Abstract

Lignin, a complex and heterogeneous biopolymer derived from wood, holds immense potential as a sustainable feedstock for various industrial applications. Kraft pulping, a widely employed process in the paper industry, generates black liquor containing lignin along with other organic and inorganic compounds. The precipitation of lignin from black liquor offers an opportunity for valorization, contributing to the circular economy and reducing the environmental impact. Although the precipitation process of softwood lignin is extensively documented and outlined in the existing literature, the identical process originating from hardwood-derived black liquor poses challenges attributed to the distinct composition of hardwood. This study systematically investigates the individual and combined influences of temperature and pH on the precipitation of hardwood lignin from kraft black liquor, utilizing a factorial design to evaluate lignin functional characteristics. The characterization of the precipitated lignin was performed using various analytical techniques, mainly NIR, elemental composition, UV-VIS, and calorimetry. The results reveal remarkable interactions between temperature and pH, indicating their synergistic effects on lignin precipitation. The optimal conditions for hardwood lignin precipitation were identified and successfully upscaled during piloting experiments conducted under industrial conditions. This research provides valuable insights into the fundamental factors governing hardwood lignin precipitation from kraft black liquor and offers a basis for the development of efficient and sustainable lignin recovery processes in the pulp and paper industry.

1. Introduction

Biomass is emerging as a crucial reservoir of diverse materials and chemicals, with lignocellulosic biomass, in particular, demonstrating vast potential to function as a sustainable replacement for traditional fossil fuels [1]. Lignin constitutes a noteworthy component of all lignocellulosic materials, yet it remains largely underutilized as a raw resource, drawing considerable attention in recent years. Ranked as the world’s second most abundant biopolymer, lignin showcases a complex structure defined by three primary building blocks and numerous distinct linkages [2,3]. The research interest in lignin application has intensified, driven by its potential to be a resource of renewable fuels and innovative materials. Keyoumu et al. (2004) [4] reported the isolation of approximately 330 to 490 kg of lignin per ton of birch and pine, respectively, highlighting the substantial yield achievable from such biomass sources. Considering the escalating production of chemical pulp, predominantly through kraft pulping, reaching almost 116 million tons in 2020 and an estimated capacity of approximately 134 million tons by 2025, the prominence of lignin is poised to rise correspondingly [5].

Accounting for lignin content, which varies between 25 and 30% in hardwood and softwood, the estimated yearly supply of lignin ranges from 67 to 81 million tons [6]. Alternatively, drawing insights from Keyoumu et al.’s (2004) projections, the anticipated lignin production solely from chemical pulping in 2025 is estimated to fall within the range of 44 to 66 million tons [6].

The established pulp and paper industry focuses on paper production using wood fibers, while the biorefinery represents a more versatile and sustainable approach to utilizing biomass resources, offering the production of a diverse array of valuable products. Nowadays, the pulp and paper industry remains in a transition phase to biorefinery, utilizing the kraft process to produce approximately 80% of the theoretically available lignin for possible material applications. With such status, most of the kraft pulp mills cannot sacrifice obtainable lignin for any other application because lignin is still a very important source of renewable energy available on site. Hence, the profitable commercialization of lignin remains an ongoing focus of research, presenting numerous opportunities for technological advancements. These opportunities extend to both the direct isolation of lignin from biomass and its extraction from pulping solutions, such as black liquor. In recent times, there has been a proliferation of methods designed to isolate lignin [7,8,9,10], and among them, the conventional lignin precipitation utilizing different acids [11] stands out. The three main current technologies to industrially extract kraft lignin from black liquor are sequential liquid-lignin recovery and purification (SLRP), and the LignoForce and LignoBoost processes [12,13,14]. High-tonnage-scale lignin production from black liquor has lately become industrially available. Companies, such as Valmet, Andritz, and NORAM Engineering have developed, to some extent, different isolation technologies, which have recently been implemented by Stora Enso, Domtar, Suzano, etc.

In general, softwood and hardwood differ in their chemical composition, particularly in terms of hemicelluloses and lignin content [15]. Softwood, composed of long fibers with a higher proportion of cellulose, contains lower amounts of hemicelluloses, compared to hardwood, which impact the filterability of lignin solution during the extraction process. Hardwood consists of shorter fibers with a higher proportion of hemicelluloses, in particular the content of xylan, compared to softwood, and contains a lower lignin content relative to softwood. Lignin in hardwood is composed of syringyl and guaiacyl units in varying ratios depending on the wood species [16], while softwood lignin is composed of guaiacyl units and varies little between species [17]. Hence, the delignification of hardwood leads to the formation of lignin fragments with reduced branching. Lignins of hardwood have a lower tendency of condensation reactions due to the additional methoxyl group in the 5-position of its phenolic ring [18]. This is a significant prerequisite for the homogeneity of lignin molecules in the alkaline solution as well as in the lignin molecule recovered from the black liquor.

Softwood lignins have been thoroughly characterized, and their precipitation behavior is relatively well understood [19,20,21,22,23,24]. Additionally, the precipitation and properties of softwood lignin do not vary significantly between species. However, the precipitation behavior of hardwood lignins remains less understood. Hence, it is critical to deepen the fundamental knowledge of how lignin recovery conditions influence the hardwood lignin properties [15]. The LignoBoost process is a technique for extracting lignin from black liquor, a by-product of the kraft process in paper manufacturing. In this process, black liquor is first treated with CO2, which lowers the pH and induces the aggregation and precipitation of lignin. During the CO2 precipitation in the LignoBoost process, the conditions such as temperature, final pH, and CO2 concentration significantly influence the efficiency of lignin recovery from black liquor. Typically, the precipitation experiments maintain a target temperature of around 60–80 °C, with the majority conducted at 80 °C, although some variations might occur depending on the treatment of black liquor, such as heat treatment which may lower the temperature to 60 °C for better processing outcomes. The final pH after CO2 addition is generally adjusted to approximately 9–10 for effective lignin precipitation. These conditions are crucial for optimizing the lignin recovery process, impacting the aggregate size and the filtration characteristics of the lignin obtained, which in turn affects its purity and suitability for further applications. After the initial precipitation and filtration in the LignoBoost process, the lignin filter cake is resuspended and subjected to acidification using sulfuric acid to further purify the lignin. This step involves resuspending the lignin at a lower pH, typically around pH 2–4, using sulfuric acid or spent acid from chlorine dioxide generation. This resuspension helps to disperse the lignin particles effectively, preparing them for a subsequent filtration process. The resuspended mixture is then filtered and washed with diluted sulfuric acid, which helps remove inorganic impurities and reduces the ash content of the lignin, making it suitable for high-value applications like carbon fibers [19,20,21,22,23,24].

The solubility dynamics of lignin in alkaline conditions are predominantly steered by phenolic hydroxyl groups, representing the primary ionizable groups in lignin [25]. These groups, typically existing in concentrations ranging from 2 to 5 mmol/g, play a pivotal role in the behavior of lignin in different chemical environments. As the pulping process unfolds, active alkali engages with lignin, instigating the fragmentation of the polymer into smaller, water/alkali-soluble fragments [26]. Within the realm of the kraft pulping process, the reactions governing lignin behavior can be broadly classified into degradation reactions and condensation reactions. Favorably, degradation reactions yield smaller lignin fragments that enhance the solubility in water/alkali solutions, facilitating dissolution [27]. Conversely, condensation reactions culminate in the formation of alkali-stable bonds, resulting in lignin insolubility in alkali solutions and a subsequent decrease in digestion efficiency [28,29]. The intricacies of the protonation process are influenced by the pKa values of lignin molecules, which, in turn, are susceptible to various parameters such as temperature, ion strength of the solution, type of solvent, and the molecular structure of lignin. Significantly, this recovery process tends to favor lignin molecules characterized by higher pKa values [25,30]. Moreover, as the acidification process progresses during lignin precipitation, a series of condensation reactions occur. These chemical reactions lead to the formation of new carbon–carbon (C-C) and carbon–oxygen–carbon (C-O-C) bonds within the lignin structure. Notably, these condensation reactions become increasingly prevalent at pH levels below 4, where the acidic environment facilitates the linking of lignin molecules through these newly formed bonds. Below pH 4, the increased concentrations of alkene and ester bonds suggest condensation and acid-catalyzed esterification reactions [31].

This multifaceted interplay of chemical reactions and environmental variables underscores the nuanced dynamics governing both the precipitation and subsequent recovery of lignin within industrial processes. The intricate understanding of these processes is pivotal for advancing sustainable and efficient lignin utilization in various applications.

Several articles have studied the influence of temperature and pH on lignin precipitation [32,33,34,35,36]. For example, one study indicates that precipitation conditions also influence different lignin properties, such as yield, color, molecular weight, etc. This study identifies pH as the primary factor affecting the recovery yield through acidification, followed by residence time and temperature, all positively correlated with yield. Lowering the pH during the recovery results in lighter-colored lignin with reduced molecular weight and increased dispersity, while higher temperatures yield darker lignin with an increased molecular weight. The molecular weight of lignins can undergo modifications, not only through alterations in functional groups but also due to precipitation conditions, with pH and temperature during the precipitation process playing crucial roles in determining the final lignin properties. Lowering the pH, for instance, not only increases the yield of precipitation but also results in a reduction in the molecular weight of lignins, indirectly elevating their Heating Value (HHV) [12].

