Flame Resistance and Bonding Performance of Plywood Fabricated by Guanidine Phosphate-Impregnated Veneers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Characterization and Measurements

3. Results and Discussion

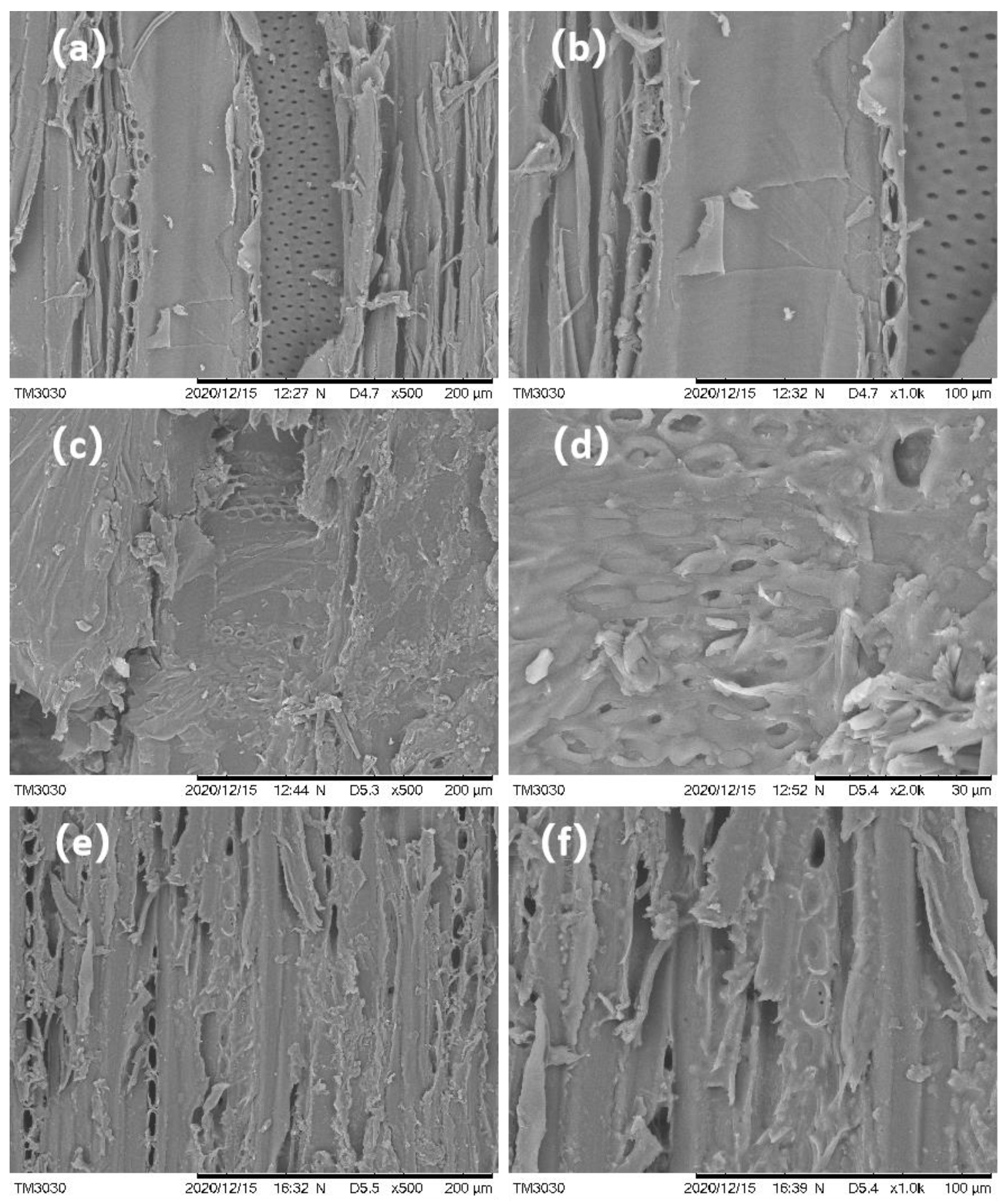

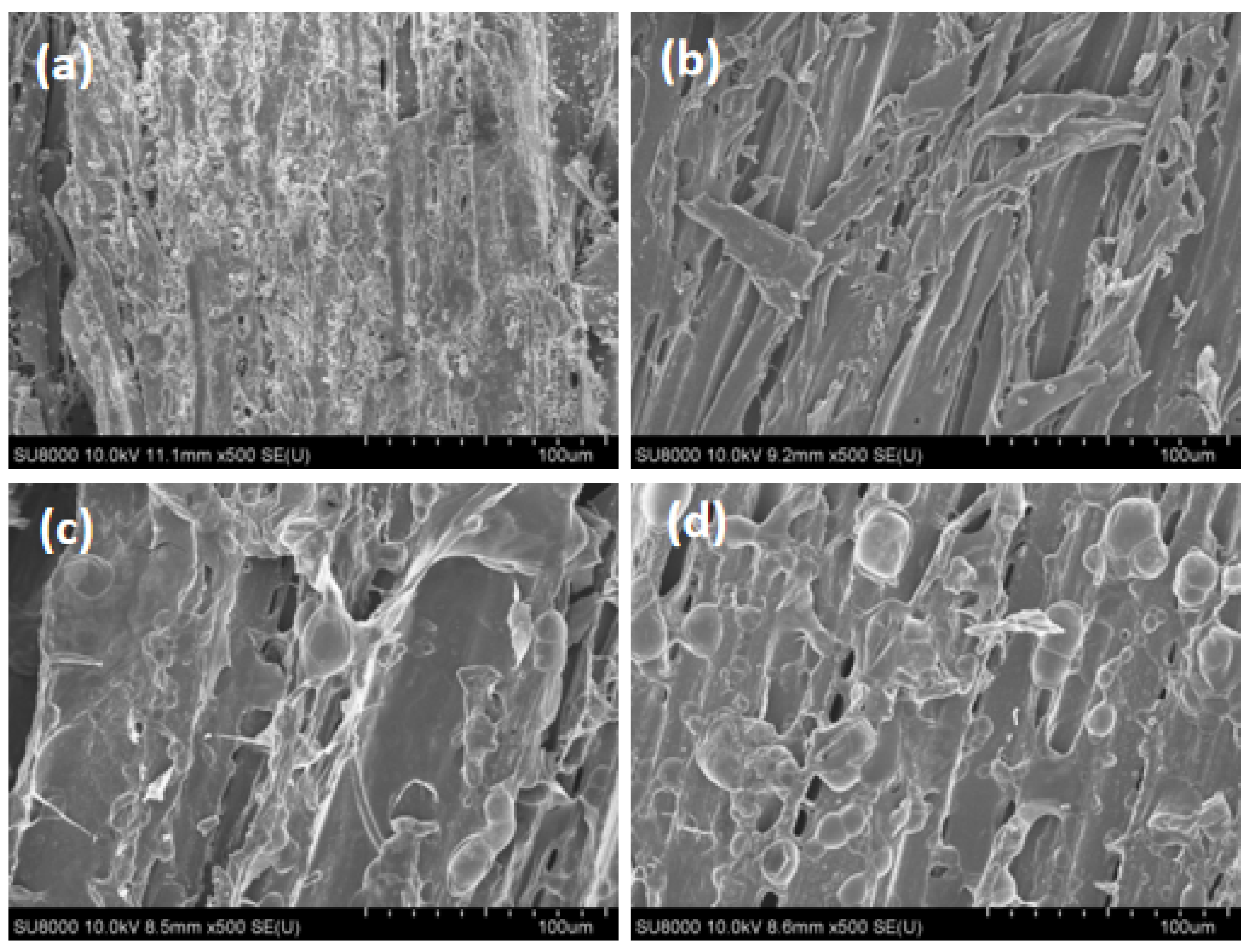

3.1. Morphology Characterization of Impregnated Wood Veneer

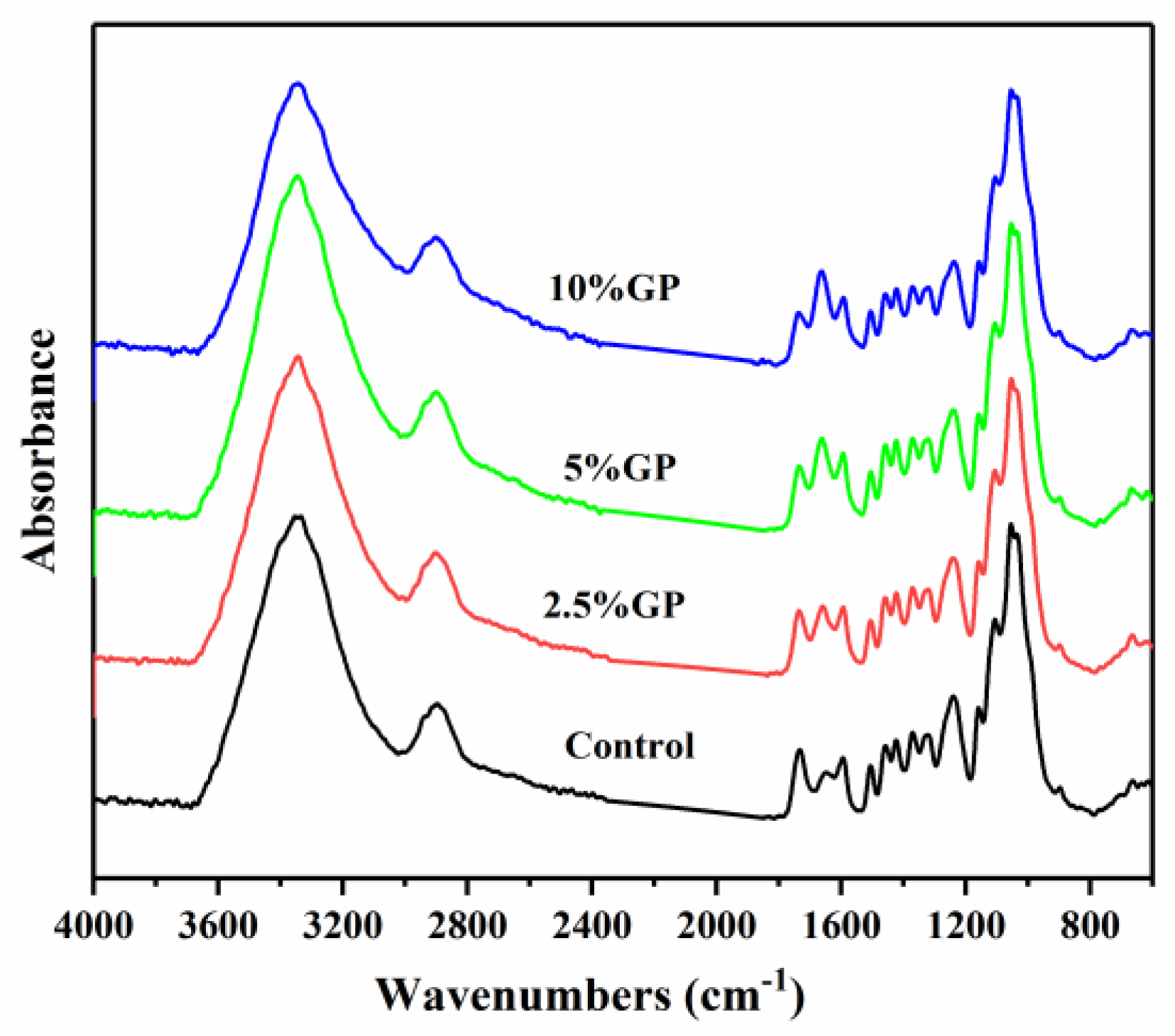

3.2. FT-IR Analysis

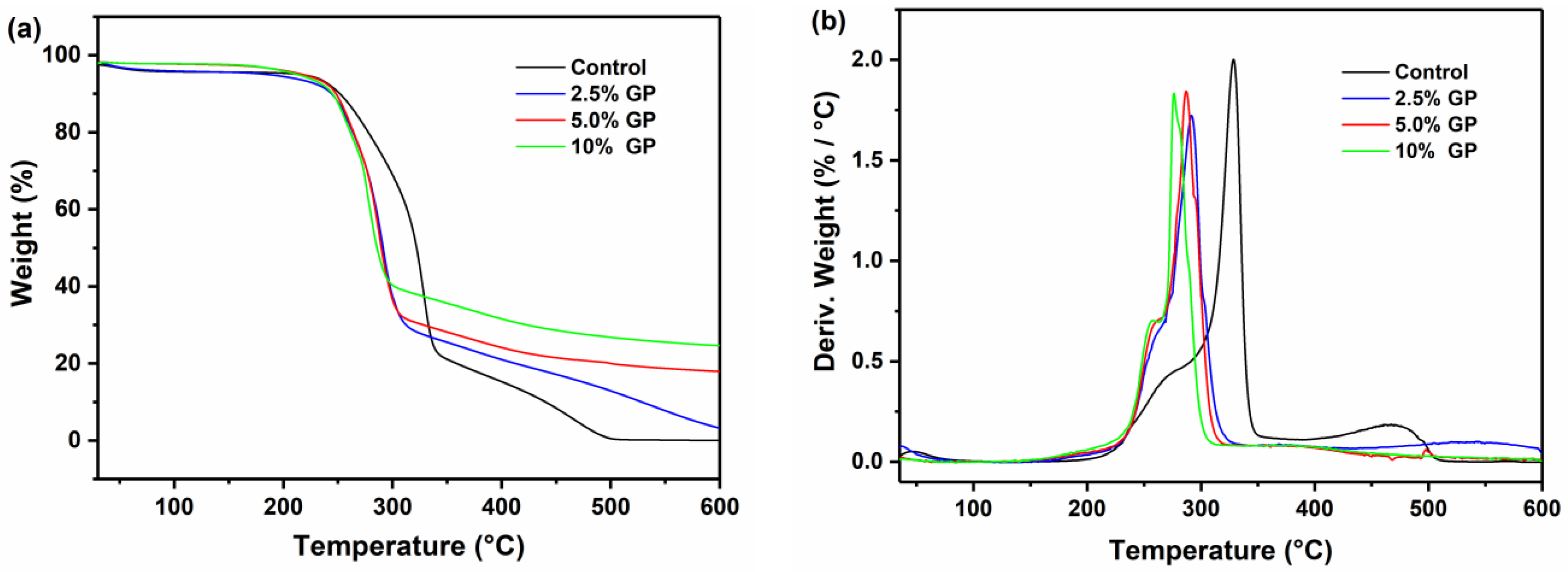

3.3. TG Analysis

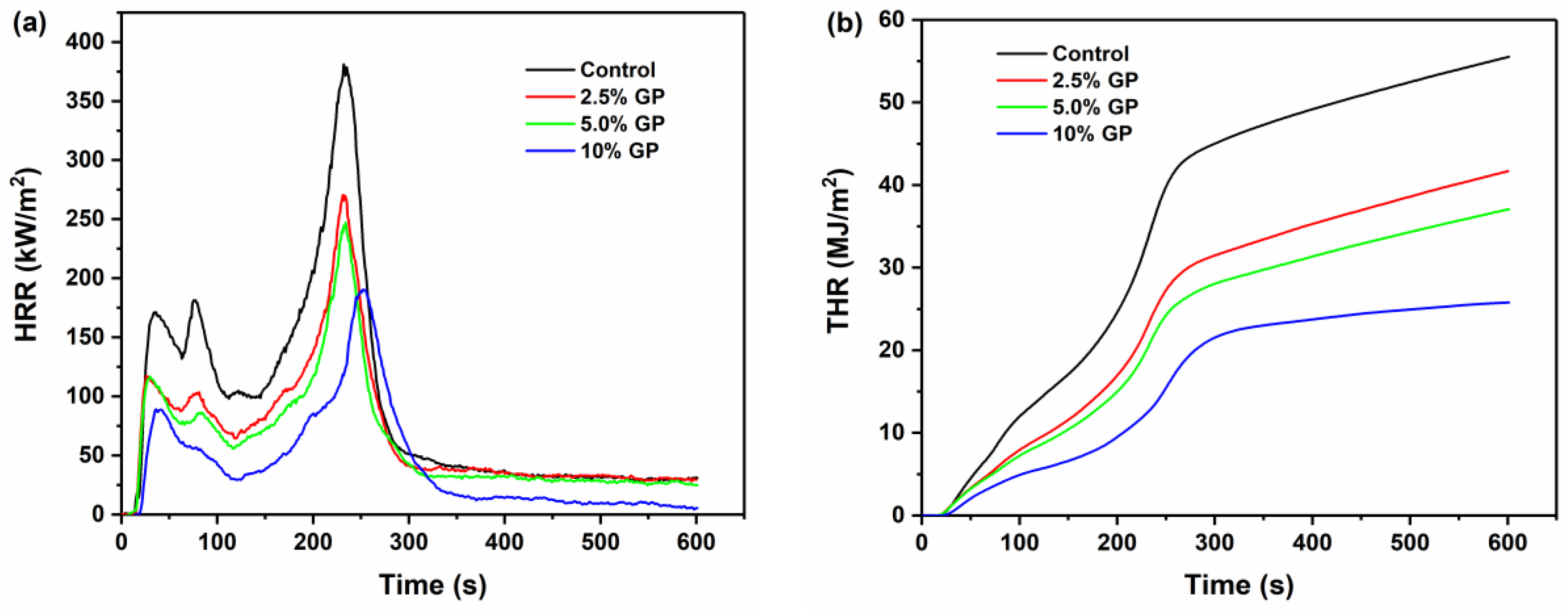

3.4. Combustion Properties Analysis

3.5. Flame-Retardant Mechanism Analysis

3.5.1. Residual Carbon Characterization

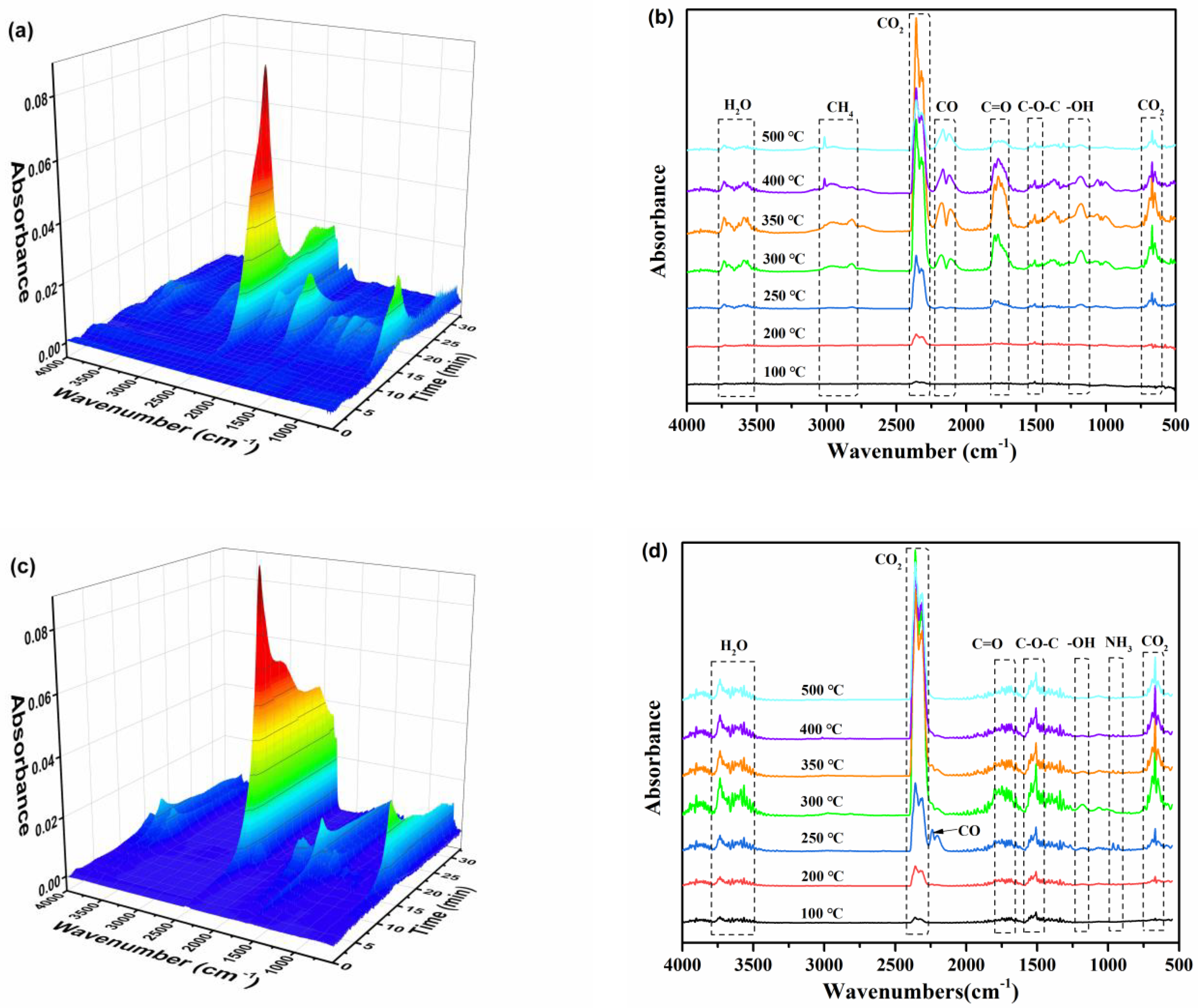

3.5.2. TG-IR Analysis

