Abstract

European beech is one of the dominating wood species in central Europe and the most abundant hardwood species in Austrian, German and Swiss forests. Today, it is predominantly used for the provision of energy and in the furniture industry. With the increasing demand on forests to provide sustainable raw materials for energy as well as products, the importance of lesser-used wood species like European beech has continuously increased over the last decade. The application in load-bearing products has gained significant interest. In order to connect the current and historical state of knowledge about this wood species, this review provides an overview of the past and present utilization of European beech wood. On the basis of the historical literature, technical approvals and standards of established products, it aims to summarize the extensive state of the art of this wood species and provide an overview of recent scientific publications in the field of wood material science. Based on the reviewed literature, current research efforts deal with different engineered wood products like glued laminated timber, cross-laminated timber and laminated veneer lumber. Furthermore, strength grading, adhesive technology as well as improving dimensional stability is of particular interest.

1. Introduction

The consequences of climate change will severely affect forest ecosystems in the near future. Forestry is reacting to these changes through adaption of tree species composition and changes in silvicultural management to maintain the ecological and economic performance of the forest wood chain in Central Europe. European beech (Fagus sylvatica L.) is one of the most important and widespread tree species in Europe, most frequently distributed in Central and Western Europe. The role of European beech in future climatic conditions is discussed elsewhere. European beech is the dominant deciduous species in Austria and Germany, with approximately 10% (around 11.8 million solid cubic meters) [1] and 15% of the total stock [2].

In 2021, timber utilization in the Austrian forest amounted to 18.42 million harvested solid cubic meters without bark. The share of coniferous wood of the total harvest in 2021 was 85.03%, that of hardwood 14.97%. A total of 26.60% of the harvest was used for energy (firewood and forest chips); the share of sawmill roundwood was 56.57%, that of industrial roundwood 16.84% [3]. In 2021, 9.34 million cubic meters of sawmill roundwood over 20 cm in diameter were available. A total of 97.10% was softwood; only 2.90% was hardwood. European beech wood accounts for 45.19% of this; however, this is only 1.31% of the total sawn roundwood. These figures make clear that the wood industry in Austria is mainly based on coniferous wood, i.e., Norway spruce (Picea abies L-Karts.). Within the hardwoods, European beech plays the major role. As the share of the harvested species in Austria will change in the future, a better knowledge of these species is necessary.

The goal of this manuscript is to present the current state of the art of European beech wood. The data are based on the description of historical wood utilization, modern testing and an overview of modern industrial products based on European beech wood. In contrast to the already-available literature, this overview connects knowledge of historical utilization with modern research interests and therefore presents a complete picture of these wood species. Furthermore, the comparison with Norway spruce throughout the review should enable a comparison of the currently dominating wood species in Europe with one of the possible bread trees of the future. That is the case for oak, too, as the amount of this species will increase in future in Austrian forests.

2. The Characteristics of European Beech Wood

Wood is a highly variable raw material, with differences occurring among species and genera, among geographic sources within a species as well as within each individual tree [4,5]. To obtain a comprehensive overview, the existing literature [6,7,8,9,10,11] from Europe was screened for figures of different wood quality traits. Table 1 shows data for European beech wood in comparison to the characteristics of Norway spruce and oak wood (Sessile oak and Pendunculate oak; Quercus petraea Liebl., Quercus robur L.), as these species are of high economic importance at the moment (Norway spruce), or will obtain high importance in the future due to climate change. Takahashi [6] cites several papers for these wood species: European beech—[12,13,14,15,16,17,18]; Norway spruce—[19,20,21,22,23,24,25,26]; and oak—[25,27,28,29,30,31]. Mean values of the wood density were calculated for the figures of these literatures as well as the figures cited in old books (1690 to 1085, named as Historical wood density in Table 1) [9]. Table 1 gives the data for the main wood characteristics: dry wood density (in comparison to historical values), tensile strength, modulus of elasticity (MOE) and the total shrinkage in tangential direction. All data were averaged without statistical weighting.

Table 1.

Main wood characteristics: dry wood density (in comparison to historical values), tensile strength, modulus of elasticity (MOE) and the total shrinkage in tangential direction of European beech, oak and spruce wood. The given numbers are mean values based on the literature. The numbers in brackets are the minimum and maximum values given in the publications (not single values).

Table 1 shows that the wood of European beech is strong and tough compared to the two other species. The wood density is slightly higher than that of oak wood. A notable difference can be seen for the total shrinkage.

As for its mechanical properties, the wood density is medium to high; it is very strong, hard, with strong shrinkage and therefore low dimensional stability. The wood can be worked well when fresh or wet, but tends to crack during drying. Tools quickly dull when working with dry European beech wood. The wood is described as short-fibered, is easy to split and can be polished and stained well. The natural durability against insects and fungi including saprophytic fungus is low.

The wood of European beech is reddish-brownish and belongs to the group of trees with pale heartwood. However, there is the exception of the so-called red heart of the European beech [23]. The red heart is a darker color, often with demarcation lines. European beech wood is characterized by big wood rays, which can be easily seen in anatomical directions, especially at the radial plane. It belongs to the group of diffuse-porous species; however, the tree rings are clearly visible.

3. The Historical Utilization of European Beech Wood in Austria

In Austria, at the moment the choice of commercially available native wood species includes approximately 24 species [32]; this is considerably less than what is indigenous, or will be present in future, in the forests. It is common knowledge that, based on differing material properties, different wood species, for example oak (Quercus spp.) and poplar (Populus spp.), cannot be used in the same field of application. Some properties are so diverse that these two wood species have to be handled like two different materials. Therefore, we have to be aware of the whole range of properties that can be covered by all available wood species, to exhaust the full potential of wooden materials. At the beginning of the 20th century, the folklorist Josef Blau [33] investigated a bohemian household and counted 27 wood species. He emphasized that all species were chosen according to their specific wood properties [33]. This indicates that knowledge about the proper utilization of wood and the selection of wood species was established at some point in history. To figure out which species have been used, a search of the historical literature (from 1690 to 1985) as well as an analysis of old wooden objects were performed. Following this, every part of the museum inventory with a given wood species was connected to its required wood properties in use and its technological demands. In this way, every wood species was characterized by its former utilization.

The wood identification of 8985 historical wooden objects from different museums in Austria showed that 48 different species were used in former times [34]. Next to the nowadays-regularly used species, some fruit-bearing trees as well as small trees and big shrubs were utilized. Excluding timber for construction purposes, European beech showed the highest share, followed by ash (Fraxinus excelsior L.) and birch (Betula spp.). A total of 20% of all analyzed object parts were made of European beech. Interestingly, European beech was not used for construction purposes in former times in Austria [35], but can be found used for these purposes in a short distance, for example in Slovenia [36]. The wide distribution was one reason for this, and the notably good wood properties the other. The wood was found at various different wooden objects, but was never seen as a specialist species. Most wood species, except European beech, were specialized. For example, almost all hardwood barrels were made of oak, 50% of all planes were made of hornbeam (Carpinus betulus L.) and for carving wood lime (Tilia spp.) or stone pine (Pinus cembra L.) were used [34].

