Abstract

To reduce waste of woody resources and to implement the circular economy for resource recovery, this research aims to test and analyze the basic properties of charcoal from earthen kiln-burned alien tree species, Cinnamomum Burnmannii, similar to Taiwan’s native Cinnamomum Osmophloeum but a threat to native tree growth. The charcoal production is not for urban energy consumption, but what for develop multi-function value-added products using charcoal various characteristics. The study results showed that the average yield of three-times-burned charcoal in an earthen kiln was 14.7%, the ash 5.96%, gross heating value 6745 kcal/kg, lower heating value 6610 kcal/kg, volatile matter 4.88%, fixed carbon 80.71%, specific surface area (BET) 426.4 m2/g, and pH 9.14. Overall, the Cinnamomum burmannii charcoal burned in this study displayed alkaline, with a high BET value and good adsorption capacity, which contributes to the development of value-added products for removing odors in the air and impurities in water, thus expanding the scope of application of Cinnamomum burmannii and its value creation, minimizing waste, and implementing the concept of the circular economy for resource recovery. In addition, the carbon conservation rate through the burning of Cinnamomum burmannii charcoal can reach 24.11%, reducing the emission of carbon dioxide and achieving positive impacts on environmental carbon reduction.

1. Introduction

Ecologists warn of threats posed by invasive alien species to the ecosystems of native species, including suppression of native tree growth, habitat destruction, and changes in native ecosystems, thereby reshaping local livelihoods. Hence, environment and ecosystem management must address minimizing the adverse environmental and socio-economic impacts from invasive alien species.

Taiwan is currently facing the threat of the spread of the alien tree species Cinnamomum burmannii, which is in the genus Cinnamomum of the family Lauraceae. It is a medium-sized tree native to the south of China, Philippines, Vietnam, Myanmar, and India in tropical Asia (Chen et al., 2008) [1], whose bark can be used as a substitute for Cinnamomum cassia, as a spice, an antioxidant in food and beverage (Utami et al., 2019) [2], and also as an herbal remedy for it contains anti-inflammatory, sedative, antispasmodic, antitussive, and phlegm removing properties (Chen et al., 2008; Al-Dhubiab, 2012) [1,3].

In addition, Cinnamon wood is used for fuel in Sumatra, Indonesia (Nasution et al., 2017) [4]. In recent years, the use of the powder of its leaf as a feed additive increases fish growth rate (Tamba et al., 2020) [5]. With their economic value for multiple purposes, cinnamon trees were once widely planted in Indonesia for high financial returns (Syu et al., 2014) [6], hence the name Indonesian cinnamon (Ervina et al., 2016) [7]. It is estimated that this tree species was first introduced to Taiwan in the 1970s. Due to its rapid growth, lush foliage, and evergreen characteristics, it was readily planted as a landscaping tree in Taiwan. In the wake of the 921 earthquakes in the year 2000, Cinnamomum osmophloeum was planted extensively in Central Taiwan as a cash crop to boost the economy of the earthquake-stricken areas.

However, since the morphological characteristics of Cinnamomum burmannii are similar to those of the higher-priced Cinnamomum osmophloeum seedlings, it has been mistakenly planted widely. Currently, it can be found across Taiwan. However, due to its strong adaptability to Taiwan’s environment and climate, it is high in growth speed, luxuriant levels of foliage, seed yield, germination rate, and tillering ability. Since 2008, some Taiwanese scholars have begun to seriously consider Cinnamomum burmannii as an invasive species jeopardizing Taiwan’s ecosystem of native plants (Chen et al., 2008) [1], instead of formerly classified as a naturalized species (Tseng et al., 2008) [8], and face up to the problem by studying and monitoring the Cinnamomum burmannii since 2012 (Tsai et al., 2017) [9].

Some International scholars claimed that Cinnamomum burmannii may have transformed into an invasive species in Hawaii, threatening the survival of local species (Horcher, 2000, Laughlin, 2000, Luo et al., 2012) [10,11,12], and it has been identified as an invasive species in 2010 (Charles et al., 2010, Taiwan Academy of Ecology 2012) [13,14]. In order to control the quantity and spread of Cinnamomum burmannii in the wild, and to maintain the ecosystem of native tree species, many forest owners having planted Cinnamomum burmannii for many years have taken the initiative to clear them for native Cinnamomum osmophloeum. Producing value-added products with processed, felled Cinnamomum burmannii wood is expected to help align reducing waste to implementing a circular economy model, that has been cut and cleared achieving the increase in the output value as well as its efficiency of carbon fixation function in growth.