The primary objective of this research was to establish the influence of the precipitation conditions on the physicochemical properties of the obtained technical lignin, with a focus on the temperature and pH of the acid precipitation step. Acid precipitation, commonly employed to extract lignin from black liquor, involves gradually reducing the pH by introducing a strong acid. Several previous studies [32,33,34,35,36] have demonstrated the impact of temperature and pH on the lignin structure, with notable effects on particle sizes, color, molecular weight, and various other characteristics. In this study, the design of experiments (DoE) was utilized to control the potential variables and assess the impact of experimental factors, specifically pH and temperature, on the properties of lignin. The laboratory experiments, aided by the modeling approaches, were followed by pilot-scale lignin recovery experiments conducted under industrial conditions, which successfully validated the previously obtained results.

2. Materials and Methods

2.1. Samples and Chemicals

Hardwood kraft black liquor (42%–43% DS, pH = 13.5) was provided by Mondi SCP (Ružomberok, Slovakia). Hardwood feedstock is based on a mixture of different species in varying ratios, where the major part comprises beech (Fagus spp.), as well as poplar (Populus spp.), ash (Fraxinus spp.), oak (Quercus spp.), larch (Larix spp.), and birch (Betula spp.). Sulfuric acid (96% w/w) was purchased from Central Chem (Bratislava, Slovakia). Carbon dioxide 2.5 was supplied by Messer Tatragas (Bratislava, Slovakia).

2.2. Methods

Approximately 100 L of kraft black liquor in one batch was precipitated using carbon dioxide with a flow of 20 L/min until a pH of around 9.5 was reached. The temperature of the process was 65 °C in one batch, and aging was conducted for 30 min after the desired pH was reached. Alkali lignin was then filtered using an Andritz filter press, air dried for 1–3 days, and transported to STUBA laboratories. The prepared amount of alkali lignin served as the raw material for further laboratory experiments. Acid-washed lignin was precipitated from alkali lignin solution using approximately 100–150 g of alkali lignin which was acidified using 50% (w/w) sulfuric acid. The acidified solution was then aged for 30 min and filtered using a Buchner funnel. The precipitation parameters (pH and temperature) were defined according to the design of experiments (see Table 1). The conditions for lignin precipitation were calculated using the design of experiments software implemented in MS Excel (ver. 16.85). The range of the factors were between 2 and 4.5 for pH and 25 and 80 °C for temperature, respectively. The borders for both factors were chosen according to the previous literature research mentioning the influence of pH and temperature during precipitation. In addition, the design of experiments can provide a wider overview of the influence of pH and temperature on the specific lignin properties and can help to predict the specific properties of lignin using modeling. The created samples were then characterized using elemental analysis, NIR, UV-VIS, and calorimetry.

Table 1.

Selected conditions for lignin precipitation from alkali lignin according to the design of experiments.

2.3. C, H, N, and S Elemental Analysis

The elemental analysis was performed using an elemental analyzer, Vario Macro Cube, from Elementar Analysensysteme GmbH (Hanau, Germany). The calibration of the instrument was carried out using sulfanilamide as a standard. A CHNS (carbon, hydrogen, nitrogen, and sulfur) module with the combustion tube temperature of 1150 °C and reduction tube temperature of 850 °C was used.

2.4. Higher Heating Value (HHV)

The higher heating value (HHV) was determined using an FTT Calorimetric Bomb (FTT Scientific, East Grinstead, UK) using a standard method [37,38].

2.5. Near-Infrared (NIR) Analysis

The spectroscopic analysis in the present work was performed by using NIR spectroscopy, and the functional groups analysis was performed by employing the multivariate calibration models recently developed by Sumerskii et al., 2023 [39]. The PLS calibration model based on 248 kraft lignins were transferred to one of the Mondi Labs and incorporated in the routine analyses of precipitated kraft lignins. Briefly, the NIR spectra of the hardwood kraft lignins were obtained by using the Multi-Purpose Analyzer FT-NIR (Bruker Optics, Ettlingen, Germany) in the wavenumber range of 800 to 2500 nm (12,500 to 4000 cm−1) with a spectral resolution of 8 cm−1. Prior to the NIR measurements, the lignin samples were dried in the oven at 50 °C. The PLS calibration model was applied to the obtained spectra and further processed via the Opus software (version 6 or newer, Bruker Optics, Ettlingen, Germany) to obtain the required lignin characteristics such as functional groups (hydroxyl, methoxyl, carboxyl groups) and number average molar mass (Mn), weight average molar mass (Mw), and dispersity index (ÐM).

2.6. UV-VIS Analysis

UV-VIS analysis was measured according to previous work [40,41,42]. The procedure was as follows: After an overnight drying period at 80 °C, approximately 5 mg of lignin was accurately weighed and dissolved in a solution containing 5 mL of dioxane and 5 mL of 0.2 M NaOH. Some solutions appeared turbid and were subsequently filtered through a 0.45 μm PVDF membrane filter. A 2 mL aliquot from each lignin solution was then diluted to a final volume of 25 mL using either a pH = 6 buffer solution (prepared from sodium citrate and citric acid to the exactly measured pH) or 0.2 M NaOH solution, resulting in a final lignin concentration of approximately 0.04 g/L. UV-VIS spectra were recorded on a CECIL spectrophotometer in the absorption range of 200–450 nm, employing a scan speed of 5 nm/s and a resolution of 1 nm. The lignin solution with pH = 6 served as a reference, against which alkaline solutions were measured. Absorbance values at 300 and 350 nm, relative to the solution containing 0.2 M NaOH, were recorded from the difference spectra. As outlined in the original work of Gartner et al. [41] six structural types of phenolic structures exist, with maxima at 300 nm and 350–360 nm attributed to unconjugated phenolic structures (I and III), and that at 350–370 nm attributed to conjugated structures (II and IV).

To obtain the concentration of individual phenolic structures in mmol/g, the following absorbance-based formulae were developed [40,41] and applied in their original form in this work:

- (a)

- Non-conjugated phenolic structures (I + III)

- (b)

- Conjugated phenolic structures (II + IV)

- (c)

- Total amount of phenolic hydroxyl groups

2.7. Optimization of the Selected Parameters

The optimization of the desired experimental conditions was systematically conducted utilizing the Solver add-in program within MS Excel. The optimization process is grounded in a regression equation of the form:

In this equation, the coefficients (b₀, b₁, b₂, b₁₂, b₁₁, b₂₂) are derived from the thorough evaluation of the design of experiments (DoE). The variables x₁ and x₂ represent the coded values assigned to the selected factors, while y symbolizes the measured values encompassing parameters such as hydroxyl groups, Higher Heating Value (HHV), elemental composition, molecular weight, and more. This rigorous computational approach enables the identification of the optimal conditions by iteratively adjusting the factors and predicting the corresponding outcomes based on the regression model. The utilization of the Solver add-in facilitates an efficient and systematic exploration of the experimental parameter space, ensuring the derivation of conditions that yield the optimized results for the specific properties under consideration.

2.8. Production of Lignin under the Piloting Conditions

Following the optimization process of the lignin properties through the statistical modeling, we established the specific laboratory conditions for lignin precipitation at 80 °C with a final pH of 2. This laboratory-prepared lignin (LL) was generated as per the protocol outlined in the previous sections. The LL underwent analytical characterization using the analytical methods described above to validate the predictive modeling. Following this, the process was upscaled to generate around 150 kg of hardwood kraft lignin in a pilot setting at Mondi SCP pulp mill in Ružomberok, Slovakia (see Figure 1).

Figure 1.

Images (a,b) representing pilot unit used for lignin precipitation and (c) shows the produced pilot lignin.

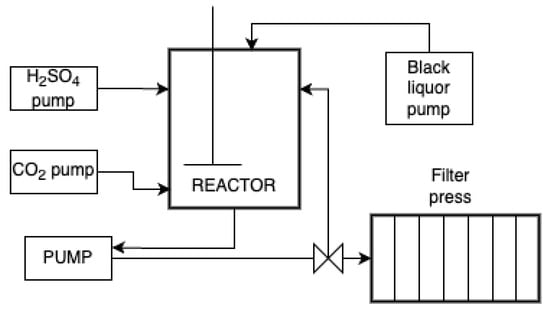

Figure 2 presents a simplified scheme of the pilot unit for lignin precipitation. At the core of the unit is the chemical reactor, which is fitted with a stirrer to ensure the mechanical mixing. The process starts with the dosing of black liquor using a dedicated pump, followed by the addition of carbon dioxide through a separate pump to acidify the black liquor. A dedicated pump supplies sulfuric acid, and an automatic pH detector adjusts the precipitation conditions accordingly. A circulation pump ensures that the mixture remains homogeneous and also aids in moving the lignin through a filter press for separation. This setup highlights the sequential and synergistic interaction of each component essential for pilot-scale lignin production. In the present study, the LignoBoost process was employed as a well-established technique for extracting kraft lignin from hardwood black liquor. The black liquor with dissolved solids of 42%–43% was taken directly from the evaporation plant of the mill. In this process, black liquor is first treated with carbon dioxide gas, which lowers the pH and induces the aggregation and precipitation of lignin. The final pH after CO2 addition is generally adjusted to approximately 9.5–10.5 for quantitative lignin precipitation. Following CO2 precipitation, the solids are filtered out, and then the obtained alkali lignin is re-suspended in water and sulfuric acid with a pH of around 2.5 to eliminate the impurities. Thus, two fractions of hardwood lignin were precipitated from black liquor at distinct pHs (pH 9.5 and 2.5). The characterization of the precipitated lignin was performed using various analytical techniques, including NIR, elemental composition, UV-VIS, and calorimetry, revealing remarkable interactions between temperature and pH that indicate their synergistic effects on lignin precipitation.

