The State of the Art of Forest Operations in Beech Stands of Europe and Western Asia

Abstract

1. Introduction

2. Materials and Methods

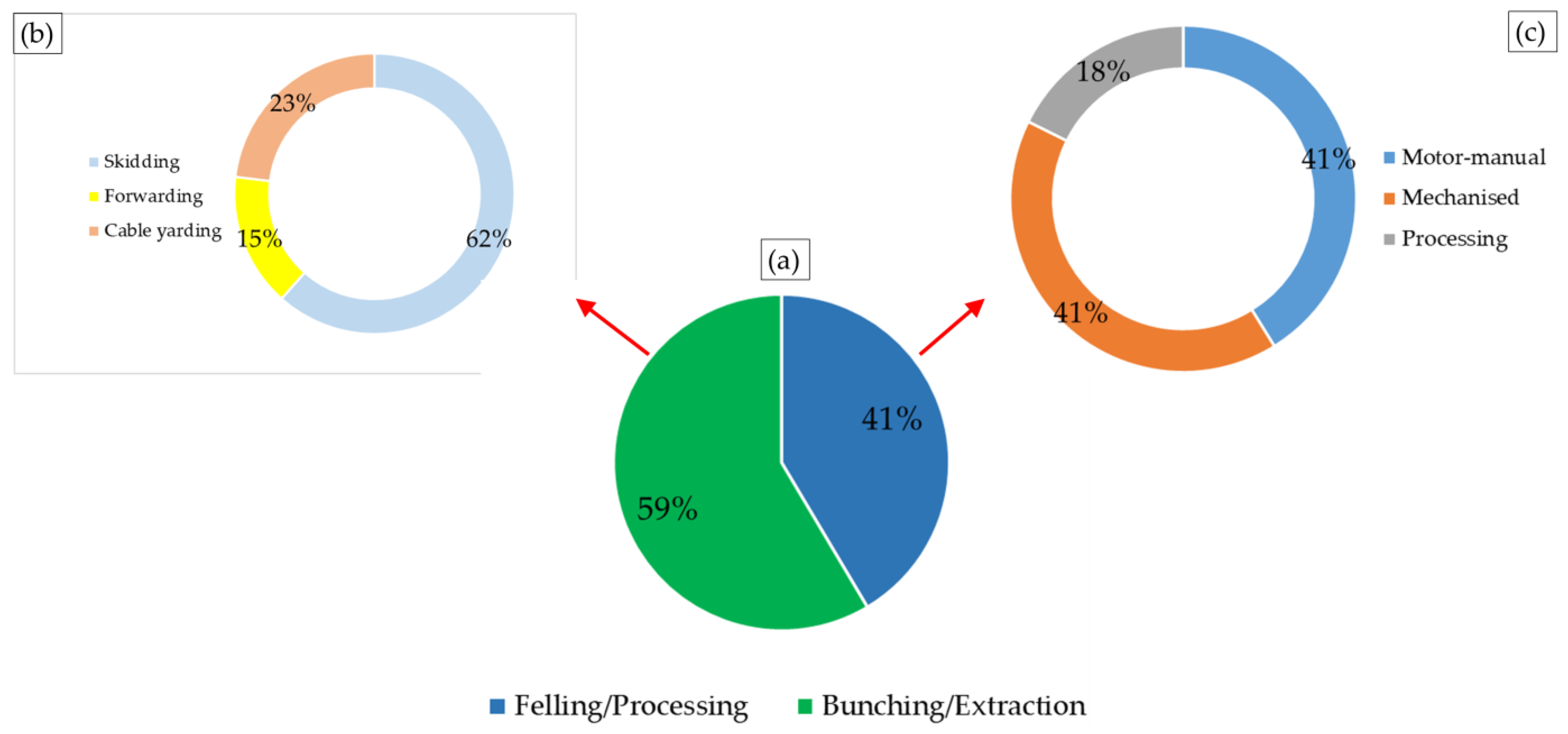

3. Felling and Processing Research Results

3.1. Motor-Manual Felling and Processing

3.2. Mechanised Felling and Processing

3.3. Processing at the Landing Site

3.4. Summary Table

4. Bunching and Extraction Research Results

4.1. Skidding and Hauling

4.2. Forwarding

4.3. Aerial Extraction Systems

4.4. Summary Table

5. Conclusions

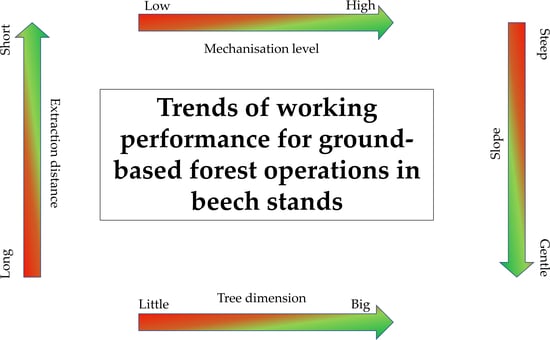

- Although motor-manual felling and processing by chainsaw are still predominant, a growing interest is expected towards the introduction of fully mechanised methodologies (fellers and harvesters) in beech forests. Research on this topic has been productive in recent years, highlighting that mechanising felling and processing operations in beech stands is possible, but that there are still different issues to be solved to achieve the productivity levels typical of these machineries in coniferous stands. The development of dedicated harvester heads specifically for broadleaf species is still far from being realised, and there are actually no research initiatives on this topic [20]. Therefore, the efforts of researchers and forest managers should be directed towards increasing the technical skills of forest operators in working with harvesters with conventional heads and applying modern technologies such as augmented reality, which can ensure effective training without compromising the safety of beginner operators [62].

- The introduction of fully mechanised felling and processing operations in beech stands is not only limited by the intrinsic characteristics of beech trees, but also by the fact that beech stands are often located in steep mountainous terrains, mostly in the Mediterranean and Western Asia zones. In light of this, it should be interesting to implement and scientifically test the economic and environmental performance of winch-assisted harvesting in beech forests. Winch-assist systems have been proven to be suitable for introducing full mechanical harvesting in difficult terrain conditions, increasing both work productivity and ergonomics for the operators [63]. Furthermore, it is interesting to observe that these systems generally show lower soil disturbance as compared to traditional harvesting systems [64]. Therefore, their introduction in the framework of beech silviculture, after proper scientific evaluation and subsequent training of the operators, could be beneficial for the implementation of SFOs in beech forests.

