Abstract

Forest policies aiming for a greener future and decarbonization require scientific support to help in decision making on resource economy and sustainability of forest operations. Timber skidding is one of the most prevalent options in wood extraction around the world. While its operational and environmental performance is affected by several factors, of which the extraction distance, removal intensity, and machine capabilities are of first importance, there are few studies on the subject in low-access and low-intensity removals. Based on a time study which accounted for production and fuel consumption, this work modeled and quantified productivity and fuel consumption for such operational conditions. Dependence of fuel and time consumption on relevant operational factors was modeled by least square stepwise ordinary regression techniques. Then, the developed models and summary statistics were used to simulate productivity and fuel consumption for a wide range of extraction distances. The main results indicate that, for removal intensities in the range of 7 to 15 m3/ha, productivity of skidding operations in mature broadleaved forests depended heavily on the extraction distance. Taking as a reference an extraction distance of 200 m, productivity halved at 800 m, and decreased to one fourth at 2000 m. For the same conditions, fuel consumption increased linearly, being doubled at 800 m and four times higher at 2000 m. Although the unit fuel consumption increased linearly as a function of extraction distance, its magnitude of increment was much lower. The results of this study indicate that shortening the extraction distances may be the best option in increasing the operational and environmental performance of skidding operations. This may be achieved by developing further the forest road network, which, in addition to the benefits for harvesting operations, could support a more sustainable forest management.

1. Introduction

Sustainability of human activities has gained a lot of momentum in the post-industrial era, and its concepts have become of first importance in forestry, including forest operations, where they were used to characterize and describe potentials for improvement [1,2]. Concerns on environmental degradation, resource depletion, resilience, and competitiveness of economy are shaping the current view in many industrial sectors, including forestry [3,4], which employs and provides goods and services for many around the world [5,6]. Dependence of human society on wood consumption is undeniable [7,8] and substantial improvements are expected in all the supply chain so as to ensure its sustainability [9,10,11]. In this context, providing updated information to support planning and decision making is of crucial importance for the forestry economic sector.

Timber harvesting is a critical cell of the wood supply chain, mainly because its performance is affected by a wide range in the operational environment-, technology-, labor-, and institutional-related factors. There is a wide variety in the options used for timber extraction, e.g., [12], and their choice is often contextual [13]. Based on the latest literature on the topic [14,15,16], skidding is one of the most important timber extraction options used in the international practice. As a rule, its performance is dependent on factors such as the silvicultural strategy reflected by the type of intervention [13], tree size, and removal intensity [17], as well as on the operating environment conditions such as the extraction distances [18,19,20]. In addition, the harvesting method used is a factor that may affect the operational and environmental performance in skidding operations; that is, productivity and unit fuel consumption may depend on the length of extracted logs [21] and payload per turn.

Although there is an important body of knowledge on the performance of skidding operations by dedicated machines [13,17,18,19,20,21,22,23,24,25,26,27,28,29], from the current perspective, most of the studies supporting it were conducted on obsolete equipment, which may be a limitation in their applicability, since significant improvements were developed in relation to the capabilities of the latest generation machines. For instance, developments in engines, transmission systems, and ergonomics have contributed significantly to the improvement of operational and environmental performance [30]. Secondly, due to the silvicultural and other contextual practices, it is believed that there is, in general, a limited transferability of operational performance assessment results between various regions of the world [12]. Third, the existing studies on skidding operations cover only a limited range of operational conditions, particularly in terms of extraction distance, which, although acknowledged as one of the most influential factors of time consumption and productivity [17,18,19,20,21,22,23,24,25,26,27,28,29], was commonly less than 500 m [31]. In addition, detailed studies relating the fuel consumption to operational conditions are scarce in skidding operations, although they may prove very useful to characterize more accurately the variation in fuel consumption based on operational steps, enabling this way a more rigorous basis for developing dependency models and simulation [32].

Operational and environmental performance assessment in forest operations relies heavily on time studies, whose scope, resolution, and extent depends largely on the available resources [33]. One of their intended goals is to understand the behavior of systems used in forest operations [34], which may be achieved by modeling. However, the applicability of the developed dependence models is thought to be constrained to the range of data from which they were developed; as such, developing a reliable set of models and statistics is of first importance for the reliability of models, which should include the range of existing operational conditions or at least to extend it. Based on models and statistics, simulation may be used to help understand the behavior of a system under changing operational conditions. From this point of view, a model is commonly defined as an approximation of the real-world standing for a representation of a system, while simulation is a method that describes the behavior of a system, which is helpful in developing understanding on how a system operates and how its operation may change [35] when certain changes occur within its boundaries of operation.

The aim of this study was to simulate productivity and fuel consumption in skidding operations carried out in low-access and low-removal-intensity conditions by cable skidders of the current generation. The study was based on work-cycle-based field measurements on fuel and time consumption, coupled with estimations of production. The objectives of the study were to (i) develop time and fuel consumption models by considering a wide range of extraction distances, (ii) develop the necessary descriptive statistics for simulation of productivity and fuel consumption, and (iii) to run simulations on productivity and fuel consumption by considering the extraction distance as a main factor affecting these performance metrics.

2. Materials and Methods

2.1. Study Locations

Data collection was implemented in three forest compartments (Table 1), which were generally characterized by a sloped terrain, presence of mixed old-grown forests, and the implementation of low-removal-intensity, selective silvicultural systems. Data supporting this study were collected in the late spring (April and May) of 2020 by taking into consideration six days of operation. The forest compartments taken into study shared a low accessibility condition, being located at more than 500 from the forest roads. The access to the felling areas was provided by skidding roads developed on the slopes. Figure 1 shows the location of the three felling areas, access roads, and landing areas.

Table 1.

Description of the compartments taken into study.

Figure 1.

Location of the forest compartments, skidding roads, and landing areas. Source: image developed in QGis based on field-collected GPS locations and freely available topography layers available for download in QGis.