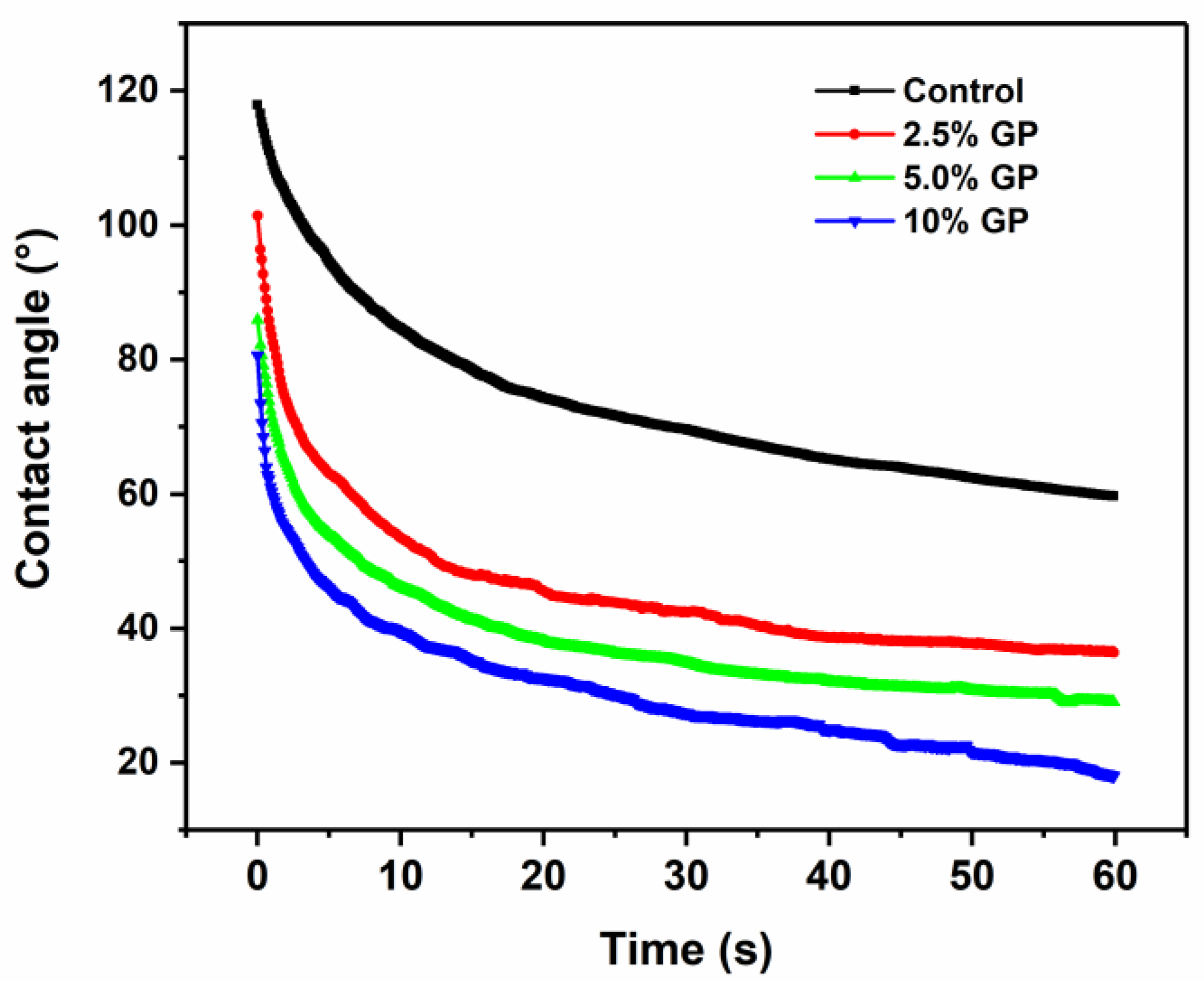

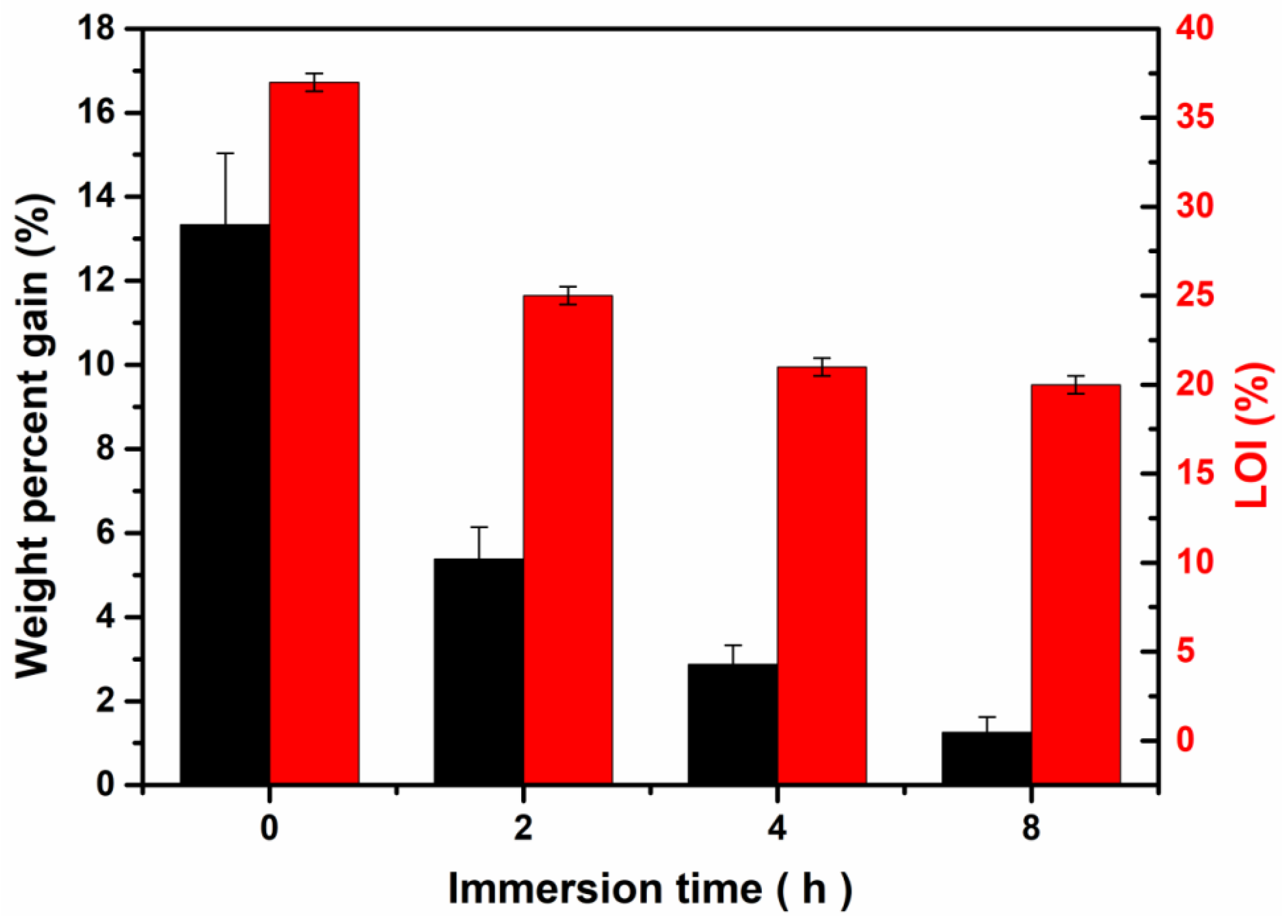

3.6. Water Resistance of GP-Modified Wood

3.6.1. Contact Angle Analysis

3.6.2. Leachability Analysis of GP-Modified Wood

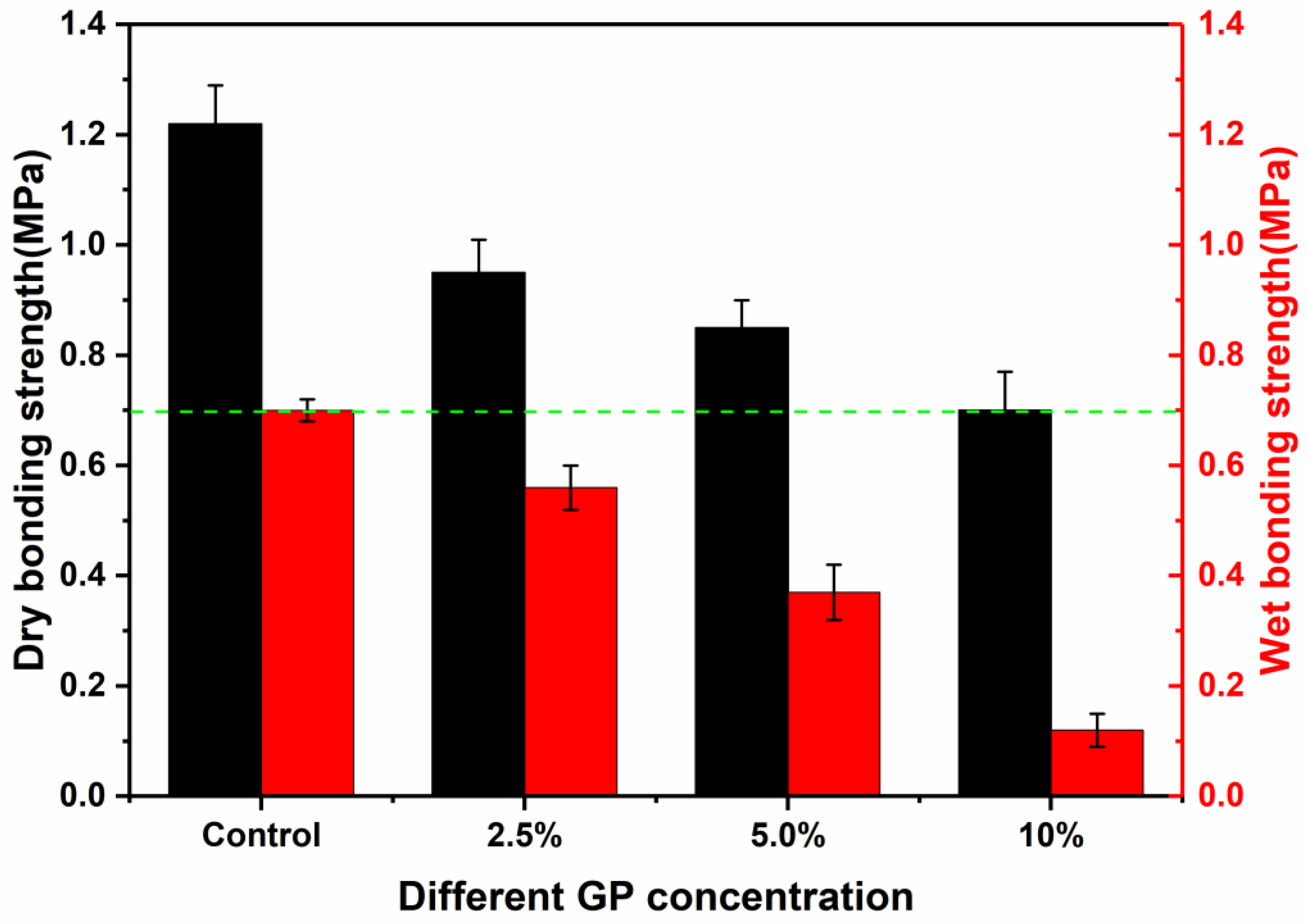

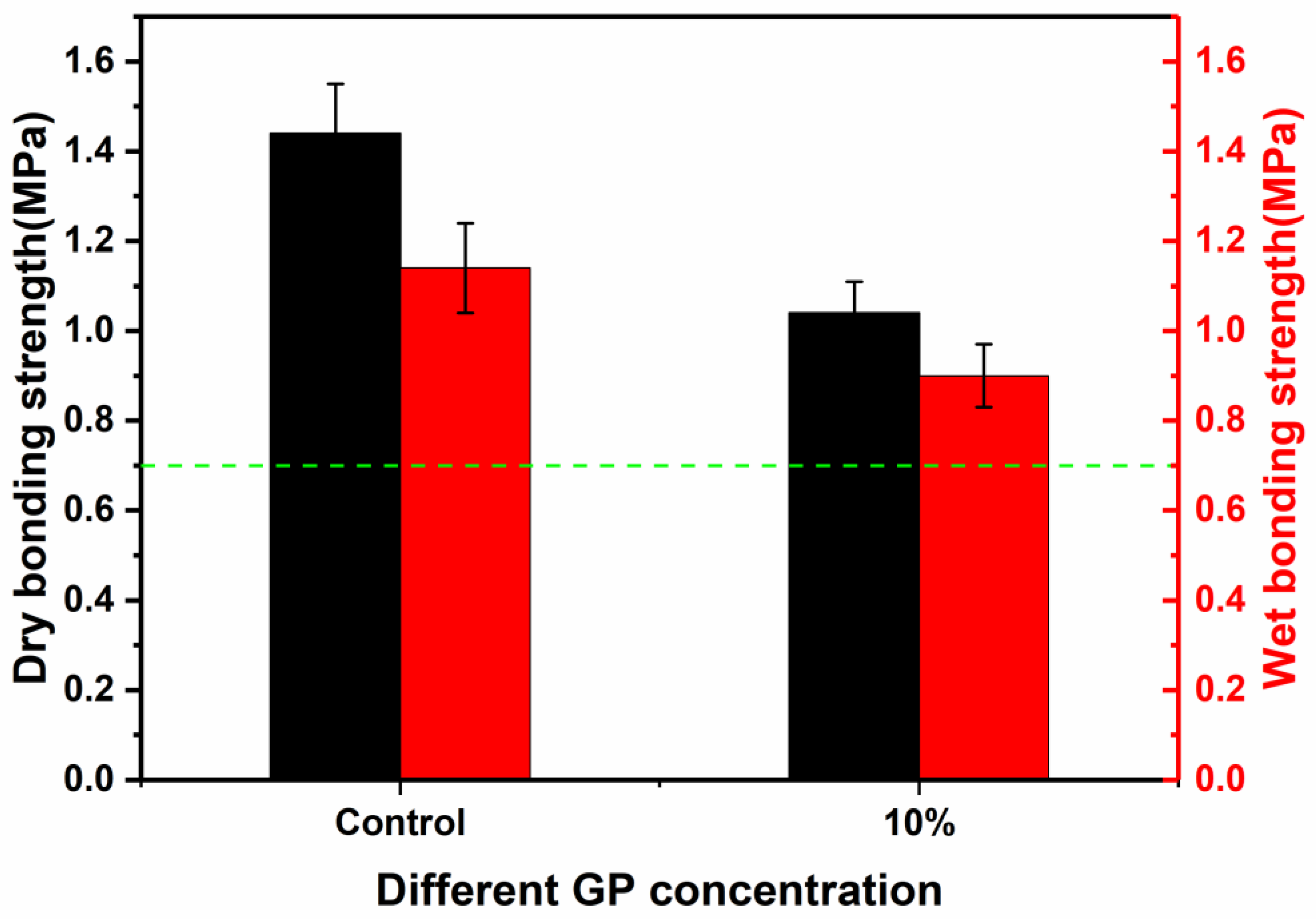

3.7. Bonding Strength of GP-Modified Wood

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, W.; Zammarano, M.; Shields, J.R.; Knowlton, E.D.; Kim, I.; Gales, J.A.; Hoehler, M.S.; Li, J. A novel application of silicone-based flame-retardant adhesive in plywood. Constr. Build. Mater. 2018, 189, 448–459. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; He, C.; Wang, X. Effects of processing parameters on