Figure 2.

Simplified scheme of pilot unit for lignin precipitation.

The resulting pilot lignin (PL) was characterized, comparing the laboratory lignin (LL) and pilot-scale product with the initial predictive models.

3. Results

3.1. Elemental Composition and Higher Heating Value (HHV)

The heating value, often referred to as the calorific value or heat of combustion, serves as a crucial parameter defining the energy content of a material, such as biomass [43]. The Higher Heating Value (HHV) represents the heat released during the combustion of a fuel with both the original and generated water in a condensed state. This parameter holds paramount importance in designing and simulating thermal systems, whether the biomass is combusted directly or co-fired with other fuels [44,45]. The correlations between the HHV and proximate analysis data, including ash content, fixed carbon, volatile matter, and moisture, have been established through various equations. Additionally, there is a direct correlation between the elemental composition of a material and its HHV [46,47,48]. The elemental composition of lignin, specifically its oxygen and hydrogen content, directly impacts the quantity and types of functional groups (mostly hydroxyl groups), as well as the polymer chain length determined by the number of carbon and hydrogen atoms. The sulfur content within lignin is particularly critical for its downstream applications. When lignin containing sulfur is incinerated, sulfur oxidizes lead to the formation of indirect greenhouse gases, predominantly sulfur dioxide (SO2) [49]. Therefore, it is essential to assess regularly the sulfur levels in lignin destined for combustion processes. Furthermore, it is prudent to minimize the sulfur content to meet international standards for various materials, ensuring both environmental protection and regulatory compliance. In Table 2, the results depict the elemental composition and HHV of lignin samples prepared according to the design of experiments.

Table 2.

Elemental composition and HHV of lignins prepared according to DoE.

3.2. Structural Characterization of Lignin via NIR Spectroscopy

The utilization of Near-Infrared (NIR) analysis offered a comprehensive evaluation of the various characteristics inherent to the prepared lignins, encompassing the molecular weight, concentrations of aliphatic and phenolic hydroxyl groups, carboxylic groups, and more. This sophisticated chemical characterization serves as a valuable tool for discerning the specific aspects of lignin samples most significantly influenced by the variations in pH and temperature during the precipitation process. Numerous research studies underscore the pivotal role played by the concentration of hydroxyl groups [7,41,50], marking it as one of the crucial determinants for subsequent applications.

By employing NIR analysis, a multifaceted understanding of lignin properties is achieved, allowing a detailed examination of the molecular attributes and functional group concentrations. This intricate chemical profiling serves as a guidepost for deciphering the nuanced impact of the precipitation conditions on the resulting lignin composition. Among these attributes, the concentration of hydroxyl groups has emerged as a focal point, recognized for its paramount importance in governing the suitability of lignins for diverse applications. The extensive data obtained by the NIR analysis not only enrich the understanding of lignin behavior but also position researchers to strategically manipulate the precipitation conditions to tailor lignin properties for specific end-use applications. The measured characteristics of lignins are presented in Table 3.

Table 3.

NIR characterization of prepared lignins.

3.2.1. Mn, ÐM, and COOH Groups’ Concentration

The preparation conditions and outcomes are detailed in Table 3, shedding light on the intricacies of the lignin precipitation under varying temperature and pH settings. The analysis underscores the stability of carboxyl group concentration, varying modestly between 0.32 and 0.36 mmol/g, and intriguingly, revealing no significant correlation with changes in temperature or pH. This implies a robustness in the formation of carboxyl groups, regardless of the conditions during the precipitation process.

The polymeric characteristics such as molar mass values obtained by means of the NIR spectroscopy revealed the dispersity index (ÐM), and the average molecular weight (Mn) exhibited a noteworthy resilience to variations in both temperature and pH, as reflected in the ÐM values spanning from 1.6 to 2.4 and Mn ranging between 2700 and 4000.

This resilience in ÐM and Mn suggests that the molecular characteristics of the precipitated lignins exhibit significant stability against fluctuations in temperature and pH levels across a spectrum of precipitation conditions.

3.2.2. Hydroxyl and Methoxyl Groups

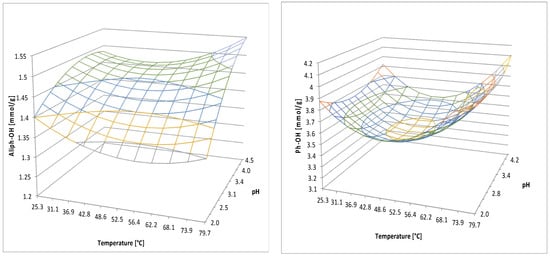

The intricate nuances in the relationship between precipitation conditions and various hydroxyl groups have been brought to light through an examination of the results. The phenolic hydroxyl groups exhibited a distinct quadratic relationship with temperature, revealing a noteworthy local minimum around 48.7 °C. This phenomenon underscores the intricate temperature sensitivity of phenolic hydroxyl concentrations during lignin precipitation. In contrast, the aliphatic hydroxyl groups presented a linear dependence on pH, with the highest concentration expected at a less acidic pH of 4.5, and the lowest value was observed under highly acidic conditions (pH = 2.0); see Figure 3. This observation aligns with the expectation that pH plays a pivotal role in influencing the concentrations of aliphatic hydroxyl groups. Similarly, the methoxyl groups showcased a quadratic dependence on temperature, with the highest concentration anticipated at 80 °C and the lowest at approximately 49.7 °C. This quadratic relationship emphasizes the intricate temperature-driven variations in methoxyl group concentrations during the precipitation process.

Figure 3.

Dependence of aliphatic hydroxyl groups (left) and phenolic hydroxyl groups (right) on precipitation conditions (pH, temperature).

3.3. Structural Characterization of Lignin via UV-VIS Spectroscopy

The phenolic hydroxyl groups can be categorized into two types: conjugated and non-conjugated hydroxyl groups. Due to the variable structure of lignin, hydroxyl groups may become conjugated via double bonds on the carbon in the phenylpropane unit. In a study examining the reactivity of various hydroxyl (-OH) groups in kraft lignin exposed to 4.4′ MDI, 31P NMR analysis revealed the complete consumption of aliphatic -OH groups in both lignin types within 15 min, with residual aromatic groups persisting after 90 min. Furthermore, a hierarchical reactivity was observed among phenolic -OH groups, with H units exhibiting the highest reactivity, followed by G and S units [50]. Non-conjugated hydroxyl groups in lignin tend to exhibit higher reactivity toward other substances compared to conjugated hydroxyl groups. Conjugated hydroxyl groups are part of aromatic rings, which exhibit reduced reactivity due to electron delocalization which decreases their nucleophilicity. However, these conjugated hydroxyl groups can still react, although the reaction occurs at a slower rate [51].

The results presented in Table 4 highlight the changes in the concentration of both the conjugated and unconjugated hydroxyl groups within the lignin structure, influenced by the variations in pH and temperature during the precipitation process. Through a thorough analysis and subsequent statistical modeling, distinct trends emerged: the unconjugated phenolic hydroxyl groups showed a quadratic relationship with temperature, while the conjugated phenolic hydroxyl groups exhibited a synergistic dependence on both pH and temperature during the precipitation process. Interestingly, the conjugated hydroxyl groups did not demonstrate any dependence on the individual precipitation conditions, while the unconjugated hydroxyl groups showed no intricate relationship with the pH during the precipitation process.

Table 4.

UV-VIS characterization of prepared lignins.

3.4. Production of Lignin under the Piloting Conditions

The design of experiments (DoE) methodology laid the groundwork for refining the precipitation process and modeling the resulting lignin’s characteristics under specific conditions. The laboratory lignin (LL) synthesis adhered to this optimization framework, with its predicted properties based on the DoE model. Additionally, pilot lignin (PL) was produced and subjected to selected analytical methods for characterization. Due to the variability in the influence of the experimental factors (pH and temperature) on the lignin’s properties, the modeling was particularly tailored to those properties demonstrably affected by the chosen conditions. The empirical data and model predictions for both LL and PL are detailed in Table 5. It is worth noting that the PL production at Mondi’s Ružomberok facility was not preceded by modeling, as was the case for the LL, due to the variable nature of the industrial-scale conditions. The production of the PL was essentially exploratory, aiming to provide a foundational understanding of Mondi’s lignin production and to gather the relevant data for the subsequent research endeavors.

Table 5.

