Abstract

Black locust is a fast-growing deciduous tree species with multiple industrial purposes due to its valuable traits. However, the heterogeneity of colour distribution between sapwood and heartwood limits its application. Thermal modification is an environment-friendly technology for improving various wood properties, especially dimensional stability, decay resistance, and colour homogeneity. In this work, black locust (Robinia pseudoacacia L.) wood samples were thermally modified at temperatures of 160, 180, and 210 °C. Extractives and main wood components were analysed by wet chemical methods, colour was measured by spectrometry, and structural changes by Fourier transform infrared spectroscopy. The obtained results show that the darkening of black locust wood, unlike other wood species of the temperate zone, is mainly caused by changes in extractives. Their content decreases during thermal treatment, but new chromophores are formed, especially in quinones. Degradation of hemicelluloses and the partial degradation of cellulose also contribute to colour changes. At higher temperatures, condensation reactions can occur in lignin, leading to the formation of some chromophores. Statistical analysis confirmed that temperature can be considered a very significant factor affecting the colour of the wood surface.

1. Introduction

Nowadays, wood modification is defined as a process implemented to improve the physical, mechanical, or aesthetic properties of sawn timber, veneer or wood particles used in the fabrication of wood composites, and other wood-based materials. This process produces a material that can be disposed of at the end of the life cycle of a product cycle without presenting any environmental hazards greater than those associated with the disposal or combustion of unmodified wood [1,2]. Thermal modification is an environment-friendly technology for improving various wood properties, especially dimensional stability, decay resistance, and colour homogeneity. Colour is one of the most important properties for consumers, and the probability of changing the natural colour of wood without chemicals is important for some markets. An attractive darker colour is an important advantage of heat-treated wood. The variation in colour of the heat-treated wood is influenced by the heterogeneous structure of wood and the different technologies that can be applied [3,4]. Moreover, colour can serve as a quality indicator for industrially manufactured ThermoWood [5].

Thermally modified wood becomes a darker brown colour; however, due to UV light, it turns silvery grey. In some cases, colour is a key factor in choosing a particular wood, as the aesthetic aspect often prevails in some end uses. Darkening can be an essential advantage of its heating, which gives the wood a more beneficial aspect in some territories where exotic wood is not found. The darker shade imparted to wood by heat treatment is due to the production of coloured degradation products from hemicelluloses [6] and extractives [7]. Patzelt et al. [8] suggested that colour change could also be used as a categorization method for thermally treated wood, as it has a considerable relationship with treatment intensity [9,10], both modulus of elasticity and bending strength [11], as well as the thermal process used. In addition, chemical, mechanical, and colour traits of thermally modified spruce wood showed close relationships, and therefore they can be used for their mutual predictions [12].

The essence of the colour change is complicated, as all the main wood components, including extractives, can contribute to the change. The colour of wood can be changed by modifying the wood structure’s main components (cellulose, hemicellulose, and lignin), mainly due to heat, humidity, light, or UV radiation [13]. Matsuo et al. [14] reported that the darker colour of heat-treated wood was attributed to the formation of degradation products from hemicelluloses, changes in extractives, and the formation of oxidation products such as quinones. The colour of thermally modified wood also depends on its origin, and heating conditions including temperature, moisture content, and presence or absence of oxygen.

Black locust (Robinia pseudoacacia L.), a fast-growing deciduous tree species, is a kind of quality wood of multiple industrial purposes due to its valuable traits of stiffness, wear resisting, and high basic density. However, the heterogeneity of colour distribution between sapwood and heartwood limits its application [15,16].

Black locust is an economically important species as a fast-growing tree producing valuable timber. Today, its wood is used to make furniture, gardens, children’s equipment, energy fuel, and as a source for biorefineries based on the production of soluble sugars and lignin [17,18]. This wood species is aboriginal to eastern North America. Its eastern range is centred on the Appalachian Mountains and extends from central Pennsylvania and southern Ohio to northeastern Alabama, northern Georgia, and northwest South Carolina. The western section of its native range includes parts of Missouri, Arkansas, and Oklahoma, and populations also exist in Indiana and Kentucky. Black locust was first introduced to Europe in the early 17th century, and since then, it has been widely introduced to temperate Asia, Australia, and New Zealand, northern and southern Africa, and temperate South America [19]. Black locust is widespread across Europe, occurring from Sicily in Italy to South Norway and longitudinally from the Portugal littoral regions up to the Caucasus. Currently, it occurs in 42 European countries, for example, 400,000 ha in Hungary, 200,000 ha in France, 250,000 ha in Romania, and 230,000 ha in Italy [20].

As the use of thermally treated wood continues to increase, many research works are focused on its physical, mechanical, and chemical changes, including colour ones. Unlike other trees of the temperate zone (spruce, pine, birch, aspen, ash, etc.), the changes in thermal treatment of black locust wood are not sufficiently investigated.

This study therefore aimed to investigate the effect of temperature on black locust chemical and colour changes during heat treatment for making products with desirable surface colour. Since this tree species is very easily available in the territory of Central Europe, thanks to this treatment, it is possible to replace exotic ones with it. Due to the fact that the heat treatment of wood leads to a deterioration of its strength, it is not recommended to use it for load-bearing and heavily mechanically stressed structural elements.