In forest compartments 29A and 39A, the applied silvicultural system was that of irregular shelterwood cuttings. This silvicultural system is characterized by very long regeneration periods (typically 50 to 60 years in the case of beech, fir, and spruce), scattered extractions which are deployed in gaps with sizes of up to one tree height and which may be coupled with other tending operations; typically, it produces uneven aged forests [36]. In forest compartment 39H, special conservation cuttings were applied; this type of removal is aimed at improving the health, coverage, and protective functionality of the aged forests exempted from production, which are either located on sloped, rocky or unstable terrains, swamps or moving sands, or they are fulfilling other functions, such as those of mitigating the effects of pollution [36].

2.2. Machine Description

Cable skidders stand for the dominant wood extraction option in Romania [16], which is due to the presence of domestic producers, such as IRUM. IRUM has improved its machines by a new concept (TAF 2012) which was released to the market in 2012 and which has undergone several improvements since then (www.irum.ro, accessed on 10 January 2023). The machine taken into study was a TAF 2012 winch skidder (Figure 2) equipped with a 110 kW Perkins engine, having a weight of 8.4 tons. It was equipped with a hydraulically powered Uniforest bi-drum winch, having a nominal traction power of 8.5 tons, supporting a line of 13 mm and a length of 70 m on each drum. More advanced technical details of the machine can be found at: https://www.irum.ro/en/vehicle-listings/skidder-2012/ (accessed on 10 January 2023).

Figure 2.

Description of the machine: (a) general overview on the TAF 2012 skidder; (b) TAF 2012 skidder during a loaded turn.

The average speed of the winch is of 0.62 m/s at 1400 rpm in the second gear and of 1.12 m/s at 1400 rpm in the third gear. The machine taken into study is articulated, which enables a steering of ±40° and an internal steering radius of 2.9 m. It featured an automatic transmission and a hydraulically powered adjustable back shield (Figure 2).

2.3. Work Organization, Data Collection, and Data Processing

The wood was dominantly extracted in the form of long logs, although some of them required further bucking at the felling area due to their very large size. As observed in the field, a skidding work cycle included the typical work elements as documented by other studies [18,20]; these included the empty turn, positioning maneuvers, cable releasing, log attachment to the cable, mechanical traction and log detachment from the cable, payload attachment, loaded turn, and landing operations, which included payload detachment, maneuvering with the logs, and piling at the road side. For simplicity reasons and due to the limited resources allocated to the study, landing operations were not further divided into work elements. The rest of the work elements were observed and described as they occurred in the field. Description and breakpoints used to delimitate these work elements were similar to other studies [18,20] and are not given herein.

Since the extraction distances were excessively long, the use of traditional methods in collecting time and fuel consumption data were not feasible. As such, the machine was equipped with a Global Positioning System unit (Garmin GPSMap 62 stc, www.garmin.com, accessed on 10 January 2023), which was placed on the machine’s cab and set to collect data at a rate of one second. A video camera was placed on the rear of the machine’s cab and set to continuously collect video files. GPS and video data were used to evaluate the time consumption and extraction distances in the office phase of the study. For instance, GPS tracks were processed in the Garmin® BaseCamp (www.garmin.com/en-US/software/basecamp/, accessed on 10 January 2023) software to extract the distances travelled by the machine on the skidding trails in a way which was similar to studies of [30,37], and the distances were extracted to the nearest 10 m. Video data were used for a detailed analysis to extract the elemental and cycle time consumption; time consumption was extracted to the nearest second. As guiding literature for the time study, the work of [33,38] was used.

Winching distances were measured for each winching repetition by the use of a Nikon Forestry Pro (www.nikon.com, accessed on 10 January 2023) laser rangefinder. A tape was used when the distance was less than 20 m, and the measurements were taken to the nearest meter. A number was given to each of the winched logs, and biometric data were collected to support volume estimations in the office phase of the study. Volume estimations were based on log lengths taken to the nearest meter and diameters taken to the nearest centimeter and were performed to the nearest cubic centimeter. Fuel consumption was measured by the method of refilling to full [39] in a way which was similar to the study of [30], and it included measurements conducted at the work cycle resolution. Each time a measurement was performed, the machine was driven to a pre-established flat location; then, a Geko G01025 (https://b2b.geko.pl/, accessed on 10 January 2023) electrically powered pump was used to refill the tank. The instrument holds a precision of ±2% and it can transfer up to 60 L of fuel/min; the measurements were taken to the nearest centiliter.

Once at the office, the data were processed and organized at the skidding work cycle level, which included the time consumption of winching, skidding, and landing operations. To support this kind of data organization, the following variables were computed:

- -

- Delay-free winching time (DFWT, h), as the sum of elemental time consumption in winching operations;

- -

- Delay-free skidding time (DFST, h), as the sum of empty turn, payload attachment, and loaded turn elemental time consumption;

- -

- Delay-free landing operations time (DFLOT, h), as the time spent at landing;

- -

- Delay-free skidding cycle time (DFSCT, h), as the sum of DFWT, DFST and DFLOT;

- -

- Delay time (DT, h), as the sum of all technical, operational, and personal delays. Delays caused by the study were excluded from the analysis;

- -

- Number of logs per cycle (NL), as the number of logs forming a payload;

- -

- Payload volume (PV, m3), as the sum of volumes of logs forming a payload;

- -

- Average winching distance (AWD, m), as the mean value of winching distances measured for all the logs forming a payload;

- -

- Average extraction distance (AED, m), as the mean value of the empty (ETD, m) and loaded turn distances (LTD, m);

- -

- Cycle-wise fuel consumption (FC, l), as measured in the field.

Productive performance was estimated for the average conditions characterizing the study in the form of gross and net efficiencies (GE, NE h/m3) and productivities (GP, NP m3/h). Gross figures were estimated based on the volume of production (P, m3, which was the sum of the volumes from all the payloads) and the total observed time (TOT, h, which was the sum of DFSCT and DT). Net figures were estimated based on the volume of production and DFSCT. Conceptually, the efficiency is the time needed to process one unit of production, while the productivity is the amount of production processed in a unit of time [38]. Data processing steps were carried out in Microsoft Excel® (www.microsoft.com, accessed on 10 January 2023).