Carbonization refers to the process by which carbonaceous organic matter is pyrolyzed through a high temperature of 450~1000 °C in an atmosphere devoid of oxygen, with carbon elements retaining a porous and dense microstructure, which is non-toxic and stable in the environment. Traditionally it is used as fuel (Hwang et al., 2010; Lo and Wang, 2007; Lo, 2008; Lu and Zhou, 2009; Das et al., 2021) [15,16,17,18,19]. However, charcoal made from wood materials usually has higher pore volumes and a higher specific surface area, and thus exerts good adsorption capacity (Lan et al., 2008) [20]. It can be used to cleanse and deodorize absorbing air and water impurities, or to extend the shelf life of food adsorbing ethylene. When applied to soil, the air permeability, water retention, and fertilizer retention of the soil are improved. (Hsu, 2008; Borchard et al., 2014; Jien and Chen, 2014; Lin, 2013) [21,22,23,24].

In addition, it has the characteristics of releasing infrared rays and conducting electricity and has been widely used in environmental protection, agriculture, and textiles in recent years (Hwang, 2016) [25]. However, from the perspective of forestry, the possible contribution of charcoal to mitigating the greenhouse effect should be emphasized. Charcoal firing is a potential method of carbon dioxide storage if it can effectively combine the Clean Development Mechanism (CDM) with regional development (Lin and Hwang, 2009; Wang and Lin, 2012) [26,27]. Carbonizing Cinnamomum burmannii materials is one of the value-added utilizations. Currently, there is no relevant research on carbonization and value-added utilization of Cinnamomum burmannii materials, so this study aims to better understand the basic properties of Cinnamomum burmannii charcoal after carbonization to lay a framework for subsequent applications for product research and development.

2. Materials and Methods

2.1. Research Materials

The Cinnamomum burmannii materials used in this study were from the green space and street trees in the Dharma Drum Mountain World Center for Buddhist Education Park (25°14′22″ N, 121°36′54″ E) in Jinshan District, New Taipei City. Having been planted for about 25–27 years with a diameter at breast height of 20–40 cm, a total of 144 trees were felled in June 2020, weighing about 16,000–16,500 kg in total. The average moisture content of Cinnamomum burmannii logs was 24.66% ± 6.41, the average specific gravity was 0.494 ± 0.043, and the carbon content ratio was 49.5%. These logs were originally meant for wood production. However, they came with numerous nails hammered in for an activity in the park previously, which may easily cause damage to the saw blade, making subsequent processing and utilization to produce angles and plates out of the question.

2.2. Cinnamomum burmannii Charcoal Producing

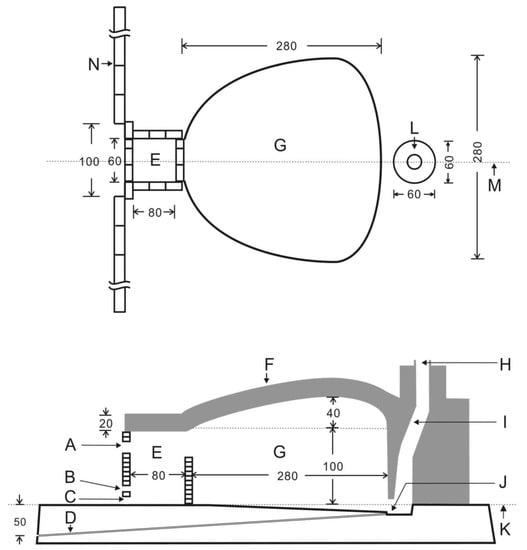

The materials were sent to proceed with carbonization at a commercial earthen kiln located in Shihtan Township, Miaoli County (24°35′14″ N, 120°56′42″ E). It was built under the supervision of the Taiwan Forestry Research Institute. The basic structure and size of the kiln are shown in Figure 1 (Lin and Hwang, 2009) [26]. The kiln type original come from Japan since 2002 and can easily be built using compacted soil and firebrick at a low cost in a few days. The kiln type is the current main business type to produce bamboo or wood charcoal in Taiwan. The heating energy of the kiln for the carbonization process all used woody fuel, no external electricity, which can reach high thermal capabilities through mature operation skills with the advantages of lower fuel cost and residues reuse.

Figure 1.

Top and side views and dimensions of earthen kiln. (Lin and Hwang 2009) [26]. A: Fuel intake; B: air intake; C: ash exit; D: scupper; E: fuel chamber; F: kiln top; G: carbonization room; H: chimney; I: smoke channel; J: smoke exhaust hole; K: horizontal baseline; L: chimney skirt; M: central line; N: revetment. Note: All dimensions are in cm.