2. Materials and Methods

2.1. Samples Preparation

Black locust (Robinia pseudoacacia L.) wood specimens (200 mm × 100 mm × 20 mm; longitudinal × tangential × radial) were air conditioned (RH 65 ± 3% and temperature 20 ± 2 °C) to an equilibrium moisture content (EMC) of 12%. Forty samples were divided into four groups. Three groups were thermally modified according to the ThermoWood process using three peak temperatures for 3 h (160, 180, and 210 °C); the fourth group without modification was left as a reference and denoted as “20 °C” [21,22]. All samples were then mechanically disintegrated and milled using a POLYMIX PX-MFC 90D laboratory mill (Kinematica, Luzern, Switzerland) and dried (4 h at 103 ± 2 °C).

2.2. Chemical Analyses

The fraction with a particle size of 0.5–1.0 mm was extracted in the Soxhlet apparatus (Sigma-Aldrich, Munich, Germany) according to ASTM D1107-21 [23]. The lignin content was determined according to the National Renewable Energy Laboratory (NREL) procedure [24], cellulose according to the Seifert’s method [25], and the holocellulose according to Wise et al. [26]. The hemicelluloses were determined by subtracting cellulose content from holocellulose.

2.3. Colour Measurement

The colour was measured using a benchtop-type Spectrophotometer CM-5 (Konica Minolta, Japan) with a wavelength resolution of 10 nm. The measurement spot diameter of 3 mm was selected on the top of the spectrophotometer according to dimensions of specimen’s surfaces prior to colour measurement. The spectrophotometer was calibrated prior each measurement according to the procedure recommended by the producer. The white standard was built in the spectrophotometer. The whole calibration was guided by a computer using the Colour Data Software CM-S100W SpectraMagicTNNX (Konica Minolta, Osaka, Japan). The reflectance spectrum was measured under illuminant D65 with specular component included. The 2°-degree standard observer was set on prior to computation of colour coordinates. The spectrophotometer provided the three parameters of CIE L*a*b* colour space and two parameters of chromaticity diagram among others. The provided lightness L*, parameter a* and b*, also served for computing polar coordinates of CIE L*a*b* colour space: saturation Cab and hue hab. The change of colour was computed according to total colour difference formula:

where index of 1 denotes target reference (unmodified sample) and of 2 denotes sample (modified sample).

The reflectance spectra were converted into K/S spectra using the Kubelka–Munk equation according to [27]. The eight samples free of visual defects (cracks) were included in the measurement of each set. The colour measurement consisted of the 64 recordings for each modified and unmodified sample on both sides of the tangential surfaces. The sets were distinguished with selected modifying temperatures. Overall, the 256 measurements were performed.

2.4. FTIR Analysis

FTIR spectroscopy measurements of wood samples were performed on a Nicolet iS10 FT-IR spectrometer (Thermo Fisher Scientific, Waltham, MA, USA). The ATR crystal plate was from Diamond, and solid materials could be placed into intimate physical contact with the sampling area. The spectra were acquired by accumulating 32 scans at a spectral resolution of 4 cm−1 in a range from 4000 to 650 cm−1. Results were evaluated by applying OMNIC 9.0 software (Thermo Fisher Scientific, Waltham, MA, USA). Each specimen was measured on the tangential face, and four measurements were performed for each sample.

2.5. Statistical Analysis

For evaluating the results, ANOVA analysis was used. Based on the P-level value and Fisher F tests, it was determined whether a factor affected the values of the monitored characteristics. Diagrams were constructed for the 95% confidence interval, reflecting the significance level of 0.05 (p < 0.05), and the results were verified with Duncan’s tests.

3. Results and Discussion

3.1. Chemical Changes

The chemical composition of untreated black locust wood (Table 1) is like the results reported previously for different Robinia species, e.g., extractives 2.5%–8.3%, cellulose 40.6%–43.1%, hemicelluloses 16.18%–33.16%, lignin 19.73%–22.7% [28,29,30,31].

Table 1.

Chemical composition of sound and thermally modified black locust wood, oven-dry weight percentages (mean ± SD).

Some extractives decompose at a higher temperature, but new ones are created due to the decomposition of main wood components. During the heating of eucalypt wood, nearly all the original extractives decomposed, and new ones were created, such as anhydrosugars, mannosan, galactosan, and levoglucosan [32]. Only a few works investigated the effect of extractives on the colour changes of black locust wood, but even those did not report changes in the content of extractives during heat treatment. [15,27,33]. Generally, extractives’ content changes depend on the wood species and heating conditions, and various trends have been published. A decrease in extractives was observed in our experiments (Table 1) and their influence on colour changes will be discussed below.

Thermal modification causes the decrease of polysaccharide content, primarily by the degradation of hemicelluloses. The amount of other wood biopolymers (lignin, cellulose) in modified wood increases (Table 1). Lignin yield generally increases at wood treatment at a low pH and high temperature. The content of acid-insoluble lignin is higher in the modified material than in the untreated ones. This trend is due to the formation of pseudo-lignin following the condensation reactions of degradation products of lignin and polysaccharides [34,35,36].

