Ultrasound-Assisted Cold Alkaline Extraction: Increasing Hemicellulose Extraction and Energy Production from Populus Wood

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization and Storage of Raw Materials

2.2. Cold Alkaline Extraction (CAE) with and without Ultrasound

2.3. Modeling and Optimization by Multiple Regression-Experimental Design

3. Results and Discussion

3.1. Chemical Characterization of the Raw Material

| Composition | (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) |

|---|---|---|---|---|---|---|---|---|

| ᾳ Cellulose (glucan) (%) | 40.3 ± 0.85 | 41.1 ± 2.1 | 38.9 ± 3.4 | 38.0 ± 2.4 | 44.0 ± 3.3 | 42.8 ± 2.0 | 33.8 ± 1.6 | 55.4 ± 2.6 |

| Klason Lignin (%) | 25.1 ± 0.16 | 24.1 ± 1.8 | 19.8 ± 1.9 | 19.0 ± 2.5 | 27.8 ± 1.1 | 21.2 ± 0.9 | 19.9 ± 0.5 | 16 ± 0.3 |

| Xylan (%) | 19.3 ± 0.09 | 17.0 ± 0.5 | 19.9 ± 1.3 | 15.7 ± 0.1 | 15.7 ± 0.2 | 17.1 ± 0.3 | 23.9 ± 0.1 | 34.6 ± 0.4 |

| Araban (%) | 0 | ----- | 0.6 ± 0.3 | 1.5 ± 0.3 | 1.1 ± 0.1 | 0.7 ± 0.1 | 0.37 ± 0.2 | 5.6 ± 0.3 |

| Acetyl groups (%) | 0.7 ± 0.02 | ----- | 4.4 ± 0.6 | 3.3 ± 0.5 | 4.4 ± 0.2 | 3.5 ± 0.1 | 4.32 ± 0.1 | ----- |

| HHV, KJul/kg od.b. | 19,982 ± 30 | ----- | 19,592 ± 28 | 18,981 ± 95 | 20,300 ± 53 | 19,326 ± 84 | 17,259 ± 25 | ----- |

3.2. Cold Alkaline Extraction of Hemicelluloses with and without Ultrasound Assistance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Parliament. Directive (EU) 2018/2001 of the European Parliament and of the Council on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, 2018, 82–209. [Google Scholar]

- REN21. Renewables 2020 Global Status Report; Renewable and Sustainable Energy Reviews; REN21 Secretariat: Paris, France, 2020; ISBN 978-3-948393-00-7. Available online: https://www.ren21.net/gsr-2020/ (accessed on 11 December 2023).

- Domínguez, E.; Nóvoa, T.; del Río, P.G.; Garrote, G.; Romaní, A. Sequential two-stage autohydrolysis biorefinery for the production of bioethanol from fast-growing Paulownia biomass. Energy Convers. Manag. 2020, 226, 113517. [Google Scholar] [CrossRef]

- Ginni, G.; Kavitha, S.; Kannah, Y.; Bhatia, S.K.; Kumar, A.; Rajkumar, M.; Kumar, G.; Pugazhendhi, A.; Chi, N.T.L. Valorization of agricultural residues: Different biorefinery routes. J. Environ. Chem. Eng. 2021, 9, 105435. [Google Scholar] [CrossRef]

- World Energy Outlook 2017 [Internet]. OECD, 2017. Available online: https://www.oecd-ilibrary.org/energy/world-energy-outlook-2017_weo-2017-en (accessed on 11 May 2021).

- Seserman, D.-M.; Pohle, I.; Veste, M.; Freese, D. Simulating climate change impacts on hybrid-poplar and black locust short rotation coppices. Forests 2018, 9, 419. [Google Scholar] [CrossRef]

- Montero, G.; Serrada, R. La Situación de los Bosques y el Sector Forestal en España; ISFE: Pontevedra, Spain, 2013. [Google Scholar]

- del Mar Contreras, M.; Romero, I.; Moya, M.; Castro, E. Olive-derived biomass as a renewable source of value-added products. Process Biochem. 2020, 97, 43–56. [Google Scholar] [CrossRef]

- Ning, P.; Yang, G.; Hu, L.; Sun, J.; Shi, L.; Zhou, Y.; Wang, Z.; Yang, J. Recent advances in the valorization of plant biomass. Biotechnol. Biofuels 2021, 14, 102. [Google Scholar] [CrossRef]

- Cristóbal, J.; Matos, C.T.; Aurambout, J.P.; Manfredi, S.; Kavalov, B. Environmental sustainability assessment of bioeconomy value chains. Biomass Bioenergy 2016, 89, 159–171. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Conrad, M.; Sun, S.N.; Sanchez, A.; Rocha, G.J.M.; Romaní, A.; Castro, E.; Torres, A.; Rodríguez-Jasso, R.M.; Andrade, L.P.; et al. Engineering aspects of hydrothermal pretreatment: From batch to continuous operation, scale-up and pilot reactor under biorefinery concept. Bioresour. Technol. 2020, 299, 122685. [Google Scholar] [CrossRef]

- Sixto, H.; Cañellas, I.; van Arendonk, J.; Ciria, P.; Camps, F.; Sánchez, M.; Sánchez-González, M. Growth potential of different species and genotypes for biomass production in short rotation in Mediterranean environments. For. Ecol. Manag. 2015, 354, 291–299. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture—Trends and Challenges; FAO: Rome, Italy, 2017; ISBN 978-92-5-109551-5. Available online: https://www.fao.org/3/i6583e/i6583e.pdf (accessed on 11 December 2023).

