Abstract

Woody biomass represents a sustainable type of fuel that is marketed directly as firewood or pre-treated by grinding, drying and compressing. Densified biomass fuels provide benefits in transport, storage and handling, and wood pellets in particular are one of the most commercially attractive products. With this in mind, the objective of the presented research was to evaluate the quality of various pellets obtained from different tree parts of five species (and various age): Eucalyptus spp., Fagus sylavtica L., Pinus eldarica Medw., Pinus radiata D.Don, and Robinia pseudoacacia L. In all the analysed cases, the wooden material was harvested according to the whole tree system (WTS), with their branches and leaves. The samples were chipped, refined by a shredder and dried. Pelletisation was finally carried out using a 4 kW Bianco line (Cuneo, Italy) pelletiser. Physical and chemical analyses were undertaken to determine the quality of the pellets as an energy source. Results of this classification showed that the best pellets, mostly due to better mechanical properties, were from plantation trees of Eucalyptus spp. (6- and 3-year-old) and from thinnings of Fagus sylavtica L. (70-year-old), whereas the least attractive types were made from 18-year-old, coppice Eucalyptus spp. and 3-year-old Robinia pseudoacacia L. Regarding the classification developed within this study, all the pellet types were found to be classifiable as none exceeded the toxic content limit. In terms of the influence of the species, management system and stem age on pellet quality, this study showed the presence of a link between cycle duration and pellet quality, with increasing stem age resulting in better pellet characteristics.

1. Introduction

Many factors have contributed to the steady rise in the use of renewable energy, such as the need to mitigate climate change [1,2,3], the global increase in demand for energy [4,5], the petroleum market and its availability, and the lower environmental impact of renewable fuels [6,7,8,9].

Woody biomass represents a sustainable type of fuel that is marketed directly as firewood or pre-treated by grinding, drying and compressing [10,11,12,13]. Densified biomass fuels provide benefits for transport, storage and handling [14,15,16], and wood pellets in particular [17,18,19,20,21] are one of the most commercially attractive products that can be placed on the market, with a price of over EUR 300 per ton in 2018 [22]. Moreover, pellets can be produced from several different feedstocks, which are also derived from the agriculture sector, such as bagasse, sorghum and soybean residues [23,24].

Europe is an important producer of pellets, but it is also a big consumer and importer [25,26,27]. After the United Kingdom, Finland and Sweden, other significant consumers are Italy, Denmark, Belgium and the Netherlands [28].

Increasing and improving the pellet chain, not only from agroforestry dedicated plants and orchards [29], but also from silviculture [30], may be an effective way to attain sustainable forest management (SFM) goals [31]. In particular, it is possible to obtain biomass for pellet production from forest operations, starting with the first commercial thinning [32,33,34], but also from the conversion of coppice forests to high stands.

The coppice itself can be a good source of wood for pellets, particularly in the Mediterranean zone [22]. However, coppice forests in the Mediterranean context have often been abandoned. In particular, this occurs in the protection of forests, which, however, need some management, such as periodic harvesting to support good forest health. However, the landscape conditions that characterise a protection forest, e.g., extremely steep terrain, sensitive soil, a remote location and the prescriptions of a specifically designed silviculture, tend to constrain harvesting and make it particularly difficult [35,36,37,38,39]. Some authors also indicate that pellet bioenergy systems have a low environmental impact globally but have a high impact on local areas [40].

Small-scale pellet production in rural zones can also contribute to the income of local farmers, and small and medium-sized forest enterprises [41,42,43]. To achieve this aim, it is important to evaluate the quality of the pellets produced from raw materials derived from forest or agroforest plants, without the need for pre-pelletisation steps such as bark or leaf removal.

High value pellets are generally produced at the industrial scale from pure sawdust [3,44]. In comparison, pellets manufactured from different feedstocks, with a high share of bark or leaves, can have lower quality [45,46].

In a comparison of the quality of poplar pellets produced from whole trees or debranched stems, Picchio et al. found that pelletised material with branches and leaves significantly decreased bulk density and ash content [22]. By comparison, detailed studies on this topic concerning the use of different tree species are missing in the current literature. The attention of the literature in the recent years has been paid mainly to pellet production from several types of agro-residue [3]. However, pellets from agricultural wastes have been identified as containing excessive heavy metals and ash, with poor mechanical properties [24].

