Influence of Chrysoporthe deuterocubensis Canker Disease on the Machining Properties of Eucalyptus urograndis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Evaluation of Machining Properties

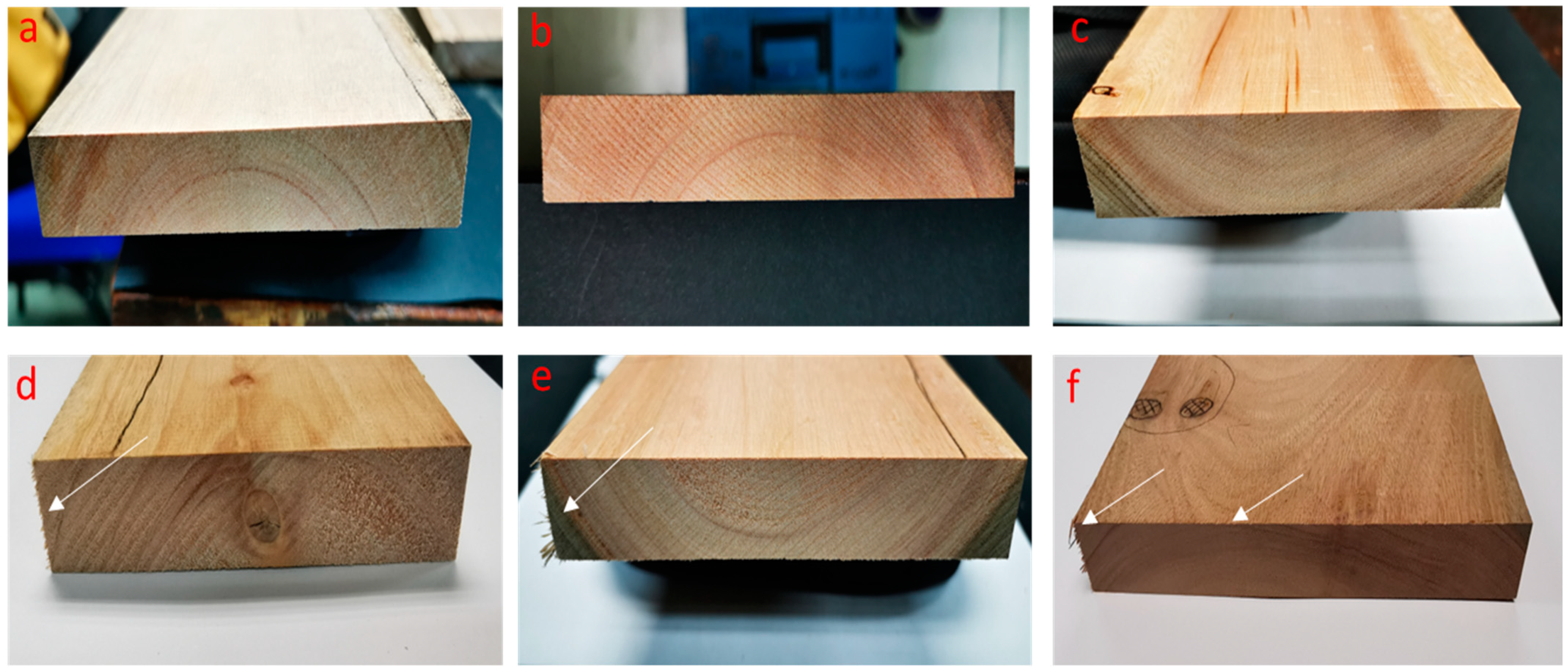

2.1.1. Sawing Quality Assessment

2.1.2. Planing Quality Assessment

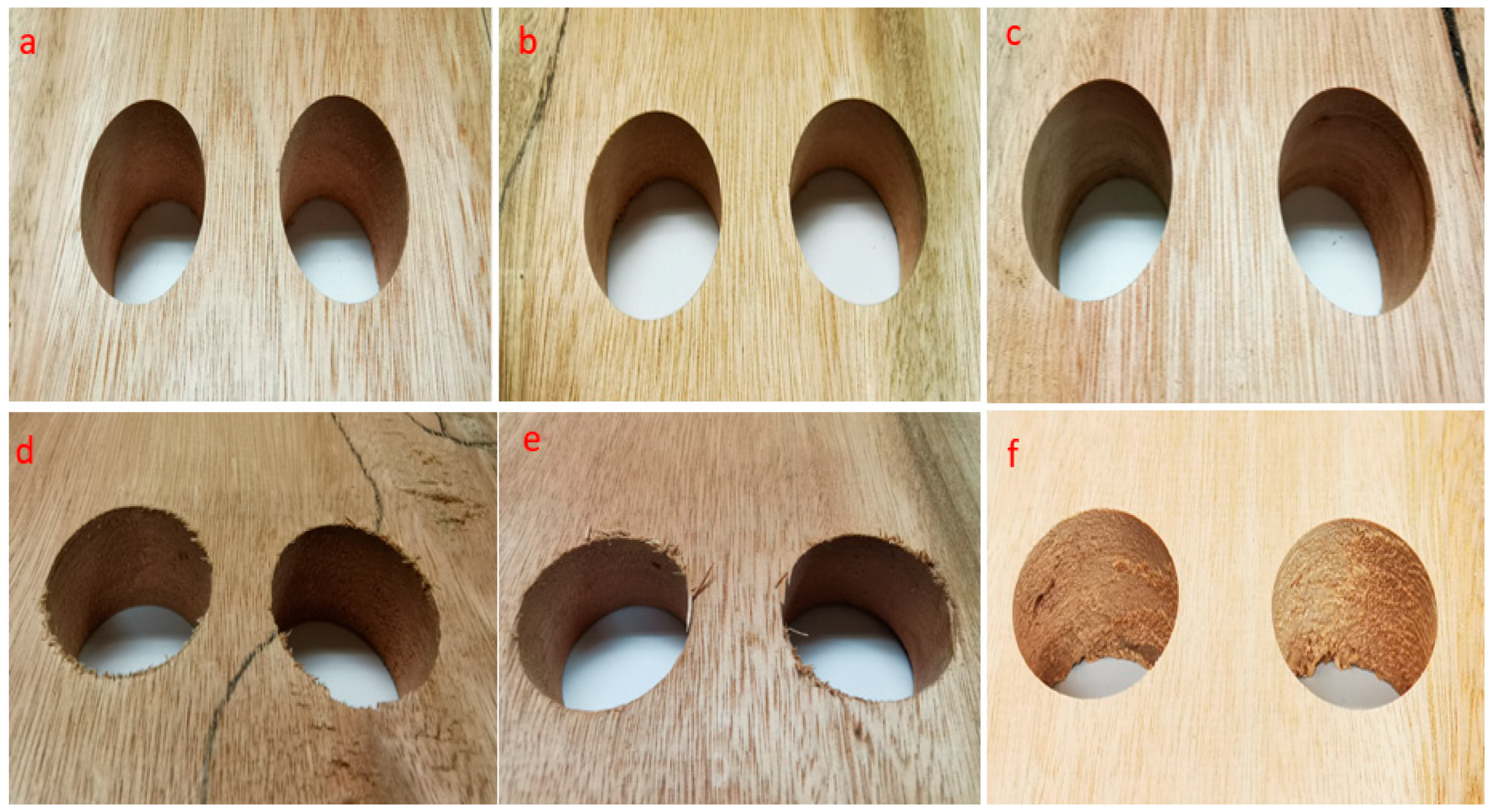

2.1.3. Boring Quality Assessment

2.1.4. Surface Roughness Test

2.2. Statistical Analysis

3. Results and Discussion

3.1. Sawing Properties

3.2. Planing Properties

3.3. Boring Properties

3.4. Surface Roughness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agricultural Organisation of the United Nations. Global Forest resources assessment 2015. In How Are the World’s Forests Changing? 2nd ed.; Food and Agricultural Organisation of the United Nations: Rome, Italy, 2016; p. 56. Available online: http://www.fao.org/3/a-i4793e.pdf (accessed on 29 March 2022).

