Abstract

In this research, acetylation was applied under industrial conditions to improve the properties of Turkey oak and Pannonia poplar wood. Both species are potential “climate winners” in Hungary, yet they are currently underused due their low durability and poor dimensional stability. The acetylation modification process may be a suitable method to improve their properties. In order to verify the effectiveness of the process, comparative chemical analyses (cellulose, hemicelluloses, lignin, extractives, ash, buffering capacity, and pH) of the untreated and acetylated heartwood and sapwood were carried out for both species for the first time. Diffuse reflectance infrared Fourier transform (DRIFT) spectroscopy was also used to support the evaluation of the chemical analyses. The weight percent gain was 11.54% for poplar and 0.94% for Turkey oak, indicating poor treatment efficiency for the latter. The cellulose, hemicelluloses, and lignin contents changed significantly in poplar, with the highest change (+81%) induced by acetylating the hemicelluloses. Only the alpha-cellulose content decreased significantly in Turkey oak, presumably due to the degradation of the non-crystalline part of the cellulose. Acetylation may improve the resistance of Pannonia poplar against moisture, weather, decay, and wood-boring insects, but the process parameters need to be optimized in order to prevent degradation and discoloration in poplar. Turkey oak was found to be less suitable for acetylation due to its low permeability and tendency to crack.

1. Introduction

Wood acetylation is one of the few modification technologies which has been commercialized. The most common reagent for acetylation is acetic anhydride [1]. It is a chemical process, specifically an esterification process, in which chemical bonds are formed between the cell wall polymers in the wood and the reagent chemical. Comparing the reactivity of the chemical constituents, lignin has the highest reactivity, followed by hemicelluloses, and then cellulose [2].

During acetylation, the wood is saturated with acetic anhydride under a vacuum-pressure process, which is then heated up to reaction temperature (above 100 °C) [3]. The ester is formed during the reaction of the hydroxyl group (OH) and the acetic anhydride. Acetic acid also forms and can be added additionally, which swells the dry cell wall in order for the reagent to access the OH groups more effectively [4]. As a result, the weight of acetylated wood increases, having a maximum weight percentage gain (WPG) of 25% [5,6]. The higher the WPG, the higher the resistance to moisture, fungi, and termites. Acetylation has been the topic of research since 1928 [7,8].

A significant part of Hungary’s wood production is made up of Pannonia poplar (Populus × euramericana cv. Pannónia) (1,306,000 m3) and Turkey oak (Quercus cerris L.) (801,000 m3) [9]. However, due to their unfavorable properties (e.g., low natural durability, poor dimensional stability), they are mainly used as firewood and in the wood-based panel production and packaging industry. Regarding future climate change scenarios for Hungary, both species are potential “climate winners”, which urges the exploration of new technologies to increase their utilization and market share [10,11,12]. One possible method of improving wood quality is the application of modification methods, which have proven their efficiency and potential in recent decades [13,14].

Poplar species, specifically Pannonia poplar, are difficult to dry and modify because the freshly-cut heartwood (ripewood) has higher moisture content than its sapwood. Also, more tyloses and extractive substances form in older trees, which enables false heartwood formation and discoloration, impairing their quality and value [15]. Because of this phenomenon, hybrid poplar species such as Pannonia poplar are mainly felled at about 15 years, especially those that are intended for veneer production. Usually its sapwood, heartwood, and juvenile wood are difficult to differentiate, especially after drying [16]. In Pannonia poplar, the borderline of sapwood and heartwood is faintly visible [17]. The difference between the physical properties of sapwood and heartwood is not significant [18]. There is no visible distinction between earlywood and latewood within the annual rings. The annual ring width varies between 2 and 30 mm [19]. Pannonia poplar has a higher density than most poplar species (>401 kg/m3), which makes it suitable for structural applications and the furniture industry [20]. The cellulose content is 52.4%–54.0%, the hemicelluloses content is 17.8%, the lignin content is 23.2%–25.2%, the extractive content is 2.3%–3.2%, and the ash content is 0.41%–0.89% for the poplar species. Its low extractive content is connected to its plain, yellowish-white color and low durability. Its pH is 5.8 [15].

The color of Pannonia poplar was successfully modified to a darker tone by steaming [21,22], thermal modification [23], and heat treatment with different oils [24,25]. Heat treating it at 180 °C and 200 °C improved its durability, dimensional stability, and compression strength [23,26,27]. Similar results were found for oil-heat-treated Pannonia poplar, which was modified using three different oils (sunflower, linseed, and rapeseed oil) at two different temperatures (160, 200 °C) with three durations (2, 4, 6 h) [24,25]. On the other hand, its color was not stable against weathering [25,27]. It gained a darker color from the hemicelluloses degradation products, but those were leached out during weathering, resulting in a greyed surface. Promising results were found with the thermo-mechanical densification of Pannonia poplar at different temperatures (160, 180, and 200 °C), different densification grades (20, 30, and 40%), and different durations (10, 20, and 30 min). As there was no thermal degradation in the inner layers, the mechanical properties increased [28].

There are several publications regarding the thermal modification [29,30], chemical modification [31,32,33,34,35], and impregnation modification [36,37,38,39] of poplar species. These processes could be applied to Pannonia hybrid as well in order to improve its physical and mechanical properties and to modify its color.

Turkey oak logs grown in optimal sites can have a diameter of 30–50 cm and length of 12–15 m, and are usually smaller than sessile or pedunculate oak species. This is due to their short lifespan: they are attacked by diseases and grow slowly after the age of 60–80 years. They are usually harvested at this age. If they grow in closed stands, they usually develop straight, cylindrical trunks, which is more favorable for industry. They have wide, light-grey sapwood and dark, reddish-brownish heartwood, often having a false heart. The wood is prone to frost ribs or cracks, ring shakes, crooks or springs, a tapered trunk, warping, splitting, and knots. Due to its inhomogeneous annual ring structure and density and its high shrinkage anisotropy, the stress results in ring shakes and cracks; the wood is less suitable for sawlog production [19]. Its usage is also hindered by the low durability against fungi species and wood-boring insects [40]. Due to its disadvantages and high calorific value (11,592 MJ/m3 for air-dry wood), it is mainly used as firewood. Turkey oak has somewhat higher density than other oaks (720–810 kg/m3), so it can be used for similar purposes, except for the production of barrels and outdoor, durable wood products. Its cellulose content is 48.1%, the hemicelluloses content is 24.9%, the lignin content is 22.85%–26.45%, the extractive content is 6.43%–6.99%, and the ash content is 0.88%–0.93%. Its low extractive content and low amount of polyphenols are connected to its low durability. Its pH is 4.83 for the sapwood and 5.01 for the heartwood [19,40,41,42].

