Optimizing Wood Composite Drilling with Artificial Neural Network and Response Surface Methodology

Abstract

:1. Introduction

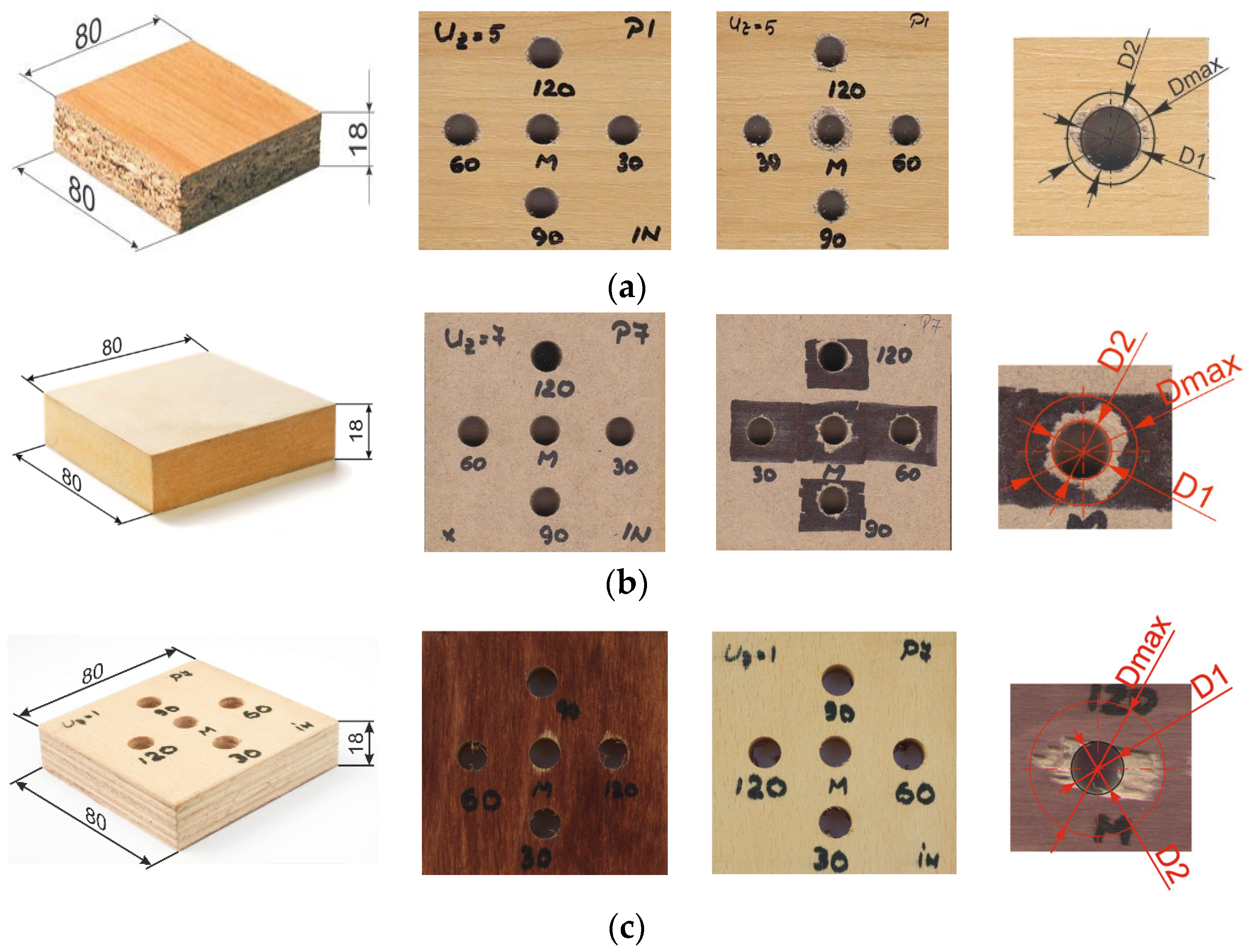

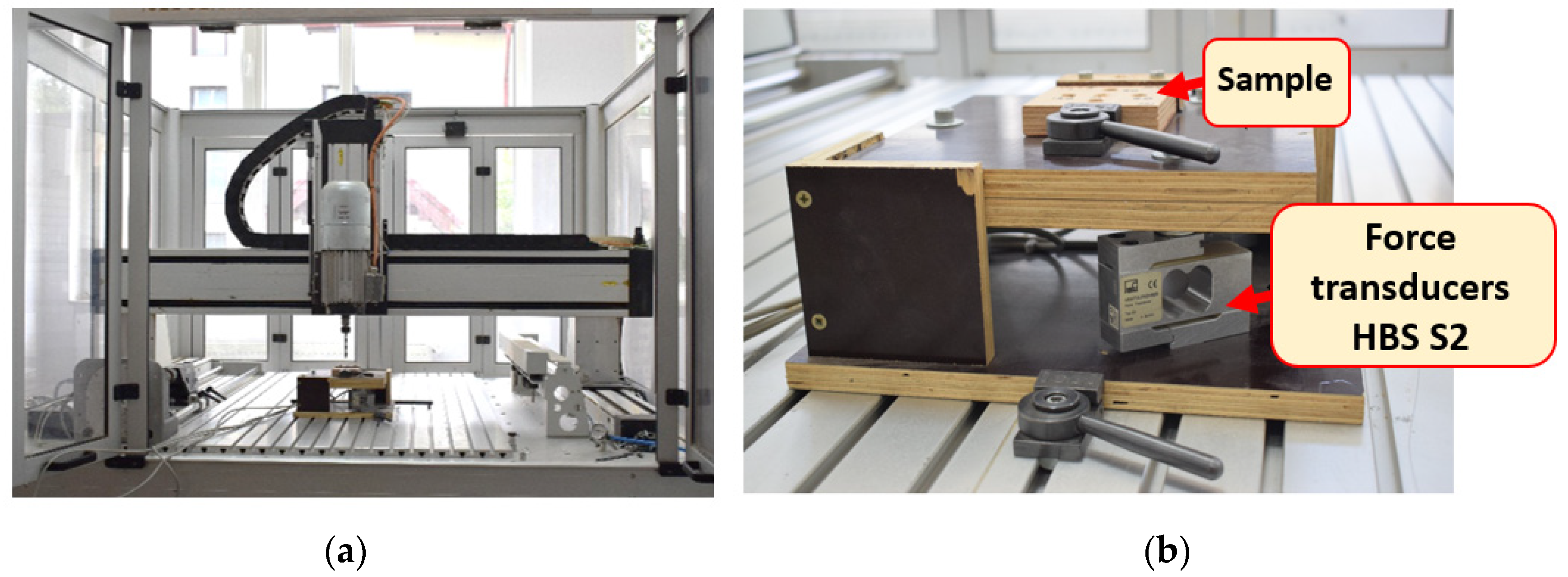

2. Materials and Methods

2.1. Experimental Part

2.2. Data Modeling

3. Results and Discussion

3.1. Designed Neural Networks

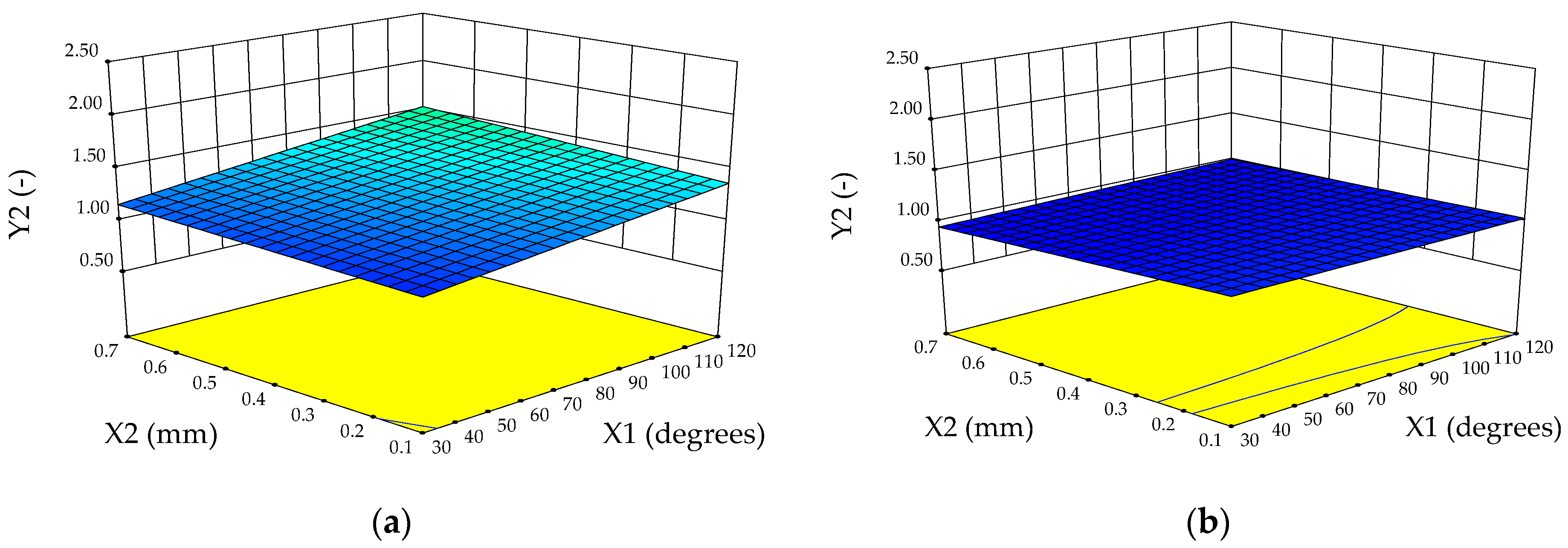

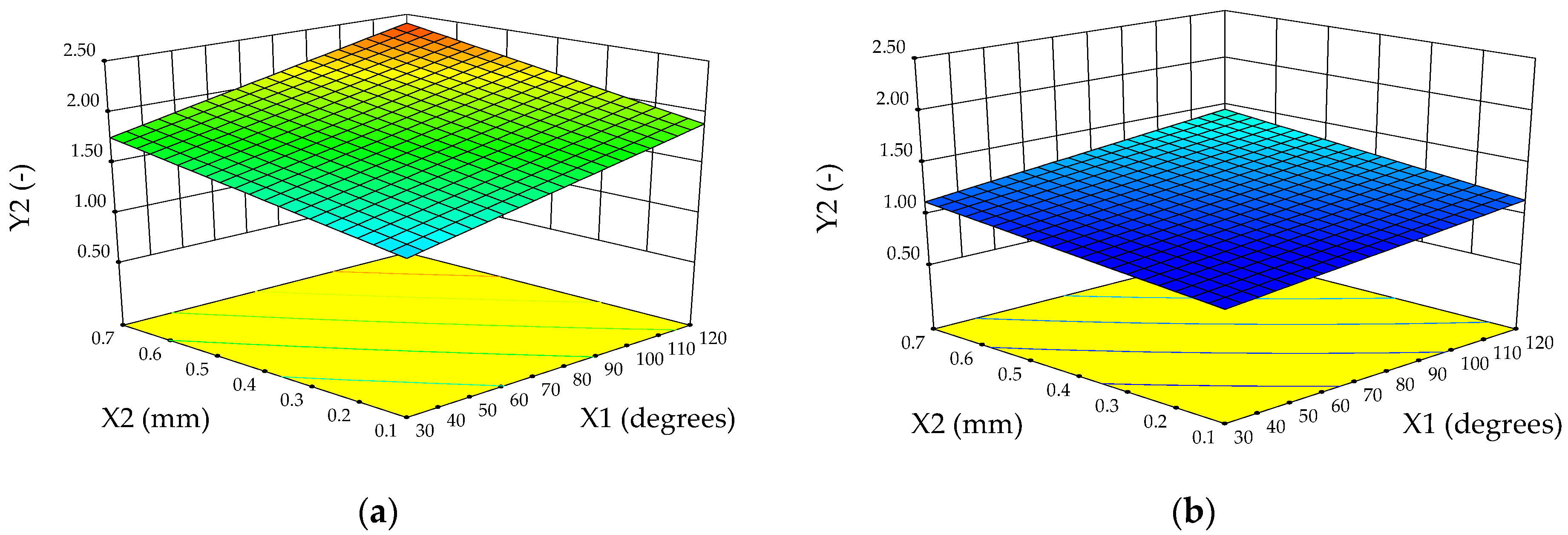

3.2. Response Surface Methodology

3.2.1. Delamination Factor at Inlet

3.2.2. Delamination Factor at Outlet

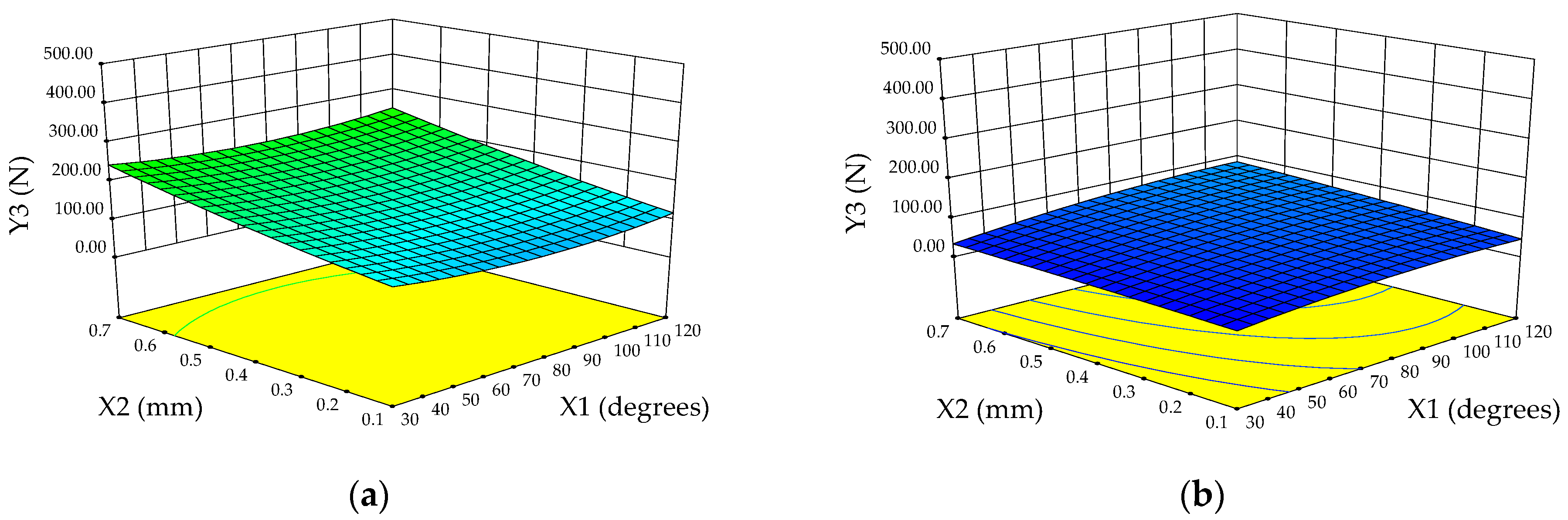

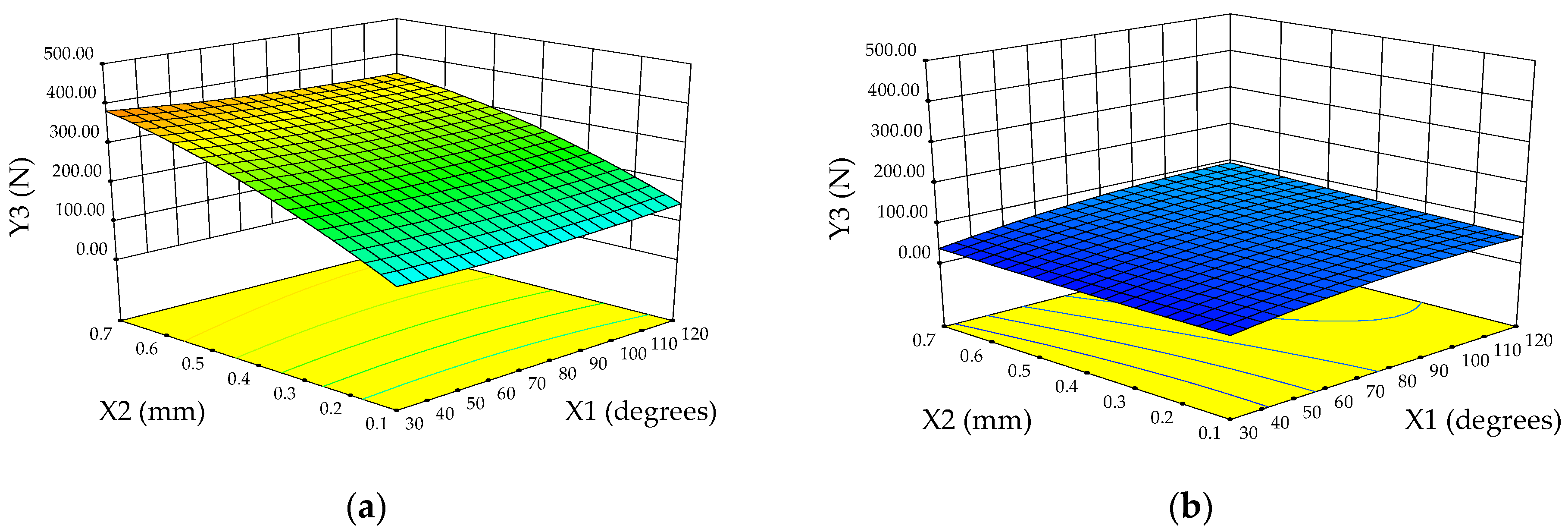

3.2.3. Thrust Force

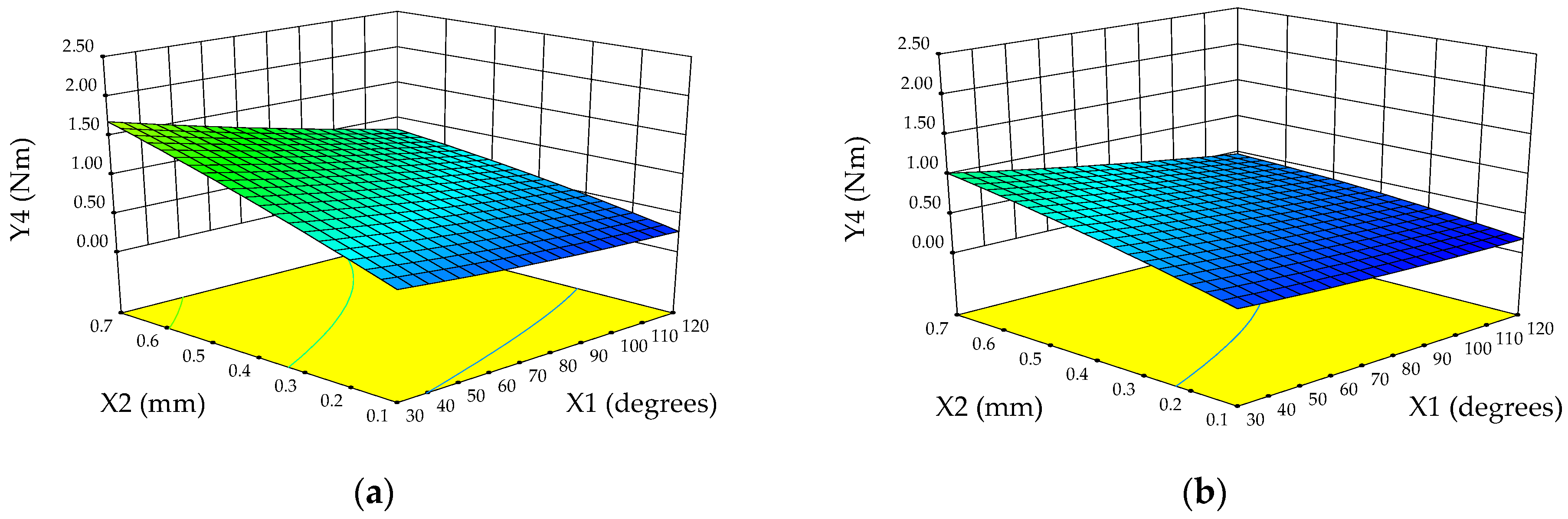