Cellulose begins to degrade at higher temperatures compared with hemicelluloses and lignin. However, its relative amount in heat-treated wood depends on the method used for the determination. In this work, the increase in cellulose content was observed during thermal modification, as determined by Seifert’s method (Table 1). A similar trend in cellulose content was observed at the ThermoWood process of poplar wood by differential scanning calorimetry [37].

In this work, the most vulnerable main wood component during thermal treatment was hemicelluloses. Their amount decreases by 81.32% in modified wood at 210 °C, accompanied by a relative increase in cellulose (28.12%) and lignin (19.54%), respectively (Table 1).

3.2. Colour Changes with Statistical Evaluation

The colour of wood is a property with probabilistic character. Heat treatment of black locust wood caused colour changes. The lightness of the surface (L*) decreased with increasing the treatment temperature, while the highest decrease was recorded on samples treated at 160 °C. The chromaticity values (a* and b*) recorded changes, which, together with the change in light, resulted in an increase in the total colour difference ΔE* up to a value of approximately 42. These colour changes can be evaluated as very significant, since the colour changed from originally pale yellowish brown to dark brown.

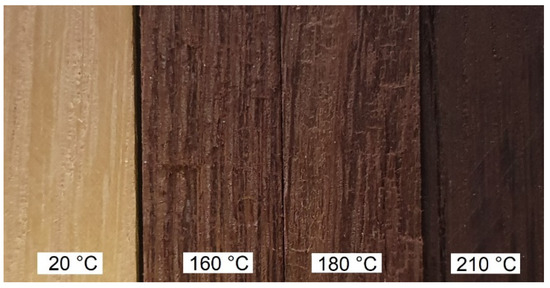

The largest colour changes were recorded on samples treated at 160 °C (Figure 1, Table 2). The most significant change was shown by the lightness value L*, where a decrease, compared with the reference sample (20 °C), of approximately 45% (from 69.5 to 38.0) was evident. Such a decrease in lightness represents a significant darkening of the surface of treated black locust wood. Chromaticity values a* and b* also changed significantly (Table 1). The a* value increased by 100%, while the b* value decreased by more than 58%. Thermal modification at 180 and 210 °C affected the colour of the surface less significantly. The decrease in the value of L* compared with the samples treated at 160 °C was already much milder. The a* and b* values had a similar trend. On the samples treated at 180 °C, the further decrease in L* was only 10%; the value of a* decreased by 17% and b* by 20%. Compared with the values measured on the samples treated at 180 °C, the samples treated at 210 °C showed a decrease in L* by another 5%, the value of a* decreased by 8%, and the value of b* decreased by 10.5%. The listed changes in L*, a*, and b* values represent a colour change of the wood surface from the original cream to dark brown (Figure 1). Our findings are analogous to those obtained for other heat-treated wood species [38,39,40].

Figure 1.

Samples of the original and thermally modified black locust wood.

Table 2.

The averages of black locust colour properties in CIE L*a*b* colour space (mean ± SD).

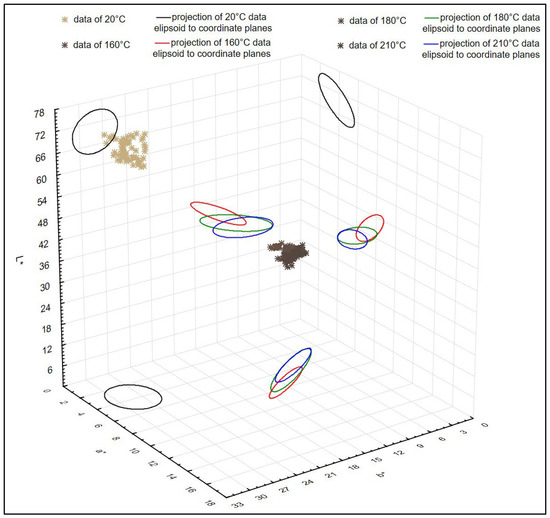

The measured colour data were visualized with the proposed method of Hrčka [41] (Figure 2). The brown crosses represent the measured data in CIE L*a*b* colour space. The black and RGB ellipses are projections of data clouds to CIE L*a*b* planes. The black ellipses represent the colour of unmodified samples (20 °C). The red ellipses represent the colour of modified samples at 160 °C. The green ellipses represent the colour of modified samples at 180 °C. The blue ellipses represent the colour of modified samples at 210 °C. The alpha level of 0.1% was selected, because of the large variability of wood colour data. Despite the alpha-level low value, the observed lightness of modified wood decreased dramatically. The average L* value of 70 at 20 °C decreased to 38 on longitudinal surfaces modified with a temperature of 160 °C. The significant drop of the b* coordinate average was also evident on longitudinal surfaces of unmodified and modified samples. The average b* value of 28 at 20 °C decreased to 12 on longitudinal surfaces modified with a temperature of 160 °C. The a* value increased with increasing temperature between 20 °C and 160 °C. The additional increasing of temperature resulted in significant decreasing of the a* coordinate. The modifying of the a* coordinate with temperature followed the characteristic behaviour observed also in the research of Tolvaj et al. [42] and Banadics et al. [43]. The hue was a less variable property than saturation. Both properties decreased with the increase in the modifying temperature (Table 2). The significant difference of wood colours indicates the possibility to prepare the interesting changes of black locust colour from almost-saturated yellow green to less-saturated dark brown.