- Lauri, P.; Havlík, P.; Kindermann, G.; Forsell, N.; Böttcher, H.; Obersteiner, M. Woody biomass energy potential in 2050. Energy Policy 2014, 66, 19–31. [Google Scholar] [CrossRef]

- Vanguelova, E.; Pitman, R. Impacts of short rotation forestry on soil sustainability. Short rotation forestry: Review of growth and environmental impacts. For. Res. Monogr. 2011, 2, 37–77. [Google Scholar]

- Madejón, P.; Alaejos, J.; García-Álbala, J.; Fernández, M.; Madejón, E. Three-year study of fast-growing trees in degraded soils amended with composts: Effects on soil fertility and productivity. J. Environ. Manag. 2016, 169, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Madadi, M.; Song, G.; Karimi, K.; Zhu, D.; Elsayed, M.; Sun, F.; Abomohra, A. One-step lignocellulose fractionation using acid/pentanol pretreatment for enhanced fermentable sugar and reactive lignin production with efficient pentanol retrievability. Bioresour. Technol. 2022, 359, 127503. [Google Scholar] [CrossRef] [PubMed]

- Penín, L.; Peleteiro, S.; Rivas, S.; Santos, V.; Parajó, J.C. Production of 5-hydroxymethylfurfural from pine wood via biorefinery technologies based on fractionation and reaction in ionic liquids. Bioresources 2019, 14, 4733–4747. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef]

- de Carvalho, D.M.; Sevastyanova, O.; de Queiroz, J.H.; Colodette, J.L. Cold alkaline extraction as a pretreatment for bioethanol production from eucalyptus, sugarcane bagasse and sugarcane straw. Energy Convers. Manag. 2016, 124, 315–324. [Google Scholar] [CrossRef]

- García, J.C.; Díaz, M.J.; Garcia, M.T.; Feria, M.J.; Gómez, D.M.; López, F. Search for optimum conditions of wheat straw hemicelluloses cold alkaline extraction process. Biochem. Eng. J. 2013, 71, 127–133. [Google Scholar] [CrossRef]

- Hutterer, C.; Schild, G.; Potthast, A. A precise study on effects that trigger alkaline hemicellulose extraction efficiency. Bioresour. Technol. 2016, 214, 460–467. [Google Scholar] [CrossRef]

- Park, Y.C.; Kim, J.S. Comparison of various alkaline pretreatment methods of lignocellulosic biomass. Energy 2012, 47, 31–35. [Google Scholar] [CrossRef]

- Longue Júnior, D.; Colodette, J.L.; Gomes, V.J. Extraction of wood hemicelluloses through NaOH leaching|Remoção de hemiceluloses da madeira por tratamento de lixiviação alcalina com NaOH. Cerne 2010, 16, 423–429. [Google Scholar] [CrossRef][Green Version]

- Tiwari, B.K. Ultrasound: A clean, green extraction technology. TrAC-Trends Anal. Chem. 2015, 71, 100–109. [Google Scholar] [CrossRef]

- Yuan, Z.; Long, J.; Wang, T.; Shu, R.; Zhang, Q.; Ma, L. Process intensification effect of ball milling on the hydrothermal pretreatment for corn straw enzymolysis. Energy Convers. Manag. 2015, 101, 481–488. [Google Scholar] [CrossRef]

- Saikia, M.; Das, T.; Hower, J.C.; Silva, L.F.O.; Fan, X.; Saikia, B.K. Oxidative chemical beneficiation of low-quality coals under low-energy ultrasonic and microwave irradiation: An environmental-friendly approach. J. Environ. Chem. Eng. 2021, 9, 104830. [Google Scholar] [CrossRef]

- Ashokkumar, M. The characterization of acoustic cavitation bubbles—An overview. Ultrason. Sonochem. 2011, 18, 864–872. [Google Scholar] [CrossRef] [PubMed]

- García, A.; Alriols, M.G.; Llano-Ponte, R.; Labidi, J. Ultrasound-assisted fractionation of the lignocellulosic material. Bioresour. Technol. 2011, 102, 6326–6330. [Google Scholar] [CrossRef] [PubMed]

- Raihan, A.; Ibrahim, S.; Muhtasim, D.A. Dynamic impacts of economic growth, energy use, tourism, and agricultural productivity on carbon dioxide emissions in Egypt. World Dev. Sustain. 2023, 2, 100059. [Google Scholar] [CrossRef]

- Li, F.; Li, Y.; Novoselov, K.S.; Liang, F.; Meng, J.; Ho, S.-H.; Zhao, T.; Zhou, H.; Ahmad, A.; Zhu, Y.; et al. Bioresource Upgrade for Sustainable Energy, Environment, and Biomedicine. Nano-Micro Lett. 2023, 15, 35. [Google Scholar] [CrossRef]

- Puițel, A.C.; Suditu, G.D.; Drăgoi, E.N.; Danu, M.; Ailiesei, G.-L.; Balan, C.D.; Chicet, D.-L.; Nechita, M.T. Optimization of Alkaline Extraction of Xylan-Based Hemicelluloses from Wheat Straws: Effects of Microwave, Ultrasound, and Freeze–Thaw Cycles. Polymers 2023, 15, 1038. [Google Scholar] [CrossRef]