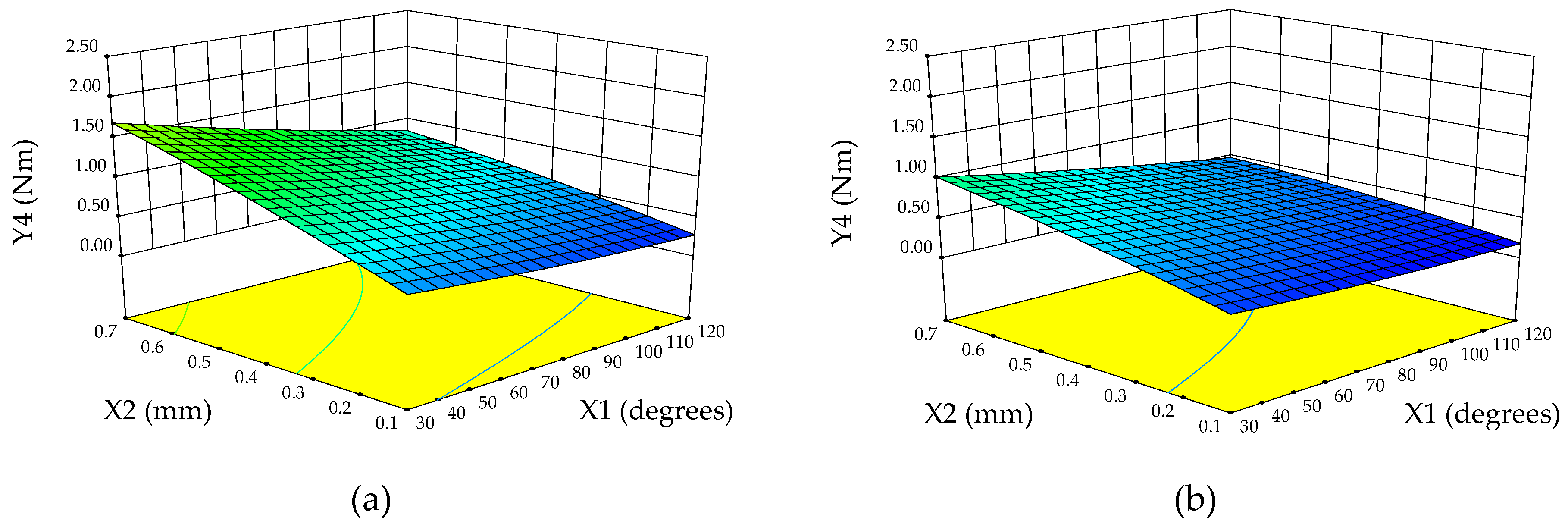

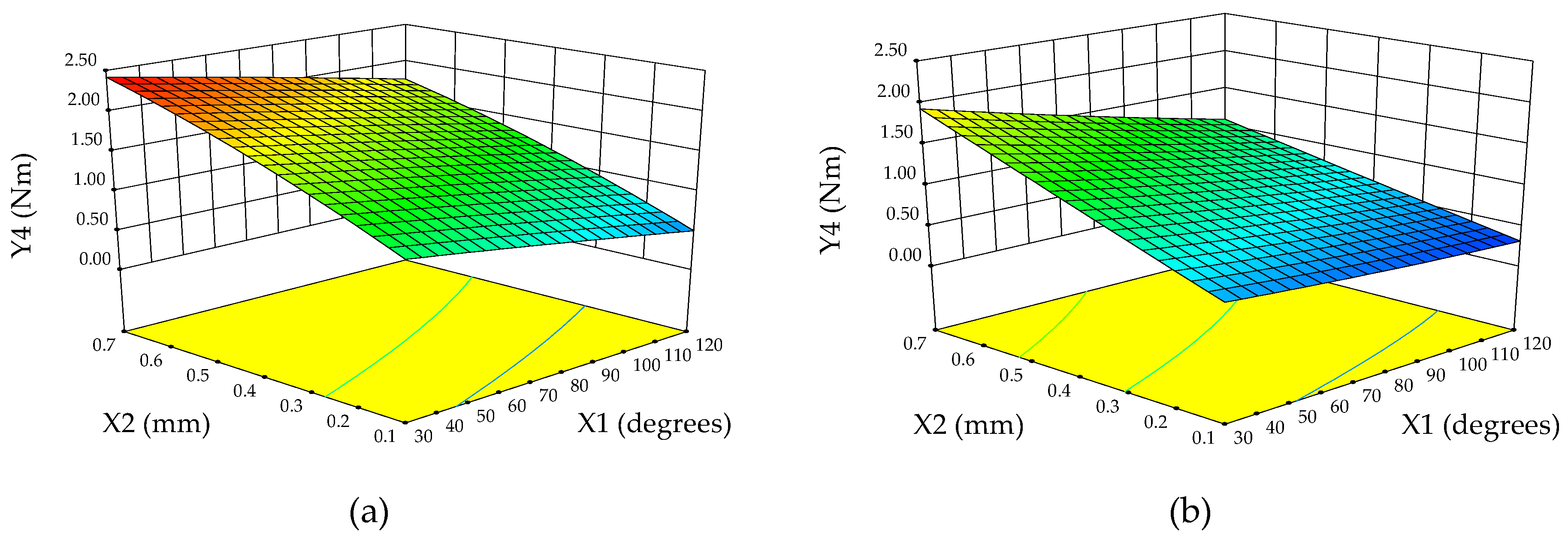

3.2.4. Drilling Torque

4. Conclusions

- Artificial neural networks (ANNs) and response surface methodology (RSM) were successfully applied to predict drilling parameters to optimize the delamination factor, thrust force, and drilling torque in a particleboard, MDF, and plywood. Compared to experimental data, both the ANN and RSM models demonstrated reasonable accuracy, as evidenced by their high coefficient of determination (R2), which indicates their effectiveness in revealing the individual influence of factors on the drilling process.

- The material type was found to significantly impact the delamination factor.