The modification of Turkey oak is less studied in the scientific literature. Hydrothermal (steaming) and thermal treatments have been carried out with promising results, like reduced equilibrium moisture content, anti-swelling efficiency, and homogenized color [23,43,44,45,46,47,48,49,50,51,52,53,54,55]. Steaming enables the homogenization and darkening of the wood color, but compared to thermal modification, it is less suitable for durability enhancement. There have been no reports found on the acetylation of Turkey oak. Red oak wood was found to have low dimensional stability despite its high weight percentage gain (WPG) [56], which may indicate complications for Turkey oak as well.

Thorough examination and selection of the raw material has to be carried out, and the process parameters have to be well optimized in order to reduce warping and crack formation, and thus to receive the highest-quality material possible. If high dimensional stability and durability are achieved, it could be used for glulam production [57]. The gluing difficulties of Turkey oak are the same as those of other oaks: too-high variation in density and permeability between earlywood and latewood hinders an adequate adhesive bond [41]. Chemical surface modification could enable better interaction between the surface of oakwood and polyurethane (PUR) adhesives [58].

In the present work, the acetylation modification of Pannonia poplar and Turkey oak was been carried out for the first time using a semi-industrial process by investigating both sapwood and heartwood. The main chemical constituents (cellulose, hemicelluloses, and lignin), as well as extractive content, ash content, buffering capacity, and pH, were measured and compared in untreated and acetylated wood. Diffuse reflectance infrared Fourier transform (DRIFT) spectroscopy supported the evaluation of the chemical analysis. The results contribute to our understanding of the chemical changes taking place during the acetylation of Pannonia poplar and Turkey oak and provide data on the elaboration of techniques for the acetylation and better utilization of these currently underused wood species.

2. Materials and Methods

2.1. Wood Material

One Pannonia poplar log was obtained from Újrónafő 11/G and one from Győr 540/B (Hungary), with breast height diameters of 21.3 cm and 39.5 cm, from 22- and 24-year-old trees, respectively. The logs were about 150 cm long. The densities of the sapwood were 444 and 427 kg/m3 for the poplar trees from Győr and Újrónafő, respectively [59]. The heartwood densities were 470 and 413 kg/m3 for the poplar trees from Győr and Újrónafő, respectively.

One Turkey oak log was obtained from the mountains of Sopron forestry (Hungary), with a breast height diameter of 30 cm and a length of about 150 cm.

2.2. Acetylation

The logs were sawn into boards 30 and 50 cm thick. There were 10 pieces of thinner and 4 pieces of thicker Pannonia poplar boards, and 7 pieces of thinner and 6 pieces of thicker Turkey oak boards. Half of them were acetylated at Accsys Technologies (Arnhem, The Netherlands) under semi-industrial conditions [60]. The process was carried out with batches of Radiata pine with corresponding thickness and process parameters. The WPG was determined at Accsys Technologies, where it was calculated by dividing the density change after acetylation by the initial oven-dry density of the boards.

2.3. Preparation of Particles for Chemical Analysis

Samples (about 100–200 g) were ground in a hammer mill and sieved. The 0.2–0.63 mm sieve fraction was taken for chemical analyses. All wet chemical analyses were run in triplicate, and the results were given based on dry wood mass. The particles were stored at 20 °C 65% relative humidity until reaching constant mass.

2.4. Measurement of Wood Polymers, Total Extractive, and Ash Content

For the purpose of determining the holocellulose content, 2.5 g of wood particles was transferred into an Erlenmeyer flask. Subsequently, 80 mL of hot distilled water, 0.5 mL of acetic acid (96%), and 1 g of sodium chlorite were added. The mixture was heated in a water bath at 70 °C for 1 h. After each succeeding hour, portions of 0.5 mL acetic acid and 1 g sodium chlorite were added by shaking. This process was repeated 7 times. After six cycles, the samples were left in the water bath overnight. At the end of 24 h of reaction, samples were cooled and filtered on a G2 glass funnel filter, and the holocellulose was washed with 10 mL acetone and water until the yellow color was removed [61]. The prepared holocellulose was dried at 105 °C and then weighed.

Then, the alpha-cellulose content was determined by transferring the previously prepared holocellulose into a 250 mL glass beaker and adding 10 mL of 17.5% NaOH solution. At 5 min intervals, portions of 5 mL NaOH solution were added until the holocellulose was fully covered with solution. The reaction time was 1 h. The α-cellulose was filtered on a G2 porosity glass funnel filter and washed with 5% NaOH, acetic acid, and water. This washing cycle was repeated twice. The prepared α-cellulose was dried at 105 °C and then weighed [61]. Similar methods were used in recent articles [62,63,64].

The hemicelluloses content was calculated by the subtraction of the alpha-cellulose content from the holocellulose content.

The acid-insoluble lignin content was determined using Klason’s method (TAPPI standard T 222).

Two solvent systems were used to assess the extractive content: cyclohexane:ethanol 50:50 (v/v) and methanol:water 50:50 (v/v). A 0.4 g sample was mixed with 40 mL solvent in a 100 mL glass beaker. The beaker was covered with aluminum foil to avoid evaporation. Samples were placed in an ultrasonic bath (Elma Transsonic T570, Elma Schmidbauer GmbH, Singen, Germany) and extracted for 60 min. Extract solutions were filtered through filter paper, and 10 mL of the clean solutions were evaporated to dryness at room temperature; then, the remaining solids were weighed. Results for the total extractive content are given as the sum of the values obtained by the two solvent systems.

2.5. Determination of pH and Buffering Capacity

In order to measure the pH and buffering capacity, extraction was carried out as follows: 2.5 g of wood was extracted with 50 mL water for 24 h in a closed beaker. The solutions were filtered and the particles were washed with water into a conical flask to a final volume of 100 mL.

The pH of the remaining part of the aqueous extract solution was determined using a Hanna HI 2550 pH meter, which corresponded to the pH of the wood. The buffering capacity of the solution was measured by titration using 0.02 M NaOH to pH = 7.00.

2.6. Equillibrium Moisture Content

An Ohaus MB 23 moisture analyzer (Ohaus Corporation, Parsippany, NJ, USA) was used to determine the equilibrium moisture content of the samples.

2.7. FTIR Analysis

The tangential surface was analyzed, and samples of 5 mm thickness × 10 mm width × 30 mm length (t × w × l) were used for diffuse reflectance infrared Fourier transform (DRIFT) spectroscopy with a JASCO FT/IR-6300 spectrophotometer and Spectra Manager program. First, the background spectrum was obtained against an aluminum plate in order to determine the contribution of the instrument and environment to the spectrum.