European beech can be described as a universalist species, because no exclusive utilization of European beech was found. In contrast to that, barberry wood (Berberis vulgaris L.), for example, was found mainly at the teeth of rakes: a specialist.

The uses described in the historical literature [9] are presented below. Products that have also been found in museums are marked with an asterisk. European beech wood was often used for energetic use: firewood and charcoal. It was used for different kinds of furniture (like clamp chests*, benches* and tables*), especially working benches*. Therefore, solid wood as well as boards (particle boards, plywood) and veneer were used. Due to the high strength, it was often found at agricultural tools, like shovels*, presses*, yokes*, rakes*, hay forks*, flails*, ploughs* and chopping blocks*. This is also the case for handicraft tools, like tool handles*, planers*, clamps*, compasses* and mallets*, as well as for machine parts, like parts of a mill*, stick-wheel*, spindle*, gear wheel* and spinning wheel*. European beech wood was used by wainwrights, turners and shoemakers to produce axles*, sledge runners*, plates*, sticks*, shoetrees*, heels* and wooden shoes. It was used for wooden troughs, bowls, vats, cloth pegs*, cooking spoons*, etc., too.

The listing of the products highlights the status of universalist and may trigger an interest in future utilization and possible products.

4. Modern Utilization of European Beech Wood

4.1. Established Products

Nowadays, particularly in central Europe, European beech is considered an essential tree species in a climate-adapted forest management [37,38,39] (and Supplementary Material of [39]) of the near future. Although the bulk of the harvested European beech wood is used for the provision of energy, it can also be utilized in higher added value streams and, similar to the versatile historical applications, can still be seen as universalist. High-quality roundwood is processed into lumber and plywood and plays an integral part in the furniture industry [38,40]. It is also utilized in parquet flooring. However, it was almost entirely substituted by oak since the early 2000s due to the trend towards darker-colored wood species. In addition, the shorter fiber length (0.5–1.7 mm) compared to conifers (e.g., Norway spruce: 1.1–6.0 mm) makes it a suitable raw material for the production of pulp and paper as well as textile fibers [41].

In regards to load-bearing applications, the superior mechanical properties compared to conifers like Norway spruce (see Table 1) underline the suitability of European beech wood for structural engineered wood products (EWP). Nevertheless, the utilization in structural products has been a niche compared to the dominant Norway spruce, which has experienced significant growth in recent years, especially through the rise of cross-laminated timber (CLT) and glued laminated timber (GLT) [42,43,44]. However, the research and development of European beech-based EWPs has also gained traction in the last decade and a variety of lumber- and veneer-based products have found their way on the market. Table 2 summarizes the selected mechanical properties of EWPs made from European beech wood. The values are based on standards and technical approvals.

Table 2.

Average of mechanical properties of available engineered wood products (EWP) made from European beech wood. Listed properties are raw density (ρ12%), characteristic bending strength (σB,char.) and mean modulus of elasticity (MOEmean). The numbers in brackets are the minimum and maximum values given in the publications.

Compared to other deciduous species such as oak, ash or maple (Acer spp.), there is a wider range of European beech-based EWPs available for purchase today. In terms of available products, European beech is therefore, together with birch, the most versatile alternative to Norway spruce [42].

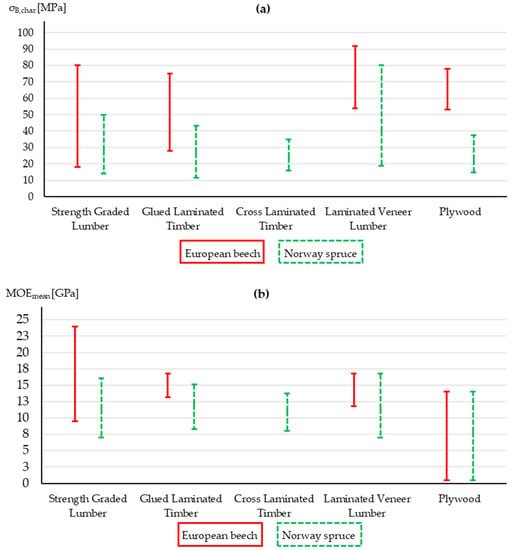

Furthermore, the mechanical properties are compared with EWPs based on Norway spruce (Table 3) in Figure 1.

Table 3.

Average of mechanical properties of available engineered wood products (EWP) made from Norway spruce wood. Listed properties are raw density (ρ12%), characteristic bending strength (σB,char.) and mean modulus of elasticity (MOEmean). The numbers in brackets are the minimum and maximum values given in the publications.

Figure 1.

Comparison of mechanical properties of available engineered wood products (EWP) made from European beech (references see Table 2) and Norway spruce (references see Table 3) wood. (a) range of characteristic bending strength (σB,char.); (b) range of mean modulus of elasticity (MOEmean). Values are based on standards and technical approvals.

It can be seen that European beech offers a higher baseline in strength (Figure 1a) and stiffness (Figure 1b) for dimensioning. This allows for slimmer geometries. However, this is mainly driven by the higher density, which also means that the resulting components usually exhibit a higher weight. This difference in density causes other challenges in regards to transportation, joinery and connection details. In addition, the inferior dimensional stability compared to Norway spruce (see Table 1) and the low durability [72] poses further risk in load-bearing applications, especially when exposed to moisture.

Overall, European beech wood can still be found along the whole wood-based value chain today. Yet, a bulk of the raw material is used for the provision of energy. In order to make the transition towards a climate-friendly society as envisioned in the European Green Deal [73,74], the material’s first utilization needs to be intensified. Therefore, applied and basic research in order to improve the technological potential of lesser-used wood species like European beech needs to be accelerated [75]. Therefore, the next chapter will investigate the current research efforts and topics dealing specifically with European beech wood.

4.2. Selected Research Fields

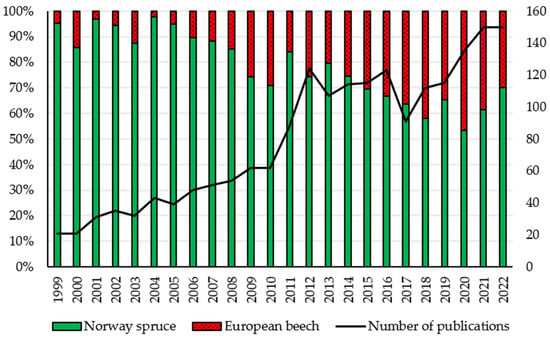

As indicated in Figure 2, the share of publications on European beech has already increased significantly compared to Norway spruce over the last couple of years. This underlines the growing interest in this wood species in the field of wood material science and wood technology.

Figure 2.

Share (primary axis) and total number of publications (secondary axis) on “Norway spruce” or “European beech” based on a title search in Web of Science™ in the field of “Wood material science” [76].