- Concerning ground-based extraction, different techniques and machineries are suitable for beech stands. Both skidding and forwarding reached comparable productivities under similar working conditions. As expected, the higher the mechanisation level, the higher the productivity. However, further time-motion studies are welcome to extend the amount of literature for comprehensive reviews and meta-analyses of the topic [65]. It is important to compare different ground-based extraction options from an environmental point of view, understanding at a deeper level the implications that a given extraction system has on various aspects of forest ecosystems, which include soil, biodiversity, natural regeneration and ecological processes [66,67,68,69].

- Aerial extraction via cable yarders is a recommended solution in the case of harvesting in steep terrains. Besides satisfactory work productivity, these methodologies can limit soil disturbances, mostly when working with fully suspended loads [70]. It is therefore imperative to comprehend that operator training is fundamental to encouraging the use of these harvesting systems in the context of SFOs in beech forests.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Antonucci, S.; Santopuoli, G.; Marchetti, M.; Tognetti, R.; Chiavetta, U.; Garfì, V. What Is Known about the Management of European Beech Forests Facing Climate Change? A Review. Curr. For. Rep. 2021, 7, 321–333. [Google Scholar] [CrossRef]

- Tavankar, F.; Nikooy, M.; Lo Monaco, A.; Picchio, R. Long-term impact of selection cutting management on frequency of stem deformity in mixed beech forests of northern Iran. Drewno 2021, 64, 5–26. [Google Scholar]

- Jagodziński, A.M.; Dyderski, M.K.; Horodecki, P. Differences in biomass production and carbon sequestration between highland and lowland stands of Picea abies (L.) H. Karst. and Fagus sylvatica L. For. Ecol. Manag. 2020, 474, 118329. [Google Scholar] [CrossRef]

