Optimization of Molding Process Parameters of Caragana korshinskii Kom. Based on Box-Behnken Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

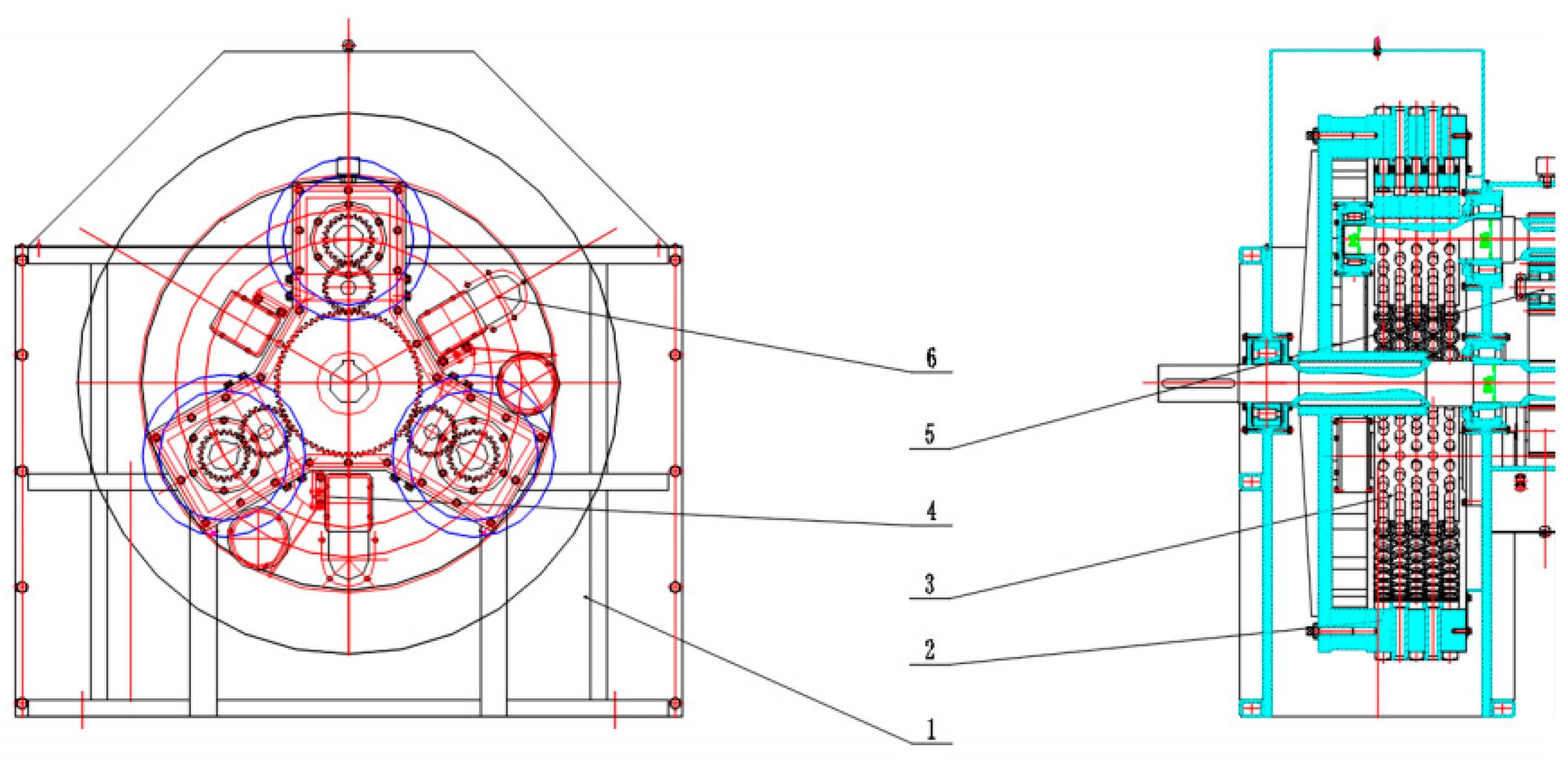

2.2. Experimental Equipment and Instruments

2.3. Experimental Methods

2.3.1. Control of the Length-to-Diameter Ratio of the Forming Mold

2.3.2. Control of Moisture Content

2.3.3. Control of Rotation Speed

2.4. Experimental Index

2.4.1. Relaxation Density of Pellets

- ρ—relaxation density of the formed pellets, in g/cm3;

- m—average mass of the formed pellets, in g;

- d—average diameter of the formed pellets, in mm;

- L—average length of the formed pellets, in mm.

2.4.2. Productivity

- Q—productivity, in kg/h;

- M—mass of the collected sample, in kg;

- H—moisture content of the formed pellets, in %;

- T—time taken to collect the sample, in seconds.

2.4.3. Energy Consumption

- W—energy consumption per ton of the pelletizer, in kW·h/t;

- P—average power consumption during the operation of the pelletizer, in kW;

- Q—productivity, in kg/h.

2.4.4. Mechanical Durability

- D—mechanical durability, in %;

- m″—mass of the pellet lumps whose sizes are not less than 3.5 mm after the test, in kg;

- m′—total mass of the formed pellets before the test, in kg.

