Quality of the Pellets Obtained with Wood and Cutting Residues of Stone Pine (Pinus pinea L.)

Abstract

1. Introduction

- -

- Manufacture and characterization of pellets obtained from the different types of biomass originated by forestry works in Pinus pinea stands.

- -

- Determine the optimal operating ranges such as pressure, particle size and moisture to obtain stone pine wood pellets.

- -

- Evaluate the properties of pellets made with a mixture of wood and residual pine biomass.

2. Materials and Methods

2.1. Assay with Residual Biomass of Pine

- -

- Needles and twigs (NTW).

- -

- Medium branches with bark (diameter between 2.5 and 7.5 cm, –MBR–)

- -

- Bark of logs of more than 20 cm in diameter at breast height (BARK).

- -

- Moisture content (%).

- -

- Bulk density (kg/m3), both with moisture just after manufacturing and based on dry mass (0% moisture).

- -

- Mechanical durability (%).

- -

- Length and diameter (mm).

- -

- Ash content (%) on a dry mass basis.

- -

- N, S, Cl, C and H content (%) on a dry mass basis (105 °C), as well as low calorific value (LCV, kWh/kg) both based on dry mass and with the moisture just after manufacturing. Kjedahl method (auto-analyzer Bran+Luebbe®, Mod. AIII; Norderstedt, Germany) for N; ICP-OES (Thermo Jarrell Ash Corporation; Franklin, MA, USA) for K and P; total extraction with HNO3 and photometry (HI 83200, Hanna® Instruments; Woonsocket, RI, USA) for Cl; Elemental analyzer (Thermo Scientific™ FLASH 2000; Chino, CA, USA) for S, C and H; automatic isoperibol calorimeter (Parr 6300®; Parr Instrument Company; Moline, IL, USA) for LCV.

- -

- Pellet particle density (kg/m3), both with moisture just after being manufactured and on a dry mass basis.

- -

- Process yield (% w/w): proportion of pellets greater than 3.15 mm in length just after manufacturing.

2.2. Factorial Assay with Debarked Thick Pine Wood

2.3. Mixtures of Residual Biomass with Debarked Pine Wood

- -

- 85% DTTB + 15% BARK (w/w)

- -

- 70% DTTB + 30% MBR (w/w)

- -

- 85% DTTB + 15% NTW (w/w)

- -

- Control (100% DTTB)

3. Results

3.1. Assay with Residual Biomass of Pine

- -

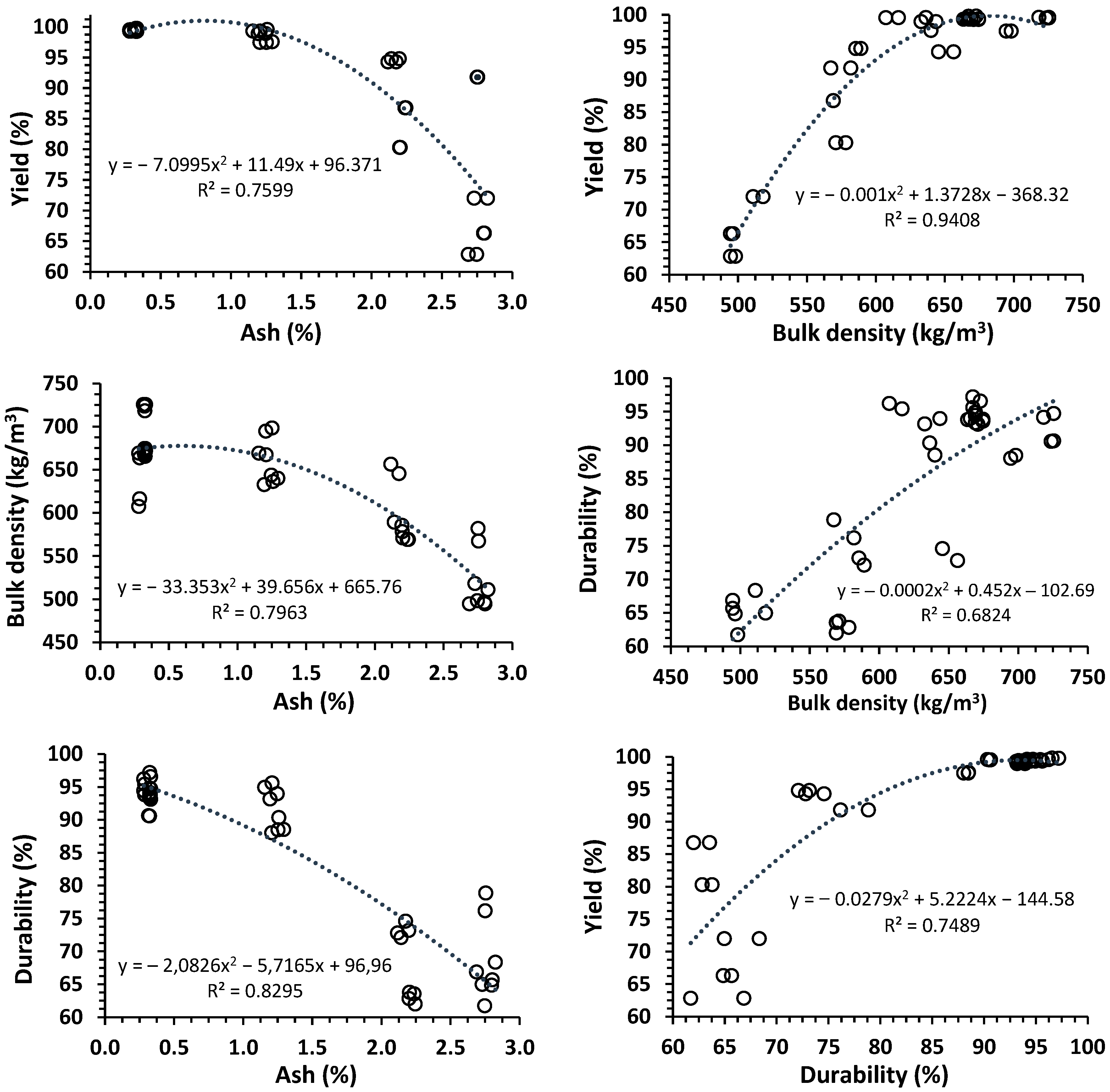

- The ash content of the raw material was significantly correlated with the bulk density, durability, production yield and length of the pellets.

- -

- In this study, a yield greater than 95% was only achieved for ash contents below 1.3%; the bulk density exceeded 600 kg/m3 for ash contents below 2.18%; and the mechanical durability exceeded 95% only if the ashes were below 1.21%.