- Fenning, T.M.; Gershenzon, J. Where will the wood come from? Plantation forests and the role of biotechnology. Trends Biotechnol. 2002, 20, 291–296. [Google Scholar] [CrossRef]

- Siry, J.P.; Cubbage, F.W.; Ahmed, M.R. Sustainable Forest management: Global trends and opportunities. For. Policy Econ. 2003, 7, 551–561. [Google Scholar] [CrossRef]

- Cabalova, I.; Vybohova, E.; Igaz, R.; Kristak, L.; Kack, F.; Antov, P.; Papadopoulos, A.N. Effect of oxidizing thermal modification on the chemical properties and thermal conductivity of Norway spruce (Picea abies L.) wood. Wood Mater. Sci. Eng. 2021, 1–10. [Google Scholar] [CrossRef]

- Ahmad, Z.Y. Evaluating the Growth Performance of 4-year-old Neolamarckia cadamba in Malaysia. Planter 2012, 88, 100–107. [Google Scholar]

- Ahmad, Z.Y. Planting of Eucalyptus in Malaysia. Acta Sci. Agric. 2020, 4, 139–140. [Google Scholar] [CrossRef]

- Ahmad, Z.Y.; Hassan, N.H.; Loon, N.T.; Heng, L.H.; Zorkarnain, F.A. Comparing the early growth performance of plantation–grown Eucalyptus hybrid and Eucalyptus pellita, South Johore, Peninsular Malaysia. WJARR 2020, 6, 234–238. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Antov, P.; Kristak, L.; Paridah, M.T. Engineering wood products from Eucalyptus spp. Adv. Mater. Sci. Eng. 2022, 2022, 8000780. [Google Scholar] [CrossRef]

- Wong, S.K.; Ahmad, Z.Y.; Charles, G.D.C.; Peter, K.C.S. Recommending Eucalyptus Species for Soft Loan Financing; Working Paper Presented at the 1st Technical Meeting on Forest Plantation Programme; Malaysian Timber Industry Board (MTIB): Kuala Lumpur, Malaysia, 2015. [Google Scholar]

- Arnold, R.; Xie, Y.; Wu, Z.; Chen, S.; Apeng, D.U.; Luo, J. Advances in eucalypt research in China. Front. Agric. Sci. Eng. 2017, 4, 10. [Google Scholar]

- Van den Berg, G.J.; Verryn, S.D.; Chirwa, P.W.; Van Deventer, F. Realised genetic gains and estimated genetic parameters of two Eucalyptus grandis × E. urophylla hybrid breeding strategies. South. For. J. For. Sci. 2018, 80, 9–19. [Google Scholar] [CrossRef]

- Melesse, S.F.; Zewotir, T. Variation in growth potential between hybrid clones of Eucalyptus trees in eastern South Africa. J. For. Resour. 2017, 28, 1157–1167. [Google Scholar] [CrossRef]

- Rauf, M.R.B.A.; McTaggart, A.R.; Marincowitz, S.; Barnes, I.; Japarudin, Y.; Wingfield, M.J. Pathogenicity of Chrysoporthe deuterocubensis and Myrtoporthe bodenii gen. et sp. nov. on Eucalyptus in Sabah, Malaysia. Australas Plant Pathol. 2020, 49, 53–64. [Google Scholar] [CrossRef]

- Li, R.; He, C.; Xu, W.; Wang, X. Modeling and optimizing the specific cutting energy of medium density fiberboard during the helical up-milling process. Wood Mater. Sci. Eng. 2022, 1–8. [Google Scholar] [CrossRef]

- Kminiak, R.; Siklienka, M.; Igaz, R.; Krišťák, Ľ.; Gergeľ, T.; Němec, M.; Réh, R.; Očkajová, A.; Kučerka, M. Effect of cutting conditions on quality of milled surface of medium-density fibreboards. BioResources 2020, 15, 746–766. [Google Scholar] [CrossRef]

- Li, R.; Yao, Q.; Xu, W.; Li, J.; Wang, X. Study of Cutting Power and Power Efficiency during Straight-Tooth Cylindrical Milling Process of Particle Boards. Materials 2022, 15, 879. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Yang, F.; Wang, X. Modeling and Predicting the Machined Surface Roughness and Milling Power in Scot’s Pine Helical Milling Process. Machines 2022, 10, 331. [Google Scholar] [CrossRef]

- Rokeya, U.K.; Akter, H.M.; Rowson, A.M.; Paul, S.P. Physical and mechanical properties of (Acacia auriculiformis × A. mangium) hybrid Acacia. J. Bangladesh Acad. Sci. 2010, 34, 181–187. [Google Scholar] [CrossRef]

- Jusoh, I.; Zaharin, F.A.; Adam, N.S. Wood quality of Acacia hybrid and second-generation Acacia mangium. BioResources 2014, 9, 150–160. [Google Scholar] [CrossRef]