These effects were removed from the samples’ spectrum by making a ratio of the sample’s single beam spectrum to the background spectrum. Secondly, the spectrometer conducted 50 scans of each sample. There were 8 untreated and 48 acetylated Pannonia poplar samples, and 10 untreated and 44 acetylated Turkey oak samples. After measurement, the spectra were smoothed with 15-point convolution. A two-point base line correction was made by setting the lowest point between 3800 cm−1 and 1900 cm−1 to a zero absorbance. The intensity of the infrared peaks was converted to Kubelka–Munk (K-M) units for quantitative analysis. The chemical changes in the wood were evaluated by observing the difference in the spectra of untreated samples subtracted from the spectra of acetylated samples. Here, the absorption increase was represented by a positive band, while an absorption decrease was represented by a negative band. The band assignments were made using the difference between the two spectra.

2.8. Statistical Analysis

Statistical analysis was performed using the Dell Statistica software (version 13, Dell Inc., Round Rock, TX, USA). Factorial analyses of variances (ANOVA) combined with the Tukey’s HSD test and Levene’s test for homogeneity of variances were conducted, and the differences were considered significant at p < 0.05.

3. Results and Discussion

Although the sapwood of Pannonia poplar seemed to be successfully acetylated, degradation and discoloration were visible in the sapwood–heartwood transition zone (Figure 1). The density of Pannonia poplar increased from 453 to 486 kg/m3 (Újrónafő) and from 476 to 489 kg/m3 (Győr). The (indicative) WPG values were 11.72% and 11.36% for poplar from Újrónafő and Győr, respectively.

Figure 1.

Pannonia poplar before (left) and after acetylation (right).

After acetylation, the quality of Turkey oak wood was impaired by a significant amount of cracks (Figure 2). The density of Turkey oak decreased from 796 to 757 kg/m3. The (indicative) WPG was low, only 0.94%.

Figure 2.

Turkey oak before (up) and after acetylation (bottom).

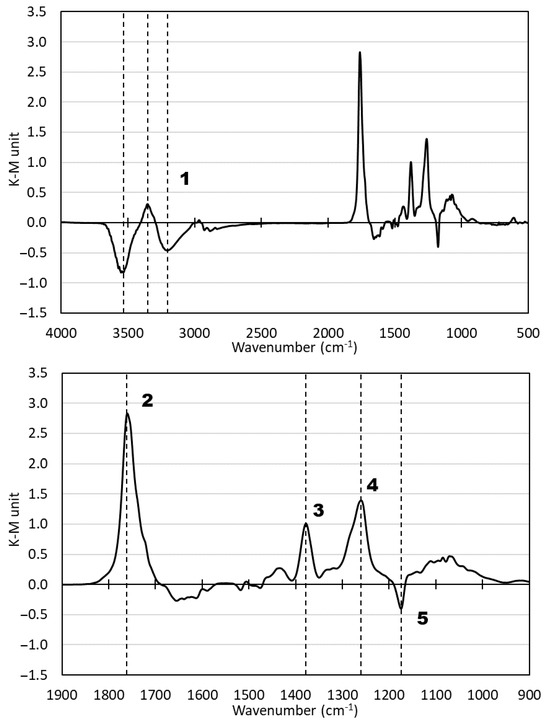

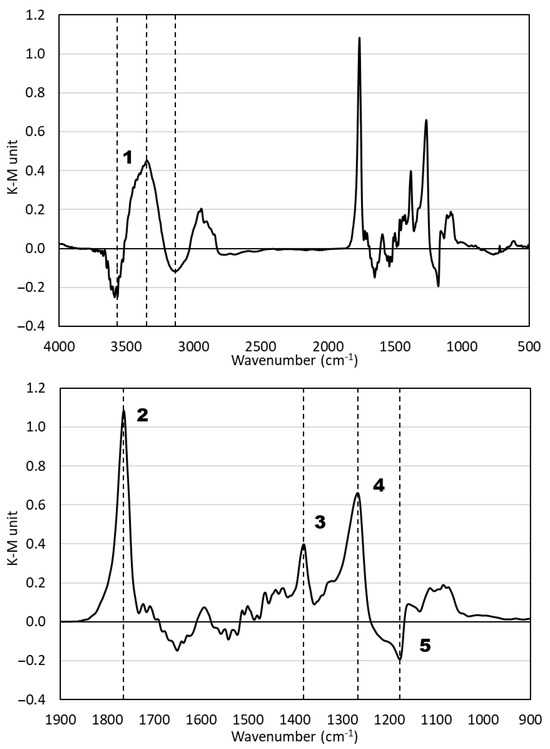

Table 1 and Table 2 lists the chemical composition, pH, and buffering capacity of Pannonia poplar and Turkey oak, respectively. Table 3 lists the most important wavenumbers for both species after acetylation, which are assigned to their difference spectra in Figure 3 and Figure 4. The band numbers are referenced in brackets in the text. The spectra of untreated and acetylated poplar are shown in Supplementary Materials Figures S1 and S2, separating sapwood from heartwood. Structural changes in the wood were evaluated according to these results and compared to the relevant literature.

Table 1.

Chemical composition, pH, and buffering capacity of untreated and acetylated Pannonia poplar, showing results for sapwood (S), heartwood (H), and the degraded part separately. Average values are presented with standard deviations in brackets. Different superscript letters in a row denote significant differences at the p < 0.05 level.

Table 2.

Chemical composition, pH, and buffering capacity of untreated and acetylated Turkey oak, showing results for sapwood (S) and heartwood (H) separately. Average values are presented with standard deviation in brackets. Different superscript letters in a row denote significant differences at the p < 0.05 level.

Figure 3.

FTIR difference spectrum of Pannonia poplar sapwood. The differential spectrum was calculated by subtracting the spectrum of untreated wood from that of acetylated wood. Descriptions and assignments of band numbers are listed in Table 3.

Figure 4.

FTIR difference spectrum of Turkey oak sapwood. The differential spectrum was calculated by subtracting the spectrum of untreated wood from that of acetylated wood. Descriptions and assignments of band numbers are listed in Table 3.

The moisture content of Pannonia poplar and Turkey oak decreased significantly by 20%–58% due to the incorporation of acetyl groups in their cell walls. Positive and negative peaks were observed between 3200 and 3600 cm−1 (1) on the spectra of both species, which are signs of OH group rearrangement in the wood structure. Their lower moisture content indicates that the wood of Pannonia poplar and Turkey oak absorbs less moisture after acetylation; thus, the material swells less in humid or wet conditions, and its dimensional stability is higher when exposed to changing climatic conditions. The degraded part of acetylated poplar had a slightly higher moisture content than its sapwood and heartwood, which may indicate lower acetyl content. Acetylation reduced the moisture content of Turkey oak less than Pannonia poplar, probably due to its lower permeability and higher density. The difference between the moisture content of sapwood and heartwood evened out after acetylation.

The holocellulose content is made up of the cellulose and hemicellulose content of the wood material. In Pannonia poplar, the hemicelluloses content increased significantly after acetylation, from 33.52% to 60.68% for sapwood and from 33.81% to 58.08% for heartwood. For Turkey oak, the hemicelluloses content increased from 29.66% to 44.95% for sapwood and from 31.73% to 38.85% for heartwood. The increase was higher in sapwood than heartwood for both wood species.