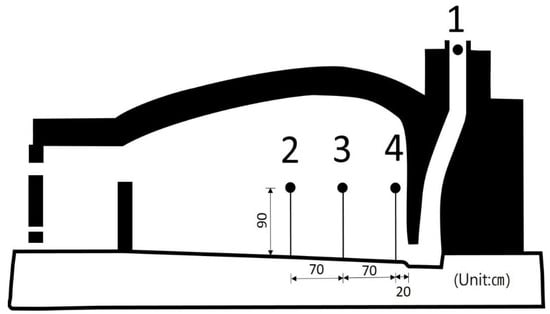

During the carbonizing process, the rise and fall in temperatures in the kiln were adjusted by controlling the fuel intake and exhaust volume of the entrances of the kiln and the chimney. The carbonization temperatures were monitored by 4 temperature sensors (K type diameter 3.2 mm) placed in the kiln as the measuring points, each being 20 cm away from the smoke outlet behind the center line of the kiln, and then based on the measuring points, two temperature sensors were added at a distance of 70 cm and 140 cm, respectively, in the direction of the kiln entrance. The height for all measurement sensors was 90 cm above the ground. There was a total of 3 sensors in the kiln with another one placed at the center point 5 cm below the chimney outlet, and the numbers of the measurement points are shown in Figure 2.

Figure 2.

The sensor no. and its points inside the kiln.

Given the capacity of the kiln chamber, the Cinnamomum burmannii logs were cut to 1 m in length before entering the kiln to accommodate the height and operational needs. The logs were stacked upright side by side in the kiln and divided into 3 batches for carbonization. The firing time of each was around 12 days. The carbonization firing process is divided into entering the kiln, pre-warming, heating-up, heating-raising, sealing the kiln, cooling, and discharging from the kiln. The main process brief was as follows:

(1) The pre-warming process was begun after the firewood was lit in the fuel chamber. The warming speed was controlled by adjusting the gap of air intake and chimney, and it lasted 3~4 days.

(2) The heating-up process was followed by filling a large amount of firewood in the open space of the air intake and the chimney gap when the planned pre-warming temperature was reached. Its purpose was to induce a self-pyrolyzation of materials in the top part of the carbonization room. The heating process generally lasted a couple of hours. Self-pyrolyzation is the specific phenomenon of the earthen kiln for carbonization process, which promotes the quality of charcoal.

(3) The intervals of the air intake and chimney gap were both enlarged when the temperature of the kiln bottom reached 350~400 °C from the heating-up process, in order to further raise the temperature to 700~800 °C, which led to a refining process to promote charcoal quality.

(4) The cooling process was begun through the closing of the air intake and chimney gap, while the beforementioned processes were completed. The temperature of the carbonization room descended slowly when the air was completely cut off. In general, it required approximately 6~9 days until the temperature reached room temperature.

The charcoal will be discharged from the kiln when the temperature reached room temperature without re-fired phenomenon. The yield of Cinnamomum burmannii charcoal was weighed and calculated with the formula below:

Y (%) = (Wc/Wo) × 100%

Y: yield (%)

Wc: mass of biochar (g)

Wo: oven-dry mass of feedstock (g)

2.3. Detection of Properties of Cinnamomum burmannii Charcoal

2.3.1. Basic Property Test

Testing of the basic properties of charcoal products includes ash, higher heating value, and lower heating value, volatile matter, fixed carbon, elemental composition, and inorganic minerals. Having been burned, the Cinnamomum burmannii charcoal was randomly sampled and sent to SGS Taiwan Ltd. (New Taipei City, Taiwan), which is certified by the Taiwan Accreditation Foundation (TAF) for testing including ash, higher heating value and lower heating value, volatile matter, fixed carbon, elemental composition, and inorganic minerals. The test methods and results of each property are listed in Table 1.

Table 1.

The charcoal yield of the 3 carbonizations. Charcoal yield (%).

2.3.2. Determination of the Brunauer–Emmett–Teller Surface Area (BET)

After the Cinnamomum burmannii charcoal was sieved with a particle size of 60 mesh, about 5 g was taken from a weighing bottle and dried in an oven at 105 °C for 24 h until completely dried. Next, about 1 g of which was weighed for detection with an American-made surface area analyzer (Micromeritics Gemini VII). The test was repeated 3 times.

2.3.3. pH Value

The pH value of Cinnamomum burmannii charcoal was determined in accordance with the No. 698 industrial activated carbon (powder) detection method specified by CNS (Chinese National Standards). First, 1 g of the sample, added with 30 mL distilled water, was put in a round-bottomed flask, and boiled under reflux for 5 min. After it was left to stand for 1 h after cooling, the upper clear liquid was taken to measure the pH value with a Suntex pH 315i portable pH meter. The test was repeated 3 times.

