Modification and Application of Bamboo-Based Materials: A Review—Part I: Modification Methods and Mechanisms

Abstract

:1. Introduction

2. Thermal Treatment

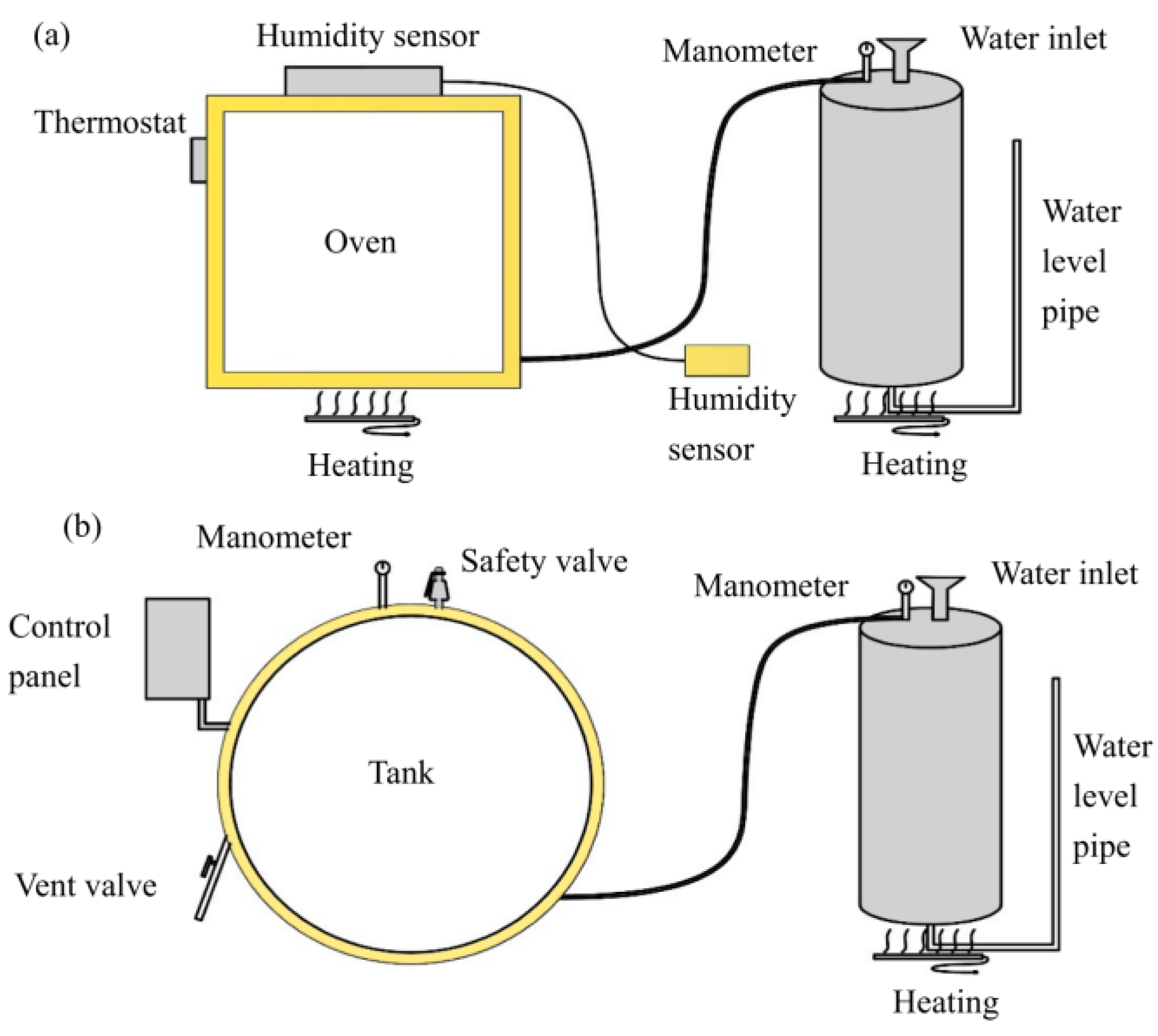

2.1. Steam Heat Treatment

2.2. Oil Heat Treatment

2.3. Air or Inert Gas Heat Treatment

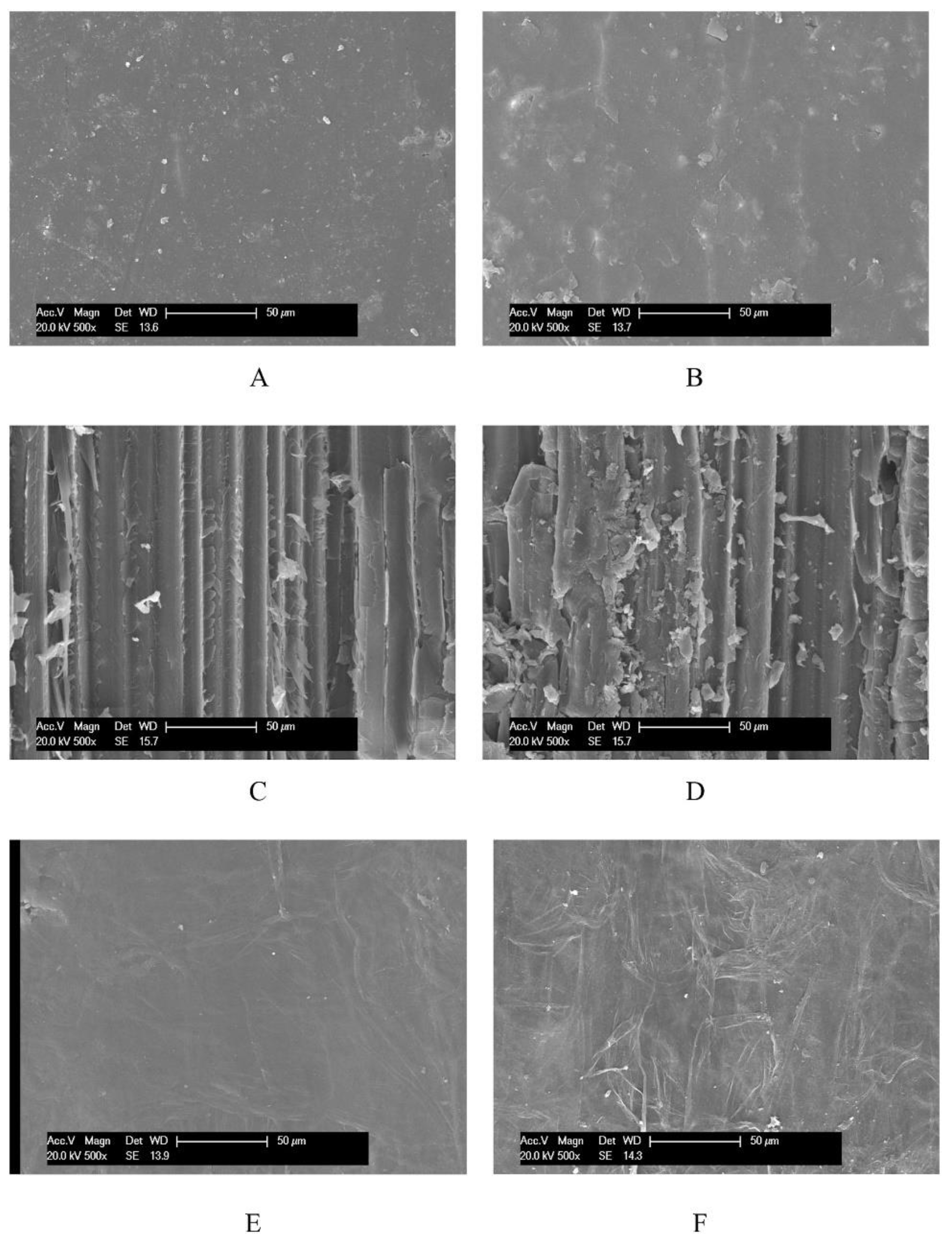

3. Chemical Modification

4. Impregnation Modification

5. Plasma Modification

6. Other Modifications

6.1. Enzymatic Modification

6.2. Microwave Modification

6.3. Nanomaterial Modification

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zuo, Y.Q.; Feng, J.; Soyol-Erdene, T.O.; Wei, Z.; Hu, T.; Zhang, Y.; Tang, W.W. Recent advances in wood-derived monolithic carbon materials: Synthesis approaches, modification methods and environmental applications. Chem. Eng. J. 2023, 463, 142332. [Google Scholar] [CrossRef]

- Aizuddin, K.; Lai, K.S.; Baharum, N.A.; Yong, W.T.L.; Hoon, L.N.; Hamid, M.Z.A.; Cheng, W.H.; Abdullah, J.O. Bamboo for biomass energy production. Bioresources 2023, 18, 2386–2407. [Google Scholar] [CrossRef]

- Liu, L.J.; Yuan, Z.Q.; Fan, X.K.; Pan, C.Q.; Li, X.Y. A review of interfacial bonding mechanism of bamboo fiber reinforced polymer composites. Cellulose 2022, 29, 83–100. [Google Scholar] [CrossRef]

- Kalderis, D.; Seifi, A.; Trang, T.K.; Tsubota, T.; Anastopoulos, I.; Manariotis, I.; Pashalidis, I.; Khataee, A. Bamboo-derived adsorbents for environmental remediation: A review of recent progress. Environ. Res. 2023, 224, 115533. [Google Scholar] [CrossRef]