Tabulated results for LL and PL, juxtaposed with DoE predictions for LL.

The data in the table illustrate the variances between the anticipated outcomes from the design of experiments (DoE) and the empirical values acquired through analytical testing.

4. Discussion

4.1. Elemental Composition and Higher Heating Value (HHV)

The results presented in Table 2 underscore the substantial impact of the precipitation conditions on the elemental composition of lignins and their Higher Heating Value. Notably, the HHV demonstrates a significant dependence on the precipitation temperature, while the pH during the precipitation process does not exert a discernible effect on the final value. In other words, the influence of pH on the HHV of the lignin falls within the experimental error range. This suggests the intriguing possibility of manipulating the Higher Heating Value of isolated lignins by adjusting the precipitation temperature. Further calculations indicate that the optimal HHV is expected at approximately 56.7 °C, with a calculated value of 26.02 ± 1.20 MJ/kg. These findings emphasize the potential to tailor lignin properties, specifically its energy content, by controlling the precipitation conditions, offering insights for the applications in various industrial processes.

The study reveals a correlation between the sulfur content and the pH value at which the precipitation occurs; specifically, an inverse relationship has been observed. Higher pH levels during the precipitation process correspond to lower sulfur incorporation into the lignin. This is a reasonable outcome, considering that using sulfuric acid in the precipitation process might result in the integration of sulfur into the lignin’s structure. Nevertheless, the sulfur content remains relatively minimal across the board, with the maximum concentration predicted by the model being 1.75 ± 0.13%. Although lignin is not directly utilized as a biofuel, it holds potential as an additive in conjunction with other substances like sawdust [52,53], or it can undergo conversion into biodiesel or biogas [54,55], processes which subsequently reduce the sulfur levels to meet the regulatory standards.

In practical terms, the ability to control the HHV through temperature adjustments holds implications for industries relying on lignin as a renewable energy source. Lignin-derived biofuels, for instance, could benefit from an optimized HHV, impacting the combustion efficiency and overall energy yield. For example, lignin serves as a valuable source of energy in the pulp and paper industry. Approximately 98% of its production is predominantly employed for heat and electricity generation [56]. The economic significance of lignin-derived heat is further emphasized by its market value, ranging from 6 to 10 USD/kJ [57]. Moreover, this finding may extend to applications beyond energy, influencing the design of lignin-based materials for diverse industrial processes. As research progresses, understanding the nuanced relationship between the precipitation conditions and HHV provides a valuable tool for customizing the lignin properties, opening avenues for the innovation in sustainable energy and materials production. Further investigations into the specific mechanisms underlying HHV sensitivity to temperature could refine these applications and contribute to the broader landscape of lignin utilization.

4.2. Structural Characterization of Lignin via NIR Spectroscopy

4.2.1. Mn, ÐM, and COOH Groups’ Concentration

However, delving deeper into the results of the analysis, an intriguing layer of complexity emerges when scrutinizing Mn, ÐM, and carboxyl groups (COOH). The data reveal a lack of specific dependence on the chosen parameters or any discernible synergistic impact resulting from the variations in pH and temperature. While the overall trends suggest minor discrepancies in the case of ÐM and COOH groups, coupled with a wider range of Mn, these nuanced variations hint at the possibility of an underlying influence from pH and/or temperature. These findings prompt further contemplation, raising the prospect that the observed influences might be more pronounced or subdued within an extended spectrum of selected parameters. It remains plausible that the molecular intricacies of lignin precipitation respond to a range of pH and temperature conditions that surpass the confines of those examined in this study. Therefore, future investigations employing a broader or more refined set of pH and temperature variations could potentially unveil subtle dependencies that have eluded detection within the specific range explored in this study. This nuanced approach to exploration is essential for unraveling the intricate interplay of factors that shape the molecular composition of precipitated lignins, contributing to a more comprehensive understanding of the precipitation process.

Despite there being no observed dependence of Mn, ÐM, and COOH groups on the temperature or pH during the lignin precipitation, this does not necessarily imply that these factors have no effect on these characteristics. Table 3 reveals the variations in these values across the different lignin samples. In summary, although the influence of temperature and pH on these parameters is evident, the variability is so significant that it becomes unpredictable in our modeling. Therefore, the primary focus has shifted to other functional groups in lignin, particularly hydroxyl groups, while there is limited interest in carboxyl groups due to their small representation among all the functional groups in lignin. To explore the potential dependencies further, it may be advisable to adjust the boundaries of the design of experiments, such as narrowing the range between the star points (the boundaries of the experiment, with coded values equal to ±1.414), which could lead to more precise results unaffected by the wide range of the experiment.

4.2.2. Hydroxyl and Methoxyl Groups

The lignin structure is rich in various functional groups, including phenolic hydroxyl groups, aliphatic hydroxyl groups, methoxy groups, carbonyl groups, and carboxylic acid groups [58]. Among these, the phenolic hydroxyl groups are typically the most reactive. This high reactivity is attributed to their ability to participate in a wide range of chemical reactions, such as oxidation, reduction, and various coupling reactions, which are crucial for modifying the lignin for different applications in materials science and bio-based products [50].

Table 6 acts as a comprehensive repository, consolidating the predicted values for the parameters displaying dependence on at least one factor. These predictions, derived through the meticulous calculations facilitated by the Solver add-in program in MS Excel, offer valuable insights into the anticipated variations in the hydroxyl group concentrations under the diverse precipitation conditions. This predictive analysis contributes significantly to our understanding of the nuanced interplay between the temperature and pH during the lignin isolation process, paving the way for informed adjustments and optimizations of the lignin precipitation protocols. From the calculated results, it can be assumed that the variability of the concentration of different functional groups is significant for phenolic hydroxyl groups and methoxyl groups where the variation represents more than ±1 mmol/g of lignin. For aliphatic hydroxyl groups, this variability is not so significant but is still present and reliable. In the realm of lignin utilization, the concentration of hydroxyl groups plays a pivotal role, catering to the diverse application needs. Higher concentrations are indispensable in fostering hydrogen bond formation with hydrophilic polymers and enhancing the surface wetting properties, crucial for bio-based polymers and coatings to improve adhesion and material compatibility [50,59]. On the other hand, lower hydroxyl group concentrations are sought after for their ability to fine-tune the chemical reactivity in specific syntheses and to modulate the solubility characteristics, aiding in the creation of materials with tailored solubility and reactivity profiles [60,61]. Lower concentrations of hydroxyl groups might be preferred in applications where reduced reactivity and higher thermal stability are desired, such as in certain thermoplastic applications, to avoid premature cross-linking or degradation during processing. This strategic manipulation of hydroxyl group concentration paves the way for optimizing lignin’s functionality across various industrial applications, underlining its versatility as a sustainable resource.

Table 6.

Predicted highest and lowest values for functional groups of lignins.

The centrality of hydroxyl groups in the lignin structure is underscored by their dual role as the most reactive sites and the most abundant functional groups. These hydroxyl functionalities serve as pivotal contributors to lignin’s reactivity, influencing its adaptability and responsiveness in various applications. Their significance is not only quantitative but also qualitative, contributing to the hydrophobic and hydrophilic properties of lignin and shaping its surface energy characteristics. In the context of lignin’s chemical structure, hydroxyl groups emerge as the primary reactive sites, fostering interactions with other compounds in the diverse chemical processes. The abundance of hydroxyl groups allows for a plethora of potential reactions, making them the key determinants in tailoring lignin for specific applications. This versatility is particularly evident in the realm of rubber preparations, where the incorporation of hydroxyl-rich lignin in combination with sufficient carbon content enhances its utility as a filler [62], influencing the material’s mechanical properties.

The synergy of aliphatic hydroxyl groups, especially in tandem with hydroxymethylation, showcases their multifaceted impact on lignin’s mechanical attributes. This phenomenon, demonstrated in the heightened tensile strength, extends to adhesive applications, where aliphatic hydroxyl content assumes a pivotal role in augmenting the properties like the thermal stability and density in polyurethane adhesives [63]. Beyond these mechanical enhancements, hydroxyl groups also play a crucial role in dictating the hydrophobic and hydrophilic nature of lignin, significantly impacting its interaction with water and other polar or non-polar substances. Moreover, these groups contribute to the surface energy properties of lignin, influencing its compatibility with various matrices and substrates.

In summary, the versatile and abundant nature of hydroxyl groups renders them as linchpins in the chemical reactivity and application-specific modifications of lignin. Their pivotal role in influencing the mechanical properties, hydrophobicity, hydrophilicity, and surface energy highlights the intricate interplay between lignin’s chemical structure and its functional attributes, further expanding the avenues for its utilization across the diverse domains. Predicting the concentration of hydroxyl and methoxyl groups in lignin based on the pH and temperature during the precipitation process can significantly impact its application in various industries. For example, in the creation of bio-based materials, the specific concentrations of these groups can influence the reactivity, solubility, and thermal stability of the lignin-derived products. This ability allows for the tailored design of lignin for its use in adhesives, coatings, and bioplastics, optimizing the performance characteristics such as adhesion strength, flexibility, and degradation resistance, thereby enhancing the value and utility of lignin in sustainable materials development. The abundance of aliphatic hydroxyl groups in lignin enhances its solubility in diols, benefiting the delignification in biomass fractionation [64]. In polyurethane production, a higher hydroxyl concentration modifies the cure rates, adds rigidity, and improves the cross-linking [65]. For the biocatalysis of carbohydrates, the selective acylation of lignin’s hydroxyl groups is key [50]. These groups also increase the solubility in water and other solvents, aiding various chemical reactions, particularly with diisocyanates [50,64]. Thus, hydroxyl-rich lignin finds wide application from delignification to chemical synthesis, underscoring its versatility and functional importance.