2.4. Statistical Analysis and Model Development

Statistical analysis was implemented in Microsoft Excel® (www.microsoft.com, accessed on 10 January 2023) software, which was extended in terms of statistical analysis functionalities by installing a copy of the Real Statistics® freeware add-in [40]. The workflow of statistical analysis included the estimation of the main descriptive statistics, checking for normality of data in estimates, running a correlation analysis to detect multicollinearity in independent variables, and modeling the dependence between time consumption, fuel consumption, and independent variables.

For modeling purposes, the automatic functionalities of multiple linear stepwise regression were used from the Real Statistics tool. This functionality allows robust models to be developed that use the best candidates from a set of independent variables. More information on how it works can be found in [40]. Models were developed at the main, operational level, expressing the dependence relations between the delay-free winching, delay-free skidding, and delay-free skidding cycle time by considering their relevant predictors. A similar approach was used to develop fuel consumption models. The maximal set of variables used to predict the delay-free winching time included the number of logs and the average winching distance, while the maximal set used to predict the delay-free skidding time included the number of logs, payload volume, and average extraction distance; delay-free skidding cycle time was predicted based on a maximal set, which included the number of logs, payload volume, average winching distance, and average extraction distance, while fuel consumption model was fitted by considering the number of logs, payload volume, and average extraction distance as the maximal set of predictors. The reason for not including the average winching distance in this model was related to the unavailability of such data, since the field researchers were concerned with fuel measurements at landing.

The analysis was complemented by checking for the significance of the predictors in a given model, as well as of the overall model, which was performed at a confidence level of 95% (α = 0.05). Moreover, the models were characterized by the variance inflation factors (VIF) and Akaike’s information criterion (AIC), which are metrics used to describe the correlation of a candidate predictor to the rest of the predictors in a given model and the quality brought by the retained predictors in a model, respectively. To check for the validity of the models, further tests were implemented to characterize the distributions of residuals and homogeneity of variance in the form of normality (Shapiro–Wilk and d’Agostino–Pearson) and homoscedasticity (Breusch–Pagan and White) tests.

2.5. Fuel Consumption and Productivity Simulation

Models developed for time consumption were based on a number of 25 finely detailed work cycles and average extraction distances ranging from 230 to 2600 m, while fuel consumption models were based on a number of 39 work cycles and average extraction distances ranging from 230 to 2640 m.

Following the statistical steps, productivity was simulated in a range of average extraction distances from 200 to 2600 m, based on the average number of logs within a payload and the mean payload volume. Skidding cycle time consumption was recalculated by using the developed time consumption model, which took as inputs the mean number of logs per turn and average extraction distances, which were incremented from 200 to 2600 m by a step of 10 m. This was because the relevant predictors of the skidding cycle time were found to be the number of logs and the average extraction distance. To simulate the productivity behavior as a function of the average extraction distance, procedurally, the volume of production was divided by the number of observed logs to compute the mean volume per log. Then, the mean number of logs per payload was multiplied by the mean volume per log to find the volume of a payload. Uncertainty in payload volume estimates was based on the standard deviation in number of logs per turn, which was used to complement the simulation. For each incremental step in the extraction distance, the productivity (as net figure) was estimated as described in Section 2.3, and it was complemented by simulated estimates of net efficiency. Simulations were implemented manually with the support of Microsoft Excel® software.

Fuel consumption was estimated in a similar way based on the descriptive statistics of mean payload volume and its standard deviation as a measure of standardized uncertainty. This was because the cycle-wise fuel consumption was found to be explained by the payload volume and average extraction distance. Simulation of fuel consumption included the representation of cycle-wise fuel consumption in the average extraction distance domain, which was complemented by figures on unit fuel consumption and fuel consumption per ton-kilometer. The last figure assumed an average density of fresh wood of 0.9 ton/m3. All the simulations, as well as the artwork used in the results, were developed in Microsoft Excel®.

3. Results

3.1. Descriptive Statistics of Operational Variables and Time Consumption

Field study covered 19.33 h of observation, of which approximately 18 h (93.2%) were recorded as productive time. Roughly 34 km were covered by the skidder’s movement, at an average movement speed of 3.14 km/h; empty and loaded turn speeds were similar in values, accounting for 3.04 and 3.25 km/h, respectively. Only part of the operational and time consumption variables passed the normality check, as shown in Table 2, Table 3, Table 4 and Table 5. The operational conditions were characterized by a mean number of logs per turn of 4.6, a mean payload volume of 7.61 m3, a mean winching distance of 22.7 m, and a mean extraction distance of 687.2 m (Table 2).

Table 2.

Statistics of operational variables.

Table 3.

Statistics of elemental time consumption within a delay-free winching work cycle.

Table 4.

Statistics of elemental time consumption within a delay-free skidding work cycle.

Table 5.

Summary statistics of the main operational steps.

In a delay-free winching work cycle (Table 3), dominant were the work elements of mechanical winching (46.69%) and cable releasing (25.27%), which are the work elements depending the most on the winching distance. Skidder’s positioning, log attachment, and log detachment accounted together for less than 30% of the winching work cycle time (Table 3).

Empty and loaded turns accounted for similar shares in the delay-free skidding time, and their proportions of more than 40% were related to the high extraction distances (Table 4). Empty turn was carried out in a downhill direction, and these work elements shared similar amounts of time due to relatively close values of empty and loaded turn distances. The differences between them could be the results of different speeds of the skidder during the two work elements. Work elements, such as log detachment (Table 3) and load attachment (Table 4), were specific only to a part of the observed work cycles. In some cases, for instance, winching logs by the two cables was sufficient to make a load for loaded turn in one pass; therefore, it was not necessary to detach the logs and to attach a load. A similar explanation may be given to the minimum value of zero for the landing operation time consumption (Table 5), as there was a case in which no such operations were observed.

The summary statistics for the main operational steps are enclosed in Table 5. In the productive time, winching, skidding, and landing operations accounted for 25, 69, and 6%, respectively, figures which relate with the high extraction distance (Table 2).