- Petritan, I.C.; Mihăilă, V.V.; Bragă, C.I.; Boura, M.; Vasile, D.; Petritan, A.M. Litterfall production and leaf area index in a virgin European beech (Fagus sylvatica L.)—Silver fir (Abies alba Mill.) forest. Dendrobiology 2020, 83, 75–84. [Google Scholar] [CrossRef]

- Stojanović, D.B.; Levanič, T.; Matović, B.; Stjepanović, S.; Orlović, S. Growth response of different tree species (oaks, beech and pine) from SE Europe to precipitation over time. Dendrobiology 2018, 79, 97–110. [Google Scholar] [CrossRef]

- Calderaro, C.; Cocozza, C.; Palombo, C.; Lasserre, B.; Marchetti, M.; Tognetti, R. Climate–growth relationships at the transition between Fagus sylvatica and Pinus mugo forest communities in a Mediterranean mountain. Ann. For. Sci. 2020, 77, 63. [Google Scholar] [CrossRef]

- Milios, E.; Papalexandris, C. Height growth of sprouts emerged from small stumps and seed origin saplings under shade, in low elevation Fagus sylvatica L. s.l. stands in Greece. Dendrobiology 2019, 82, 1–7. [Google Scholar] [CrossRef]

- Martinez del Castillo, E.; Zang, C.S.; Buras, A.; Hacket-Pain, A.; Esper, J.; Serrano-Notivoli, R.; Hartl, C.; Weigel, R.; Klesse, S.; Resco de Dios, V.; et al. Climate-change-driven growth decline of European beech forests. Commun. Biol. 2022, 5, 163. [Google Scholar] [CrossRef]

- Leuschner, C.; Feldmann, E.; Pichler, V.; Glatthorn, J.; Hertel, D. Forest management impact on soil organic carbon: A paired-plot study in primeval and managed European beech forests. For. Ecol. Manag. 2022, 512, 120163. [Google Scholar] [CrossRef]

- Vančura, K.; Šimková, M.; Vacek, Z.; Vacek, S.; Gallo, J.; Šimůnek, V.; Podrázský, V.; Štefančík, I.; Hájek, V.; Prokůpková, A.; et al. Effects of environmental factors and management on dynamics of mixed calcareous forests under climate change in Central European lowlands. Dendrobiology 2022, 87, 79–100. [Google Scholar] [CrossRef]

- Zumr, V.; Remeš, J.; Nakládal, O. Small-scale spontaneous dynamics in temperate beech stands as an importance driver for beetle species richness. Sci. Rep. 2022, 12, 11974. [Google Scholar] [CrossRef]

- Marenče, J.; Šega, B.; Gornik Bučar, D. Monitoring the Quality and Quantity of Beechwood from Tree to Sawmill Product. Croat. J. For. Eng. 2020, 41, 119–128. [Google Scholar] [CrossRef]

- Heshmatol Vaezin, S.M.; Moftakhar Juybari, M.; Sadeghi, S.M.M.; Banaś, J.; Marcu, M.V. The Seasonal Fluctuation of Timber Prices in Hyrcanian Temperate Forests, Northern Iran. Forests 2022, 13, 761. [Google Scholar] [CrossRef]

- Štefančík, I.; Vacek, Z.; Sharma, R.P.; Vacek, S.; Rösslová, M. Effect of thinning regimes on growth and development of crop trees in Fagus sylvatica stands of central Europe over fifty years. Dendrobiology 2018, 79, 141–155. [Google Scholar] [CrossRef]

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable Forest Operations (SFO): A new paradigm in a changing world and climate. Sci. Total Environ. 2018, 634, 1385–1397. [Google Scholar] [CrossRef]

- Koehler, D.A.; Hecht, A.D. Sustainability, well being, and environmental protection: Perspectives and recommendations from an Environmental Protection Agency forum. Sustain. Sci. Pract. Policy 2006, 2, 22–28. [Google Scholar] [CrossRef]

- Kastenhofer, K.; Rammel, C. Obstacles to and potentials of the societal implementation of sustainable development: A comparative analysis of two case studies. Sustain. Sci. Pract. Policy 2005, 1, 5–13. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Mederski, P.S.; Tocci, D.; Venanzi, R.; Stefanoni, W.; Pari, L. Applications of GIS-Based Software to Improve the Sustainability of a Forwarding Operation in Central Italy. Sustainability 2020, 12, 5716. [Google Scholar] [CrossRef]