- Gufe, C.; Thantsha, M.S.; Malgas, S. Recovery of xylan from Acacia mearnsii using ultrasound-assisted alkaline extraction. Biofuels Bioprod. Biorefining 2023, 17, 976–987. [Google Scholar] [CrossRef]

- Tareen, A.K.; Punsuvon, V.; Parakulsuksatid, P. Conversion of steam exploded hydrolyzate of oil palm trunk to furfural by using sulfuric acid, solid acid, and base catalysts in one pot. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–12. [Google Scholar] [CrossRef]

- Gil, M.V.; Jablonka, K.M.; García, S.; Pevida, C.; Smit, B. Biomass to energy: A machine learning model for optimum gasification pathways. Digit. Discov. 2023, 2. [Google Scholar] [CrossRef]

- Tofani, G.; Cornet, I.; Tavernier, S. Multiple linear regression to predict the brightness of waste fibres mixtures before bleaching. Chem. Pap. 2022, 76, 4351–4365. [Google Scholar] [CrossRef]

- TAPPI T264 cm-07; Preparation of Wood for Chemical Analysis. TAPPI Press: Atlanta, GA, USA, 2007.

- TAPPI 211 om-02; Ash in Wood, Pulp, Paper and Paperboard: Combustion at 525 °C. TAPPI Press: Atlanta, GA, USA, 2002.

- TAPPI T204 cm-07; Solvent Extractives of Wood and Pulp. TAPPI Press: Atlanta, GA, USA, 2007.

- TAPPI T249 cm-09; Carbohydrate Composition of Extractive-Free Wood and Wood Pulp by Gas-Liquid Chromatography. TAPPI Press: Atlanta, GA, USA, 2009.

- Romaní, A.; Garrote, G.; Ballesteros, I.; Ballesteros, M. Second generation bioethanol from steam exploded Eucalyptus globulus wood. Fuel 2013, 111, 66–74. [Google Scholar] [CrossRef]

- TAPPI T222 om-11; Acid-Insoluble Lignin in Wood and Pulp. TAPPI Press: Atlanta, GA, USA, 2011.

- CEN/TS Solid Biofuels-Method for the Determination of Calorific Value CEN/TS 14918:2005. 2005. Available online: https://standards.iteh.ai/catalog/standards/cen/21f53010-bfdf-41aa-8f73-3ad9e2ab444f/cen-ts-14918-2005 (accessed on 11 December 2023).

- UNE 16001 EX; Solid Biofuels, Method for the Determination of Calorific Value. Spanish Association for Standardization: Madrid, Spain, 2005. Available online: https://infostore.saiglobal.com/preview/is/en/2005/i.s.cents14918-2005.pdf?sku=675235 (accessed on 11 December 2023).

- Civitarese, V.; Faugno, S.; Picchio, R.; Assirelli, A.; Sperandio, G.; Saulino, L.; Crimaldi, M.; Sannino, M. Production of selected short-rotation wood crop species and quality of obtained biomass. Eur. J. For. Res. 2018, 137, 541–552. [Google Scholar] [CrossRef]

- Magagnotti, N.; Spinelli, R.; Kärhä, K.; Mederski, P.S. Multi-tree cut-to-length harvesting of short-rotation poplar plantations. Eur. J. For. Res. 2020, 140, 345–354. [Google Scholar] [CrossRef]

- Constantí, M.; Reguant, C.; Poblet, M.; Zamora, F.; Mas, A.; Guillamón, J.M. Molecular analysis of yeast population dynamics: Effect of sulphur dioxide and inoculum on must fermentation. Int. J. Food Microbiol. 1998, 41, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Ebringerová, A.; Hromádková, Z. An overview on the application of ultrasound in extraction, separation and purification of plant polysaccharides. Cent. Eur. J. Chem. 2010, 8, 243–257. [Google Scholar] [CrossRef]

- Alfaro, A.; López, F.; Pérez, A.; García, J.C.; Rodríguez, A. Integral valorization of tagasaste (Chamaecytisus proliferus) under hydrothermal and pulp processing. Bioresour. Technol. 2010, 101, 7635–7640. [Google Scholar] [CrossRef]

- López, F.; Alfaro, A.; García, M.; Díaz, M.J.; Calero, A.M.; Ariza, J. Pulp and paper from tagasaste (Chamaecytisus proliferus L.F. ssp. palmensis). Chem. Eng. Res. Des. 2004, 82, 1029–1036. [Google Scholar] [CrossRef]

- Feria, M.J.; García, J.C.; Pérez, A.; Gomide, J.L.; Colodette, J.L.; López, F. Process optimization in kraft pulping, bleaching, and beating of Leucaena diversifolia. Bioresources 2012, 7, 283–297. [Google Scholar] [CrossRef]

- Caparrós, S.; Ariza, J.; López, F.; Nacimiento, J.A.; Garrote, G.; Jiménez, L. Hydrothermal treatment and ethanol pulping of sunflower stalks. Bioresour. Technol. 2008, 99, 1368–1372. [Google Scholar] [CrossRef] [PubMed]

- García, J.C.; Zamudio, M.A.M.; Pérez, A.; De Alva, H.E.; López, F. Paulownia as a raw material for the production of pulp by soda-anthraquinone cooking with or without previous autohydrolysis. J. Chem. Technol. Biotechnol. 2011, 86, 608–615. [Google Scholar] [CrossRef]

- López, F.; Pérez, A.; Zamudio, M.A.M.; De Alva, H.E.; García, J.C. Paulownia as raw material for solid biofuel and cellulose pulp. Biomass Bioenergy 2012, 45, 77–86. [Google Scholar] [CrossRef]