Based on a qualitative literature search in Web of Science™ [76] and Google Scholar [77], current key research areas were identified and are summarized in the following section. Only literature dealing with European beech wood published since the year 2000 was considered for a more detailed investigation. Further selection was based on the published field, which only included wood material science and wood technology, as, for example, forestry and botany are not in the expertise of the authors. Finally, the title, keywords and abstract of the remaining publications were screened in order to identify common research areas.

In regards to different products, it can be seen that research into EWPs like GLT [78,79,80,81,82,83,84], CLT [85,86,87,88,89] and laminated veneer lumber (LVL) [90,91,92,93,94,95,96] has increased in the last decade. Ehrhart et al. [79] carried out an extensive research into the required strength grading, possible production and resulting mechanical properties of GLT utilizing European beech wood. According to the presented findings, it was possible to produce beams of strength classes GL40, GL48 and GL55 [52]. A similar potential was reported by Blaß et al. [84], who reported that beams of a strength class of GL48 can be produced by a combination of machine and visual grading and reported a possible mean bending MOE of 17 GPa and a characteristic bending strength bigger than 44.5 Mpa in some of the specimens. With regards to CLT, Franke [88] as well as Sciomenta et al. [86] reported the satisfactory mechanical performance of homogenous CLT panels from European beech, especially in comparison with CLT based on Norway spruce. However, both point out that further research and tests are necessary in order to confirm their statements. In addition to homogenous build-ups, European beech was also investigated as part of hybrid CLT build-ups by Aicher et al. [85] and Hematabadi et al. [87]. While Aicher et al. [85] tested a hybrid of European beech and Norway spruce, Hematabadi at al. [87] combined European beech with white poplar (Populus alba L.). Both reported improved performance compared to the homogenous counterparts made with Norway spruce or poplar and Aicher et al. [85] concluded that hybrid build-ups show great potential in order to enable a utilization of low-quality hardwoods. With regards to LVL, Knorz et al. [94] reported a characteristic bending strength of 73.5 MPa for European beech and 48 MPa for Norway spruce, concluding that the design possibilities can be significantly improved when using LVL made from European beech. However, Fabbri et al. [90] as well as Kobel et al. [95] underline the need for improved connection details in order to unlock the full mechanical potential. Furthermore, according to Grönquist et al. [91] and Benthien et al. [96] the behavior under changing moisture conditions poses an additional challenge in regards to LVL due to the change in physical properties during processing (multiple heat and pressure treatments) and the high swelling and shrinking coefficients of European beech wood.

The utilization of EWPs like Oriented Strand Board (OSB) [97,98,99,100,101,102] and particle board [103,104] has also been investigated recently. Findings by Thole [97] as well as Akrami et al. [98,100] suggest that European beech offers a suitable addition to the currently dominating pine species in the production of OSB. However, according to Akrami et al. [100] the ratio of wood species mixtures needs to be considered in order to achieve optimal properties. He reported that a mixture of European beech and poplar strands led to better properties (modulus of rupture, internal bond strength and thickness swelling) than panels made from 100% European beech wood.

At the level of intermediate products (e.g., boards), recent research deals with strength grading and quality assessment [105,106,107,108,109,110,111,112,113,114], adhesive technology [89,115,116,117,118,119,120,121,122,123,124] as well as improving dimensional stability [125,126,127,128,129,130,131,132]. The grading of European beech logs and boards for the use in structural products is of increasing importance [105,113,114]. According to Brunetti et al. [114], one of the most prominent differences to softwood grading is the more significant influence of the local grain angle compared to the usually dominating density. This also explains why some publications deal specifically with the determination of the local fiber angle in European beech [106,108,111,112]. The presented measuring methods include laser scattering, microwave and electric field strength as presented by Schlotzhauer et al. [106] and Rais et al. [108] as well as image-based methods as published by Ehrhart [111,112]. A similar focus towards load-bearing applications is also given with regards to adhesive technology. Schmidt et al. [118], Ohnesorge et al. [120] as well as Aicher and Reinhardt [121] investigated the delamination behavior of European beech laminations based on a melamine–urea –formaldehyde- and a polyurethane-based adhesive. They reported sufficient glue-line performance for the investigated sample dimensions. However, they also underline the need for adopted test methods and adhesive systems for load-bearing bonding of European beech. In regards to improving dimensional stability, thermal modification is of particular interest [126,127,130,131,132], especially the influence of heat treatments on the mechanical properties. According to Widmann et al. [127], thermal modification decreases the strength of European beech wood (except for compression parallel to the grain) but does not influence its stiffness. Furthermore, they also reported that thermal modification promotes brittle material failure. Similar findings were reported by Gómez-Royuela et al. [130], using static and dynamic compression tests in combination with 3D digital image correlation. Therefore, special attention must be paid to the mechanical characterization of thermally modified European beech when utilized in load-bearing applications. Further ongoing research fields include clear wood properties [133,134,135,136,137,138] and processing parameters [139,140,141,142].

Overall, it can be seen that the majority of research is conducted concerning load-bearing products (GLT, CLT, LVL and OSB), their properties as well as their production (quality assessment, modification and adhesive technology).

5. Summary and Conclusions

Historically, European beech can be characterized as a wood species with a high strength that is easy to machine. The low natural durability, but, especially, the high amount of shrinkage, is limiting the possible utilization. Nevertheless, European beech wood can be frequently found at various products. European beech can therefore be described as universalist, as there was no special utilization in former times. The description and understanding of its former use may trigger new kinds of utilization or new products.

Today, European beech wood can still be found along the whole wood-based value chain and its importance will further grow in the face of the European Green Deal. Here, wood-based products (e.g., based on European beech wood) will be needed to successfully implement several initiatives (e.g., green transportation, sustainable buildings and clean and efficient energy). At the same time, the biodiversity in forests is to be protected and they are to be preserved as a place for recreation and relaxation.

Considering the reviewed literature, current research efforts aim to improve the suitability of European beech wood for load-bearing applications and further deepen the understanding of these wood species for its utilization in engineered wood products. Compared with the currently dominating Norway spruce, products made with European beech wood offer a higher mechanical performance. However, the quality assessment, adhesive technologies and dimensional stability need to be further improved in order to offer an equivalent substitute for EWPs made from Norway spruce.

It can be concluded that the ongoing research on European beech wood needs to be intensified in order to further strengthen our understanding of this wood species and enable its efficient and effective material utilization.

Author Contributions

Conceptualization, M.G.; methodology, M.G. and M.P.; formal analysis, M.G. and M.P.; investigation, M.G. and M.P.; data curation, M.G. and M.P.; writing—original draft preparation, M.G. and M.P.; writing—review and editing, M.G. and M.P.; visualization, M.P.; supervision, M.G. and M.P.; project administration, M.G. and M.P.; funding acquisition, M.G. and M.P. All authors have read and agreed to the published version of the manuscript.