Judging by the data range, the highest variation was in the skidding time, accounting for more than 1.7 h, followed by winching (0.3 h) and landing operations (0.1 h). On average, a delay-free skidding cycle time took 0.72 h, but it varied between 0.28 and more than 2 h (Table 5).

3.2. Summary of Efficiency, Productivity, and Fuel Consumption

Based on the observed data, the gross and net figures of productivity and efficiency for the observed operational steps are given in Table 6. Delays affected the figures only to a minor extent for on-trail skidding, as their dominance was found in the case of winching and landing operations.

Table 6.

Productivity and efficiency of operations in the observed conditions.

Fuel consumption was estimated based on 39 work cycles, a production of 305.54 m3, and a measured fuel consumption of 297.4 L. It accounted for an average value of 7.626 L and varied between 2.99 and 23.28 L/work cycle. These values were returned for average conditions characterized by 4.51 logs per work cycle (range = 2 to 9), a payload volume of 7.834 m3 (range = 3.92 to 13.39 m3), and an extraction distance of 765.64 m (range = 230 to 2640 m). Excepting the payload volume, none of these variables passed the normality assumption.

3.3. Dependence Models

The developed dependence models expressing the mathematical relationships between time and fuel consumption, on the one hand, and the significant operational variables, on the other hand, are shown in Table 7. Time consumption in winching operations (DFWT) depended only on the number of logs (NL) winched to form a payload. The dependence relation was characterized by an R2 value of 0.59, which indicates that there were other important factors explaining this time consumption category, which were not accounted for. On-trail skidding time (DFST) depended on the average extraction distance (AED) to a significant extent (R2 = 0.83) and skidding operation time consumption (DFSCT) depended to a great extent (R2 = 0.79) on the average extraction distance and number of logs winched per turn.

Table 7.

Time and fuel consumption dependence models.

Fuel consumption per turn (FC) depended on the average extraction distance and the payload volume (PV). The dependence relationship was very strong (R2 = 0.89), indicating a high influence of the payload volume, in addition to that of the extraction distance. By the developed model, for a distance of 500 m, a payload of 13 m3 would contribute to a fuel consumption that would be almost two times higher as compared to a payload of 4 m3. According to the values of the variance inflation factors, multicollinearity was absent in the developed models. All the models have passed the homoskedasticity assumption, indicating that the variance was homogeneous in relation to the magnitude of the explanatory variables. However, only the model developed for the fuel consumption passed the test of normality in residuals. Most probably, these were related to a higher amount of data available to develop the fuel consumption model as opposed to the time consumption ones.

3.4. Simulation of Fuel Consumption, Efficiency, and Productivity

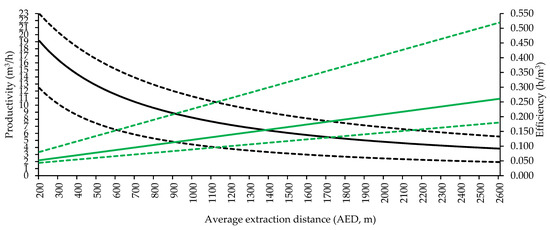

Results of simulations are presented in Figure 3 and Figure 4. Figure 3, for instance, shows the dependence of simulated productivity on the average extraction distance. For an average extraction distance of ca. 700 m, which was close to that observed in the field, the simulated productivity accounted for ca. 10.5 m3/h, which was very close to the figure based on the time study data (Table 6).

Figure 3.

Simulated productivity and efficiency. Note: black lines stand for productivity and green lines stand for efficiency; continuous lines stand for the estimated figures and dashed lines stand for standardized uncertainty.

Figure 4.

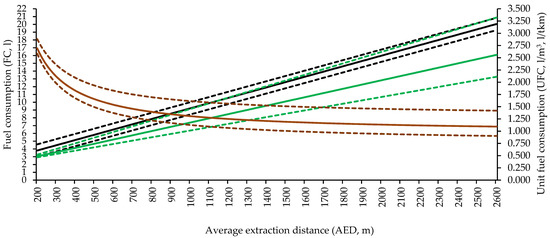

Simulated fuel consumption. Note: black lines stand for fuel consumption, green lines stand for unit fuel consumption expressed in L/m3, and brown lines stand for unit fuel consumption expressed in L/tkm; continuous lines stand for the estimated figures and dashed lines stand for standardized uncertainty.

Taking as a reference an extraction distance of 200 m, the simulated productivity will be halved at 800 m. For a distance of 2000 m, the productivity loss will be four-fold. As shown (Figure 3), there was found a large standardized uncertainty in the simulated productivity, particularly in the lower ranges of extraction distance. As opposed to the productivity trend, the simulated efficiency figures increased linearly with the average extraction distance, although the proportions were similar by taking as a reference the value at 200 m.

The simulated fuel consumption (Figure 4) increased linearly with the average extraction distance. Taking as a reference a distance of 200 m, the fuel consumption was almost two times higher at 800 m and almost four times higher at a distance of 2000 m. For distances of 2600 and 2640 m, field measurements returned an average fuel consumption value of 20.5 L, which is a value very close to that simulated (20.2 L). Unit fuel consumption (L/m3) increased linearly with the extraction distance but to a lower degree of magnitude, and it preserved the same increment proportions as in the case of cycle-wise fuel consumption. However, the unit fuel consumption simulated by considering the effort of moving mass over distance (L/tkm) had a decreasing trend in the range of extraction distances from 200 to ca. 1000 m, showing a stabilizing trend afterwards (Figure 4). For a distance of 200 m, it had a value of 2.694 L/tkm, which was almost half at 800 m and almost 2.4 times lower at a distance of 2000 m.