- Loaiza, J.M.; López, F.; García, M.T.; Fernández, O.; Díaz, M.J.; García, J.C. Selecting the pre-hydrolysis conditions for eucalyptus wood in a fractional exploitation biorefining scheme. J. Wood Chem. Technol. 2016, 36, 211–223. [Google Scholar] [CrossRef]

- López, F.; García, M.; Feria, M.; García, J.; de Diego, C.; Zamudio, M.; Díaz, M. Optimization of furfural production by acid hydrolysis of eucalyptus globulus in two stages. Chem. Eng. J. 2014, 240, 195–201. [Google Scholar] [CrossRef]

- Pan, X.; Sano, Y. Fractionation of wheat straw by atmospheric acetic acid process. Bioresour. Technol. 2005, 96, 1256–1263. [Google Scholar] [CrossRef]

- Fernández, M.; Alaejos, J.; Andivia, E.; Madejón, P.; Díaz, M.J.; Tapias, R. Short rotation coppice of leguminous tree Leucaena spp. improves soil fertility while producing high biomass yields in Mediterranean environment. Ind. Crops Prod. 2020, 157, 112911. [Google Scholar] [CrossRef]

- Hu, M.; Chen, Z.; Wang, S.; Guo, D.; Ma, C.; Zhou, Y.; Chen, J.; Laghari, M.; Fazal, S.; Xiao, B.; et al. Thermogravimetric kinetics of lignocellulosic biomass slow pyrolysis using distributed activation energy model, Fraser-Suzuki deconvolution, and iso-conversional method. Energy Convers. Manag. 2016, 118, 1–11. [Google Scholar] [CrossRef]

- Fernández, M.; Alaejos, J.; Andivia, E.; Vázquez-Piqué, J.; Ruiz, F.; López, F.; Tapias, R. Eucalyptus x urograndis biomass production for energy purposes exposed to a Mediterranean climate under different irrigation and fertilisation regimes. Biomass Bioenergy 2018, 111, 22–30. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, Q.; Wang, X.; Xiao, B.; Liu, S. Pyrolysis behaviors and kinetic studies on Eucalyptus residues using thermogravimetric analysis. Energy Convers. Manag. 2015, 105, 251–259. [Google Scholar] [CrossRef]

- Methrath Liyakathali, N.A.; Muley, P.D.; Aita, G.; Boldor, D. Effect of frequency and reaction time in focused ultrasonic pretreatment of energy cane bagasse for bioethanol production. Bioresour. Technol. 2016, 200, 262–271. [Google Scholar] [CrossRef] [PubMed]

| Variables | With Ultrasound | Without Ultrasound | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| XA | Xt | XT | Yield (%) | Glucan (%) | Xylan (%) | Klason Lignin (%) | Yield (%) | Glucan (%) | Xylan (%) | Klason Lignin (%) |