Funding

The study of the historical wood utilization was funded by the Austrian Science Fund (FWF—TRP 21-B16) and Sparkling Science (SPA 05-013 “Wert-Holz”). The study of the modern utilization is part of the research project “Strong Hardwood” (FTI20-003). The financial support by Amt der Niederösterreichischen Landesregierung is gratefully acknowledged.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank Lukas Malzl, Simon Lux and Tobias Josef Nenning for providing literature for this review.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Schadauer, K.; Freudenschuss, A. Zwischenauswertung Der ÖWI 2016/18—Bund. Available online: https://bfw.ac.at/cms_stamm/500/images/OEWI/Bundesergebnisse_OEWI_16_18.pdf (accessed on 24 May 2023).

- BMEL Dritte Bundeswaldinventur. Available online: https://bwi.info/inhalt1.3.aspx?Text=1.04%20Baumartengruppe%20(rechnerischer%20Reinbestand)&prRolle=public&prInv=BWI2012&prKapitel=1.04 (accessed on 22 May 2023).

- BMLFUW. Holzeinschlagsmeldung Über Das Kalenderjahr 2020; BMLFUW: Vienna, Austria, 2021.

- Zobel, B.J.; van Buijtenen, J.P. Wood Variation. Its Causes and Control; Springer: Berlin/Heidelberg, Germany, 1989. [Google Scholar]

- Wimmer, R. Structural, Chemical and Mechanical Trends within Coniferous Trees. In Modelling of Tree-Ring Development—Cell Structure and Environment; Spiecker, H., Kahle, H.P., Eds.; Institut für Waldwachstum, Universität Freiburg: Freiburg, Germany, 1994; pp. 2–11. [Google Scholar]

- Takahashi, A.; Tanaka, C.; Shiota, Y. Compilation of Data on the Mechanical Properties of Foreign Woods. (Part IV) European Woods; Reprint from Research Report of Foreign Wood (No. 11); Faculty of Forestry Shimane University: Matsue, Japan, 1983. [Google Scholar]

- Wagenführ, R. Holzatlas; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2006; ISBN 978-3-446-40649-0. [Google Scholar]

- Sell, J. Eigenschaften und Kenngrößen von Holzarten; Baufachverlag AG: Zürich, Switzerland, 1989. [Google Scholar]

- Grabner, M. WerkHolz. Eigenschaften und Historische Nutzung 60 Mitteleuropäischer Baum- und Straucharten; Verlag Kessel: Remagen, Germany, 2017; ISBN 978-3-945941-24-9. [Google Scholar]

- Koch, G.; Koch, S. Demonstration of the Database MacroHOLZdata Computer-Aided Identification and Description of Trade Timbers. In Proceedings of the 8th Hardwood Conference, Sopron, Hungary, 25–26 October 2018; pp. 72–73. [Google Scholar]

- Koch, G.; Koch, S. Holzartenwissen im App-Format: Neue App "Macroholzdata" zur Holzartenbestimmung und -beschreibung. Furnier Magazin. 2022, 26, 52–56. [Google Scholar]

- Anonymous. Forest Products Research: A Handbook of Empire Timbers; Dept. of Scientific and lndustrial Research: London, UK, 1945.

- Vorreiter, L. Holztechnologisches Handbuch, Band I.; Verlag Georg Fromme &Co.: Wien, Austria, 1949. [Google Scholar]

- Mozina, I. Comparative Studies of Home-Grown Timbers, Beech (Komparativna Raziskovanja Lesa Domacih Drevesnih Vrst Bukev). Zb. Kmet. Gozd. 1958, 5. [Google Scholar]

- Ursulescu, A.; Pana, G.I. The Physical and Mechanical Properties of Rumanian Beech and Spruce Wood (Contributii La Stabil-irea Proprietailor Fizico-Mecanice Ale Lemnului de Fag Si Molid Din R.P.R.). Ind. Lemn. 1959, 3, 86–91. [Google Scholar]

- Anonymous. Houtinstituut, T.N.0.: Europees Beuken, Europees Lariks; Houtinstitut: Delft, The Netherland, 1967. [Google Scholar]

- Horvat, I. The Principal Physical and Mechanical Properties of Beech Wood from the Zumberak, Petrova Gora, Senjsko Bilo, and Velebit Forest District (Osnovne Fizicke i Mehanicke Karak-teristike Bukovine s Podrucja Zumberka, Petrove Gore, Senjskog Bila i Velebita). Drv. Ind. 1969, 20, 183–277. [Google Scholar]

- Stajduhar, F. Physical and Mechanical Properties of Beech Wood in Croatia (Prilog Istraživanja Fizičko-Mehaničkih Svojstava Bukovine u Hrvatskoj). Drv. Ind. 1973, 24, 43–59. [Google Scholar]

- Kühne, H.; Vodoz, J. Über Das Schwinden und Quellen Einiger Schweizerischer Hölzer; EMPA-Bericht Nr.179b: Zürich, Switzerland, 1951. [Google Scholar]

- Kühne, H.; Fischer, H.; Vodoz, J.; Wagner, T. About the Influence of Water Content, Density, Grain Direction, and Annual Ring Position on Strength and Deformability of Swiss Spruce, Fir, Larch, European Beech, and Oak; EMPA-Bericht Nr.183: Zürich, Switzerland, 1955. [Google Scholar]

- Fischer, H.; Kühne, H. Über Die Knickfestigkeit von Schweizerischem Firchten-, Tannen-, Lärchen-, Rotbuchen- Und Eichenholz. Bericht 1960, 190, 7–44. [Google Scholar]

- Lenz, O. The Wood of Conifers in the Chestnutregion of Ticino (Le Bois Des Coniferes de l ’etage Du Chataignier Au Tessin). In Mitteilungen der Schweizerischen Anstalt für das Forstl. Versuchswes; Birmensdorf, Switzerland, 1964; Volume 40. [Google Scholar]

- Bosshard, H.H. Holzkunde. Band 1, Mikroskopie Und Makroskopie Des Holzes; Birkhäuser Verlag: Basel und Stuttgart, Germany, 1974. [Google Scholar]

- Neusser, H.; Krames, U.; Strobach, D.; Zentner, M. Über Die Technologischen Eigenschaften von in Österreich Gewachsenen Douglasien. Holzforsch. Holzverwert. 1977, 29, 101–112. [Google Scholar]

- Giordano, G. Tecnologiadel Legno. Unione Tipogr. Torinese 1976, 3, 377–445. [Google Scholar]

- Marcu, G. Researches on Extending the Area of Plantation Ofsilver Firin Rumania (Cercetari Privindextinderea Culturii Bradului in Republica Socialista Romania); Editura Ceres: Bucharest, Romania, 1980. [Google Scholar]

- Göhre, K.; Wagenknecht, E. Die Roteiche Und Ihr Holz; Deutscher Bauernverlag: Berlin, Germany, 1955. [Google Scholar]

- Todorovski, S. Some Mechanical Properties of Wood of Quercus Cerris; Godisen Zbornik, Zemjodelsko-Sumarski Fakultet na Univer zitetot: Skopje, Yugoslavia, 1963. [Google Scholar]

