (more flexible fibers) and the greater the suitability of the raw material for papermaking purposes.

This ratio is a measure of the harmony and cohesion of the paper.

As the distribution of almost all analyzed properties significantly differed from the norm, which was checked using the Shapiro–Wilk test, we used the Kruskal–Wallis non-parametric alternative for the analysis of variance, as well as post hoc Mann–Whitney paired comparisons to determine the effect of age or diameter class on the mean values of the investigated parameters. Calculations were carried out using PAST 4.12 software [

34] and a significance level of 0.05 was assumed for all the analyses.

3. Results

3.1. Fiber Length

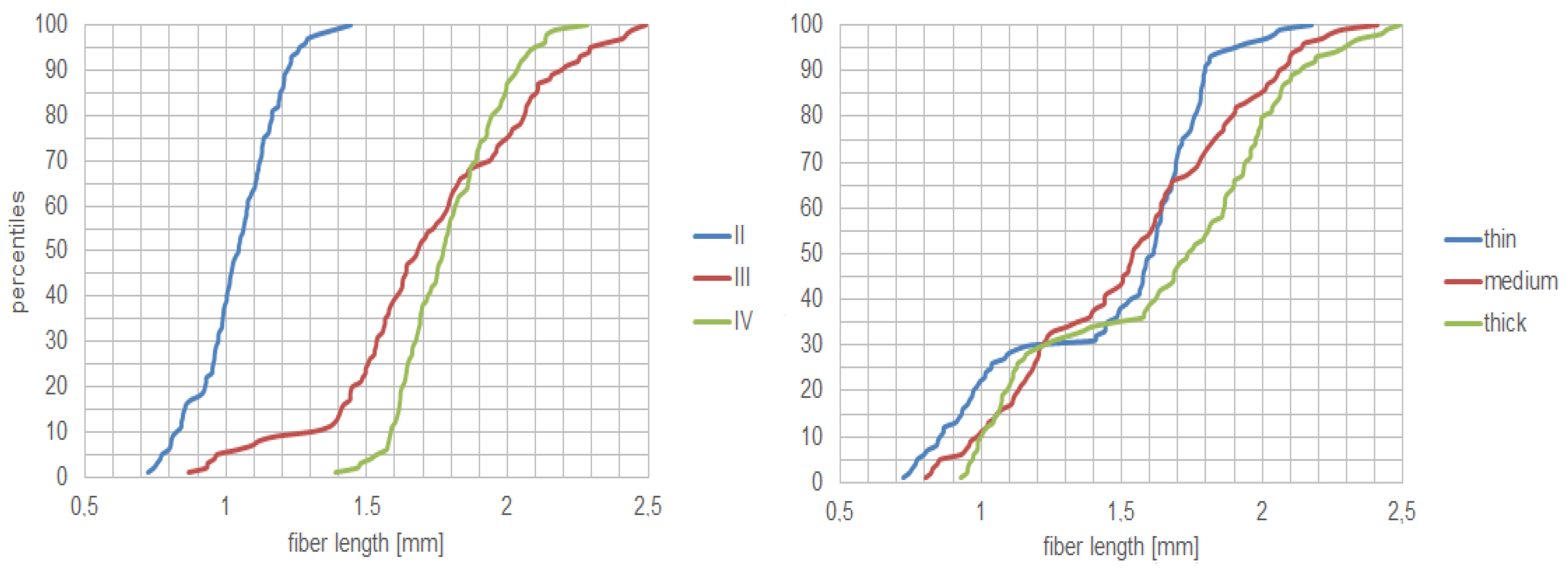

The fiber length equaled 1.541 mm on average, ranging from 0.708 mm for the youngest and thinnest trees to 2.491 mm for the thickest trees in the middle age class (

Table 2). Long fibers (>1.7 mm) that are responsible for high strength properties constituted approximately 38.6% of the analyzed material. No such fibers were found for the youngest trees, while for the medium-aged and older ones, their fractions amounted to 47.5% and 62.3%, respectively. In the analyzed size classes, long fibers were the least abundant (1.3%) in thin trees, while for medium and thick ones, they constituted 33.3% and 52.8% of the total, respectively (

Figure 2). The highest variability in fiber length was found in the middle age class, while the lowest was observed for the oldest trees. For the whole material, standard deviation (SD) was quite high, amounting to 0.411 mm.

Both age and size significantly affected fiber length (HK-W = 289.2, p << 0.001 and HK-W = 21.5, p < 0.001, respectively). Each age class differs significantly one from another with the oldest trees having the longest fibers. Within the size classes, the thin and medium specimens have a similar fiber length, while for the thickest trees, this parameter is significantly higher.