mass loss and coating properties of poplar plywood during CO2 laser modification. Eur. J. Wood Wood Prod. 2022, 80, 899–906. [Google Scholar] [CrossRef]

- Hughes, M. Plywood and other veneer-based products. In Wood Composites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 69–89. [Google Scholar]

- Chou, C.-S.; Lin, S.-H.; Wang, C.-I. Preparation and characterization of the intumescent fire retardant coating with a new flame retardant. Adv. Powder Technol. 2009, 20, 169–176. [Google Scholar] [CrossRef]

- Wang, F.; Gao, Z.; Zheng, M.; Sun, J. Thermal degradation and fire performance of plywood treated with expanded vermiculite. Fire Mater. 2016, 40, 427–433. [Google Scholar] [CrossRef]

- Bo, C.; Yiqun, F.; Yueyue, S.; Fengqiang, W.; Bo, S.; Yongming, S.; Qingwen, W. Flame retardancy of ammonium polyphosphate-chitosan/boron nitride on plywood surface via layer-by-layer self-assembly method. Acta Mater. Compos. Sin. 2021, 38, 1252–1261. [Google Scholar]

- Peng, L.; Jun, L.; Weigen, T.; Liangxiao, L.; Miao, L. Urea-Formaldehyde Resin Combined with Nitrogen-Phosphorous for Manufacturing Fire Retardant Plywood. China Wood Ind. 2016, 30, 39–42. [Google Scholar]

- Wang, M.; Ji, H.; Li, L. Synergistic effect of 3A zeolite on the flame retardant properties of poplar plywood treated with APP. J. Korean Wood Sci. Technol. 2015, 43, 258–264. [Google Scholar] [CrossRef]