2.5. Experimental Design

3. Results

3.1. Experimental Results

3.2. Regression Equation for the Relaxation Density of Formed Particles

3.3. Regression Equation for the Productivity of the Pelletizer

4. Discussion

4.1. The Primary and Secondary Effects of the Experimental Factors on the Experimental Response Variables

4.2. The Impact of Interactions Between Experimental Response Variables

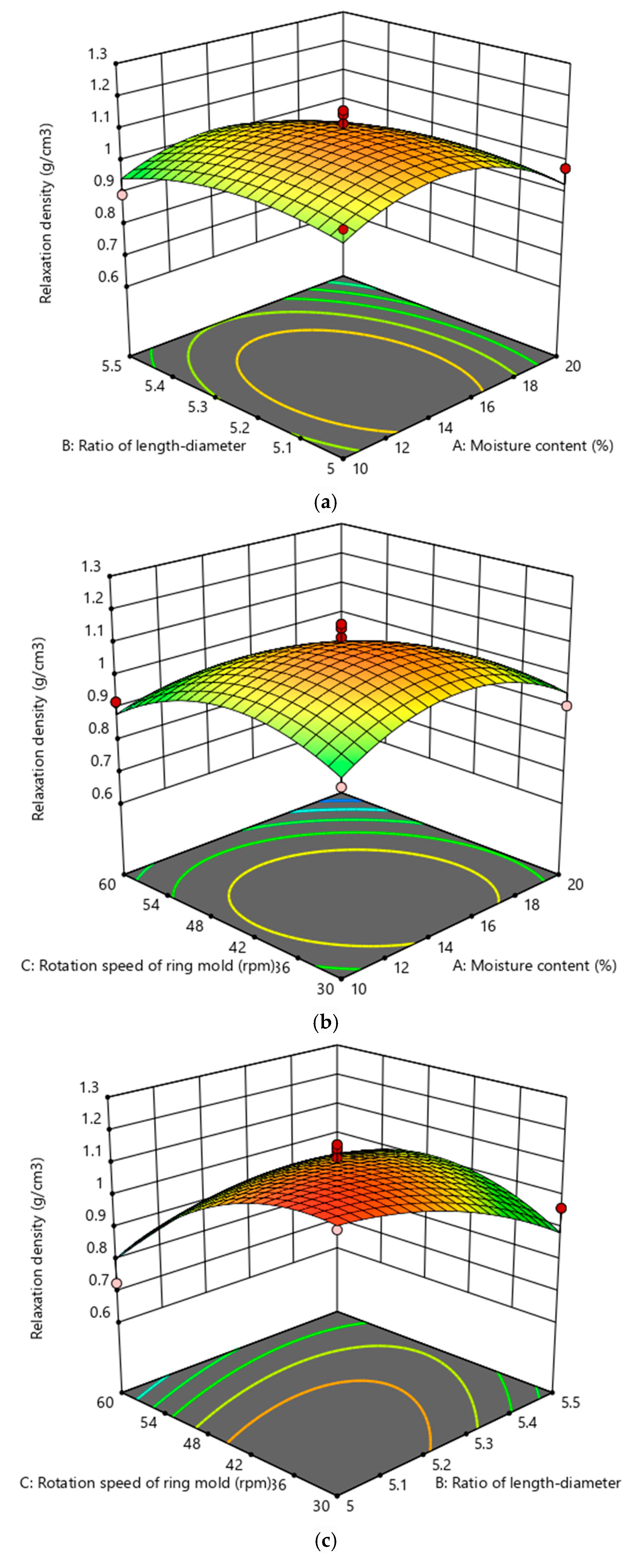

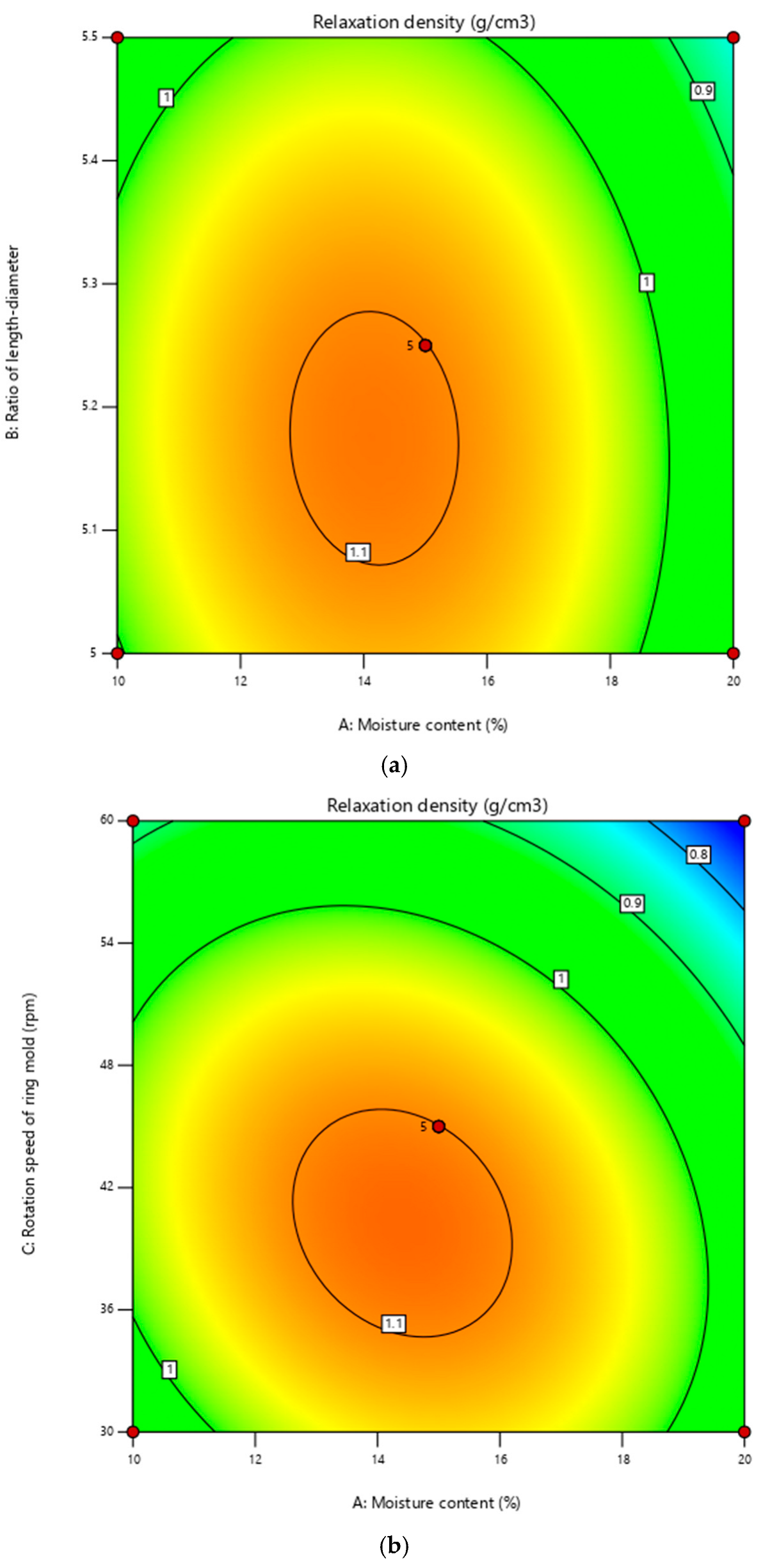

4.2.1. The Influence of Experimental Factors on the Relaxation Density

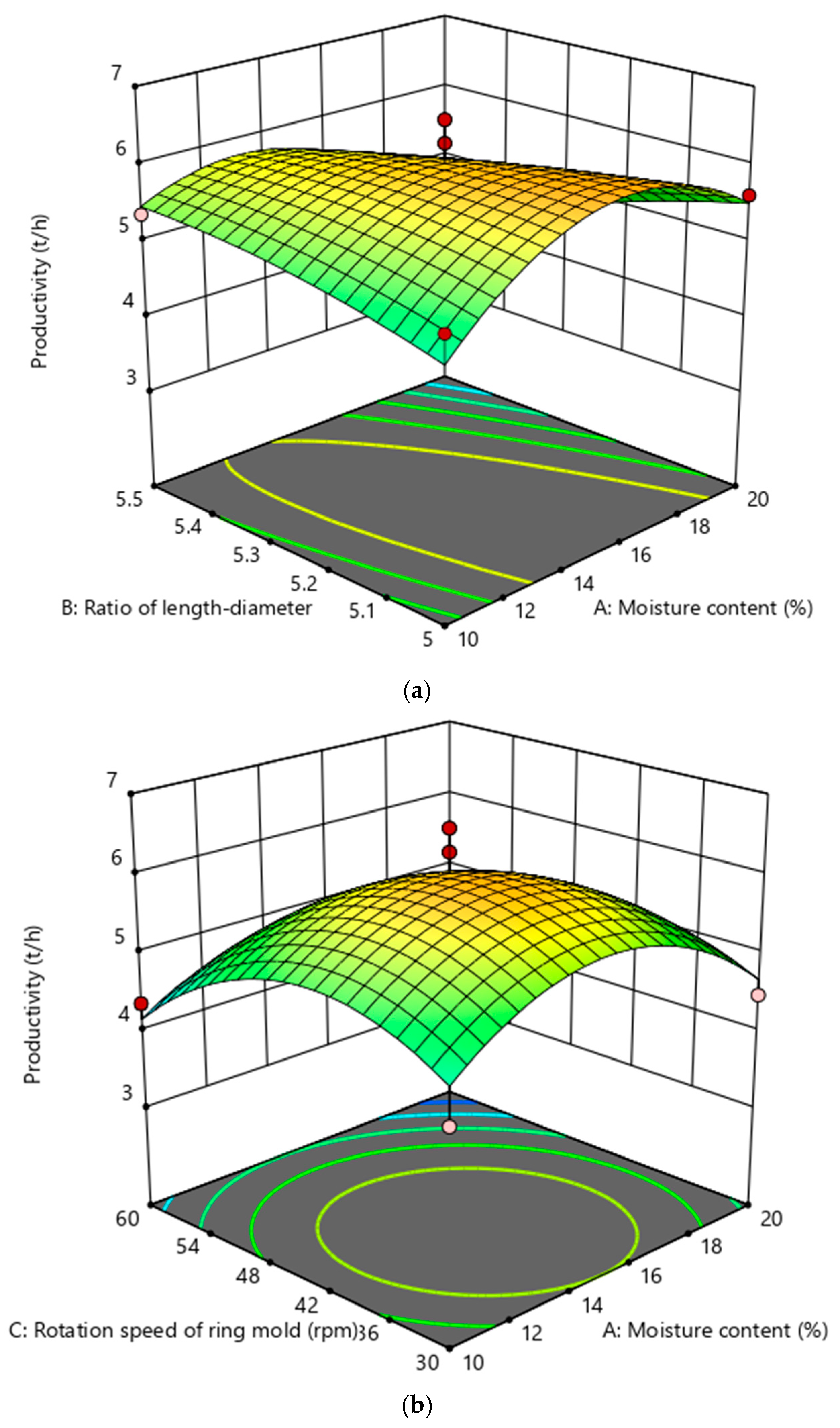

