Thermal, Mechanical and Morphological Properties of Cellulose/Lignin Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Nanocellulose and Nanolignin

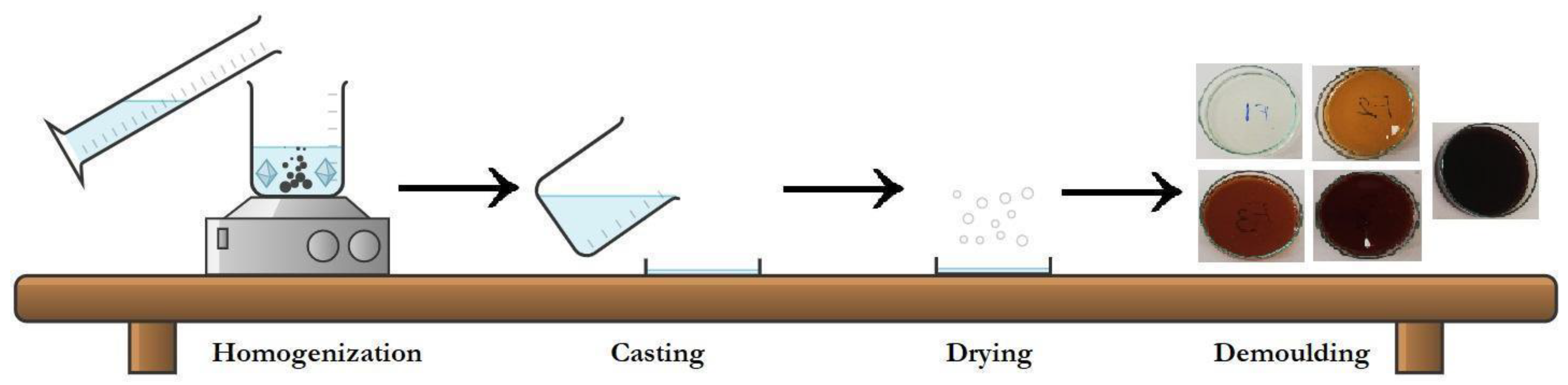

2.2. Preparation of Nanocomposite Films

2.3. Characterization

3. Results and Discussion

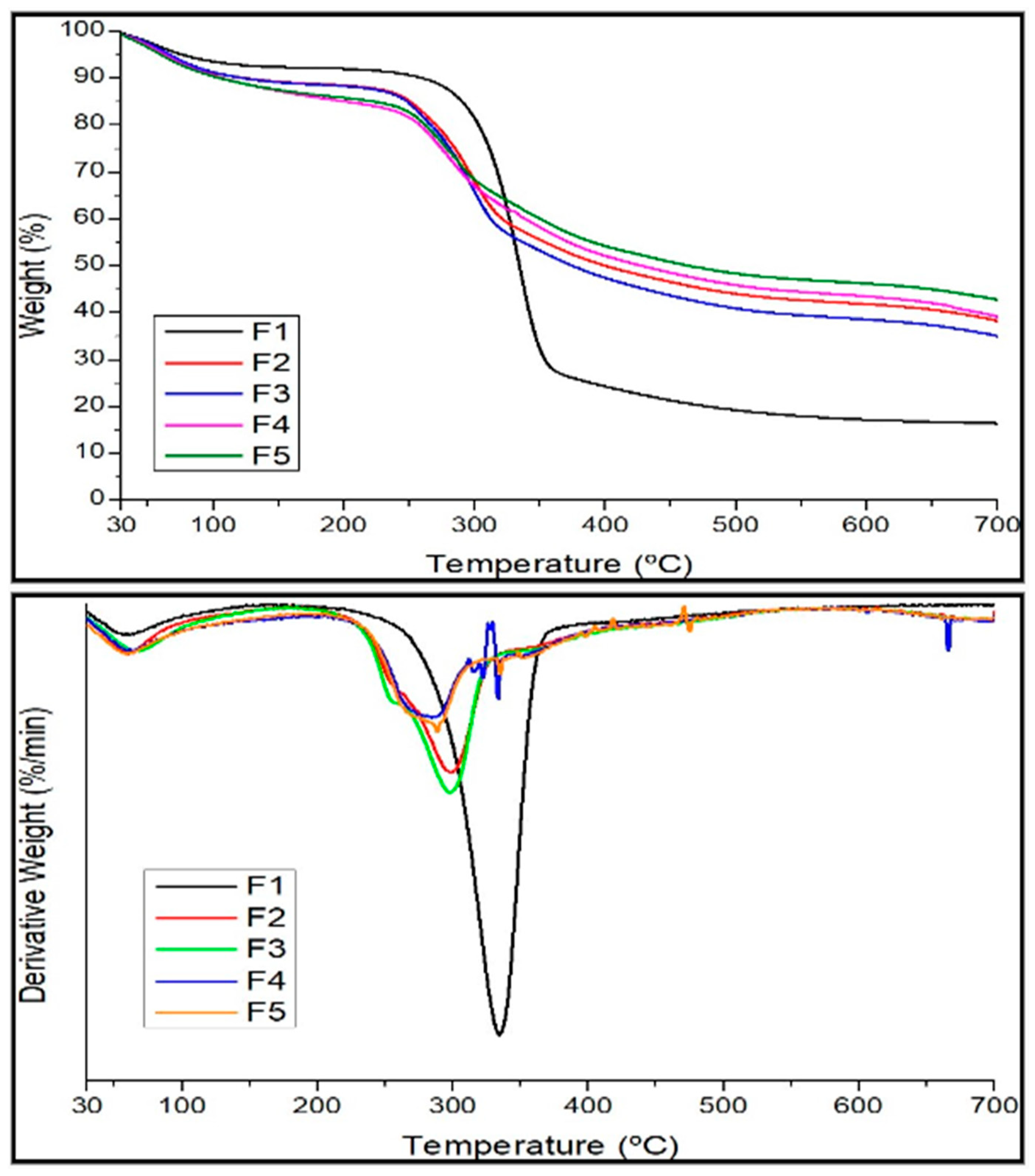

3.1. Thermal Properties of the Nanocomposite Films

3.2. Mechanical Properties of the Nanocomposite Films

3.3. Morphological Properties of the Nanocomposite Films

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Grząbka-Zasadzińska, A.; Amietszajew, T.; Borysiak, S. Thermal and mechanical properties of chitosan nanocomposites with cellulose modified in ionic liquids. J. Therm. Anal. Calorim. 2017, 130, 143–154. [Google Scholar] [CrossRef]

- Candan, Z.; Tozluoglu, A.; Gonultas, O.; Yildirim, M.; Fidan, H.; Alma, M.H.; Salan, T. Nanocellulose: Sustainable biomaterial for developing novel adhesives and composites. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 49–137. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A new family of nature-based materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef]

- Lin, N.; Dufresne, A. Nanocellulose in biomedicine: Current status and future prospect. Eur. Polym. J. 2014, 59, 302–325. [Google Scholar] [CrossRef]

- Thomas, B.; Raj, M.C.; Athira, K.B.; Rubiyah, M.H.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a Versatile Green Platform: From Biosources to Materials and Their Applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef]