3. Results

3.1. Carbonizing Temperature and Charcoal Yield

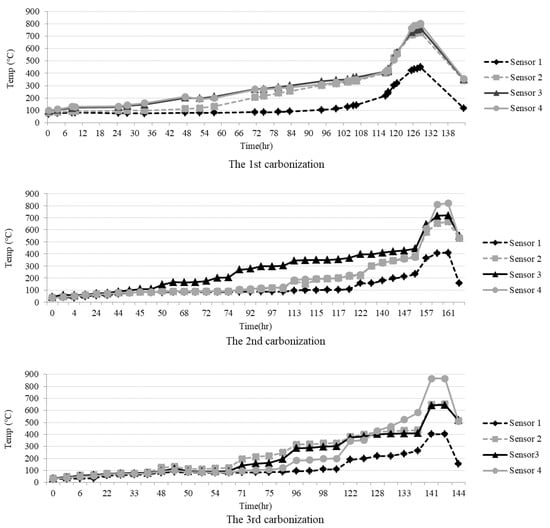

Carbonization occurred three times in the kiln, and the carbonizing temperature curve and firing time of each kiln is shown in Figure 3. The heating rate in each kiln showed that the No. 4 temperature measuring point was higher than its counterparts No. 2 and No. 3, with the highest temperature appearing at the No. 4 temperature measuring point. The highest carbonization temperature in the No. 1–3 kiln was 803, 820, and 866 °C, respectively. To avoid the reduction in carbon collection rate during the carbonizing process, the kiln was sealed when the temperature measuring point No. 4 was higher than 800 °C to stop the heating and carbonization reaction in the earthen kiln, allowing the temperature in the kiln to cool down naturally. The discharge from the kiln was not operated until the temperature dropped to normal (20~25 °C). The total air-dry weight of the wood entering the kiln three times was 12,420 kg, with an average moisture content of 24.66% ± 6.41. The absolutely dry weight was 9963 kg, and the Cinnamomum burmannii charcoal after carbonization was 1461 kg. The average charcoal yield was 14.7% (Table 1).

Figure 3.

The temperature curve of the 3 carbonization times and the sensor position in the kiln.

3.2. The Basic Properties of Cinnamomum burmannii Charcoal

The basic properties of Cinnamomum burmannii charcoal were tested with the results shown in Table 2. The ash of Cinnamomum burmannii charcoal was 5.96%. The gross heating value was 6745 kcal/kg, while the lower heating value was 6610 kcal/kg, with little differences. Volatile matter was 4.88%, and fixed carbon 80.71%; the elemental composition was oxygen (O) 13.7%, nitrogen (N) 0.442%, carbon (C) 81.4%, hydrogen (H) 1.80%, sulfur (S) 0.05%, chlorine (Cl) 0.118%, elements of inorganic mineral were aluminum (Al) 0.00937%, calcium (Ca) 1.44%, chromium (Cr) 0.0072%, copper (Cu) 0.014%, iron (Fe) 0.145%, potassium (K) 1.60%, magnesium (Mg) 0.163%, manganese (Mn) 0.044%, nickel (Ni) 0.00514%, sodium (Na) 0.535%, phosphorus (P) 0.459%, silicon (Si) 0.0643%, strontium (Sr) 0.00424%, tin (tin, Sn) 0.0059%, and zinc (Zn) 0.0207%. The specific surface area (BET) was repeatedly detected as 425.24 ± 2.89 m2/g, and the pH was 9.14 (Table 3).

Table 2.

The basic properties of Cinnamomum burmannii charcoal. Testing method.

Table 3.

Comparison of charcoal properties between different feedstocks.

4. Discussions

4.1. Carbonization Temperature and Charcoal Yield

Carbonization is pyrolysis. Tomczyk et al. (2020) [32] compiled related research and classified pyrolysis into 3 types: fast pyrolysis at 400–600 °C, slow pyrolysis at 350–800 °C, and gasification at 700–1500 °C, the output ratio of which was liquid bio-oil (30%) from slow pyrolysis, 35% from gaseous synthetic gas, and 35% from solid biochar.

To obtain the same quality of charcoal and meet the market’s demand, the Cinnamomum burmannii charcoal in this study was produced directly in commercial charcoal kilns controlled at a similar temperature, other than being fired at different temperatures in laboratory-scale kilns. Many studies have shown that the heating rate, soak time, and carbonization temperature of the firing process will affect the charcoal yield and properties. In general, the charcoal yield will decrease with the increase in carbonization temperature (Askeland et al., 2019; Das et al., 2021; Jayasanka et al., 2020) [19,28,30].

Compared with the research of domestic and foreign scholars on charcoal products burned at more than 600 °C (Table 3), the general charcoal yield is 20%–35%, and the difference is also affected by materials and carbonization equipment. The charcoal yield from firing in an electric kiln or a box gasifier stove is usually higher than that in an earthen kiln.

In this study, either the charcoal yield from an individual kiln or the average from three kilns is only about 14%–15%, which is relatively lower compared with the research results (20%–35%) from the other literature. The differences are estimated to lie in an average of the highest carbonization temperature exceeding 800 °C, longer carbonization time of the material, and higher consumption of fuel during the burning process. On top of that, the irregular cylinder shapes of the prepared material made it difficult to be closely arranged when entering the kiln, which also led to a lot of material loss during the firing process.