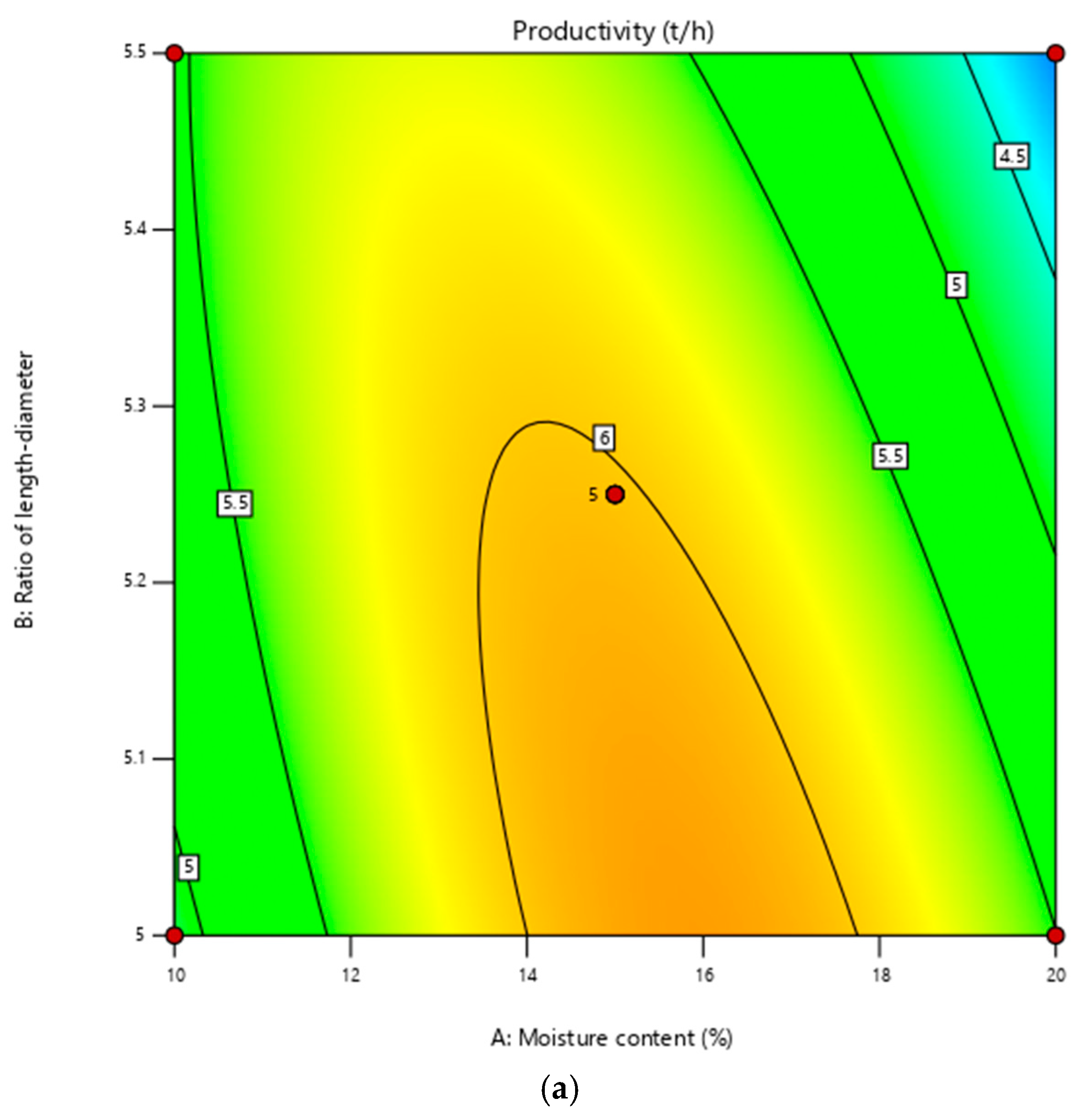

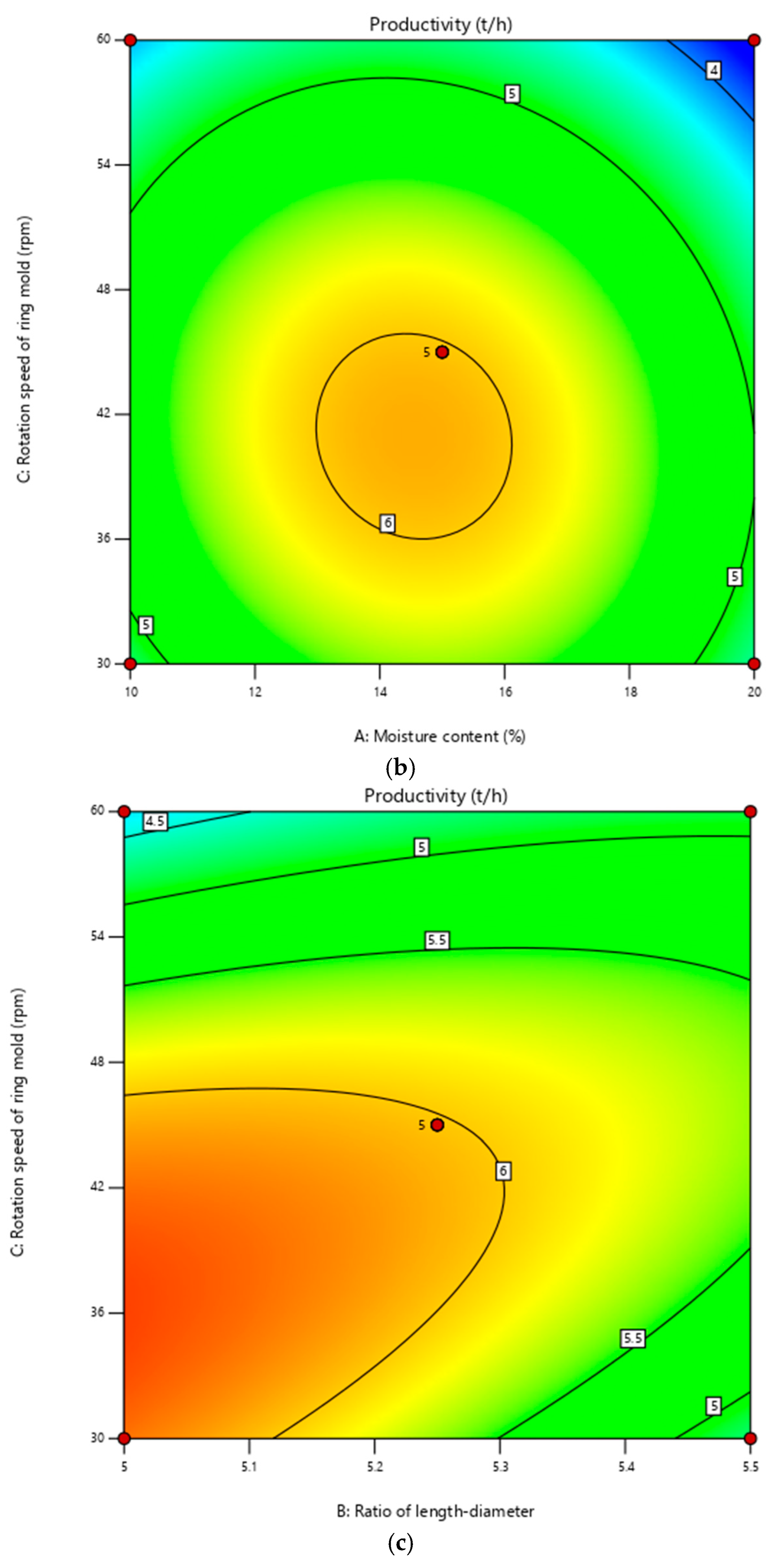

4.2.2. The Influence of Experimental Factors on Productivity

4.3. Optimization of the Pelletizing Process Parameters

4.4. Experimental Verification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bapat, D.W.; Kulkarni, S.V.; Bhandarkar, V.P. Design and operating experience on fluidized bed boiler burning biomass fuels with high alkali ash. In Proceedings of the 14th International Conference on Fluidized Bed Combustion, Vancouver, BC, Canada, 11–16 May 1997. [Google Scholar]