- Alavi, M. Modifications of microcrystalline cellulose (MCC), nanofibrillated cellulose (NFC), and nanocrystalline cellulose (NCC) for antimicrobial and wound healing applications. E-Polymers 2019, 19, 103–119. [Google Scholar] [CrossRef]

- Jasmania, L.; Thielemans, W. Preparation of nanocellulose and its potential application. For. Res. 2018, 7, 222. [Google Scholar] [CrossRef]

- Naz, S.; Ali, J.S.; Zia, M. Nanocellulose isolation characterization and applications: A journey from non-remedial to biomedical claims. Bio-Des. Manuf. 2019, 2, 187–212. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From fundamentals to advanced applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef] [PubMed]

- Baghban, M.H.; Mahjoub, R. Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review. Appl. Sci. 2020, 10, 357. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, X.; Guan, S.; Dou, Y.; Gao, X. Preparation of lignin containing cellulose nanofibers and its application in PVA nanocomposite films. Int. J. Bio Macromol. 2020, 158, 1259–1267. [Google Scholar] [CrossRef] [PubMed]

- Du, L.; Zhong, T.; Wolcott, M.P.; Zhang, Y.; Qi, C.; Zhao, B.; Wang, J.; Yu, Z. Dispersing and stabilizing cellulose nanoparticles in acrylic resin dispersions with unreduced transparency and changed rheological property. Cellulose 2018, 25, 2435–2450. [Google Scholar] [CrossRef]

- Tang, Z.; Yang, M.; Qiang, M.; Li, X.; Morrell, J.J.; Yao, Y.; Su, Y. Preparation of cellulose nanoparticles from foliage by bio-enzyme methods. Materials 2021, 14, 4557. [Google Scholar] [CrossRef]

