Effect of High-Intensity Microwave Treatment on Structural and Chemical Characteristics of Chinese Fir

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

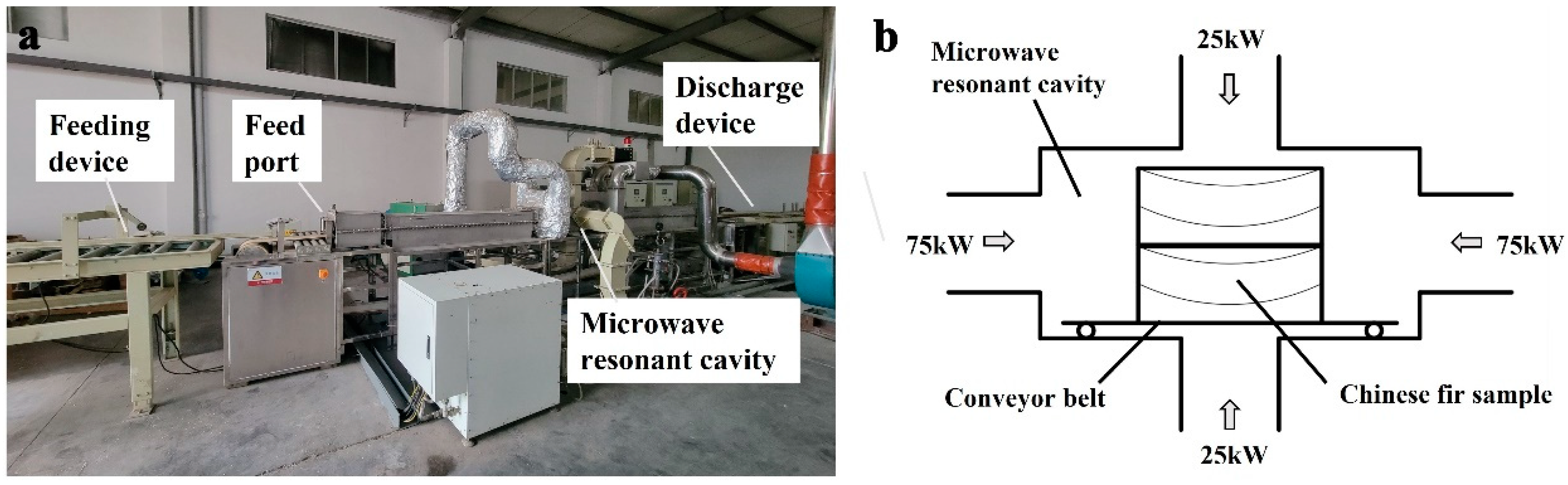

2.2. High-Intensity Microwave (HIMW) Treatment

2.3. Macroscopic Observation

2.4. Optical Microscope Observation

2.5. Scanning Electron Microscope (SEM) Observation