- Dlamini, L.C.; Fakudze, S.; Makombe, G.G.; Muse, S.; Zhu, J.G. Bamboo as a valuable resource and its utilization in historical and modern-day china. Bioresources 2022, 17, 1926–1938. [Google Scholar] [CrossRef]

- Iroegbu, A.O.C.; Ray, S.S. Bamboos: From bioresource to sustainable materials and chemicals. Sustainability 2021, 13, 12200. [Google Scholar] [CrossRef]

- Ding, Y.; Pang, Z.Q.; Lan, K.; Yao, Y.; Panzarasa, G.; Xu, L.; Lo Ricco, M.; Rammer, D.R.; Zhu, J.Y.; Hu, M.; et al. Emerging engineered wood for building applications. Chem. Rev. 2023, 123, 1843–1888. [Google Scholar] [CrossRef]

- Fang, C.H.; Jiang, Z.H.; Sun, Z.J.; Liu, H.R.; Zhang, X.B.; Zhang, R.; Fei, B.H. An overview on bamboo culm flattening. Build. Mater. 2018, 171, 65–74. [Google Scholar] [CrossRef]

- Dauletbek, A.; Li, H.; Xiong, Z.; Lorenzo, R. A review of mechanical behavior of structural laminated bamboo lumber. Sustain. Struct. 2021, 1, 116898. [Google Scholar] [CrossRef]

- Mimendi, L.; Lorenzo, R.; Li, H. An innovative digital workflow to design, build and manage bamboo structures. Sustain. Struct. 2022, 2, 11. [Google Scholar] [CrossRef]

- Su, J.; Li, H.; Xiong, Z.; Lorenzo, R. Structural design and construction of an office building with laminated bamboo lumber. Sustain. Struct. 2021, 1, 10. [Google Scholar] [CrossRef]

- Xue, X.; Zhou, W.; Sayed, U.; Feng, Z.; Li, H.; Li, Y.; Huang, Z.; Ashraf, M.; Lorenzo, R. Design and construction of “Bamboo Cubic” facade with laminated bamboo lumber. Sustain. Struct. 2023, 3, 30. [Google Scholar] [CrossRef]

- Dauletbek, A.; Xue, X.; Shen, X.; Li, H.; Feng, Z.; Lorenzo, R.; Liu, K.; Zea Escamilla, E.; Yao, L.; Zheng, X. Lightweight bamboo structures—Report on 2021 international collaboration on bamboo construction. Sustain. Struct. 2023, 3, 25. [Google Scholar] [CrossRef]

- Alejandro Méndez Quintero, M.; Patricia Takeuchi Tam, C.; Li, H. Structural analysis of a guadua bamboo bridge in Colombia. Sustain. Struct. 2022, 2, 20. [Google Scholar] [CrossRef]

- Su, M.L.; Zhang, R.; Li, J.P.; Jin, X.B.; Zhang, X.F.; Qin, D.C. Tailoring growth of MOF199 on hierarchical surface of bamboo and its antibacterial property. Cellulose 2021, 28, 11713–11727. [Google Scholar] [CrossRef]

- Huang, X.D.; Shupe, T.F.; Hse, C.Y. Study of moso bamboo’s permeability and mechanical properties. Mater. Res. 2015, 4, 130–138. [Google Scholar] [CrossRef]

- Arman, N.S.N.; Chen, R.S.; Ahmad, S. Review of state-of-the-art studies on the water absorption capacity of agricultural fiber-reinforced polymer composites for sustainable construction. Constr. Build. Mater. 2021, 302, 124174. [Google Scholar] [CrossRef]

- Li, Z.Z.; Luan, Y.; Hu, J.B.; Fang, C.H.; Liu, L.T.; Ma, Y.F.; Liu, Y.; Fei, B.H. Bamboo heat treatments and their effects on bamboo properties. Constr. Build. Mater. 2022, 331, 127320. [Google Scholar] [CrossRef]

- Chen, G.W.; Luo, H.Y. Asymmetric flexural process and fracture behaviors of natural bamboo node with gradient discontinuous fibers. Compos. Commun. 2021, 24, 100647. [Google Scholar] [CrossRef]

- Wang, X.Z.; Song, L.L.; Cheng, D.L.; Liang, X.Y.; Xu, B. Effects of saturated steam pretreatment on the drying quality of moso bamboo culms. Eur. J. Wood Wood Prod. 2019, 77, 949–951. [Google Scholar] [CrossRef]