4.3. Structural Characterization of Lignin via UV-VIS Spectroscopy

Lignin’s hydroxyl functionalities, comprising both aliphatic and phenolic types, are fundamental to its chemical behavior and utility across a spectrum of applications. These groups are pivotal in the manufacture of polyurethanes, the facilitation of biocatalytic processes, and the delignification step in biomass processing [51,66]. Their reactivity is a key determinant of lignin’s performance in chemical synthesis, influencing the hydrogen bonding capabilities and enhancing the surface wetness [67]. Furthermore, the nature and quantity of these hydroxyl groups affect lignin’s molecular weight distribution and compatibility, broadening its applicability in the fields of material science and biotechnology [68]. The presence and reactivity of these groups thus dictate lignin’s solubility and its functional fit for various industrial and scientific uses. Drawing from the referenced materials, it emerges that the phenolic hydroxyl groups in lignin are more consequential than their aliphatic counterparts. These groups are integral to defining the physical and chemical characteristics of lignin, exerting a profound influence on the commercial processes such as pulping, bleaching, and various modification reactions, attributable to their heightened reactivity and functional versatility. The role of phenolic hydroxyl groups extends to governing the structure, reactivity, and breakdown pathways of lignin, establishing them as pivotal factors in determining lignin’s overall properties and its potential industrial applications [69]. Hence, the consensus from the provided literature points to the phenolic hydroxyl group’s predominance in importance within lignin’s structure.

The phenolic hydroxyl groups in lignin, differentiated into conjugated and non-conjugated varieties, hold substantial importance, meriting the focused research of these entities. Employing UV-VIS spectroscopy, researchers can differentiate between conjugated and non-conjugated phenolic hydroxyl groups, shedding light on the effects of the precipitation conditions on these groups. According to the literature [41,42,69,70], the concentration of conjugated phenolic hydroxyl groups is approximately 0.39 mmol/g, while the non-conjugated phenolic hydroxyl groups range from 1.03 to 1.67 mmol/g. The non-conjugated groups, in particular, are essential for lignin’s reactivity and play a decisive role in the critical industrial processes such as pulping, bleaching, and chemical modifications. Their pronounced influence on lignin’s physical and chemical properties confirms that the non-conjugated phenolic hydroxyl groups as more central to lignin’s functionality in various chemical applications, surpassing the conjugated groups in terms of importance within the lignin structure.

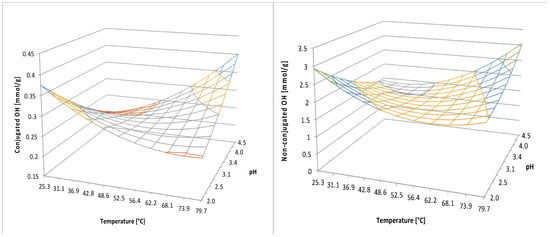

Our analysis, augmented via statistical modeling, suggests that the concentration of conjugated hydroxyl groups in lignin is synergistically influenced by both the pH and temperature during the precipitation process, whereas the presence of non-conjugated hydroxyls demonstrates a quadratic dependence on the precipitation temperature alone (see Figure 4). It is encouraging to note that a relationship has been established between the precipitation conditions and the corresponding lignin parameters. Specifically, the phenolic hydroxyl groups exhibit a quadratic dependency on the precipitation temperature, a pattern that holds true for the non-conjugated hydroxyl groups, which are also found in greater abundance than their conjugated counterparts. Upon closer examination, we observed that the conjugated hydroxyl groups’ concentration, which is notably lower than that of the non-conjugated hydroxyls, is affected by both the pH and temperature. This synergy, however, does not significantly impact the overall concentration of the total phenolic hydroxyl groups. The literature indicates that the non-conjugated hydroxyl groups in kraft lignin typically range from 1.03 to 1.67 mmol/g [42,69,71]. Our results indicate a broader range of 1.35 to 3.09 mmol/g for lignins prepared under DoE-guided conditions, as shown in Table 7. Despite a higher than anticipated error margin, it is the intrinsic variability and complexity of lignin’s structure that predominantly contributes to this discrepancy, underscoring the challenges in predicting lignin properties due to its inherent heterogeneity. For the conjugated hydroxyl groups, the observed range of 0.18–0.39 mmol/g aligns with the existing literature values, approximately 0.39 mmol/g [42]. The smaller modeling error for the conjugated hydroxyls compared to the non-conjugated ones is attributed to their lower concentration and reduced structural variability.

Figure 4.

Dependence of conjugated hydroxyl groups (left) and non-conjugated hydroxyl groups (right) on precipitation conditions (pH, temperature).

Table 7.

Predicted highest and lowest values for phenolic hydroxyl groups of lignins.

The previous results showed that it is possible not only to affect the concentration of the functional groups, but it is possible to specify the properties of lignin on a very concrete level, such as the non-conjugated or conjugated type of phenolic hydroxyl groups. By precisely adjusting the precipitation conditions to affect either the conjugated or non-conjugated phenolic hydroxyl groups in lignin, we can customize the lignin-based materials to exhibit the desired characteristics specific to their intended applications. This targeted approach could enhance the performance of lignin in the production of resins and adhesives [72,73], where the reactivity of the non-conjugated hydroxyl groups is particularly valuable. Similarly, the modification of the conjugated hydroxyl groups might be leveraged to fine-tune the thermal stability and interaction properties of lignin polymers [51,69,74]. Such selective adjustment during the lignin precipitation stage not only offers a more environmentally friendly and cost-effective route compared to post-synthesis chemical modifications but also ensures greater consistency and quality in the end-product’s performance, tapping into the full potential of lignin as a versatile bioresource.

4.4. Production of Lignin under Piloting Conditions

To enhance our understanding of lignin variability, we scaled up its production, starting with a lab-scale batch of approximately 2.5 kg, analyzed in line with the DoE for lignins for comparison. The results for this lab-scale lignin (LL) are detailed in Table 5. Subsequently, we aimed to validate the scalability of our approach by producing around 150 kg of pilot-scale lignin, assessing its compatibility with industrial-scale operations in the hardwood black liquor processing pulp mills. This scaling process emphasized the evaluation of the crucial lignin properties influenced by the precipitation conditions. However, transitioning from the lab to an industrial scale introduces challenges such as process scalability, equipment adaptation, and economic feasibility. While the lab experiments underscore the potential for lignin extraction, scaling to the pulp mill operations necessitates the optimization of the separation techniques, ensuring the efficient extraction, and modifying the equipment for mass production. Economic assessments are vital to ensure the cost-effectiveness of the scaled-up processes, underpinning the investment in the necessary infrastructure and technology for comprehensive lignin valorization. Successfully scaling lignin production requires the addressing of these technical, operational, and economic hurdles to leverage lignin’s full value in industrial applications [75,76].

Table 5 reveals the discrepancies between the design of experiments (DoE) model predictions and the real-world measurements for the laboratory lignin (LL). The DoE model anticipated a non-conjugated hydroxyl group content of 1.98 mmol/g with an error margin of ±1.068, suggesting a significant variability; however, the actual LL value measured was outside of this range at 1.64 mmol/g. Similarly, the conjugated hydroxyl group content was predicted to be 0.24 mmol/g with an error of ±0.086, while the real value was slightly higher at 0.30 mmol/g. The predicted total Ph-OH of 4.13 mmol/g, with an error of ±0.231, also overestimated the real measurement of 3.89 mmol/g. For the pilot-scale lignin (PL), not intended for direct comparison due to different processing conditions, we observed an actual non-conjugated OH content of 2.02 mmol/g, which is higher than both the predicted and the actual values for the LL. The conjugated OH and total Ph-OH contents for the PL also deviated from the LL’s values, emphasizing the impact of different production conditions. The errors from the DoE calculations are notably wide for some measurements, such as the non-conjugated OH group, indicating a high degree of uncertainty in the model’s predictions. The aliphatic hydroxyl groups (R-OH), methoxyl groups (OCH3), and molecular weight (Mw) also differed significantly between the predicted and actual values for the LL, with the actual molecular weight of the LL and PL far exceeding the model’s expectation, indicating that the model may not fully capture the complex polymerization dynamics that occur during lignin processing. These variations between the model and actual measurements underscore the complexities of lignin chemistry and highlight the challenges in scaling up from DoE to actual industrial processes, reaffirming the importance of the empirical adjustments based on real-world data.