Trees absorb carbon dioxide to grow. As long as Cinnamomum burmannii charcoal, made from burning Cinnamomum burmannii wood, does not burn, the carbon in the carbon dioxide can be fixed in the charcoal products, and will not be released back into the atmosphere, reducing carbon emissions and achieving carbon storage with benefits. The carbon conservation rate of the Cinnamomum burmannii burned into charcoal was calculated as 24.11% (=(1461 kg × 81.4%)/(9963 kg × 49.5%)). This means the burning of Cinnamomum burmannii charcoal can reduce the carbon dioxide released back into the atmosphere if the original material is not properly used and decays, thus a positive function of carbon dioxide reduction in the environment.

4.2. Comparison of the Basic Properties of Cinnamomum burmannii Charcoal

Table 3 is an analysis comparing the basic properties of Cinnamomum burmannii charcoal products and those of similar carbon products burned at over 600 °C by other domestic and foreign scholars. The pH of Cinnamomum burmannii charcoal was 9.14, close to the pH of 9.4 of Moso bamboo charcoal burnt at the approximate carbonization temperature in the table. According to the analysis of Tomczyk et al. (2020) [32] after having compiled research studies, the biochar after biomass is carbonized usually is alkaline (between 7.1–10.5), and the pH difference of biochar is related to not only the carbonization temperature but the type of biomass. Under similar carbonization conditions, the pH of biochar produced from lignified materials is often lower than that of non-lignified biomass. However, when Jayasanka et al. (2020) [28] studied the properties of Cinnamomum zeylanicum charcoal, belonging to the same genus as Cinnamomum burmannii, the charcoal was burned in a traditional drum kiln at a carbonization temperature as high as 500 °C, and pH tuned out to be 10.5. The alkalinity of biochar is good for acid soil improvement.

In addition to the pH of charcoal, the BET value of charcoal is also one of the important indicators to evaluate the adsorption capacity (Lin et al., 2005, Lin et al., 2007) [33,34]. The higher the BET value is, the better the adsorption capacity is, and the more effective it is in regulating air, moisture, metal substances, or volatile substances. The BET value of Cinnamomum burmannii charcoal burned in this study was 425.24 ± 2.89 m2/g, which was higher than that of Moso bamboo charcoal burned at 800 °C (369.7 m2/g), but was still not as high as that of peanut charcoal (448.2 m2/g) burned at 700 °C by scholars Ahmad et al. (2012) [35].

Zhao et al. (2017) [36] used apple branches to discuss the properties of biochar burned at different carbonization temperatures of 300–600 °C. The results showed that the increase in carbonization temperature was positively correlated with the specific surface area, that is, the higher the carbonization temperature, the larger the specific surface area of biochar would be. Das et al. (2021) [19] also showed a similar conclusion according to the results of analyzing the biochar research literature over the years. The higher temperature often changes the structure of the functional group composed of carbon, resulting in more micro pores to increase the specific surface area.

The ash of Cinnamomum burmannii charcoal was 5.96%, which was higher than the 1.63% of Moso bamboo charcoal and the 1.57% of Ma bamboo charcoal, but lower than the 9% of ash of Cinnamomum zeylanicum studied by Jayasanka et al. (2020) [28]. Zhang et al. (2019) [37] indicated in a study that the ash of wood charcoal (1.5–3.0%) was lower than that of peanut shell charcoal (7.0–12.0%). In addition, Askeland et al. (2019) [30] pointed out that the type of feedstock was a more decisive factor than the carbonization temperature in affecting the ash ratio of biochar. Generally, the ash ratio of biochar burned from herbal feedstock is higher than that from the wood feedstock. This is similar to the result in the literature complied in Table 3 that the ash ratio of charcoal burned from herbal biomass materials is higher.

Moreover, Table 3 presents that wood charcoal has a higher fixed carbon ratio than herbal charcoal, such as Cinnamomum burmannii charcoal, 80.71%, LC charcoal (Lantana camara), 57.67% (Das et al., 2021) [19], and RH charcoal (Rice husk), 51.1% (Tsai, 2014) [31]. The type of feedstock is considered to be one of the main factors affecting the fixed carbon ratio of biochar. Wood charcoal usually has a higher fixed carbon ratio than herbal charcoal does. Similar results can be found in the research by Askeland et al. (2019) [30] and Zhao et al. (2017) [37]. Carbonization temperature also influences the ratio of fixed carbon and volatile matter. The proportion of fixed carbon is often positively correlated with the carbonization temperature. The higher the carbonization temperature is, the greater the proportion of fixed carbon. On the other hand, the volatile matter is negatively correlated with the carbonization temperature. The higher the carbonization temperature is, the smaller the proportion of volatile matter (Askeland et al., 2019; Das et al., 2021; Zhao et al., 2017) [19,30,37]. For example, the volatile matter of pine bark charcoal was 38.5%, 29.3%, and 6.0%, respectively, at carbonization temperatures of 350, 450, and 750 °C (Tomczyk et al., 2020) [32]. The study of the carbonization of apple branches by Zhao et al. (2017) [37] also pointed to a similar trend. When the carbonization temperature went from 300 to 700 °C, the volatile matter decreased from 60.77% to 41.86%.