- Sallenave, P. Proprietes Physiques et Mecaniques Des Bois Tropicaux de L’union Francaise; Publication du Centre Technique Forestier Tropical: Nogent-sur-marne, France, 1964. [Google Scholar]

- Enchev, E.A. Study of the Mechanical Properties of Wood of Quercus Petraea. Gorskostop. Nauk. 1972, 9, 53–64. [Google Scholar]

- Neusser, H.; Krames, U.; Serentschy, W.; Zentner, M. Vergleichsuntersuchung Heimischer Eichenarten Unter Besonderer Berücksichtigung Der Zerreiche, Teil II. Holzforsch. Holzverwertung 1975, 27, 99–108. [Google Scholar]

- Fellner, J.; Teischinger, A.; Zschokke, W. Holzspektrum—Ansichten, Beschreibungen Und Vergleichswerte; proHolz Austria: Wien; Österreich, 2006. [Google Scholar]

- Josef, B. Böhmerwälder Hausindustrie Und Volkskunst. Band 1: Wald- Und Holzarbeit; Calve: Prague, Czech Republic, 1917. [Google Scholar]

- Klein, A.; Bockhorn, O.; Mayer, K.; Grabner, M. Central European Wood Species: Characterisation Using Old Knowledge. J. Wood Sci. 2016, 62, 194–202. [Google Scholar] [CrossRef]

- Nemestothy, S.; Wächter, E.; Buchinger, G.; Grabner, M. Roof Constructions in Austria—An Overview. Int. J. Wood Cult. 2023, 3, 47–63. [Google Scholar] [CrossRef]

- Čufar, K.; Bizjak, M.; Kuzman, M.K.; Merela, M.; Grabner, M.; Brus, R. Castle Pišece, Slovenia—Building History and Wood Economy Revealed by Dendrochronology, Dendroprovenancing and Historical Sources. Dendrochronologia 2014, 32, 357–363. [Google Scholar] [CrossRef]

- BML. Holzeinschlagsmeldung Über Das Kalenderjahr 2022; BMLFUW: Vienna, Austria, 2023.

- Nordwestdeutsche Forstliche Versuchsanstalt. Ergebnisse Angewandter Forschung Zur Buche; Universitätsverlag Göttingen: Göttingen, Germany, 2008; ISBN 9783940344441. [Google Scholar]

- Hanewinkel, M.; Cullmann, D.A.; Schelhaas, M.J.; Nabuurs, G.J.; Zimmermann, N.E. Climate Change May Cause Severe Loss in the Economic Value of European Forest Land. Nat. Clim. Chang. 2013, 3, 203–207. [Google Scholar] [CrossRef]

- Grosser, D.; Teetz, W. Buche. In Einheimische Nutzhölzer (Loseblattsammlung); Holzabsatzfonds: Bonn, Germany, 1998. [Google Scholar]

- Geoffrey, D. Wood and Fibre Morphology. In Pulp and Paper Chemistry and Technology; De Gruyter: Stockholm, Sweden, 2009; Volume 1, p. 320. ISBN 9783110213393. [Google Scholar]

- Torno, S.; Jentsch, A.; Lattke, F. Special—European Hardwood Structural Building Products (Spezial—Konstruktive Bauprodukte Aus Europäischen Laubhölzern); Informationsverein Holz e. V.: Düsseldorf, Germany, 2017; p. 60. [Google Scholar]

- Jauk, G.; Nöstler, M.; Fingerlos, B.; Zeman, R.; Gruber, B.; Pfeffer, C. BSP-Special 2021; Holzkurier: Vienna, Austria, 2021. [Google Scholar]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross Laminated Timber (CLT): Overview and Development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- EN 338; Bauholz Für Tragende Zwecke—Festigkeitsklassen. Austrian Standards International: Vienna, Austria, 2009.

- ETA-18/1018; Brettschichtholz Aus Laubholz—Buchenfurnierschichtholz Für Tragende Zwecke. Österreichisches Institut für Bautechnik: Vienna, Austria, 2018.

- Z-9.1-679; BS-Holz Aus Buche Und BS-Holz Buche-Hybridträger und Zugehörige Bauarten. Deutsches Institut für Bautechnik: Wuppertal, Germany, 2019.

- ETA-14/0354; Träger Baubuche GL75. Österreichisches Institut für Bautechnik: Vienna, Austria, 2018.

- Z-9.1-838; Platte BauBuche S und Platte BauBuche Q. Deutsches Institut für Bautechnik: Wuppertal, Germany, 2018.

- Z-9.1-841; Sperrholz Aus Buchenfurnieren. Deutsches Institut für Bautechnik: Wuppertal, Germany, 2013.

- ÖNORM EN 12369-2; Holzwerkstoffe—Charakteristische Werte Für Die Berechnung und Bemessung von Holzbauwerken—Teil 2: Sperrholz. Austrian Standards International: Vienna, Austria, 2011.

- ÖNORM EN 14080; Holzbauwerke—Brettschichtholz und Balkenschichtholz—Anforderungen. Austrian Standards International: Vienna, Austria, 2013.

- ANSI 117-2020; Standard Specifications for Structural Glued Laminated Timber of Softwood Species. APA—The Engineered Wood Association: Tacoma, DC, YSA, 2004.

- ETA-11/0218; Diemme Legno—CLT. Holzforschung Austria: Vienna, Austria, 2016.

- ETA-06/009; Binderholz Brettsperrholz BBS. Deutsches Institut für Bautechnik: Wuppertal, Germany, 2017.

- ETA-12/0281; Hasslacher Cross Laminated Timber. Österreichisches Institut für Bautechnik: Vienna, Austria, 2020.

- ETA-06/0138; KLH-Massivholzplatten/KLH Solid Wood Slabs. Österreichisches Institut für Bautechnik: Vienna, Austria, 2017.

- ETA-09/0036; MM—Crosslam. Österreichisches Institut für Bautechnik: Vienna, Austria, 2015.

- ETA-14/0349; CLT—Cross Laminated Timber. Österreichisches Institut für Bautechnik: Vienna, Austria, 2020.

- EN 14374; Holzbauwerke—Furnierschichtholz Für Tragende Zwecke—Anforderungen. Austrian Standards International: Vienna, Austria, 2005.

- Eurofins Expert Service. DoP MW/LVL/311-001/CPR Kerto LVL S-Beam; Eurofins Expert Service: Espoo, Finland, 2019. [Google Scholar]

- Eurofins Expert Service. DoP MW/LVL/314-001/CPR Kerto LVL T-Stud; Eurofins Expert Service: Espoo, Finland, 2019. [Google Scholar]

- Eurofins Expert Service. DoP MW/LVL/312-001/CPR Kerto LVL Q-Panel; Eurofins Expert Service: Espoo, Finland, 2019. [Google Scholar]

- ETA-17/0941; VVR Wood Kerto Ripa Elements. VTT Publications: Espoo, Finland, 2018.