- -

- Yield exceeded 95% only when mechanical durability surpassed 88%, which only happened for MBR and DTTB. Durability values above 96% were only achieved by DTTB. Pellets with a durability greater than 95% were not obtained if the bulk density did not exceed 600 kg/m3. Similarly, the 95% yield was only achieved when the bulk density exceeded 600 kg/m3.

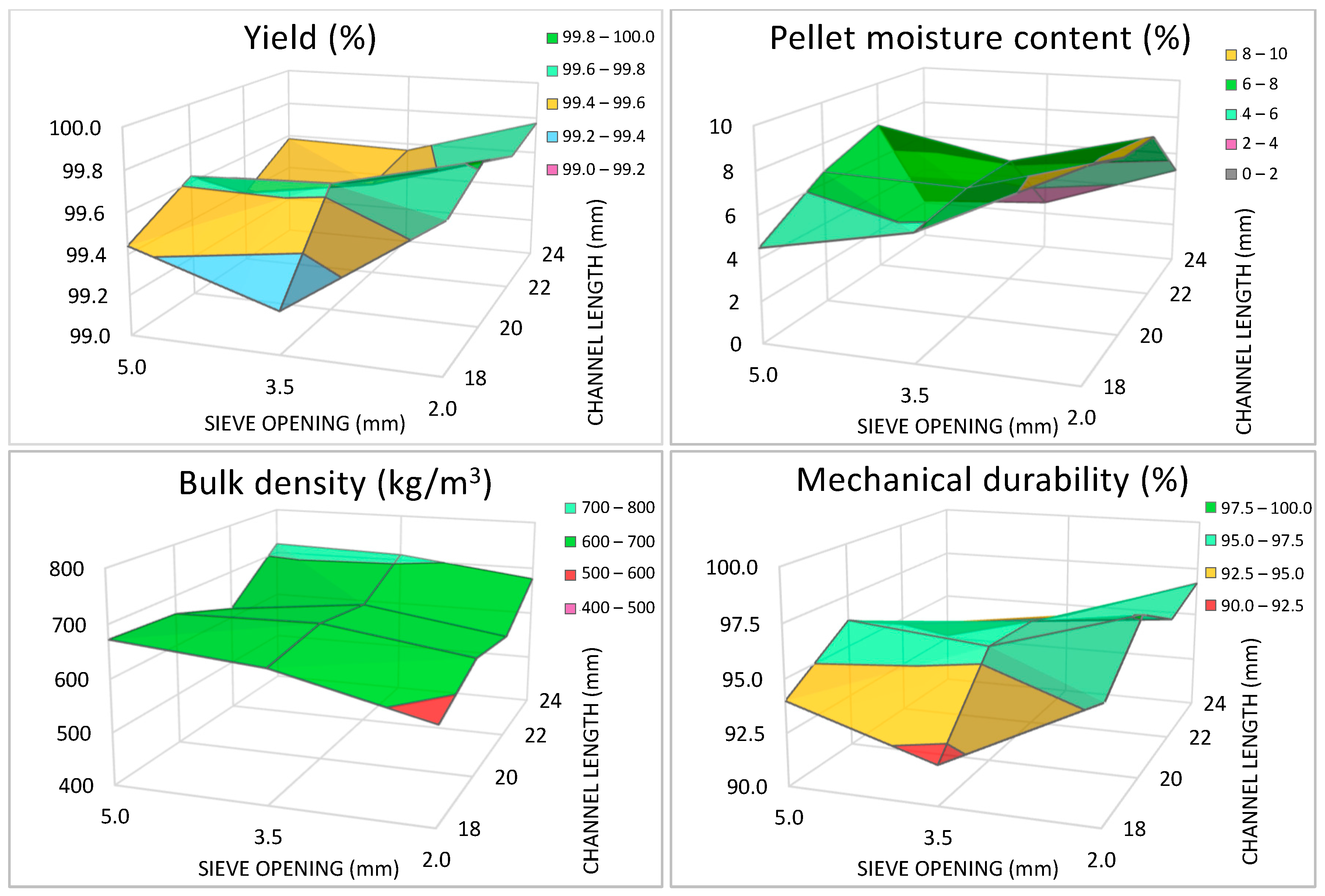

3.2. Factorial Assay with Debarked Thick Pine Wood

- -

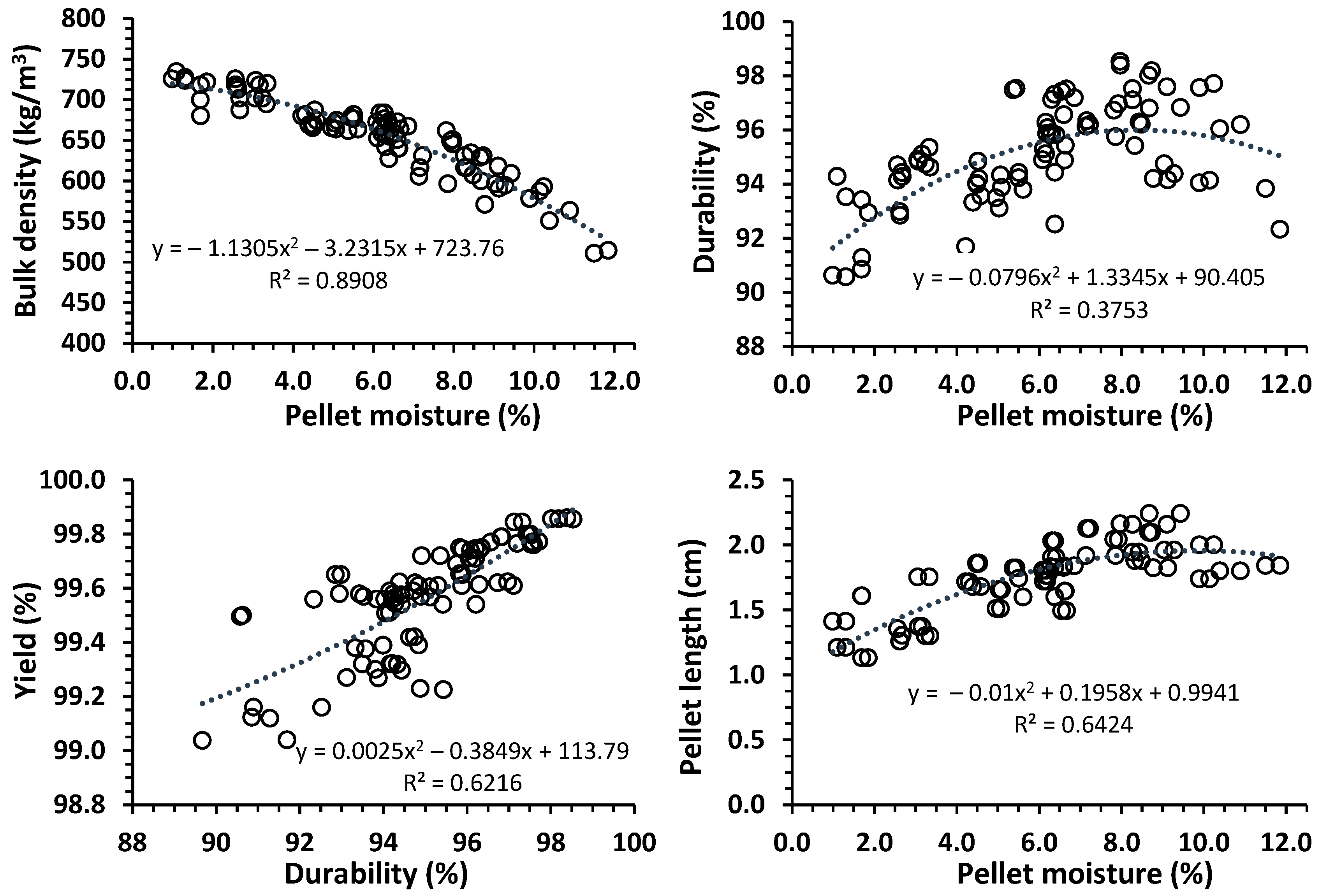

- In this study, a bulk density greater than 600 kg/m3 was only achieved for pellet moisture below 9%, while durability greater than 97.5% was achieved for pellet moisture between 5 and 10%. Therefore, this optimal range of 5%–9% corresponded to pellets with a mean length of 1.5–2.3 cm, very suitable for commercial use.

- -

- Yield exceeded 96.6% only when durability was greater than 96%, and 99.7% for durability of 97.5%. These are values of fairly optimal yield in the process of manufacturing commercial grade pellets.

- -

- Pellet moisture (%) = 8.600 − 0.029 P − 0.871 S + 0.341 MsR = 0.669, R2corr = 0.428, p < 0.001