The basic composition of Cinnamomum burmannii charcoal contains 13.7% of O, which is an average among various kinds of wood charcoal. For example, in the case when researchers Lu Kun-zong and ZhouKun-chi (2009) burned six domestic economic bamboo species at 600 °C (Long-shoot bamboo, Thorn bamboo, Moso bamboo, Makino bamboo, Green bamboo, and Ma bamboo), the O was between 9.16%–33.24%. However, the O of apple branches charcoal burned at 300–600 °C accounted for 24.21%–6.59% (Zhao et al., 2017) [37], while the O constituted 24.47%–12.44% when pine branch charcoal was burned at 400–600 °C (Das et al., 2021) [19]. The O ratio of charcoal varied with different types of feedstocks and displayed a decreasing trend with the increase in carbonization temperature, and so did the proportions of H and of N in charcoal. By contrast, the proportion of C content increases with the rising carbonization temperatures (Askeland et al., 2019; Das et al., 2021; Zhao et al., 2017) [19,30,37]. In this study, the C content of Cinnamomum burmannii charcoal accounted for 81.4%.

The inorganic mineral elements detected in Cinnamomum burmannii charcoal consisted of Al, Ca, Cr, Cu, Fe, K, Mg, Mn, Ni, Na, P, Si, Sr, Sn, Zn, etc., among which the content ratio greater than 0.5% included Ca (1.44%), K (1.60%) and Na (0.535%), and the content of K was the highest. The types of inorganic mineral elements in different charcoals vary according to the types of feedstock. Regarding the research literature on charcoal, the inorganic mineral elements that have been mentioned and detected are Ca, Cr, Cu, Fe, K, Mg, Mn, P, and Zn, among which K and P are often discussed (Das et al., 2021; Jayasanka et al., 2020; Zhao et al., 2017) [19,28,37]. Though the less discussed Al and Sr were also detected in this study, their content percentages were lower than 0.01%.

5. Conclusions

To reduce waste of woody resources and to implement the circular economy for resource recovery, this study, using a current common business earthen kiln in Taiwan for carbonizing alien tree species, Cinnamomum Burnmannii, analyzed the basic properties of Cinnamomum burmannii charcoal burned at a carbonization temperature of over 800 °C. The analysis indicated that the specific surface area (BET) value reached 426.4 m2/g, pH 9.14, fixed carbon 80.71%. The results are favorable for applying Cinnamomum burmannii charcoal for the development and application of value-added products that require adsorption functions, such as deodorants and water purifiers to remove odors in the air and impurities in water. In addition, carbonization can fix the carbon originally in the wood, giving full play to the environmental carbon fixation function with a 24.11% carbon conservation rate. This contributes positively to carbon reduction in the environment, preventing the carbon absorbed during the growth of Cinnamomum burmannii trees from being released back into the atmosphere due to improper use after cutting, thereby decaying or burning unattended.

Author Contributions

Conceptualization, C.-H.F.; resources, J.-C.L.; validation, L.-C.L.; writing-review and editing, S.-H.W.; writing-origina.l draft preparation, Y.-J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Taiwan Forestry Research Institute, 109 Agriculture Science-15.1.3-Forest-G2; 109 Agriculture Science-15.1.2-Forest-G1.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not adopting publicly archived datasets.

Acknowledgments

This study was supported by the Science and Technology program: 109 Agriculture Science-15.1.3-Forest-G2 and 109 Agriculture Science-15.1.2-Forest-G1, of the Taiwan Forestry Research Institute of the Council of Agriculture, Executive Yuan. In addition, our appreciation also extends to the Dharma Drum Mountain World Center for Buddhist Education Park in Jinshan District, New Taipei county, Taiwan, which provided research materials free of charge. Without their generosity, this research wouldn’t have been made possible.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, C.F.; Yin, H.W.; Lu, S.Y. Facing the impact of Cinnamomoum burmannii on Cinnamomoum osmophloeum. Taiwan For. J. 2008, 34, 26–30. (In Chinese) [Google Scholar]

- Utami, R.; Khasanah, L.U.; Manuhara, G.J.; Ayuningrum, Z.K. Effects of Cinnamon Bark Essential Oil (Cinnamomum burmannii) on Characteristics of Edible Film and Quality of Fresh Bee. Pertanika J. Trop. Agric. Sci. 2019, 42, 1173–1184. [Google Scholar]

- Al-Dhubiab, B.E. Pharmaceutical applications and phytochemical profile of Cinnamomum burmannii. Pharmacogn. Rev. 2012, 6, 125–131. [Google Scholar] [CrossRef] [PubMed]