In our study, the discrepancies observed between the DoE model predictions and the empirical measurements can be attributed to a range of factors. Firstly, the inherent limitations of the DoE model may not have fully encapsulated the complex interactions or accounted for all the variables influencing the lignin precipitation process. Secondly, the process variability could lead to deviations, especially when the conditions such as temperature and pH may fluctuate beyond the controlled parameters set within the experimental design. Thirdly, the scale-up from the laboratory to pilot scale can introduce new dynamics—differences in the mixing rates, heat and mass transfer efficiencies, and residence times—that were not present or considered during the modeling phase. These factors collectively contribute to the variation between the predicted and actual values, underscoring the challenges of modeling complex biopolymer processes like lignin precipitation.

For a better understanding of lignin behavior under the precipitation conditions, it is necessary to deeply understand the changes in the lignin properties during the whole process. To be able to precisely model and predict the lignin properties, it can help to conduct other DoE not only at the lab scale but try to implement this DoE at the pilot scale. In addition, under the industrial conditions, there are some factors which are hard to influence, and there are some factors which can also affect the properties of lignin. The possible parameters which can enhance the model and affect the properties of lignin indicated in the literature are the precipitation and filtration temperature [77,78], the concentration of acid [79,80], the final pH [81,82], and also the type of the acid [80,83] used for the precipitation process.

5. Conclusions

In summary, our investigation advances the comprehension of hardwood lignin precipitation from kraft black liquor, emphasizing the significant role that the precipitation conditions play in shaping lignin’s physicochemical traits. Through methodical experimentation and detailed analysis, we have described several critical insights as follows:

- The phenolic and aliphatic hydroxyl groups’ concentration is crucially influenced by the precipitation conditions, specifically the temperature and pH, showcasing the potential for targeted property modification.

- The conjugated hydroxyl groups demonstrate a synergistic dependency on both the pH and temperature, whereas the non-conjugated hydroxyl groups exhibit a quadratic dependency primarily on the temperature.

- Scaling up the lignin extraction process from the lab to pilot process under the industrial conditions has validated the applicability of our results.

- The differences between the DoE predictions and actual measurements highlight the inherent complexities of lignin chemistry and the necessity for empirical adjustments.

For future research directions, the following steps could be pivotal in further enhancing the utility and application of lignin:

- Broadening the scope of the DoE to include pilot-scale experiments, thereby providing a more comprehensive understanding of the scalability and industrial applicability of the process.

- Investigating additional parameters that may influence the lignin properties, such as acid concentration and type, to refine the predictive model and optimize lignin’s functional characteristics.

Author Contributions

Conceptualization, R.N. and M.M.; methodology, R.N.; formal analysis, R.N. and G.Z.; investigation, R.N. and M.Š.; resources, G.Z.; data curation, R.N.; writing—original draft preparation, R.N. and G.Z.; writing—review and editing, A.H., M.J. and G.Z.; supervision, A.H.; project administration, A.H.; funding acquisition, A.H. All authors have read and agreed to the published version of the manuscript.

Funding

The FFG-Austrian Research Promotion Agency is acknowledged for their funding of the Projects KraftPell (FFG-Nr. 884529) co-financed by the Slovak Research and Development Agency under the contracts APVV-22-0388, APVV-22-0034, and VEGA 1/0743/24. Furthermore, this publication was supported by the project LigBioMat: Modifications of lignin for the preparation of new biomaterials (Grant STU Bratislava for young researchers).

Data Availability Statement

The data supporting the findings of this study are not publicly available due to privacy concerns. However, the data can be made available upon reasonable request to the corresponding author, subject to the approval of the co-authors.

Acknowledgments

We gratefully acknowledge Klaus Eibinger, Zellstoff Pöls AG, Austria for providing the pilot equipment for the lignin piloting trial. We deeply acknowledge Mondi SCP pulp mill in Slovakia for their support of the lignin piloting trial. We also would like to thank Wilfried Pichler, Holzforschung Austria for his moral support of the pilot trial.

Conflicts of Interest

Author Grigory Zinovyev was employed by the company Mondi. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Rosillo-Calle, F.; de Groot, P.; Hemstock, S.L. Non Woody Biomass and Secondary Fuels. In The Biomass Assessment Handbook: Energy for a Sustainable Environment; Rosillo-Calle, F., de Groot, P., Hemstock, S.L., Woods, J., Eds.; Routledge: London, UK, 2015; pp. 1–336. ISBN 9781138019652. [Google Scholar]

- Vanholme, R.; Demedts, B.; Morreel, K.; Ralph, J.; Boerjan, W. Lignin Biosynthesis and Structure. Plant Physiol. 2010, 153, 895–905. [Google Scholar] [CrossRef] [PubMed]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany, 1984; ISBN 3935638396. [Google Scholar]

- Keyoumu, A.; Sjödahl, R.; Henriksson, G.; Ek, M.; Gellerstedt, G.; Lindström, M.E. Continuous Nano- and Ultra-Filtration of Kraft Pulping Black Liquor with Ceramic Filters: A Method for Lowering the Load on the Recovery Boiler While Generating Valuable Side-Products. Ind. Crops Prod. 2004, 20, 143–150. [Google Scholar] [CrossRef]

- FAO. Pulp and Paper Capacities, Survey 2020–2025|Capacités de la Pâte et du Papier, Enquête 2020–2025|Capacidades de Pulpa y Papel, Estudio 2020–2025; FAO: Rome, Italy, 2021. [Google Scholar]

- Nadányi, R.; Ház, A.; Lisý, A.; Jablonský, M.; Šurina, I.; Majová, V.; Baco, A. Lignin Modifications, Applications, and Possible Market Prices. Energies 2022, 15, 6520. [Google Scholar] [CrossRef]

- Yue, X.; Suopajärvi, T.; Sun, S.; Mankinen, O.; Mikkelson, A.; Huttunen, H.; Komulainen, S.; Romakkaniemi, I.; Ahola, J.; Telkki, V.V.; et al. High-Purity Lignin Fractions and Nanospheres Rich in Phenolic Hydroxyl and Carboxyl Groups Isolated with Alkaline Deep Eutectic Solvent from Wheat Straw. Bioresour. Technol. 2022, 360, 127570. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Fakayode, O.A.; Ahmed Yagoub, A.E.G.; Ji, Q.; Zhou, C. Lignin Fractionation from Lignocellulosic Biomass Using Deep Eutectic Solvents and Its Valorization. Renew. Sustain. Energy Rev. 2022, 156, 111986. [Google Scholar] [CrossRef]

- Deepa, K.; Arthanareeswaran, G. Influence of Various Shapes of Alumina Nanoparticle in Integrated Polysulfone Membrane for Separation of Lignin from Woody Biomass and Salt Rejection. Environ. Res. 2022, 209, 112820. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Kollberg, L.; Almqvist, H.; Xu, B.; Hulteberg, C. Maximizing Yield of Liquid-Lignin from Membrane Filtration Retentate of Kraft Black Liquor. Ind. Crops Prod. 2021, 169, 113657. [Google Scholar] [CrossRef]

- Kienberger, M.; Maitz, S.; Pichler, T.; Demmelmayer, P. Systematic Review on Isolation Processes for Technical Lignin. Processes 2021, 9, 804. [Google Scholar] [CrossRef]

- Zhu, W.; Westman, G.; Theliander, H. Investigation and Characterization of Lignin Precipitation in the Lignoboost Process. J. Wood Chem. Technol. 2014, 34, 77–97. [Google Scholar] [CrossRef]

- Lake, M.A.; Blackburn, J.C. SLRPTM-An innovative lignin-recovery technology. Cellulose Chem. Technol. 2014, 48, 799–804. [Google Scholar]

- Kouisni, L.; Holt-Hindle, P.; Maki, K.; Paleologou, M. The Lignoforce systemtm: A New Process for the Production of High-Quality Lignin from Black Liquor. J. Sci. Technol. For. Prod. Process. 2012, 2, 4. [Google Scholar]

- Jardim, J.M.; Hart, P.W.; Lucia, L.A.; Jameel, H.; Chang, H.M. The Effect of the Kraft Pulping Process, Wood Species, and PH on Lignin Recovery from Black Liquor. Fibers 2022, 10, 16. [Google Scholar] [CrossRef]

- Santos, R.B.; Capanema, E.A.; Balakshin, M.Y.; Chang, H.M.; Jameel, H. Lignin Structural Variation in Hardwood Species. J. Agric. Food Chem. 2012, 60, 4923–4930. [Google Scholar] [CrossRef] [PubMed]

- Akiyama, T.; Goto, H.; Nawawi, D.S.; Syafii, W.; Matsumoto, Y.; Meshitsuka, G. Erythro/Threo Ratio of β-O-4-Structures as an Important Structural Characteristic of Lignin. Part 4: Variation in the Erythro/Threo Ratio in Softwood and Hardwood Lignins and Its Relation to Syringyl/Guaiacyl Ratio. Holzforschung 2005, 59, 276–281. [Google Scholar] [CrossRef]

- Jardim, J.M.; Hart, P.W.; Lucia, L.; Jameel, H. Insights into the Potential of Hardwood Kraft Lignin to Be a Green Platform Material for Emergence of the Biorefinery. Polymers 2020, 12, 1795. [Google Scholar] [CrossRef] [PubMed]