- Kartal, S.N.; Ayrilmis, N.; Imamura, Y. Decay and termite resistance of plywood treated with various fire retardants. Build. Environ. 2007, 42, 1207–1211. [Google Scholar] [CrossRef]

- Aydin, I.; Colakoglu, G. Variation in surface roughness, wettability and some plywood properties after preservative treatment with boron compounds. Build. Environ. 2007, 42, 3837–3840. [Google Scholar] [CrossRef]

- Ghani, R.S.M. A review of different barriers and additives to reduce boron movement in boron dual treated wood. Prog. Org. Coat. 2021, 160, 106523. [Google Scholar] [CrossRef]

- Lu, J.; Huang, Y.; Jiang, P.; Chen, Z.; Bourbigot, S.; Fontaine, G.; Chang, L.; Zhang, L.; Pan, F. Universal circulating impregnation method for the fabrication of durable flame-retardant plywood with low hygroscopicity and leaching resistance. Polym. Degrad. Stab. 2022, 195, 109799. [Google Scholar] [CrossRef]

- Yona, A.M.C.; Žigon, J.; Matjaž, P.; Petrič, M. Potentials of silicate-based formulations for wood protection and improvement of mechanical properties: A review. Wood Sci. Technol. 2021, 55, 887–918. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Candan, Z.; White, R. Physical, mechanical, and fire properties of oriented strandboard with fire retardant treated veneers. Holz Roh Werkst. 2007, 65, 449–458. [Google Scholar] [CrossRef]

- Dundar, T.; Ayrilmis, N.; Candan, Z.; Sahin, H.T. Dimensional stability of fire-retardant-treated laminated veneer lumber. For. Prod. J. 2009, 59, 18–23. [Google Scholar] [CrossRef]

- Wang, N.; Liu, Y.; Liu, Y.; Wang, Q. Properties and mechanisms of different guanidine flame retardant wood pulp paper. J. Anal. Appl. Pyrolysis 2017, 128, 224–231. [Google Scholar] [CrossRef]

- Wang, N.; Liu, Y.; Xu, C.; Liu, Y.; Wang, Q. Acid-base synergistic flame retardant wood pulp paper with high thermal stability. Carbohydr. Polym. 2017, 178, 123–130. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, Q.; Li, Y.; Ouyang, Y. Hydrophobic microcapsule modification of nitrogen–phosphorus flame retardant and its application in lignocellulosic materials. J. Therm. Anal. Calorim. 2022, 147, 13217–13229. [Google Scholar] [CrossRef]