- Huang, H.; Gao, Y.; Chen, H.; Wu, Y.; Wang, J.; Yu, C.; Li, J.; Zou, C. Biomass briquette fuel, boiler types and pollutant emissions of industrial biomass boiler: A review. Particuology 2023, 77, 79–90. [Google Scholar] [CrossRef]

- Wei, W.; Zhao, R.; Feng, M.; Li, L.N.; Zhang, S.B. The development of biomass solid moulding fuel, craft and performance analysis. Wood Process. Mach. 2012, 6, 44–46. [Google Scholar]

- Xianmiao, L.; Zhijia, L.; Benhua, F.; Zhiyong, C.; Zheui, J.; Xinge, L. Comparative Properties of Bamboo and Rice Straw Pellets. Bioresources 2013, 8, 638–647. [Google Scholar]

- Eranki, P.L.; Bals, B.D.; Dale, B.E. Advanced regional biomass processing depots: A key to the logistical challenges of the cellulosic biofuel industry. Biofuels Bioprod. Biorefin. 2011, 5, 621–630. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Kenney, K.L. A technical review on biomass processing: Densification, pre-processing, modelling, and optimization. In Proceedings of the 2010 ASABE Annual International Meeting, Pittsburgh, PA, USA, 29 July–1 August 2010. [Google Scholar]

- Kažimírová, V.; Kubík, L.; Mihina, Š.E. Valuation of properties of pellets made of swine manure. Acta Technol. Agric. 2020, 23, 137–143. [Google Scholar]