- Ziesig, R.; Tomani, P.; Schweinebarth, H.; Norberg, L. Production of a Pure Lignin Product, Part 1: Distribution and Removal of Inorganics in Eucalyptus Globulus Kraft Lignin. Tappi J. 2014, 13, 65–72. [Google Scholar]

- Ziesig, R.; Tomani, P.; Theliander, H. Production of a pure lignin product part 2: Separation of lignin from membrane filtration permeates of black liquor. Cellul. Chem. Technol. 2014, 48, 805–811. [Google Scholar]

- Tomani, P. The lignoboost process. Cellulose Chem. Technol. 2010, 44, 53–58. [Google Scholar]

- Öhman, F.; Wallmo, H.; Theliander, H. Precipitation and Filtration of Lignin from Black Liquor of Different Origin. Nord. Pulp Paper Res. J. 2007, 22, 188–193. [Google Scholar] [CrossRef]

- Öhman, F.; Wallmo, H.; Theliander, H. A Novel Method for Washing Lignin Precipitated from Kraft Black Liquor–Laboratory Trials. Nord. Pulp Paper Res. J. 2007, 22, 9–16. [Google Scholar] [CrossRef]

- Wallmo, H.; Theliander, H.; Richards, T. Lignin Precipitation from Kraft Black Liquors: Kinetics and Carbon Dioxide Absorption. Pap. Puu Pap. Timber 2007, 89, 436–442. [Google Scholar]

- Norgren, M.; Lindström, B. Dissociation of Phenolic Groups in Kraft Lignin at Elevated Temperatures. Holzforschung 2000, 54, 519–527. [Google Scholar] [CrossRef]

- Chakar, F.S.; Ragauskas, A.J. Review of Current and Future Softwood Kraft Lignin Process Chemistry. Ind. Crops Prod. 2004, 20, 131–141. [Google Scholar] [CrossRef]

- Gierer, J. The Reactions of Lignin during Pulping. Sven. Papperstidning 1970, 18, 571–596. [Google Scholar]

- Azadi, P.; Inderwildi, O.R.; Farnood, R.; King, D.A. Liquid Fuels, Hydrogen and Chemicals from Lignin: A Critical Review. Renew. Sustain. Energy Rev. 2013, 21, 506–523. [Google Scholar] [CrossRef]

- Gierer, J. Chemistry of Delignification–Part 1: General Concept and Reactions during Pulping. Wood Sci. Technol. 1985, 19, 289–312. [Google Scholar] [CrossRef]

- Ragnar, M.; Lindgren, C.T.; Nilvebrant, N.O. PKa-Values of Guaiacyl and Syringyl Phenols Related to Lignin. J. Wood Chem. Technol. 2008, 20, 277–305. [Google Scholar] [CrossRef]

- Andeme Ela, R.C.; Spahn, L.; Safaie, N.; Ferrier, R.C.; Ong, R.G. Understanding the Effect of Precipitation Process Variables on Hardwood Lignin Characteristics and Recovery from Black Liquor. ACS Sustain. Chem. Eng. 2020, 8, 13997–14005. [Google Scholar] [CrossRef]

- Crestini, C.; Lange, H.; Sette, M.; Argyropoulos, D.S. On the Structure of Softwood Kraft Lignin. Green Chem. 2017, 19, 4104–4121. [Google Scholar] [CrossRef]

- Singh, S.P.; Jawaid, M.; Yadav, B.; Sarmin, S.N. Effect of PH, Temperature, and Solids Content on Rheological Properties of Wheat Straw Black Liquor. Biomass Convers. Biorefin. 2023, 13, 10865–10875. [Google Scholar] [CrossRef]

- Quan, P.; Kiziltas, A.; Ong, R.G.; DeVallance, D.; Xu, J.; Xie, X. Lignin with Tunable and Predictable Yield and Molecular Properties. ACS Sustain. Chem. Eng. 2023, 11, 2861–2870. [Google Scholar] [CrossRef]

- Zhu, W.; Theliander, H. Precipitation of Lignin from Softwood Black Liquor: An Investigation of the Equilibrium and Molecular Properties of Lignin. Bioresources 2015, 10, 1696–1714. [Google Scholar] [CrossRef]

- Lourençon, T.V.; de Lima, G.G.; Ribeiro, C.S.P.; Hansel, F.A.; Maciel, G.M.; da Silva, K.; Winnischofer, S.M.B.; de Muniz, G.I.B.; Magalhães, W.L.E. Antioxidant, Antibacterial and Antitumoural Activities of Kraft Lignin from Hardwood Fractionated by Acid Precipitation. Int. J. Biol. Macromol. 2021, 166, 1535–1542. [Google Scholar] [CrossRef] [PubMed]

- Sivaramakrishnan, K.; Ravikumar, P. Determination of Higher Heating Value of Biodiesels. Int. J. Eng. Sci. Technol. (IJEST) 2011, 3, 7981–7987. [Google Scholar]

- Telmo, C.; Lousada, J. The Explained Variation by Lignin and Extractive Contents on Higher Heating Value of Wood. Biomass Bioenergy 2011, 35, 1663–1667. [Google Scholar] [CrossRef]

- Sumerskii, I.; Böhmdorfer, S.; Tsetsgee, O.; Sulaeva, I.; Khaliliyan, H.; Musl, O.; Dorninger, K.; Tischer, A.; Potthast, K.; Rosenau, T.; et al. Tapping the Full Potential of Infrared Spectroscopy for the Analysis of Technical Lignins. ChemSusChem 2024, 17, e202301840. [Google Scholar] [CrossRef] [PubMed]

- Zakis, G.F. Functional Analysis of Lignins and Their Derivatives; Joyce, T., Brezny, R., Eds.; Tappi Press: Riga, Latvia, 1994; ISBN 0898522587. [Google Scholar]

- Gärtner, A.; Gellerstedt, G.; Tamminen, T. Determination of Phenolic Hydroxyl Groups in Residual Lignin Using a Modified UV-Method. Nord. Pulp Paper Res. J. 1999, 14, 163–170. [Google Scholar] [CrossRef]

- Jablonský, M.; Kočiš, J.; Ház, A.; Šima, J. Characterization and Comparison by UV Spectroscopy of Precipitated Lignins and Commercial Lignosulfonates. Cellul. Chem. Technol. 2015, 49, 267–274. [Google Scholar]

- Werther, J.; Saenger, M.; Hartge, E.U.; Ogada, T.; Siagi, Z. Combustion of Agricultural Residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Sami, M.; Annamalai, K.; Wooldridge, M. Co-Firing of Coal and Biomass Fuel Blends. Prog. Energy Combust. Sci. 2001, 27, 171–214. [Google Scholar] [CrossRef]

- Sheng, C.; Azevedo, J.L.T. Estimating the Higher Heating Value of Biomass Fuels from Basic Analysis Data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Özkan, K.; Işık, Ş.; Günkaya, Z.; Özkan, A.; Banar, M. A Heating Value Estimation of Refuse Derived Fuel Using the Genetic Programming Model. Waste Manag. 2019, 100, 327–335. [Google Scholar] [CrossRef] [PubMed]

- Qian, C.; Li, Q.; Zhang, Z.; Wang, X.; Hu, J.; Cao, W. Prediction of Higher Heating Values of Biochar from Proximate and Ultimate Analysis. Fuel 2020, 265, 116925. [Google Scholar] [CrossRef]

- Maksimuk, Y.; Antonava, Z.; Krouk, V.; Korsakova, A.; Kursevich, V. Prediction of Higher Heating Value (HHV) Based on the Structural Composition for Biomass. Fuel 2021, 299, 120860. [Google Scholar] [CrossRef]

- Rupasinghe, R.L.; Perera, P.; Bandara, R.; Amarasekera, H.; Vlosky, R. Insights into Properties of Biomass Energy Pellets Made from Mixtures of Woody and Non-Woody Biomass: A Meta-Analysis. Energies 2024, 17, 54. [Google Scholar] [CrossRef]

- Antonino, L.D.; Gouveia, J.R.; de Sousa Júnior, R.R.; Garcia, G.E.S.; Gobbo, L.C.; Tavares, L.B.; Dos Santos, D.J. Reactivity of Aliphatic and Phenolic Hydroxyl Groups in Kraft Lignin towards 4,4′ MDI. Molecules 2021, 26, 2131. [Google Scholar] [CrossRef] [PubMed]

- Šurina, I.; Jablonský, M.; Ház, A.; Sladková, A.; Briškárová, A.; Kačík, F.; Šima, J. Characterization of Non-Wood Lignin Precipitated with Sulphuric Acid of Various Concentrations. Bioresources 2015, 10, 1408–1423. [Google Scholar] [CrossRef]

- Elniski, A.; Dongre, P.; Bujanovic, B.M. Lignin Use in Enhancing the Properties of Willow Pellets. Forests 2023, 14, 2041. [Google Scholar] [CrossRef]

- Rueda, S.J.; de Vasconcelos, B.R.; Duret, X.; Lavoie, J.M. Lignin Pellets for Advanced Thermochemical Process—From a Single Pellet System to a Laboratory-Scale Pellet Mill. Energies 2022, 15, 3007. [Google Scholar] [CrossRef]