During acetylation, some of the hydroxyl groups are substituted by acetyl groups, which increase the weight of the polymer. As the hemicelluloses fraction has proportionally the most hydroxyl groups, its weight increased after acetylation. Higher absorption of carbonyl groups in xylan (2), symmetric C-H deformation in hemicelluloses (3), and absorption of C-O stretching in xylan (4) confirmed this finding on the differential spectrum. The increment at these wavenumbers after acetylation was found by other researchers as well [65], e.g., for spruce [66], for Scots pine and beech [67], for European hornbeam [68,69], and for Jacaranda copaiba [70].

In the transition zone of acetylated Pannonia poplar, the hemicelluloses content was only 54.44%, lower than that of sapwood and heartwood. This may indicate a lower rate of acetylation and WPG. On the other hand, there was no remarkable difference between the FTIR spectra of acetylated Pannonia poplar sapwood, heartwood, or the degraded part.

In a study where Populus ussuriensis was acetylated under laboratory conditions at 100 °C, 120 °C, and 140 °C, WPG values of 12.6%, 19.7%, and 21.3% were achieved, respectively [71]. According to the report, the intensities at peaks of 1740, 1370, and 1230 cm−1 increased with increasing WPG, which corresponds to our results.

The alpha-cellulose content of both wood species decreased significantly, by 15%–30%, after acetylation. There was a negative peak of C-O-C stretching in cellulose (5) on the FTIR differential spectra. As the cellulose, hemicelluloses, and lignin fractions were not analyzed separately by FTIR, only assumptions can be drawn. The increase in hemicelluloses content and the reduction in cellulose content can be explained by the difference in reactivity. Acetylation mainly affects the hemicelluloses and lignin, as they are more reactive than cellulose [66,72,73,74]. This leads to their increased share in chemical composition. As only the cellulose changed significantly in Turkey oak, here, the amorphous parts of the cellulose chains were degraded in the acidic medium, reducing its crystallinity. Fodor and colleagues examined acetylated hornbeam and reported no remarkable elevation of the soluble carbohydrate content or the levunilic acid concentration, which are the main breakdown products of cellulose [68]. Comparing the results of these species, Pannonia poplar had a higher WPG then Turkey oak, which corresponds to the higher increment of hemicelluloses content. On the other hand, the reduction in cellulose content was comparable, leading to the assumption that cellulose did degrade during acetylation.

Table 3.

Wavenumber characterization [67,75] of the infrared spectra of untreated and acetylated Pannonia poplar and Turkey oak. Band number: numbers assigned to the bands in Figure 3 and Figure 4.

| Band Number | Wavenumber (cm−1) Pannonia Poplar | Wavenumber (cm−1) Turkey Oak | Functional Group | Assignment |

|---|---|---|---|---|

| 1 | 3534 3351 3201 | 3567 3348 3135 | OH stretching (bonded) | |

| 2 | 1761 | 1765 | C=O (carbonyl) stretching in unconjugated acetyl groups | Xylan (hemicelluloses) |

| 3 | 1378 | 1382 | Symmetric C-H deformation in CH3 | Cellulose and hemicelluloses |

| 4 | 1260 | 1267 | Syringyl ring and C-O stretching in the ester bond | Lignin and xylan (hemicelluloses) |

| 5 | 1174 | 1177 | Asymmetric C-O-C stretching | Cellulose and hemicelluloses |

The lignin content of Pannonia poplar decreased significantly, by more than half, after acetylation, while the lignin of Turkey oak changed at a lower rate. The initial values were not remarkably different between its sapwood and heartwood, a result similar to those in the literature [50]. The higher the rate of acetylation, the more lignin is degraded or dissolved in the acidic medium [61]. Here, the Klason (acid-insoluble) lignin content decreased due to acetylation because some parts of lignin (e.g., ester bonds) hydrolyze during reaction with acetic anhydride and dissolve [76]. In a study on acetylated hornbeam, only internal structural changes took place in the lignin matrix, without any significant change in the lignin content [68]. The color darkening was also attributed to the change in lignin and extractive content.

The extractive content was exceptionally higher for sapwood than heartwood in Pannonia poplar, and decreased after acetylation. As the tested material was felled after its “optimal” age (after 15 years), it also had higher extractive content than the corresponding literature data. After acetylation, the difference between the extractive content of sapwood and heartwood was less remarkable. It can be hypothesized that there is no actual difference between the extractive content in sapwood and in heartwood, as Pannonia poplar has no colored heartwood, which would indicate this. The sapwood contains more sugars and starch, which may explain its higher water-soluble extractive content. Related scientific articles have reported an average extractive content of poplar species below 3% [77,78].

Turkey oak has a low extractive content, corresponding to its low durability. Compared to pedunculate oak, it has a similar content of proanthocyanidins (condensed tannin). However, it cannot accumulate ellagitannins as much as pedunculate oak, which reduces its biological resistance [41]. In general, heartwood has higher durability due to its higher extractive content, which was found to be true in the case of Turkey oak. Similar results were found for Turkey oak [50]. The extractive content did not change remarkably after acetylation, indicating a low rate of acetylation.

It is known that the anatomy and components of sapwood and heartwood are the same, except for extractives [61]. These impregnate the individual cells after they die to form heartwood. The heartwood of Pannonia poplar and Turkey oak can develop tyloses, which inhibit the rate of acetylation.

The ash content seemingly decreased for both wood species, but it was probably not affected by acetylation. A similar result was found for acetylated hornbeam [68]. Heartwood had higher values than sapwood. Compared to literature data, the inorganic content was slightly higher for both wood species [79], which can be associated with its different climatic and soil conditions.

As the acetylation process takes place in an acidic medium, and acetic acid forms as a byproduct, the acetylated material becomes more acidic, having a lower pH and a higher buffering capacity [80]. In Pannonia poplar and the heartwood of Turkey oak, the pH decreased accordingly. The buffering capacity results did not show a clear trend or a great difference. The compatibility of the wood material with adhesives and coatings is influenced by its pH and the buffering capacity, and thus, it is an important factor of the finished product. If it is too acidic, base needs to be added for better bonding strength or coating stability. Turkey oak fundamentally has problems with bonding and surface finishing (stains) [41].

Based on the work of Beckers et al., the degree of acetylation or HPLC acetyl content can be determined approximately by correlating the peak of 1740 to 1510 cm−1 [81] (Table 4). Here, the HPLC acetyl content is only an indicated value, but the differences between Pannonia poplar and Turkey oak, as well as the differences between sapwood, heartwood, and degraded wood can be observed. The values for Pannonia poplar and Turkey oak were read from the correlation diagram for acetylated poplar and beech, respectively. The results were higher than the WPG calculated from weight, which was also shown in the acetylated hornbeam [68].