2.6. Transmission Electron Microscope (TEM) Observation

2.7. Fourier-Transform Infrared Spectroscopy (FTIR) Analyzing

2.8. X-ray Diffraction (XRD)

3. Results and Discussion

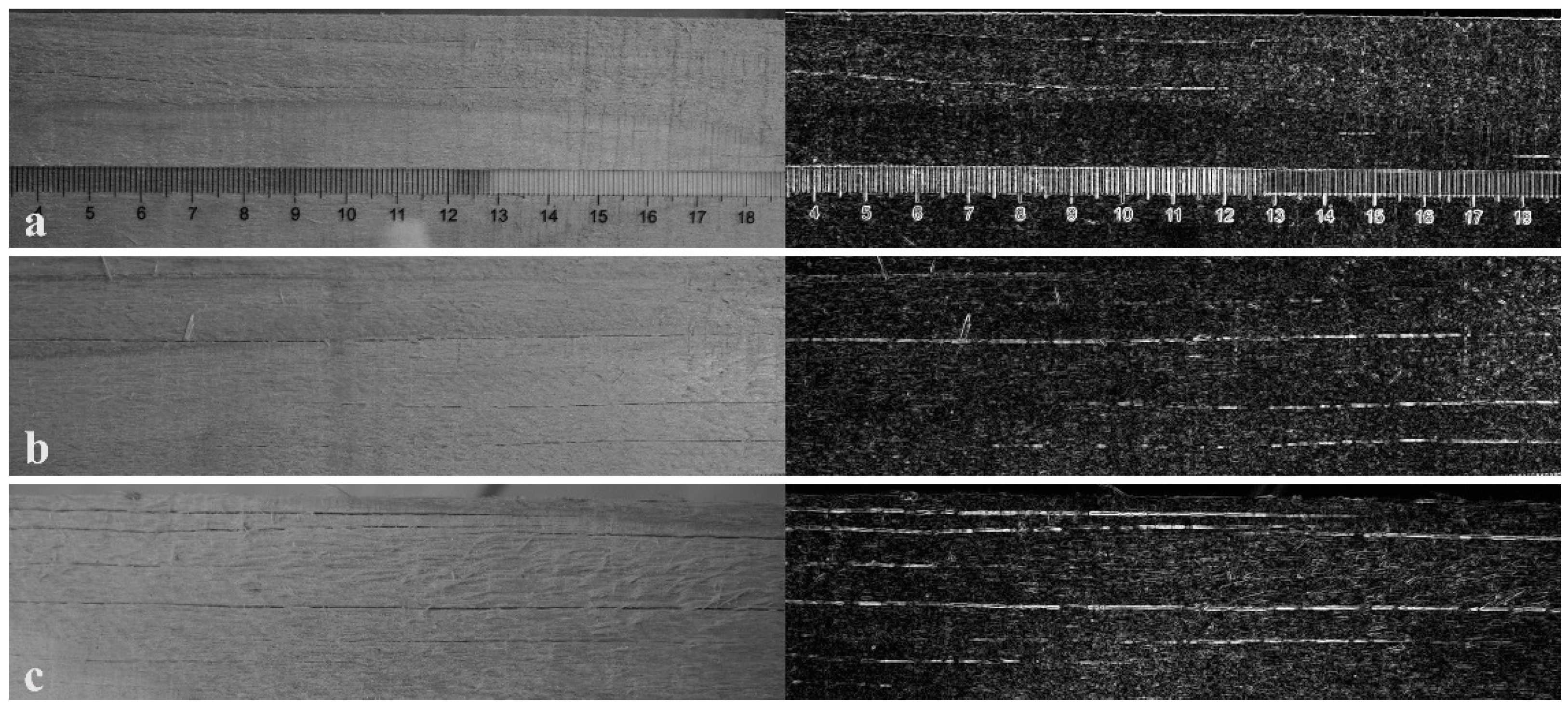

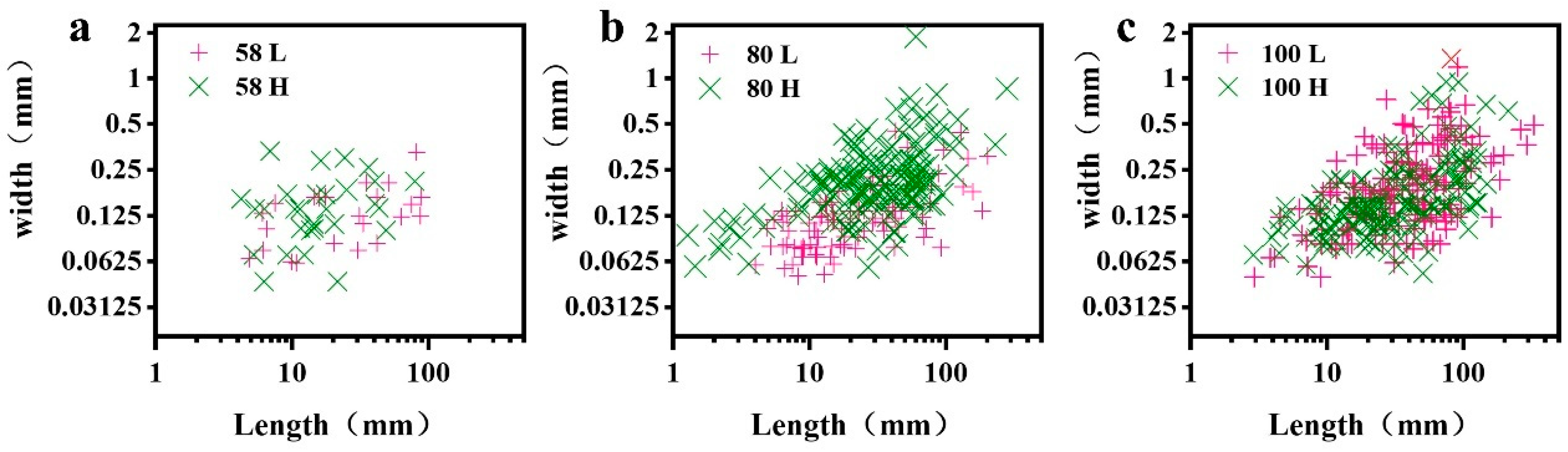

3.1. Macroscopic Surface Cracks Analysis

3.2. Damage in Cell Wall Analysis

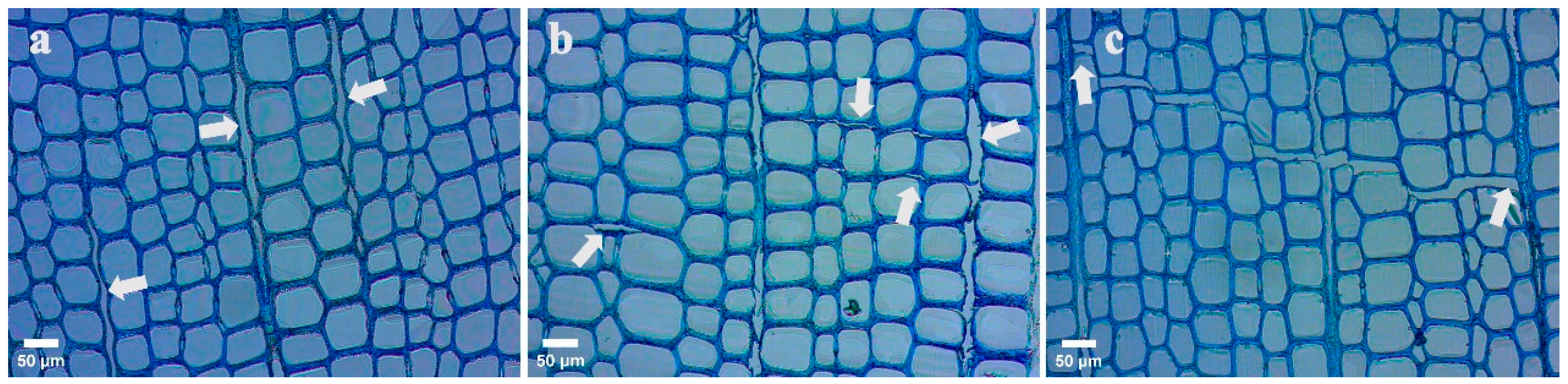

3.2.1. Optical Microscope Analysis