With this in mind, the objective of the presented research was to evaluate differences in the qualitative characteristics of various pellets obtained from woody material (including branches and leaves) of forest and agroforest origin. Analyses were carried out on the different pellet samples in order to find out which tree species and which form of management resulted in the best pellet quality. In this study, a number of pellets were considered, obtained from wood biomass originating from various forest species grown under different forms of management.

2. Materials and Methods

The analysis involved 13 different wood materials originating from various forest species and from forestry or agroforestry management systems (Table 1).

Table 1.

Different types of wood material used for pellet production.

In all the analysed operations, the wooden material was harvested according to the whole tree system (WTS); therefore, in every case the trees were extracted together with their branches and leaves so that the pellets were produced from every part of the trees. An exception was in FS30CST, where coppicing was performed in winter and the pellets were only produced from the stems and branches but not the leaves. The samples were chipped by a Farmi Forest (Iisalmi, Finland) CH260 forestry chipper, refined by a BL-100 shredder (Cuneo, Italy) with a 6 mm grid and then subjected to a drying process. Pelletisation was finally carried out using a 4 kW Bianco line (Cuneo, Italy) pelletiser. For each pellet type, ca. 50 kg of pellets was selected for analysis.

However, commercial pellets CP1 and CP2 were obtained from the manufacturer, and they consisted of pure wood pellets without bark and leaves.

A list of the characteristics of the investigated pellets is given in Table 2.

Table 2.

List of investigated parameters and influence of single parameter on pellet quality.

From a macro sample of 30 kg of pellets for each investigated pellet type, 5 samples of 100 g each were used for analysis regarding each parameter, with the exception of pellet size, where 50 single pellets were used as a sample.

Ash content was determined according to EN ISO 18122 (2016) using a Lenton EF11/8B (Hope Valley, UK) muffle furnace. Samples of 1 g were heated to 250 °C for one hour and then to 550 °C for two hours, with the ash content measured as the weight loss of the samples after the heating process. For the fusion analysis (ash melting behaviour), according to EN ISO 21404 (2020), cylindrical ash samples of fine and homogeneous powder were placed in a Sylab SHV-IF 1500 (Metz, France) analyser, which identified by means of image analysis the temperature at which deformation occurred in the sample.

The heating value was determined according to EN ISO 18125 (2017) using an Anton Paar 6400 (Moline, IL, USA) calorimeter for higher heating value (HHV) and a logarithmic formula for the lower heating value (LHV). The pre-treatment of the samples involved two sequential shredding processes, with a Retsch SM 100 (Düsseldorf, Germany) knife mill and a Retsch ZM 200 (Düsseldorf, Germany) centrifuge mill, and the preparation of 1 g tablets using a Pellet Press 2810 (Düsseldorf, Germany).

After pre-treatment of the samples (500 mg each) consisting of acid attack (HNO3 and H2O2) using a microwave digester (Start D, Milestone, Sorisole, Italy), the heavy metal content was determined according to EN ISO 16968 (2015) using an Agilent 7700 ICP–MS (Santa Clara, CA, USA).

According to EN ISO 16948 (2015), ten capsules of 1 mg each were placed into a CHNS-O Costech ECS 4010 (Cernusco sul Naviglio, Italy) combustion oven to analyse the carbon (C), hydrogen (H), nitrogen (N), and oxygen (O) content.

The bulk density was evaluated in accordance with EN ISO 17828 (2016) by weighing a standard container of known weight and volume (0.005 m3, height-to-diameter ratio within 1.25 and 1.50), filled with pellets. The average pellet length and diameter were determined according to EN ISO 17829 (2016) by measuring 50 pellets selected randomly.

Mechanical durability was analysed by means of a mechanical durability tester (Andritz Sprout (Graz, Austria) rotation pellet testing apparatus) according to EN ISO 17831-1 (2016). After sieving (using a 3.15 mm sieve), the sample was subjected to a tumbling process in a durability tester. After this, the sample was re-sieved through the 3.15 mm sieve. The mechanical durability was expressed as the percentage weight of pellets that did not break down into grains smaller than 3.15 mm after the tumbling process.