- The drill type (twist vs. spade) primarily influenced the thrust force.

- The chipload (feed rate) was identified as the most critical factor affecting drilling torque.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Szwajka, K.; Trzepiecinski, T. On the machinability of medium density fiberboard by drilling. Bioresources 2019, 13, 8263–8278. [Google Scholar] [CrossRef]

- Bedelean, B.; Ispas, M.; Răcășan, S. Artificial neural networks as a predictive tool for thrust force and torque during drilling of wood-based composites. In Proceedings of the 11th Hardwood Conference, Sopron, Hungary, 30–31 May 2024. [Google Scholar] [CrossRef]

- Górski, J. The review of new scientific developments in drilling in wood-based panels with particular emphasis on the latest research trends in drill condition monitoring. Forests 2022, 13, 242. [Google Scholar] [CrossRef]

- Bedelean, B.; Ispas, M.; Răcășan, S. Applying the Artificial Neural Network and Response Surface Methodology to Optimize the Drilling Process of Plywood. Appl. Sci. 2023, 13, 11343. [Google Scholar] [CrossRef]

- Patel, P.; Chaudhary, V. Delamination evaluation in drilling of composite materials—A review. Mater. Today Proc. 2022, 56, 2690–2695. [Google Scholar] [CrossRef]

- Agarwal, G.; Mishra, A. Fatigue Behavior of Wooden Fiber Reinforced Epoxy Composites. AIP Conf. Proc. 2021, 2317, 020024. [Google Scholar] [CrossRef]