- Iranparast Bodaghi, A.; Nikooy, M.; Naghdi, R.; Venanzi, R.; Latterini, F.; Tavankar, F.; Picchio, R. Ground-Based Extraction on Salvage Logging in Two High Forests: A Productivity and Cost Analysis. Forests 2018, 9, 729. [Google Scholar] [CrossRef]

- Mederski, P.S.; Schweier, J.; Đuka, A.; Tsioras, P.; Bont, L.G.; Bembenek, M. Mechanised Harvesting of Broadleaved Tree Species in Europe. Curr. For. Rep. 2022, 8, 1–19. [Google Scholar] [CrossRef]

- Hoffmann, S.; Jaeger, D. Insights on motor-manual tree felling in Germany, recent developments to ensure efficient operations in singletree selection harvest. Eur. J. For. Eng. 2021, 7, 39–44. [Google Scholar] [CrossRef]

- Sadowski, J.; Moskalik, T.; Zastocki, D. Basic parameters of timber harvesting processes in mountain beech stands in Komancza Forest Inspectorate. Acta Sci. Pol. Silvarum Colendarum Ratio Ind. Lignaria 2012, 11, 37–44. [Google Scholar]

- Kortoci, Y.; Kellezi, M. Comparison of time consumption and productivity during beech forest felling and processing in two different working conditions. Bilge Int. J. Sci. Technol. Res. 2020, 4, 43–47. [Google Scholar] [CrossRef]

- Marčeta, D.; Košir, B. Comparison of two felling & processing methods in beech forests. Croat. J. For. Eng. 2016, 37, 163–174. [Google Scholar]

- Berendt, F.; Fortin, M.; Suchomel, C.; Schweier, J. Productivity, Costs, and Selected Environmental Impacts of Remote-Controlled Mini Forestry Crawlers. Forests 2018, 9, 591. [Google Scholar] [CrossRef]

- Behjou, F.K.; Majnounian, B.; Dvořák, J.; Namiranian, M.; Saeed, A.; Feghhi, J. Productivity and cost of manual felling with a chainsaw in Caspian forests. J. For. Sci. 2009, 55, 96–100. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Naghdi, R.; Ghajar, I.; Nikooy, M. Time Prediction Models and Cost Evaluation of Cut-To-Length (CTL) Harvesting Method in a Mountainous Forest. Small-Scale For. 2013, 12, 181–192. [Google Scholar] [CrossRef]

- Neri, F.; Laschi, A.; Marchi, E.; Marra, E.; Fabiano, F.; Frassinelli, N.; Foderi, C. Use of Battery- vs. Petrol-Powered Chainsaws in Forestry: Comparing Performances on Cutting Time. Forests 2022, 13, 683. [Google Scholar] [CrossRef]

- Dembure, T.P.; McEwan, A.; Spinelli, R.; Magagnotti, N.; Ramantswana, M. A comparison between two alternative harvesting systems in the thinning of fast-growing pine plantations under the conditions of low labour cost. Eur. J. For. Res. 2019, 138, 43–52. [Google Scholar] [CrossRef]

- Laitila, J.; Niemistö, P.; Väätäinen, K. Productivity of multi-tree cutting in thinnings and clear cuttings of young downy birch (Betula pubescens) dominated stands in the integrated harvesting of pulpwood and energy wood. Balt. For. 2016, 22, 116–131. [Google Scholar]

- Horváth, A.L.; Szakálos-Mátyás, K.; Horváth, B. Investigation of the applicability of multi-operational logging machines in Hardwood stands. Acta Silv. Lignaria Hung. 2012, 8, 133–144. [Google Scholar] [CrossRef]

- Bergström, D.; Fernandez-Lacruz, R.; de la Fuente, T.; Höök, C.; Krajnc, N.; Malinen, J.; Nuutinen, Y.; Triplat, M.; Nordfjell, T. Effects of boom-corridor thinning on harvester productivity and residual stand structure. Int. J. For. Eng. 2022, 33, 226–242. [Google Scholar] [CrossRef]

