Experimental Analysis of the Performance of Doweled Connections Reinforced with Glass-Fiber-Reinforced Polymer (GFRP) in Wood Pinus spp.

Abstract

1. Introduction

2. Materials and Methods

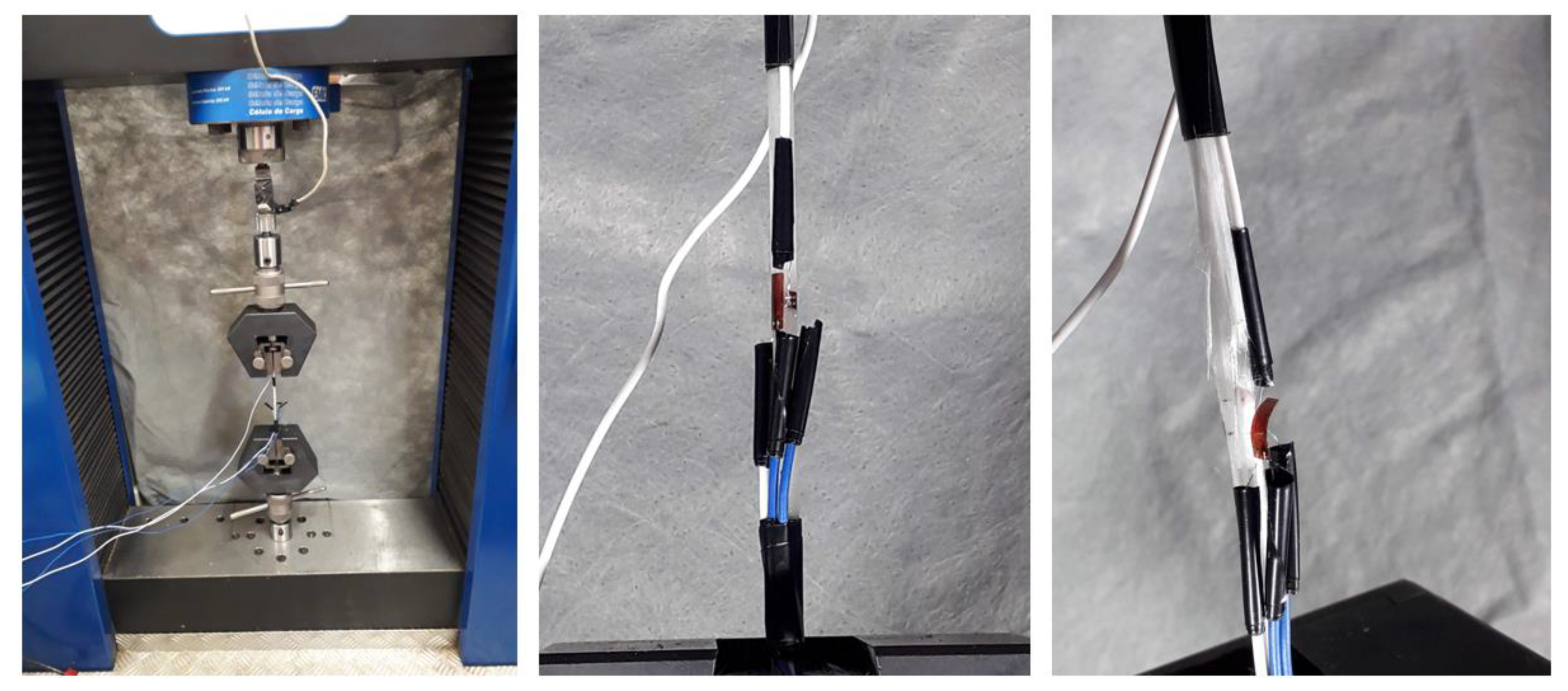

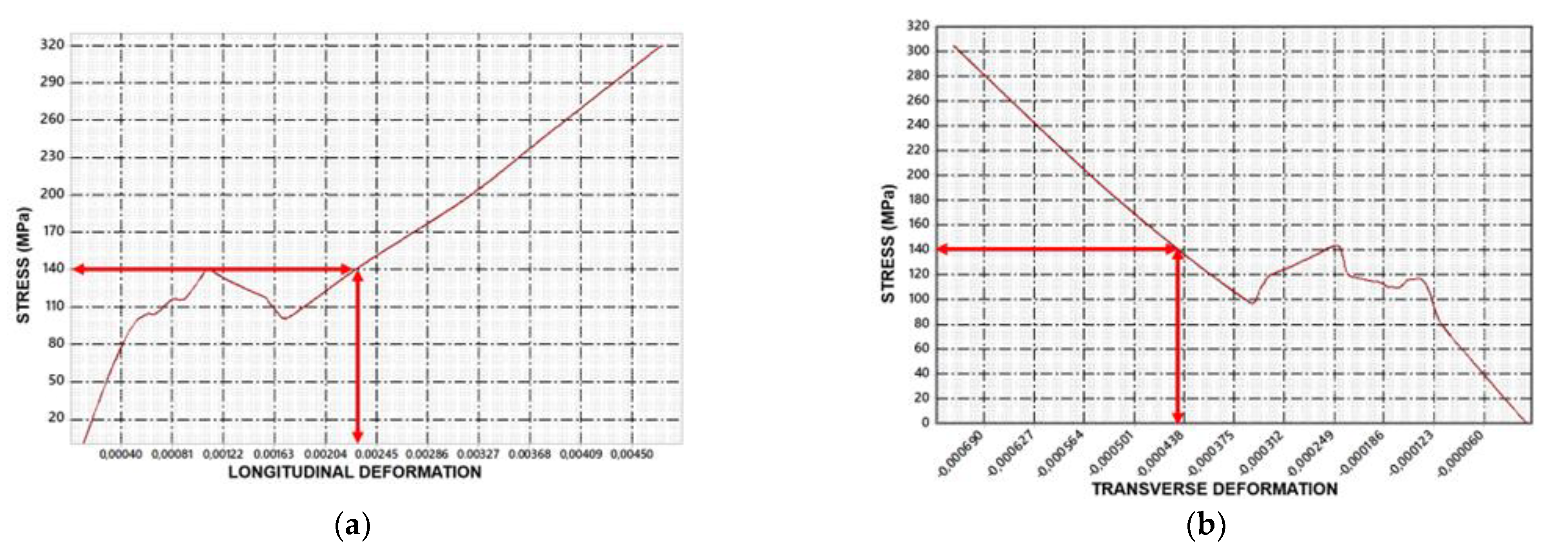

2.1. Characterization of the GFRP Dowels

2.2. Wood Characterization

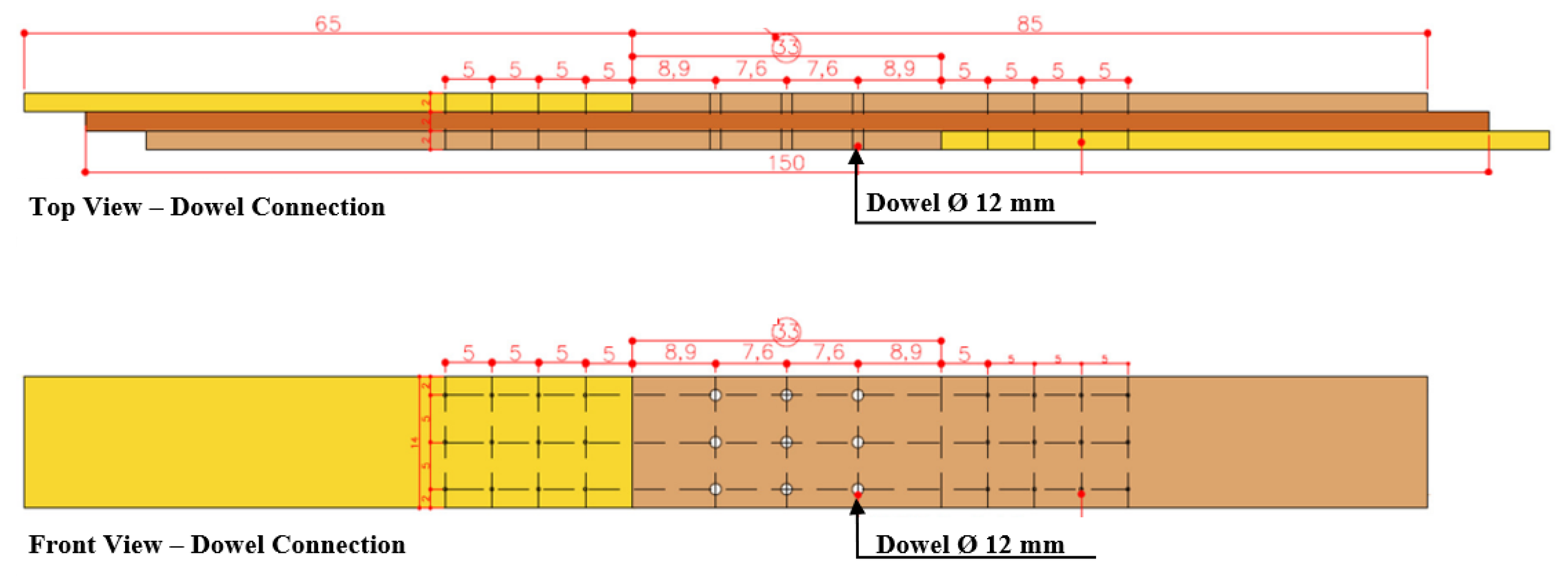

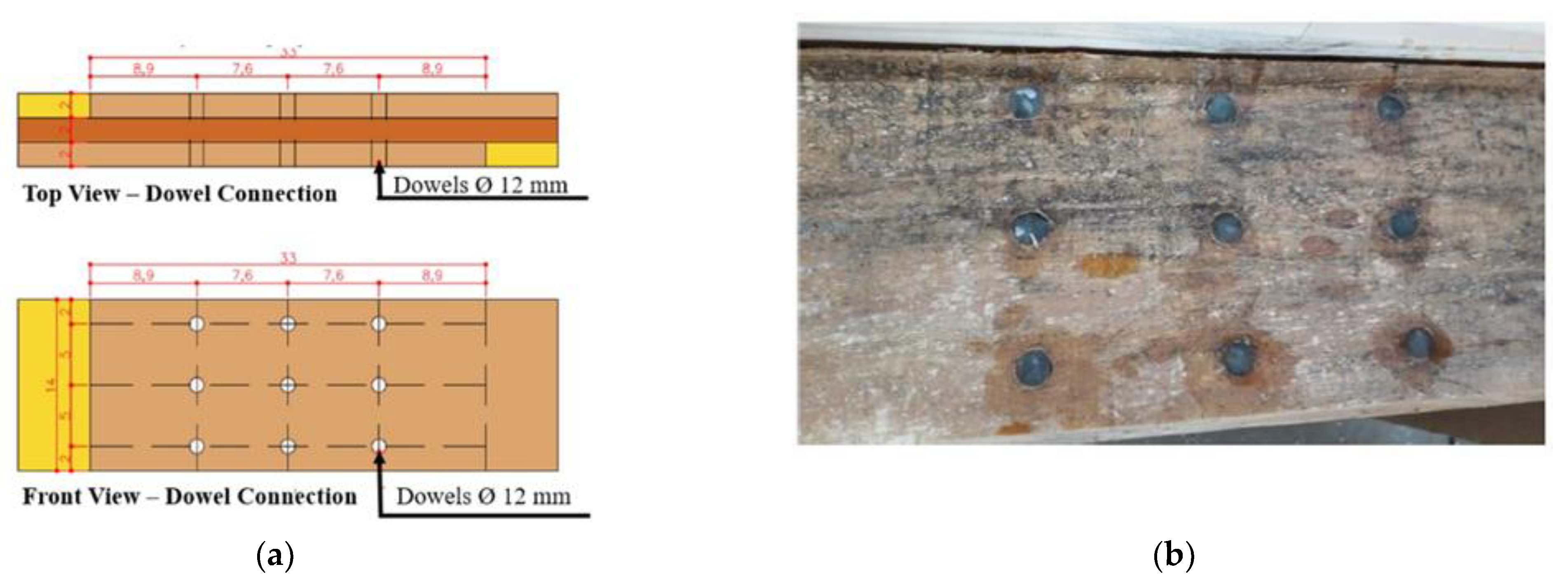

2.3. Tested Connection Specimen

2.4. Calculation of the Connection’s Stiffness

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- O’Ceallaigh, C.; Conway, M.; Mehra, S.; Harte, A.M. Numerical Investigation of Reinforcement of Timber Elements in Compression Perpendicular to the Grain Using Densified Wood Dowels. Constr. Build. Mater. 2021, 288, 122990. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W. Comparative Sustainability Evaluation of Two Engineered Wood-Based Construction Materials: Life Cycle Analysis of CLT versus GLT. Build. Environ. 2021, 204, 108112. [Google Scholar] [CrossRef]

- Goldhahn, C.; Cabane, E.; Chanana, M. Sustainability in Wood Materials Science: An Opinion about Current Material Development Techniques and the End of Lifetime Perspectives. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2021, 379, 20200339. [Google Scholar] [CrossRef] [PubMed]

- Biazzon, J.C.; Lima, M.P.; Munis, R.A.; De Araujo, V.A.; Morales, E.A.M.; Gonçalves, M.T.T.; Bueno, M.A.P.; Moizes, F.A.; Leite, S.S.; Salvadeo, V.M.; et al. Shear Strength of Eucalyptus Saligna Wood Joints Bonded with Polyvinyl Acetate Adhesive. BioResources 2019, 14, 4590–4602. [Google Scholar] [CrossRef]

- Vilela, R.; Mascia, N.T. Avaliação de Propriedades Mecânicas Da Madeira de Pinus Taeda Provenientes de Placas de Cross Laminated Timber. Ambient. Construído 2021, 21, 89–110. [Google Scholar] [CrossRef]

- Ballarin, A.S.; Rodrigues, S.A.; Ballarin, A.W.; Júnior, C.C. Classificação Visual e Mecânica Simplificada Da Madeira de Pinus Spp—Avaliação Com Estatística Multivariada. In Proceedings of the XVI Encontro Brasileiro em Madeiras e em Estruturas de Madeira e III Congresso Latino-Americano de Estruturas de Madeira, São Carlos, Brazil, 26–28 March 2018; pp. 1–12. [Google Scholar]

- Lahr, F.A.R.; Christoforo, A.L.; Fiorelli, J. Influence of Nails Size and Layout to Obtain the Reduction Coefficient of Moment of Inertia for Timber Beams with Composite Cross Section. Eng. Agric. 2016, 36, 715–723. [Google Scholar] [CrossRef]

- Bolgenhagen, A. Avaliação Comparada Dos Parâmetros Que Influenciam Na Colagem Lateral De Painéis De Madeira De Pinus Elliottii E Pinus Taeda. Rev. Eletrônica Alto Val. Itajaí 2018, 10, 31–48. [Google Scholar] [CrossRef]

- de Oliveira, F.L.; de Lima, I.L.; Garcia, J.N.; Florsheim, S.M.B. Propriedades Da Madeira de Pinus Taeda Em Função Da Idade e Da Posição Radial Da Tora. Rev. Inst. Flor. 2006, 18, 59–70. [Google Scholar]

- Teodorescu, I.; Pereira, B.; Aquino, C.D.; Branco, J.M. Experimental Evaluation of Dowel-Type Timber Joints with Wooden Dowels. Proc. Inst. Civ. Eng. Struct. Build. 2020, 173, 927–938. [Google Scholar] [CrossRef]

- Izzi, M.; Rinaldin, G.; Polastri, A.; Fragiacomo, M. A Hysteresis Model for Timber Joints with Dowel-Type Fasteners. Eng. Struct. 2018, 157, 170–178. [Google Scholar] [CrossRef]

- EN 1995-1-1:2004+A1; Design of Timber Structures—Part 1-1: General Common Rules for Buildings Eurocode 5. CEN: Brussels, Belgium, 2004; Volume 1.