- Sydor, M.; Rogoziński, T.; Stuper-Szablewska, K.; Starczewski, K. The accuracy of holes drilled in the side surface of plywood. BioResources 2020, 15, 117–129. [Google Scholar] [CrossRef]

- Sydor, M.; Potok, Z.; Pędzik, M.; Hitka, M.; Rogoziński, T. The influence of feed rate during pilot hole drilling on screw withdrawal resistance in particleboard. Eur. J. Wood Prod. 2024, 82, 5–13. [Google Scholar] [CrossRef]

- Podziewski, P.; Szymanowski, K.; Gorski, J.; Czarniak, P. Relative Machinability of Wood-Based Boards in the Case of Drilling—Experimental Study. BioResources 2018, 13, 1761–1772. [Google Scholar] [CrossRef]

- Kumar, M.; Jayakumar, K. Drilling studies on particle board composite using HSS twist drill and spade drill. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012029. [Google Scholar] [CrossRef]

- Szwajka, K.; Zielińska-Szwajka, J.; Trzepieciński, T. Experimental Analysis of Smart Drilling for the Furniture Industry in the Era of Industry 4.0. Materials 2024, 17, 2033. [Google Scholar] [CrossRef]

- Kurek, J.; Antoniuk, I.; Swiderski, B.; Jegorowa, A.; Bukowski, M. Application of Siamese Networks to the Recognition of the Drill Wear State Based on Images of Drilled Holes. Sensors 2020, 20, 6978. [Google Scholar] [CrossRef] [PubMed]

- Jegorowa, A.; Kurek, J.; Kruk, M.; Górski, J. The Use of Multilayer Perceptron (MLP) to Reduce Delamination during Drilling into Melamine Faced Chipboard. Forests 2022, 13, 933. [Google Scholar] [CrossRef]

- Kurek, J.; Krupa, A.; Antoniuk, I.; Akhmet, A.; Abdiomar, U.; Bukowski, M.; Szymanowski, K. Improved Drill State Recognition during Milling Process Using Artificial Intelligence. Sensors 2023, 23, 448. [Google Scholar] [CrossRef] [PubMed]

- Zbieć, M. Application of Neural Network in Simple Tool Wear Monitoring and Identification System in MDF Milling. Drv. Ind. 2011, 62, 43–54. [Google Scholar] [CrossRef]

- Özşahin, S.; Singer, H. Prediction of noise emission in the machining of wood materials by means of an artificial neural network. N. Z. J. For. Sci. 2022, 52, 1–10. [Google Scholar] [CrossRef]

- Tiryaki, S.; Özşahin, Ş.; Aydin, A. Employing artificial neural networks for minimizing surface roughness and power con-sumption in abrasive machining of wood. Eur. J. Wood Wood Prod. 2017, 75, 347–358. [Google Scholar] [CrossRef]

- Watanabe, K.; Korai, H.; Matsushita, Y.; Hayashi, T. Predicting internal bond strength of particleboard under outdoor exposure based on climate data: Comparison of multiple linear regression and artificial neural network. J. Wood Sci. 2015, 61, 151–158. [Google Scholar] [CrossRef]

- Hazir, E.; Koc, K.H.; Baray, S.A.; Esnaf, S. Improvement of adhesion strength for wood-based material coating process using design of experiment methodology. Eur. J. Wood Wood Prod. 2020, 78, 301–312. [Google Scholar] [CrossRef]

- Prakash, S.; LillyMercy, J.; Manoj, K.S.; Vineeth, K.S.M. Optimization of drilling characteristics using Grey Relational Analysis (GRA) in Medium Density Fiber Board (MDF). Mater. Today Proc. 2015, 2, 1541–1551. [Google Scholar] [CrossRef]

- Bedelean, B.; Ispas, M.; Răcășan, S. Combining Artificial Neural Network and Response Surface Methodology to Optimize the Drilling Operating Parameters of MDF Panels. Forests 2023, 14, 2254. [Google Scholar] [CrossRef]

- Podziewski, P.; Górski, J. Effect of the feed rate on the cutting forces during drilling in a standard hardwood plywood. Ann. Wars. Univ. Life Sci.-SGGW For. Wood Technol. 2012, 79, 170–172. [Google Scholar]

- Whitcomb, P.J.; Anderson, M.J. RSM Simplified: Optimizing Processes Using Response Surface Methods for Design of Experiments, 1st ed.; Productivity Press: Indianapolis, IN, USA, 2016. [Google Scholar]

| Numeric Factor | Level | |||||

|---|---|---|---|---|---|---|

| −α * | −1 | 0 | +1 | +α * | ||

| Drill tip angle (X1), ° | 30 | 30 | 75 | 120 | 120 | |

| Chipload (X2), mm | 0.1 | 0.1 | 0.4 | 0.7 | 0.7 | |

| Categoric Factor | Level 1 | Level 2 | Level 3 | |||

| Drill type (X3) | Spade (−1) | Twist (+1) | - | |||

| Material type (X4) | Particleboard | MDF | Plywood | |||

| Run # | Independent Variables (Factors) | Dependent Variables (Responses) | ||||||

|---|---|---|---|---|---|---|---|---|

| Drill Tip Angle (X1), ° | Chipload (X2), mm | Drill Type (X3) | Material Type (X4) | Y1 | Y2 | Y3 | Y4 | |

| 1. | 30 | 0.1 | Spade | Plywood | 1.08 | 1.40 | 177.80 | 1.09 |

| 2. | 30 | 0.1 | Twist | Particleboard | 1.10 | 1.00 | 23.67 | 0.32 |

| 3. | 120 | 0.1 | Twist | Plywood | 1.01 | 1.11 | 72.72 | 0.32 |

| 4. | 30 | 0.1 | Spade | MDF | 1.07 | 1.06 | 125.88 | 0.53 |

| 5. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 6. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 7. | 120 | 0.7 | Twist | Plywood | 1.25 | 1.42 | 117.43 | 1.08 |

| 8. | 75 | 0.7 | Twist | Plywood | 1.18 | 1.24 | 93.59 | 1.52 |

| 9. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 10. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 11. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 12. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 13. | 120 | 0.1 | Twist | MDF | 1.00 | 1.02 | 65.24 | 0.19 |

| 14. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 15. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 16. | 75 | 0.1 | Spade | MDF | 1.06 | 1.21 | 143.74 | 0.37 |

| 17. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 18. | 120 | 0.4 | Twist | Particleboard | 1.24 | 1.06 | 69.43 | 0.36 |

| 19. | 120 | 0.4 | Spade | MDF | 1.13 | 1.47 | 276.23 | 0.60 |

| 20. | 120 | 0.1 | Twist | Particleboard | 1.14 | 1.05 | 45.24 | 0.19 |

| 21. | 75 | 0.7 | Spade | Particleboard | 1.29 | 1.40 | 228.28 | 1.24 |

| 22. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 23. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 24. | 75 | 0.7 | Spade | MDF | 1.09 | 1.28 | 343.49 | 1.24 |