- Ruiz, A.F.; Gonzalez, P.; Hernandez, V.J.I.; Romero, M.A.; Fuentes, M.S. Mechanical properties of wood of two Mexican oaks: Relationship to selected physical properties. Eur. J. Wood Wood Prod. 2018, 76, 69–77. [Google Scholar] [CrossRef]

- Dahali, R.; Md Tahir, P.; Roseley, A.S.M.; Hua, L.S.; Bakar, E.S.; Ashaari, Z.; Abdul Rauf, M.R.; Zainuddin, N.A.; Mansoor, N.S. Influence of Chrysoporthe deuterocubensis Canker Disease on the Physical and Mechanical Properties of Eucalyptus urograndis. Forests 2021, 12, 639. [Google Scholar] [CrossRef]

- ASTM (American Society for Testing and Materials). ASTM D 1666-11; Standard Test Methods for Conducting Machining Tests of Wood and Wood-Based Materials. ASTM International: West Conshohocken, PA, USA, 2011.

- ISO 4288; Geometrical Product Specifications (GPS). Surface Texture. Profile Method. Rules and Procedures for The Assessment of Surface Texture. British Standards Institute: London, UK, 1996.

- Abdulrachman, A.J.; Karnasudirdja, S. Sifat Permesinan Kayu-Kayu Indonesia. Lap. BPHH 1982, 160, 23–37. [Google Scholar]

- Ginoga, B. Sifat Pemesinan Enam Jenis Kayu Indonesia. Jurnal Penelitian Hasil Hutan. Pusat Penelitian dan Pengembangan Hasil Hutan dan Sosial Ekonomi Kehutanan. Badan Penelit. Pengemb. Kehutan. Bogor. 1995, 13, 246–251. [Google Scholar] [CrossRef]

- Sucipto, T. Pengerjaan Kayu dan Sifat Pemesinan Kayu; Universitas Sumatera Utara, Digital Library: Medan, Indonesia, 2009. [Google Scholar]

- Redzuan, M.S.J.; Paridah, M.T.; Anwar, U.M.K.; Juliana, A.H.; Lee, S.H.; Norwahyuni, M.Y. Effects of surface pretreatment on wettability of Acacia mangium wood. J. Trop. For. Sci. 2019, 31, 249–258. [Google Scholar] [CrossRef]

- Davis, E.M. Machining and Related Characteristics of United States Hardwoods. Technical Bulletin No. 1267; Wood Technologist, Forest Products Laboratory: Madison, WI, USA, 1962; pp. 1–68. [Google Scholar]

- Siswanto, N. Sifat-Sifat Pemesinan Kayu Pilang (Acacia leucophloea Willd) Dibandingkan dengan Kayu Gmelina (Gmelina arborea Roxb) dan Mangium (Acacia mangium Willd). Skripsi Fak. Kehutanan. Inst. Pertan. Bogor. Bogor. 2002; Unpublished. [Google Scholar]

- Roger, R. Sifat Pemesinan Kayu Ekaliptus; Program Studi Kehutanan Fakultas Pertanian, Universitas Sumatera Utara: Medan, Indonesia, 2011. [Google Scholar]

- Gearson, F. How to Prevent Tearout on A Table Saw in Hobbies. 2002. Available online: http://www.goarticles.com/cgi-bin/showa.Cgi?C=2298287 (accessed on 12 May 2022).

- Wong, T.C.; Chan, C.S.; Ting, K.B.; Khairul, M. Chapter 4: Sawing and Machining. In Testing Methods for Plantation Grown Tropical Timbers; Tan, Y.E., Lim, N.P.T., Gan, K.S., Wong, T.C., Lim, S.C., Thilagawaty, M., Eds.; FRIM: Selangor, Malaysia, 2010; pp. 45–78. [Google Scholar]

- Malkocoglu, A.; Ozdemir, T. The machining properties of some hardwoods and softwoods naturally grown in Eastern Black Sea Region of Turkey. J. Mater. Processing Technol. 2006, 173, 315–320. [Google Scholar] [CrossRef]

- Malaysian Timber Industrial Board (MTIB). Medium Hardwood Eucalyptus. In 100 Malaysian Timbers-2010 Edition; Malaysian Timber Industry Board: Kuala Lumpur, Malaysia, 2010; pp. 132–133. [Google Scholar]