- -

- Bulk density (kg/m3) = 601.003 + 0.542 P + 15.793 S − 5.582 MsR = 0.666, R2corr = 0.424, p < 0.001

- -

- Pellet length (cm) = 2.545 − 0.004 P − 0.065 SR = 0.707, R2corr = 0.489, p < 0.001

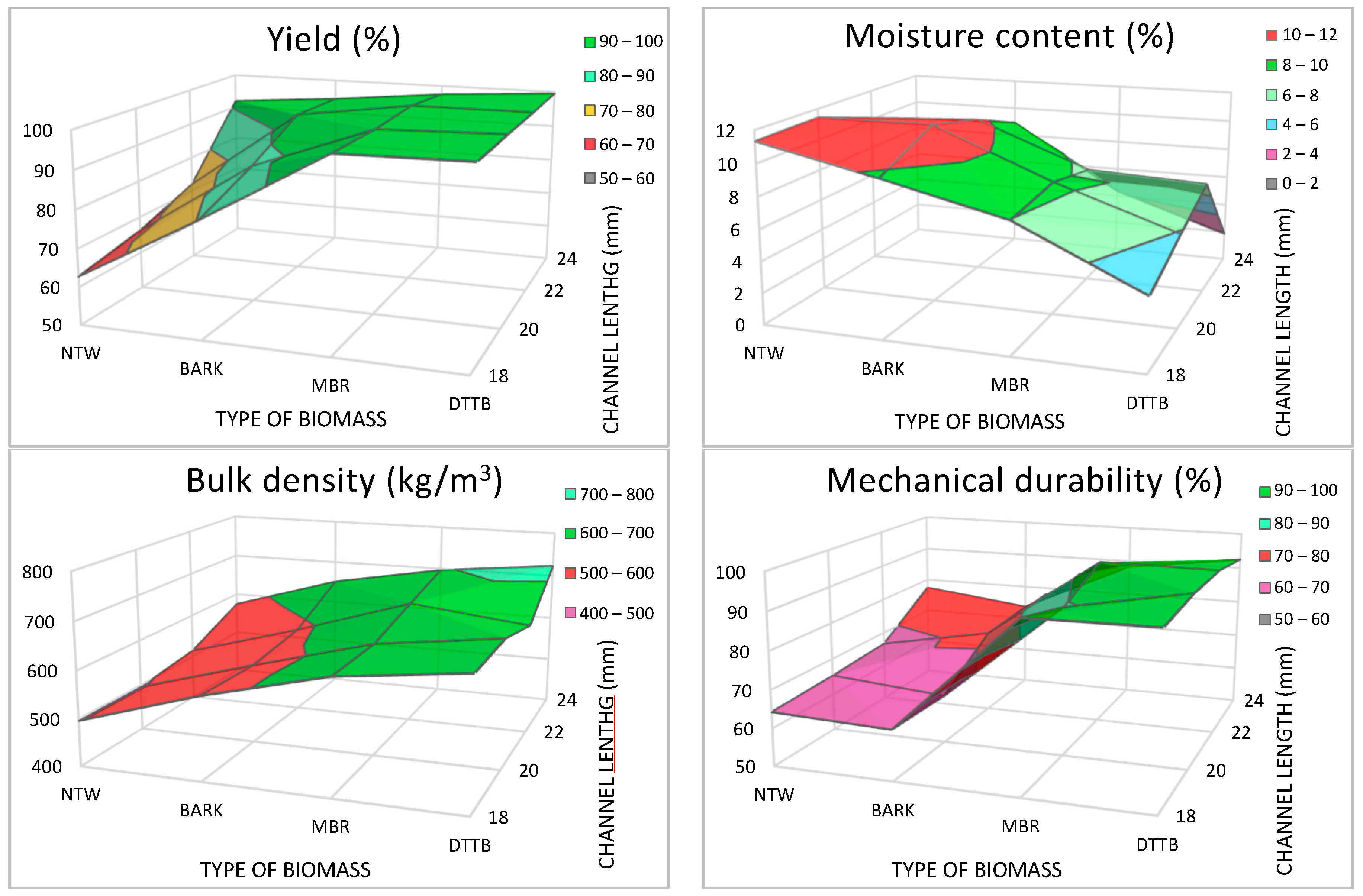

3.3. Mixtures of Residual Biomass with Debarked Pine Wood

4. Discussion

- -

- The fine branches and needles (NTW) do not meet the minimum criteria for commercial quality with any of the matrices used, so that, in addition to their poor chemical quality (high ash and mineral element content), they are mechanically unsuitable for pelletizing. The latter limits the proportion of this type of biomass that could be mixed with thick debarked pine wood if maximum commercial quality is to be achieved. The longest die used in this trial (24 mm) achieved acceptable levels for pellet yield and moisture content, but not for mechanical durability or bulk density. It is the only biomass type for which pellets could be produced with a longer die (26 mm, 276.7 MPa), but still failed to reach acceptable durability levels.