| 25. | 30 | 0.4 | Spade | MDF | 1.07 | 1.15 | 286.01 | 1.17 |

| 26. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 27. | 75 | 0.1 | Spade | Plywood | 1.14 | 1.57 | 183.66 | 0.78 |

| 28. | 120 | 0.4 | Twist | MDF | 1.00 | 1.02 | 78.50 | 0.36 |

| 29. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 30. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 31. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 32. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 33. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 34. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 35. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 36. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 37. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 38. | 120 | 0.7 | Spade | Plywood | 1.35 | 2.46 | 393.07 | 1.76 |

| 39. | 30 | 0.7 | Spade | Plywood | 1.10 | 1.86 | 433.92 | 2.38 |

| 40. | 30 | 0.4 | Spade | Particleboard | 1.21 | 1.21 | 186.72 | 1.17 |

| 41. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 42. | 120 | 0.7 | Spade | MDF | 1.12 | 1.48 | 356.70 | 0.86 |

| 43. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 44. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 45. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 46. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 47. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 48. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 49. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 50. | 30 | 0.7 | Spade | MDF | 1.07 | 1.15 | 390.75 | 1.69 |

| 51. | 120 | 0.1 | Spade | Particleboard | 1.20 | 1.29 | 123.15 | 0.28 |

| 52. | 30 | 0.7 | Twist | Particleboard | 1.19 | 1.06 | 36.44 | 1.03 |

| 53. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 54. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 55. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 56. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 57. | 30 | 0.4 | Twist | Plywood | 1.07 | 1.06 | 36.06 | 1.25 |

| 58. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 59. | 120 | 0.7 | Twist | Particleboard | 1.47 | 1.06 | 86.94 | 0.49 |

| 60. | 30 | 0.7 | Twist | MDF | 1.08 | 1.00 | 41.66 | 1.03 |

| 61. | 75 | 0.7 | Spade | Plywood | 1.25 | 2.24 | 376.07 | 2.14 |

| 62. | 120 | 0.4 | Twist | Plywood | 1.40 | 1.39 | 94.84 | 0.72 |

| 63. | 30 | 0.4 | Twist | MDF | 1.00 | 1.00 | 28.62 | 0.73 |

| 64. | 75 | 0.1 | Twist | MDF | 1.00 | 1.01 | 66.47 | 0.24 |

| 65. | 120 | 0.7 | Twist | MDF | 1.20 | 1.02 | 97.14 | 0.49 |

| 66. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 67. | 30 | 0.1 | Twist | MDF | 1.00 | 1.00 | 30.49 | 0.32 |

| 68. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 69. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 70. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 71. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 72. | 75 | 0.1 | Twist | Plywood | 1.10 | 1.06 | 72.53 | 0.42 |

| 73. | 75 | 0.7 | Twist | MDF | 1.01 | 1.01 | 74.31 | 0.71 |

| 74. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 75. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 76. | 30 | 0.4 | Twist | Particleboard | 1.23 | 1.00 | 26.19 | 0.73 |

| 77. | 30 | 0.1 | Twist | Plywood | 1.07 | 1.07 | 37.63 | 0.58 |

| 78. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 79. | 30 | 0.7 | Twist | Plywood | 1.02 | 1.12 | 46.96 | 1.93 |

| 80. | 75 | 0.1 | Spade | Particleboard | 1.14 | 1.29 | 98.23 | 0.37 |

| 81. | 120 | 0.1 | Spade | MDF | 1.08 | 1.44 | 141.47 | 0.28 |

| 82. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 83. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 84. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 85. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 86. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 87. | 75 | 0.1 | Twist | Particleboard | 1.11 | 1.01 | 46.42 | 0.24 |

| 88. | 75 | 0.7 | Twist | Particleboard | 1.24 | 1.06 | 68.61 | 0.71 |

| 89. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 90. | 30 | 0.7 | Spade | Particleboard | 1.25 | 1.36 | 238.52 | 1.69 |

| 91. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 92. | 120 | 0.4 | Spade | Plywood | 1.25 | 2.40 | 325.32 | 1.19 |

| 93. | 75 | 0.4 | Spade | Plywood | 1.20 | 1.80 | 318.25 | 1.54 |

| 94. | 120 | 0.4 | Spade | Particleboard | 1.25 | 1.55 | 170.50 | 0.60 |

| 95. | 75 | 0.4 | Twist | Plywood | 1.17 | 1.13 | 72.70 | 0.95 |

| 96. | 120 | 0.1 | Spade | Plywood | 1.20 | 1.87 | 178.39 | 0.54 |

| 97. | 30 | 0.1 | Spade | Particleboard | 1.13 | 1.20 | 121.92 | 0.53 |

| 98. | 75 | 0.4 | Spade | MDF | 1.11 | 1.28 | 272.07 | 0.85 |

| 99. | 30 | 0.4 | Spade | Plywood | 1.12 | 1.40 | 339.87 | 1.87 |

| 100. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 101. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 102. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| 103. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 104. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 105. | 75 | 0.4 | Twist | MDF | 1.00 | 1.01 | 69.33 | 0.53 |

| 106. | 120 | 0.7 | Spade | Particleboard | 1.32 | 1.57 | 252.92 | 0.86 |

| 107. | 75 | 0.4 | Spade | Particleboard | 1.25 | 1.32 | 153.37 | 0.85 |

| 108. | 75 | 0.4 | Twist | Particleboard | 1.23 | 1.06 | 61.58 | 0.53 |

| Model Output | Number of Neurons in the Layers of ANN Models | R | R2 | RMSE | MAPE | ||

|---|---|---|---|---|---|---|---|

| Input | Hidden | Outlet | |||||

| Delamination factor at the inlet | 4 | 23 | 1 | 0.62 | 0.39 | 0.131 | 6.88 |

| Delamination factor at the outlet | 4 | 6 | 1 | 0.91 | 0.83 | 0.265 | 9.65 |

| Thrust force | 4 | 8 | 1 | 0.98 | 0.96 | 20.57 | 10.4 |

| Drilling torque | 4 | 4 | 1 | 0.96 | 0.94 | 0.129 | 11.25 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Observation |