- Zheng, Q.; Li, Z.; Watanabe, M. Production of solid fuels by hydrothermal treatment of wastes of biomass, plastic, and biomass/plastic mixtures: A review. J. Bioresour. Bioprod. 2022, 7, 221–244. [Google Scholar] [CrossRef]

- Spirchez, C.; Lunguleasa, A.; Gaceu, L. Researches on grape husk waste obtained from the winery and its use as pellets for combustion. Wood Res. 2019, 64, 549–556. [Google Scholar]

- García, R.; Gil, M.V.; Rubiera, F.; Pevida, C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel 2019, 251, 739–753. [Google Scholar] [CrossRef]

- Tabakaev, R.; Kahn, V.; Dubinin, Y.; Rudmin, M.; Yazykov, N.; Skugarov, A.; Alekseenko, E.; Zavorin, A.; Preis, S. High-strength fuel pellets made of flour milling and coal slack wastes. Energy 2022, 243, 123071. [Google Scholar] [CrossRef]

- Solís, A.; Rocha, S.; König, M.; Adam, R.; Garcés, H.O.; Candia, O.; Muñoz, R.; Azócar, L. Preliminary assessment of hazelnut shell biomass as a raw material for pellet production. Fuel 2023, 333, 126517. [Google Scholar] [CrossRef]

- He, H.; Wang, Y.; Sun, W.; Sun, Y.; Wu, K. Effects of different biomass feedstocks on the pelleting process and pellet qualities. Sustain. Energy Technol. Assess. 2024, 69, 103912. [Google Scholar] [CrossRef]

- Long, Y.; Liang, F.; Zhang, J.; Xue, M.; Zhang, T.; Pei, X. Identification of drought response genes by digital gene expression (DGE) analysis in Caragana korshinskii Kom. Gene 2020, 725, 144170. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Wang, Z.; Li, Y.; He, J.; Wu, X. Dynamic growth models for Caragana korshinskii shrub biomass in china. J. Environ. Manag. 2020, 269, 110675. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Y.; Kang, F.; Kan, J. Multi-objective optimization of cross-section integrity rate and sawing power consumption in sawing Caragana korshinskii Kom. branches. Ind. Crop. Prod. 2023, 193, 116244. [Google Scholar] [CrossRef]

- Li, W.; Zhang, S.; Zhang, T.; Shen, Y.; Han, L.; Peng, Z.; Xie, Z.; Zhong, C.; Jia, S. Bacterial cellulose production from ethylenediamine pretreated Caragana korshinskii kom. Ind. Crop. Prod. 2021, 164, 700–711. [Google Scholar] [CrossRef]

- Ren, P.H. Study on Forming Mechanism and Equipment of Caranaga korshinskii. Master’s Dissertation, Shanxi Agriculture University, Jinzhong, China, 2014. [Google Scholar]

- Zhang, J.; Guo, Y. Physical properties of solid fuel briquettes made from Caragana korshinskii Kom. Powder Technol. 2014, 256, 293–299. [Google Scholar] [CrossRef]

- Xu, X.; Yu, G.; Wang, J.; Zhang, W.; Xu, Y. Study on preparation technology of high-quality biomass fuel pellets using Caragana korshinskii kom. powder. Wood Res. 2024, 69, 157–168. [Google Scholar] [CrossRef]

- Wu, C.G.; Zhang, J.; Guo, Y.M.; Li, X.B. Optimization of caragana solid forming fuel process parameters based on Taguchi method. J. Shanxi Agric. Univ. (Nat. Sci. Ed.) 2015, 35, 478–483. [Google Scholar]

- Qi, L.; Zhang, J. Study on creep characteristics of solid fuel made from Caragana korshinshi in the process of compression. J. Chin. Agric. Mech. 2017, 38, 77–80. [Google Scholar]

- Daoren, D.L. Study on biological characteristics and industrialization of Caragana korshinskii kom. Inn. Mong. For. Investig. Des. 2008, 31, 93–94. [Google Scholar]

- Ning, T.Z.; Yu, G.S.; Yuan, X.Y.; Liu, W.G.; Pi, S.M. Design and Experiment of Roller Briquetting Machine with Plungers. Trans. Agric. Mach. 2016, 47, 203–210. [Google Scholar] [CrossRef]

- Ning, T.Z.; Yu, G.S.; Pi, S.M.; Chen, Z.J.; Yuan, X.Y. Optimization of Forming Parameters on Roler Briquetting Machine with Plunger. Trans. Agric. Mach. 2016, 47, 208–215. [Google Scholar]

- Ning, T.Z. Development of Roller Briquetting Machine with Plungers and Optimization of Parameters. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2016. [Google Scholar]

- ISO 17831-1:2015; Solid Biofuel. Determination of Mechanical Durability of Pellets and Briquettes. Part 1. Pellets. ISO: Geneva, Switzerland, 2015.