- Hamzah, N.N.; Bakar, E.S.; Ashaari, Z.; Hua, L.S. Assessment of oil palm wood quality improvement through integrated treatment process as function of sawing pattern and slab thickness. J. Oil Palm Res. 2017, 29, 366–372. [Google Scholar] [CrossRef]

- Sitinjak, H. Sifat Pemesinan Kayu Kemiri (Aleurites moluccana Willd); Skripsi Departemen Kehutanan, Universitas Sumatera Utara: Medan, Indonesia, 2008. [Google Scholar]

- Belleville, B.; Ashley, P.; Ozarska, B. Wood machining properties of Australian plantation-grown Eucalypts. Maderas.-Cienc. Tecnol. 2016, 18, 677–688. [Google Scholar] [CrossRef]

- Gupta, S.; Singh, C.P.; Kishan-Kumar, V.S.; Shukla, S. Machining properties of Melia dubia wood. Maderas. Cienc. Tecnol. 2019, 21, 197–208. [Google Scholar] [CrossRef]

- Shortle, W.D.; Dudzik, K.R. Wood Decay in Living and Dead Trees: A Pictorial Overview; United States Department of Agriculture Forest Service Northern Research Station: Nashville, TN, USA, 2012. [Google Scholar]

- Gunduz, G.; Oral, M.A.; Akyuz, M.; Aydemir, D.; Yaman, B.; Asik, N.; Bulbul, A.S.; Allahverdiyev, A. Physical, Morphological Properties and Raman Spectroscopy of Chestnut Blight Diseased Castanea Sativa Mill. Wood. CERNE 2016, 22, 43–58. [Google Scholar] [CrossRef]

- Paiman, B.; Lee, S.H.; Zaidon, A. Machining properties of natural regeneration and planted Acacia Mangium × A. Auriculiformis hybrid. J. Trop. For. Sci. 2018, 30, 135–142. [Google Scholar] [CrossRef]

- Tan, W.S. Machining Properties of Stressed and Non-Stressed Wood of H. brasiliensis, A. mangium and A. auriculiformis. BSc Dissertation, Universiti Putra Malaysia, Serdang, Malaysia, 2002. [Google Scholar]

- Naji, H.R.; Bakar, E.S.; Sahri, M.H.; Soltani, M.; Hamid, H.A.; Ebadi, S.E. Variation in mechanical properties of two rubberwood clones in relation to planting densities. J. Trop. For. Sci. 2014, 26, 503–512. [Google Scholar]

- Lubis, M.A.R.; Park, B.D.; Lee, S.M. Performance of hybrid adhesives of blocked-pMDI/melamine-urea-formaldehyde resins for the surface lamination on plywood. J. Korean Wood Sci. Technol. 2019, 47, 200–209. [Google Scholar] [CrossRef]

- Tulik, M. Cambial history of Scots pine trees (Pinus sylvestris) prior and after the Chernobyl accident as encoded in the xylem. Environ. Exp. Bot. 2001, 46, 1–10. [Google Scholar] [CrossRef]

| Class | Category | Symptom |

|---|---|---|

| 1 | Healthy | Stem appears normal without any symptom of being infected |

| 2 | Moderate | Swollen bark (callus) |

| Cracking | ||

| Fruiting structure | ||

| Fresh kino pocket | ||

| Canker | ||

| 3 | Severe | Swollen bark (callus) |

| Cracking | ||

| Fruiting structure | ||

| Fresh kino pocket and fresh kino/gummosis | ||

| Canker | ||

| Sunken | ||

| Rotten | ||

| 4 | Very severe | Swollen bark (callus) |

| Cracking | ||

| Fruiting structure | ||

| Dried kino pocket and dried kino/gummosis | ||

| Canker | ||

| Sunken | ||

| Rotten | ||

| Shoots |

| Quality Grade | Machining Quality | Defect Free Area (%) |

|---|---|---|

| I | Very good (no defects) | 81–100 |

| II | Good (few slight defects which can be eliminated by light sanding) | 61–80 |

| III | Fair (lots of slight defects, some obvious defects which can be eliminated by sanding) | 41–60 |

| IV | Poor (serious defects (deep and big) which are hard to eliminate) | 21–40 |