- Tozluoglu, A.; Poyraz, B.; Mcdonald, A.G.; Candan, Z. Developing nanocellulose-based biofilms from kraft and NaBH4—Modified kraft pulp. Cellul. Chem. Technol. 2018, 52, 223–237. [Google Scholar]

- Zhang, B.; Huang, C.; Zhao, H.; Wang, J.; Yin, C.; Zhang, L.; Zhao, Y. Effects of cellulose nanocrystals and cellulose nanofibers on the structure and properties of polyhydroxybutyrate nanocomposites. Polymers 2019, 11, 2063. [Google Scholar] [CrossRef]

- Sertkaya, S.; Arslan, R.; Tozluoğlu, A.; Fidan, H.; Erol, Ö.; Ünal, H.İ.; Candan, Z. The effect of different enzymatic pretreatment processes on the production of nanocellulose from wheat straw. J. Fac. Eng. Archit. Gazi Univ. 2023, 38, 2055–2067. [Google Scholar] [CrossRef]

- Ali, S.S.; Abdelkarim, E.A.; Elsamahy, T.; Al-Tohamy, R.; Li, F.; Kornaros, M.; Zuorro, A.; Zhu, D.; Sun, J. Bioplastic production in terms of life cycle assessment: A state-of-the-art review. Environ. Sci. Ecotechnol. 2023, 15, 100254. [Google Scholar] [CrossRef]

- Vahabi, H.; Brosse, N.; Abd Latif, N.H.; Fatriasari, W.; Solihat, N.N.; Hashim, R.; Hazwan Hussin, M.; Laoutid, F.; Saeb, M.R. Nanolignin in materials science and technology—Does flame retardancy matter? In Biopolymeric Nanomaterials; Kanwar, S., Kumar, A., Nguyen, T.A., Sharma, S., Slimani, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 515–559. [Google Scholar] [CrossRef]

- Henn, A.; Mattinen, M.L. Chemo-enzymatically prepared lignin nanoparticles for value-added applications. World J. Microbiol. Biotechnol. 2019, 35, 125. [Google Scholar] [CrossRef]

- Chauhan, P.S. Lignin nanoparticles: Eco-friendly and versatile tool for new era. Bioresour. Technol. Rep. 2020, 9, 100374. [Google Scholar] [CrossRef]

- Liao, J.J.; Latif, N.H.A.; Trache, D.; Brosse, N.; Hussin, M.H. Current advancement on the isolation, characterization and application of lignin. Int. J. Biol. Macromol. 2020, 162, 985–1024. [Google Scholar] [CrossRef]

- Tribot, A.; Amer, G.; Alio, M.A.; de Baynast, H.; Delattre, C.; Pons, A.; Mathias, J.D.; Callois, J.M.; Vial, C.; Michaud, P.; et al. Wood-lignin: Supply, extraction processes and use as bio-based material. Eur. Polym. J. 2019, 112, 228–240. [Google Scholar] [CrossRef]

- Vishtal, A.; Kraslawski, A. Challenges in industrial applications of technical lignins. BioResources 2011, 6, 3547–3568. [Google Scholar] [CrossRef]

- Dong, H.; Zheng, L.; Yu, P.; Jiang, Q.; Wu, Y.; Huang, C.; Yin, B. Characterization and application of lignin–carbohydrate complexes from lignocellulosic materials as antioxidants for scavenging in vitro and in vivo reactive oxygen species. ACS Sustain. Chem. Eng. 2019, 8, 256–266. [Google Scholar] [CrossRef]

- Upton, B.M.; Kasko, A.M. Strategies for the conversion of lignin to high-value polymeric materials: Review and perspective. Chem. Rev. 2016, 116, 2275–2306. [Google Scholar] [CrossRef]

- Zhang, Z.; Terrasson, V.; Guénin, E. Lignin nanoparticles and their nanocomposites. Nanomaterials 2021, 11, 1336. [Google Scholar] [CrossRef]

- Makri, S.P.; Xanthopoulou, E.; Klonos, P.A.; Grigoropoulos, A.; Kyritsis, A.; Tsachouridis, K.; Anastasiou, A.; Deligkiozi, I.; Nikolaidis, N.; Bikiaris, D.N. Effect of micro- and nano-lignin on the thermal, mechanical, and antioxidant properties of biobased PLA-lignin composite films. Polymers 2022, 14, 5274. [Google Scholar] [CrossRef]

