Abstract

Within-stem variation in the mechanical properties of Portuguese oak wood was analysed, considering different locations (three sites in the centre and north of Portugal—Site 1, Site 2, Site 3) and positions within the tree (two distances to pith—P1, P2). The study comprised compression parallel to the grain, bending strength and modulus of elasticity. Ultimately, this study aims at assuring the building of a body of knowledge on the technological quality and processing options for this species. The results showed for one provenance, Site 1, a significant effect of the distance to pith in the mechanical properties, which can be related to a different soil composition. For this provenance, a decrease in the compression and bending strength was verified from pith to bark. For the other provenances (Site 2 and Site 3), no effect was noticed. The overall behaviour showed noticeable correlations between the mechanical properties and density.

1. Introduction

Oak woods (Quercus) are considered to be valuable timber, generally appreciated as wooden species since they are associated with an image of beauty and mechanical resistance, and their properties determined for structural and non-structural end uses; they are one of the most important and widely used sources of structural timber in Europe [1,2,3].

Studies focused on the relationships between the mechanical properties of English oak (Q. robur) and the effects of different features for predicting the strength and elasticity in beams for construction concluded that the presence of sapwood did not exhibit significant influence on strength performance [4,5]. Merela et al., 2013 rejected the hypothesis that the properties of red oak (Q. cerris) are inferior to those of white oaks [6]. Properties like density, bending strength, compressive strength and Brinell hardness were assessed for white (Q. petraea and Q. robur) and red oaks (Q. cerris). In all cases, the properties of Q. cerris had higher values than those of white oaks, and red oak sapwood had the highest values. Green et al. demonstrated that relationships between mechanical property values for structural lumber produced from northern oak are similar to those found for softwood species [7]. Babiak et al. studied the differences in modulus of elasticity (MOE) of the three-and four-point bending of oak wood and obtained an average MOE = 10,431 Nmm−2 for samples with different moisture contents [8].

Knapic et al. studied the qualities of cork oak (Q. suber L.) wood for flooring, namely its dimensional stability, swelling, hardness, and wear resistance, and concluded that cork oak properties present a similar performance to other oak woods currently used for floor coverings [9]. Knapic et al. indicated that Q. suber presents a very dense and homogeneous wood, alongside with a reduced variability in the density components within the tree along the stem and a small intra-ring variability regarding differences between earlywood and latewood, as well as between minimum and maximum density values [10,11]. Although density could be used as an indirect reference for defining wood quality, the prediction of possible end uses is always dependent upon the determination of the strength and stiffness as well as its durability. Xu showed that oak wood (Q. rubra) MOE increases linearly with density [12]. An increase in density increases values for modulus of elasticity (MOE) and bending strength.

Kránitz et al. studied MOE values of recent and old European oak; however, due to different densities, the results cannot be directly related to aging. A study focusing on aged wood concluded that an aging effect on the mechanical properties could not be ascertained due to a potential influence of the annual ring structure on the elastic behaviour [13]. Analysing the mechanical and physical properties of common oak wood (Q. robur) under the influence of heat pressure steaming (HPS) showed that the analysed modification process does not affect the elastic properties, although a decrease in bending and tensile strength was observed [14].

Jiang et al. determined the effects of temperature on the compressive strength of Mongolian oak (Q. mongolica) and concluded that the relationship between compression strength (fc0) and temperature could be described by a polynomial model [15].

Bi et al. showed that the transverse vibration method, a non-destructive test (NDT), presents higher correlation between the dynamic elastic modulus (MOEDynamic) and static elastic modulus (MOEstatic) when compared with other methods [16]. Hu et al. studied the influence of the height in elastic moduli (EL, ER, and ET) and shear moduli (GL, GR, and GT) and concluded that these parameters increased with height for the same cross-sectional area but decreased with increasing cross-sectional area with the same height [17]. Hu et al. concluded, through transverse vibration method, that the effect of the wood species on MOE was significant [18].

There is at present a renewed interest in valuing autochthonous species for reasons of sustainability, biodiversity and conservation as well as the reduction of the risk of forest fires. Moreover, the urgent reshape of the rural landscape has led to a more urgent need to value all our autochthonous trees, rethinking silvicultural plans and planning added valued products, with the underlying thought of adding value to the forest owner and the value chain while addressing the challenges of maritime pine issues with diseases. Among the autochthonous species, the Portuguese oak (Q. faginea Lam.) is considered a potential source of high-quality wood products [19]. The last Portuguese National Forest Inventory (IFN) tallied deciduous oak tree forest land of around 81.7 mil ha (IFN, 2015), around 2.5% of the total forest land area. The extended use of oak timber mainly during the maritime expansion policy (XIV and XVI century), along with other reasons, explains this actual scenario [20].

Different studies addressed the variations in density of different oak species. Knapic et al. indicated that Portuguese oak wood compares favourably with other oak species regarding wood density characteristics [21]. The values and uniformity in wood density are an advantage when considering using this wood for solid wood products.

Although some studies of Portuguese oak (Q. faginea) found that this wood showed appealing aesthetics, high density and considerable mechanical strength [1,3,11,21], there is still a lack of information regarding its compressive and bending strength. This is the underlined objective of this paper, to contribute to the body of knowledge on Portuguese oak (Q. faginea Lam.) focusing on the technological quality and processing options for this species.

2. Material and Methods

Regarding the distribution of the Q. faginea population in Portuguese territory, it is possible to verify the existence of two areas, a larger one which corresponds to the natural occurrence area of this oak because it has favourable ecological conditions and a smaller area that corresponds to mixed or pure populations that were mapped in the 1990s [22].

The trees were harvested at three different locations in the centre and north of Portugal, Alcobaça (site 1—S1), Cortiços (site 2—S2) and Gralhós (site 3—S3), in natural regeneration stands with ages ranging from 34 to 60 years.

From S1 were sampled ten trees, three from S2 and seven from S3. According to [23], S1 is characterized by fine soil texture; pH between 5.5–6.5; soil thickness between 25 and 30; presence of physical barriers (narrow terraces), characterized as a soil with high ecological value, low to moderate potential permeability and low to moderate current permeability. S2 is characterized by coarse and medium soil texture; pH between 4.5 and 6.5; soil thickness between 10 and 30; presence of some physical barriers (R2 rocky outcrops > 25%–40% area), characterized as soil with very low ecological value, low to moderate potential permeability, low to moderate current permeability and some maximum infiltration area (type I and type II). S3 is characterized by coarse soil texture; pH between 5 and 5.5; soil thickness between 50 and 100, characterized as soil with reduced ecological value, high potential permeability and high current permeability and considered a maximum infiltration area (type II). The maximum infiltration areas are the current permeability class with higher permeability. They are classified into two classes (type I and type II) that indicate different degrees of sensitivity and the need to consider different planning and management measures [23].

Variability occurs due to several factors, and for most species, a horizontal or vertical pattern of variation can be detected [24]. For this reason, in each tree, two logs were cut, one approximately at diameter at breast height (DBH) and one above 3.4 m, except for S1, where only a log at DBH was obtained for reasons of harvest logistics.

The samples were prepared according to the standard used for the mechanical tests IPQ standard (1973) NP 618 and 619. The mechanical testing was carried out using a Shimadzu AG-I universal machine capable of measuring the load applied with an accuracy of 1% in the range 1 kN to 250 kN.

Samples were cut with the dimensions indicated by the standards used at different distances from the pith (10% and 90% of the radius, P1 and P2, respectively) and later conditioned at 20 °C ± 2 °C temperature and 65% ± 5% relative humidity until a constant mass state was reached.