- -

- Pine bark only showed acceptable values for yield, moisture and bulk density with the 24 mm die, but also did not reach acceptable levels of mechanical durability. The high ash and mineral content also limits its pelleting quality.

- -

- As expected, biomass from debarked logs and thick branches (DTTB) showed the best properties. In some cases, the medium branches with bark were close to the DTTB values, without significant differences, but in general with poorer quality. Although the differences between the 4 dies were not very pronounced for these four properties, the 20 and 22 mm dies showed better results. For the 24 mm die, the DTTB moisture content was too low (<2%).

- -

- The ash content of a plant tissue is closely related to the concentration of mineral nutrients (N, P, K, etc.). Non-woody or less woody tissues, such as leaves, the cambium-phloem region and part of the bark usually have higher nutrient concentrations than wood, as shown in Table 1. Likewise, it has been shown that the physical-mechanical characteristics of the pellets (e.g., bulk density, mechanical durability) are closely related to their composition, mainly lignin, which is more abundant in woody than non-woody tissues [8,23,31]. For this reason, this relationship between ash content and physical-mechanical properties of the different types of pine biomass used has been revealed and quantified, highlighting a reduction in yield and quality of the pellets with the increase in ash content. The positive relationship between yield, mechanical durability and bulk density is more logical, since if the operating conditions are adequate, the sawdust particles bind well, resulting in compact pellets and less production of unbound fine elements.

- -

- No sample made with sawdust moisture content of 11.5% met all the minimum commercial quality criteria, reducing the choice in this study to moisture contents between 14.0 and 16.5%.

- -

- No sample made with the 18 mm die met all the minimum commercial quality criteria, which narrows the choice in this study to dies between 20 and 24 mm, corresponding to pelleting pressures of 120 to 210 MPa.

- -

- The smallest particle size (2.0 mm sieve) with a sawdust moisture content of 16.5% usually presents problems of excess moisture in pellets and low bulk density for shorter dies (18 to 22 mm). This restricts the use of this particle size to 14 % moisture for 20–22 mm matrices, or to 24 mm matrices if 16.5% moisture is used.

- -

- The maximum temperature range used for the tests as a whole, 95–125 °C, is within a range in which the effect of temperature on the properties of the pellets is not too high [10,50], at least for pines [17]. However, it could have partially affected the differences obtained between the factors tested.

- -

- With the range of pellet moisture content obtained (2.6%–11.7%) the actual lower calorific value at pellet moisture content at the pelletizer outlet ranged from 4.95 to 4.47 kWh/kg. This indicates that the combination of short die and sawdust with high moisture content can result in pellets that do not meet the marketing standard for LCV. The moisture content of the pellets will depend on factors such as sawdust moisture, pelletizing temperature, pressure, etc. An excess of moisture in the pellets decreases the mechanical durability and the bulk density, perhaps due to a high amount of water in the sawdust that hinders the formation of hydrogen bonds during the bonding of the particles [17]. The calorific value increases the lower the moisture, however a moisture content too low gave rise to shorter and more compact pellets that increased the bulk density too much, almost exceeding the recommended commercial limits (750 kg/m3), and made them more brittle, decreasing their mechanical durability. For this reason, the most appropriate range of pellets moisture was between 5% and 9%.

- -

- The intermediate and larger particle sizes (3.5 and 5.0 mm sieves, respectively) presented mechanical durability problems with the 24 mm matrix.

- -

- Of the 88 individual samples produced, 8 (11%) meet the highest commercial quality, ENplus A1, with mechanical durability values > 98.0%, pellet moisture < 10% and bulk density > 600 kg/m3, and a yield of more than 98.5%. The pellets with these requirements were: in the case of the finest particle size (2 mm sieve) those obtained with a 20 mm die and a moisture content of 16.5%. For 5 mm particle size, quality pellets are obtained with 24 mm die and 14.0 to 16.5% moisture, as well as with 20 mm matrix and 14.0% particle moisture. These would be our reference ranges for moisture, particle size and die for the pelletizer used, which will serve as a reference for the next test on mixtures of residual biomass with wood.

5. Conclusions

- -

- Residual biomass from pine forest operations can be varied and have significant differences (p < 0.001) not only for chemical but also for physical-mechanical properties, depending on whether they are branches, bark, twigs or leaves. For. Example, for all the tested channel length of dies as a whole and 13% of sawdust moisture, DTTB, MBR, BARK and NTW averaged, respectively: 4.9, 7.1, 10.1 and 10.4% for pellet moisture; 676, 660, 596 and 520 kg/m3 for bulk density; and 94.2, 91.6, 68.1 and 68.4% for mechanical durability.

- -

- Residual pine biomass can be valorized for energetic use, but its valorization after transformation into pellets would not reach commercial quality standards for use in domestic or industrial boilers by itself. An exception could be the industrial use of biomass from medium branches (2.5–7.5 cm diameter) with bark.

- -

- Residual biomass could be mixed with biomass from coarse wood (debarked trunk and thick branches) up to a limit in weight ratio and still obtain pellets of the highest commercial quality. This limit will vary depending on the type of residual biomass, around 15% for bark (BARK), 30% for medium branches (MBR) and less than 15% for needles and fine branches (NTW), not only because of the limitations in chemical composition but also because of the devaluation of the physical-mechanical properties of the pellets.

- -

- More tests could be carried out to more accurately determine the maximum percentages of residues, more specifically in the case of middle branches (MBR) and bark. However, the values will be very close to those established in the last test, 30% and 15%, respectively, since the values of some properties, especially mechanical durability, are very close to the minimums admitted for an ENPlus A1 quality.

- -

- It would be appropriate to plan silvicultural treatments to take advantage of both the trunk and medium branches (MBR) and bark (77.7% of the aboveground dry biomass). In this way, the thin branches and needles (the remaining 22.3%) would remain in the forest, which would contribute to the recycling of nutrients (55%–65% of N, K and P) and their incorporation into the soil.