- Wan, C.; Zhang, G.; Zhang, F. A novel guanidine ammonium phosphate for preparation of a reactive durable flame retardant for cotton fabric. Cellulose 2020, 27, 3469–3483. [Google Scholar] [CrossRef]

- Gao, M.; Ling, B.; Yang, S.; Zhao, M. Flame retardance of wood treated with guanidine compounds characterized by thermal degradation behavior. J. Anal. Appl. Pyrolysis 2005, 73, 151–156. [Google Scholar] [CrossRef]

- Sun, Y.J.; Yang, Y.L.; Gao, M. Thermal degradation of hemp treated with guanidine dihydrogen phosphate. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 983, pp. 175–178. [Google Scholar]

- Yan, Y.; Dong, Y.; Li, C.; Chen, H.; Zhang, S.; Li, J. Optimization of reaction parameters and characterization of glyoxal-treated poplar sapwood. Wood Sci. Technol. 2015, 49, 241–256. [Google Scholar] [CrossRef]

- Akech, S.R.O.; Harrison, O.; Saha, A. Removal of a potentially hazardous chemical, tetrakis (hydroxymethyl) phosphonium chloride from water using biochar as a medium of adsorption. Environ. Technol. Innov. 2018, 12, 196–210. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Q.; Wang, X. Progress in research on fire retardant–treated wood and wood-based composites: A Chinese perspective. For. Prod. J. 2010, 60, 668–678. [Google Scholar] [CrossRef]

- Yan, Y.-W.; Chen, L.; Jian, R.-K.; Kong, S.; Wang, Y.-Z. Intumescence: An effect way to flame retardance and smoke suppression for polystryene. Polym. Degrad. Stab. 2012, 97, 1423–1431. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, P.; Chen, Z.; Li, L.; Huang, Y. Flame retardancy, thermal stability, and hygroscopicity of wood materials modified with melamine and amino trimethylene phosphonic acid. Constr. Build. Mater. 2021, 267, 121042. [Google Scholar] [CrossRef]

- Gu, X.; Ma, X.; Li, L.; Liu, C.; Cheng, K.; Li, Z. Pyrolysis of poplar wood sawdust by TG-FTIR and Py–GC/MS. J. Anal. Appl. Pyrolysis 2013, 102, 16–23. [Google Scholar] [CrossRef]

- Gao, N.; Li, A.; Quan, C.; Du, L.; Duan, Y. TG–FTIR and Py–GC/MS analysis on pyrolysis and combustion of pine sawdust. J. Anal. Appl. Pyrolysis 2013, 100, 26–32. [Google Scholar] [CrossRef]

- Zhang, L.; Ran, Y.; Peng, Y.; Wang, W.; Cao, J. Combustion behavior of furfurylated wood in the presence of montmorillonite and its char characteristics. Wood Sci. Technol. 2022, 56, 623–648. [Google Scholar] [CrossRef]

- Kim, J.-S.; Nam, H.; Kim, H.J.; Lee, J.H.; Park, B.H. Real-time measurement of Ammonia (NH3) in artillery smoke using a passive FT-IR remote sensor. ACS Omega 2019, 4, 16768–16773. [Google Scholar] [CrossRef] [PubMed]

- Gou, J.; Song, L.; Liu, H.; Shen, D.; Hu, W.; Wang, W.; Ren, X.; Chang, J. Release profile of nitrogen during thermal treatment of waste wood packaging materials. J. Bioresour. Bioprod. 2019, 4, 166–176. [Google Scholar]

- Wu, Z.; Deng, X.; Luo, Z.; Zhang, B.; Xi, X.; Yu, L.; Li, L. Improvements in fire resistance, decay resistance, anti-mold property and bonding performance in plywood treated with manganese chloride, phosphoric acid, boric acid and ammonium chloride. Coatings 2021, 11, 399. [Google Scholar] [CrossRef]

| Sample | Tonset (°C) | Tmax (°C) | Maximum Mass Loss Rate (°C/%) | Char Yield (%) |

|---|---|---|---|---|

| Control | 251.73 | 328.53 | 2.04 | 0.84 |

| 2.5% GP | 244.18 | 291.66 | 1.72 | 3.99 |

| 5.0% GP | 248.27 | 287.05 | 1.84 | 17.96 |

| 10% GP | 245.08 | 276.10 | 1.83 | 24.67 |

| Samples | pHRR (kW/m2) | HRR (kW/m2) | THR (MJ/m2) | TSP (m2) | Weight Gain (%) | LOI (%) |

|---|---|---|---|---|---|---|

| Control | 381.13 | 94.14 | 55.54 | 0.77 | —— | 19 |

| 2.5% GP | 270.58 | 70.53 | 41.68 | 0.23 | 4.10 | 25 |

| 5.0% GP | 247.22 | 62.63 | 37.08 | 0.08 | 7.68 | 28 |

| 10% GP | 190.41 | 43.94 | 25.79 | 0.11 | 13.33 | 37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Wang, J.; Shen, Z.; Bi, H.; Shentu, B. Flame Resistance and Bonding Performance of Plywood Fabricated by Guanidine Phosphate-Impregnated Veneers. Forests 2023, 14, 741. https://doi.org/10.3390/f14040741

Yan Y, Wang J, Shen Z, Bi H, Shentu B. Flame Resistance and Bonding Performance of Plywood Fabricated by Guanidine Phosphate-Impregnated Veneers. Forests. 2023; 14(4):741. https://doi.org/10.3390/f14040741

Chicago/Turabian StyleYan, Yutao, Jinhui Wang, Zhou Shen, Haiming Bi, and Baoqing Shentu. 2023. "Flame Resistance and Bonding Performance of Plywood Fabricated by Guanidine Phosphate-Impregnated Veneers" Forests 14, no. 4: 741. https://doi.org/10.3390/f14040741

APA StyleYan, Y., Wang, J., Shen, Z., Bi, H., & Shentu, B. (2023). Flame Resistance and Bonding Performance of Plywood Fabricated by Guanidine Phosphate-Impregnated Veneers. Forests, 14(4), 741. https://doi.org/10.3390/f14040741