Table 4.

Wavenumber characterization for the determination of acetylation degree. The ratio was calculated by dividing the absorption at peak ~1740 cm−1 by the absorption at peak ~1510 cm−1. HPLC acetyl content was determined from the correlation diagram of Beckers et al. [81].

As diverse as they are, wood species react to the same acetylation process diversely and show different properties, which have been well studied in the literature [31,82,83,84].

The degraded part of Pannonia poplar was found on the borderline of sapwood and heartwood, in the transition zone. This part may have been a wet pocket in the original material. The initially higher moisture content in these parts can account for their lower acetyl content. Poplars are well-known for having wet pockets, water pockets, or wetwood, which complicate the drying process and cause the formation of wood defects like warping, splitting, checks, and collapses [85]. These are associated with a bacterial infection of the living tree, where the moisture content grows as the bacteria grows while a bacterial slime prevents the moisture from leaving the wetwood zone; thus, it will have an exceedingly (at least +5%) higher moisture content compared to the rest of the wood [86].

Turkey oak was not successfully acetylated under industrial conditions, which was confirmed by its low WPG and slight changes in its chemical properties and FTIR differential spectrum.

4. Conclusions

In this research, semi-industrial acetylation was carried out on Pannonia poplar and Turkey oak. These wood species are less utilized and have not been subjected to acetylation before. The moisture content of both Pannonia poplar and Turkey oak decreased significantly by 20%–58% after acetylation. The ratio of alpha-cellulose decreased significantly by 15%–30% for both wood species. A higher hemicelluloses content was found after acetylation for both wood species, increased by 22%–81%. The increase was higher in sapwood than in heartwood and in Pannonia poplar compared to Turkey oak. The lignin content decreased for both wood species, indicating that a part of the lignin degraded or dissolved in the acidic medium during acetylation. The extractive and ash content were not affected by acetylation for either tested wood species. The wood material became more acidic as the pH decreased after acetylation. After acetylation, the changes were less significant in the degraded part than in the rest of Pannonia poplar, which indicates a lower WPG and lower acetyl content. Sapwood is more suitable for acetylation than heartwood, having a higher WPG. Based on these results, acetylation may improve the resistance of Pannonia poplar against moisture, weather, decay, and wood-boring insects, but the process parameters need to be optimized in order to exclude the probability of degradation in poplar. Turkey oak was found to be less suitable for acetylation due to its low permeability and tendency to form cracks.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/f15010207/s1, Figure S1: FTIR spectra of untreated (CO) and acetylated (AC) Pannonia poplar wood. Description and assignments of band numbers are listed in Table 3. Figure S2: FTIR spectra of untreated (CO) and acetylated (AC) Turkey oak wood. Description and assignments of band numbers are listed in Table 3.

Author Contributions

Conceptualization, F.F.; methodology, T.H.; validation, F.F. and T.H.; formal analysis, T.H.; investigation, T.H.; resources, F.F. and T.H.; writing—original draft preparation, F.F.; writing—review and editing, F.F. and T.H.; visualization, F.F.; supervision, T.H.; project administration, F.F. and T.H.; funding acquisition, F.F. and T.H. All authors have read and agreed to the published version of the manuscript.

Funding

This article was made in the framework of the project TKP2021-NKTA-43, which has been implemented with the support provided by the Ministry of Culture and Innovation of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021-NKTA funding scheme.

Data Availability Statement

Data are contained within the article and Supplementary Materials.

Acknowledgments

The authors would like to thank Accsys Technologies PLC for providing the acetylated material for this research, and the helpful, valuable insights of Tim Holtus. The authors would like to express their gratitude to Péter Pál Gecseg, Bálint Radvánszki, and Péter Martin Szeles for their contribution to wet chemistry assays. The constructive remarks of László Tolvaj were also greatly appreciated.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rowell, R.M. Chemical Modification of Wood. Commonw. For. Bur. 1983, 6, 363–382. [Google Scholar]

- Boonstra, M.G.; Pizzi, A.; Tekely, P.; Pendlebury, J. Chemical Modification of Norway Spruce and Scots Pine. A 13 C NMR CP-MAS Study of the Reactivity and Reactions of Polymeric Wood Components with Acetic Anhydride. Holzforsch.-Int. J. Biol. Chem. Phys. Technol. Wood 1996, 50, 215–220. [Google Scholar] [CrossRef]

- Brelid, P.L.; Simonson, R. Acetylation of Solid Wood Using Microwave heating Part 2. Experiments in Laboratory Scale. Holz Als. Roh-Und. Werkst. 1999, 57, 383–389. [Google Scholar] [CrossRef]

- Beckers, E.P.J.; Militz, H. Acetylation of Solid Wood. Initial Trials on Lab and Semi Industrial Scale. In Proceedings of Second Pacific Rim Bio-Based Composites Symposium; University of British Columbia: Vancouver, BC, Canada, 1994; pp. 125–133. [Google Scholar]

- Hill, C.; Jones, D. The Dimensional Stabilization of Corsican Pine Sapwood by Reaction with Carboxylic Acid Anhydrides. Eff. Chain. Length 1996, 50, 457–462. [Google Scholar]

- Popescu, C.-M.; Hill, C.A.S.; Curling, S.; Ormondroyd, G.; Xie, Y. The Water Vapour Sorption Behaviour of Acetylated Birch Wood: How Acetylation Affects the Sorption Isotherm and Accessible Hydroxyl Content. J. Mater. Sci. 2014, 49, 2362–2371. [Google Scholar] [CrossRef]

- Fuchs, W. Genuine Lignin. I. Acetylation of Pine Wood. Berichte Der Dtsch. Chem. Ges. 1928, 61, 61B948-51. [Google Scholar]

- Niemz, P.; Teischinger, A.; Sandberg, D. Springer Handbook of Wood Science and Technology; Springer International Publishing: Berlin/Heidelberg, Germany, 2023; ISBN 978-3-030-81314-7. [Google Scholar]

- HCSO. Fakitermelés Az Erdőgazdálkodási Célú Erdőterületeken Fafajcsoportok Szerint [Ezer M3]. 2021. Available online: https://www.ksh.hu/stadat_files/kor/hu/kor0006.html (accessed on 17 December 2023).