The moisture content was determined, according to EN ISO 18134-1 (2015), as a percentage of the weight loss after processing in a drying oven (Memmert UFP800 (Schwabach, Germany)) at 105 ± 2 °C.

Shear resistance was determined using a MetroCom (Garbagna Novarese, Italy) MI10 machine for testing the shear resistance of the material. As this is not a regulated parameter, there is not a specific protocol for biomass fuels; therefore, this parameter was evaluated according to the protocol for the shear resistance of other materials.

Particle density was determined according to EN ISO 18847 (2017) using the metric/weight approach.

Statistical analyses were carried out using Statistica 7.0 Software (Statsoft, Tulsa, OK, USA). These consisted of ANOVA, MANOVA and Tukey’s HSD Test. The non-metric multidimensional scaling (nMDS) approach was used to analyse differences in the main characteristics of the tested pellet performance.

In addition, in order to have a clear link between research results and technical applications, various pellet types were categorised, firstly according to a simple classification developed within this study (S1) (consisting of three classes: M as “medium”, G as “good”, and O as “optimum”) and then according to EN ISO 17225-2 (S2). This classification was developed in view of the objective of the present study, which was focused on a rural value chain in which, starting from wooden material without any pre-treatment such as debarking, pellets can be produced for a short energy supply chain. Such a theoretical supply chain takes into consideration pellets burnt on commercial boilers; therefore, the reference standard considered is the one for commercial pellets. However, such a standard was developed with a view to evaluating commercial pellets generally produced by big manufacturers from relatively pure feedstock. Therefore, the classification developed for the present study may be suitable to evaluate pellet quality from unusual raw materials.

3. Results

3.1. Physical Parameters

Among the various pellet types, most variables showed the presence of statistically significant differences in physical parameters (Table 3 and Table 4).

Table 3.

Average ± standard deviation for some physical parameters of various pellet types. It can be seen that most parameters show statistically significant differences. The highest values are highlighted in Bold, while the lowest values are in Bold-Italic. Different letters show statistically different groups (at a significance level of 5%) following Tukey’s test for physical parameters. (d.m.: dry matter).

Table 4.

Average ± standard deviation for some physical and physico-chemical parameters of various pellet types (most of the parameters show statistically significant differences). Upper values are highlighted in Bold, while lower values are in Bold-Italic. Different letters show statistically significant differences between groups (at a significance level of 5%) following Tukey’s test for physical parameters. (d.m.: dry matter; d.b.: dry basis).

The average diameter of the cylinders was over 6 mm, with a minimum of 5.99 mm for FS30CST and a maximum of 6.64 mm for CP2, and a length range between 8.72 mm for RP3SRF and 18.83 mm for ES6SRF.

Bulk density, which is one of the principal parameters of pellet quality, varied from 0.438 g/cm3 for RP3SRF to 0.640 g/cm3 for ES6SRF, which showed the best value for this variable.

In terms of moisture, PE18TH had the highest value, whereas the lowest value was found in ES18C, although all the samples showed values under 10%.

For shear resistance, ES6SRF performed the best with 7.13 N/mm2. In contrast, the lowest value was shown by PR18TH with 3.87 N/mm2, but PE18TH and RP3SRF also yielded very low values. In terms of particle density, the higher value was achieved by FS70TH with 1.39 g/cm3, with the lowest shown by PE18TH with only 1.26 g/cm3.

Mechanical durability is, along with bulk density, one of the most important physical parameters of pellets. This indicates the percentage of pellets that can disintegrate due to mechanical damage, e.g., during transport. A low amount of pellet dust in the end-user’s store room is one of the most important product features. Mechanical durability ranged from 94.95% for RP6SRF to 98.17% of ES3SRF.

Another key parameter, and perhaps the most significant when characterising a substance as fuel, is the heating value, which is given by the amount of energy produced by the combustion of a unitary mass of fuel. The higher heating value (HHV) detected for various pellet types ranged between 17.656 for ES3SRF and 20.302 MJ/kg for PE40TH, with statistically significant differences. Regarding the lower heating value (LHV), the results were in line with the HHV, with PE40TH having the highest result (17.415 MJ/kg) and ES3SRF the lowest (14.29 MJ/kg).