Figure 2.

The measured colour data of black locust and their projections to coordinate planes of CIE L*a*b*.

The statistical analysis of the variance evaluating the impact of different temperature values on the parameters L*, a*, b*, and ΔE (Table 3, Table 4, Table 5 and Table 6) show that in all observed cases temperature can be considered a very significant factor affecting colour parameters.

Table 3.

Statistical evaluation of the factors affecting the change in the L* value.

Table 4.

Statistical evaluation of the factors affecting the change in the a* value.

Table 5.

Statistical evaluation of the factors affecting the change in the b* value.

Table 6.

Statistical evaluation of the factors affecting the change in the ΔE value.

A graphic presentation of the results describing the interaction of different temperature values on the colour parameter is shown in Figure 1, Table 2. A significant decrease in L* values caused by the effect of a temperature of 160 °C compared with the untreated samples can be observed. A further increase in temperature (180 and 210 °C) caused only a slight decrease in the lightness value.

In the case of parameter a*, we observed the opposite trend (Table 2). Because of the temperature of 160 °C, a statistically significant increase in the values of the parameter a* can be observed in comparison with the untreated test specimens (20 °C). Due to the influence of higher temperatures (180 °C and 210 °C), a statistically significant decrease in parameter values can be observed compared with the values measured in bodies treated with a temperature of 160 °C.

The parameter b*, as well as the whole curve, have an identical course with the curve describing the values of parameter L* (Table 2). Even in this case, we can observe a significant drop in values caused by the effect of the temperature of 160 °C compared with untreated ones. As a result of the influence of external temperatures (180 °C and 210 °C), this decrease increased statistically significantly, but the difference between the values was already significantly lower.

When looking at the ΔE parameters, its significant increase caused by the effect of increasing temperature values is evident in all observed cases (Table 2).

Chemical reactions during heat treatment often cause the formation of coloured oxidation and degradation products. These changes are complex and require detailed study. Chen et al. [27,33] reported that the effect of degradation of hemicellulose on colour changes at thermal treatment of black locust wood should be relatively small compared with lignin. Furthermore, other authors discovered a good correlation between lightness decrease changes and chemical changes in glucose, hemicelluloses, and lignin [32]. In this work, no good correlation between colour changes and contents of main wood components were observed. Black locust wood contains a large content of extractives, and we assume that their changes during thermal treatment can significantly affect colour changes, as observed by several authors [15,27,33] during the thermal treatment of extracted and non-extracted black locust wood. This is supported by the decrease in the yellow index b* (Table 2); a similar trend was discovered at the heat treatment of black locust wood [15]. On the other hand, the b* parameter indicated increased values compared with untreated timber at the thermal treatment of ailanthus, spruce, and pine wood [6,39].

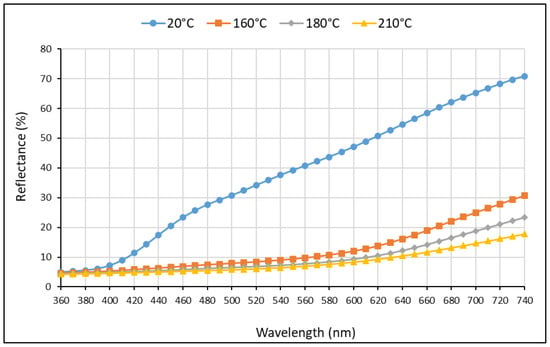

The colour of any material depends on its chemical composition, namely, a combination of chromophores that absorb certain wavelengths of the visible light, in such a way, altering the spectral composition of the reflected radiation, which, when entering the human eye, creates a sense of definite colour. Therefore, the reflection curve in the visible light region is an accurate representation of the colour of a material [44,45].

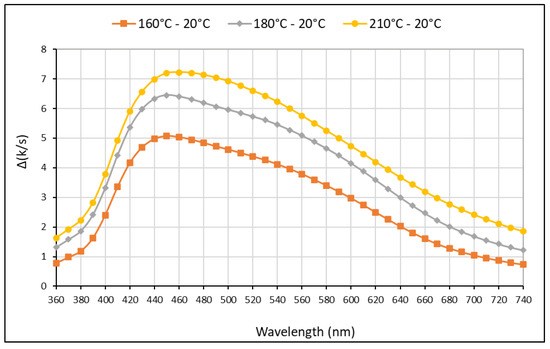

It is obvious that there was an absorption change in visible region (Figure 3) and the difference in absorption spectra (Figure 4) can represent changes due to heat treatment. These changes indicated the generation of some types of chromophores in the degradation, condensation, and oxidation processes. They can be assigned to the formation of coloured quinoid compounds, arising from the degradation and oxidation of the aromatic hydroxyls of lignin and aromatic extractives upon heat treatment. Regions between 420 and 160 nm can be caused mainly by p-quinone, and the region between 500 and 580 nm can be caused mainly by o-quinone [27,46,47,48].

Figure 3.

VIS reflectance spectra of untreated and heat-treated black locust wood.

Figure 4.

Absorption difference spectra Δ(k/s) of heat-treated black locust wood.