- de Rigo, D.; Enescu, C.M.; Durrant, T.H.; Caudullo, G. Quercus Cerris in Europe: Distribution, Habitat, Usage and Threats. In European Atlas of Forest Tree Species; Publication Office of the European Union: Luxembourg, 2016; pp. 148–149. [Google Scholar]

- Komán, S.; Németh, R.; Báder, M. An Overview of the Current Situation of European Poplar Cultures with a Main Focus on Hungary. Appl. Sci. 2023, 13, 12922. [Google Scholar] [CrossRef]

- Najib, R.; Houri, T.; Khairallah, Y.; Khalil, M. Quercus cerris L.: An Overview. For. Stud. 2021, 74, 1–9. [Google Scholar] [CrossRef]

- Németh, R.; Horváth, N.; Fodor, F.; Báder, M.; Bak, M. Wood Modification for Under-Utilised Hardwood Species. IOP Conf. Ser. Earth Environ. Sci. 2020, 505, 012017. [Google Scholar] [CrossRef]

- Mai, C.; Militz, H. Wood Modification. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer Handbooks; Springer International Publishing: Cham, Switzerland, 2023; pp. 873–910. ISBN 978-3-030-81315-4. [Google Scholar]

- Komán, S. Nemesnyár-Fajták Korszerű Ipari És Energetikai Hasznosítását Befolyásoló Faanatómiai És Fizikai Jellemzők. Doctoral Thesis, University of West Hungary, Sopron, Hungary, 2012. [Google Scholar]

- Németh, R.; Ott, Á.; Takáts, P.; Bak, M. The Effect of Moisture Content and Drying Temperature on the Colour of Two Poplars and Robinia Wood. BioResources 2013, 8, 2074–2083. [Google Scholar] [CrossRef]

- Horváth, N.; Schantl, I. Hazai Ültetvényes Pannonia Nyár Fatestének Anyagtudományi Vizsgálata. In Alföldi Erdőkért Egyesület Kutatói Nap: Tudományos Eredmények a Gyakorlatban; Alföldi Erdőkért Egyesület: Kecskemét, Hungary, 2017; pp. 149–154. [Google Scholar]

- Molnár, S.; Németh, R.; Paukó, A.; Göbölös, P. A Fehérnyár Hibridek Faanyagminőségének Javítási Lehetőségei. Faipar 2002, 50, 24–26. [Google Scholar]

- Molnár, S.; Bariska, M. Magyarország Ipari Fái; Szaktudás Kiadó Ház Zrt: Budapest, Hungary, 2002. [Google Scholar]

- Mirzaei, G.; Mohebby, B.; Ebrahimi, G. Glulam Beam Made from Hydrothermally Treated Poplar Wood with Reduced Moisture Induced Stresses. Constr. Build. Mater. 2017, 135, 386–393. [Google Scholar] [CrossRef]

- Banadics, E.A.; Tolvaj, L. Colour Modification of Poplar Wood by Steaming for Brown Colour. Eur. J. Wood Prod. 2019, 77, 717–719. [Google Scholar] [CrossRef]

- Banadics, E.A.; Tolvaj, L.; Varga, D. Steaming of Poplar, Black Locust and Beech Timbers Simultaneously to Investigate Colour Modification Effect of Extractive Transport. Drewno Pr. Nauk. Doniesienia Komun. 2022, 65, 209. [Google Scholar] [CrossRef]

- Molnár, S.; Csupor, K.; Horváth, N. The Effect of Thermal Modification on the Durability of Wood against Fungal Decay. In Proceedings of the 5th International Symposium Wood Structure and Properties ’06, Valiug, Romania, 19–23 September 2006; Technical University in Zvolen: Zvolen, Slovakia, 2006; p. 517. [Google Scholar]

- Bak, M.; Németh, R. Changes in Swelling Properties and Moisture Uptake Rate of Oil-Heat-Treated Poplar (Populus x Euramericana Cv. Pannónia) Wood. Bioresources 2012, 7, 5128–5137. [Google Scholar] [CrossRef][Green Version]

- Bak, M.; Németh, R.; Tolvaj, L. The Colour Change of Oil-Heat-Treated Timber During Weathering. Óbuda Univ. e-Bull. 2012, 3, 339–345. [Google Scholar]

- Horváth, N. A Termikus Kezelés Hatása a Faanyag Tulajdonságaira, Különös Tekintettel a Gombaállóságra. Doctoral Thesis, University of West Hungary, Sopron, 2008. [Google Scholar]

- Csizmadia, P. Hőkezelt és KEZELETLEN faanyagok Kültéri Kitettségi Vizsgálatai. Bachelor Thesis, University of West Hungary, Sopron, Hungary, 2015. [Google Scholar]

- Ábrahám, J.; Németh, R.; Molnár, S. Thermo-Mechanical Densification of Pannonia Poplar. In Proceedings of the Final Conference of COST Action E53: ‘Quality Control for Wood & Wood Products’, Edinburgh, Scotland, 4–7 May 2010; pp. 282–292. [Google Scholar]

- Bytner, O.; Drożdżek, M.; Laskowska, A.; Zawadzki, J. Influence of Thermal Modification in Nitrogen Atmosphere on the Selected Mechanical Properties of Black Poplar Wood (Populus nigra L.). Materials 2022, 15, 7949. [Google Scholar] [CrossRef]

- Cheng, A.; Tu, D.; Zhu, Z.; Zhou, Q.; Wei, W.; Hu, C.; Liu, X. Study on Machining Properties and Surface Coating Properties of Heat Treated Densified Poplar Wood. Wood Res. 2022, 67, 1032–1045. [Google Scholar] [CrossRef]

- Bongers, F.; Beckers, E.P.J. Mechanical Properties of Acetylated Solid Wood Treated on Pilot Plant Scale. In Proceedings of the First European Conference on Wood Modification; Ghent University: Ghent, Belgium, 2003; pp. 341–350. [Google Scholar]

- Ozmen, N. Dimensional Stabilisation of Fast Growing Forest Species by Acetylation. J. Appl. Sci. 2007, 7, 710–714. [Google Scholar] [CrossRef][Green Version]

- Yuan, J.; Hu, Y.; Li, L.; Cheng, F. The Mechanical Strength Change of Wood Modified with DMDHEU. BioResources 2013, 8, 1076–1088. [Google Scholar] [CrossRef]

- Dong, Y.; Qin, Y.; Wang, K.; Yan, Y.; Zhang, S.; Li, J.; Zhang, S. Assessment of the Performance of Furfurylated Wood and Acetylated Wood: Comparison among Four Fast-Growing Wood Species. BioResources 2016, 11, 3679–3690. [Google Scholar] [CrossRef]

- Yang, T.; Ma, E.; Cao, J. Synergistic Effects of Partial Hemicellulose Removal and Furfurylation on Improving the Dimensional Stability of Poplar Wood Tested under Dynamic Condition. Ind. Crops Prod. 2019, 139, 111550. [Google Scholar] [CrossRef]

- Gan, W.; Xiao, S.; Gao, L.; Gao, R.; Li, J.; Zhan, X. Luminescent and Transparent Wood Composites Fabricated by Poly(Methyl Methacrylate) and γ-Fe2O3@YVO4:Eu3+ Nanoparticle Impregnation. ACS Sustain. Chem. Eng. 2017, 5, 3855–3862. [Google Scholar] [CrossRef]