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stovers and switch grass. Bioresour. Technol. 2009, 101, 1082–1090. [Google Scholar] [CrossRef]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europaea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Hu, K.K.; Liu, X.P.; Cai, H.B.; Tan, W.S. Optimization of avian influenza vaccine culturing by Box-Behnken design and response surface methodology. J. Chem. Eng. Chin. Univ. 2019, 33, 394–399. [Google Scholar] [CrossRef]

- Fan, C.; Zhan, X.; Chen, J. Application of response surface methodology(rsm) to optimize the preparation conditions of PDMS/PVDF composite membranes. J. Chem. Eng. Chin. Univ. 2012, 26, 374–381. (In Chinese) [Google Scholar] [CrossRef]

- Radaei, P.; Mashayekhan, S.; Vakilian, S. Modeling and optimization of gelatin-chitosan micro-carriers preparation for soft tissue engineering: Using Response Surface Methodology. Mater. Sci. Eng. C 2017, 75, 545–553. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Mandø, M.; Rosenørn, A.B. Review of die design and process parameters in the biomass pelleting process. Powder Technol. 2020, 364, 971–985. [Google Scholar] [CrossRef]

- Said, N.; Daiem, M.M.A.; García-Maraver, A.; Zamorano, M. Influence of densification parameters on quality properties of rice straw pellets. Fuel Process. Technol. 2015, 138, 56–64. [Google Scholar] [CrossRef]

- Wang, Y.M.; Chen, Z.J.; Yuan, X.Y.; Yu, G.S. Influence of die temperature and moisture content on the densification of bamboo powder using die heating method. Wood Res. 2018, 63, 655–668. [Google Scholar]

- Tu, D.Y.; Li, A.X.; He, G.S. Hot pressing forming experiment of the rice straw and sawdust mixed material. Trans. Chin. Soc. Agric. Eng. 2015, 31, 205–211. [Google Scholar]

- Liu, D.; Ma, Y.; Li, J.; Teng, D.; Qiu, S.; Li, Y.; Mao, X.; Wang, H. Optimization of parameters associated with pellets made from bio-mass residue from anaerobic digestion using Box-Behnken Design. Bioresources 2022, 17, 2743–2767. [Google Scholar] [CrossRef]

- Yılmaz, H.; Çanakcı, M.; Topakcı, M.; Karayel, D. The effect of raw material moisture and particle size on agri-pellet production parameters and physical properties: A case study for greenhouse melon residues. Biomass Bioenergy 2021, 150, 106125. [Google Scholar] [CrossRef]

- Zhang, Y.W. The Structure Optimization and Experiment of Molding Die of Plunger Type Roller Ring Die Molding Machine. Master’s Dissertation, Beijing Forestry University, Beijing, China, 2021. [Google Scholar]

- ISO 17225-6:2021; Solid Biofuels. Fuel Specifications and Classes. Part 6. Graded Non-Woody Pellets. ISO: Geneva, Switzerland, 2021.

- Lykidis, C.; Kamperidou, V.; Mantanis, G.I. The Use of Black Pine Bark for Improving the Properties of Wood Pellets. Forests 2023, 14, 1069. [Google Scholar] [CrossRef]

- Elniski, A.; Dongre, P.; Bujanovic, B.M. Lignin Use in Enhancing the Properties of Willow Pellets. Forests 2023, 14, 2041. [Google Scholar] [CrossRef]

| Moisture Content | Crude Protein | Crude Fat | Crude Fiber | Nitrogen-Free Extract | Ash | Phosphorus | Potassium |

|---|---|---|---|---|---|---|---|

| 6.51% | 15.13% | 2.43% | 39.67% | 37.18% | 5.39% | 4.32% | 2.31% |

| Design Parameters | Value of Calculation |

|---|---|

| Theoretical efficiency | 1500 kg/h |

| Diameter of pellets | 20 mm |

| Relaxation density | 1.15 g/cm3 |

| Mechanical durability | 96.3% |

| Motor power | 132 kW |

| Number of ring mold rows | 6 |

| Number of rollers | 3 |

| Ring mold hole distribution | 60/row |

| Diameter of plungers | 20 mm |

| Engagement circle’s diameter of ring mold | 1100 mm |

| Engagement circle’s diameter of rollers | 440 mm |

| Maximum revolution speed of ring mold | 60 rpm |

| Percentage of forming | 90% |

| Energy consumption per ton | 50 kWh |

| Coding Level | Factors | ||

|---|---|---|---|

| Moisture Content (%) | Length-to-Diameter Ratio of Forming Die | Rotational Speed of Ring Mold (rpm) | |

| −1 | 10 | 5 | 30 |

| 0 | 15 | 5.25 | 45 |

| 1 | 20 | 5.5 | 60 |

| Sequence Number | X1 (%) | X2 | X3 (rpm) | Y1 (g/cm3) | Y2 (t/h) |

|---|---|---|---|---|---|

| 1 | 15 | 5.5 | 60 | 0.934 | 4.78 |

| 2 | 10 | 5.25 | 60 | 0.921 | 4.36 |

| 3 | 15 | 5 | 30 | 1.127 | 6.35 |

| 4 | 10 | 5.25 | 30 | 0.918 | 4.33 |

| 5 | 15 | 5.25 | 45 | 1.078 | 5.94 |

| 6 | 20 | 5.25 | 60 | 0.736 | 3.93 |

| 7 | 15 | 5.25 | 45 | 1.145 | 6.58 |

| 8 | 20 | 5.5 | 45 | 0.807 | 3.64 |

| 9 | 20 | 5 | 45 | 0.979 | 5.61 |

| 10 | 10 | 5.5 | 45 | 0.896 | 5.36 |

| 11 | 15 | 5 | 60 | 0.726 | 3.72 |

| 12 | 20 | 5.25 | 30 | 0.909 | 4.47 |

| 13 | 10 | 5 | 45 | 1.033 | 5.23 |

| 14 | 15 | 5.25 | 45 | 1.158 | 5.58 |

| 15 | 15 | 5.25 | 45 | 1.003 | 5.71 |

| 16 | 15 | 5.25 | 45 | 1.118 | 6.28 |

| 17 | 15 | 5.5 | 30 | 0.963 | 5.33 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Modal | 0.2458 | 9 | 0.0273 | 4.78 | 0.0255 | Significant |