- Bhat, A.H.; Dasan, Y.K.; Khan, I. Extraction of Lignin from Biomass for Biodiesel Production. In Agricultural Biomass Based Potential Materials; Springer: Berlin/Heidelberg, Germany, 2015; pp. 155–179. [Google Scholar] [CrossRef]

- Bušić, A.; Kundas, S.; Morzak, G.; Belskaya, H.; Mardetko, N.; Šantek, M.I.; Komes, D.; Novak, S.; Šantek, B. Recent Trends in Biodiesel and Biogas Production. Food Technol. Biotechnol. 2018, 56, 152. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Pourhashem, G.; Ullah, A.H.; Bajwa, S.G. A Concise Review of Current Lignin Production, Applications, Products and Their Environmental Impact. Ind. Crops Prod. 2019, 139, 111526. [Google Scholar] [CrossRef]

- Holladay, J.E.; White, J.F.; Bozell, J.J.; Johnson, D. Top Value-Added Chemicals from Biomass–Volume II—Results of Screening for Potential Candidates from Biorefinery Lignin; Pacific Northwest National Laboratory (PNNL): Richland, WA, USA, 2007. [CrossRef]

- Huang, J.; Fu, S.; Gan, L. (Eds.) Structure and Characteristics of Lignin. In Lignin Chemistry and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 25–50. ISBN 978-0-12-813941-7. [Google Scholar]

- Verdini, F.; Gaudino, E.C.; Canova, E.; Tabasso, S.; Behbahani, P.J.; Cravotto, G. Lignin as a Natural Carrier for the Efficient Delivery of Bioactive Compounds: From Waste to Health. Molecules 2022, 27, 3598. [Google Scholar] [CrossRef]

- Mandal, S.; Chatterjee, B.; Layek, B. Cellulose-Based Nanomaterials in Drug Delivery Applications. In Biopolymer-Based Nanomaterials in Drug Delivery and Biomedical Applications; Bera, H., Hossain, C.H.M., Saha, S., Eds.; Academic Press: London, UK, 2021; pp. 57–86. ISBN 9780128208748. [Google Scholar]

- Capanema, E.A.; Balakshin, M.Y.; Kadla, J.F. Quantitative Characterization of a Hardwood Milled Wood Lignin by Nuclear Magnetic Resonance Spectroscopy. J. Agric. Food Chem. 2005, 53, 9639–9649. [Google Scholar] [CrossRef] [PubMed]

- Intapun, J.; Rungruang, T.; Suchat, S.; Cherdchim, B.; Hiziroglu, S. The Characteristics of Natural Rubber Composites with Klason Lignin as a Green Reinforcing Filler: Thermal Stability, Mechanical and Dynamical Properties. Polymers 2021, 13, 1109. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, H.; Zhu, Z.; Fu, S. High-Value Utilization of Hydroxymethylated Lignin in Polyurethane Adhesives. Int. J. Biol. Macromol. 2020, 152, 775–785. [Google Scholar] [CrossRef] [PubMed]

- Yong, K.J.; Wu, T.Y. Recent Advances in the Application of Alcohols in Extracting Lignin with Preserved β-O-4 Content from Lignocellulosic Biomass. Bioresour. Technol. 2023, 384, 129238. [Google Scholar] [CrossRef] [PubMed]

- Ahvazi, B.; Ngo, T.-D.; Ahvazi, B.; Ngo, T.-D. Application of Lignins in Formulation and Manufacturing Bio- Based Polyurethanes by 31P NMR Spectroscopy. In Lignin–Trends and Applications; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Zhang, Y.; Stepanova, S.; Van Aelst, K.; Sels, B.F. Consider Lignin’s Hydroxyl Groups Content and Type, Its Molecular Weight and Content When Converting It into Epoxy Resin. Curr. Opin. Green Sustain. Chem. 2023, 40, 100750. [Google Scholar] [CrossRef]

- Kazzaz, A.; Feizi, Z.; Chemistry, P.F.-G. Grafting Strategies for Hydroxy Groups of Lignin for Producing Materials. 2019. Available online: https://pubs.rsc.org/en/content/articlehtml/2019/gc/c9gc02598g (accessed on 10 January 2023).

- Lee, J.H.; Kim, T.M.; Choi, I.G.; Choi, J.W. Phenolic Hydroxyl Groups in the Lignin Polymer Affect the Formation of Lignin Nanoparticles. Nanomaterials 2021, 11, 1790. [Google Scholar] [CrossRef] [PubMed]

- Lai, Y.Z. Determination of Phenolic Hydroxyl Groups. In Methods in Lignin Chemistry; Lin, S.Y., Dence, C.W., Eds.; Springer: Berlin/Heidelberg, Germany, 1992; pp. 423–434. ISBN 978-3-642-74065-7. [Google Scholar]

- Kenny, J.K.; Medlin, J.W.; Beckham, G.T. Quantification of Phenolic Hydroxyl Groups in Lignin via 19F NMR Spectroscopy. ACS Sustain. Chem. Eng. 2023, 11, 5644–5655. [Google Scholar] [CrossRef]

- Liitiä, T.; Tamminen, T. Direct Method for the Determination of Phenolic Hydroxyl Groups in Pulp. Holzforschung 2007, 61, 623–627. [Google Scholar] [CrossRef]

- Gioia, C.; Colonna, M.; Tagami, A.; Medina, L.; Sevastyanova, O.; Berglund, L.A.; Lawoko, M. Lignin-Based Epoxy Resins: Unravelling the Relationship between Structure and Material Properties. Biomacromolecules 2020, 21, 1920–1928. [Google Scholar] [CrossRef] [PubMed]

- Gadhave, R.V.; Srivastava, S.; Mahanwar, P.A.; Gadekar, P.T.; Gadhave, R.V.; Srivastava, S.; Mahanwar, P.A.; Gadekar, P.T. Lignin: Renewable Raw Material for Adhesive. Open J. Polym. Chem. 2019, 9, 27–38. [Google Scholar] [CrossRef]

- Li, X.; Meng, Y.; Cheng, Z.; Li, B. Research Progress and Prospect of Stimuli-Responsive Lignin Functional Materials. Polymers 2023, 15, 3372. [Google Scholar] [CrossRef] [PubMed]

- Bostan, L.; Hosseinaei, O.; Fourné, R.; Herrmann, A.S. Upscaling of Lignin Precursor Melt Spinning by Bicomponent Spinning and Its Use for Carbon Fibre Production. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2021, 379, 20200334. [Google Scholar] [CrossRef] [PubMed]

- Svensson, I.; Roncal, T.; De Winter, K.; Van Canneyt, A.; Tamminen, T.; Mikkelson, A.; Barrio, A. Valorisation of hydrolysis lignin rest from bioethanol pilot plant: Process development and upscaling. Ind. Crops Prod. 2020, 156, 112869. [Google Scholar] [CrossRef]

- Sewring, T.; Durruty, J.; Schneider, L.; Schneider, H.; Mattsson, T.; Theliander, H. Acid Precipitation of Kraft Lignin from Aqueous Solutions: The Influence of PH, Temperature, and Xylan. J. Wood Chem. Technol. 2019, 39, 1–13. [Google Scholar] [CrossRef]

- Adamcyk, J.; Serna-loaiza, S.; Beisl, S.; Miltner, M.; Friedl, A. Influence of Temperature and Lignin Concentration on Formation of Colloidal Lignin Particles in Solvent-Shifting Precipitation. Sustainability 2022, 14, 1219. [Google Scholar] [CrossRef]

- Posoknistakul, P.; Tangkrakul, C.; Chaosuanphae, P.; Deepentham, S.; Techasawong, W.; Phonphirunrot, N.; Bairak, S.; Sakdaronnarong, C.; Laosiripojana, N. Fabrication and Characterization of Lignin Particles and Their Ultraviolet Protection Ability in PVA Composite Film. ACS Omega 2020, 5, 20976–20982. [Google Scholar] [CrossRef] [PubMed]

- Priyanto, S.; Intan, A.P.; Rianto, B.; Kusworo, T.D.; Pramudono, B.; Untoro, E.; Ratu, P. The Effect of Acid Concentration (H2SO4) on the Yield and Functional Group during Lignin Isolation of Biomass Waste Pulp and Paper Industry. Reaktor 2019, 19, 162–167. [Google Scholar] [CrossRef]

- Sun, R.; Tomkinson, J.; Bolton, J. Effects of Precipitation PH on the Physico-Chemical Properties of the Lignins Isolated from the Black Liquor of Oil Palm Empty Fruit Bunch Fibre Pulping. Polym. Degrad. Stab. 1999, 63, 195–200. [Google Scholar] [CrossRef]

- Zhu, W. Equilibrium of Lignin Precipitation the Effects of PH, Temperature, Ion Strength and Wood Origins. Master’s Thesis, Forest Products and Chemical Engineering, Gothenburg, Sweden, 2013. [Google Scholar]

- Hu, G.; Hu, J.; Chen, H.; Song, S.; Chu, F. Influence of PH and Ionic Strength on the Aggregation Behaviors of Xylan Rich Hemicelluloses with Alkaline Lignins. Bioresources 2021, 16, 7608–7622. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).