- -

- It must be considered that the nutrient content of the thin branches and needles is the highest of the entire tree, for example 10 times more N concentration than in the wood. Also, due to their higher N and S content on combustion, they release more NO2 and SO2 than biomass from other parts of the plant. This, together with the low physical-mechanical quality of the pellets obtained with these fine branches and needles (≤575 kg/m3 bulk density, and ≤77.5% mechanical durability), as can be deduced from the tests carried out in this work, makes it advisable to leave these residues on the forest.

- -

- In any case, if the lightest residues, or even others, are left in the forest, they should always be shredded or chipped in situ to avoid the risk of fire and facilitate their incorporation into the soil.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Pinto, L.C.; Sousa, S.; Valente, M. Forest bioenergy as a land and wildfire management tool: Economic valuation under different informational contexts. Energy Policy 2022, 161, 112765. [Google Scholar] [CrossRef]

- Madrigal, J.; Fernández-Migueláñez, I.; Hernando, C.; Guijarro, M.; Vega-Nieva, D.J.; Tolosana, E. Does forest biomass harvesting for energy reduce fire hazard in the Mediterranean basin? a case study in the Caroig Massif (Eastern Spain). Eur. J. For. Res. 2017, 136, 13–26. [Google Scholar] [CrossRef]

- Omi, P.N. Theory and Practice of Wildland Fuels Management. Curr. For. Rep. 2015, 1, 100–117. [Google Scholar] [CrossRef]

- Reinhardt, E.D.; Keane, R.E.; Calkin, D.E.; Cohen, J.D. Objectives and considerations for wildland fuel treatment in forested ecosystems of the interior western United States. For. Ecol. Manag. 2008, 256, 1997–2006. [Google Scholar] [CrossRef]

- Balat, M.; Ayar, G. Biomass Energy in the World, Use of Biomass and Potential Trends. Energy Sources 2005, 27, 931–940. [Google Scholar] [CrossRef]

- International Energy Agency. Energy Technology Perspectives; IEA: Paris, French, 2023; p. 462. Available online: https://www.iea.org/reports/energy-technology-perspectives-2023 (accessed on 15 March 2023).

- Kaliyan, N.R.; Morey, V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Mixed biomass pellets for thermal energy production: A review of combustion models. Appl. Energy 2014, 127, 135–140. [Google Scholar] [CrossRef]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europaea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- World Bioenergy Association. Global Bioenergy Statistics 2021. Available online: https://www.worldbioenergy.org/uploads/211214%20WBA%20GBS%202021.pdf (accessed on 15 December 2022).

- Bioenergy Europe. Policy Brief: Pellets. Bioenergy Europe Statistical Report 2021. Available online: https://bioenergyeurope.org/article/328-pellets.html (accessed on 10 December 2022).

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sust. Energ. Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Bergström, D.; Israelsson, S.; Öhman, M.; Dahlqvist, S.A.; Gref, R.; Boman, C.; Wästerlund, I. Effects of raw material particle size distribution on the characteristics of Scots pine sawdust fuel pellets. Fuel Process. Technol. 2008, 89, 1324–1329. [Google Scholar] [CrossRef]

- Samuelsson, R.; Thyrel, M.; Sjöström, M.; Lestander, T.A. Effect of biomaterial characteristics on pelletizing properties and biofuel pellet quality. Fuel Process. Technol. 2009, 90, 1129–1134. [Google Scholar] [CrossRef]

- Holm, J.K.; Henriksen, U.B.; Wand, K.; Hustad, J.E.; Posselt, D. Experimental verification of novel pellet model using a single pelleter unit. Energy Fuels 2007, 21, 2446–2449. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Poulsen, T.; Felby, C. Importance of temperature, moisture content, and species for the conversion process of wood residues into fuel pellets. Wood Fiber Sci. 2009, 41, 414–425. [Google Scholar]

- Rhén, R.; Öhman, M.; Gref, R.; Wästerlund, I. Effect of raw material composition in woody biomass pellets on combustion characteristics. Biomass Bioenergy 2007, 31, 66–72. [Google Scholar] [CrossRef]

- Riva, L.; Wang, L.; Ravenni, G.; Bartocci, P.; Buø, T.V.; Skreiberg, Ø.; Fantozzi, F.; Nielsen, H.N. Considerations on factors affecting biochar densification behavior based on a multiparameter model. Energy 2021, 221, 119893. [Google Scholar] [CrossRef]

- Shang, L.; Nielsen, N.P.K.; Stelte, W.; Dahl, J.; Ahrenfeldt, J.; Holm, J.K.; Arnavat, M.P.; Bach, L.S.; Henriksen, U.B. Lab and bench-scale pelletization of torrefied wood chips-process optimization and pellet quality. BioEnergy Res. 2014, 7, 87–94. [Google Scholar] [CrossRef]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.A.; Lestander, T. The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 2008, 89, 1442–1447. [Google Scholar] [CrossRef]

- Lehtikangas, P. Storage effects on pelletised sawdust, logging residues and bark. Biomass Bioenergy 2000, 19, 287–293. [Google Scholar] [CrossRef]

- Lehtikangas, P. Quality properties of pelletised sawdust, logging residues and bark. Biomass Bioenergy 2001, 20, 351–360. [Google Scholar] [CrossRef]

- Ståhl, M.; Granström, K.; Berghel, J.; Renström, R. Industrial processes for biomass drying and their effects on the quality properties of wood pellets. Biomass Bioenergy 2004, 27, 621–628. [Google Scholar] [CrossRef]

- Holm, J.K.; Henriksen, U.B.; Hustad, J.E.; Sørensen, L.H. Toward an understanding of controlling parameters in softwood and hardwood pellets production. Energy Fuels 2006, 20, 2686–2694. [Google Scholar] [CrossRef]

- Lestander, T.A.; Johnsson, B.; Grothage, M. NIR techniques create added values for the pellet and biofuel industry. Bioresour. Technol. 2009, 100, 1589–1594. [Google Scholar] [CrossRef]

- Latterini, F.; Civitarese, V.; Walkowiak, M.; Picchio, R.; Karaszewski, Z.; Venanzi, R.; Bembenek, M.; Mederski, P.S. Quality of pellets obtained from whole trees harvested from plantations, coppice forests and regular thinnings. Forests 2022, 13, 502. [Google Scholar] [CrossRef]