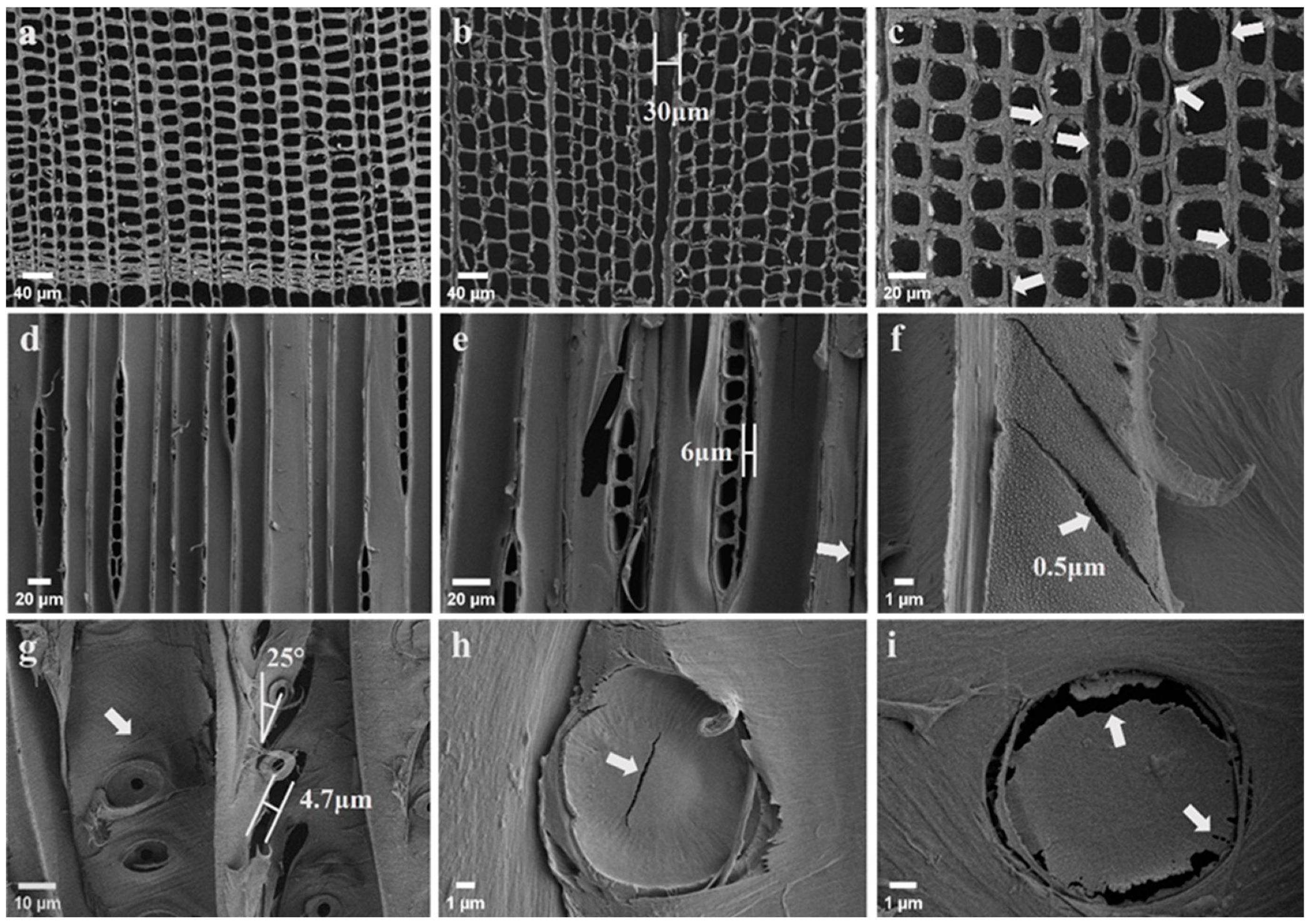

3.2.2. SEM Analysis

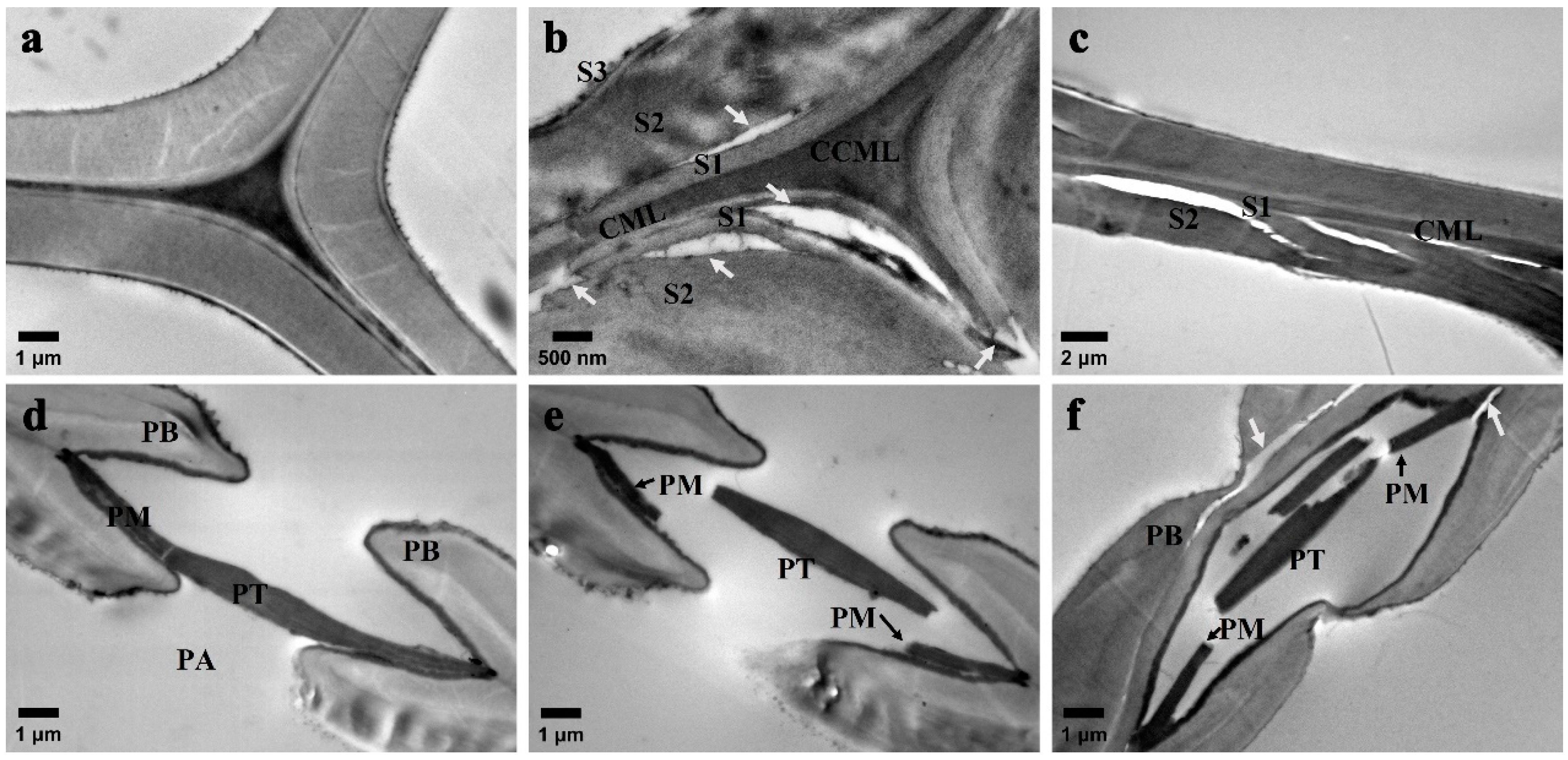

3.2.3. TEM Analysis

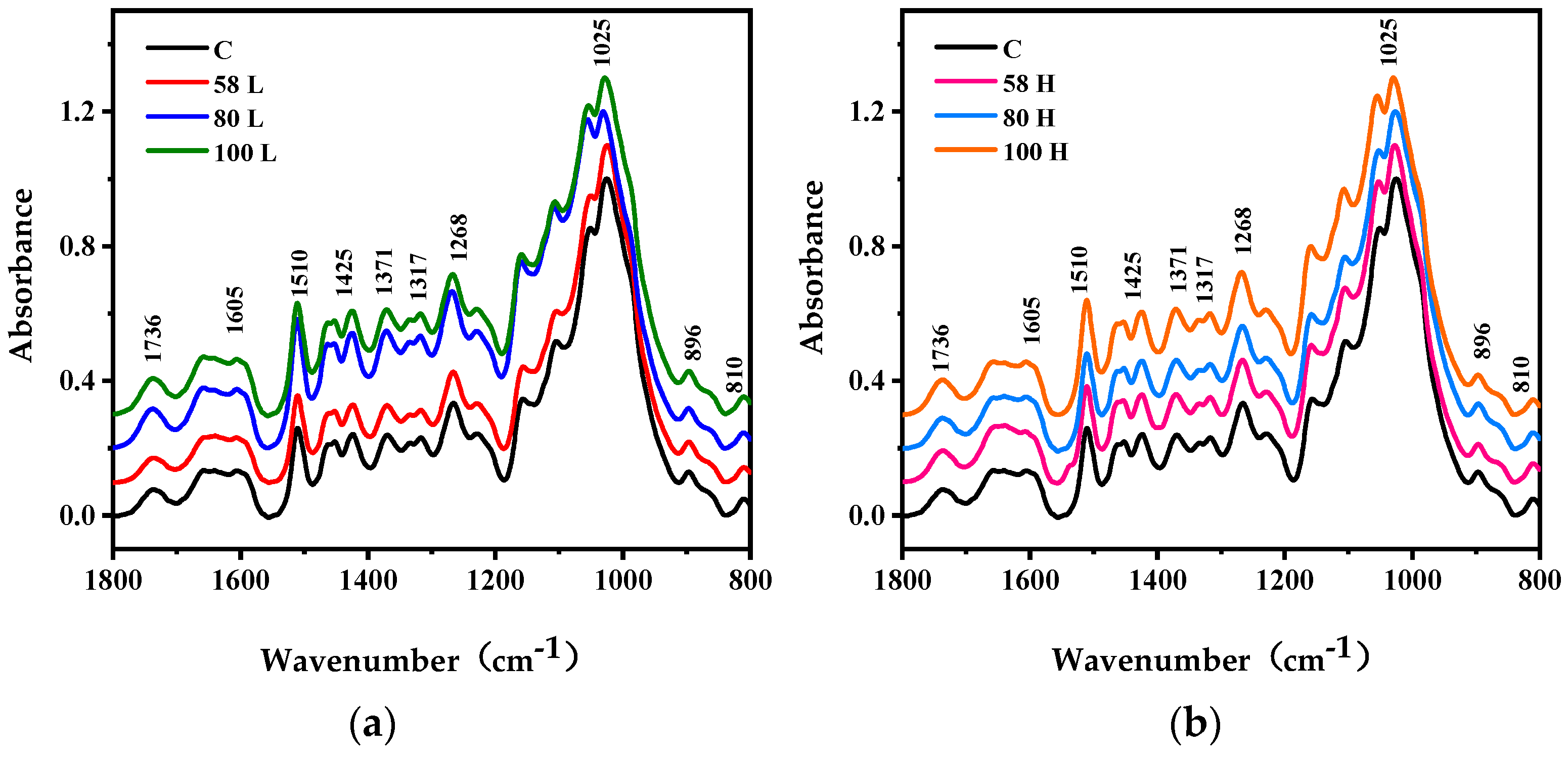

3.3. FTIR Spectroscopy Analysis

3.4. Cellulose Crystalline Structure Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ganguly, S.; Hom, S.K.; Tripathi, S.; Ghosh, S.; Kanyal, R.; Samani, A. Quantitative evaluation of microwave irradiation on short-rotation plantation wood species. Maderas-Cienc. Tecnol. 2021, 23, 1–14. [Google Scholar] [CrossRef]

- Yu, X.Y.; Wei, N.F.; Liu, Q.S.; Wu, Z.Y.; Fan, M.Z.; Zhao, W.G.; Zeng, Q.Z. Study on microwave pretreatment technology to improve theeffect of shellac impregnation of fast-growing Chinese Fir. J. Renew. Mater. 2022, 8, 2041–2053. [Google Scholar] [CrossRef]

- Okon, K.E.; Lin, F.C.; Lin, X.; Chen, C.X.; Chen, Y.D.; Huang, B. Modification of Chinese fir (Cunninghamia lanceolata L.) wood by silicone oil heat treatment with micro-wave pretreatment. Eur. J. Wood Wood Prod. 2017, 76, 221–228. [Google Scholar] [CrossRef]

- Petty, J.A. Permeability and structure of the wood of Sitka spruce. Proc. R. Lond. 1970, 175, 149–166. [Google Scholar]