- Song, W.; Zhang, S.B.; Fei, B.H.; Zhao, R.J. Mussel-inspired polydopamine modification of bamboo flour for superior interfacial compatibility of bamboo plastic composites: Influence of oxidant type. Cellulose 2021, 28, 8567–8580. [Google Scholar] [CrossRef]

- Huang, J.K.; Young, W.B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. B Eng. 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Du, J.; Yang, K.L.; Yuan, Z.Q.; Liu, Z.M.; Li, X.Y.; Liu, S.J.; Li, C.C.; Meng, S.T.; Wu, R.M. Effect of physical treatment methods on the properties of natural bamboo materials. Constr. Build. Mater. 2023, 394, 132170. [Google Scholar] [CrossRef]

- Feng, Q.M.; Huang, Y.H.; Ye, C.Y.; Fei, B.H.; Yang, S.M. Impact of hygrothermal treatment on the physical properties and chemical composition of Moso bamboo (Phyllostachys edulis). Holzforschung 2021, 75, 614–625. [Google Scholar] [CrossRef]

- Huang, S.S.; Jiang, Q.F.; Yu, B.; Nie, Y.J.; Ma, Z.Q.; Ma, L.F. Combined chemical modification of bamboo material prepared using vinyl acetate and methyl methacrylate: Dimensional stability, chemical structure, and dynamic mechanical properties. Polymers 2019, 11, 1651. [Google Scholar] [CrossRef]

- Yang, T.H.; Lee, C.H.; Lee, C.J.; Cheng, Y.W. Effects of different thermal modification media on physical and mechanical properties of moso bamboo. Constr. Build. Mater. 2016, 119, 251–259. [Google Scholar] [CrossRef]

- Li, W.J.; Liu, M.H.; Zhai, H.B.; Wang, H.K.; Yu, Y. Preparing highly durable bamboo materials via bulk furfurylation. Constr. Build. Mater. 2020, 262, 120726. [Google Scholar] [CrossRef]

- Wu, C.J.; Zhou, S.F.; Li, R.G.; Wang, D.Q.; Zhao, C.S. Reactivity Improvement of Bamboo Dissolving Pulp by Xylanase Modification. Bioresources 2015, 10, 4970–4977. [Google Scholar] [CrossRef]

- Fu, J.J.; Li, X.Q.; Gao, W.D.; Wang, H.B.; Cavaco-Paulo, A.; Silva, C. Bio-processing of bamboo fibres for textile applications: A mini review. Biocatal. Biotransformation 2012, 30, 141–153. [Google Scholar] [CrossRef]

- Chen, H.; Wu, J.Y.; Shi, J.J.; Zhang, W.F.; Wang, H.K. Effect of alkali treatment on microstructure and thermal stability of parenchyma cell compared with bamboo fiber. Ind. Crops Prod. 2021, 164, 113380. [Google Scholar] [CrossRef]

- De, J.; Baxi, R.N. Experimental investigation and analysis of mercerized and citric acid surface treated bamboo fiber reinforced composite. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 12154. [Google Scholar] [CrossRef]

- Rocky, B.P.; Thompson, A.J. Production of natural bamboo fibers-1: Experimental approaches to different processes and analyses. J. Text. Inst. 2018, 109, 1381–1391. [Google Scholar] [CrossRef]

- He, Z.B.; Yang, F.; Yi, S.L.; Gao, J.M. Effect of ultrasound pretreatment on vacuum drying of Chinese catalpa wood. Dry. Technol. 2012, 30, 1750–1755. [Google Scholar] [CrossRef]

- Yuan, T.C.; Liu, J.; Hu, S.H.; Wang, X.Z.; Liu, X.M.; Li, Y.J. Multi-scale characterization of the effect of saturated steam on the macroscale properties and surface changes of moso bamboo. Mater. Express 2021, 11, 740–748. [Google Scholar] [CrossRef]

- Han, X.; Lou, Z.C.; Yuan, C.L.; Wu, X.W.; Liu, J.; Weng, F.J.; Li, Y.J. Study on the effect of two-step saturated steam heat treatment process on the properties of reconstituted bamboo. J. Renew. Mater. 2022, 10, 3313–3334. [Google Scholar] [CrossRef]

- Wang, X.Z.; Cheng, D.L.; Huang, X.N.; Song, L.L.; Gu, W.L.; Liang, X.Y.; Li, Y.J.; Xu, B. Effect of high-temperature saturated steam treatment on the physical, chemical, and mechanical properties of moso bamboo. J. Wood Sci. 2020, 66, 52. [Google Scholar] [CrossRef]

- Manalo, R.D.; Acda, M.N. Effects of hot oil treatment on physical and mechanical properties of three species of philippine bamboo. J. Trop. For. Sci. 2009, 21, 19–24. [Google Scholar]