3.3. Changes in FTIR Spectra

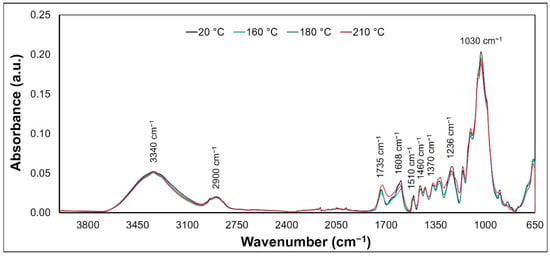

FTIR spectra (Figure 5) were measured on the surface of untreated wood (20 °C, considered as a reference) and subsequently after heat treatment (at 160, 180, and 210 °C).

Figure 5.

FTIR spectra of untreated and thermally treated black locust wood.

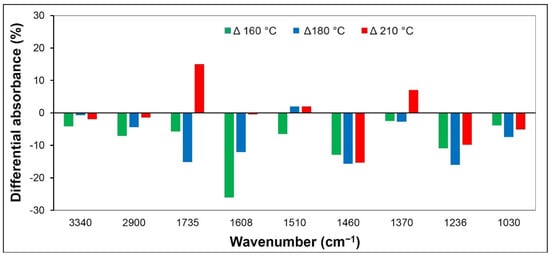

The height of each bar in differential FTIR spectra (Figure 6) represents the difference between the absorbance of a given band of the thermally treated sample and that of the reference sample for a given wavenumber. Positive values mean an increase, and negative values mean a decrease in absorbance.

Figure 6.

Differential FTIR spectra of untreated and thermally treated black locust wood.

It follows from the obtained spectral dependences that the band changes between 3000 and 3600 cm−1 show the decrease, which is in line with the observations of Chen et al. [27]. This widest band is due to O−H vibrations in lignin and hemicelluloses [49]. The band with a maximum absorbance at 2900 cm−1 is due to symmetric and asymmetric C−H stretching vibrations in aliphatic compounds. Inari et al. [50] show a similar behaviour. More evident changes were observed in bands in the region from 1800 to 800 cm−1 (bands are assigned to tensile and deformational vibrations of all wood components). This area is characteristic for wooden materials. At the band 1735 cm−1 (C=O stretching in unconjugated carbonyl groups) [51], a decrease in absorbance was initially recorded (samples treated at 160 and 180 °C). The increase was observed only at the highest temperature (210 °C). Analogous statements have been reported by Lagaňa et al. [52] about the thermal modification of beech wood. The drop at the early stage of the heat treatment may be due to the breaking of acetyl or acetoxy groups in xylan due to the lowest thermal stability of hemicelluloses compared with cellulose and lignin.

The increased intensity of these bands with longer thermal treatment may be due to an increase in carbonyl or carboxyl groups in lignin or in carbohydrates by oxidation [53]. In our case, the decrease in the band can be mainly caused by the deacetylation of hemicelluloses during the thermal treatment of the wood surface components [54]. Thermally caused processes are related with the degradation of carbonyl groups in lignin as well as in hemicelluloses, where the cleavage of C=O bonds affects the change in the content of chromophores. These structures are particularly responsible for the colouring of the wood surface. The band in the vicinity of 1600 cm−1 (C=C stretching vibration conjugated with aromatic ring in lignin) decreased continuously, while the lowest decrease occurred at 210 °C. Slight changes were noted by the band at approximately 1500 cm−1 (C=C stretching vibration and aromatic skeleton vibration). A decrease, practically independent of temperature, was characteristic of the band at 1460 cm−1 (asymmetric CH3 bending in methoxyl groups in lignin). At 1370 cm−1 (symmetric and asymmetric CH3 bending) [55], the absorbance also decreased (except for a temperature of 210 °C, where the opposite trend was observed). The band at 1236 cm−1 is assigned to lignin and hemicelluloses [56,57]. Its decrease was the lowest at the highest temperature (210 °C). The decrease in the absorbance of the analysed wavenumber areas supports the assumption of degradation processes in lignin, caused by the splitting of bonds and the subsequent disintegration of its structure. At higher temperatures, condensation reactions can occur in lignin [58]. The permanent decrease in the band at 1030 cm−1 (C−O deformation vibrations in cellulose) points to the degradation changes of cellulose [59].

4. Conclusions

This work presents the results of a study focused on the colour and chemical changes of black locust wood caused by thermal degradation. Wood samples were heat treated, during the ThermoWood process, at temperatures of 160, 180, and 210 °C. The temperature of 160 °C caused a significant darkening of the wood surface (a decrease in lightness L*), while a further increase in temperature had a less significant effect on lightness. Changes in chromatic values (a*, b*) indicate a gradual shift from the original pale-yellow colour to dark brown. Thermal degradation of wood leads to the formation of chromophore structures, which is reflected in a change in its colour. Because black locust contains a large content of extractives, it can be assumed that thermal oxidation processes in these substances have a significant role in changing wood colour. Statistical analysis confirmed that temperature can be considered a statistically very significant factor affecting the wood surface colour.