| V | Very poor (very serious defects and prohibited to use) | 0–20 |

| Tracing Direction | Across the Grain |

|---|---|

| Tracing speed | 0.1 mm/s |

| Cut off length | 0.8 mm (sawing and boring), and 2.5 mm (planing) |

| Stylus tip radius | 2 µm |

| Stylus tip angle | 90° |

| Tracing length | 4 mm (sawing and boring), and 12.5 mm (planing) |

| Defect Types | Value | Infection Classes | p-Value | |||

|---|---|---|---|---|---|---|

| 1 (Healthy) | 2 (Moderate) | 3 (Severe) | 4 (Very Severe) | |||

| Defect-free area (%) | Mean 1 | 84.04 b | 81.35 b | 83.88 b | 76.67 a | 0.001 *** |

| SD | 5.85 | 6.68 | 8.29 | 10.01 | ||

| Defective area (%) | Mean | 15.96 a | 18.65 a | 16.11 a | 23.33 b | 0.001 *** |

| SD | 5.85 | 6.68 | 8.29 | 10.01 | ||

| Fuzzy grain (%) | Mean | 8.57 a | 10.11 ab | 9.60 ab | 12.77 b | 0.064 |

| SD | 4.97 | 6.28 | 6.97 | 6.46 | ||

| Tearout (%) | Mean | 7.39 a | 8.54 ab | 6.51 a | 10.57 b | 0.002 ** |

| SD | 2.69 | 3.33 | 3.32 | 6.17 | ||

| Infection Classes | Grade I (Very Good) | Grade II (Good) | Grade III (Fair) | Grade IV (Poor) | Grade V (Very Poor) |

|---|---|---|---|---|---|

| 1 (Healthy) | 22 | 8 | 0 | 0 | 0 |

| 2 (Moderate) | 19 | 10 | 1 | 0 | 0 |

| 3 (Severe) | 22 | 6 | 2 | 0 | 0 |

| 4 (Very severe) | 15 | 11 | 4 | 0 | 0 |

| Defect Types | Value | Infection Classes | ||||

|---|---|---|---|---|---|---|

| 1 (Healthy) | 2 (Moderate) | 3 (Severe) | 4 (Very Severe) | p-Value | ||

| Defect-free area (%) | Mean 1 | 83.60 b | 78.90 ab | 76.93 ab | 71.71 a | 0.011 ** |

| SD | 10.42 | 14.75 | 13.39 | 15.81 | ||

| Defective area (%) | Mean | 16.40 a | 21.00 ab | 23.07 ab | 28.29 b | 0.011 ** |

| SD | 10.42 | 14.75 | 13.39 | 15.81 | ||

| Fuzzy grain (%) | Mean | 1.20 a | 1.12 a | 1.30 a | 2.05 a | 0.286 |

| SD | 1.93 | 1.92 | 1.83 | 2.53 | ||

| Chip grain (%) | Mean | 4.91 a | 8.00 ab | 8.22 ab | 10.42 c | 0.093 |

| SD | 5.34 | 9.32 | 7.50 | 10.44 | ||

| Chip mark (%) | Mean | 10.29 a | 11.98 a | 13.56 a | 15.82 a | 0.279 |

| SD | 8.05 | 12.99 | 11.21 | 12.41 | ||

| Infection Classes | Grade I (Very Good) | Grade II (Good) | Grade III (Fair) | Grade IV (Poor) | Grade V (Very Poor) |

|---|---|---|---|---|---|

| 1 (Healthy) | 25 | 3 | 2 | 0 | 0 |

| 2 (Moderate) | 13 | 14 | 2 | 1 | 0 |

| 3 (Severe) | 18 | 9 | 1 | 2 | 0 |

| 4 (Very severe) | 10 | 13 | 3 | 4 | 0 |

| Defect Types | Value | Infection Classes | p-Value | |||

|---|---|---|---|---|---|---|

| 1 (Healthy) | 2 (Moderate) | 3 (Severe) | 4 (Very Severe) | |||

| Defect-free area (%) | Mean 1 | 82.82 c | 81.30 bc | 77.26 ab | 74.81 a | 0.001 *** |

| SD | 6.58 | 8.65 | 9.47 | 8.25 | ||

| Defective area (%) | Mean | 17.80 a | 18.70 ab | 22.74 bc | 25.19 c | 0.001 *** |