- Slugeň, J.; Peniaško, P.; Messingerová, V.; Jankovský, M. Productivity of a John Deere harvester unit in deciduous stands. Acta Univ. Agric. Silvic. Mendel. Brun. 2014, 62, 231–238. [Google Scholar] [CrossRef]

- Labelle, E.; Breinig, L.; Sycheva, E. Exploring the Use of Harvesters in Large-Diameter Hardwood-Dominated Stands. Forests 2018, 9, 424. [Google Scholar] [CrossRef]

- Labelle, E.R.; Windisch, J.; Gloning, P. Productivity of a single-grip harvester in a beech dominated stand: A case-study under Bavarian conditions. J. For. Res. 2019, 24, 100–106. [Google Scholar] [CrossRef]

- Coup, C.E.; Benjamin, J.G.; Wagner, R.G. Harvesting Biomass to improve low-value beech dominated hardwood stands in Maine. In Proceedings of the 31st Annual Meeting of the Council on Forest Engineering (COFE), Charleston, SC, USA, 22–25 June 2008; pp. 1–6. [Google Scholar]

- Manzone, M.; Spinelli, R. Efficiency of small-scale firewood processing operations in Southern Europe. Fuel Process. Technol. 2014, 122, 58–63. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Nati, C. Options for the Mechanized Processing of Hardwood Trees. Int. J. For. Eng. 2009, 20, 39–44. [Google Scholar]

- Spinelli, R.; Magagnotti, N. Performance of a small-scale chipper for professional rural contractors. For. Sci. Pract. 2013, 15, 206–213. [Google Scholar] [CrossRef]

- Labelle, E.R.; Windisch, J. Productivity of a single-grip TimberPro 620 harvester with a LogMax 7000 harvesting head in a beech dominated stand. In Proceedings of the 49th FORMEC Symposium, Warsaw, Poland, 4–7 September 2016; pp. 77–82. [Google Scholar]

- Marra, E.; Laschi, A.; Fabiano, F.; Foderi, C.; Neri, F.; Mastrolonardo, G.; Nordfjell, T.; Marchi, E. Impacts of wood extraction on soil: Assessing rutting and soil compaction caused by skidding and forwarding by means of traditional and innovative methods. Eur. J. For. Res. 2022, 141, 71–86. [Google Scholar] [CrossRef]

- Melemez, K.; Tunay, M.; Emir, T. A Comparison of Productivity in Five Small-Scale Harvesting Systems. Small-Scale For. 2014, 13, 35–45. [Google Scholar] [CrossRef]

- Ozturk, T.; Senturk, N. Productivity and time studies of MB Trac 900 tractor at beech stands on mountainous areas in Turkey. Balt. For. 2010, 16, 132–138. [Google Scholar]

- Ozturk, T. Productivity of MB Trac 900 tractor at beech stands on mountainous areas in Blacksea region. Afr. J. Agric. Res. 2010, 5, 28–33. [Google Scholar]

- Özturk, T. Productivity of New Holland farm tractor at beech stands on mountainous areas in Black Sea Region. For. Ideas 2010, 16, 39. [Google Scholar]

- Spinelli, R.; Magagnotti, N. Wood Extraction with Farm Tractor and Sulky: Estimating Productivity, Cost and Energy Consumption. Small-Scale For. 2012, 11, 73–85. [Google Scholar] [CrossRef]

- Zečić, Ž.; Krpan, A.P.B.; Vukušić, S. Productivity of C Holder 870 F tractor with double drum winch Igland 4002 in thinning beech stands. Croat. J. For. Eng. 2006, 27, 49–57. [Google Scholar]

- Borz, S.A.; Ignea, G.; Popa, B.; Iordache, E.; Spârchez, G. Estimating time consumption and productivity of roundwood skidding in group shelterwood system—A case study in a broadleaved mixed stand located in reduced accessibility conditions. Croat. J. For. Eng. 2015, 36, 137–146. [Google Scholar]

- Knežević, J.; Gurda, S.; Musić, J.; Halilović, V.; Vranović, A. Productivity of the Ecotrac 120V Skidder for Timber Skidding in the Area of Mu “Igman”. Rad. Šumarskog Fak. Univ. U Sarajev. 2018, 48, 17–32. [Google Scholar] [CrossRef]