- Hansmann, C.; Gindl, W.; Wimmer, R.; Teischinger, A. Permeability of wood—A Review. Wood Res. 2002, 47, 1–16. [Google Scholar]

- Wardrop, A.B.; Davies, G.W. Morphological factors relating to the penetration of liquids into wood. Holzforschung 1961, 15, 129–141. [Google Scholar] [CrossRef]

- Bailey, P.J.; Preston, R.D. Some aspects of softwood permeability I. Structural studies with Douglas fir sapwood and heartwood. Holzforschung 1969, 23, 113–120. [Google Scholar] [CrossRef]

- Palin, M.A.; Petty, J.A. Permeability to water of the cell wall material of spruce heartwood. Wood Sci. Technol. 1981, 15, 161–166. [Google Scholar] [CrossRef]

- Torgovnikov, G.; Vinden, P. High-intensity microwave wood modification for increasing permeability. For. Prod. J. 2009, 59, 84–92. [Google Scholar]

- Torgovnikov, G.; Vinden, P. Microwave method for increasing the permeability of wood and its applications. For. Prod. J. 2010, 60, 303–311. [Google Scholar]

- Fan, Z.Q.; Peng, L.M.; Liu, M.H.; Feng, Y.; He, J.R.; Wu, S.Q. Analysis of influencing factors on sound absorption capacity in microwave-treated Pinus radiata wood. Eur. J. Wood Wood Prod. 2022, 80, 985–995. [Google Scholar] [CrossRef]

- Hermoso, E.; Vega, A. Effect of microwave treatment on the impregnability and mechanical properties of Eucalyptus globulus wood. Maderas-Cienc. Tecnol. 2016, 18, 55–64. [Google Scholar] [CrossRef]

- Zhang, J.X.; Luo, Y.F.; Liao, C.R.; Xiong, F.; Li, X.; Sun, L.L.; Li, X.J. Theoretical investigation of temperature distribution uniformity in wood during microwave drying in three-port feeding circular resonant cavity. Dry. Technol. 2017, 35, 409–416. [Google Scholar] [CrossRef]

- Weng, X. Study on the Influence Mechanism of Microwave Treatment on Drying Characteristics of Chinese Fir Wood. Ph.D. Thesis, Research Institute of Wood Industry, Chinese Academy of Forestry, Beijing, China, 2020. [Google Scholar]

- Mascarenhas, F.J.R.; Dias, A.M.P.G.; Christoforo, A.L. State of the art of microwave treatment of wood: Literature review. Forests 2021, 12, 745. [Google Scholar] [CrossRef]

- He, S.; Yu, H.; Wu, Z.X.; Chen, Y.H.; Fu, F. Effect of microwave treatment on liquid impregnate property of Pinus Sylvestris, L. var Lumber. J. Microw. 2016, 32, 90–96. [Google Scholar]

- Zhang, Y.L.; Jia, K.; Cai, L.P.; Shi, S.Q. Acceleration of moisture migration in Larch wood through microwave pre-treatments. Dry. Technol. 2013, 31, 666–671. [Google Scholar] [CrossRef]

- Xing, X.F.; Li, S.M.; Jin, J.W.; Lin, L.Y.; Zhou, Y.D.; Peng, L.M.; Fu, F. Improving gas permeability and characterizing the multi-scale pore size distribution of radiata pine (Pinus radiata D. Don) treated via high-intensity microwave. Wood Sci. Technol. 2023, 57, 1345–1367. [Google Scholar] [CrossRef]

- Terashima, N.; Fukushima, K.; He, L.F.; Takabe, K. Comprehensive model of the lignified plant cell wall. In Forage Cell Wall Structure and Digestibility; American Society of Agronomy, Inc.: Madison, WI, USA, 1993; pp. 247–270. [Google Scholar]

- Salmén, L.; Burgret, I. Cell wall features with regard to mechanical performance. A review COST Action E35 2004-2008: Wood machining-micromechanics and fracture. Holzforschung 2009, 63, 121–129. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1962, 29, 786–794. [Google Scholar] [CrossRef]

- Nishiyama, Y.; Kuga, S.; Okano, T. Mechanism of mercerization revealed by X-ray diffraction. J. Wood Sci. 2000, 46, 452–457. [Google Scholar] [CrossRef]

- Saporiti, J. Effect of microwave treatment on oak compression strength. Silva Lusit. 2006, 14, 51–58. [Google Scholar]

- Kol, H.S.; Çayır, B. The effects of increasing preservative uptake by microwave pre-treatment on the microstructure and mechanical properties of Oriental spruce. Wood Mater. Sci. Eng. 2023, 18, 732–738. [Google Scholar] [CrossRef]

- Li, Z.; Zhan, T.; Eder, M.; Jiang, J.; Lyu, J.; Cao, J. Comparative studies on wood structure and microtensile properties between compression and opposite wood fibers of Chinese fir plantation. J. Wood Sci. 2021, 67, 12–18. [Google Scholar] [CrossRef]