- Nasution, A.; Chikmawati, T.; Walujo, E.B.; Zuhud, E.A.M. Ethnoecology of Mandailing Tribe in Batang Gadis National Park. In Proceedings of the IOP Conference Series: Earth and Environmental Science 197(012017), The 2nd International Conference on Biosciences (ICoBio), Bogor, Indonesia, 8–10 August 2017; IPB International Convention Center: Bogor, Indonesia, 2017; pp. 1–9. [Google Scholar]

- Tamba, J.T.; Komariyah, S.; Faisal, T.M. Summation of Cinnamon Leaf Flour (Cinnamomum burmannii) with Different Concentrations in Feed on Growth of Snakehead (Channa striata). J. Perikan. Trop. 2020, 7, 35–44. [Google Scholar] [CrossRef]

- Syu, Y.C.; Fang, Y.L.; Hsu, W.C.; Chang, K.C. Study on Naturalized Distribution and Hybridization Test of Cinnamomoum burmannii. In Proceedings of the Symposium at 2014 Flatland Afforestation Test Research and Monitoring, Taipei, Taiwan, 17 September 2014; Taiwan Forestry Research Institute of 4F Conference Room: Taipei, Taiwan, 2014; pp. 9–13. (In Chinese). [Google Scholar]

- Ervina, M.; Nawu, Y.E.; Esar, S.Y. Comparison of in vitro antioxidant activity of infusion, extract and fractions of Indonesian Cinnamon (Cinnamomum burmannii) bark. Int. Food Res. J. 2016, 23, 1346–1350. [Google Scholar]

- Tseng, Y.H.; Liu, C.Y.; Wang, C.C.; Ou, C.H. Cinnamomum burmannii (Nees) Blume (Lauraceae), a Newly Naturalized Tree in Taiwan. Q. J. For. Res. 2008, 30, 25–30. [Google Scholar]

- Tsai, J.H.; Chen, H.Y.; Ye, Z.Y.; Su, S.W. Exotic Plant, Cinnamomoum burmannii plant groupings: Slopeland located in the west of Taichung Metropolitan Park as an example. In Proceedings of the Symposium at 2017 International Forum on Taichungology, Taichung, Taiwan, 27–29 October 2017; National Chung Hsing University: Taichung, Taiwan, 2017; pp. 393–410, (In Chinese with an English Summary). [Google Scholar]

- Horcher, A.T. Stand Dynamics of Cinnamomum Burmannii, an Invasive Tree, on O’ahu, Hawaii. Master’s Thesis, The University of Montana, Missoula, MT, USA, 2000. [Google Scholar]

- Laughlin, S.E. Avian Seed Dispersal of Cinnamomum burmannii in Nuuanu Valley O’ahu Hawaii and Its Implications for Alien Species Invasion. Master’s Thesis, The University of Montana, Missoula, MT, USA, 2000. [Google Scholar]

- Luo, Y.Y.; Liao, S.P.; Chen, C.F.; Chen, S.Y.; Koh, C.N. Study on Gut Passage Effect of Taiwan’s Native Avian Frugivores on Seed Germination of Cinnamomum burmannii. Q. J. Chin. For. 2012, 45, 55–66, (In Chinese with an English Summary). [Google Scholar]

- Chimera, C.; Drake, D.R. Effects of pulp removal on seed germination of five invasive plants in Hawaii. Plant Prot. Q. 2010, 25, 137–140. [Google Scholar]

- Taiwan Academy of Ecology. Cinnamomum burmannii Invades the Forests of Taiwan, an Artificial Ecological Crisis. Taiwan Acad. Ecol. Epaper. 2012, p. 320. Available online: https://drive.google.com/file/d/1IeuU7EFdHN2-ks4vEjKbip6fOpqaOIpz/view (accessed on 4 May 2021).

- Hwang, G.S.; Lee, C.M.; Wang, C.H.; Yu, H.Y. Making Charcoal from Wood of Leucaena leucocephala in Kenting National Park. J. Natl. Park 2010, 20, 25–33, (In Chinese with an English Summary). [Google Scholar]

- Lo, S.F.; Wang, S.Y. Effects of Carbonization Condition on the Basic Properties of Charcoals Made from Moso Bamboo and Ma Bamboo-(I) Charcoal Yield, Shrinkage, True Density, and Element Analysis. For. Prod. Ind. 2007, 26, 117–132, (In Chinese with an English Summary). [Google Scholar]

- Lo, S.F. Basic Properties of Bamboo Charcoals and Adsorption Capacities of Heavy Metal Ions by Bamboo Activated Carbons. Ph.D. Thesis, National Taiwan University, Taipei, Taiwan, 2008. (In Chinese with an English Summary). [Google Scholar]

- Lu, K.T.; Zhou, K.C. Manufacture of Bamboo Charcoals and Vinegars from Major Domestic Bamboos. Q. J. For. Res. 2009, 31, 55–64. [Google Scholar]