| SD | 6.58 | 8.65 | 9.47 | 8.25 | ||

| Fuzzy grain (%) | Mean | 7.43 a | 8.90 ab | 10.58 b | 11.75 b | 0.027 ** |

| SD | 2.97 | 6.51 | 7.64 | 5.08 | ||

| Tearout (%) | Mean | 9.75 a | 9.80 a | 12.17 b | 13.44 b | 0.001 *** |

| SD | 4.49 | 3.40 | 3.30 | 4.94 | ||

| Infection Classes | Grade I (Very Good) | Grade II (Good) | Grade III (Fair) | Grade IV (Poor) | Grade V (Very Poor) |

|---|---|---|---|---|---|

| 1 (Healthy) | 18 | 11 | 1 | 0 | 0 |

| 2 (Moderate) | 12 | 12 | 6 | 0 | 0 |

| 3 (Severe) | 16 | 11 | 3 | 0 | 0 |

| 4 (Very severe) | 4 | 22 | 4 | 0 | 0 |

| Infection Classes | Sawing | Planing | Boring | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Value | Ra (µm) | Rz (µm) | Rmax (µm) | Ra (µm) | Rz (µm) | Rmax (µm) | Ra (µm) | Rz (µm) | Rmax (µm) | |

| 1 (Healthy) | Mean 1 | 7.82 a | 31.24 a | 54.99 a | 8.31 a | 27.81 a | 52.96 a | 6.90 a | 56.6 a | 73.40 a |

| SD | 1.91 | 9.78 | 11.66 | 1.92 | 10.89 | 16.79 | 0.96 | 7.58 | 8.41 | |

| 2 (Moderate) | Mean | 7.62 a | 30.67 a | 54.54 a | 8.76 ab | 27.92 a | 52.78 a | 6.69 a | 56.64 a | 74.68 a |

| SD | 1.76 | 10.37 | 11.56 | 1.80 | 7.69 | 10.73 | 0.87 | 7.81 | 9.37 | |

| 3 (Severe) | Mean | 8.06 a | 29.28 a | 53.99 a | 9.48 b | 26.25 a | 52.66 a | 7.76 b | 57.25 a | 71.95 a |

| SD | 1.20 | 10.12 | 11.82 | 2.12 | 12.85 | 13.75 | 0.93 | 7.65 | 7.53 | |

| 4 (Very severe) | Mean | 8.10 a | 29.54 a | 51.32 a | 9.80 b | 29.17 a | 55.77 a | 8.25 b | 58.15 a | 73.96 a |

| SD | 1.61 | 10.10 | 11.28 | 2.28 | 12.86 | 21.71 | 1.14 | 7.33 | 10.25 | |

| p-Value | 0.640 | 0.859 | 0.629 | 0.023 ** | 0.797 | 0.859 | 0.000 *** | 0.846 | 0.684 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dahali, R.; Lee, S.H.; Md. Tahir, P.; Bakar, E.S.; Muhammad Roseley, A.S.; Ibrahim, S.A.; Mohd Yusof, N.; Mohammad Suffian James, R. Influence of Chrysoporthe deuterocubensis Canker Disease on the Machining Properties of Eucalyptus urograndis. Forests 2022, 13, 1366. https://doi.org/10.3390/f13091366

Dahali R, Lee SH, Md. Tahir P, Bakar ES, Muhammad Roseley AS, Ibrahim SA, Mohd Yusof N, Mohammad Suffian James R. Influence of Chrysoporthe deuterocubensis Canker Disease on the Machining Properties of Eucalyptus urograndis. Forests. 2022; 13(9):1366. https://doi.org/10.3390/f13091366

Chicago/Turabian StyleDahali, Rasdianah, Seng Hua Lee, Paridah Md. Tahir, Edi Suhaimi Bakar, Adlin Sabrina Muhammad Roseley, Siti Aminah Ibrahim, Norwahyuni Mohd Yusof, and Redzuan Mohammad Suffian James. 2022. "Influence of Chrysoporthe deuterocubensis Canker Disease on the Machining Properties of Eucalyptus urograndis" Forests 13, no. 9: 1366. https://doi.org/10.3390/f13091366

APA StyleDahali, R., Lee, S. H., Md. Tahir, P., Bakar, E. S., Muhammad Roseley, A. S., Ibrahim, S. A., Mohd Yusof, N., & Mohammad Suffian James, R. (2022). Influence of Chrysoporthe deuterocubensis Canker Disease on the Machining Properties of Eucalyptus urograndis. Forests, 13(9), 1366. https://doi.org/10.3390/f13091366