3.2. Fiber Diameter

Mean fiber diameter amounted to 0.029 ± 0.008 mm. The thinnest fiber (0.012 mm) was recorded for the youngest and the thinnest trees, while the thickest (0.048 mm) was recorded for the medium and thick trees, which were among the oldest ones (

Table 3). The standard deviation of fiber diameter was the lowest for the youngest trees, valuing half as much as in the case of the medium-aged or oldest trees.

Fiber diameter significantly depends on both the age and size of the trees (HK-W = 329.4, p << 0.001 and HK-W = 8.9, p < 0.001, respectively). Each age class differs significantly one from another, with the oldest trees having the widest fibers. Within the size classes, the thin and medium specimen have a similar fiber diameter, while for the thickest trees this parameter is significantly higher.

3.3. Fiber Lumen

Average fiber lumen equaled 0.012 mm. Recorded values varied from 0.003 mm for the youngest trees to 0.031 mm for the medium-sized trees in the oldest age class (

Table 4). The highest variability was observed in the middle age class and the oldest trees, while the lowest was observed for the youngest trees. For all materials, standard deviation was quite high and amounted to 0.006 mm.

Only age had a significant impact on fiber lumen (HK-W = 315.4, p << 0.001). Each age class differs significantly one from another, with the oldest trees having the highest fiber lumen. We found no effect of size class on the fiber lumen (HK-W = 0.1, p = 0.972).

3.4. Fiber Wall Thickness

The fiber wall thickness equaled 0.008 ± 0.002 mm on average, ranging from 0.003 mm for the youngest and thinnest trees to 0.013 mm for the oldest specimens (

Table 5). The variability of this feature was very similar across analyzed age or size classes.

Both age and size significantly affected fiber length (HK-W = 192.3, p << 0.001 and HK-W = 22.6, p < 0.001, respectively). Each age class differs significantly one from another, with the oldest trees having the thickest fiber walls. In the case of size classes, the thin and medium specimens were found to have a similar wall thickness, while for the thickest trees this parameter is slightly but significantly higher.

3.5. Slenderness Ratio

The mean fiber slenderness ratio amounted to 53.97 ± 9.19. The least slender fiber (S = 32.46) was recorded for the youngest and the thinnest tree, while the most slender fiber (S = 94.08) was recorded for the thickest middle-aged tree (

Table 6). The variability of this feature was very diversified. It decreased with tree age from 10.24 to 6.68. Within the size classes, the highest value (S = 10.10) was observed for the medium trees, while the thinnest and the thickest specimens exhibited similar variability in slenderness (8.14 and 8.29, respectively).

The slenderness ratio was significantly related to both the age and size of the trees (HK-W = 41.2, p < 0.001 and HK-W = 24.6, p < 0.001, respectively). The age classes differed significantly one from another, with the youngest trees having the least slender fibers on average. As for the size classes, for the thinnest trees, this parameter was significantly lower, while medium and thick specimens had a similar fiber slenderness.

3.6. Runkel Ratio

The average value of the Runkel ratio equaled 1.605. The lowest value (0.444) was observed for the medium-sized trees in the oldest age class, while the highest (5.000) was observed for the thickest trees in the youngest age class (

Table 7). The highest variability was found in the youngest age class, while for the middle-aged and the oldest trees this feature had similar values. For the whole material, standard deviation was relatively high and amounted to 0.741.

Both analyzed independent variables, i.e., tree age and size, significantly affected the Runkel ratio (HK-W = 224.9, p << 0.001 and HK-W = 8.6, p = 0.014, respectively). Within age class, significant differences were found between the youngest and the middle-aged or oldest trees. A clear decrease in Runkel ratio can be observed with increasing age. In the case of size classes, the thin and medium specimens had a similar Runkel ratio, while for the thickest trees this parameter was significantly higher.

3.7. Rigidity Index

The rigidity index ranged from 15.4%, recorded for the medium-thick trees in the oldest age class, to 41.7%, obtained for the thickest and the youngest specimens. On average this ratio equaled 29.4% with a standard deviation of 5.3% (

Table 8). The highest variability was found in the medium age class, while this feature was the lowest for the youngest trees.

The rigidity index was significantly related to both the age and size of the trees (HK-W = 224.8, p << 0.001 and HK-W = 8.6, p = 0.014, respectively). The youngest trees had the most stiff fibers on average, while no significant difference was observed between the medium-aged and the oldest specimens. For the thickest trees, this parameter was significantly higher, while thin and medium-sized specimens had a similar rigidity index.