- Eurofins Expert Service. DoP SEWPVARDOP 05 LVL by Stora Enso, s Grade; Eurofins Expert Service: Espoo, Finland, 2020. [Google Scholar]

- Eurofins Expert Service. DoP SEWPVARDOP 04 LVL by Stora Enso. T Grade; Eurofins Expert Service: Espoo, Finland, 2020. [Google Scholar]

- Eurofins Expert Service. DoP SEWPVARDOP 06 LVL by Stora Enso, x Grade; Eurofins Expert Service: Espoo, Finland, 2020. [Google Scholar]

- ETA-20/0291; LVL G by Stora Enso. Eurofins Expert Service: Espoo, Finland, 2021.

- Z-9.1-890; Pollmeier Fichte LVL S Und Pollmeier Fichte LVL Q. Deutsches Institut für Bautechnik: Wuppertal, Germany, 2019.

- DoP MW/PW/421-001/CPR Metsä Wood Konstruktives Fichten Sperrholz 2019.

- Finnish Forest Industries Federation. Handbook of Finnish Plywood; Finnish Forest Industries Federation: Helsinki, Finland, 2022. [Google Scholar]

- ÖNORM EN 350-2; Dauerhaftigkeit von Holz Und Holzprodukten—Prüfung und Klassifikation Der Dauerhaftigkeit von Holz und Holzprodukten Gegen Biologischen Angriff. Austrian Standards International: Vienna, Austria, 2017.

- European Commission. A European Green Deal—Striving to Be the First Climate-Neutral Continent. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 23 May 2023).

- European Commission. Biodiversity Strategy for 2030. Available online: https://environment.ec.europa.eu/strategy/biodiversity-strategy-2030_en (accessed on 23 May 2023).

- Pramreiter, M.; Nenning, T.; Malzl, L.; Konnerth, J. A Plea for the Efficient Use of Wood in Construction. Nat. Rev. Mater. 2023, 8, 217–218. [Google Scholar] [CrossRef]

- Web of Science Search Results for “Norway Spruce” or “European Beech”. Available online: https://www-1webofscience-1com-100124bcy0f63.pisces.boku.ac.at/wos/woscc/basic-search (accessed on 24 May 2023).

- Google Scholar. Available online: https://scholar.google.de/schhp?hl=de (accessed on 3 July 2023).

- Ehrhart, T.; Steiger, R.; Frangi, A. Brettschichtholz Aus Buche. Bautechnik 2021, 98, 104–114. [Google Scholar] [CrossRef]

- Ehrhart, T.; Steiger, R.; Lehmann, M.; Frangi, A. European Beech (Fagus Sylvatica L.) Glued Laminated Timber: Lamination Strength Grading, Production and Mechanical Properties. Eur. J. Wood Wood Prod. 2020, 78, 971–984. [Google Scholar] [CrossRef]

- Ehrhart, T.; Steiger, R.; Palma, P.; Gehri, E.; Frangi, A. Glulam Columns Made of European Beech Timber: Compressive Strength and Stiffness Parallel to the Grain, Buckling Resistance and Adaptation of the Effective-Length Method According to Eurocode 5. Mater. Struct. 2020, 53, 91. [Google Scholar] [CrossRef]

- Aicher, S.; Ohnesorge, D. Shear Strength of Glued Laminated Timber Made from European Beech Timber. Eur. J. Wood Wood Prod. 2011, 69, 143–154. [Google Scholar] [CrossRef]

- Frese, M.; Riedler, T. Untersuchung von Buchenschnittholz (Fagus Sylvatica L.) Hinsichtlich Der Eignung Für Brettschichtholz. Eur. J. Wood Wood Prod. 2010, 68, 445–453. [Google Scholar] [CrossRef]

- Derkowski, A.; Kuliński, M.; Trociński, A.; Kawalerczyk, J.; Mirski, R. Mechanical Characterization of Glued Laminated Beams Containing Selected Wood Species in the Tension Zone. Materials 2022, 15, 6380. [Google Scholar] [CrossRef] [PubMed]

- Blaß, H.J.; Frese, M.; Glos, P.; Linsenmann, P.; Denzler, J. Biegefestigkeit von Brettschichtholz Aus Buche [Bending Strength of Beech Glued Laminated Timber]. Karlsruher Berichte zum Ingenieurholzbau, 2005; Universität Karlsruhe (TH): Karlsruhe, Germany, 2005; p. 137. [Google Scholar]

- Aicher, S.; Hirsch, M.; Christian, Z. Hybrid Cross-Laminated Timber Plates with Beech Wood Cross-Layers. Constr. Build. Mater. 2016, 124, 1007–1018. [Google Scholar] [CrossRef]

- Sciomenta, M.; Spera, L.; Bedon, C.; Rinaldi, V.; Fragiacomo, M.; Romagnoli, M. Mechanical Characterization of Novel Homogeneous Beech and Hybrid Beech-Corsican Pine Thin Cross-Laminated Timber Panels. Constr. Build. Mater. 2021, 271, 121589. [Google Scholar] [CrossRef]

- Hematabadi, H.; Madhoushi, M.; Khazaeian, A.; Ebrahimi, G. Structural Performance of Hybrid Poplar-Beech Cross-Laminated-Timber (CLT). J. Build. Eng. 2021, 44, 102959. [Google Scholar] [CrossRef]

- Franke, S. Mechanical Properties of Beech CLT. In Proceedings of the World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Brunetti, M.; Nocetti, M.; Pizzo, B.; Negro, F.; Aminti, G.; Burato, P.; Cremonini, C.; Zanuttini, R. Comparison of Different Bonding Parameters in the Production of Beech and Combined Beech-Spruce CLT by Standard and Optimized Tests Methods. Constr. Build. Mater. 2020, 265, 120168. [Google Scholar] [CrossRef]

- Fabbri, A.; Minghini, F.; Tullini, N. Monotonic and Cyclic Pull-Pull Tests on Dowel-Nut Connector in Laminated Veneer Lumber Made of European Beech Wood. Constr. Build. Mater. 2022, 359, 129461. [Google Scholar] [CrossRef]

- Grönquist, P.; Weibel, G.; Leyder, C.; Frangi, A. Calibration of Electrical Resistance to Moisture Content for Beech Laminated Veneer Lumber “BauBuche S” and “BauBuche Q”. Forests 2021, 12, 635. [Google Scholar] [CrossRef]

- Zimmermann, M.; Raßbach, H. A Study of the Deformation Behaviour of Veneers Resulting from Water Storage (A Methodological Approach for Determining the Swelling Characteristic Using the Example of European Beech Veneer). Eur. J. Wood Wood Prod. 2018, 76, 1677–1683. [Google Scholar] [CrossRef]

- Stepinac, M.; Rajčić, V.; Hunger, F.; van de Kuilen, J.W.G. Glued-in Rods in Beech Laminated Veneer Lumber. Eur. J. Wood Wood Prod. 2016, 74, 463–466. [Google Scholar] [CrossRef]

- Knorz, M.; Van De Kuilen, J.W.G. Development of a High-Capacity Engineered Wood Product—LVL Made of European Beech (Fagus Sylvatica L.). In Proceedings of the WCTE 2012—World Conference on Timber Engineering, Auckland, New Zealand, 15–19 July 2012. [Google Scholar]