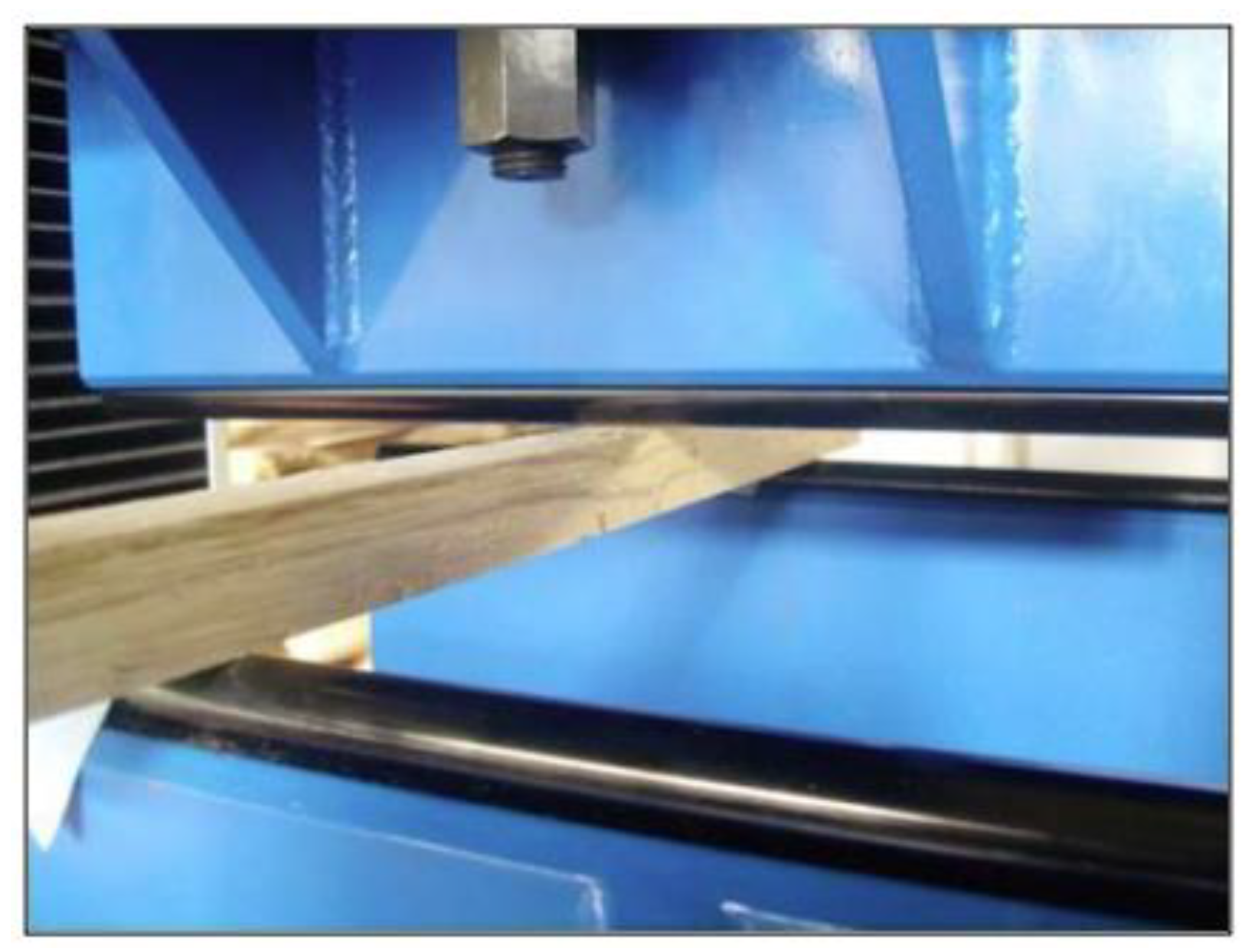

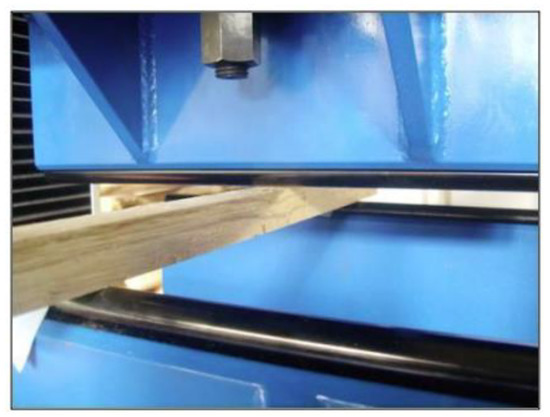

After conditioning, the test pieces were tested in three-point bending with a distance between supports of 280 mm, following the recommendations of ISO 13061-3 [25]. Figure 1 shows a detail of the test setup.

Figure 1.

A detail of the Bending test setup ISO 13061-3.

The modulus of elasticity (MOE) and modulus of rupture (σm) were determined according to Equations (1) and (2). The tests were carried out under the same deformation-controlled rate (4 mm/min).

where Fmax represents the maximum load; l represents the distance between supports; b represents the width and h the height of the test piece; ΔF represents the variation of load between 10% and 40% of the maximum load; and Δw represents the variation of deflection between 10% and 40% for the maximum load.