4. Discussion

This study aimed at simulating the productivity and fuel consumption of skidding in low-access and low-removal-intensity conditions based on a sample of field-collected data. Indeed, as described in the study, the removal intensity was low, but this applied to exceptionally high tree sizes, which contributed to a high quantity of wood readily available in concentrated locations throughout the felling areas, making the winching effort less extensive and enabling the extraction of high payloads. Both productivity and fuel consumption simulations were based on time and fuel consumption models developed by considering the most significant predictors. Although there are several studies reporting time consumption dependence models, only a few of them considered low-access conditions and their background data on operational variables were different; therefore, comparisons to existing work are rather difficult to make. For instance, the study of [18] reported a time consumption for on-trail skidding that would be almost half of that reported herein for an extraction distance of ca. 1 km. However, their overall net productivity for a distance of 1.7 km was of ca. 4 m3/h, as opposed to that of almost 5.5 m3/h found by this study for the same distance. Largely, this may come from the important differences in the number of logs winched, payload per turn, and the machine taken into study, which was older in the mentioned study. The study of [20] provided detailed statistics and models for older TAF machines observed in low-access and low-extraction-intensity operations. They reported similar winching distances, slightly higher numbers of logs per turn, and slightly lower payloads for two TAF skidders. Their study was based on average skidding distances of ca. 1000 and 900 m, respectively, for which their time consumption models would return values of 0.83 and 0.91 h, respectively. For the same distances as of this study, the time consumption for skidding operations would be of 0.93 and 0.86 h, respectively, which is close to that reported by [20]. The same applies when comparing the productivity at 1000 m, which was of 8.2 m3/h in this study, as opposed to 7.7 m3/h in the study of [20], which was carried out on the predecessor of TAF 2012. However, for a distance of 900 m, the simulated productivity of this study would be of ca. 8.8 m3/h, being much higher as opposed to that of an older TAF machine (5.6 m3/h, [20]), with the difference probably coming largely from the payload size and machine capabilities.

Other studies on skidding performance were concerned with developing predictive models, while some have described how the equipment, methods used, and the silvicultural practice may affect the outcomes of skidding in terms of performance. For instance, study of [17] characterized how the extraction intensity may affect the skidding performance, study of [21] addressed the problem of payload’s effect on performance in the view of harvesting method used, while the study of [22] has compared the performance of skidding as an effect of operational capabilities. In addition, the size of the used skidder, as well as the relation between the size and payloads, may bring both limits in capabilities and contrasting figures in productivity. For instance, the study of [13] reported on productive and environmental performance of an Ecotrac 55V model, which was observed in thinning and regeneration cuts. The authors have found productivities in the range of 3.20 to 4.95 m3/h for removal intensities of 33.91 to 125.47 m3/ha and extraction distances of 210 to 260 m. Their time consumption models included the payload volume and extraction distance as significant predictors, which supports the findings of this study on the models. However, the size of the payloads was much lower, accounting for approximately 1 m3, which explains the figures in productivity, in relation to the skidder size.

Fuel consumption data in the form of aggregated statistics are already accessible in the international literature [41], but studies reporting predictive fuel consumption models are rather scarce. To our knowledge, only the study of [32] has attempted to relate fuel consumption to operational variables in skidding operations. Although one may readily use statistics such as hourly fuel consumption to relate it to time consumption or productivity models or to regress fuel consumption based on operational characteristics [13], it is likely that these approaches would be less robust as opposed to those developed based on direct measurements taken in a wide range of operational conditions. In addition, many of such statistics may come from observations run in rather limited ranges of extraction distances. Measuring cycle-wise fuel consumption is one of the merits of this study because such data allowed a robust model to be built by relating it to the extraction distance and payload per turn. It turns out that the failure of the number of winched logs and of winching distance to become significant predictors of cycle-wise fuel consumption is surprising in the context of this study. This is because, in detailed analyses and modeling approaches, winching distance was typically found to be an important predictor of time consumption [19]. However, the winching distance of this study was averaged over individual, piece-by-piece distances, and the payloads per turn were quite high as opposed to most of those reported in other skidding studies [31]. Therefore, it is likely that an increased mass per turn of the extracted wood has affected the fuel consumption more as opposed to the time (and fuel) consumption needed to winch the logs piece by piece. This may come from the effect of moving high masses over high distances, which also indicates that the entrepreneurs tend to overload their machines to compensate productivity losses in low-access conditions. To what extent operating with payloads exceeding the machine’s design limits would be a good option for machine maintenance and service life remains to be checked as, for instance, the allowable mass to be extracted by the machine taken into study is of ca. 5 tons; this requirement was met only in 4 of the 39 cases of this study for a reference density of 0.9 t/m3. Moreover, to what extent machine overloading would affect the skid trails, soil, and the remaining trees is of concern. It is likely that repeated high payload extractions on high distances and on the same skid trails will cause significant erosion in time [42]. In terms of fuel consumption, however, this can be beneficial, as the unit fuel consumption would be lower as the payloads per turn increase. From both perspectives, however, and by considering also productivity, a better developed forest road network would contribute to improvements by lowering the unit fuel consumption, increasing productivity and lowering the impact on the soil. In addition, under a more general perspective, it would be better to concentrate the transportation processes on higher capacities because this would result in lowering overall unit fuel consumption and emissions [43]. A similar mechanism would apply herein, where lowering the share of offroad low-payload transportation will not only increase productivity and profitability of operations, but will also contribute positively to saving resources and lowering carbon emissions. This may be applicable to several countries, including Romania and part of the Eastern European countries where road density is still very low [44].

For the used reference data, simulations on efficiency, productivity, and fuel consumption returned values which were very close to the averages yielded by the field study, indicating, therefore, the usefulness of the models shown in Figure 3 and Figure 4. However, from a statistical point of view, only the fuel consumption model has met the assumption of normality in residuals. As such, the prediction intervals of the time consumption models could be less accurate and their results should be interpreted with more caution. The general pattern in the mentioned figures is also consistent with similar processes described in [32]. Excepting the average extraction distance, the most influential factor in productivity simulation was the average payload per turn. Therefore, the value used for this factor may change significantly the outcomes in terms of allure of curves shown in Figure 3. The real-world experiment, on the one hand, has proved that payloads larger than the recommended ones may be extracted without any breakdowns of the machine. However, the design concepts and recommendations limit this payload to a much lower value. As such, it is likely that the value used for simulation would finely resemble the reality, although it could cause machine breakdowns in the long term. Productivity decreased considerably from a reference distance of 200 m to those of 800 and 2000 m, being two and four times lower. Acknowledging that the operational speeds reported in this study are typical for offroad transportation [30] and they may resemble the conditions of typical ground-based extraction operations, the shape of the time consumption models would be preserved. In this scenario, a drop in the average payload size by 1 m3 will lead to a drop in productivity by 13, 14, and 15% at 200, 800, and 2000 m, respectively. For an average payload size in acceptable limits (5 m3), the productivity will be even more sensitive, dropping by 35% for the considered extraction distances.