- Das, S.K.; Ghosh, G.K.; Avasthe, R.K.; Sinha, K. Compositional heterogeneity of different biochar: Effect of pyrolysis temperature and feedstocks. J. Environ. Manag. 2021, 278, 111501. [Google Scholar] [CrossRef] [PubMed]

- Lan, F.L.; Lai, H.L.; Teng, W.F. Study on the Moso Bamboo Charcoal Property. Crop. Environ. Bioinform. 2008, 5, 180–186, (In Chinese with an English Summary). [Google Scholar]

- Hsu, L.Y. Effect of Multiple-Step Carbonization on the Basic Properties and Adsorption Capacities of Moso Bamboo Charcoals. Master’s Thesis, National Chung Hsing University, Taichung, Taiwan, 2008. (In Chinese with an English Summary). [Google Scholar]

- Borchard, N.; Siemens, J.; Ladd, B.; Möller, A.; Amelung, W. Application of biochars to sandy and silty soil failed to increase maize yield under common agricultural practice. Soil Tillage Res. 2014, 144, 184–194. [Google Scholar] [CrossRef]

- Jien, S.H.; Chen, W.C. Effects of Co-applying Compost and Rice Hull Biochar on Release Potential of Nitrogen and Phosphorus in Slope land Soils. J. Taiwan Agric. Eng. 2014, 60, 61–71. [Google Scholar]

- Lin, D.F. Effects of Feedstock and Pyrolysis Temperature on Agronomic Performance of Biochar. Master’s Thesis, National Taiwan University, Taipei, Taiwan, 2013. (In Chinese with an English Summary). [Google Scholar]

- Hwang, G.S. Effects of Carbonization Temperatures in an Earthen Kiln on the Properties of Bamboo Charcoal. Taiwan J. Sci. 2016, 31, 285–291. [Google Scholar]

- Lin, Y.J.; Hwang, G.S. Charcoal from biomass residues of a Cryptomeria plantation and analysis of its carbon fixation benefit in Taiwan. Biomass Bioenergy 2009, 33, 1289–1294. [Google Scholar] [CrossRef]

- Wang, Y.C.; Lin, J.C. Air quality enhancement zones in Taiwan: A carbon reduction benefit assessment. For. Policy Econ. 2012, 23, 40–45. [Google Scholar] [CrossRef]

- Jayasanka, D.J.; Jayasinghe, G.Y.; Maheepala, S. Cinnamon Wood Biochar Characteristics and Application Rates Influence on Crop Growth and Properties of Problematic Soil in Southern Sri Lanka. Int. J. Innov. Technol. Explor. Eng. (IJITEE) 2020, 9, 30–33. [Google Scholar]

- Lin, Y.J.; Ho, C.L.; Yu, H.Y.; Hwang, G.S. Study on Charcoal Production with Branches and Tops Wood of Cryptomeria Japonica Using an Earthen Kiln. Q. J. Chin. For. 2008, 41, 549–558, (In Chinese with English Summary). [Google Scholar]

- Askeland, M.; Clarke, B.; Paz-Ferreiro, J. Comparative characterization of biochars produced at three selected pyrolysis temperatures from common woody and herbaceous waste streams. PeerJ 2019, 7, e6784. [Google Scholar] [CrossRef] [PubMed]

- Tsai, C.C. Amelioration of Degradation Potential of Facilities Soils with Rice Husk Biochar: The Effects on Soil Physic-Chemical Properties, Soil Fertility, and Crop Growth. Ministry of Science and Technology Special Research Project Achievement Report. 2014. Available online: https://www.grb.gov.tw/search/planDetail?id=3101246 (accessed on 6 May 2021).

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Bio/Technol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Lin, Y.J.; Lin, J.C.; Hwang, G.S.; Wei, M.T. Establishing Bamboo Charcoal Quality Evaluation Indicators in Taiwan. Taiwan J Sci 2005, 20, 269–281. [Google Scholar]

- Lin, Y.J.; Lin., J.C.; Hwang, G.H.; Lee, K.C. Application of the Analytic Hierarchy Process (AHP) to Analyze the Importance of Bamboo Charcoal Quality Indicators. Taiwan J. Sci. 2007, 22, 15–28. [Google Scholar]

- Ahmad, M.; Lee, S.S.; Dou, X.; Mohan, D.; Sung, J.K.; Yang, J.E.; Ok, Y.S. Effects of pyrolysis temperature on soybean stove and peanut shell-derived biochar properties and TCE adsorption in water. Bioresour. Technol. 2012, 118, 536–544. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.X.; Ta, N.; Wang, X.D. Effect of Temperature on the Structural and Physicochemical Properties of Biochar with Apple Tree Branches as Feedstock Material. Energies 2017, 10, 1293. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Zhu, Z.; Shen, B.; Liu, L. Insights into biochar and hydrochar production and applications: A review. Energy 2019, 171, 581–598. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).