- Cao, S.; Cai, J.; Wu, M.; Zhou, N.; Huang, Z.; Cai, L.; Zhang, Y. Surface Properties of Poplar Wood after Heat Treatment, Resin Impregnation, or Both Modifications. BioResources 2021, 16, 7562–7577. [Google Scholar] [CrossRef]

- Xue, J.; Xu, W.; Zhou, J.; Mao, W.; Wu, S. Effects of High-Temperature Heat Treatment Modification by Impregnation on Physical and Mechanical Properties of Poplar. Materials 2022, 15, 7334. [Google Scholar] [CrossRef]

- Yang, H.; Wang, D.; Han, Y.; Tian, P.; Gao, C.; Yang, X.; Mu, H.; Zhang, M. Preparation and Properties of Modified Poplar Impregnated with PVA-Nano Silica Sol Composite Dispersion System. J. Wood Chem. Technol. 2022, 42, 211–221. [Google Scholar] [CrossRef]

- Bajraktari, A.; Nunes, L.; Knapic, S.; Pimenta, R.; Pinto, T.; Duarte, S.; Miranda, I.; Pereira, H. Chemical Characterization, Hardness and Termite Resistance of Quercus Cerris Heartwood from Kosovo. Maderas. Cienc. Y Tecnol. 2018, 20, 305–314. [Google Scholar] [CrossRef]

- Lavisci, P.; Masson, D.; Deglise, X. Quality of Turkey Oak (Quercus cerris L.) Wood. II. Analysis of Some Physico-Chemical Parameters Related to Its Gluability. Holzforschung 1991, 45, 415–418. [Google Scholar] [CrossRef]

- Winkler, A. Faforgácslapok; Szaktudás Kiadó Ház Zrt: Budapest, Hungary, 1998; ISBN 3000000295236. [Google Scholar]

- Horváth, N.; Altgen, M.; Németh, R.; Militz, H.; Joóbné Preklet, E. Chemical and Structural Changes of Heat Treated Turkey Oak and Hornbeam—Overview and Preliminary Results. In Proceedings of the Eco-efficient Resource Wood with Special Focus on Hardwoods; University of West Hungary Press: Sopron, Hungary, 2016; pp. 100–101. [Google Scholar]

- Molnár, S.; Tolvaj, L.; Németh, R. Holzqualität Und Homogenisierung Der Farbe von Zerreiche (Quercus cerris L.) Mittels Dämpfprozess. Holztechnologie 2006, 47, 20–23. [Google Scholar]

- Tolvaj, L.; Molnár, S. Colour Homogenisation of Hardwood Species by Steaming. Acta Silv. Et Lignaria Hung. 2006, 2, 105–112. [Google Scholar]

- Todaro, L. Effect of Steaming Treatment on Resistance to Footprints in Turkey Oak Wood for Flooring. Eur. J. Wood Wood Prod. 2012, 70, 209–214. [Google Scholar] [CrossRef]

- Todaro, L.; Zanuttini, R.; Scopa, A.; Moretti, N. Influence of Combined Hydro-Thermal Treatments on Selected Properties of Turkey Oak (Quercus cerris L.) Wood. Wood Sci. Technol. 2012, 46, 563–578. [Google Scholar] [CrossRef]

- Todaro, L.; Zuccaro, L.; Marra, M.; Basso, B.; Scopa, A. Steaming Effects on Selected Wood Properties of Turkey Oak by Spectral Analysis. Wood Sci. Technol. 2012, 46, 89–100. [Google Scholar] [CrossRef]

- Ferrari, S.; Allegretti, O.; Cuccui, I.; Moretti, N.; Marra, M.; Todaro, L. A Revaluation of Turkey Oak Wood (Quercus cerris L.) Through Combined Steaming and Thermo-Vacuum Treatments. BioResources 2013, 8, 5051–5066. [Google Scholar] [CrossRef]

- Todaro, L.; Dichicco, P.; Moretti, N.; D’Auria, M. Effect of Combined Steam and Heat Treatments on Extractives and Lignin in Sapwood and Heartwood of Turkey Oak (Quercus cerris L.) Wood. BioResources 2013, 8, 1718–1730. [Google Scholar] [CrossRef]

- Todaro, L.; Rita, A.; Moretti, N.; Cuccui, I.; Pellerano, A. Assessment of Thermo-Treated Bonded Wood Performance: Comparisons among Norway Spruce, Common Ash, and Turkey Oak. BioResources 2014, 10, 772–781. [Google Scholar] [CrossRef][Green Version]

- Todaro, L.; D’Auria, M.; Langerame, F.; Salvi, A.M.; Scopa, A. Surface Characterization of Untreated and Hydro-Thermally Pre-Treated Turkey Oak Woods after UV-C Irradiation. Surf. Interface Anal. 2015, 47, 206–215. [Google Scholar] [CrossRef]

- Todaro, L.; Rita, A.; Pucciariello, R.; Mecca, M.; Hiziroglu, S. Influence of Thermo-Vacuum Treatment on Thermal Degradation of Various Wood Species. Eur. J. Wood Wood Prod. 2018, 76, 541–547. [Google Scholar] [CrossRef]

- Cetera, P.; Todaro, L.; Lovaglio, T.; Moretti, N.; Rita, A. Steaming Treatment Decreases MOE and Compression Strength of Turkey Oak Wood. Wood Res. 2016, 61, 255–265. [Google Scholar]

- Cetera, P.; Russo, D.; Milella, L.; Todaro, L. Thermo-Treatment Affects Quercus Cerris L. Wood Properties and the Antioxidant Activity and Chemical Composition of Its by-Product Extracts. Ind. Crops Prod. 2019, 130, 380–388. [Google Scholar] [CrossRef]

- Rowell, R.M. The Chemistry of Solid Wood; American Chemical Society: Washington, DC, USA, 1984. [Google Scholar]

- Uzelac Glavinić, I.; Boko, I.; Lovrić Vranković, J.; Torić, N.; Abramović, M. An Experimental Investigation of Hardwoods Harvested in Croatian Forests for the Production of Glued Laminated Timber. Materials 2023, 16, 1843. [Google Scholar] [CrossRef] [PubMed]

- Sahula, L.; Šedivka, P.; Zachara, T.; Borůvka, V. The effect of chemical modification of the surface of the glued surface on the strength of the structural joint of oak wood. Cent. Eur. For. J. 2023, 69, 120–125. [Google Scholar] [CrossRef]

- Horváth, N.; Csiha, C. Measurements of the Load-Bearing Structural Aspects of Pannónia Poplar from Sites in Western Transdanubia, Hungary. Acta Silv. Et Lignaria Hung. 2022, 18, 119–127. [Google Scholar] [CrossRef]

- Girotra, K. Process for Wood Acetylation and Product Thereof 2013. Available online: https://patents.google.com/patent/US8512815B2/en (accessed on 17 December 2023).