Fuel consumption increased linearly by the average extraction distance at a magnitude of ca. 7 L per kilometer, which was much higher than that of the unit fuel consumption. However, it reflects only what one can expect to use for different extraction distances, while the unit fuel consumption (L/m3, L/tkm) is a better metric for analysis and comparison. The simulated results fitted well the reference values of the field-collected data, indicating the robustness of the model used. Taking the same values of extraction distance as a reference, for a drop in the payload size of 1 m3, the relative increment in unit fuel consumption (L/m3) will be of 3, 9, and 12%, respectively, while for payload sizes of 5 m3, the increments in unit fuel consumption would be of 11, 35, and 46%, respectively, proving the high sensitivity of this metric to the variations in payload size.

The results of this study are indicative for practice and science, giving an overview on the performance of skidding operations in low-access and low-removal-intensity conditions. They only characterize and fit these specific conditions and further studies should clarify how other silvicultural practices may affect the outcomes of productivity and fuel use in low-access forests. Moreover, extending the sample of data used in modeling could bring the benefits of generating even more robust models [33], an approach which could be considered so as to obtain more reliable results. Until such data or studies will be released, the results of this study may stand for a good approximation of practices and can be further processed for similar conditions to make an idea on variation in these parameters. Such approaches may prove to be of high importance in the current context of finding ways to mitigate climate changes and to increase carbon neutrality and may support the practice of planning, as well as decision making at a strategic level. While the results account for estimations and dependence relations in resources used and their expected outcomes, they do not characterize the environmental impact of low-access forest operations, which should be studied further for those regions characterized by such forestry conditions. A lot of effort has been given, for instance, to quantify the environmental impact of forest operations [13,39,45,46,47,48,49,50,51,52,53,54,55,56], but these studies are typically based on different assumptions in terms of operational conditions, removal intensities, tree sizes, methods, and equipment used. As such, quantifying the environmental impact of low-access forest operations may help understand further which type of forest management practices are better fit to climate neutrality, while models such as those developed in this study may support the advanced simulation and optimization of complex operational settings [57].

5. Conclusions

Skidding performance in low-access and low-removal-intensity forests depends largely on the extraction distances and the payload size. Based on the simulations of this study and taking as a reference an extraction distance of 200 m, productivity decreases two and four times at distances of 800 and 2000, while fuel consumption increases by the same proportions, indicating significant drops in profitability of operations, as well as a higher environmental footprint. Further studies should consider more detailed environmental and economic assessments to clarify to what extent the low-access forest operations burden the environment and economy. Such studies should be integrative and systemic so as to encompass all the components of the wood supply chain and may help extending our understanding on how different forest management practices contribute to climate neutrality and decarbonization.

Author Contributions

Conceptualization, S.A.B.; methodology, S.A.B. and N.K.; validation, S.A.B.; formal analysis, A.-C.M.; investigation, A.-C.M.; resources, S.A.B. and A.-C.M.; data curation, S.A.B. and A.-C.M.; writing—original draft preparation, S.A.B., A.-C.M. and N.K.; writing—review and editing, S.A.B., A.-C.M. and N.K.; supervision, S.A.B.; project administration, S.A.B.; funding acquisition, S.A.B. and A.-C.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Office of the Ministry of Higher Education, Science, Research and Innovation and the Thailand Science Research and Innovation through the Kasetsart University Reinventing University Program 2022. Furthermore, part of this research was funded by the Transilvania University of Brasov, through a grant “Proiectul meu de diplomă” granted to the second author of the study.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the Department of Forest Engineering, Forest Management Planning and Terrestrial Measurements, Faculty of Silviculture and Forest Engineering, Transilvania University of Brasov for providing the equipment needed in the field phase of the study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable forest operations (SFO): A new paradigm in a changing world and climate. Sci. Total Environ. 2018, 634, 1385–1397. [Google Scholar] [CrossRef] [PubMed]

- Heinimann, H.R. Forest operations engineering and management—The ways behind and ahead of a scientific discipline. Croat. J. For. Eng. 2007, 28, 107–121. [Google Scholar]

- FAO. Strategic Framework 2022–2031. Available online: https://www.fao.org/3/cb7099en/cb7099en.pdf. (accessed on 7 January 2023).

- European Commission. New EU Forest Strategy for 2030. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, COM(2021) 572 Final; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- The World Bank. Forests Generate Jobs and Incomes. Available online: https://www.worldbank.org/en/topic/forests/brief/forests-generate-jobs-and-incomes. (accessed on 7 January 2023).

- Jenkins, M.; Schaap, B. Background Analytical Study 1: Forest Ecosystem Services. Global Forest Goals; United Nations Forum on Forest. Available online: https://www.un.org/esa/forests/wp-content/uploads/2018/05/UNFF13_BkgdStudy_ForestsEcoServices.pdf (accessed on 7 January 2023).