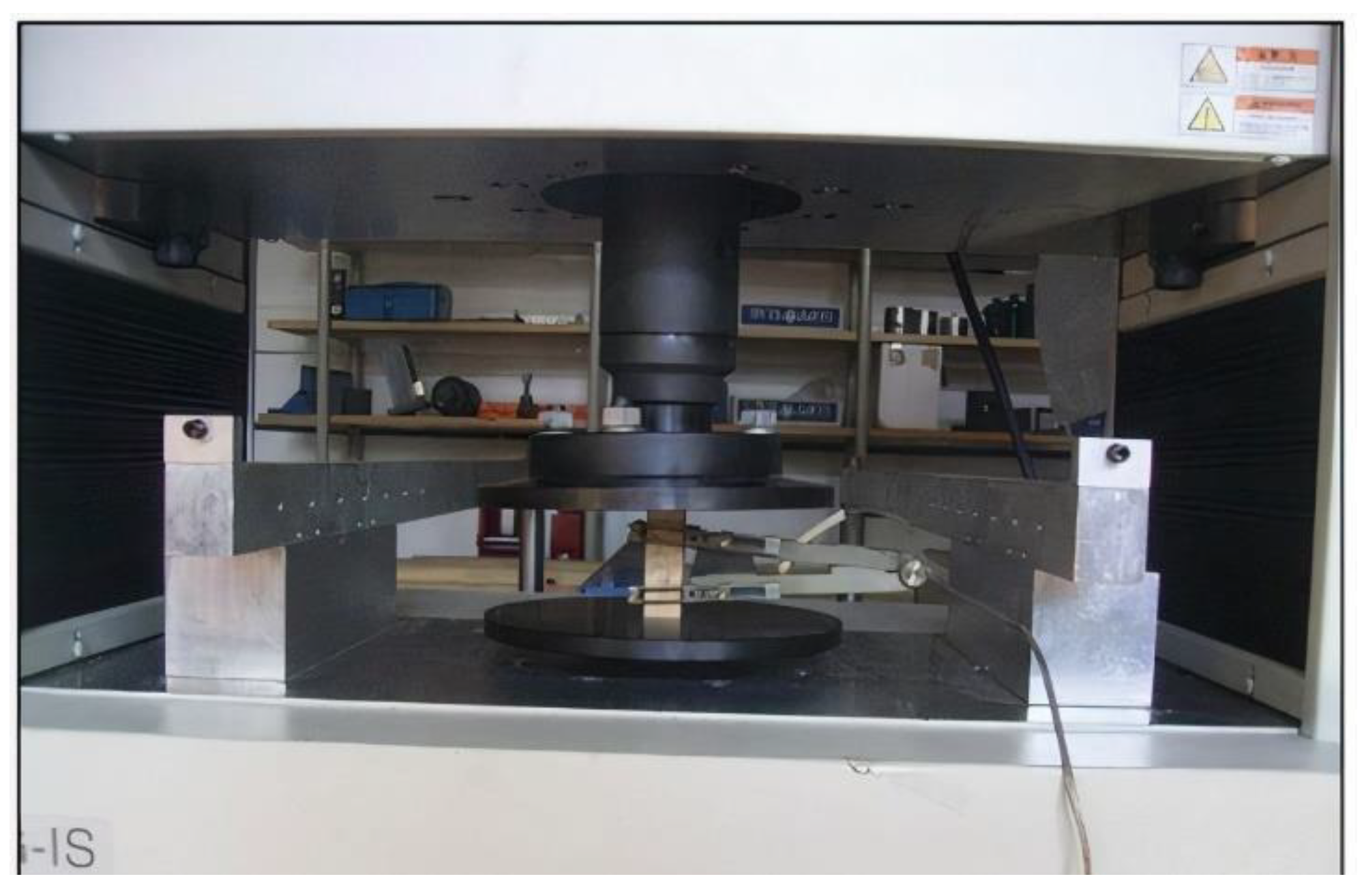

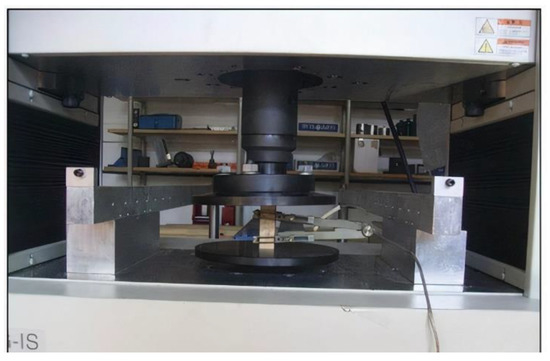

After bending from each end of each test piece, a specimen for compressive parallel to the grain was obtained with the dimensions according to the standard used. The tests were carried out under the same deformation-controlled rate (1 mm/min) (Figure 2).

Figure 2.

Compression test setup.

The compressive strength parallel to the grain was determined (σc,0) as follows:

All values were adjusted to 12% moisture content according to the recommendations provided in each corresponding standard.

Density was determined by the determination of the ratio mass/volume adjusted to a moisture content of 12%. For this purpose, compressive test pieces were measured and weighed following the procedure for density determination described in ISO 13061-2. Moisture content was determined following the procedure described in ISO 13061-1. [26,27]

Statistical analysis was performed using SPSS® statistical software (version 19.0; SPSS Inc., Chicago, IL, USA). A statistical ANOVA was performed regarding the site (S1 = Alcobaça; S2 = Cortiços; S3 = Gralhós), position (P1 = 10% of the radius; P2 = 90% of the radius), bending strength, modulus of elasticity and compressive strength. In the regression analyses, the significance level was set at 5%. In the tests for normality, the Kolmogorov–Smirnov test was used.

3. Results and Discussion

Influence of Site and Position in the Tree

Table 1 displays the average and standard deviation of density, compressive strength and bending strength for the three different locations and two positions (distance to the pith) in the tree.

Table 1.

Density, MOE bending and compressive and bending strength for the tree sites and two distances to the pith considered.

Büyüksari et al. studied the micro-mechanical properties of oak wood Q. petraea to compare with standard-size test specimens’ values [28]. Six trees with straight stems were selected as sample trees. The MOEs of the standard-size samples ranged from 9994.4 MPa to 12,532.1 MPa. The compressive strength ranged from 42 MPa to 52.1 MPa and the bending strength ranged from 87.4 MPa to 113.6 MPa. Similar results were observed in the present study.