- Li, T.; Cheng, D.L.; Wålinder, M.E.P.; Zhou, D.G. Wettability of oil heat-treated bamboo and bonding strength of laminated bamboo board. Ind. Crops Prod. 2015, 69, 15–20. [Google Scholar] [CrossRef]

- Tang, T.; Chen, X.F.; Zhang, B.; Liu, X.M.; Fei, B.H. Research on the physico-mechanical properties of moso bamboo with thermal treatment in tung oil and its influencing factors. Materials 2019, 12, 599. [Google Scholar] [CrossRef]

- Hao, X.M.; Wang, Q.Y.; Wang, Y.H.; Han, X.; Yuan, C.L.; Cao, Y.; Lou, Z.C.; Li, Y.J. The effect of oil heat treatment on biological, mechanical and physical properties of bamboo. J. Wood Sci. 2021, 67, 26. [Google Scholar] [CrossRef]

- Piao, X.X.; Zhao, Z.B.; Guo, H.X.; Wang, Z.; Jin, C.D. Improved properties of bamboo by thermal treatment with wood wax oil. Colloids Surf. A Physicochem. Eng. Asp. 2022, 643, 128807. [Google Scholar] [CrossRef]

- Lee, C.H.; Yang, T.H.; Cheng, Y.W.; Lee, C.J. Effects of thermal modification on the surface and chemical properties of moso bamboo. Constr. Build. Mater. 2018, 178, 59–71. [Google Scholar] [CrossRef]

- Deng, L.P.; Chen, F.M.; Ren, X.Y.; Jiang, Z.H. An environmentally friendly and efficient method to improve the acoustic vibration performance of bamboo for musical instruments: Nitrogen-protected heat treatment. Ind. Crops Prod. 2022, 188, 115554. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Yu, Y.L.; Yu, W.J. Effect of thermal treatment on the physical and mechanical properties of phyllostachys pubescen bamboo. European Eur. J. Wood Wood Prod. 2013, 71, 61–67. [Google Scholar] [CrossRef]

- Nguyen, C.T.; Wagenführ, A.; Phuong, L.X.; Dai, V.H.; Bremer, M.; Fischer, S. The effects of thermal modification on the properties of two vietnamese bamboo species, part I: Effects on physical properties. Bioresources 2012, 7, 5355–5366. [Google Scholar] [CrossRef]

- Li, W.J.; Chen, L.F.; Li, Y.X.; Li, X.W. Bamboo modification with 1,3-dimethylol-4,5-dihydroxyethyleneurea (DMDHEU) catalyzed by maleic anhydride. J. Wood Chem. Technol. 2020, 40, 126–135. [Google Scholar] [CrossRef]

- Wu, H.P.; Yang, X.S.; Rao, J.; Zhang, Y.; Sun, F.L. Improvement of bamboo Properties via in situ construction of polyhydroxyethyl methylacrylate and polymethyl methylacrylate networks. Bioresources 2018, 13, 6–14. [Google Scholar] [CrossRef]

- Yao, X.L.; Peng, R.; Du, C.G.; Hua, Y.T.; Zhang, J.J.; Huang, Q.L.; Liu, H.Z. A two-step method for fabricating bamboo culm coated with MgAl-LDHs and its fire resistance properties. Bioresources 2019, 14, 5150–5161. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, W.F.; Wang, X.H.; Wang, H.K.; Wu, Y.; Zhong, T.H.; Fei, B.H. Effect of alkali treatment on wettability and thermal stability of individual bamboo fibers. J. Wood Sci. 2018, 64, 398–405. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, L.Y.; Xiao, Z.H.; Li, X.J.; Fan, Y.H.; Li, C.Z. Preparation and properties of bamboo/polymer composites enhanced by in situ polymerization of furfuryl alcohol. Mater. Express 2019, 9, 712–722. [Google Scholar] [CrossRef]

- Chen, S.Q.; Li, Q.; Liu, C.L.; Du, C.G.; Shan, Y.Y.; Yin, W.X.; Yang, F.; Shao, Y.R.; Wang, Y.T. Process and anti-mildew properties of tea polyphenol-modified citral-treated bamboo. Molecules 2022, 27, 7549. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.W.; Zhang, H.L.; Peng, D.D.; Wang, H.; Han, S.B.; Zhang, Y.; Wu, X.X.; Sun, F.L. In-situ cinnamaldehyde modification confers bamboo long-acting mold resistance and its reaction mechanisms. Ind. Crops Prod. 2023, 192, 116059. [Google Scholar] [CrossRef]