3.8. Mühlsteph Index

The average Mühlsteph index equaled 0.819. The lowest value (0.521) was found for the medium-sized trees in the oldest age class, while the highest (0.972) was found for the thickest trees in the youngest age class (

Table 9). The highest variability was observed in the middle-aged and the oldest specimens. The standard deviation, calculated for the whole material, was quite high and amounted to 0.090.

Both tree age and tree size significantly affected the Mühlsteph index value (HK-W = 224.8, p << 0.001 and HK-W = 8.6, p = 0.014, respectively). Within the age class, significant differences were found between the youngest and the middle-aged or oldest trees. Mühlsteph index decreases with age; however, this change was only significant between the II and III age classes. For size classes, the thickest trees showed a slightly but significantly higher value for this parameter.

3.9. Flexibility Coefficient

The flexibility coefficient amounted to 0.412 on average, ranging from 0.167 for the youngest and thickest trees to 0.692 for the medium-size and the oldest specimens (

Table 10). The variability of this feature was similar across analyzed age or size classes. The youngest trees had the least variable flexibility coefficient.

The flexibility coefficient was significantly dependent on both the age (HK-W = 224.8, p << 0.001) and size (HK-W = 8.6, p = 0.014) of the trees. The youngest trees had significantly less flexible fibers than the older ones. Furthermore, this parameter was significantly lower for the thickest trees.

3.10. Solids Index

The mean solids index was 0.00046; the lowest value (0.00012) was recorded for the thinnest and youngest trees, while the highest (0.00095) was recorded for the medium-sized trees in the oldest age class (

Table 11). The variability of the solids index was similar across age or size classes, with values increasing for older trees.

Both tree age and tree size significantly affected the solids index (HK-W = 214.4, p << 0.001 and HK-W = 13.3, p = 0.001, respectively). Significant differences were found between all distinguished age classes, with the highest values being observed for the oldest trees. Regarding the size classes, we found that medium-sized trees had significantly lower values for this feature than the other size classes.

4. Discussion

Due to their fast growth and rapidly increasing biomass, and the wood’s particular features, especially its durability, the wood of black locust has become a raw material of interest in the pulp and paper industry [

21,

35]. However, the research on wood properties, including an investigation of the fiber attributes, is still limited in both number and in the range of analyzed parameters. Hence, the cited literature usually refers to research from long ago or modern case studies.

Factors that influence the properties of black locust wood cover a wide spectrum of environmental conditions [

36,

37,

38,

39,

40]. However, tree age and size were also found to be of great importance [

17,

41,

42]. The presented study finds this relationship to also be true for fiber parameters, as previously reported for inter alia silver birch [

7], Norway and Sitka spruces, Scots and loblolly pines [

43], and flooded gum [

44], to name a few examples. Also, genetic diversity affects the properties of black locust wood, as indicated by [

45,

46].

Length is one of the most diversified traits of in wood fibers, even within individual trees. This attribute is responsible for high-strength properties, so the paper and pulp industry utilize wood with long fibers (1–3.5 mm in length). However, fibers from deciduous tree species have fiber lengths within approximately 1–2 mm, which, in general, is less than the fiber lengths observed in coniferous species [

27,

28,

29]. High-strength properties in sheets of paper are obtained through the use of wood with long fibers (>1.7 mm). Intermediate fibers (0.5–1.7 mm) reduce static properties and increase dynamic strength properties, while short fibers (<0.5 mm) increase static strength properties [

29].

In general, studies to date describe black locust wood as having short to intermediate fibers: 0.76–1.25 mm [

47] or 0.59–1.35 mm [

48]. The fibers from our study were substantially longer, as the range of this parameter varied from 0.71 to 2.49 mm; hence, they were classified as intermediate or long [

49]. Fiber length increases with age, but individuals from age classes III and IV have similar, but significantly different, values (

Table 2). Therefore, in terms of the paper and pulp industry requirements, potentially the best fibers would be obtained from age class IV. The recorded values differed from those reported for other sites in Poland—0.9 mm [

32], 0.76–1.25 mm [

50], and 0.41–1.16 mm [

51]—or in other regions, such as Hungary [

19], Greece [

52], Serbia [

45], the USA [

53], or Turkey [

24]. The average value (1.54 mm) is very close to that reported for silver birch [

7]. We confirmed a positive relationship between the age of the trees (wood) and fiber length, which had been previously observed for the investigated species [

51].

Thin-walled fibers, contrary to thick-walled ones, produce paper with a relatively compact structure and correspondingly high strength properties thanks to their relatively good deformability, even when slightly milled or in an unmilled state [

27,

28,

29]. In general, black locust fibers have thick walls and medium lumen diameters [

16,

47]. In our research, fiber diameter increases with age, but fibers from classes III and IV have similar values (

Table 3).