Author Contributions

F.K., I.K. and D.K. conceived and designed the experiments; J.B., M.G. and D.K. prepared samples; I.K. measured and evaluated FTIR spectra; R.H. performed and evaluated colour measurements; D.K., I.K., J.B., M.G. and F.K. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency under the Contract No. APVV-16-0326 (20%), APVV-20-0159 (20%), and by the Scientific Grant Agency of the Ministry of Education SR and the Slovak Academy of Sciences, Grant No. 1/0117/22 (50%) and 1/0577/22 (10%).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jones, D.; Kržišnik, D.; Hočevar, M.; Zagar, A.; Humar, M.; Popescu, C.-M.; Popescu, M.-C.; Brischke, C.; Nunes, L.; Curling, S.F.; et al. Evaluation of the Effect of a Combined Chemical and Thermal Modification of Wood though the Use of Bicine and Tricine. Forests 2022, 13, 834. [Google Scholar] [CrossRef]

- Bekhta, P.; Krystofiak, T.; Lis, B.; Bekhta, N. The Impact of Sanding and Thermal Compression of Wood, Varnish Type and Artificial Aging in Indoor Conditions on the Varnished Surface Color. Forests 2022, 13, 300. [Google Scholar] [CrossRef]

- Esteves, B.; Ayata, U.; Gurleyen, L. Effect of heat treatment on the colour and glossiness of black locust, wild pear, linden, alder and willow wood. Drewno 2019, 62, 39–52. [Google Scholar] [CrossRef]

- Zhan, T.; Zhu, J.; Liu, Z.; Li., T.; Peng, H.; Jiang, J.; Lyu, J. Meta-analysis of chromatic properties of heat-treated wood. Eur. J. Wood Prod. 2022, 80, 851–858. [Google Scholar] [CrossRef]

- Torniainen, P.; Jones, D.; Sandberg, D. Colour as a quality indicator for industrially manufactured ThermoWood®. Wood Mater. Sci. Eng. 2021, 16, 287–289. [Google Scholar] [CrossRef]

- Liu, X.Y.; Tu, X.W.; Liu, U. Effects of light thermal treatments on the color, hygroscopity and dimensional stability of wood. Wood Res. 2021, 66, 95–104. [Google Scholar] [CrossRef]

- Sundqvist., B.; Morén, T. The influence of wood polymers and extractives on wood colour induced by hydrothermal treatment. Eur. J. Wood Wood Prod. 2002, 60, 375–376. [Google Scholar] [CrossRef]

- Patzelt, M.; Emsenhuber, G.; Stingl, R. Colour Measurement as means of quality control of thermally treated wood. In Proceedings of the Abstracts of the first European conference on wood modification, Ghent, Belgium, 3–4 April 2003. [Google Scholar]

- Mitsui, K.; Takada, H.; Sugiyama, M.; Hasegawa, R. Changes in the properties of light-irradiated wood with heat treatment: Part 1 Effect of treatment conditions on the change in colour. Holzforschung 2001, 55, 601–605. [Google Scholar] [CrossRef]

- Jiang, H.C.; Lu, Q.J.; Li, G.J.; Li, M.; Li, J.N. Effect of heat treatment on the surface color of rubber wood (Hevea brasiliensis). Wood Res 2020, 65, 633–644. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 2003, 57. [Google Scholar] [CrossRef]

- Kačíková, D.; Kačík, F.; Čabalová, I.; Durkovič, J. Effects of thermal treatment on chemical, mechanical and colour traits in Norway spruce wood. Bioresour. Technol. 2013, 144, 669–674. [Google Scholar] [CrossRef]

- Kubovský, I.; Kačík, F. Changes of the wood surface colour induced by CO2 laser and its durability after the xenon lamp exposure. Wood Res. 2013, 58, 581–590. [Google Scholar]

- Matsuo, M.; Yokoyama, M.; Umemura, K.; Gril, J.; Yano, K.; Kawai, S. Color changes in wood during heating: Kinetic analysis by applying a time temperature superposition method. Appl. Phys. A 2010, 99, 47–52. [Google Scholar] [CrossRef]

- Fan, Y.; Gao, J.; Chen, Y. Colour responses of black locust (Robinia pseudoacacia L.) to solvent extraction and heat treatment. Wood Sci. Technol. 2010, 44, 667–678. [Google Scholar] [CrossRef]

- Moya, R.; Fallas, R.S.; Bonilla, P.J.; Tenorio, C. Relationship Between Wood Color Parameters Measured by the CIELab System and Extractive and Phenol Content in Acacia mangium and Vochysia guatemalensis from Fast-Growth Plantations. Molecules 2012, 17, 3639–3652. [Google Scholar] [CrossRef]

- Rédei, K.; Veperdi, I. The role of black locust (Robinia pseudoacacia L.) in establishment of short-rotation energy plantations in Hungary. Int. J. Hortic. Sci. 2009, 15, 41–44. [Google Scholar] [CrossRef]

- Jiménez-López, L.; Martín-Sampedro, R.; Eugenio, M.E.; Santos, J.I.; Sixto, H.; Cañellas, I.; Ibarra, D. Co-production of soluble sugars and lignin from short rotation white poplar and black locust crops. Wood Sci. Technol. 2020, 54, 1617–1643. [Google Scholar] [CrossRef]