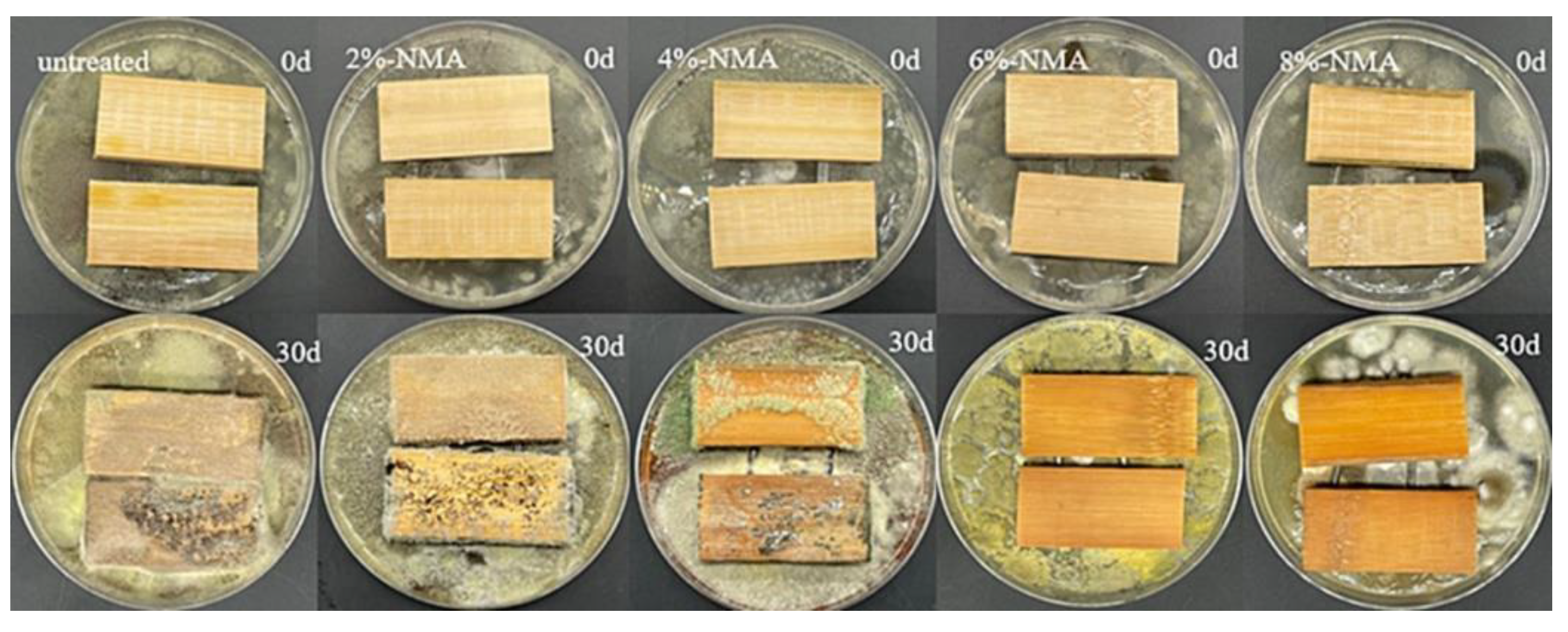

- Sun, J.Y.; Lin, X.Y.; Qiu, Y.H.; Wang, R.Y.; Zhang, Y.F.; Hu, C.S.; Zhang, W.W. In situ polymerization of N-methylol acrylamide (NMA) for bamboo anti-mold modification. Constr. Build. Mater. 2023, 363, 129887. [Google Scholar] [CrossRef]

- Dong, Y.M.; Liu, X.Y.; Liu, J.J.; Yan, Y.T.; Liu, X.R.; Wang, K.L.; Li, J.Z. Evaluation of anti-mold, termite resistance and physical-mechanical properties of bamboo cross-linking modified by polycarboxylic acids. Constr. Build. Mater. 2021, 272, 121953. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, Z.; Xiao, H.L.; Chen, Z. Tensile properties of surface modified bamboo slices coated with epoxy resin considering the corrosion of acid and alkali environment. Wood Res. 2021, 66, 183–194. [Google Scholar] [CrossRef]

- Hung, K.C.; Wu, J.H. Mechanical and interfacial properties of plastic composite panels made from esterified bamboo particles. J. Wood Sci. 2010, 56, 216–221. [Google Scholar] [CrossRef]

- Weng, B.B.; Wang, Z.G.; Wang, F.L.; Xu, R.M.; Cheng, D.; Zhang, K.T.; Hong, L.; Guo, Y.; Chen, Y.X. Synergistic effect of luffa seed oil and microwave treatment on the physicochemical properties of bamboo slices. Ind. Crops Prod. 2023, 192, 116033. [Google Scholar] [CrossRef]