In our research, fiber diameter ranged from 0.012 to 0.048 mm, which is a bit higher than that reported for this species in Turkey [

24], but in line with the values provided for other regions [

48,

49,

54]. For older age classes, we achieved diameter values close to those obtained for Scots pine [

32,

55].

The wall thickness of fibers in black locust wood ranges between 0.002 and 0.006 mm [

48], reaching 0.003–0.004 mm on average [

24,

32,

53]. The results obtained in this study (0.003–0.031 mm) indicate that this wood is a thick-walled raw material [

49]. Fiber wall thickness increases with tree age (

Table 5), so potentially the best fibers are obtained from age class II, as fibers with thinner walls are more suitable for deformation. On the other hand, higher cell-wall thickness values increase the indices of other wood properties.

The slenderness ratio should be as high as possible, as this translates to paper strength [

33]. Wood from fast-growing trees is characterized by a low slenderness ratio, resulting in a low tearing index [

56,

57]. The average slenderness ratio for deciduous trees amounts to 50, while for black locust, it is 70 [

32]. Similar values were also reported for silver birch [

7]. The average value achieved in the study was 54, ranging from 47 to 59, which is in line with the average value for deciduous trees but deviates from the values presented for black locust in a study from Turkey (83) [

24]. The slenderness ratio decreased with age (

Table 6), so potentially the best fibers could be obtained from age class II.

Runkel ratio has a significant influence on the susceptibility of raw material to molding [

31]. Its value should be as low as possible to increase the wood’s suitability for use in the paper industry [

32]. Fibers from the wood of fast-growing trees species have very low values for this parameter [

56,

57]. For coniferous fibers, this index reaches a value of 0.3, while for deciduous species this index varies strongly [

32]. Black locust fibers have a Runkel ratio within the range of 0.52–0.78 [

48]. Similar values (0.64) were also observed for Robinia wood from Turkey [

24]. The average values for the material investigated in the present study equaled 1.6, which is an unfavorable result for the utilization of this raw material in the pulp and paper industry. On the other hand, these values are relatively low compared to those obtained for birch (4.89) [

7]. In the tested material, the Runkel ratio reached the highest values (about 2.4) for the youngest trees, while for the older specimens it was much lower and oscillated around 1.2–1.3 (

Table 7).

The rigidity index is characterized by an inversely proportional effect on rupture stress [

6]. Wood from fast-growing trees has a very low rigidity index [

56,

57]. The higher the value, the lower the paper sheet strength. The values for analyzed wood amount to 29.4% on average, which is a higher value than the 19.5% reported for black locust from Turkey [

24], but much lower than the 40.7% reported for birch [

7]. For the studied fibers, the rigidity index decreases significantly with age (

Table 8), so better raw material in terms of paper or pulp production could potentially originate from older trees.

The Mühlsteph index shows an inversely proportional tendency in relation to fiber deformation during drying [

30]. The smaller the index, the greater the tendency to flatten. In our research, the index achieved a satisfactory level of 0.819. This is a bit higher than the 0.629 reported for black locust wood from Turkey [

24], but much higher in comparison to the wood of fast-growth tree species [

56,

57].

As either the fiber width increases or its diameter decreases, the flexibility coefficient increases. The more flexible the fibers, the greater the suitability of the wood as a raw material for paper production [

6]. The values obtained in this study equaled 0.412, which is lower than those obtained for material from Turkey (0.609) [

24], but remarkably higher than the 0.18 obtained for silver birch [

7]. The values were also twice as low as those of fast-growing tree species [

56,

57]. Similarly to the Mühlsteph index, the youngest trees (age class II) had the least favorable values (

Table 10).

A low solids index increases break length and paper density [

58] and indicates good strength properties. The mean solids index for the analyzed material was 0.00046, which can be considered a low value. However, it is much higher than the values recorded for Paulownia COTEVISA-2 (0.00019) [

57]. The most favorable values were found for the youngest trees (

Table 11).

Because of the parameters of its fibers, black locust wood is, in general, considered a suitable raw material for the paper and/or pulp industry [

24].

R. pseudoacacia has the pulp with the lowest fiber strength and the smallest fiber length compared with hornbeam, oak, birch, beech, and poplar. However, its fiber-bending capacity increases when the pulp is beaten, as beating positively affects its tensile strength [

22].

It is crucial to mention that the present study has some interpretative limitations. Because of the labor-intensiveness of the preparation and measurements of the material, the sample collection design was difficult and was hence based only on single trees. They are still representative of the given size or age classes to a large extent; however, conclusions from the obtained results should be drawn with care.