In order to define pellet quality, it is also important to know the ash content. A high ash content can cause problems in the combustion of biomass, because it produces slag, encrustations and corrosion in the combustion device, with an inevitable reduction in the performance of the plant itself [47]. In this study, the ash content ranged from 0.64% for FS70TH to 1.3% for RP3SRF.

For most parameters, with the exception of the ash melting point, ANOVA, MANOVA, and Tukey’s HSD test showed statistically significant differences (p < 0.05) among the various pellet types.

3.2. Chemical Parameters

Most chemical parameters showed the presence of statistically significant differences among the various pellet types (Table 5 and Table 6).

Table 5.

Average ± standard deviation for chemical composition of various pellet types. The upper value is highlighted in Bold, the lower value in Bold-Italic.

Table 6.

Average ± standard deviation for chemical composition of various pellet types. The upper value is highlighted in Bold, the lower value in Bold-Italic. Different letters show statistically significant differences (at a significance level of 5%) between groups, following Tukey’s test for physical parameters.

As mentioned above, the heavy metal content did not show statistically significant differences (p > 0.05) among the various pellet types. However, for other variables, there were statistically significant differences (p < 0.05).

Regarding carbon content, which considerably influences the heating value, the best performances were shown by the pine pellet types, in particular PE18TH and PR50TH, with 50.7 and 50.33, respectively. The lowest carbon content was shown by ES18C. ES6SRF had the highest oxygen content (45.88%), whereas PE18TH had the lowest (42.00%). In terms of hydrogen, the highest value was in PR18TH, whereas ES3SRF had the lowest value. FS30CST showed the highest percentage of nitrogen (0.65%) and ES6SRF had the lowest content (0.22%). Finally, in terms of pH, all the types showed a sub-acid value, which ranged from 4.2 (PR18TH and PR50TH) to 4.9 (RP3SRF).