- Yang, X.; Huang, Y.H.; Ye, C.Y.; Lin, X.Y.; Su, N.; Fei, B.H. Improving the dimensional stability of round bamboo by environment-friendly modified rosin. Constr. Build. Mater. 2023, 365, 130078. [Google Scholar] [CrossRef]

- Weng, B.B.; Xu, K.K.; Yan, B.; Zhang, Z.; Li, C.Y.; Tan, Y.Q.; Zhang, K.T.; Lv, Y.; Wang, F.L.; Guo, Y.; et al. Microcapsules of chitosan-loaded luffa seed oil for improving the mold-resistance of bamboo. Ind. Crops Prod. 2023, 199, 116772. [Google Scholar] [CrossRef]

- Jiang, J.; Han, S.B.; Ren, X.; Wang, H.; Yu, H.W.; Sun, F.L. Enhanced durability of round bamboo treated with copper naphthenate under heat-cold impregnation. Royal Soc. Open Sci. 2022, 9, 220247. [Google Scholar] [CrossRef]

- Rao, J.; Jiang, J.; Prosper, N.K.; Yang, X.S.; Liu, T.S.; Cai, W.; Wang, H.; Sun, F.L. Combination of polyethylene glycol impregnation and paraffin heat treatment to protect round bamboo from cracking. R. Soc. Open Sci. 2019, 6, 190105. [Google Scholar] [CrossRef] [PubMed]

- Su, N.; Fang, C.H.; Zhou, H.; Tang, T.; Zhang, S.Q.; Fei, B.H. Hydrophobic treatment of bamboo with rosin. Constr. Build. Mater. 2021, 271, 121507. [Google Scholar] [CrossRef]

- Yu, H.L.; Du, C.G.; Liu, H.Z.; Wei, J.G.; Zhou, Z.X.; Huang, Q.L.; Yao, X.L. Preparation and characterization of bamboo strips impregnation treated by silver-loaded thermo-sensitive nanogels. Bioresources 2017, 12, 8390–8401. [Google Scholar] [CrossRef]

- Sun, C.W.; Liu, A.J.; Du, G. Plasma treatment of bamboo fibers on the tribological property of polyimide composite filled with graphite. Surf. Interface Anal. 2018, 50, 234–239. [Google Scholar] [CrossRef]

- Wu, J.F.; Yuan, H.M.; Wang, W.; Wu, Q.R.; Guan, X.; Lin, J.G.; Li, J.Q. Development of laminated bamboo lumber with high bond strength for structural uses by O2 plasma. Constr. Build. Mater. 2021, 269, 121269. [Google Scholar] [CrossRef]

- Rao, J.P.; Bao, L.X.; Wang, B.W.; Fan, M.Z.; Feo, L. Plasma surface modification and bonding enhancement for bamboo composites. Compos. B Eng. 2018, 138, 157–167. [Google Scholar] [CrossRef]

- Peng, L.H.; Guo, R.H.; Lan, J.W.; Jiang, S.X.; Wang, X.; Li, C.; Li, J. Synthesis of silver nanoparticles on bamboo pulp fabric after plasma pretreatment. J. Mater. Sci. Mater. Electron. 2016, 27, 5925–5933. [Google Scholar] [CrossRef]

- Sun, H.X.; Li, X.H.; Li, H.T.; Hui, D.; Gaff, M.; Lorenzo, R. Nanotechnology application on bamboo materials: A review. Nanotechnol. Rev. 2022, 11, 1670–1695. [Google Scholar] [CrossRef]

- Jin, C.D.; Yao, Q.F.; Li, J.P.; Fan, B.T.; Sun, Q.F. Fabrication, superhydrophobicity, and microwave absorbing properties of the magnetic γ-Fe2O3/bamboo composites. Mater. Des. 2015, 85, 205–210. [Google Scholar] [CrossRef]

- Paul, D.; Gaff, M.; Tesarová, D.; Hui, D.; Li, H.T. Recent advancements in nanotechnology application on wood and bamboo materials: A review. Nanotechnol. Rev. 2023, 12, 20220528. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, R.; Guo, Q.; Xu, G.; Zhang, L.; Sun, P.; Cao, Y.; Hu, S.L. The use of newly isolated fungal cultures for the selective delignification of bamboo culms. Front. Bioeng. Biotechnol. 2023, 11, 1265420. [Google Scholar] [CrossRef] [PubMed]

- Verma, S.; Hashmi, S.A.R.; Mili, M.; Hada, V.; Prashant, N.; Naik, A.; Rathore, S.K.S.; Srivastava, A.K. Extraction and applications of lignin from bamboo: A critical review. Eur. J. Wood Wood Prod. 2021, 79, 1341–1357. [Google Scholar] [CrossRef]