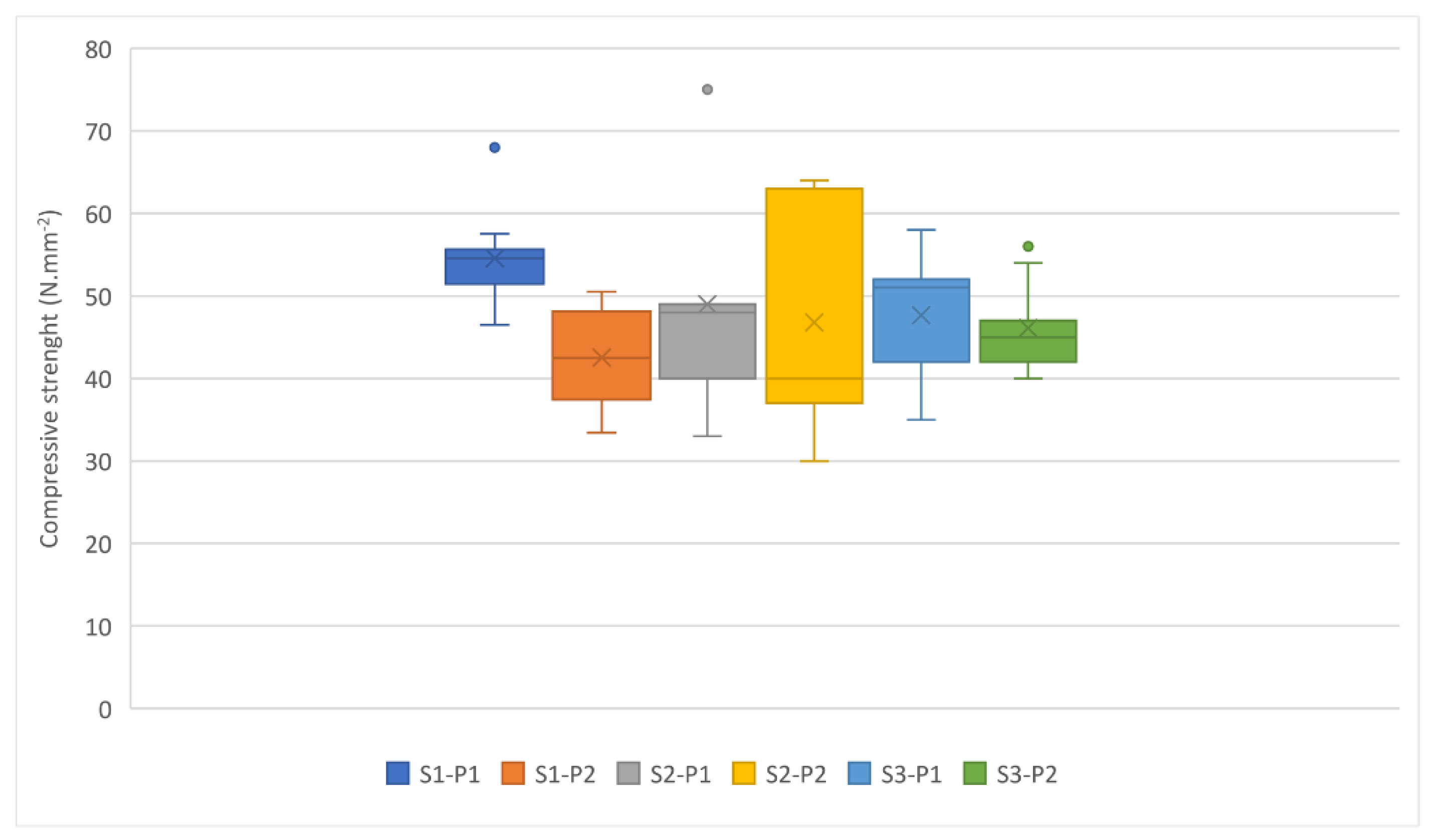

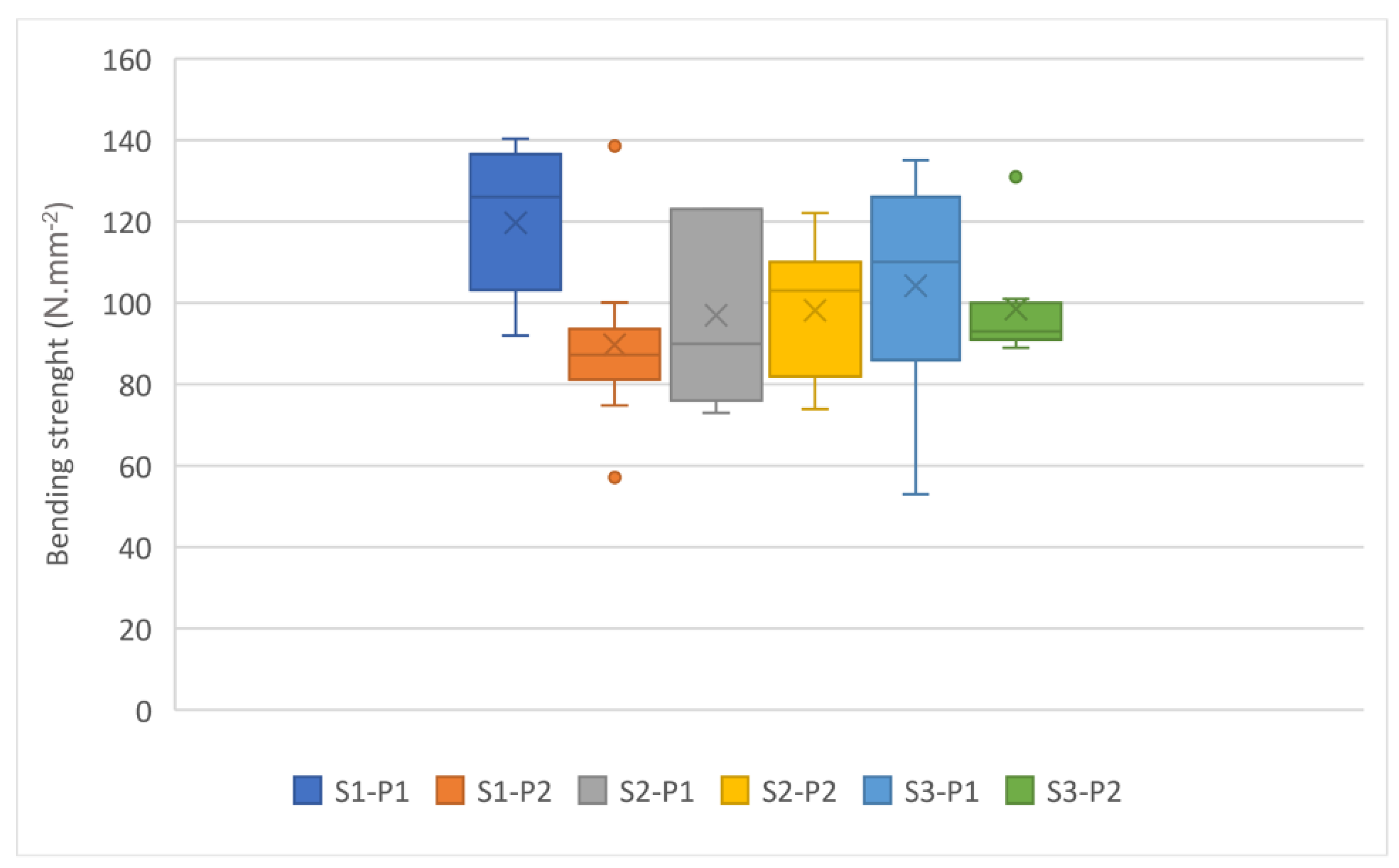

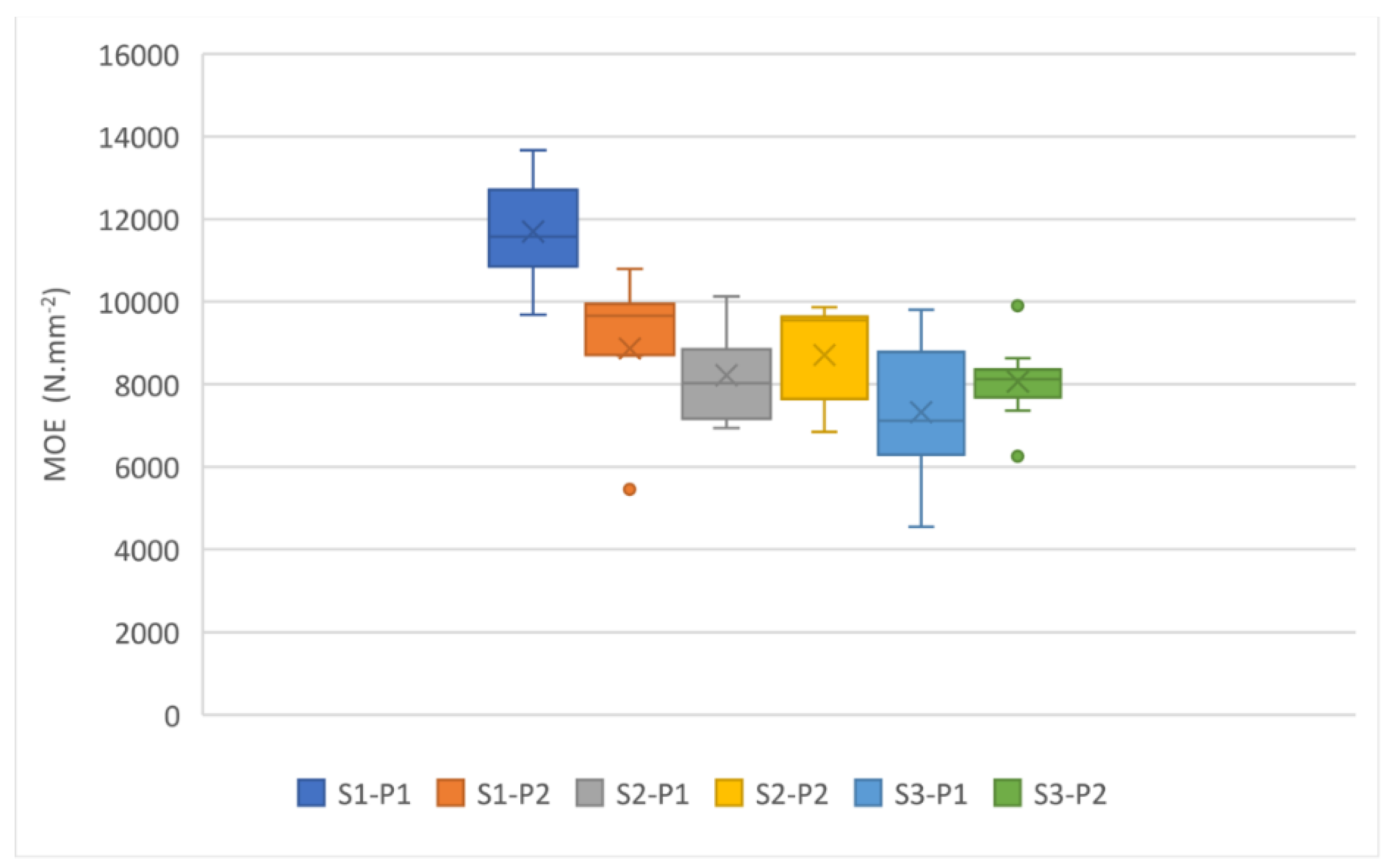

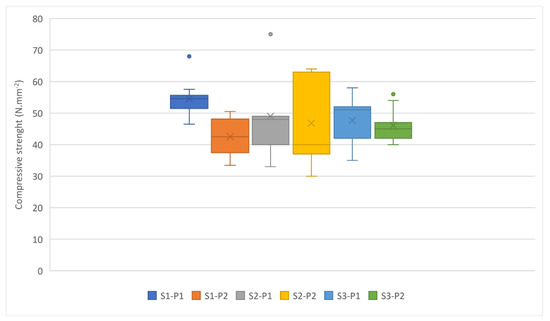

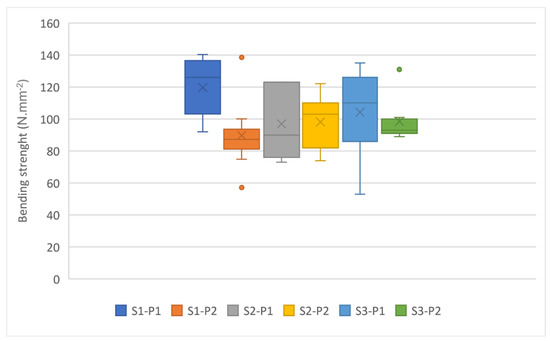

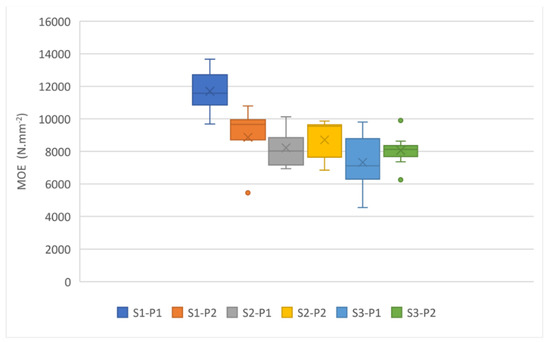

The dispersion values for the three different locations and two positions in the tree are presented in Figure 3, Figure 4 and Figure 5. These figures represent the variability between sites for compressive strength (Figure 3), bending strength (Figure 4) and modulus of elasticity and MOE (Figure 5) for S1, S2 and S3 considering different locations in the cross-section (position 1%–10% of the radius and position 2%–90% of the radius).

Figure 3.

Compressive strength at sites 1, 2, 3 and both distances to the pith (P1—10%; P2—90%).

Figure 4.

Bending strength at sites 1, 2, 3 and both distances to the pith (P1—10%; P2—90%).

Figure 5.

MOE at sites 1, 2, 3 and both distances to the pith (P1—10%; P2—90%).

The results indicate that the location in the cross-section (P1 versus P2) showed only significant differences for S1,for modulus of elasticity (MOE), compressive strength and bending strength. These results are in line with the mean density values obtained for the same provenance and location in the stem (Table 1). In the regression analyses, the significance level was set at 5%. In the tests for normality, the Kolmogorov–Smirnov test was used. Site S1 showed a fine soil texture, whereas site 2 and site 3 showed coarse and medium soil textures. The effects of soil on other oak species was already stated as regards their growth [29] and wood density [30]. In this case, a finer soil texture led to more hydric stress, which is reflected in the first layers of wood produced, which showed higher density (high proportion of latewood in the growth ring).

Q. faginea wood has a global average MOE of 8815 Nmm−2 (static bending). It is well below the values reported in the literature for other oak species, such as [25], which identified Q. Petrae MOEs between 9994.4 Nmm−2 and 11,553.7 Nmm−2. Carvalho presented values from 10,500 Nmm−2 (Q. robur) to 13,000 Nmm−2 (Q. rubra) [2]. As regards bending strength, the mean result found (101.2 Nmm−2) agrees with the values found in the literature for other oaks [1].

It was verified that the density determined for the test pieces used in the mechanical tests has a normal distribution (normality test). According to the classification table for the characteristic values of the woods presented by [1], Q. faginea wood falls within the heavy wood class according to the density range for other oak species [31]. When considering the densities presented for Q. rubra, Q. alba and Q. robur, the results are higher but with no significative differences [2].