- Makri, S.P.; Xanthopoulou, E.; Valera, M.A.; Mangas, A.; Marra, G.; Ruiz, V.; Koltsakidis, S.; Tzetzis, D.; Zoikis Karathanasis, A.; Deligkiozi, I.; et al. Poly(lactic acid) composites with lignin and nanolignin synthesized by in situ reactive processing. Polymers 2023, 15, 2386. [Google Scholar] [CrossRef]

- Zhang, S.; Cheng, X.; Fu, Q.; Li, Y.; Wu, P.; Qiao, Y.; Yan, J.; Si, L.; Waterhouse, G.I.N.; Li, H.; et al. Pectin-nanolignin composite films with water resistance, UV resistance, and antibacterial activity. Food Hydrocoll. 2023, 143, 108783. [Google Scholar] [CrossRef]

- Yang, W.; Ding, H.; Qi, G.; Li, C.; Xu, P.; Zheng, T.; Zhu, X.; Kenny, J.M.; Puglia, D.; Ma, P. Highly transparent PVA/nanolignin composite films with excellent UV shielding, antibacterial and antioxidant performance. React. Funct. Polym. 2021, 162, 104873. [Google Scholar] [CrossRef]

- Peng, X.; Ren, J.; Zhong, L.; Sun, R. Nanocomposite films based on xylan-rich hemicelluloses and cellulose nanofibers with enhanced mechanical properties. Biomacromol 2011, 12, 3321–3329. [Google Scholar] [CrossRef] [PubMed]

- Frangville, C.; Rutkevičius, M.; Richter, A.P.; Velev, O.D.; Stoyanov, S.D.; Paunov, V.N. Fabrication of environmentally biodegradable lignin nanoparticles. Chem. Phys. Chem. 2012, 13, 4235–4243. [Google Scholar] [CrossRef]

- Mohammadi, A.; Barikani, M.; Barmar, M. Synthesis and investigation of thermal and mechanical properties of in situ prepared biocompatible Fe3O4/polyurethane elastomer nanocomposites. Polym. Bull. 2015, 72, 219–234. [Google Scholar] [CrossRef]

- Chollet, B.; Lopez-Cuesta, J.-M.; Laoutid, F.; Ferry, L. Lignin nanoparticles as a promising way for enhancing lignin flame retardant effect in polylactide. Materials 2019, 12, 2132. [Google Scholar] [CrossRef] [PubMed]

| Sample | Nanocellulose (g) | Nanolignin (g) |

|---|---|---|

| F1 | 5 | - |

| F2 | 5 | 0.125 |

| F3 | 5 | 0.25 |

| F4 | 5 | 0.5 |

| F5 | 5 | 1 |

| Sample | T5% (°C) | T50% (°C) | Max. Weight Loss (°C) | Char Yield (%) |

|---|---|---|---|---|

| F1 | 77 | 334 | 334 | 16.44 |

| F2 | 62 | 400 | 298 | 38.13 |

| F3 | 67 | 375 | 297 | 34.96 |

| F4 | 63 | 428 | 287 | 39.05 |

| F5 | 60 | 464 | 288 | 42.72 |

| Sample | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|

| F1 | 8.25 (±2.62) 1 | 15.58 |

| F2 | 13.38 (±0.37) 1 | 2.62 |

| F3 | 12.62 (±0.95) 1 | 1.88 |

| F4 | 8.69 (±1.98) 1 | 1.59 |

| F5 | 0.25 (±0.31) 1 | Not observed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zor, M.; Şen, F.; Yazıcı, H.; Candan, Z. Thermal, Mechanical and Morphological Properties of Cellulose/Lignin Nanocomposites. Forests 2023, 14, 1715. https://doi.org/10.3390/f14091715

Zor M, Şen F, Yazıcı H, Candan Z. Thermal, Mechanical and Morphological Properties of Cellulose/Lignin Nanocomposites. Forests. 2023; 14(9):1715. https://doi.org/10.3390/f14091715

Chicago/Turabian StyleZor, Mustafa, Ferhat Şen, Hikmet Yazıcı, and Zeki Candan. 2023. "Thermal, Mechanical and Morphological Properties of Cellulose/Lignin Nanocomposites" Forests 14, no. 9: 1715. https://doi.org/10.3390/f14091715

APA StyleZor, M., Şen, F., Yazıcı, H., & Candan, Z. (2023). Thermal, Mechanical and Morphological Properties of Cellulose/Lignin Nanocomposites. Forests, 14(9), 1715. https://doi.org/10.3390/f14091715