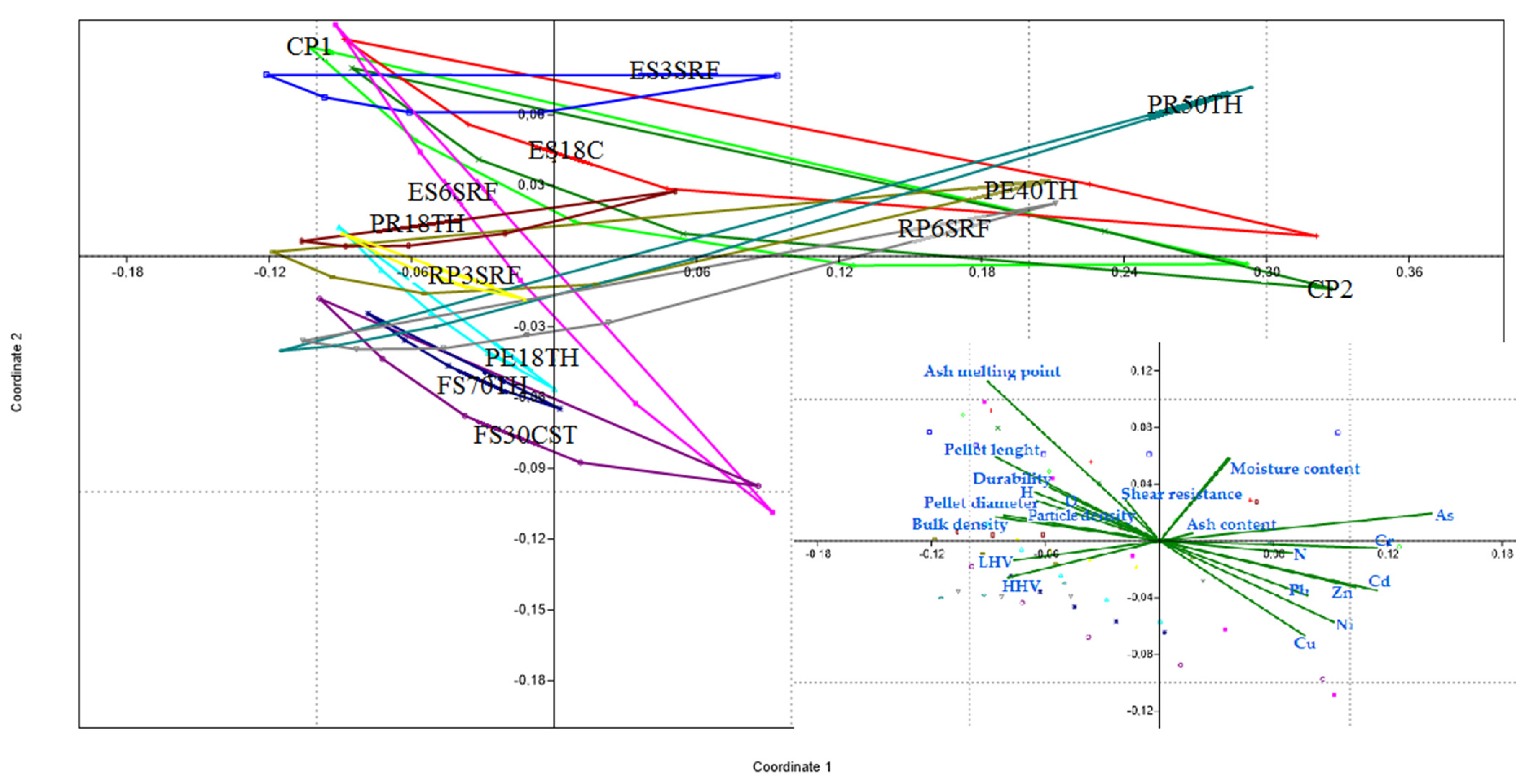

Principal non-metric multidimensional scaling (nMDS) tests produced a two-dimensional ranking (Figure 1) that provided a significantly greater reduction in statistical stress than expected by chance (α = 0.05). The nMDS diagram of the main pellet characteristics matrix (Figure 1) was created to discover any linear correlations between the pellet production system/species and the characteristics of the thirteen types studied. For the pellet characteristics, the principal components, “Coordinate 1” and “Coordinate 2”, explained 75% and 22% of the total variance, respectively. The twenty-three variables analysed showed the maximum correlation with the ordination axes (Figure 1). Almost all the variables studied (18) illustrated the pellet characteristics on the weighted scale of axis 1 (Figure 1). The pellet characterisation along axis 2 was dominated mainly by ash melting point, shear resistance, moisture, and Cu and Ni content, but only partially by pellet length and durability (Figure 1). According to the nMDS results (Figure 1), the best features were for ES6SRF, FS70TH, FS30CST, and PR50TH, but good results were also found for PE18TH, RP6SRF, and PE40TH. In terms of the influence of species, treatment, and stem age on pellet quality, this study showed the presence of a link between cycle duration and pellet quality, with increasing stem age resulting in better pellet characteristics.

Figure 1.

nMDS analysis of main pellet characteristics in terms of possible differences among thirteen pellet types studied (light green: CP1; dark green: CP2; red: ES18C; blue: ES3SRF; violet: ES6SRF; dark violet: FS30CST; dark blue: FS70TH; light blue: PE18TH; olive green: PE40TH; dark red: PR18TH; teal: PR50TH; yellow: RP3SRF; light grey: RP6SRF). The diagram in the right corner shows the detail of the biplot analysis for the relationship among studied coordinates and characteristics.

4. Discussion

4.1. Pellet Quality

The overall data obtained highlighted that ES6SRF, FS70TH, FS30CST, and PR50TH reached a high quality (Figure 1). A good level of quality performance was achieved by three types: PE18TH, RP6SRF, and PE40TH. In these cases, the parameter values were remarkable. Medium quality was attained by the last six investigated pellet types: ES18C, CP1, CP2, RP3SRF, ES3SRF, and PR18TH.

In comparison with these findings, this research group developed a technical classification (Table S1) in order to provide an overview of the effectiveness of these pellets in domestic plants. The overall classification did not take into consideration the heavy metal content, because all pellet types reached the “O” class for these parameters.

In accordance with the analytical results, the pellet types ES6SRF, FS30CST, FS70TH, and PR50TH reached high quality. This means that they were tractable in simple energetic chains with no specialised structures and showed good pelletisation efficiency. A good level of quality performance, not completely confirmed by analytical results, was achieved by five types: ES18C, PE40TH, RP6SRF, CP1, and CP2. In these cases, the parameter values were remarkably high, but at the same time seemed to be less tractable in less complex pelletisation systems.