- Rowell, R. Handbook Of Wood Chemistry And Wood Composites; CRC Press: Boca Raton, FL, USA, 2012; ISBN 978-0-8493-1588-6. [Google Scholar]

- Ghavidel, A.; Hofmann, T.; Bak, M.; Sandu, I.; Vasilache, V. Comparative Archaeometric Characterization of Recent and Historical Oak (Quercus spp.) Wood. Wood Sci. Technol. 2020, 54, 1121–1137. [Google Scholar] [CrossRef]

- Ghavidel, A.; Gelbrich, J.; Kuqo, A.; Vasilache, V.; Sandu, I. Investigation of Archaeological European White Elm (Ulmus laevis) for Identifying and Characterizing the Kind of Biological Degradation. Heritage 2020, 3, 1083–1093. [Google Scholar] [CrossRef]

- Amato, D.; Squillaci, G.; Giudicianni, P.; Morana, A.; Ragucci, R.; Cara, F.L. Valorization of Agroindustrial Waste from Chestnut Production. Chem. Eng. Trans. 2021, 87, 445–450. [Google Scholar] [CrossRef]

- Stefke, B.; Windeisen, E.; Schwanninger, M.; Hinterstoisser, B. Determination of the Weight Percentage Gain and of the Acetyl Group Content of Acetylated Wood by Means of Different Infrared Spectroscopic Methods. Anal. Chem. 2008, 80, 1272–1279. [Google Scholar] [CrossRef]

- Schwanninger, M.; Stefke, B.; Hinterstoisser, B. Qualitative Assessment of Acetylated Wood with Infrared Spectroscopic Methods. J. Near Infrared Spectrosc. 2011, 19, 349–357. [Google Scholar] [CrossRef]

- Mohebby, B. Application of ATR Infrared Spectroscopy in Wood Acetylation. J. Agric. Sci. Technol. 2008, 10, 253–259. [Google Scholar]

- Fodor, F.; Németh, R.; Lankveld, C.; Hofmann, T. Effect of Acetylation on the Chemical Composition of Hornbeam (Carpinus betulus L.) in Relation with the Physical and Mechanical Properties. Wood Mater. Sci. Eng. 2018, 13, 271–278. [Google Scholar] [CrossRef]

- Bari, E.; Jamali, A.; Nazarnezhad, N.; Nicholas, D.D.; Humar, M.; Najafian, M. An Innovative Method for the Chemical Modification of Carpinus Betulus Wood: A Methodology and Approach Study. Holzforschung 2019, 73, 839–846. [Google Scholar] [CrossRef]

- Baufleur, A.M.Y.; Stangerlin, D.M.; de Vasconcelos, L.G.; Pariz, E.; Junior, F.R.; Paula, E.A. de O.; de Melo, R.R. Effect of Acetylation on Technological Characteristics of Jacaranda Copaia wood: Part 2—Chemical and Colorimetric Changes. Nativa 2022, 10, 283–289. [Google Scholar] [CrossRef]

- Chai, Y.; Liu, J.; Wang, Z.; Zhao, Y. Dimensional Stability and Mechanical Properties of Plantation Poplar Wood Esterified Using Acetic Anhydride. BioResources 2016, 12, 912–922. [Google Scholar] [CrossRef]

- Rowell, R.M. Acetylation of Wood: Journey from Analytical Technique to Commercial Reality. For. Prod. J. 2006, 56, 4–12. [Google Scholar]

- Cetin, N.S.; Ozmen, N. Acetylation of Wood Components and Fourier Transform Infra-Red Spectroscopy Studies. AJB 2011, 10, 3091–3096. [Google Scholar] [CrossRef]

- Ohkoshi, M.; Kato, A. 13C-NMR Analysis of Acetyl Groups in Acetylated Wood II. Acetyl Groups in Lignin. Mokuzai Gakkaishi 1997, 43, 364–369. [Google Scholar]

- Tolvaj, L. A Faanyag Optikai Tulajdonságai; University of West Hungary: Sopron, Hungary, 2013. [Google Scholar]

- Ying, W.; Ouyang, J.; Lian, Z.; Xu, Y.; Zhang, J. Lignin Removal Improves Xylooligosaccharides Production from Poplar by Acetic Acid Hydrolysis. Bioresour. Technol. 2022, 354, 127190. [Google Scholar] [CrossRef]

- Osman, N.B.; McDonald, A.G.; Laborie, M.-P.G. Characterization of Water-Soluble Extracts from Hot-Pressed Poplar. Eur. J. Wood Wood Prod. 2013, 71, 343–351. [Google Scholar] [CrossRef]

- Szadkowska, D.; Zawadzki, J.; Kozakiewicz, P.; Radomski, A. Identification of Extractives from Various Poplar Species. Forests 2021, 12, 647. [Google Scholar] [CrossRef]

- Pettersen, R.C. The Chemical Composition of Wood. In The Chemistry of Solid Wood; Advances in Chemistry; American Chemical Society: Washington, DC, USA, 1984; Volume 207, pp. 57–126. ISBN 978-0-8412-0796-7. [Google Scholar]

- Bongers, F.; Meijerink, T.; Lütkemeier, B.; Lankveld, C.; Alexander, J.; Militz, H.; Lehringer, C. Bonding of Acetylated Wood. Int. Wood Prod. J. 2016, 7, 102–106. [Google Scholar] [CrossRef]

- Beckers, E.P.J.; Bongers, F.; van der Zee, M.E.; Sander, C. Acetyl Content Determination Using Different Analytical Techniques. In Proceedings of the First European Conference on Wood Modification; Ghent University: Ghent, Belgium, 2003; pp. 83–103. [Google Scholar]

- Dreher, W.A.; Goldstein, I.S.; Cramer, G.R. Mechanical Properties of Acetylated Wood. For. Prod. J. 1964, 14, 66–68. [Google Scholar]

- Papadopoulos, A.N.; Tountziarakis, P. The Effect of Acetylation on the Janka Hardness of Pine Wood. Eur. J. Wood Wood Prod. 2011, 69, 499–500. [Google Scholar] [CrossRef][Green Version]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies—Principles, Sustainability, and the Need for Innovation; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-1-351-02822-6. [Google Scholar]

- Boever, L.D.; Vansteenkiste, D.; Stevens, M.; Acker, J.V. Kiln Drying of Poplar Wood at Low Temperature: Beam Distortions in Relation to Wood Density, Tension Wood Occurence and Moisture Distribution. Wood Res. 2011, 56, 245–256. [Google Scholar]

- Ward, J.C.; Pong, W.Y. Wetwood in Trees: A Timber Resource Problem; U.S. Department of Agriculture, Forest Service, Pacific Northwest Forestry and Range Experiment Station: Madison, MI, USA, 1980; p. 56.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).