- Fernández-Puratich, H.; Hernández, D.; Lerma-Arce, V. Characterization and cost savings of pellets fabricated from Zea mays waste from corn mills combined with Pinus radiata. Renew. Energy 2017, 114, 448–454. [Google Scholar] [CrossRef]

- Lerma-Arce, V.; Oliver-Villanueva, J.V.; Segura-Orenga, G. Influence of raw material composition of Mediterranean pinewood on pellet quality. Biomass Bioenergy 2017, 99, 90–96. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Castellano, J.M.; Gómez, M.; Fernández, M.; Esteban, L.S.; Carrasco, J.E. Study on the effects of raw materials composition and pelletization conditions on the quality and properties of pellets obtained from different woody and non woody biomasses. Fuel 2015, 139, 629–636. [Google Scholar] [CrossRef]

- Akdeniz, R.C.; Esmer, O. Effects of length on mechanical durability of various wood pellets. Hung. Agric. Eng. 2018, 32, 62–71. [Google Scholar] [CrossRef]

- Siyal, A.A.; Mao, X.; Liu, Y.; Ao, W.; Jiang, Z.; Wahab, N.; Ran, C.; Zhang, R.; Liu, G.; Dai, J. Pellet production from furfural residue and sawdust: Evaluating the characteristics and quality of pellets and their dependency on process parameters. Biomass Bioenergy 2021, 149, 106087. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Stachowicz, P.; Dudziec, P. Wood pellet quality depending on dendromass species. Renew. Energy 2022, 199, 498–508. [Google Scholar] [CrossRef]

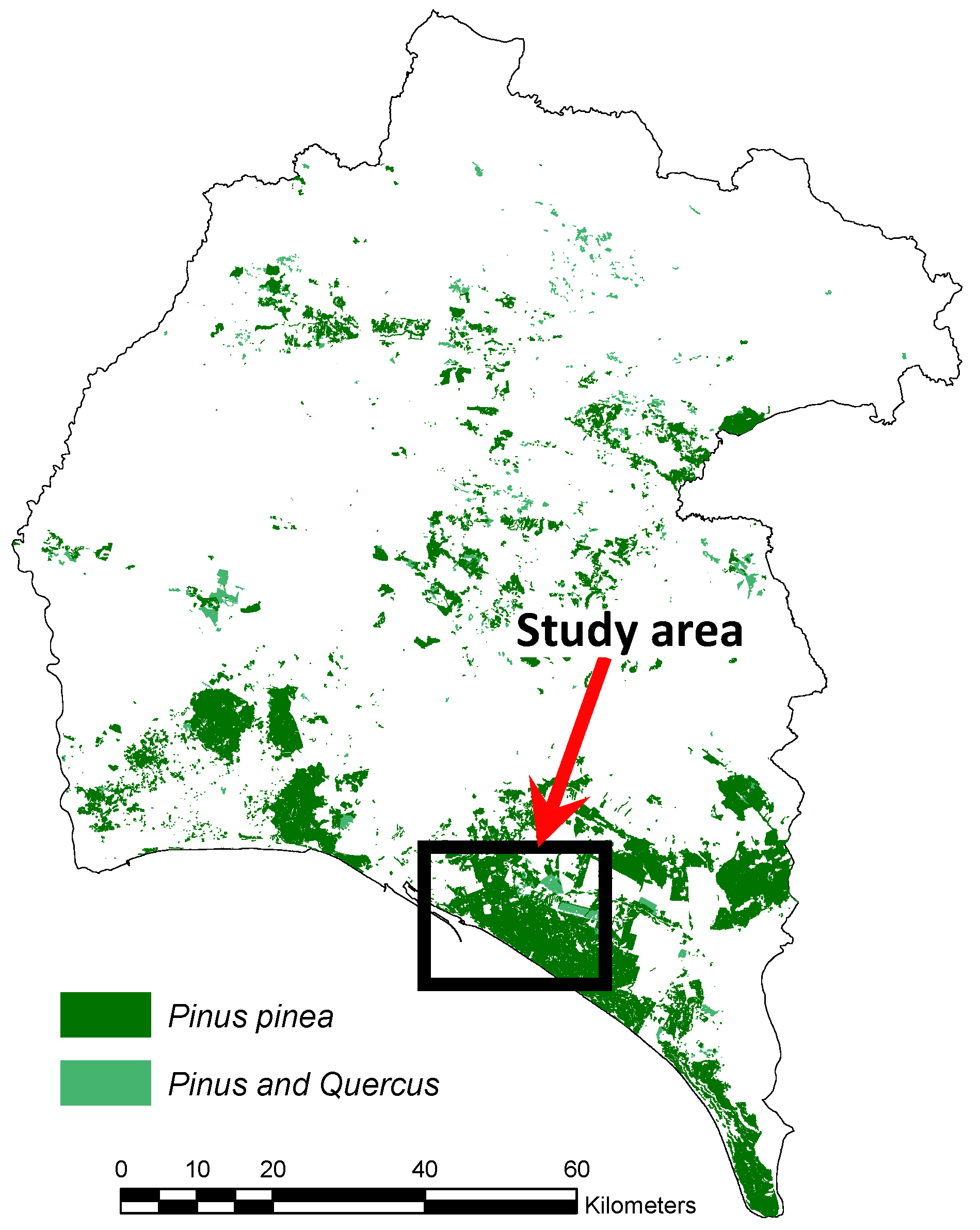

- Mutke, S.; Calama, R.; González-Martínez, S.C.; Montero, G.; Gordo, F.J.; Bono, D.; Gil, L. Mediterranean Stone Pine: Botany and Horticulture. Hortic. Rev. 2011, 39, 153–201. [Google Scholar] [CrossRef]

- Abad Viñas, R.; Caudullo, G.; Oliveira, S.; de Rigo, D. Pinus pinea in Europe: Distribution, habitat, usage and threats. In European Atlas of Forest Tree Species; San-Miguel-Ayanz, J., de Rigo, D., Caudullo, G., Houston Durrant, T., Mauri, A., Eds.; Publications Office of the EU: Luxembourg, 2021; pp. 130–131. [Google Scholar] [CrossRef]

- Mechergui, K.; Altamimi, A.S.; Jaouadi, W.; Naghmouchi, S. Climate change impacts on spatial distribution, tree-ring growth, and water use of stone pine (Pinus pinea L.) forests in the Mediterranean region and silvicultural practices to limit those impacts. iForest 2021, 14, 104–112. [Google Scholar] [CrossRef]