- Associação Brasileira de Normas Técnicas. NBR 7190-1: Projetos de Estruturas Em Madeira; ABNT: Rio de Janeiro, Brazil, 2022; ISBN 9788507091424. [Google Scholar]

- Ceraldi, C.; D’Ambra, C.; Lippiello, M.; Prota, A. Restoring of Timber Structures: Connections with Timber Pegs. Eur. J. Wood Wood Prod. 2017, 75, 957–971. [Google Scholar] [CrossRef]

- William, D.; Callister, J. Ciência e Engenharia de Materiais: Uma Introdução; Cengage Learning: Rio de Janeiro, Brasil, 2000. [Google Scholar]

- Yahng, J.S.; Yee, D.S. High-Speed Time-and Frequency-Domain Terahertz Tomography of Glass-Fiber-Reinforced Polymer Laminates with Internal Defects. Appl. Sci. 2021, 11, 4933. [Google Scholar] [CrossRef]

- Liu, J.L.; Mencattelli, L.; Zhi, J.; Chua, P.Y.; Tay, T.E.; Tan, V.B.C. Lightweight, Fiber-Damage-Resistant, and Healable Bio-Inspired Glass-Fiber Reinforced Polymer Laminate. Polymers 2022, 14, 475. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Jeong, S.; Jang, J.W.; Woo, J.H.; Oh, D. Ultrasonic Attenuation Characteristics of Glass-Fiber-Reinforced Polymer Hull Structure. Appl. Sci. 2021, 11, 6614. [Google Scholar] [CrossRef]

- Han, Z.; Jang, J.; Lee, S.G.; Lee, D.; Oh, D. Error Analysis of Non-Destructive Ultrasonic Testing of Glass Fiber-Reinforced Polymer Hull Plates. J. Compos. Sci. 2021, 5, 238. [Google Scholar] [CrossRef]

- de Almeida, A.C.; de Melo Moura, J.D. Mechanical Behavior of GFRP Dowel Connections to Cross Laminated Timber-CLT Panels. Forests 2022, 13, 320. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Practice for Preparation of Metallographic Specimens. ASTM International: West Conshohocken, PA, USA, 2016; Volume 82, pp. 1–15.

- Recco, E.G. Análise Experimental Do Sistema de Cobertura Caibro Treliçado Em MLP (Madeira Laminada Pregada) Utilizando Madeira Serrada de Pinus Spp; Universidade Estadual de Londrina: Londrina, Brazil, 2015. [Google Scholar]

- EN 26891:1991; Timber Structures. Joints Made with Mechanical Fasteners. General Principles for The Determination of Strength and Deformation Characteristics (ISO 6891:1983). CEN: Brussels, Belgium, 1991.

- do Vale Barcarolo, L.R. Estudo de Eficiência de Ligações Por Cavilha de Compósito Estrutural Em Vigas de Madeira Laminada, Dissertação (Mestrado em Arquitetura e Urbanismo). Ph.D. Thesis, Centro de Tecnologia e Urbanismo, Universidade Estadual de Londrina, Londrina, Brazil, 2019. [Google Scholar]

- Branco, J.M.G. Comportamento Das Ligações Tipo Cavilha Em Estruturas Mistas Madeira-Betão. Master’s Thesis, Universidade do Minho, Braga, Portugal, 2003; p. 150. [Google Scholar]

- Almeida, A.C. de Aplicação de Compósitos Poliméricos Reforçados Com Fibras de Vidro—GFRP Em Ligações Cavilhadas Para CLT. Master’s Thesis, Universidade Estadual de Londrina, Londrina, Brazil, 2019. [Google Scholar]

| Properties | Structural Features of the Dowel |

|---|---|

| Ultimate normal strength (σ) | 320 MPa |

| Longitudinal deformation (ε1) | 0.00228 |

| Cross-sectional deformation (ε2) | 0.00044 |

| Poisson ratio (ν) | 0.195 |

| Longitudinal modulus of elasticity (E) | 61,403.5 MPa |

| Transverse modulus of elasticity (G) | 25,691.8 MPa |

| Shear stress () | 14.4 MPa |

| Modulus of Elasticity of the Connection Pieces | ||||

|---|---|---|---|---|

| IC 95%; Ec0 = 5492.19 MPa–Ec0 = 6695.15 MPa | ||||

| Piece Reference | Ec0 (MPa) | Piece Reference | Ec0 (MPa) | Average Ec0 (MPa) |