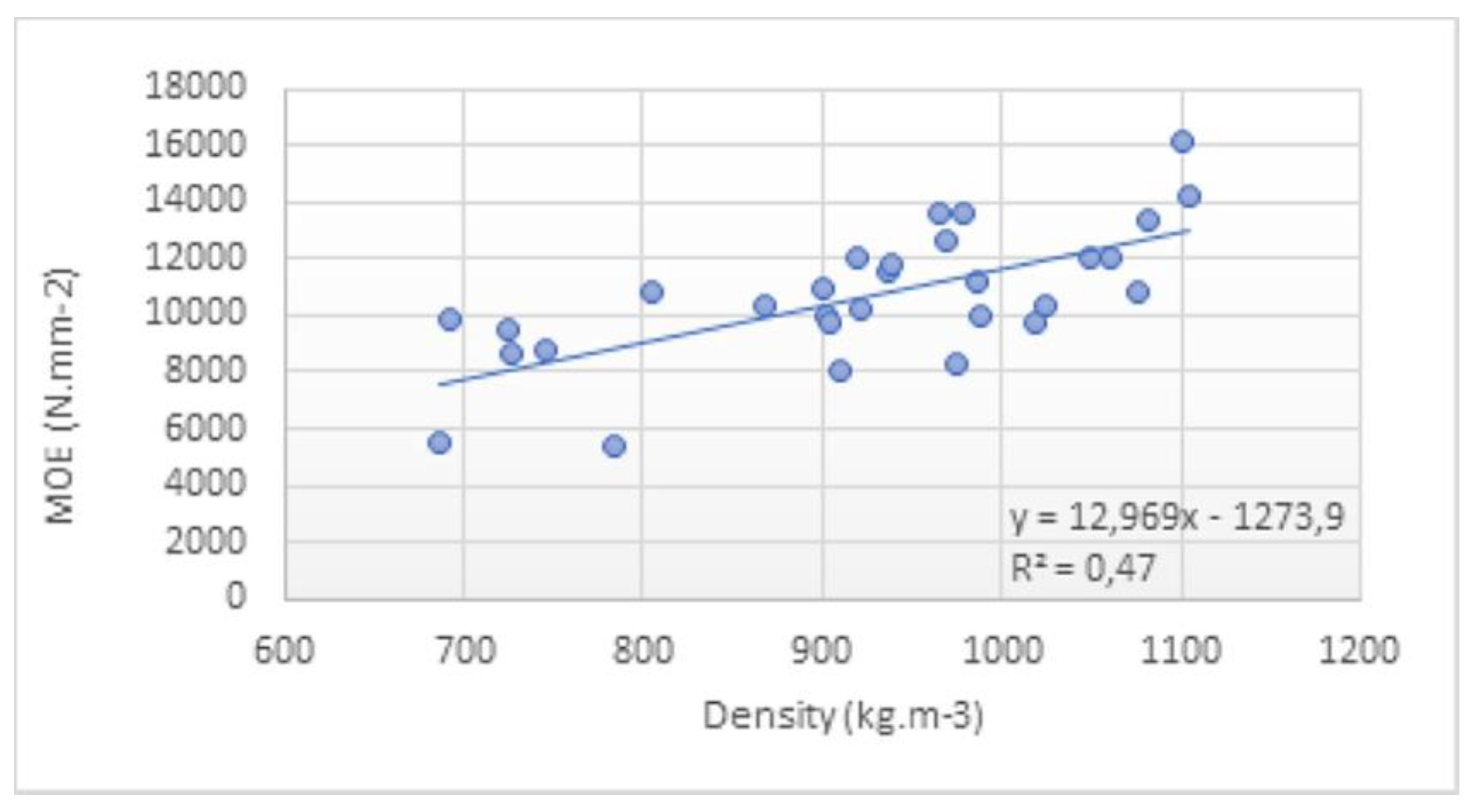

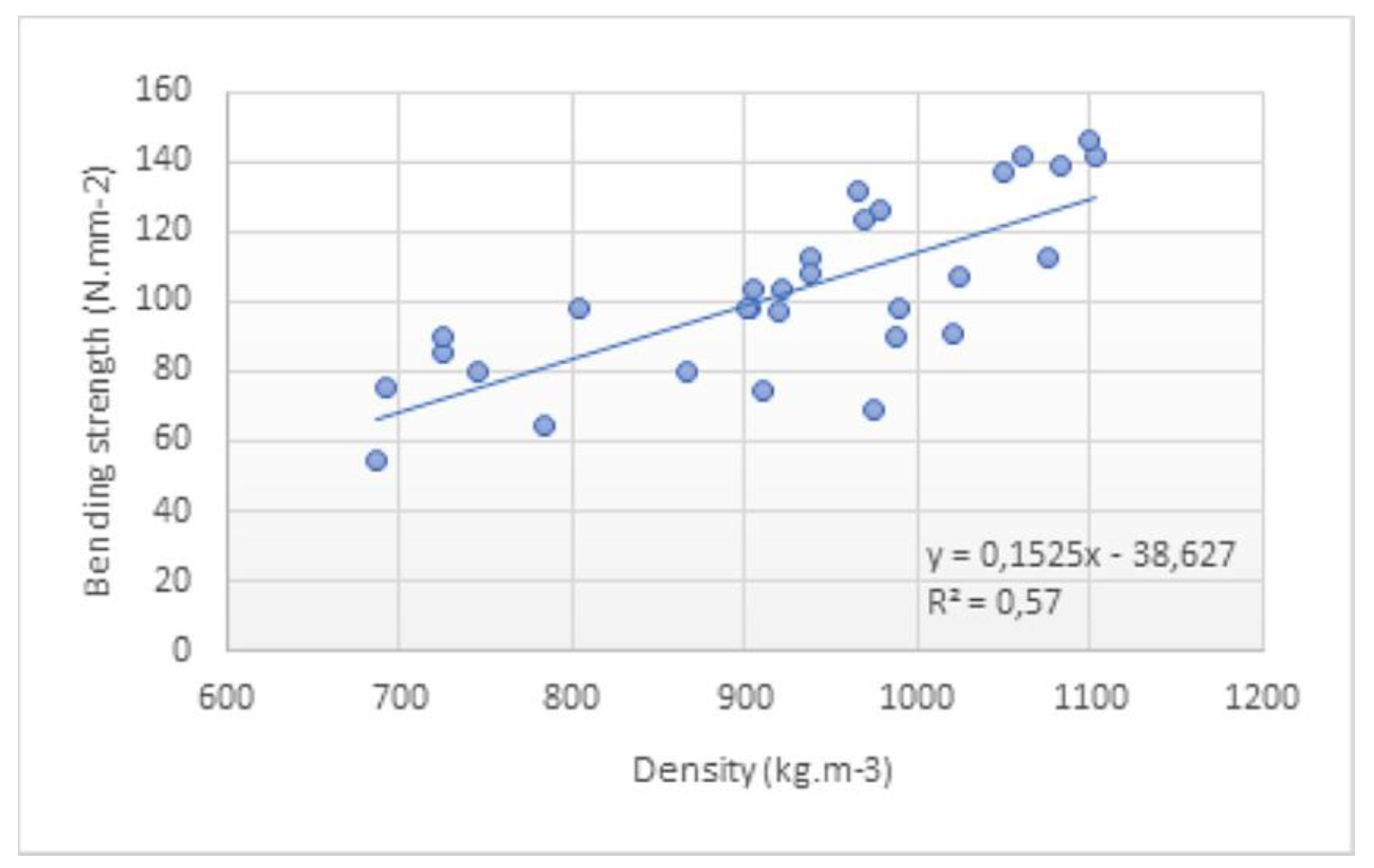

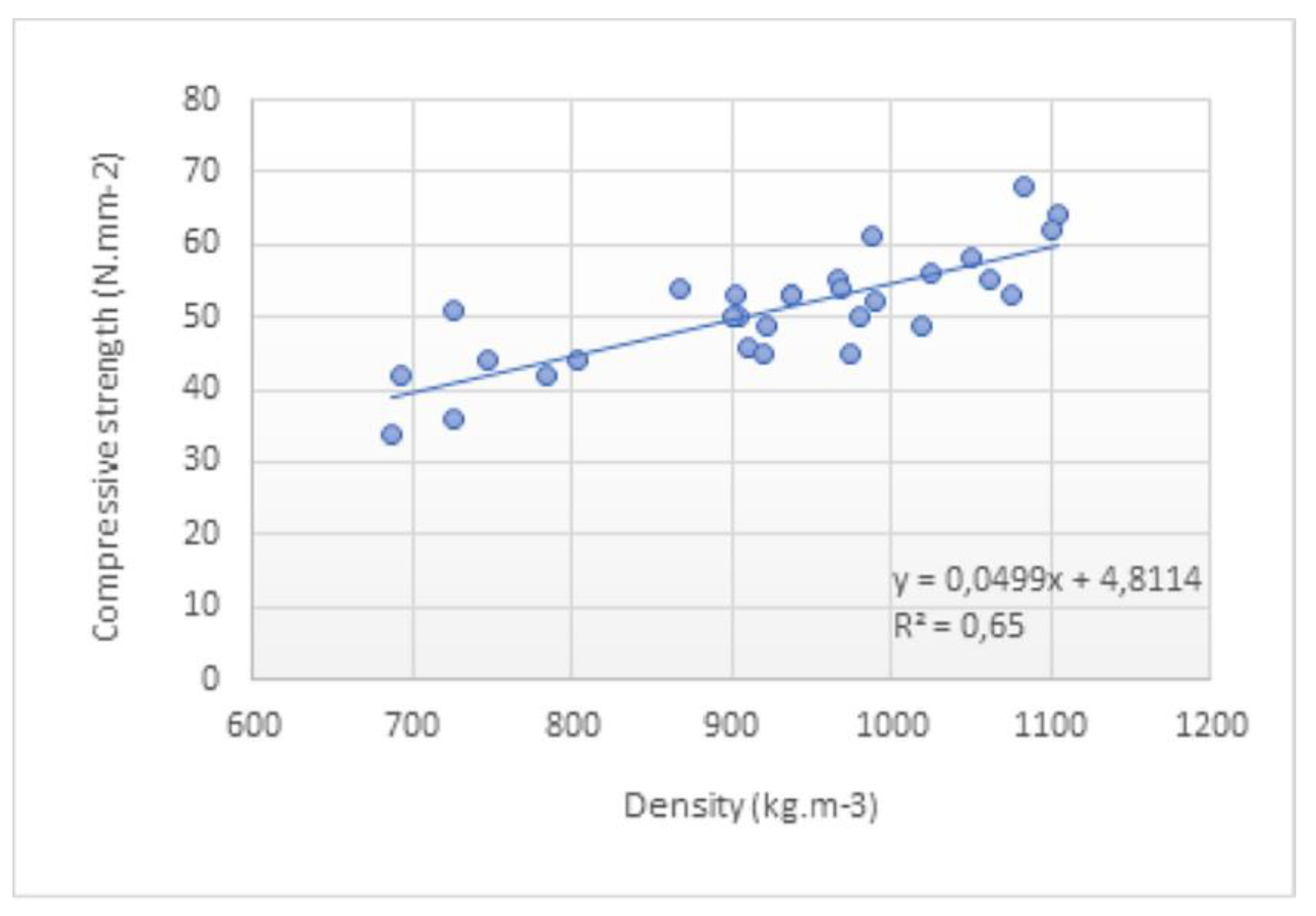

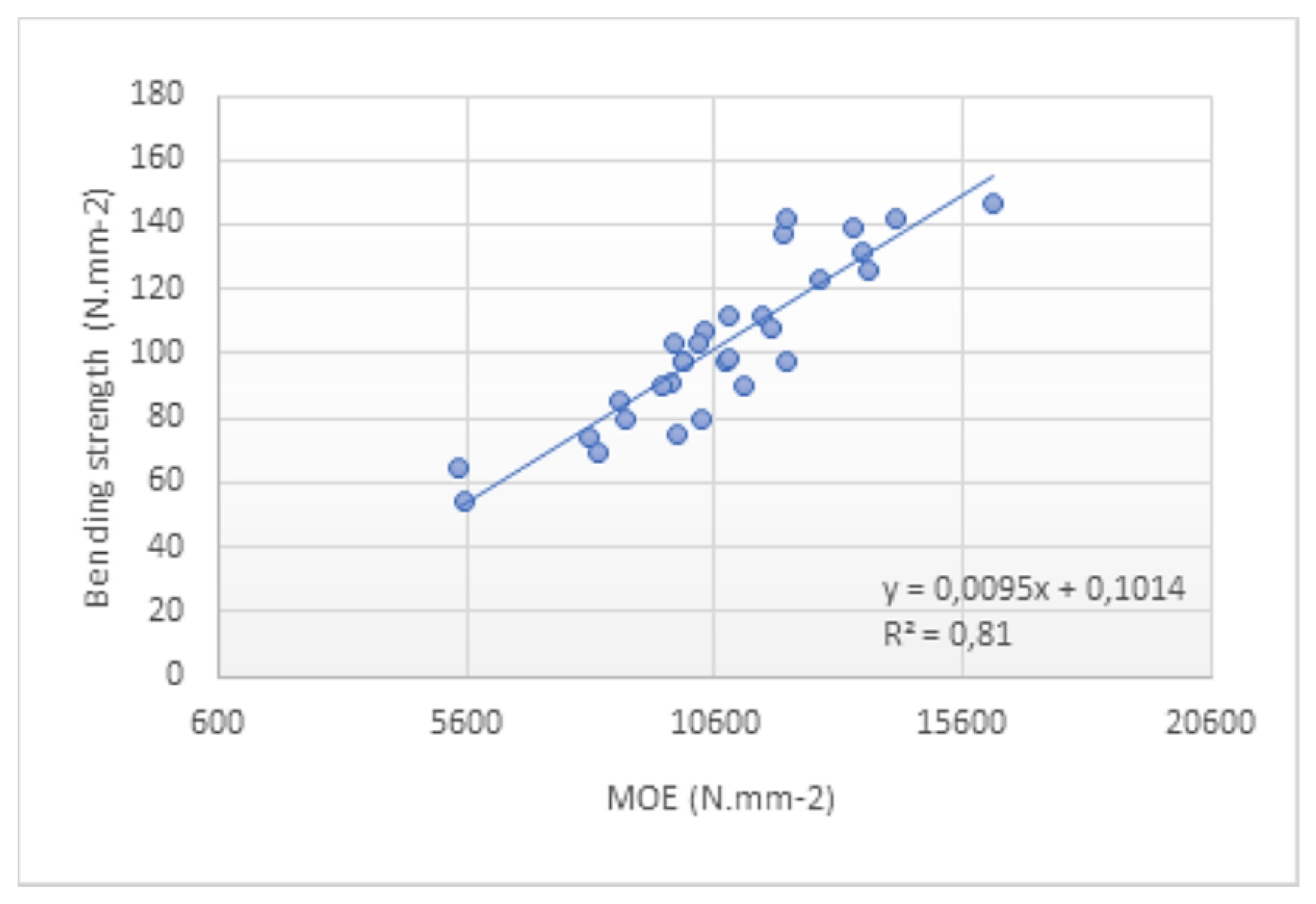

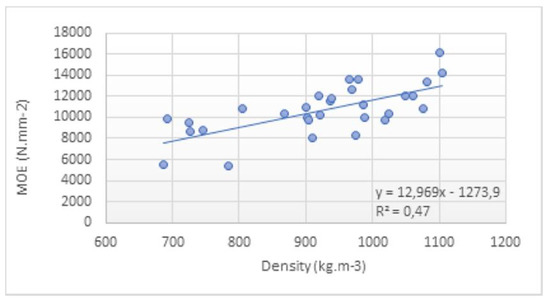

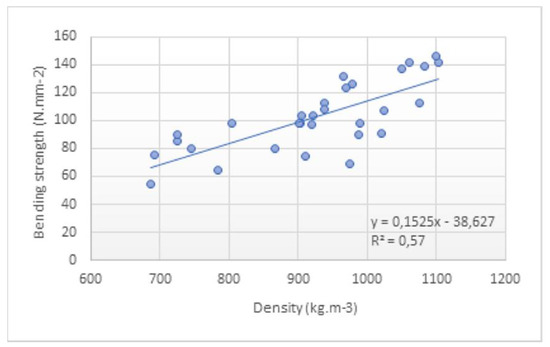

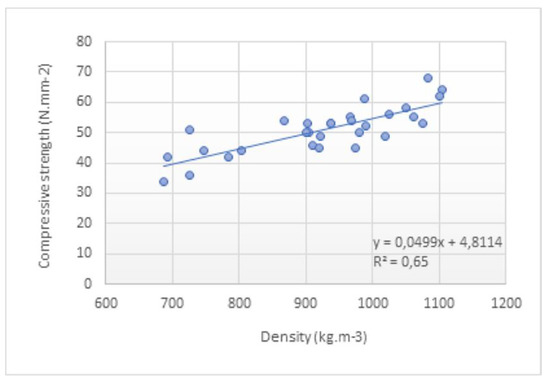

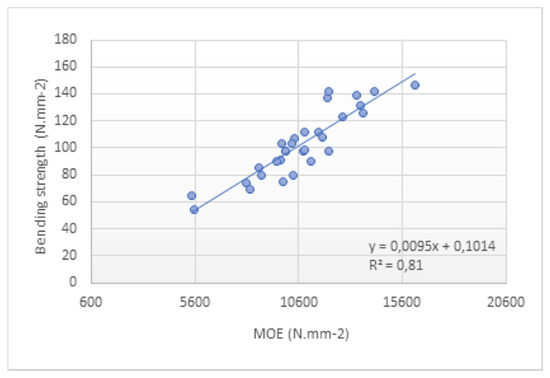

Figure 6, Figure 7, Figure 8 and Figure 9 present correlations between MOE and density, bending strength and density, compressive strength and density and bending strength and MOE, respectively.

Figure 6.

Correlations between MOE and density for all sites.

Figure 7.

Correlations between bending strength and density for all sites.

Figure 8.

Correlations between compressive strength and density for all sites.

Figure 9.

Correlations between bending strength and MOE for all sites.

Sonderegger et al. investigated various aspects of natural aging on European oak and presented a correlation of MOE and bending strength depending on density for recent and aged oak [32]. The mechanical properties of oak wood Q. petraea were studied, namely bent at different radii for locations of the tension and compressive sides of wood using micro-mechanical test specimens [33]. This study obtained MOE values between approximately 9000 and 11,000 Nmm−2, which indicates that the order of magnitude is close to the values obtained in the bending tests of this study.

It was possible to observe that strength of wood increases as its density increases. The density is important in determining the strength properties and according to [34] correlates more with bending strength than with MOE. The values obtained are consistent with the correlation based on the literature and were verified in Figure 6 for MOE, Figure 7 for bending strength and Figure 8 for compression parallel to the grain.

4. Conclusions

The results for site 1 showed a significant effect of the distance to pith, which could be related to its different soil composition as compared with site 2 and site 3. This higher density led to higher compression and bending strength as well as modulus of elasticity near the pith, with the results obtained closer to the bark similar to the ones observed for the other provenances. A noticeable correlation between the mechanical properties and density was observed (r2 = 0.47 for modulus of elasticity; r2 = 0.57 for bending strength and r2 = 0.65 for compression parallel to the grain).