- Loewe, V.; Delard, C. Stone pine (Pinus pinea L.): An interesting species for agroforestry in Chile. Agrofor. Syst. 2019, 93, 703–713. [Google Scholar] [CrossRef]

- Jaouadi, M.; Alsubeie, M.; Mechergui, K.; Naghmouchi, S. Silviculture of Pinus pinea L. in North Africa and The Mediterranean Areas: Current potentiality and economic value. J. Sustain. For. 2021, 40, 656–674. [Google Scholar] [CrossRef]

- Ilari, A.; Pedretti, E.F.; De Francesco, C.; Duca, D. Pellet production from residual biomass of greenery maintenance in a small-scale company to improve sustainability. Resources 2021, 10, 122. [Google Scholar] [CrossRef]

- Rabaçal, M.; Fernandes, U.; Costa, M. Combustion and emission characteristics of a domestic boiler fired with pellets of pine, industrial wood wastes and peach stones. Renew. Energ. 2013, 51, 220–226. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Spanish biofuels heating value estimation. Part I: Ultimate analysis data. Fuel 2014, 117, 1130–1138. [Google Scholar] [CrossRef]

- Fernández, M.; Alaejos, J.; Andivia, E.; Vázquez-Piqué, J.; Ruiz, F.; López, F.; Tapias, R. Eucalyptus x urograndis biomass production for energy purposes exposed to a Mediterranean climate under different irrigation and fertilisation regimes. Biomass Bioenergy 2018, 111, 22–30. [Google Scholar] [CrossRef]

- Akyol, A.; Örücü, Ö.K.; Arslan, E.S. Habitat suitability mapping of stone pine (Pinus pinea L.) under the effects of climate change. Biologia 2020, 75, 2175–2187. [Google Scholar] [CrossRef]

- Calama, R.; Cañadas, N.; Montero, G. Inter-regional variability in site index models for even-aged stands of stone pine (Pinus pinea L.) in Spain. Ann. For. Sci. 2003, 60, 259–269. [Google Scholar] [CrossRef]

- Ovando, P.; Oviedo, J.L.; Campos, P. Measuring total social income of a stone pine afforestation in Huelva (Spain). Land Use Policy 2016, 50, 479–489. [Google Scholar] [CrossRef]

- Ruiz-Peinado, R.; del Rio, M.; Montero, G. New models for estimating the carbon sink capacity of Spanish softwood species. For. Syst. 2011, 20, 176–188. [Google Scholar] [CrossRef]

- ENplus. ENplus Handbook. Part 3: Pellet Quality Requirements; Version 3.0; European Pellet Council: Brussels, Belgium, 2015; p. 10. Available online: https://enplus-pellets.eu/en-in/component/attachments/?task=download&id=103 (accessed on 15 March 2023).

- International Organization for Standardization. Solid Biofuels. Fuel Specifications and Classes. Part 2: Graded Wood Pellets; ISO: Geneva, Switzerland, 2021; p. 9. Available online: https://www.iso.org/standard/76088.html (accessed on 15 March 2023).

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

| Type of Biomass | N | P | K | S | Cl | H | C | LCV (1) | LCV (2) |

|---|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) | (%) | (%) | (kWh/kg) | (kWh/kg) | |

| BARK | 0.38 | 0.020 | 0.14 | 0.060 | 0.025 | 5.7 | 52.1 | 5.09 | 4.52 |

| DTTB | 0.16 | 0.010 | 0.10 | 0.025 | 0.015 | 6.3 | 50.8 | 5.13 | 4.86 |

| MBR | 0.32 | 0.015 | 0.15 | 0.040 | 0.020 | 6.2 | 51.5 | 5.18 | 4.78 |

| NTW | 1.05 | 0.072 | 0.47 | 0.115 | 0.030 | 6.4 | 50.4 | 5.12 | 4.53 |

| Yield (%) | Pellet Moisture (%) | Durability (%) | Bulk Density (kg/m3) | Pellet Length (cm) | Particle Density (kg/m3) | |

|---|---|---|---|---|---|---|

| Channel length of the die (mm) | ||||||

| 18 | 88.2 ± 15.4 (a) | 7.61 ± 2.91 (b) | 81.8 ± 15.6 (a) | 609.6 ± 70.1 (a) | 1.48 ± 0.39 (b) | 1190.5 ± 105.5 (a) |

| 20 | 90.1 ± 13.6 (b) | 8.62 ± 2.68 (c) | 81.6 ± 15.3 (a) | 609.1 ± 71.7 (a) | 1.38 ± 0.40 (ab) | 1218.2 ± 67.8 (ab) |

| 22 | 92.3 ± 11.2 (c) | 8.50 ± 1.76 (bc) | 84.9 ± 13.3 (b) | 609.7 ± 60.1 (a) | 1.01 ± 0.38 (ab) | 1169.6 ± 79.7 (ab) |

| 24 | 96.5 ± 3.2 (d) | 5.14 ± 3.35 (a) | 84.9 ± 8.4 (b) | 673.7 ± 59.4 (b) | 1.25 ± 0.18 (a) | 1278.0 ± 59.2 (b) |

| Biomass type | ||||||

| NTW | 73.2 ± 12.0 (a) | 10.41 ± 1.17 (c) | 68.4 ± 6.0 (a) | 520.2 ± 34.8 (a) | 1.09 ± 0.13 (a) | 1111.5 ± 65.3 (a) |

| BARK | 89.0 ± 6.4 (b) | 10.14 ± 1.04 (c) | 68.1 ± 5.5 (a) | 595.5 ± 35.2 (b) | 0.88 ± 0.09 (b) | 1153.7 ± 74.5 (a) |

| MBR | 98.6 ± 0.9 (c) | 7.08 ± 1.72 (b) | 91.6 ± 3.1 (b) | 660.2 ± 26.1 (c) | 1.61 ± 0.22 (c) | 1248.1 ± 37.5 (b) |

| DTTB | 99.5 ± 0.2 (c) | 4.86 ± 2.22 (a) | 94.2 ± 1.8 (c) | 675.8 ± 34.4 (c) | 1.66 ± 0.19 (c) | 1278.4 ± 44.1 (b) |