- Kobel, P.; Steiger, R.; Frangi, A. Experimental Analysis on the Structural Behaviour of Connections with LVL Made of Beech Wood. In Proceedings of the Materials and Joints in Timber Structures; Springer: Dordrecht, Germany, 2014; Volume 9, pp. 211–220. [Google Scholar]

- Benthien, J.T.; Riegler, M.; Engehausen, N.; Nopens, M. Specific Dimensional Change Behavior of Laminated Beech Veneer Lumber (Baubuche) in Terms of Moisture Absorption and Desorption. Fibers 2020, 8, 47. [Google Scholar] [CrossRef]

- Thole, V. Oriented Strand Boards (OSB) Aus Buchenholz. Holztechnologie 2008, 49, 12–15. [Google Scholar]

- Akrami, A.; Frühwald, A.; Barbu, M.C. Supplementing Pine with European Beech and Poplar in Oriented Strand Boards. Wood Mater. Sci. Eng. 2015, 10, 313–318. [Google Scholar] [CrossRef]

- Akrami, A.; Fruehwald, A.; Barbu, M.C. The Effect of Fine Strands in Core Layer on Physical and Mechanical Properties of Oriented Strand Boards (OSB) Made of Beech (Fagus Sylvatica) and Poplar (Populus Tremula). Eur. J. Wood Wood Prod. 2014, 72, 521–525. [Google Scholar] [CrossRef]

- Akrami, A.; Barbu, M.C.; Fruehwald, A. Characterization of Properties of Oriented Strand Boards from Beech and Poplar. Eur. J. Wood Wood Prod. 2014, 72, 393–398. [Google Scholar] [CrossRef]

- Akrami, A.; Barbu, M.C.; Frühwald, A. European Hardwoods for Reducing Dependence on Pine for Oriented Strand Board. Int. Wood Prod. J. 2014, 5, 133–135. [Google Scholar] [CrossRef]

- Akrami, A. Development and Characterization of Oriented Strand Boards Made from the European Hardwood Species: Beech (Fagus sylvatica L.) and Poplar (Populus tremula L.). Ph.D. Dissertation, University of Hamburg, Hamburg, Germany, 2014. [Google Scholar]

- Weigl, M.; Harm, M.; Wimmer, R. Influence of Wood Mixture on Particle Board Properties. In Proceedings of the Proceedings of the 42nd International Wood Composites Symposium, Seattle, DC, USA, 1–2 April 2018. [Google Scholar]

- Weigl, M.; Wimmer, R.; Leder, S.; Harm, M. Achieving Lower Density for Particle Boards by Means of Raw Material Selection. In Proceedings of the COST Action E49 International Workshop in Slovenia on Lightweight Wood–Based Composites—Production, Properties and Usage, Landudno, Wales; 2007; pp. 67–80. [Google Scholar]

- Breinig, L.; Linsenmann, P.; Brüchert, F.; Weidenhiller, A.; Sauter, U.H. Mechanical Properties of Roundwood and Boards of European Beech and Ash and Their Relationships. Holztechnologie 2019, 60, 35–48. [Google Scholar]

- Schlotzhauer, P.; Wilhelms, F.; Lux, C.; Bollmus, S. Comparison of Three Systems for Automatic Grain Angle Determination on European Hardwood for Construction Use. Eur. J. Wood Wood Prod. 2018, 76, 911–923. [Google Scholar] [CrossRef]

- Purba, C.Y.C.; Dlouha, J.; Ruelle, J.; Fournier, M. Mechanical Properties of Secondary Quality Beech (Fagus Sylvatica L.) and Oak (Quercus Petraea (Matt.) Liebl.) Obtained from Thinning, and Their Relationship to Structural Parameters. Ann. For. Sci. 2021, 78, 81. [Google Scholar] [CrossRef]

- Rais, A.; Bacher, M.; Khaloian-Sarnaghi, A.; Zeilhofer, M.; Kovryga, A.; Fontanini, F.; Hilmers, T.; Westermayr, M.; Jacobs, M.; Pretzsch, H.; et al. Local 3D Fibre Orientation for Tensile Strength Prediction of European Beech Timber. Constr. Build. Mater. 2021, 279, 122527. [Google Scholar] [CrossRef]

- Rais, A.; Pretzsch, H.; van de Kuilen, J.W.G. European Beech Log and Lumber Grading in Wet and Dry Conditions Using Longitudinal Vibration. Holzforschung 2020, 74, 939–947. [Google Scholar] [CrossRef]

- Plos, M.; Fortuna, B.; Šuligoj, T.; Turk, G. From Visual Grading and Dynamic Modulus of European Beech (Fagus Sylvatica) Logs to Tensile Strength of Boards. Forests 2022, 13, 77. [Google Scholar] [CrossRef]

- Ehrhart, T.; Steiger, R.; Frangi, A. A Non-Contact Method for the Determination of Fibre Direction of European Beech Wood (Fagus Sylvatica L.). Eur. J. Wood Wood Prod. 2018, 76, 925–935. [Google Scholar] [CrossRef]

- Ehrhart, T.; Palma, P.; Schubert, M.; Steiger, R.; Frangi, A. Predicting the Strength of European Beech (Fagus Sylvatica L.) Boards Using Image-Based Local Fibre Direction Data. Wood Sci. Technol. 2022, 56, 123–146. [Google Scholar] [CrossRef]

- Kovryga, A.; Stapel, P.; van de Kuilen, J.W.G. Mechanical Properties and Their Interrelationships for Medium-Density European Hardwoods, Focusing on Ash and Beech. Wood Mater. Sci. Eng. 2020, 15, 289–302. [Google Scholar] [CrossRef]

- Brunetti, M.; Nocetti, M.; Pizzo, B.; Aminti, G.; Cremonini, C.; Negro, F.; Zanuttini, R.; Romagnoli, M.; Scarascia Mugnozza, G. Structural Products Made of Beech Wood: Quality Assessment of the Raw Material. Eur. J. Wood Wood Prod. 2020, 78, 961–970. [Google Scholar] [CrossRef]

- Ammann, S.; Niemz, P. Fibre and Adhesive Bridging at Glue Joints in European Beech Wood. Wood Res. 2014, 59, 303–312. [Google Scholar]

- Stoeckel, F.; Konnerth, J.; Gindl-Altmutter, W. Mechanical Properties of Adhesives for Bonding Wood-A Review. Int. J. Adhes. Adhes. 2013, 45, 32–41. [Google Scholar] [CrossRef]

- Ammann, S.; Niemz, P. Specific Fracture Energy at Glue Joints in European Beech Wood. Int. J. Adhes. Adhes. 2015, 60, 47–53. [Google Scholar] [CrossRef]

- Pečnik, J.G.; Pondelak, A.; Burnard, M.D.; Sebera, V. Mode I Fracture of Beech-Adhesive Bondline at Three Different Temperatures. Wood Mater. Sci. Eng. 2022, 1–11. [Google Scholar] [CrossRef]