| 0 | 0 | 0 | 68.8 | 86.4 | 40.4 | 67.0 | 73.2 | 89.8 | 45.4 | 88.5 |

| 0 | 0 | 0 | 68.8 | 86.4 | 40.4 | 67.0 | 73.2 | 89.8 | 45.4 | 88.5 |

| 1 | 1 | 1 | 63.3 | 80.4 | 45.0 | 58.4 | 68.5 | 93.2 | 56.8 | 80.1 |

| 1 | 1 | −1 | 67.9 | 84.3 | 43.5 | 62.4 | 77.8 | 95.7 | 49.3 | 83.4 |

| 1 | −1 | 1 | 69.0 | 84.8 | 49.5 | 73.9 | 73.3 | 96.5 | 54.7 | 97.5 |

| 1 | −1 | −1 | 75.0 | 95.8 | 50.2 | 67.4 | 80.8 | 98.2 | 47.4 | 90.6 |

| −1 | 1 | 1 | 64.7 | 96.2 | 47.2 | 51.5 | 69.3 | 98.1 | 43.3 | 71.6 |

| −1 | 1 | −1 | 70.9 | 96.2 | 51.6 | 66.7 | 77.6 | 98.2 | 51.3 | 90.9 |

| −1 | −1 | 1 | 69.5 | 85.7 | 49.9 | 69.2 | 71.6 | 89.8 | 53.0 | 89.5 |

| −1 | −1 | −1 | 74.6 | 87.6 | 55.7 | 77.7 | 78.5 | 92.1 | 60.2 | 98.9 |

| 1 | 0 | 0 | 67.3 | 91.0 | 44.4 | 60.9 | 72.7 | 98.7 | 47.4 | 79.7 |

| −1 | 0 | 0 | 69.4 | 95.6 | 50.3 | 61.3 | 73.1 | 97.4 | 47.6 | 79.6 |

| 0 | 1 | 0 | 66.5 | 81.7 | 39.2 | 68.7 | 73.7 | 88.1 | 46.4 | 93.3 |

| 0 | −1 | 0 | 71.0 | 84.6 | 44.2 | 74.4 | 75.4 | 85.1 | 52.0 | 98.1 |

| 0 | 0 | 1 | 68.6 | 82.1 | 40.9 | 68.4 | 71.1 | 86.3 | 49.5 | 90.6 |

| 0 | 0 | −1 | 73.5 | 84.1 | 42.6 | 72.9 | 78.7 | 87.8 | 50.1 | 96.0 |

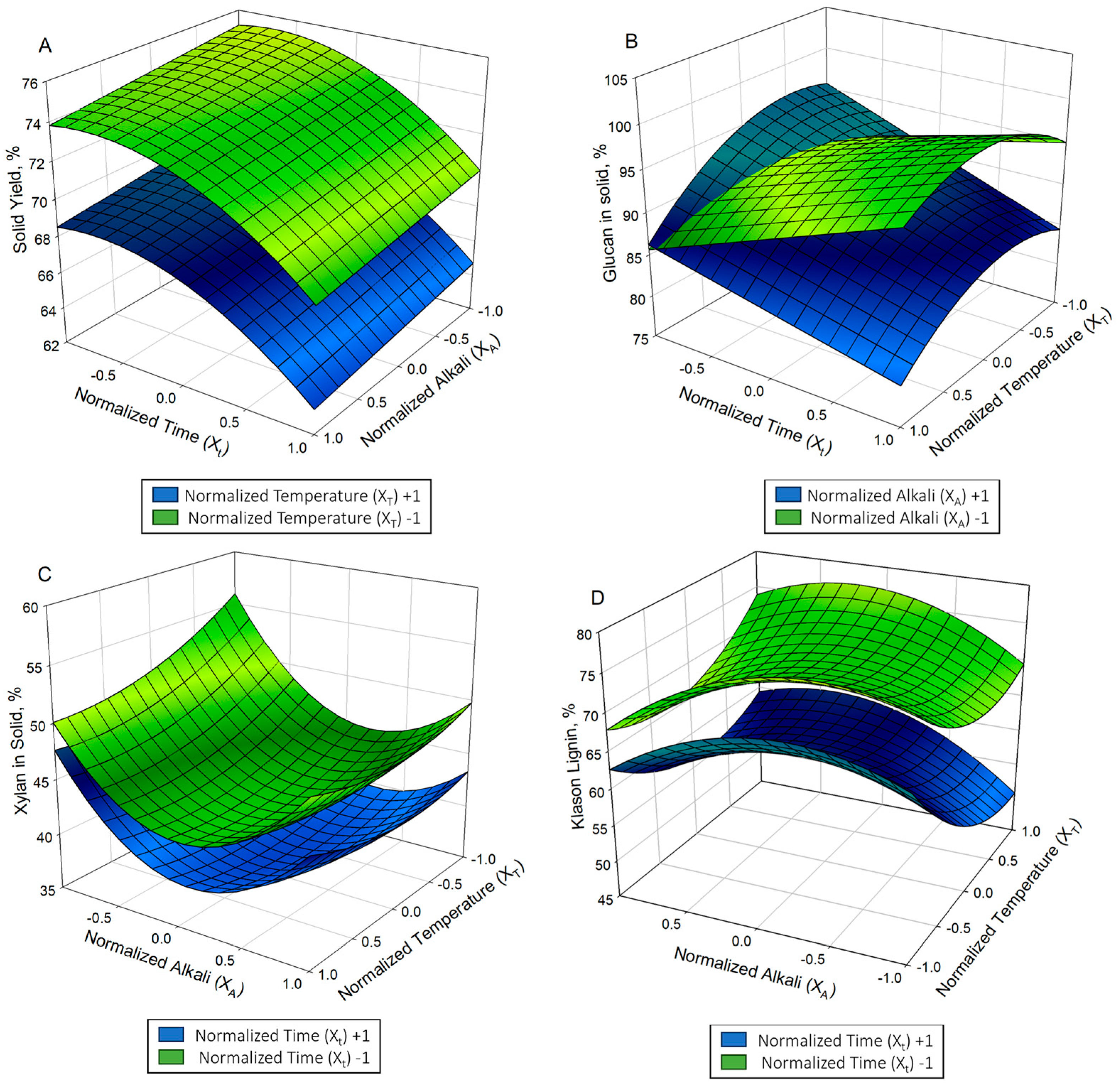