| TOTAL MEAN | 92.0 ± 11.8 | 7.47 ± 2.99 | 83.3 ± 13.0 | 625.5 ± 69.0 | 1.38 ± 0.37 | 1214.0 ± 87.2 |

| Property | p (Significance Level) | ||

|---|---|---|---|

| Biomass Type | Die | Die × Biomass | |

| Yield (%) | <0.001 | <0.001 | <0.001 |

| Pellet moisture (%) | <0.001 | <0.001 | 0.001 |

| Durability (%) | <0.001 | <0.001 | <0.001 |

| Bulk density (kg/m3) | <0.001 | <0.001 | 0.003 |

| Bulk density 0% moisture (kg/m3) | <0.001 | <0.001 | 0.003 |

| Pellet length (cm) | <0.001 | <0.001 | <0.001 |

| Particle density (kg/m3) | <0.001 | <0.001 | 0.004 |

| Particle density 0% moisture (kg/m3) | <0.001 | <0.001 | 0.010 |

| Yield (%) | Pellet Moisture (%) | Durability (%) | Bulk Density (kg/m3) | Pellet Length (cm) | Particle Density (kg/m3) | |

|---|---|---|---|---|---|---|

| Channel length of the die (mm) | ||||||

| 18 | 99.4 ± 0.3 (a) | 6.64 ± 2.98 (b) | 93.7 ± 2.0 (a) | 631.5 ± 53.5 (a) | 1.86 ± 0.18 (b) | 1273.6 ± 48.5 (a) |

| 20 | 99.7 ± 0.3 (b) | 7.02 ± 1.50 (b) | 96.3 ± 1.6 (c) | 654.6 ± 28.7 (a) | 1.89 ± 0.16 (b) | 1267.2 ± 22.9 (a) |

| 22 | 99.5 ± 0.2 (ab) | 7.48 ± 1.61 (b) | 95.6 ± 1.3 (bc) | 627.7 ± 36.4 (a) | 1.82 ± 0.19 (b) | 1224.2 ± 26.0 (a) |

| 24 | 99.6 ± 0.1 (ab) | 3.05 ± 1.62 (a) | 94.5 ± 1.9 (b) | 706.1 ± 22.9 (b) | 1.40 ± 0.21 (a) | 1298.7 ± 35.0 (b) |

| Pellets moisture content (%) | ||||||

| MOI1 | 99.5 ± 0.2 (a) | 5.10 ± 1.82 (a) | 94.5 ± 1.9 (a) | 668.8 ± 27.4 (b) | 1.73 ± 0.23 (a) | 1271.2 ± 34.2 (b) |

| MOI2 | 99.6 ± 0.3 (a) | 6.16 ± 2.77 (b) | 95.4 ± 1.7 (b) | 655.5 ± 45.2 (ab) | 1.76 ± 0.31 (a) | 1268.7 ± 47.3 (ab) |

| MOI3 | 99.6 ± 0.2 (a) | 6.81 ± 2.98 (b) | 95.0 ± 2.3 (ab) | 640.4 ± 64.5 (a) | 1.72 ± 0.26 (a) | 1255.9 ± 44.6 (a) |

| Particle size (mm) | ||||||

| SF | 99.5 ± 0.2 (b) | 5.24 ± 2.41 (b) | 94.4 ± 2.0 (b) | 669.0 ± 41.5 (a) | 1.70 ± 0.25 (b) | 1273.3 ± 43.3 (a) |

| SM | 99.5 ± 0.2 (a) | 5.53 ± 2.58 (a) | 94.5 ± 1.8 (a) | 666.0 ± 40.6 (b) | 1.67 ± 0.28 (a) | 1276.4 ± 42.5 (b) |

| SC | 99.8 ± 0.1 (a) | 7.71 ± 2.37 (a) | 96.5 ± 1.4 (a) | 622.5 ± 52.5 (b) | 1.91 ± 0.20 (ab) | 1241.0 ± 35.7 (b) |

| Property | p (Significance Level) | ||||

|---|---|---|---|---|---|

| Sieve | Die | Moisture | S × D | S × M | |

| Yield (%) | <0.001 | <0.001 | 0.542 | 0.641 | 0.579 |

| Pellet moisture (%) | <0.001 | <0.001 | <0.001 | 0.002 | <0.001 |

| Durability (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Bulk density (kg/m3) | <0.001 | <0.001 | <0.001 | 0.001 | <0.001 |

| Bulk density 0% moisture (kg/m3) | <0.001 | <0.001 | <0.001 | 0.002 | <0.001 |

| Pellet length (cm) | 0.016 | 0.001 | 0.358 | 0.654 | 0.372 |

| Particle density (kg/m3) | <0.001 | <0.001 | 0.041 | 0.001 | 0.002 |

| Particle density 0% moisture (kg/m3) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Biomass Mix Type | ||||

|---|---|---|---|---|

| Property | 85% DTTB 15% NTW | 85% DTTB 15% BARK | 70% DTTB 30% MBR | 100% DTTB |

| Yield (%) | >99.5% (no significant differences, p = 0.120) | |||

| Pellet moisture (%) | 7.9 ± 0.4 b | 6.5 ± 0.4 ab | 5.6 ± 0.4 a | 5.7 ± 0.3 a |

| Durability (%) | 97.0 ± 0.4 a | 98.1 ± 0.4 a | 98.6 ± 0.4 a | 98.0 ± 0.3 a |

| Bulk density (kg/m3) | 596.2 ± 4.0 a | 617.2 ± 4.0 b | 644.0 ± 4.0 c | 644.2 ± 2.8 c |

| Pellet length mm) | 20.5 ± 4.0 (no significant differences, p = 0.488) | |||

| Particle density (kg/m3) | 1142 ± 11 a | 1196 ± 11 b | 1192 ± 11 b | 1252 ± 8 c |

| Pellets classes | Does not comply | A1 | A1 | A1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández, M.; Tapias, R.; Camacho, V.; Alaejos, J. Quality of the Pellets Obtained with Wood and Cutting Residues of Stone Pine (Pinus pinea L.). Forests 2023, 14, 1011. https://doi.org/10.3390/f14051011

Fernández M, Tapias R, Camacho V, Alaejos J. Quality of the Pellets Obtained with Wood and Cutting Residues of Stone Pine (Pinus pinea L.). Forests. 2023; 14(5):1011. https://doi.org/10.3390/f14051011

Chicago/Turabian StyleFernández, Manuel, Raúl Tapias, Victoriano Camacho, and Joaquín Alaejos. 2023. "Quality of the Pellets Obtained with Wood and Cutting Residues of Stone Pine (Pinus pinea L.)" Forests 14, no. 5: 1011. https://doi.org/10.3390/f14051011

APA StyleFernández, M., Tapias, R., Camacho, V., & Alaejos, J. (2023). Quality of the Pellets Obtained with Wood and Cutting Residues of Stone Pine (Pinus pinea L.). Forests, 14(5), 1011. https://doi.org/10.3390/f14051011