- Li, G.; Xu, G.; Guo, K.; Du, S. Mapping the Global Potential Geographical Distribution of Black Locust (Robinia Pseudoacacia L.) Using Herbarium Data and a Maximum Entropy Model. Forests 2014, 5, 2773–2792. [Google Scholar] [CrossRef]

- Sitzia, T.; Cierjacks, A.; de Rigo, D.; Caudullo, G. Robinia pseudoacacia in Europe: Distribution, Habitat, Usage and Threats. In European Atlas of Forest Tree Species; San-Miguel-Ayanz, J., de Rigo, D., Caudullo, G., Houston Durrant, T., Mauri, A., Eds.; Publications Office of the EU: Luxembourg, 2016; p. e014e79+. [Google Scholar]

- Sikora, A.; Kačík, F.; Gaff, M.; Vondrová, V.; Bubeníková, T.; Kubovský, I. Impact of thermal modification on color and chemical changes of spruce and oak wood. J. Wood Sci. 2018, 64, 406–416. [Google Scholar] [CrossRef]

- Sikora, A.; Hájková, K.; Jurczyková, T. Degradation of Chemical Components of Thermally Modified Robinia pseudoacacia L. Wood and Its Effect on the Change in Mechanical Properties. Int. J. Mol. Sci. 2022, 23, 15652. [Google Scholar] [CrossRef] [PubMed]

- ASTM D1107-21; Standard Test Method for Ethanol-Toluene Solubility of Wood. ASTM International: West Conshohocken, PA, USA, 2021.

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in biomass: Laboratory Analytical Procedure (LAP); NREL/TP-510-42618. Version 08-03-2012; National Renewable Energy Laboratory: Golden, CO, USA.

- Seifert, V.K. Über ein neues Verfahren zur Schnellbestimmung der Rein—Cellulose. Papier 1956, 10, 301–306. [Google Scholar]

- Wise, L.E.; Maxine, M.; D’Addieco, A.A. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Paper Trade J. 1946, 122, 35–43. [Google Scholar]

- Chen, Y.; Fan, Y.; Gao, J.; Stark, N.M. The effect of heat treatment on the chemical and color change of black locust (Robinia pseudoacacia) wood flour. BioResources 2012, 7, 1157–1170. [Google Scholar] [CrossRef]

- Ferreira, S.; Gil, N.; Queiroz, J.A.; Duarte, A.P.; Domingues, F.C. An evaluation of the potential of Acacia dealbata as raw material for bioethanol production. Bioresour. Technol. 2011, 102, 4766–4773. [Google Scholar] [CrossRef]

- Yáñez, R.; Romaní, A.; Garrote, G.; Alonso, J.L.; Parajó, J.C. Experimental evaluation of alkaline treatment as a method for enhancing the enzymatic digestibility of autohydrolysed Acacia dealbata. J. Chem. Technol. Biotechnol. 2009, 84, 1070–1077. [Google Scholar] [CrossRef]

- Hoa, D.T.; Man, T.D.; Hau, N.V. Pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Asian J. Appl. Sci. Technol. 2008, 25, 341–346. [Google Scholar] [CrossRef]

- Kačík, F.; Ďurkovič, J.; Kačíková, D.; Zenková, E. Changes in the chemical composition of black locust wood after hot-water pretreatment before bioethanol production. Acta Facultatis Xylologiae Zvolen. 2016, 58, 15–23. [Google Scholar] [CrossRef]

- Esteves, B.; Graca, J.; Pereira, H. Extractive composition and summative chemical analysis of thermally treated eucalypt wood. Holzforschung 2008, 62, 344–351. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, J.; Fan, Y.; Tshabalala, M.A.; Stark, N.M. Heat-induced chemical and color changes of extractive-free black locust (Robinia pseudoacacia) wood. BioResources 2012, 7, 2236–2248. [Google Scholar] [CrossRef]

- Hu, F.; Jung, S.; Ragauskas, A. Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresour. Technol. 2012, 117, 7–12. [Google Scholar] [CrossRef]

- Shinde, S.D.; Meng, X.; Kumar, R.; Ragauskas, A.J. Recent advances in understanding the pseudo-lignin formation in a lignocellulosic biorefinery. Green Chem. 2018, 20, 2192–2205. [Google Scholar] [CrossRef]

- Kučerová, V.; Lagaňa, R.; Výbohová, E.; Hýrošová, T. The Effect of Chemical Changes during Heat Treatment on the Color and Mechanical Properties of Fir Wood. Bioresources 2016, 11, 9079–9094. [Google Scholar] [CrossRef]

- Bayani, S.; Bazyar, B.; Mirshokraie, S.A.; Taghiyari, H.R. Effects of heat treatment on the relative amounts of cellulose in nanosilver-impregnated and untreated poplar wood (Populus alba). Floresta Ambiente 2019, 26, e20160398. [Google Scholar] [CrossRef]

- Nguyen, T.H.V.; Nguyen, T.T.; Ji, X.; Minghui Guo, M. Predicting Color Change in Wood During Heat Treatment Using an Artificial Neural Network Model. BioResources 2018, 13, 6250–6264. [Google Scholar] [CrossRef]

- Torniainen, P.; Popescu, C.-M.; Jones, D.; Scharf, A.; Sandberg, D. Correlation of Studies between Colour, Structure and Me-chanical Properties of Commercially Produced ThermoWood® Treated Norway Spruce and Scots Pine. Forests 2021, 12, 1165. [Google Scholar] [CrossRef]