- Mederski, P.; Bembenek, M.; Erler, J.; Giefing, D.F.; Karaszewski, Z. The Enhancement of Skidding Productivity Resulting From Changes in Construction: Grapple Skidder Vs Rope Skidder. In Proceedings of the FORMEC 2010 Forest Engineering: Meeting the Needs of the Society and the Environment, Padua, Italy, 11–14 July 2010; pp. 1–7. [Google Scholar]

- Ruch, P.; Vigneau, N.; Loye, H.; Francois, D.; Montagny, X.; Santini, O.; Vuillermoz, M. TVS20, a Multifunction Tool to Up-Grade an Excavator into a Versatile Winch-Based Haulage Equipment for Hard-to-Reach Areas: Lessons Learnt from 6 Operations with the Prototype. In Proceedings of the COFE-FORMEC 2021—Forest Engineering Family: Growing Forward Together, Corvallis, OR, USA, 27–30 September 2021; pp. 155–163. [Google Scholar]

- Sowa, J.M.; Szewczyk, G. Time Consumption of Skidding in Mature Stands Performed by Winches Powered by Farm Tractor. Croat. J. For. Eng. 2013, 34, 255–264. [Google Scholar]

- Gallis, C. Comparative cost estimation for forwarding small-sized beech wood with horses and mini-skidder in northern Greece. For. Prod. J. 2004, 54, 84–90. [Google Scholar]

- Suadicani, K.; Talbot, B. Extracting and chipping hardwood crowns for energy. Scand. J. For. Res. 2010, 25, 455–461. [Google Scholar] [CrossRef]

- Zimbalatti, G.; Proto, A.R. Productivity of forwarders in South Italy. In Proceedings of the FORMEC 2010, Forest Engineering: Meeting the Needs of the Society and the Environment, Padua, Italy, 11–14 July 2010; pp. 1–7. [Google Scholar]

- Spinelli, R.; Magagnotti, N.; Lombardini, C. Performance, capability and costs of small-scale cable yarding technology. Small-Scale For. 2010, 9, 123–135. [Google Scholar] [CrossRef]

- Eroǧlu, H.; Özkaya, M.S.; Acar, H.H.; Karaman, A.; Yolasigmaz, H.A. An investigation on roundwood extraction of Fagus orientalis lipsky, Abies nordmanniana (Stew.) Spach. and Picea orientalis (L.) Link. by Urus M III forest skyline on snow. Afr. J. Biotechnol. 2009, 8, 1082–1089. [Google Scholar]

- Munteanu, C.; Yoshida, M.; Iordache, E.; Borz, S.A.; Ignea, G. Performance and cost of downhill cable yarding operations in a group shelterwood system. J. For. Res. 2019, 24, 125–130. [Google Scholar] [CrossRef]

- Stoilov, S. Productivity and Costs of Cable Yarding in Group Shelterwood System in Deciduous Forests. For. Ideas 2021, 27, 331–342. [Google Scholar]

- Bembenek, M.; Mederski, P.S.; Erler, J.; Giefing, D.F. Results of large-size timber extracting with a grapple skidder. Acta Sci. Pol. 2011, 10, 5–14. [Google Scholar]

- Marčeta, D.; Petković, V.; Košir, B. Comparison of two skidding methods in beech forests in mountainous conditions. Nov. Meh. Sumar. 2014, 35, 51–62. [Google Scholar]

- Molinaro, M.; Orzes, G. From forest to finished products: The contribution of Industry 4.0 technologies to the wood sector. Comput. Ind. 2022, 138, 103637. [Google Scholar] [CrossRef]

- Holzfeind, T.; Visser, R.; Chung, W.; Holzleitner, F.; Erber, G. Development and Benefits of Winch-Assist Harvesting. Curr. For. Rep. 2020, 6, 201–209. [Google Scholar] [CrossRef]

- Visser, R.; Stampfer, K. Expanding ground-based harvesting onto steep terrain: A review. Croat. J. For. Eng. 2015, 36, 321–331. [Google Scholar]