- Chen, W.H.; Chu, Y.S.; Lee, W.J. Influence of bio-solution pretreatment on the structure, reactivity and torrefaction of bamboo. Energy Convers. Manag. 2017, 141, 244–253. [Google Scholar] [CrossRef]

- El-Khatib, H.S.; Badr, A.A.; Diyab, W.A.; Atia, R.M. Part I: Enzymatic treatment of Bamboo, Bamboo/Cotton knitted fabric using brewer’s yeast suspension. Alex. Eng. J. 2019, 58, 819–825. [Google Scholar] [CrossRef]

- Liu, L.F.; Cheng, L.D.; Huang, L.Q.; Yu, J.Y. Enzymatic treatment of mechanochemical modified natural bamboo fibers. Fibers Polym. 2012, 13, 600–605. [Google Scholar] [CrossRef]

- Lv, H.F.; Yang, S.; Zhu, Y.X.; Shu, X.; Cao, W.S.; Xu, B.; Fei, B.H. Effects of microwave drying on the cell wall structures of round bamboo. Bioresources 2023, 18, 4071–4084. [Google Scholar] [CrossRef]

- Lv, H.F.; Lian, C.P.; Xu, B.; Shu, X.; Yang, J.; Fei, B.H. Effects of microwave-assisted drying on the drying shrinkage and chemical properties of bamboo stems. Ind. Crops Prod. 2022, 187, 115547. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, S.L.; Wang, Z.W.; Ji, N.; Li, D.; Wu, Y.Q. Preparation of bamboo-epoxy resin materials with microwave assistance. J. Mater. Res. Technol. 2022, 18, 3266–3272. [Google Scholar] [CrossRef]

- Rai, R.; Ranjan, R.; Kant, C.; Ghosh, U.U.; Dhar, P. Environmentally benign partially delignified and microwave processed bamboo-based drinking straws. Adv. Sustain. Syst. 2023, 7, 2300057. [Google Scholar] [CrossRef]

- Sun, F.B.; Yu, Y.; Jiang, Z.H.; Ren, H.Q.; Wang, G.; Liu, X.E. Nano TiO2 modification of bamboo and its antibacterial and mildew resistance performance. Spectrosc. Spect. Anal. 2010, 30, 1056–1060. [Google Scholar]

- Wang, Y.Y.; Li, Y.Q.; Xue, S.S.; Zhu, W.B.; Wang, X.Q.; Huang, P.; Fu, S.Y. Superstrong, Lightweight, and Exceptional Environmentally Stable SiO2@GO/Bamboo Composites. ACS Appl. Mater. Interfaces 2022, 14, 7311–7320. [Google Scholar] [CrossRef] [PubMed]

- Ba, Z.Y.; Luo, H.Y.; Guan, J.; Luo, J.; Gao, J.J.; Wu, S.J.; Ritchie, R.O. Robust flexural performance and fracture behavior of TiO2 decorated densified bamboo as sustainable structural materials. Nat. Commun. 2023, 14, 1234. [Google Scholar] [CrossRef] [PubMed]

- Tang, A.R.; Huang, Y.Q.; Zhang, W.; Yu, Y.; Yang, Y.; Yuan, Z.R.; Wang, X.Z. Effect of the nano-titanium dioxide (nano-TiO2) coating on the photoaging properties of thermally treated bamboo. Wood Mater. Sci. Eng. 2022, 17, 895–904. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; Yan, N.; Lou, Z.; Jiang, X.; Zhang, X.; Chen, S.; Xu, R.; Liu, C.; Xu, L. Modification and Application of Bamboo-Based Materials: A Review—Part I: Modification Methods and Mechanisms. Forests 2023, 14, 2219. https://doi.org/10.3390/f14112219

Zheng Z, Yan N, Lou Z, Jiang X, Zhang X, Chen S, Xu R, Liu C, Xu L. Modification and Application of Bamboo-Based Materials: A Review—Part I: Modification Methods and Mechanisms. Forests. 2023; 14(11):2219. https://doi.org/10.3390/f14112219

Chicago/Turabian StyleZheng, Zhiyu, Nina Yan, Zhichao Lou, Xizhi Jiang, Xiaomei Zhang, Shan Chen, Rui Xu, Chun Liu, and Lei Xu. 2023. "Modification and Application of Bamboo-Based Materials: A Review—Part I: Modification Methods and Mechanisms" Forests 14, no. 11: 2219. https://doi.org/10.3390/f14112219

APA StyleZheng, Z., Yan, N., Lou, Z., Jiang, X., Zhang, X., Chen, S., Xu, R., Liu, C., & Xu, L. (2023). Modification and Application of Bamboo-Based Materials: A Review—Part I: Modification Methods and Mechanisms. Forests, 14(11), 2219. https://doi.org/10.3390/f14112219