| X1 | 0.0142 | 1 | 0.0142 | 2.49 | 0.1588 | |

| X2 | 0.0088 | 1 | 0.0088 | 1.54 | 0.2549 | |

| X3 | 0.045 | 1 | 0.045 | 7.88 | 0.0262 | |

| AB | 0.0003 | 1 | 0.0003 | 0.0537 | 0.8235 | |

| AC | 0.0077 | 1 | 0.0077 | 1.36 | 0.2823 | |

| BC | 0.0346 | 1 | 0.0346 | 6.06 | 0.0433 | |

| A2 | 0.0597 | 1 | 0.0597 | 10.46 | 0.0144 | |

| B2 | 0.0116 | 1 | 0.0116 | 2.04 | 0.1964 | |

| C2 | 0.0512 | 1 | 0.0512 | 8.98 | 0.02 | |

| Residual | 0.04 | 7 | 0.0057 | |||

| Lack of fit | 0.0244 | 3 | 0.0081 | 2.08 | 0.2455 | Not significant |

| Pure error | 0.0156 | 4 | 0.0039 | |||

| Cor total | 0.2857 | 16 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Source |

|---|---|---|---|---|---|---|

| Modal | 11.73 | 9 | 1.3 | 4.25 | 0.0348 | Significant |

| X1 | 0.3321 | 1 | 0.3321 | 1.08 | 0.3328 | |

| X2 | 0.405 | 1 | 0.405 | 1.32 | 0.2884 | |

| X3 | 1.7 | 1 | 1.7 | 5.55 | 0.0507 | |

| AB | 1.1 | 1 | 1.1 | 3.59 | 0.0999 | |

| AC | 0.0812 | 1 | 0.0812 | 0.2647 | 0.6228 | |

| BC | 1.08 | 1 | 1.08 | 3.52 | 0.1026 | |

| A2 | 3.53 | 1 | 3.53 | 11.49 | 0.0116 | |

| B2 | 0.0858 | 1 | 0.0858 | 0.2796 | 0.6133 | |

| C2 | 2.9 | 1 | 2.9 | 9.46 | 0.0179 | |

| Residual | 2.15 | 7 | 0.3069 | |||

| Lack of fit | 1.47 | 3 | 0.4902 | 2.9 | 0.1655 | Not significant |

| Pure error | 0.6773 | 4 | 0.1693 | |||

| Cor total | 13.88 | 16 |

| Experimental Index | Value of Contribution Rate of Experimental Factors | Ranking of Contribution Rate | ||

|---|---|---|---|---|

| X1 | X2 | X3 | ||

| Y1 | 2.49 | 1.54 | 7.88 | X2 > X3 > X1 |

| Y2 | 1.08 | 1.32 | 5.55 | X1 > X2 > X3 |

| Relaxation Density Y1 (g/cm3) | Relative Error (%) | Productivity Y2 (t/h) | Relative Error (%) | Mechanical Durability (%) | Energy Consumption (kW·h/t) | ||

|---|---|---|---|---|---|---|---|

| Experimental Value | Predicted Value | Experimental Value | Predicted Value | ||||

| 1.146 | 1.142 | 0.349 | 6.342 | 6.419 | 1.214 | 97.03 | 40.9 |

| 1.141 | 1.142 | 0.088 | 6.505 | 6.419 | 1.322 | 96.88 | 40.1 |

| 1.139 | 1.142 | 0.263 | 6.278 | 6.419 | 2.250 | 96.21 | 41.3 |

| 1.143 | 1.142 | 0.0877 | 6.409 | 6.419 | 0.156 | 96.92 | 40.7 |

| 1.140 | 1.142 | 0.175 | 6.424 | 6.419 | 0.078 | 96.71 | 40.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Huang, J.; Wang, J.; Yu, G.; Xu, X. Optimization of Molding Process Parameters of Caragana korshinskii Kom. Based on Box-Behnken Design. Forests 2024, 15, 2086. https://doi.org/10.3390/f15122086

Xu Y, Huang J, Wang J, Yu G, Xu X. Optimization of Molding Process Parameters of Caragana korshinskii Kom. Based on Box-Behnken Design. Forests. 2024; 15(12):2086. https://doi.org/10.3390/f15122086

Chicago/Turabian StyleXu, Yuyao, Junyan Huang, Jue Wang, Guosheng Yu, and Xiaofeng Xu. 2024. "Optimization of Molding Process Parameters of Caragana korshinskii Kom. Based on Box-Behnken Design" Forests 15, no. 12: 2086. https://doi.org/10.3390/f15122086

APA StyleXu, Y., Huang, J., Wang, J., Yu, G., & Xu, X. (2024). Optimization of Molding Process Parameters of Caragana korshinskii Kom. Based on Box-Behnken Design. Forests, 15(12), 2086. https://doi.org/10.3390/f15122086