| L08 | 4040.44 | L17 | 8878.15 | 6359.29 |

| L02 | 4418.14 | L23 | 8557.19 | 6487.66 |

| L14 | 4473.72 | L06 | 8208.25 | 6340.99 |

| L01 | 4692.05 | L18 | 8050.00 | 6371.03 |

| L04 | 4787.96 | L24 | 7705.64 | 6246.80 |

| L10 | 4801.14 | L19 | 7446.18 | 6123.66 |

| L07 | 4858.28 | L11 | 7086.68 | 5972.48 |

| L13 | 5005.07 | L12 | 6743.05 | 5874.06 |

| L09 | 5195.28 | L15 | 6415.38 | 5805.33 |

| L21 | 5349.68 | L22 | 6342.58 | 5846.13 |

| L05 | 5438.28 | L16 | 6182.16 | 5810.22 |

| Specimen | Ultimate Load of the Connection (kN) | Displacement (mm) | EN 26891 (1991) Kser (kN/mm) | Linear Regression Kser (kN/mm) |

|---|---|---|---|---|

| SP4 | 73.70 | 2.23 | 38.50 | 41.67 |

| SP7 | 74.50 | 1.48 | 35.93 | 58.91 |

| SP10 | 51.00 | 3.03 | 29.59 | 16.62 |

| SP11 | 28.80 | 1.30 | 32.58 | 25.99 |

| SP12 | 34.80 | 2.68 | 13.19 | 14.34 |

| SP14 | 75.40 | 1.67 | 27.70 | 38.54 |

| Average | 56.37 | 2.07 | 29.58 | 32.68 |

| Standard deviation (STD) | 21.19 | 0.70 | 16.06 | 16.98 |

| Coefficient of variation (COV) | 37.60% | 33.69% | 47.05% | 51.97% |

| Designation | Branco (2003) Smooth Common Nail (90°) | Almeida (2019) Half-Lap Composite Dowel | Barcarolo (2019) Composite Dowel | Recco (2015) Coiled Shank (Ardox) Nail |

|---|---|---|---|---|

| Doweled connection, F (kN) | 3.51 | 13.18 | 56.37 | 33.84 |

| Displacement max. (mm) | 14.03 | 14.73 | 2.07 | -- |

| Number of connectors | 2 | 4 | 9 | 9 |

| Diameter of connectors (mm) | 3.8 | 6 | 12 | 3.4 |

| Length of connectors (mm) | 100 | 100 | 60 | 72 |

| Resistance per connector (kN) | 0.88 | 1.65 | 3.13 | 1.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camargo, M.V.d.; Christoforo, A.L.; Barcarolo, L.R.d.V.; Moura, J.D.d.M. Experimental Analysis of the Performance of Doweled Connections Reinforced with Glass-Fiber-Reinforced Polymer (GFRP) in Wood Pinus spp. Forests 2023, 14, 931. https://doi.org/10.3390/f14050931

Camargo MVd, Christoforo AL, Barcarolo LRdV, Moura JDdM. Experimental Analysis of the Performance of Doweled Connections Reinforced with Glass-Fiber-Reinforced Polymer (GFRP) in Wood Pinus spp. Forests. 2023; 14(5):931. https://doi.org/10.3390/f14050931

Chicago/Turabian StyleCamargo, Marcos Vinício de, André Luis Christoforo, Laisa Rebeca do Vale Barcarolo, and Jorge Daniel de Melo Moura. 2023. "Experimental Analysis of the Performance of Doweled Connections Reinforced with Glass-Fiber-Reinforced Polymer (GFRP) in Wood Pinus spp." Forests 14, no. 5: 931. https://doi.org/10.3390/f14050931

APA StyleCamargo, M. V. d., Christoforo, A. L., Barcarolo, L. R. d. V., & Moura, J. D. d. M. (2023). Experimental Analysis of the Performance of Doweled Connections Reinforced with Glass-Fiber-Reinforced Polymer (GFRP) in Wood Pinus spp. Forests, 14(5), 931. https://doi.org/10.3390/f14050931