| Equation with Ultrasounds | Equation Number | Adjusted R2/Snedecor’s F-Value |

|---|---|---|

| YI = 68.5 − 0.67XA − 2.57Xt − 2.66XT − 1.83Xt2+ 2.58XT2 | (3) | 0.95/56 |

| GL = 87.0 − 2.50XA − 1.87XT + 5.98XA2 − 4.03XT2 − 4.39XAXt − 1.6XAXT + 1.19XtXT | (4) | 0.98/59 |

| X = 40.2 − 2.28XA − 2.24Xt − 1.12XT + 7.23XA2 + 1.62XT2 − 0.56XAXt + 1.37XAXT + 0.44XtXT | (5) | 0.98/138 |

| KL = 66.6 − 5.96Xt − 2.57XT − 5.33XA2 + 4.58XT2 + 1.04XAXt + 3.28XAXT − 2.34XtXT | (6) | 0.98/114 |

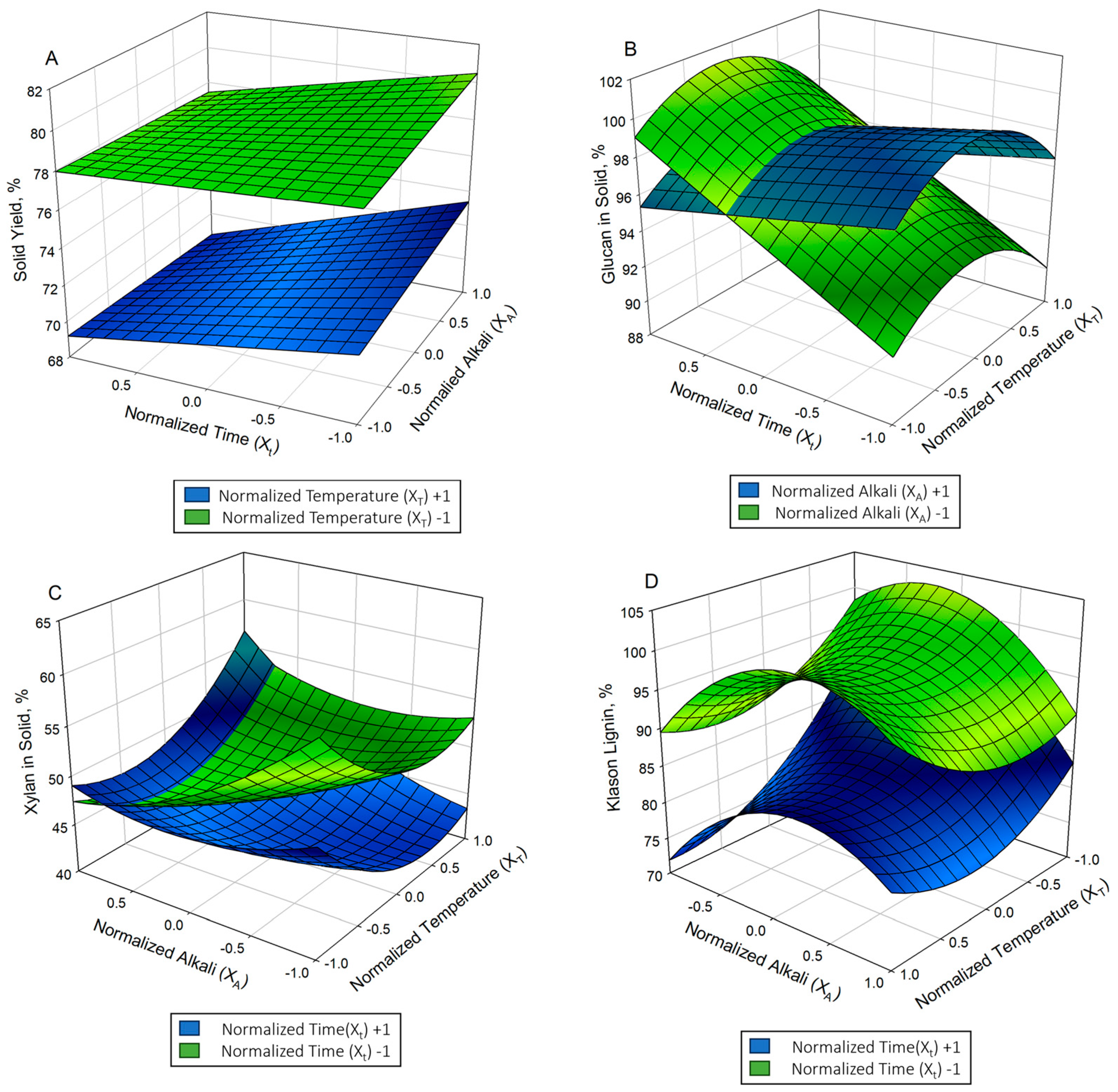

| Equation without Ultrasounds | Equation Number | Adjusted R2/Snedecor’s F-Value |

| YI = 73.0 + 0.3 XA − 1.38X t − 3.97XT + 1.68XT2 − 0.57XAXt − 0.42XtXT | (7) | 0.98/202 |

| GL = 89.7 + 0.67XA + 1.16Xt − 0.80XT + 8.37XA2 − 2.86XT2 − 2.53XAXt | (8) | 0.99/189 |

| X= 45.2 − 2.02Xt + 2.39XA2 + 4.39XT2 + 2.84XAXt + 3.76XAXT | (9) | 0.99/211 |

| KL = 88.04 − 6.08Xt − 3.05XT − 8.14XA2 + 2.61Xt2 + 5.24XT2 + 4.05XAXT − 2.75XtXT | (10) | 0.99/251 |

| Normalized Values | Cold Alkaline Extraction (CAE) with Ultrasound | |||||||

|---|---|---|---|---|---|---|---|---|

| XA | Xt | XT | H (%) | S (%) | C (%) | O (%) | Moisture (%) | LHV at Constant Volume (J/g o.d.b.) |