Author Contributions

Conceptualization, J.S.M. and S.K.; investigation, S.K. and C.S.F.L.; writing—original draft preparation, S.K. and C.S.F.L.; writing—review and editing, J.S.M. and S.K.; visualization, J.S.M. and S.K.; supervision, J.S.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was partly financed by FCT/MCTES through national funds (PIDDAC) under the R&D Unit Institute for Sustainability and Innovation in Structural Engineering (ISISE) under reference no. UIDB/04029/2020 and the project F4F—Forest for Future under reference no. CENTRO-08-5864-FSE-000031.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Carvalho, A. Madeiras Portuguesas: Estrutura anatómica, Propriedades, Utilizações; Direcção-Geral das Florestas: Lisboa, Portugal, 1997; Volume II. [Google Scholar]

- Casaus, G.; Esteban, G. Especies de Maderas Para Carpintería, Construcción y Mobiliario; Asociación de Investigación Técnica de las Industrias de la Madera, AITIM: Madrid, Spain, 1997; p. 250. [Google Scholar]

- Knapic, S.; Louzada, J.L.; Leal, S.; Pereira, H. Radial variation of wood density components and ring width in cork oak trees. Ann. For. Sci. 2007, 64, 211–218. [Google Scholar] [CrossRef] [Green Version]

- Muñoz, G.R.; Gete, A.R. Relationships between mechanical properties of oak timber (Q. robur L.). Holzforschung 2011, 65, 749–755. [Google Scholar] [CrossRef]

- Muñoz, G.R.; Gete, A.R. Prediction of strength and elasticity in oak beams on the basis of external wood characteristics. Adv. Mater. Res. 2013, 778, 152–158. [Google Scholar] [CrossRef]

- Merela, M.; Čufar, K. Mechanical properties of sapwood versus heartwood, in three different oak species. Drv. Ind. 2013, 64, 323–334. [Google Scholar] [CrossRef]

- Green, D.W.; Mcdonald, K.A. Investigation of the mechanical properties of red oak 2 by 4’s. Wood Fiber Sci. 2007, 25, 35–45. [Google Scholar]

- Babiak, M.; Gaff, M.; Sikora, A.; Hysek, Š. Modulus of elasticity in three-and four-point bending of wood. Compos. Struct. 2018, 204, 454–465. [Google Scholar] [CrossRef]

- Knapic, S.; Saporiti, J.S.M.; Pereira, H. Performance of cork oak as solid wood flooring. Constr. Build. Mater. 2012, 30, 569–573. [Google Scholar] [CrossRef]

- Knapic, S.; Tavares, F.; Pereira, H. Heartwood and sapwood variation in Acacia melanoxylon R. Br. trees in Portugal. Forestry 2006, 79, 371–380. [Google Scholar]

- Knapic, S.; Louzada, J.L.; Leal, S.; Pereira, H. Within and between-tree variation of wood density components in cork oak trees in two sites in Portugal. Forestry 2008, 81, 465–473. [Google Scholar] [CrossRef]

- Xu, W. Influence of vertical density distribution on bending modulus of elasticity of wood composite panels: A theoretical consideration. Wood Fiber Sci. 2007, 31, 277–282. [Google Scholar]

- Kránitz, K.; Deublein, M.; Niemz, P. Strength estimation of aged wood by means of ultrasonic devices. In Future of Quality Control for Wood & Wood Products, Proceedings of the Final Conference of COST Action E53: Quality Control for Wood & Wood Products, Edinburgh, UK, 4–7 May 2010; Edinburgh Napier University: Edinburgh, UK, 2010. [Google Scholar]

- Volkmer, T.; Lorenz, T.; Hass, P.; Niemz, P. Influence of heat pressure steaming (HPS) on the mechanical and physical properties of common oak wood. Eur. J. Wood Prod. 2014, 72, 249–259. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, J.; Zhou, Y.; Zhao, Y.; Zhao, L. Compressive strength and modulus of elasticity parallel to the grain of oak wood at ultra-low and high temperatures. Bioresources 2014, 9, 3571–3579. [Google Scholar] [CrossRef]

- Bi, J.; Fu Wang, Q.; Wu, S.; Song, X. Study on dynamic viscoelasticity of cork from Quercus variabilis. J. For. Eng. 2020, 5, 59–65. [Google Scholar]

- Hu, W.; Wan, H.; Guan, H. Size effect on the elastic mechanical properties of beech and its application in finite element analysis of wood structures. Forests 2019, 10, 783. [Google Scholar] [CrossRef] [Green Version]

- Hu, W.; Li, S.; Liu, Y. Vibrational Characteristics of Four Wood Species Commonly Used in Wood Products. Bioresources 2021, 16, 7101–7111. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Zhong, Y. Structure-property relationship of wood in East-Liaoning oak. Wood Sci. Technol. 1992, 26, 139–149. [Google Scholar] [CrossRef]

- Reboredo, F.; Pais, J. Evolution of forest cover in Portugal: From the Miocene to the present. In Forest Context and Policies in Portugal; Springer: Cham, Switzerland, 2014; pp. 1–37. [Google Scholar]

- Knapic, S.; Louzada, J.L.; Pereira, H. Variation of density components with and within Q. faginea trees. Can. J. For. Res. 2011, 41, 1212–1219. [Google Scholar] [CrossRef]

- Capelo, J.; Catry, F. A Distribuição do Carvalho-Português em Portugal (The Distribution of Portuguese oak in Portugal); Fundação Luso-Americana para o Desenvolvimento/Público/Liga para a Protecção da Natureza: Lisboa, Portugal, 2007; pp. 83–94. [Google Scholar]

- EPIC WebGIS Portugal. Available online: http://epic-webgis-portugal.isa.ulisboa.pt/ (accessed on 15 January 2022).

- Machado, J.S.; Cruz, H.P. Within stem variation of Maritime pine timber mechanical properties. Holz Als Roh-Und Werkst. 2005, 63, 154–159. [Google Scholar] [CrossRef]

- ISO 13061-3; Physical and Mechanical Properties of Wood. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 13061-2; Physical and Mechanical Properties of Wood. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 13061-1; Physical and Mechanical Properties of Wood. International Organization for Standardization: Geneva, Switzerland, 2014.

- Büyüksari, Ü.; As, N.; Dündar, T.; Korkmaz, O. Micro-mechanical properties of Oak wood and comparison with standard-sized samples. Maderas Cienc. Y Tecnol. 2017, 19, 481–494. [Google Scholar]

- Souad, E.M.; Bendriss Amraoui, M. Effect of Soil Properties on Growth of Quercus ilex L. in Humid and Cold Mountains of Morocco. Appl. Environ. Soil Sci. 2020, 2020, 8869975. [Google Scholar]

- Sousa, V.; Silva, M.E.; Louzada, J.L.; Pereira, H. Wood density and ring width in Quercus rotundifolia Trees in Southern Portugal. Forests 2021, 12, 1499. [Google Scholar] [CrossRef]

- Tsoumis, G. Science and Technology of Wood: Structure, Properties, Utilization; Van Nostrand Reinhold: New York, NY, USA, 1991; Volume 115. [Google Scholar]

- Sonderegger, W.; Kránitz, K.; Bues, C.T.; Niemz, P. Aging effects on physical and mechanical properties of spruce, fir and oak wood. J. Cult. Herit. 2015, 16, 883–889. [Google Scholar] [CrossRef]

- As, N.; Hindman, D.; Büyüksari, Ü. The effect of bending parameters on mechanical properties of bent oak wood. Eur. J. Wood Wood Prod. 2018, 76, 633–641. [Google Scholar] [CrossRef]

- Ivkovic, M.; Gaspare, W.J.; Abarquez, A.; Ilic, J.; Powell, M.B.; Wu, H.X. Prediction of wood stiffness, strength, and shrinkage in juvenile wood of radiata pine. Wood Sci. Technol. 2009, 43, 237–257. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).