- Schmidt, M.; Glos, P.; Wegener, G. Verklebung von Buchenholz Für Tragende Holzbauteile. Eur. J. Wood Wood Prod. 2010, 68, 43–57. [Google Scholar] [CrossRef]

- Ohnesorge, D.; Richter, K.; Becker, G. Influence of Wood Properties and Bonding Parameters on Bond Durability of European Beech (Fagus Sylvatica L.) Glulams. Ann. For. Sci. 2010, 67, 601. [Google Scholar] [CrossRef]

- Fortuna, B.; Azinović, B.; Plos, M.; Šuligoj, T.; Turk, G. Tension Strength Capacity of Finger Joined Beech Lamellas. Eur. J. Wood Wood Prod. 2020, 78, 985–994. [Google Scholar] [CrossRef]

- Aicher, S.; Reinhardt, H.W. Delaminierungseigenschaften Und Scherfestigkeiten von Verklebten Rotkernigen Buchenholzlamellen. Holz. Roh Werkst. 2007, 65, 125–136. [Google Scholar] [CrossRef]

- Konnerth, J.; Kluge, M.; Schweizer, G.; Miljković, M.; Gindl-Altmutter, W. Survey of Selected Adhesive Bonding Properties of Nine European Softwood and Hardwood Species. Eur. J. Wood Wood Prod. 2016, 74, 809–819. [Google Scholar] [CrossRef]

- Luedtke, J.; Amen, C.; van Ofen, A.; Lehringer, C. 1C-PUR-Bonded Hardwoods for Engineered Wood Products: Influence of Selected Processing Parameters. Eur. J. Wood Wood Prod. 2015, 73, 167–178. [Google Scholar] [CrossRef]

- Baar, J.; Brabec, M.; Slávik, R.; Čermák, P. Effect of Hemp Oil Impregnation and Thermal Modification on European Beech Wood Properties. Eur. J. Wood Wood Prod. 2021, 79, 161–175. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Olek, W.; Weres, J. Effects of Heat Treatment on Thermal Properties of European Beech Wood. Eur. J. Wood Wood Prod. 2020, 78, 425–431. [Google Scholar] [CrossRef]

- Widmann, R.; Fernandez-Cabo, J.L.; Steiger, R. Mechanical Properties of Thermally Modified Beech Timber for Structural Purposes. Eur. J. Wood Wood Prod. 2012, 70, 775–784. [Google Scholar] [CrossRef]

- Grönquist, P.; Schnider, T.; Thoma, A.; Gramazio, F.; Kohler, M.; Burgert, I.; Rüggeberg, M. Investigations on Densified Beech Wood for Application as a Swelling Dowel in Timber Joints. Holzforschung 2019, 73, 559–568. [Google Scholar] [CrossRef]

- Pečnik, J.G.; Kutnar, A.; Militz, H.; Schwarzkopf, M.; Schwager, H. Fatigue Behavior of Beech and Pine Wood Modified with Low Molecular Weight Phenol-Formaldehyde Resin. Holzforschung 2021, 75, 37–47. [Google Scholar] [CrossRef]

- Gómez-Royuela, J.L.; Majano-Majano, A.; José Lara-Bocanegra, A.; Reynolds, T.P.S. Determination of the Elastic Constants of Thermally Modified Beech by Ultrasound and Static Tests Coupled with 3D Digital Image Correlation. Constr. Build. Mater. 2021, 302, 124270. [Google Scholar] [CrossRef]

- Altgen, M.; Willems, W.; Militz, H. Wood Degradation Affected by Process Conditions during Thermal Modification of European Beech in a High-Pressure Reactor System. Eur. J. Wood Wood Prod. 2016, 74, 653–662. [Google Scholar] [CrossRef]

- Cermák, P.; Horácek, P.; Rademacher, P. Measured Temperature and Moisture Profiles during Thermal Modification of Beech (Fagus Sylvatica L.) and Spruce (Picea Abies L. Karst.) Wood. Holzforschung 2014, 68, 175–183. [Google Scholar] [CrossRef]

- Hering, S.; Keunecke, D.; Niemz, P. Moisture-Dependent Orthotropic Elasticity of Beech Wood. Wood Sci. Technol. 2012, 46, 927–938. [Google Scholar] [CrossRef]

- Hering, S.; Niemz, P. Moisture-Dependent, Viscoelastic Creep of European Beech Wood in Longitudinal Direction. Eur. J. Wood Wood Prod. 2012, 70, 667–670. [Google Scholar] [CrossRef]

- Niemz, P.; Ozyhar, T.; Hering, S.; Sonderegger, W. Zur Orthotropie Der Physikalisch-mechanischen Eigenschaften von Rotbuchenholz. Bautechnik 2015, 92, 3–8. [Google Scholar] [CrossRef]

- Ozyhar, T.; Hering, S.; Niemz, P. Moisture-Dependent Elastic and Strength Anisotropy of European Beech Wood in Tension. J. Mater. Sci. 2012, 47, 6141–6150. [Google Scholar] [CrossRef]

- Han, L.; Kutnar, A.; Sandberg, D. Creep Behaviour of Densified European Beech and Scots Pine under Constant Climate. Wood Mater. Sci. Eng. 2022, 17, 1025–1027. [Google Scholar] [CrossRef]

- Brabec, M.; Tippner, J.; Sebera, V.; Milch, J.; Rademacher, P. Standard and Non-Standard Deformation Behaviour of European Beech and Norway Spruce during Compression. Holzforschung 2015, 69, 1107–1116. [Google Scholar] [CrossRef]

- Jankowska, A.; Kozakiewicz, P.; Zbieć, M. The Effects of Slicing Parameters on Surface Quality of European Beech Wood. Drv. Ind. 2021, 72, 57–63. [Google Scholar] [CrossRef]

- Kubík, P.; Šebek, F.; Krejčí, P.; Brabec, M.; Tippner, J.; Dvořáček, O.; Lechowicz, D.; Frybort, S. Linear Woodcutting of European Beech: Experiments and Computations. Wood Sci. Technol. 2023, 57, 51–74. [Google Scholar] [CrossRef]

- Rohumaa, A.; Viguier, J.; Girardon, S.; Krebs, M.; Denaud, L. Lathe Check Development and Properties: Effect of Log Soaking Temperature, Compression Rate, Cutting Radius and Cutting Speed during Peeling Process of European Beech (Fagus Sylvatica L.) Veneer. Eur. J. Wood Wood Prod. 2018, 76, 1653–1661. [Google Scholar] [CrossRef]

- Dvoracek, O.; Lechowicz, D.; Krenke, T.; Möseler, B.; Tippner, J.; Haas, F.; Emsenhuber, G.; Frybort, S. Development of a Novel Device for Analysis of High-Speed Cutting Processes Considering the Influence of Dynamic Factors. Int. J. Adv. Manuf. Technol. 2021, 113, 1685–1697. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).