|---|---|---|---|---|---|---|

| Model | 0.91 | 14 | 0.065 | 49.58 | <0.0001 | Significant |

| Drill tip angle (X1) | 0.084 | 1 | 0.084 | 64.41 | <0.0001 | Significant |

| Chipload (X2) | 0.097 | 1 | 0.097 | 73.75 | <0.0001 | Significant |

| Drill type (X3) | 0.06 | 1 | 0.06 | 45.85 | <0.0001 | Significant |

| Material type (X4) | 0.57 | 2 | 0.29 | 218.07 | <0.0001 | Significant |

| X1X2 | 0.028 | 1 | 0.028 | 21.13 | <0.0001 | Significant |

| X1X3 | 5.96 × 10−4 | 1 | 5.96 × 10−4 | 0.46 | 0.5016 | Not significant |

| X1X4 | 0.026 | 2 | 0.013 | 10.1 | 0.0001 | Significant |

| X2X3 | 4.35 × 10−3 | 1 | 4.35 × 10−3 | 3.32 | 0.0716 | Not significant |

| X2X4 | 0.014 | 2 | 7.06 × 10−3 | 5.39 | 0.0061 | Significant |

| X3X4 | 0.024 | 2 | 0.012 | 9.06 | 0.0003 | Significant |

| R2 | 0.88 | |||||

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Observation |

|---|---|---|---|---|---|---|

| Model | 9.92 | 14 | 0.71 | 237.24 | <0.0001 | Significant |

| Drill tip angle (X1) | 0.58 | 1 | 0.58 | 193.82 | <0.0001 | Significant |

| Chipload (X2) | 0.27 | 1 | 0.27 | 91.35 | <0.0001 | Significant |

| Drill type (X3) | 4.68 | 1 | 4.68 | 1565.29 | <0.0001 | Significant |

| Material type (X4) | 2.66 | 2 | 1.33 | 444.89 | <0.0001 | Significant |

| X1X2 | 7.16 × 10−3 | 1 | 7.16 × 10−3 | 2.4 | 0.1249 | Not significant |

| X1X3 | 0.23 | 1 | 0.23 | 76.69 | <0.0001 | Significant |

| X1X4 | 0.19 | 2 | 0.093 | 31.19 | <0.0001 | Significant |

| X2X3 | 0.092 | 1 | 0.092 | 30.7 | <0.0001 | Significant |

| X2X4 | 0.2 | 2 | 0.099 | 32.99 | <0.0001 | Significant |

| X3X4 | 1.02 | 2 | 0.51 | 171.49 | <0.0001 | Significant |

| R2 | 0.97 | |||||

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Observation |

|---|---|---|---|---|---|---|

| Model | 1.30 × 106 | 35 | 37,174.59 | 1698.76 | <0.0001 | Significant |

| Drill tip angle (X1) | 3138.56 | 1 | 3138.56 | 143.42 | <0.0001 | Significant |

| Chipload (X2) | 1.03 × 105 | 1 | 1.03 × 105 | 4689.81 | <0.0001 | Significant |

| Drill type (X3) | 8.96 × 105 | 1 | 8.96 × 105 | 40,937.1 | <0.0001 | Significant |

| Material type (X4) | 1.23 × 105 | 2 | 61,670.7 | 2818.15 | <0.0001 | Significant |

| X1X2 | 2.11 | 1 | 2.11 | 0.096 | 0.7573 | Not Significant |

| X1X3 | 7039.54 | 1 | 7039.54 | 321.68 | <0.0001 | Significant |

| X1X4 | 1.12 | 2 | 0.56 | 0.025 | 0.9748 | Not Significant |

| X2X3 | 63,908.62 | 1 | 63,908.6 | 2920.41 | <0.0001 | Significant |

| X2X4 | 4403.39 | 2 | 2201.7 | 100.61 | <0.0001 | Significant |

| X3X4 | 81,685.81 | 2 | 40,842.9 | 1866.39 | <0.0001 | Significant |

| X12 | 67.29 | 1 | 67.29 | 3.07 | 0.0838 | Not Significant |

| X22 | 1241.97 | 1 | 1241.97 | 56.75 | <0.0001 | Significant |

| X1X2X3 | 1106.41 | 1 | 1106.41 | 50.56 | <0.0001 | Significant |

| X1X2X4 | 328.27 | 2 | 164.14 | 7.5 | 0.0011 | Significant |

| X1X3X4 | 444.17 | 2 | 222.08 | 10.15 | 0.0001 | Significant |

| X2X3X4 | 5366.35 | 2 | 2683.17 | 122.61 | <0.0001 | Significant |

| X12X3 | 3537.74 | 1 | 3537.74 | 161.66 | <0.0001 | Significant |

| X12X4 | 191.55 | 2 | 95.78 | 4.38 | 0.0161 | Significant |

| X22X3 | 2153.66 | 1 | 2153.66 | 98.42 | <0.0001 | Significant |

| X22X4 | 1151.5 | 2 | 575.75 | 26.31 | <0.0001 | Significant |

| X1X2X3X4 | 281.3 | 2 | 140.65 | 6.43 | 0.0027 | Significant |

| X12X3X4 | 116.54 | 2 | 58.27 | 2.66 | 0.0766 | Not Significant |

| X22X3X4 | 2446 | 2 | 1223 | 55.89 | <0.0001 | Significant |

| R2 | 0.99 | |||||

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Observation |

|---|---|---|---|---|---|---|

| Model | 21.85 | 35 | 0.62 | 4044.71 | <0.0001 | Significant |

| Drill tip angle (X1) | 2.22 | 1 | 2.22 | 14,369.9 | <0.0001 | Significant |

| Chipload (X2) | 6.47 | 1 | 6.47 | 41,930.8 | <0.0001 | Significant |

| Drill type (X3) | 4.34 | 1 | 4.34 | 28,086.3 | <0.0001 | Significant |

| Material type (X4) | 7.3 | 2 | 3.65 | 23,650.4 | <0.0001 | Significant |

| X1X2 | 0.29 | 1 | 0.29 | 1869.47 | <0.0001 | Significant |

| X1X3 | 0.057 | 1 | 0.057 | 370.51 | <0.0001 | Significant |

| X1X4 | 0.036 | 2 | 0.018 | 115.06 | <0.0001 | Significant |

| X2X3 | 0.23 | 1 | 0.23 | 1504.98 | <0.0001 | Significant |

| X2X4 | 0.5 | 2 | 0.25 | 1628.48 | <0.0001 | Significant |

| X3X4 | 0.28 | 2 | 0.14 | 900.26 | <0.0001 | Significant |

| X12 | 8.54 × 10−3 | 1 | 8.54 × 10−3 | 55.31 | <0.0001 | Significant |

| X22 | 0.034 | 1 | 0.034 | 219.16 | <0.0001 | Significant |

| X1X2X3 | 9.61 × 10−4 | 1 | 9.61 × 10−4 | 6.22 | 0.0149 | Significant |

| X1X2X4 | 8.84 × 10−3 | 2 | 4.42 × 10−3 | 28.64 | <0.0001 | Significant |

| X1X3X4 | 8.49 × 10−3 | 2 | 4.24 × 10−3 | 27.49 | <0.0001 | Significant |

| X2X3X4 | 0.011 | 2 | 5.70 × 10−3 | 36.9 | <0.0001 | Significant |

| X12X3 | 1.58 × 10−4 | 1 | 1.58 × 10−4 | 1.02 | 0.3156 | Not Significant |

| X12X4 | 2.45 × 10−3 | 2 | 1.23 × 10−3 | 7.93 | 0.0008 | Significant |

| X22 X3 | 4.36 × 10−3 | 1 | 4.36 × 10−3 | 28.26 | <0.0001 | Significant |

| X22 X4 | 1.48 × 10−4 | 2 | 7.40 × 10−5 | 0.48 | 0.621 | Not Significant |

| X1X2X3X4 | 0.04 | 2 | 0.02 | 130.07 | <0.0001 | Significant |

| X12X3X4 | 1.52 × 10−3 | 2 | 7.61 × 10−4 | 4.93 | 0.0099 | Significant |

| X22X3X4 | 7.73 × 10−3 | 2 | 3.86 × 10−3 | 25.03 | <0.0001 | Significant |

| R2 | 0.99 | |||||

| Independent Variables | Goal Settings | Minimum Value | Maximum Value | Level of Factor Importance |