Furthermore, in this case, partially in accordance with the analytical results, the medium quality level was attained by the last four investigated pellet types: RP3SRF, ES3SRF, PE18TH, and PR18TH. These types may be therefore treatable only in industrial plants and showed an overall quality that is not suitable for small domestic plants.

Finally, as a further check of the results obtained with respect to the official technical classification (Table S2), the final classification was undertaken according to EN-ISO 17225-2, which identified three classes, A1, A2, and B, with A1 as the best and B as the worst. For some parameters, the EN ISO 17225-2 standard did not distinguish different classes, but it indicated whether the pellet reached the minimum standard, marked as 1, or did not reach that standard, marked as 0 (Table S2). For example, moisture had to be <10% for classes A1, A2, and B.

Before discussing the results, it is important to underline that practically none of the types, apart from the pine pellets and RP6SRF, reached the minimum LHV level for classification, which is 16.5 MJ/kg.

The pellet ES6SRF did not reach the standard for the lower heating value only. Other Eucalyptus pellets, ES3SRF and ES18C, showed significant shortfalls in durability, LHV, and bulk density level.

These results are in line with previous studies [48]. For the other parameters, ES3SRF fell between classes A1 and A2, but was closer to A1. By comparison, ES18C was between A2 and B, but still closer to the A2 class.

The pine pellets, PR18TH, PE18TH, PE40TH, and PR50TH, showed many similarities, although there was a slight difference in terms of classification. They all showed deficits in durability and bulk density level. It is important to underline that only these pine pellets reached the minimum standard for LHV due to their high resin, lignin, and C content. Pellets PE18TH and PE40TH were classified as class A2, whereas PR18TH and PR50TH were classified as class B.

The beech pellets, FS30CST and FS70TH, reached the A1 or A2 class requirements for the majority of the parameters. In these cases, the main deficits were in HHV, mechanical durability, and bulk density, with the same explanations given above for other pellet types. Finally, the commercial pellets, CP1 and CP2, showed the same deficits as the other pellet types in terms of bulk density, HHV, and mechanical durability level, demonstrating that these standards were also reachable with difficulty in terms of industrial production.

After the final classification, it is possible to assert that the best pellets were ES6SRF, followed by FS70TH and ES3SRF, whereas the worst types can be identified as ES18C and RP3SRF. According to the technical regulation for pellet quality 17225-2, standard reference values of diameter, length, moisture, heavy metals content, and ash melting point were achieved by all the pellet types. Therefore, in order to give a quality ranking, it is necessary to focus on the remaining five parameters, i.e., LHV, bulk density, durability, ash content, and N.

ES6SRF and FS70TH both achieved standard values for four of the above-mentioned parameters, but the former achieved the A1 class for three variables, in comparison to two A1 scores for FS70TH. PE18TH, PE40TH, PR18TH, PR50TH, RP3SRF, RP6SRF, and ES3SRF achieved the standard values for three of five variables, but ES3SRF was the only one to achieve the A1 class for N content.

Finally, ES18C, RP3SRF, CP1, and CP2 achieved the target values for only two of five parameters. However, ES18C and RP3SRF showed higher ash content in comparison to the commercial pellets, i.e., B vs. A2.

The results obtained yield some interesting suggestions for forest management when pellet production is, or can be, seen as one of the products targets. Firstly, the two best types, i.e., ES6SRF and FS70TH, derive from two markedly different management concepts, the first from an artificial plantation and the second from a natural forest. Starting from the beech stand, the high quality of the obtained pellets is certainly interesting for the development of a rural value chain. However, it is crucial to highlight that beech trees of that age can also provide high quality timber [49,50,51]. Therefore, as suggested in the New European Forest Strategy [52], the development of a wood pellet value chain from beech forests, but also other species, should be based on low value material, i.e., branches and tree tops [53,54]. The situation is different for ES6SRF—the results highlighted that increasing the length of the management cycle from short (3 years in this case) to longer, but still short (6 years in this case), rotation forestry led to a substantial improvement in pellet quality. In the present study, the main cause of this difference can be attributed to the lower ratio between bark and wood shown by the six-year-old trees in comparison to three-year-old ones, which may have led to an increase in pellet quality, mostly in terms of mechanical characteristics such as bulk density.