- Louis, L.T.; Kizha, A.R.; Daigneault, A.; Han, H.-S.; Weiskittel, A. Factors Affecting Operational Cost and Productivity of Ground-Based Timber Harvesting Machines: A Meta-analysis. Curr. For. Rep. 2022, 8, 38–54. [Google Scholar] [CrossRef]

- Labelle, E.R.; Hansson, L.; Högbom, L.; Jourgholami, M.; Laschi, A. Strategies to Mitigate the Effects of Soil Physical Disturbances Caused by Forest Machinery: A Comprehensive Review. Curr. For. Rep. 2022, 8, 20–37. [Google Scholar] [CrossRef]

- Schweier, J.; Magagnotti, N.; Labelle, E.R.; Athanassiadis, D. Sustainability Impact Assessment of Forest Operations: A Review. Curr. For. Rep. 2019, 5, 101–113. [Google Scholar] [CrossRef]

- Picchio, R.; Venanzi, R.; Tavankar, F.; Luchenti, I.; Iranparast Bodaghi, A.; Latterini, F.; Nikooy, M.; Di Marzio, N.; Naghdi, R. Changes in soil parameters of forests after windstorms and timber extraction. Eur. J. For. Res. 2019, 138, 875–888. [Google Scholar] [CrossRef]

- Lo Monaco, A.; Luziatelli, G.; Latterini, F.; Tavankar, F.; Picchio, R. Structure and Dynamics of Deadwood in Pine and Oak Stands and their Role in CO2 Sequestration in Lowland Forests of Central Italy. Forests 2020, 11, 253. [Google Scholar] [CrossRef]

- Varch, T.; Erber, G.; Visser, R.; Spinelli, R.; Harrill, H.; Stampfer, K. Advances in Cable Yarding: A Review of Recent Developments in Skyline Carriage Technology. Curr. For. Rep. 2021, 7, 181–194. [Google Scholar] [CrossRef]

| Intervention | Machinery | Wood System | Average dbh (cm) | Slope Class * | Productivity (m3 SMH−1) | Cost (EUR m−3) | Notes | Reference |

|---|---|---|---|---|---|---|---|---|

| Group selection | Chainsaw | SWS–TLS | 21–35 | II–III | 1.80–8.00 | Lower productivity for SWS method | [24] | |

| Single selection | Chainsaw | CTL | 88 | I–III | 20.6 | 1.05 | [26] | |

| Thinning | Chainsaw | CTL | 20–50 | II | 0.40–1.75 | [22] | ||

| Thinning | Chainsaw | CTL | 50–60 | III | 3.50 | [23] | ||

| Thinning | Feller-buncher | WTH | 60–75 | [36] | ||||

| Selective regeneration cutting | Harvester | CTL | 27 | 10.4 | [31] | |||

| Thinning | Harvester | CTL | 8–10 | I | 3.3–5.6 | [32] | ||

| Thinning | Harvester | CTL | 35–50 | I | 29–43 | Data refer to net productivity | [34] | |

| Thinning | Harvester | CTL | 30–39 | I | 28–29 | Data refer to net productivity | [40] | |

| Thinning | Harvester | CTL | 22–27 | I | 5.35 | [33] |

| Intervention | Extraction Technique | Extraction System | Wood System | Average dbh (cm) | Slope Class * | Extraction Distance (m) | Productivity (m3 SMH−1) | Cost (EUR m−3) | Notes | Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| Selection cutting | Forwarding | Animals | CTL | 15–20 | II | 55–950 | 3.53 | [42] | ||

| Thinning | Forwarding | Forwarder | CTL | 36 | I | 68 | 9.5 | 9 | [54] | |

| Shelterwood | Forwarding | Forwarder | CTL | II | 1000–1100 | 14–15 | [55] | |||

| Selection cutting | Forwarding | Mini tractors | CTL | 15–20 | I | 270–360 | 2.47 | [53] | ||

| Thinning | Hauling | Forestry-fitted farm tractor with winch | TLS | 15–30 | 50 | 1.92–4.54 | [42] | |||

| Thinning | Hauling | Prototype for winching logs | CTL | III | 27–55 | 7.6–8.5 | 14.1–15.7 | Values refer only to winching operation | [51] | |