| 0 | 0 | 0 | 6.105 | 0.00018 | 45.60 | 47.19 | 9.9 | 18,843 |

| 1 | 1 | 1 | 5.867 | 0.00000 | 41.01 | 52.03 | 8.2 | 19,233 |

| 1 | 1 | −1 | 5.872 | 0.00000 | 42.36 | 50.68 | 7.8 | 19,033 |

| 1 | −1 | 1 | 5.918 | 0.00024 | 44.70 | 48.23 | 10.0 | 18,115 |

| 1 | −1 | −1 | 5.922 | 0.00011 | 45.18 | 47.81 | 8.1 | 18,570 |

| −1 | 1 | 1 | 5.841 | 0.00000 | 42.00 | 51.07 | 11.2 | 18,504 |

| −1 | 1 | −1 | 5.858 | 0.00016 | 43.88 | 49.17 | 8.2 | 18,530 |

| −1 | −1 | 1 | 5.861 | 0.00020 | 43.85 | 49.20 | 10.0 | 18,516 |

| −1 | −1 | −1 | 5.908 | 0.00032 | 44.15 | 48.86 | 8.9 | 18,675 |

| 1 | 0 | 0 | 6.023 | 0.00014 | 44.00 | 49.01 | 11.2 | 18,965 |

| −1 | 0 | 0 | 5.981 | 0.00030 | 44.25 | 48.71 | 8.8 | 18,872 |

| 0 | 1 | 0 | 5.972 | 0.00004 | 44.69 | 48.25 | 8.2 | 18,734 |

| 0 | −1 | 0 | 5.962 | 0.000140 | 45.547 | 47.4 | 8.1 | 18,477 |

| 0 | 0 | 1 | 5.870 | 0.000165 | 44.359 | 48.78 | 9.8 | 18,482 |

| 0 | 0 | −1 | 5.890 | 0.000205 | 45.076 | 47.78 | 9.7 | 18,686 |

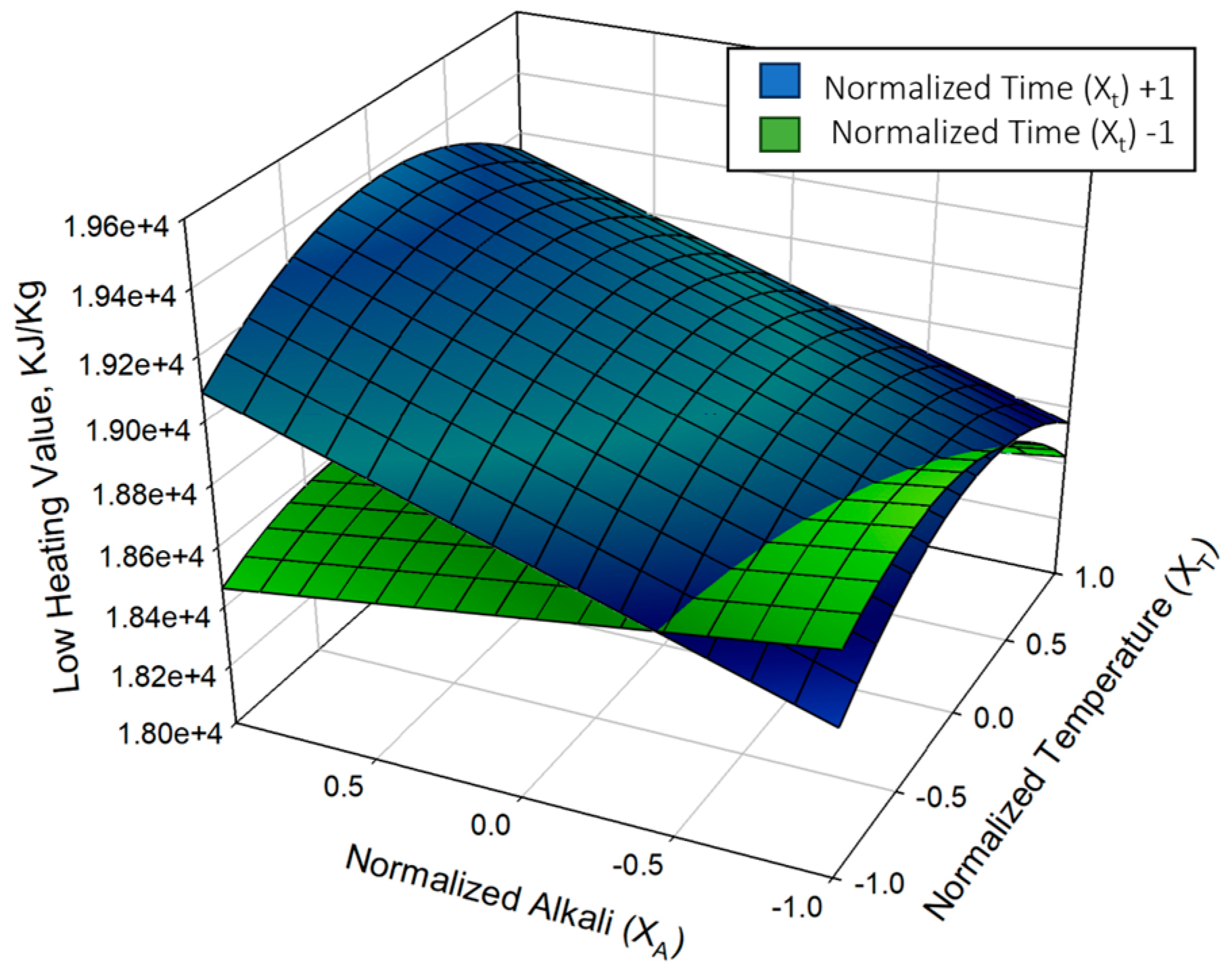

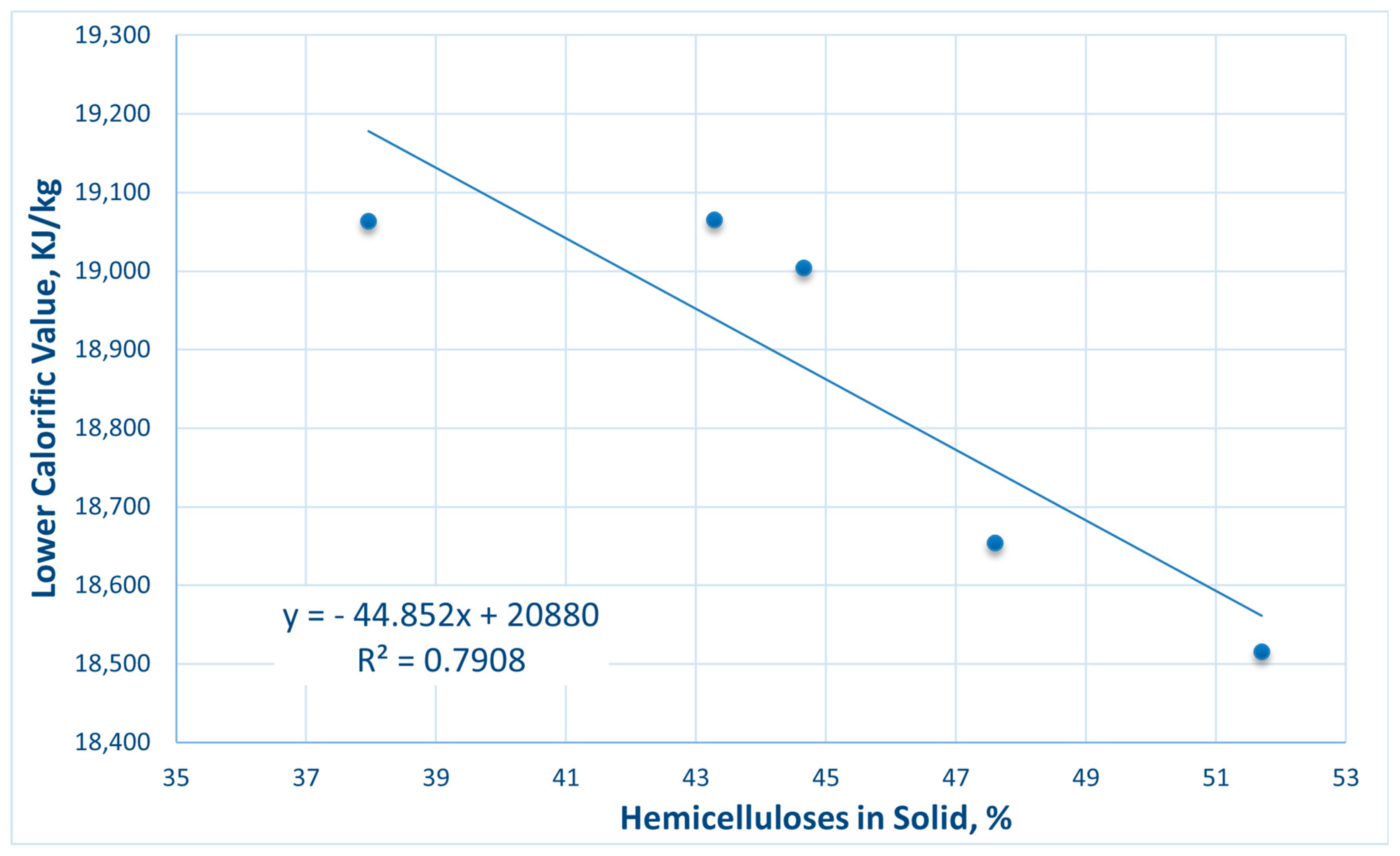

| Equation with Ultrasounds | Equation Number | Adjusted R2/Snedecor’s F-Value |

|---|---|---|

| H = 6.100 + 0.015XA − 0.016Xt − 0.093XA2 + 0.092Xt2 − 0.220XT2 | (11) | 0.96/70 |

| S = 0.000180 − 0.000049XA − 0.000086Xt − 0.000019XT + 0.000036XA2 − 0.000089Xt2 + 0.000050XAXT − 0.000023XtXT | (12) | 0.95/40 |