- FAO. Forest pathways for green recovery and building inclusive, resilient and sustainable economies. In The State of the World’s Forests 2022; FAO: Rome, Italy, 2022; p. 166. [Google Scholar] [CrossRef]

- Forest Europe. Ministerial Conference on the Protection of Forests in Europe FOREST EUROPE. In State of Europe’s Forests 2020; Liaison Unit Bratislava: Bratislava, Slovakia, 2020. [Google Scholar]

- Picchi, G.; Sandak, J.; Grigolato, S.; Panzacchi, P.; Tognetti, R. Chapter 9, smart harvest operations and timber processing for improved forest management. In Climate-Smart forestry in Mountain Regions; Tognelli, R., Smith, M., Panzacchi, P., Eds.; Springer: Cham, Switzerland, 2022; Volume 40, pp. 317–359. [Google Scholar]

- Rauch, P.; Borz, S.A. Reengineering the Romanian Timber Supply Chain from a Process Management Perspective. Croat. J. Eng. 2020, 41, 85–94. [Google Scholar] [CrossRef]

- Rezapour, S.; Farahani, R.Z.; Dullaertc, W.; De Borger, B. Designing a new supply chain for competition against an existing supply chain. Transport. Res. Part E Logist. Transport. Rev. 2014, 67, 124–140. [Google Scholar] [CrossRef]

- Hiesl, P.; Benjamin, J.G. Applicability of international harvesting equipment productivity studies in Maine, U.S.A.: A literature review. Forests 2013, 4, 898–921. [Google Scholar] [CrossRef]

- Vusić, D.; Šušnjar, M.; Marchi, E.; Spina, R.; Zečić, Ž.; Picchio, R. Skidding operations in thinning and shelterwood cut of mixed stands—Work productivity, energy inputs and emissions. Ecol. Eng. 2013, 61, 216–223. [Google Scholar] [CrossRef]

- Lundbäck, M.; Häggström, C.; Nordfjell, T. Worldwide trends in methods for harvesting and extracting industrial roundwood. Int. J. For. Eng. 2021, 32, 202–215. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Visser, R.; O’Neal, B. A survey of skidder fleet of Central, Eastern and Southern Europe. Eur. J. For. Res. 2021, 140, 901–911. [Google Scholar] [CrossRef]

- Moskalik, T.; Borz, S.A.; Dvorák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdinš, A.; Styranivsky, O. Timber harvesting methods in Eastern European countries: A review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Kluender, R.; Lortz, D.; McCoy, W.; Stokes, B.; Klepac, J. Removal intensity and tree size effects on harvesting cost and profitability. For. Prod. J. 1998, 48, 54–59. [Google Scholar]

- Borz, S.A.; Ignea, G.; Popa, B.; Sparchez, G.; Iordache, E. Estimating time consumption and productivity of roundwood skidding in group shelterwood system—A case study in a broadleaved mixed stand located in reduced accessibility conditions. Croat. J. For. Eng. 2015, 36, 137–146. [Google Scholar]

- Borz, S.A.; Ignea, G.; Popa, B. Modelling and comparing timber winching performance in windthrow and uniform selective cuttings for two Romanian skidders. J. For. Res. 2014, 19, 473–482. [Google Scholar] [CrossRef]

- Borz, S.A.; Dinulica, F.; Birda, M.; Ignea, G.; Ciobanu, V.D.; Popa, B. Time consumption and productivity of skidding Silver fir (Abies alba Mill.) round wood in reduced accessibility conditions: A case study in windthorw salvage logging from Romanian Carpathians. Ann. For. Res. 2013, 56, 363–375. [Google Scholar]

- Mousavi, R. Effect of log length on productivity and cost of Timberjack 450C skidder in the Hyrcanian forest in Iran. J. For. Sci. 2012, 58, 473–482. [Google Scholar] [CrossRef]

- Proto, A.R.; Macri, G.; Visser, R.; Russo, D.; Zimbalatti, G. Comparison of timber extraction productivity between winch and grapple skidding: A case study in Southern Italian Forests. Forests 2018, 9, 61. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Naghdi, R.; Ghajar, I.; Nikooy, M. Time prediction models and cost evaluation of cut-to-length (CTL) harvesting method in a mountainous forest. Small Scale For. 2013, 12, 181–192. [Google Scholar] [CrossRef]

- Behjou, F.K. A techno-economic evaluation of skidding operation by Timberjack 450C and Clark Ranger 666DBS in Caspian forests. J. Food Agric. Environ. 2010, 8, 1020–1023. [Google Scholar] [CrossRef]

- Naghdi, R.; Mohammadi, L. Optimal forest road density based on skidding and road construction costs in Iranian Caspian forests. Casp. J. Environ. Sci. 2009, 7, 79–86. [Google Scholar]

- Behjou, F.K.; Majnounian, B.; Namiranian, M.; Dvořák, J. Time study and skidding capacity of wheeled skidder Timberjack 450C in Caspian forests. J. For. Sci. 2008, 54, 183–188. [Google Scholar] [CrossRef]

- Sabo, A.; Poršinsky, T. Skidding of fir roundwood by Timberjack 240C from selective forests of Gorski Kotar. Croat. J. For. Eng. 2005, 26, 13–27. [Google Scholar]

- Kluender, R.; Lortz, D.; McCoy, W.; Stokes, B.; Klepac, J. Productivity of rubber-tired skidders in southern pine forests. J. For. Prod. 1997, 47, 53–58. [Google Scholar]

- Wang, J.; Long, C.; McNeel, J.; Baumgras, J. Productivity and cost of manual felling and cable skidding in central Appalachian hardwood forests. For. Prod. J. 2004, 54, 45–51. [Google Scholar]

- Borz, S.A.; Marcu, M.V.; Cataldo, M.F. Evaluation of an HSM 208F 14tone HVT-R2 Forwarder prototype under conditions of steep-terrain low-access forests. Croat. J. For. Eng. 2021, 42, 185–200. [Google Scholar] [CrossRef]

- Borz, S.A. A review of the Romanian and international practices in skidding operations. In Proceedings of the XIV World Forestry Congress, Durban, South Africa, 11 September 2015; p. 11. [Google Scholar]

- Borz, S.A.; Mititelu, V.B. Productivity and fuel consumption in skidding roundwood on flat terrains by a Zetor farm tractor in group shelterwood cutting of mixed oak forests. Forests 2022, 13, 1294. [Google Scholar] [CrossRef]