- Muzamal, M. Structural Modifications in Spruce Wood during Steam Explosion Pretreatment. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Tong, Y.P.; Zhao, G.J. Structure of bordered pit membrane of Cunninghamia lanceolata tracheid. Sci. Silvae Sin. 2007, 43, 151–153. [Google Scholar]

- Bao, F.C.; Lyu, J.X.; Zhao, Y.K. Effect of different positions of bordered pit torus in Yezo Spruce on its permeability. Acta Bot. Sin. 2001, 43, 119–126. [Google Scholar]

- Booker, R.E.; Sell, J. The nanostructure of the cell wall of softwoods and its functions in living tree. Holz Roh Werkst. 1998, 56, 1–8. [Google Scholar] [CrossRef]

- Zhai, C.K.; Teng, N.; Pan, B.H.; Chen, J.; Liu, F.; Zhu, J.; Na, H.N. Revealing the importance of non-thermal effect to strengthen hydrolysis of cellulose by synchronous cooling assisted microwave driving. Carbohydr. Polym. 2018, 197, 414–421. [Google Scholar] [CrossRef] [PubMed]

- Bichot, A.; Lerosty, M.; Radoiu, M.; Méchin, V.; Bernet, N.; Delgenès, J.-P.; García-Bernet, D. Decoupling thermal and non-thermal effects of the microwaves for lignocellulosic biomass pretreatment. Energy Convers. Manag. 2020, 203, 112220. [Google Scholar] [CrossRef]

- Fackler, K.; Stevanic, J.S.; Ters, T.; Hinterstoisser, B.; Schwanninger, M.; Salmén, L. FTIR imaging microscopy to localise and characterise simultaneous and selective white-rot decay within spruce wood cells. Holzforschung 2011, 65, 411–420. [Google Scholar] [CrossRef]

- Temiz, A.; Terziev, N.; Jacobsen, B.; Eikenes, M. Weathering, water absorption and durability of silicon, acetylated and heat-treated wood. J. Appl. Polym. Sci. 2006, 102, 4506–4513. [Google Scholar] [CrossRef]

- Popescu, C.M.; Singurel, G.; Popescu, M.C.; Vasile, C.; Argyropoulos, D.S.; Willfor, S. Vibrational spectroscopy and X-ray diffraction methods to establish the differences between hardwood and softwood. Carbohydr. Polym. 2009, 77, 851–857. [Google Scholar] [CrossRef]

- Lionetto, F.; Sole, R.D.; Cannoletta, D.; Vasapollo, G.; Maffezzoli, A. Monitoring wood degradation during weathering by cellulose crystallinity. Materials 2012, 5, 1910–1922. [Google Scholar] [CrossRef]

- Huang, X.N.; Kocaefe, D.; Kocaefe, Y.; Boluk, Y.; Krause, C. Structural analysis of heat-treated birch (Betule papyrifera) surface during artificial weathering. Appl. Surf. Sci. 2013, 264, 117–127. [Google Scholar] [CrossRef]

- Carrillo, F.; Colom, X.; Sunol, J.; Saurina, J. Structural FTIR analysis and thermal characterisation of lyocell and viscose-type fibres. Eur. Polym. J. 2004, 40, 2229–2234. [Google Scholar] [CrossRef]

- Li, M.Y.; Cheng, S.C.; Li, D.; Wang, S.N.; Huang, A.M.; Sun, S.Q. Structural characterization of steam-heat treated Tectona grandis wood analyzed by FT-IR and 2D-IR correlation spectroscopy. Chin. Chem. Lett. 2015, 26, 221–225. [Google Scholar] [CrossRef]

- Guo, J.; Song, K.L.; Salmén, L.; Yin, Y.F. Changes of wood cell walls in response to hygro-mechanical steam treatment. Carbohydr. Polym. 2015, 115, 207–214. [Google Scholar] [CrossRef]

- Tarmian, A.; Mastouri, A. Changes in moisture exclusion efficiency and crystallinity of thermally modified wood with aging. iFor.-Biogeosci. For. 2019, 12, 92–97. [Google Scholar] [CrossRef]

- Dwianto, W.; Tanaka, F.; Inoue, M.; Norimoto, M. Crystallinity changes of wood by heat or steam treatment. Wood Res. 1996, 83, 47–49. [Google Scholar]

- Tribulová, T.; Kačík, F.; Evtuguin, D.V.; Čabalová, I.; Ďurkovič, J. The effects of transition metal sulfates on cellulose crystallinity during accelerated ageing of silver fir wood. Cellulose 2019, 26, 2625–2638. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Inagaki, T.; Siesler, H.W.; Mitsui, K.; Tsuchikawa, S. Difference of the crystal structure of cellulose in wood after hydrothermal and aging degradation: A NIR spectroscopy and XRD study. Biomacromolecules 2010, 11, 2300–2305. [Google Scholar] [CrossRef] [PubMed]