| C = 45.62 − 1.02Xt − 0.470XT − 1.514XA2 − 0.711XT2 − 0.549XAXt − 0.363XtXT | (13) | 0.97/77 |

| O = 47.22 + 1.04Xt + 0.50XT + 1.60XA2 + 0.81XT2 + 0.56XAXt | (14) | 0.97/79 |

| LHV = 18,881 + 82XA + 186Xt − 64XT − 251XT2 + 217XAXt + 90XtXT | (15) | 0.95/27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozano-Calvo, S.; Loaiza, J.M.; García, J.C.; García, M.T.; López, F. Ultrasound-Assisted Cold Alkaline Extraction: Increasing Hemicellulose Extraction and Energy Production from Populus Wood. Forests 2024, 15, 109. https://doi.org/10.3390/f15010109

Lozano-Calvo S, Loaiza JM, García JC, García MT, López F. Ultrasound-Assisted Cold Alkaline Extraction: Increasing Hemicellulose Extraction and Energy Production from Populus Wood. Forests. 2024; 15(1):109. https://doi.org/10.3390/f15010109

Chicago/Turabian StyleLozano-Calvo, S., J. M. Loaiza, J. C. García, M. T. García, and F. López. 2024. "Ultrasound-Assisted Cold Alkaline Extraction: Increasing Hemicellulose Extraction and Energy Production from Populus Wood" Forests 15, no. 1: 109. https://doi.org/10.3390/f15010109

APA StyleLozano-Calvo, S., Loaiza, J. M., García, J. C., García, M. T., & López, F. (2024). Ultrasound-Assisted Cold Alkaline Extraction: Increasing Hemicellulose Extraction and Energy Production from Populus Wood. Forests, 15(1), 109. https://doi.org/10.3390/f15010109