| Thinning | Hauling | Remote-controlled mini forest crawler | WTH | 21 | I–III | 17.5 | 6.55 | 13.93 | [25] | |

| Selection cutting | Skidding | Animals | CTL | 20–50 | II | 100 | 3.80 | [42] | ||

| Group selection | Skidding | Cable skidder | SWS–CTL | 21–35 | II–III | 500 | 2.68–3.12 | 4.50–7.03 | Lower productivity values and higher cost for SWS wood system | [61] |

| Group shelterwood | Skidding | Cable skidder | TLS | I | 1700 | 3.12 | [48] | |||

| Salvage logging | Skidding | Cable skidder | CTL | 58 | II | 308 | 1.54 | [19] | ||

| Skidding | Cable skidder | CTL | I | 490 | 3.41–9.13 | [49] | ||||

| Final shelterwood felling | Skidding | Cable skidder | TLS | 42–48 | I | 200–300 | 14.70 | [50] | ||

| Thinning | Skidding | Forestry-fitted farm tractor with winch | CTL | 20–50 | II | 100 | 6.25 | [42] | ||

| Thinning | Skidding | Forestry-fitted farm tractor with winch | CTL | II | 55–105 | 8.85–14.85 | 3.50–9.60 | [43] | ||

| Thinning | Skidding | Forestry-fitted farm tractor with winch | CTL | 22 | 25–250 | 1.75–2.70 | 9.18–14.19 | [47] | ||

| Thinning | Skidding | Forestry-fitted farm tractor with winch | CTL | II–III | 140–320 | 7.70–11.35 | 4.50–8.60 | [45] | ||

| Selection cutting | Skidding | Forestry-fitted farm tractor with winch | CTL | 30 | II | 216 | 3.70 | 9.90 | [46] | |

| Thinning | Skidding | Grapple skidder | CTL | 20–50 | II | 1200 | 1.80–2.15 | [22] | ||

| Final shelterwood felling | Skidding | Grapple skidder | TLS | 42–47 | I | 200–300 | 21.00 | [60] | ||

| Final shelterwood felling | Skidding | Grapple skidder | TLS | 42–48 | I | 200–300 | 32.80 | [50] | ||

| Clear cut | Yarding | Cable car | 40 | II–III | 800–900 | 4.73 | [23] | |||

| Selection cutting | Yarding | Cable yarder | CTL | 20–50 | II | 100 | 10.09 | [42] | ||

| Thinning | Yarding | Cable yarder | CTL | 40 | II | 400 | 1.69–4.08 | lower productivity values for downhill yarding | [57] | |

| Group shelterwood | Yarding | Cable yarder | CTL | 60 | II | 326 | 8.80 | 7.40 | [58] | |

| Group shelterwood | Yarding | Cable yarder | CTL | 34 | III | 160–250 | 8.41 | 13.00 | [59] | |

| Thinning | Yarding | Mini cable yarders | WTH | 17–19 | III | 67–118 | 1.50–2.40 | 24–30 | [56] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latterini, F.; Jagodziński, A.M.; Horodecki, P.; Stefanoni, W.; Venanzi, R.; Picchio, R. The State of the Art of Forest Operations in Beech Stands of Europe and Western Asia. Forests 2023, 14, 318. https://doi.org/10.3390/f14020318

Latterini F, Jagodziński AM, Horodecki P, Stefanoni W, Venanzi R, Picchio R. The State of the Art of Forest Operations in Beech Stands of Europe and Western Asia. Forests. 2023; 14(2):318. https://doi.org/10.3390/f14020318

Chicago/Turabian StyleLatterini, Francesco, Andrzej M. Jagodziński, Paweł Horodecki, Walter Stefanoni, Rachele Venanzi, and Rodolfo Picchio. 2023. "The State of the Art of Forest Operations in Beech Stands of Europe and Western Asia" Forests 14, no. 2: 318. https://doi.org/10.3390/f14020318

APA StyleLatterini, F., Jagodziński, A. M., Horodecki, P., Stefanoni, W., Venanzi, R., & Picchio, R. (2023). The State of the Art of Forest Operations in Beech Stands of Europe and Western Asia. Forests, 14(2), 318. https://doi.org/10.3390/f14020318