- Acuna, M.; Bigot, M.; Guerra, S.; Hartsough, B.; Kanzian, C.; Kärhä, K.; Lindroos, O.; Magagnotti, N.; Roux, S.; Spinelli, R.; et al. Good Practice Guidelines for Biomass Production Studies; CNR IVALSA Sesto Fiorentino (National Research Council of Italy—Trees and Timber Institute): Sesto Fiorentino, Italy, 2012; p. 52. [Google Scholar]

- Visser, R.; Spinelli, R. Determining the shape of productivity function for mechanized felling and felling-processing. J. For. Res. 2012, 17, 397–402. [Google Scholar] [CrossRef]

- Sokolowski, J.A.; Banks, C.M. (Eds.) Principles of Modeling and Simulation—A Multidisciplinary Approach; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2009; p. 259. [Google Scholar]

- Nicolescu, V.N. Silvicultură. Vol II. Silvotehnică (in Romanian); Aldus Publishing House: Brasov, Romania, 2014; p. 289. [Google Scholar]

- Cataldo, M.F.; Marcu, M.V.; Iordache, E.; Zimbalatti, G.; Proto, A.R.; Borz, S.A. Performance of forwarding operations in biomass recovery from apple orchards. Small-Scale For. 2022, 21, 349–367. [Google Scholar] [CrossRef]

- Björheden, R.; Apel, K.; Shiba, M.; Thompson, M. IUFRO Forest Work Study Nomenclature; Swedish University of Agricultural Science, Department of Operational Efficiency: Grapenberg, Sweden, 1995; p. 16. [Google Scholar]

- Ignea, G.; Ghaffaryian, M.R.; Borz, S.A. Impact of operational factors on fossil energy inputs in motor-manual tree felling and processing: Results of two case studies. Ann. For. Res. 2017, 60, 161–172. [Google Scholar] [CrossRef]

- Real Statistics Using Excel. Available online: https://www.real-statistics.com/multiple-regression/stepwise-regression/ (accessed on 24 October 2022).

- Holzleitner, F.; Stampfer, K.; Visser, R. Utilization rates and cost factors in timber harvesting based on long-term machine data. Croat. J. For. Eng. 2011, 32, 501–508. [Google Scholar]

- Duţă, C.I.; Sălăjan, A.; Borz, S.A. Estimating current state of soil erosion induced by skid trails geometry in mountainous conditions. Environ. Eng. Man. J. 2018, 17, 697–704. [Google Scholar]

- Palander, T.; Haavikko, H.; Kortelainen, E.; Kärhä, K.; Borz, S.A. Improving environmental and energy efficiency in wood transportation for a carbon-neutral forest industry. Forests 2020, 11, 1194. [Google Scholar] [CrossRef]

- Lyons, C.K.; Borz, S.A.; Harvey, C.; Ramantswana, M.; Sakai, H.; Visser, R. Forest roads: Regional perspectives from around the world. Int. J. For. Eng. 2022, 11, 1194. [Google Scholar] [CrossRef]

- Karjalainen, T.; Asikainen, A. Greenhouse gas emissions from the use of primary energy in forest operations and long-distance transportation of timber in Finland. Forestry 1996, 69, 215–228. [Google Scholar] [CrossRef]

- Berg, S.; Lindholm, E.-L. Energy use and environmental impacts of forest operations in Sweden. J. Clean. Prod. 2005, 13, 33–42. [Google Scholar] [CrossRef]

- Markewitz, D. Fossil fuel emissions from silviculture: Impacts on net carbon sequestration in forests. For. Ecol. Manag. 2006, 236, 153–161. [Google Scholar] [CrossRef]

- Picchio, R.; Maesano, M.; Savelli, S.; Marchi, E. Productivity and energy balance in conversion of a Quercus cerris L. coppice stand into a high forest stand in Central Italy. Croat. J. For. Eng. 2009, 30, 15–26. [Google Scholar]

- Magagnotti, N.; Spinelli, R. Financial and energy cost of low-impact wood extraction in environmentally sensitive areas. Ecol. Eng. 2011, 37, 601–606. [Google Scholar] [CrossRef]

- Balimunsi, H.; Grigolato, S.; Picchio, R.; Nyombi, K.; Cavalli, R. Productivity and energy balance of forest plantation harvesting in Uganda. For. Stud. China 2012, 14, 279–282. [Google Scholar] [CrossRef]

- Engel, A.-M.; Wegener, J.; Lange, M. Greenhouse gas emissions of two mechanised wood harvesting methods in comparison with the use of draft horses for logging. Eur. J. Forest. Res. 2012, 131, 1139–1149. [Google Scholar] [CrossRef]

- Maesano, M.; Picchio, R.; Lo Monaco, A.; Neri, F.; Lasserre, B.; Marchetti, M. Productivity and energy consumption in logging operation in a Cameroonian tropical forest. Ecol. Eng. 2013, 57, 149–153. [Google Scholar] [CrossRef]

- Ezzati, S.; Tavankar, F.; Ghaffariyan, M.R.; Venanzi, R.; Latterini, F.; Picchio, R. The impact of weather and slope conditions on the productivity, cost, and GHG emissions of a ground-based harvesting operation in mountain hardwoods. Forests 2021, 12, 1612. [Google Scholar] [CrossRef]

- Klvač, R.; Fischer, R.; Skoupy, A. Energy use of and emissions from operation phase of a medium distance cableway system. Croat. J. For. Eng. 2013, 34, 265–272. [Google Scholar]

- González-García, S.; Moreira, M.T.; Dias, A.C.; Mola-Yudego, B. Cradle-to-gate Life Cycle Assessment of forest operations in Europe: Environmental and energy profiles. J. Clean. Prod. 2014, 66, 188–198. [Google Scholar] [CrossRef]

- Berendt, F.; Fortin, M.; Suchomel, C.; Schweier, J. Productivity, costs, and selected environmental impacts of remote-controlled mini forestry crawlers. Forests 2018, 9, 591. [Google Scholar] [CrossRef]

- Ezzati, S.; Najafi, A.; Yaghini, M.; Hashemi, A.A.; Bettinger, P. An optimization model to solve skidding problem in steep slope terrain. J. For. Econ. 2015, 21, 250–268. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).