- Rayirath, P.; Avramidis, S.; Mansfield, S.D. The effect of wood drying on crystallinity and microfibril angle in black spruce (Picea mariana). J. Wood Chem. Technol. 2008, 28, 167–179. [Google Scholar] [CrossRef]

- Bhuiyan, M.T.R.; Hirai, N.; Sobue, N. Changes of crystallinity in wood cellulose by heat treatment under dried and moist conditions. J. Wood Sci. 2000, 46, 431–436. [Google Scholar] [CrossRef]

- Guo, J.; Rennhofer, H.; Yin, Y.F.; Lichtenegger, H.C. The influence of thermo-hygro-mechanical treatment on the micro- and nanoscale architecture of wood cell walls using small- and wide-angle X-ray scattering. Cellulose 2016, 23, 2325–2340. [Google Scholar] [CrossRef]

- Xing, D.; Li, J.; Wang, X.Z.; Wang, S.Q. In situ measurement of heat-treated wood cell wall at elevated temperature by nanoindentation. Ind. Crops Prod. 2016, 87, 142–149. [Google Scholar] [CrossRef]

| Input Power (kW) | Reflected Power (kW) | Absorbed Power (kW) | Effective MW Energy Density (kWh/m3) |

|---|---|---|---|

| 60 | 17.9 | 42.1 | 58 |

| 80 | 22.28 | 57.72 | 80 |

| 100 | 27.81 | 72.19 | 100 |

| Samples | Width/mm | Length/mm | Length Proportion of Totality/% | Width Proportion of Totality/% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Below 10 mm | 10–40 mm | 40–80 mm | Above 80 mm | Below 0.1 mm | 0.1–0.2 mm | 0.2–0.4 mm | Above 0.4 mm | |||

| 58 L | 0.123 ± 0.056 | 28.69 ± 23.09 | 28.9 | 44.4 | 20.0 | 6.7 | 42.2 | 55.6 | 2.2 | 0 |

| 58 H | 0.150 ± 0.073 | 20.28 ± 16.84 | 27.6 | 57.2 | 17.2 | 0 | 17.2 | 62.1 | 20.7 | 0 |

| 80 L | 0.130 ± 0.067 | 31.82 ± 34.43 | 24.7 | 49.5 | 17.9 | 7.9 | 34.7 | 52.6 | 11.6 | 1.1 |

| 80 H | 0.245 ± 0.191 | 40.55 ± 35.85 | 11.5 | 46.5 | 45.8 | 7.7 | 7.7 | 36.8 | 44.5 | 11 |

| 100 L | 0.240 ± 0.194 | 49.27 ± 46.37 | 9.3 | 43.5 | 32.3 | 14.9 | 15.5 | 38.8 | 32 | 13.7 |

| 100 H | 0.199 ± 0.171 | 44.30 ± 37.18 | 12.8 | 47.7 | 25.6 | 13.9 | 15.1 | 52.9 | 24.4 | 7.6 |

| Assignment | FTIR Peak (cm−1) | Functional Group |

|---|---|---|

| Hemicellulose | 810 | Glucomannan in softwood |

| Cellulose | 896 | C−H bending and asymmetric out-of-plane ring stretching |

| Lignin | 1268 | C−O stretching vibrations of the methyl and phenyl propane units |

| Cellulose | 1317 | CH2 wagging |

| Cellulose | 1371 | C−H bending vibrations in polysaccharides |

| Cellulose | 1425 | C=C aromatic skeleton vibration and CH2 bending vibration |

| Lignin | 1510 | C=C stretching of the aromatic ring |

| Lignin | 1605 | C=O stretching vibration and C=C aromatic ring vibration |

| Hemicellulose and xylan | 1736 | C=O stretching of acetyl or carboxylic acid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, X.; Fang, X.; Gao, X.; Yi, S.; Zhou, Y. Effect of High-Intensity Microwave Treatment on Structural and Chemical Characteristics of Chinese Fir. Forests 2024, 15, 516. https://doi.org/10.3390/f15030516

Liao X, Fang X, Gao X, Yi S, Zhou Y. Effect of High-Intensity Microwave Treatment on Structural and Chemical Characteristics of Chinese Fir. Forests. 2024; 15(3):516. https://doi.org/10.3390/f15030516

Chicago/Turabian StyleLiao, Xiaomei, Xuan Fang, Xin Gao, Songlin Yi, and Yongdong Zhou. 2024. "Effect of High-Intensity Microwave Treatment on Structural and Chemical Characteristics of Chinese Fir" Forests 15, no. 3: 516. https://doi.org/10.3390/f15030516

APA StyleLiao, X., Fang, X., Gao, X., Yi, S., & Zhou, Y. (2024). Effect of High-Intensity Microwave Treatment on Structural and Chemical Characteristics of Chinese Fir. Forests, 15(3), 516. https://doi.org/10.3390/f15030516