- Piernik, M.; Woźniak, M.; Pinkowski, G.; Szentner, K.; Ratajczak, I.; Krauss, A. Color as an Indicator of Properties in Thermally Modified Scots Pine Sapwood. Materials 2022, 15, 5776. [Google Scholar] [CrossRef]

- Hrčka, R. Identification of discoloration of beech wood in CIELAB space. Wood Res. 2008, 53, 119–124. [Google Scholar]

- Tolvaj, L.; Molnár, S.; Németh, R.; Varga, D. Color modification of black locust depending on the steaming parameters. Wood Res. 2010, 55, 81–88. [Google Scholar]

- Banadics, E.A.; Tolvaj, L.; Varga, D. Steaming of Poplar, Black Locust and Beech Timbers Simultaneously to Investigate Colour Modification Effect of Extractive Transport. Drewno 2022, 65. [Google Scholar] [CrossRef]

- Hon, D.N.S. Weathering and photochemistry. In Wood and Cellulosic Chemistry; Hon, D.N., Shiraishi, N., Eds.; Marcel Dekker: New York, NY, USA, 2001; pp. 513–546. [Google Scholar]

- Cirule, D.; Kuka, E.; Kevers, M.; Andersone, I.; Andersons, B. Photodegradation of Unmodified and Thermally Modified Wood Due to Indoor Lighting. Forests 2021, 12, 1060. [Google Scholar] [CrossRef]

- Polčin, J.; Rapson, W.H. Effect of Bleaching Agents on the Absorption of Lignin in Groundwood Pulps. Part II. Oxidative-Reductive Bleaching. Pulp Paper Mag. Can. 1971, 72, 80–91. [Google Scholar]

- Tribulová, T.; Kačík, F.; Evtuguin, D.; Čabalová, I. Assessment of chromophores in chemically treated and aged wood by UV-VIS diffuse reflectance spectroscopy. Cellul. Chem. Technol. 2016, 50, 659–667. [Google Scholar]

- Wei, Y.X.; Wang, M.J.; Zhang, P.; Chen, Y.; Gao, J.M.; Fan, Y.M. The role of phenolic extractives in color changes of locust wood (Robinia pseudoacacia) during heat treatment. Bioresources 2017, 12, 7041–7055. [Google Scholar]

- Kubovský, I.; Kačíková, D.; Kačík, F. Structural Changes of Oak Wood Main Components Caused by Thermal Modification. Polymers 2020, 12, 485. [Google Scholar] [CrossRef]

- Inari, G.N.; Petrissans, M.; Gerardin, P. Chemical reactivity of heat-treated wood. Wood Sci. Technol. 2007, 41, 157–168. [Google Scholar] [CrossRef]

- Tolvaj, L. Traditions, anomalies, mistakes and recommendations in infrared spectrum measurement for wood. Wood. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Lagaňa, R.; Csiha, C.; Horváth, N.; Tolvaj, L.; Andor, T.; Kúdela, J.; Németh, R.; Kačík, F.; Ďurkovič, J. Surface properties of thermally treated European beech wood studied by PeakForce Tapping atomic force microscopy and Fourier-transform infrared spectroscopy. Holzforschung 2021, 75, 56–64. [Google Scholar] [CrossRef]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H. Chemical changes of heat treated pine and eucalypt wood monitored by FTIR. Maderas Cienc. Tecnol. 2013, 15, 245–258. [Google Scholar] [CrossRef]

- Kubovský, I.; Kačík, F. Colour and chemical changes of the lime wood surface due to CO2 laser thermal modification. Appl. Surf. Sci. 2014, 321, 261–267. [Google Scholar] [CrossRef]

- Müller, G.; Schöpper, C.; Vos, H.; Kharazipour, A.; Polle, A. FTIR-ATR spectroscopic analysis of changes in wood properties during particle and fibreboard production of hard and softwood trees. BioResources 2009, 4, 49–71. [Google Scholar] [CrossRef]

- Kubovský, I.; Oberhofnerová, E.; Kačík, F.; Pánek, M. Surface changes of selected hardwoods due to weather conditions. Forests 2018, 9, 557. [Google Scholar] [CrossRef]

- Bhagia, S.; Ďurkovič, J.; Lagaňa, R.; Kardošová, M.; Kačík, F.; Cernescu, A.; Schäfer, P.; Yoo, C.G.; Ragauskas, A.J. Nanoscale FTIR and Mechanical Mapping of Plant Cell Walls for Understanding Biomass Deconstruction. ACS Sustainable Chem. Eng. 2022, 10, 3016–3026. [Google Scholar] [CrossRef]

- Popescu, M.C.; Froidevaux, J.; Navi, P.; Popescu, C.M. Structural modifications of Tilia cordata wood during heat treatment investigated by FT-IR and 2D IR correlation spectroscopy. J. Mol. Struct. 2013, 1033, 176–186. [Google Scholar] [CrossRef]

- Ciolacu, D.; Ciolacu, F.; Popa, V.I. Amorphous cellulose-structure and characterization. Cellul. Chem. Technol. 2011, 45, 13–21. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).