|---|---|---|---|---|

| Drill tip angle (X1) | In range | 30 | 120 | 3 |

| Chipload (X2) | 0.1 | 0.7 | 3 | |

| Drill type (X3) | Spade | Twist | 3 | |

| Material type (X4) | Equal to | PB | MDF | Plywood |

| Dependent Variables | ||||

| Delamination factor at the inlet (Y1) | Minimize | 1 | 1.46 | 3 |

| Delamination factor at the outlet (Y2) | 1 | 2.45 | 3 | |

| Thrust force (Y3) | 23.66 | 433.91 | 3 | |

| Drilling torque (Y4) | 0.18 | 2.38 | 3 |

| Solution No. | X1 | X2 | X3 | Delamination Factor at the Outlet | Delamination Factor at the Inlet | Thrust Force (N) | Drilling Torque (Nm) | D | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y1 | ER1 | Y2 | ER2 | Y3 | ER3 | Y4 | ER4 | |||||||||

| Prelaminated particleboard (PB) | ||||||||||||||||

| 1 | 31.47 * | 0.1 | Twist | 1.12 | 1.00 | 12.0 | 1.08 | 1.08 | 0.00 | 23.66 | 21.48 | 10.15 | 0.329 | 0.37 | 11.08 | 0.896 |

| 2 | 120 | 0.1 | Twist | 1.14 | 1.09 | 4.59 | 1.01 | 1.10 | 8.18 | 46.48 | 38.67 | 20.20 | 0.184 | 0.192 | 4.17 | 0.894 |

| 3 | 60 | 0.1 | Twist | 1.13 | 1.01 | 11.8 | 1.05 | 1.16 | 9.48 | 41.09 | 42.41 | 3.11 | 0.260 | 0.248 | 4.84 | 0.892 |

| 4 | 90 | 0.1 | Twist | 1.14 | 1.01 | 12.87 | 1.03 | 1.13 | 8.85 | 49.08 | 50.89 | 3.56 | 0.209 | 0.194 | 7.73 | 0.892 |

| 5 | 63.18 ** | 0.1 | Spade | 1.17 | 1.28 | 8.59 | 1.20 | 1.05 | 14.29 | 101.39 | 64.92 | 56.18 | 0.409 | 0.35 | 16.86 | 0.793 |

| 6 | 90 | 0.1 | Spade | 1.17 | 1.28 | 8.59 | 1.27 | 1.21 | 4.96 | 100.36 | 93.49 | 7.35 | 0.332 | 0.317 | 4.73 | 0.788 |

| 7 | 30 | 0.1 | Spade | 1.17 | 1.27 | 7.87 | 1.11 | 1.20 | 7.50 | 125.34 | 126.64 | 1.03 | 0.535 | 0.611 | 12.44 | 0.781 |

| MDF | ||||||||||||||||

| 8 | 30 | 0.1 | Twist | 1.00 | 1.00 | 0.00 | 1.04 | 1.00 | 4.00 | 31.23 | 24.66 | 26.64 | 0.33 | 0.373 | 11.53 | 0.97 |

| 9 | 120 | 0.1 | Twist | 1.00 | 1.00 | 0.00 | 1.03 | 1.15 | 10.43 | 67.57 | 59.03 | 14.47 | 0.184 | 0.154 | 19.48 | 0.96 |

| 10 | 56 ** | 0.1 | Twist | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | 0.00 | 53.50 | 59.93 | 10.73 | 0.268 | 0.322 | 16.77 | 0.96 |

| 11 | 89.91 *** | 0.1 | Twist | 1.00 | 1.00 | 0.00 | 1.04 | 1.00 | 4.00 | 67.88 | 75.10 | 9.61 | 0.211 | 0.147 | 43.54 | 0.96 |

| 12 | 61.18 ** | 0.1 | Spade | 1.08 | 1.06 | 1.89 | 1.16 | 1.16 | 0.00 | 129.22 | 130.05 | 0.64 | 0.415 | 0.453 * | 8.39 | 0.832 |

| 13 | 37.07 * | 0.1 | Spade | 1.09 | 1.03 | 5.83 | 1.08 | 1.13 | 4.42 | 130.95 | 121.00 | 8.22 | 0.506 | 0.450 * | 12.44 | 0.828 |

| 14 | 119.71 **** | 0.1 | Spade | 1.06 | 1.08 | 1.85 | 1.36 | 1.32 | 3.03 | 147.73 | 135.24 | 9.24 | 0.275 | 0.212 | 29.72 | 0.812 |

| Plywood | ||||||||||||||||

| 15 | 30.00 | 0.1 | Twist | 1.03 | 1.05 | 1.90 | 1.00 | 1.00 | 0.00 | 38.93 | 28.00 | 39.04 | 0.572 | 0.539 | 6.12 | 0.923 |

| 16 | 90.75 | 0.1 | Twist | 1.04 | 1.05 | 0.95 | 1.00 | 1.07 | 6.54 | 73.11 | 80.65 | 9.35 | 0.381 | 0.352 | 8.24 | 0.873 |

| 17 | 30.00 | 0.1 | Spade | 1.11 | 1.11 | 0.00 | 1.31 | 1.17 | 11.97 | 183.73 | 175.11 | 4.92 | 1.08 | 1.02 | 5.88 | 0.681 |

| 18 | 90.00 | 0.1 | Spade | 1.17 | 1.11 | 5.41 | 1.70 | 2.10 | 19.05 | 172.18 | 181.92 | 5.35 | 0.70 | 0.617 | 13.45 | 0.630 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bedelean, B.; Ispas, M.; Răcășan, S. Optimizing Wood Composite Drilling with Artificial Neural Network and Response Surface Methodology. Forests 2024, 15, 1600. https://doi.org/10.3390/f15091600

Bedelean B, Ispas M, Răcășan S. Optimizing Wood Composite Drilling with Artificial Neural Network and Response Surface Methodology. Forests. 2024; 15(9):1600. https://doi.org/10.3390/f15091600

Chicago/Turabian StyleBedelean, Bogdan, Mihai Ispas, and Sergiu Răcășan. 2024. "Optimizing Wood Composite Drilling with Artificial Neural Network and Response Surface Methodology" Forests 15, no. 9: 1600. https://doi.org/10.3390/f15091600

APA StyleBedelean, B., Ispas, M., & Răcășan, S. (2024). Optimizing Wood Composite Drilling with Artificial Neural Network and Response Surface Methodology. Forests, 15(9), 1600. https://doi.org/10.3390/f15091600