Focusing instead on the worst types, i.e., ES18C and RP3SRF, a possible explanation for the results obtained is the difference between the two pellet types. On the one hand, RP3SRF showed poor pellet quality, as expected when dealing with short rotation forestry trees, as a consequence of both the above-mentioned high bark/wood ratio and the harvesting system for such plants. Indeed, SRF plantations are generally harvested in the form of wood chips from modified self-propelled forage harvesters, systems which can easily lead to the entrance of foreign matter within the harvester (soil and little rocks), lowering the quality of the material obtained and mostly resulting in increased ash content [55]. Regarding ES18C, the explanation is more complex since an increase in pellet quality should be expected with increasing tree age, as a consequence of a lower bark/wood ratio. Instead, the overall quality of ES18C is much lower than that of ES6SRF. This may be related to the physiology of Eucalyptus spp. Indeed, these trees with increasing age develop thicker leaves [56]. Therefore, the ratio between leaf biomass and wood biomass increases with increasing age. This may be the reason for the poor mechanical properties of the ES18C pellets, which showed lower bulk density and durability in comparison to the Eucalyptus pellets from younger trees.

4.2. Comparison with Other Similar Studies

The results obtained were compared with other similar studies on wood pellet characterisation from the physical and chemical point of view. Previous literature studies focused on different types of pellets, including black locust and beech pellets, regarding ash content, bulk density, and HHV [57].

Pellet types in the present study performed better than those reported in literature concerning ash content, with a reduction of about 45% for black locust and 35% for beech in comparison to the literature data [57]. HHV values reported in the present study were also higher than those reported in literature, with an increase of about 9% for black locust and 12% for beech. In contrast, Giungato et al. [57] revealed higher bulk density both for black locust and beech.

Concerning black locust, different values reported by Giungato et al. [57] are probably related to variations in forest management systems. In their study, there were few details on the management system (growing and harvesting) for black locust, but it was simply reported that the black locust wood chips were obtained from a local mountainous area. Therefore, it can be speculated that the wooden material was collected from a black locust coppice forest. This would explain the higher ash content, which may be related to a different harvesting system in harsher terrain conditions [58], in which skidding causes logs to be contaminated with soil, finally increasing the ash content. A different management system may again explain the higher bulk density; in this case, due to a different rotation age, which in natural black locust coppice is generally higher than 10 years. Regarding beech, the material from Giungato et al. [57] was a commercial pellet; therefore, in this case, too, the higher bulk density presented in the literature can be explained by the different raw material used for pellet production, which in this case was probably just wood without leaves and bark.

Focusing on pine species, Garcia et al. [59] found values similar to those reported in the present study concerning HHV. By comparison, the results of the Brazilian study reported lower ash content and higher bulk density and durability.

The lower value of bulk density obtained in the present study, and the less attractive properties regarding ash and lower pellet durability, are probably related to the kind of feedstock for pellet production. Indeed, Garcia et al. [59] used pure pine sawdust for pellets, without leaves and bark, which were instead incorporated in the pellets produced in the present study.

The results of another study carried out in Spain concerning pine pellets [60] also revealed higher bulk density and lower ash content in comparison with the results of the present manuscript. By comparison, results similar to those of the present study were obtained concerning heating values and chemical characteristics such as carbon content and hydrogen content. However, a substantially lower N content of 0.09% was reported in the Spanish study [60], probably as a consequence of different environmental conditions in which biomass was collected.

Focusing on Eucalyptus pellets, the obtained results are in line with those reported for commercial Eucalyptus pellets concerning ash content, HHV, and bulk density, and even higher concerning mechanical durability [61].

Another interesting comparison for Eucalyptus pellets can be made with a recent study carried out in Chile [44]. This study analysed the quality of pellets obtained from a 5-year rotation Eucalyptus plant; that is, a similar management system to that investigated in this study but in a different part of the world. The results obtained in the present study are in line with the literature data from Pegoretti Leite de Souza et al. concerning mechanical durability and HHV, but a substantially higher bulk density (increased by about 8%) was reported in the Chilean study [44].

Recently, Civitarese et al. [22] analysed various poplar (Populus × euroamericana AF-6 clone) pellet characteristics for LHV, ash content, ash melting point, and heavy metal content. In particular, they studied the differences among 3-, 6- and 9-year-old poplar pellets obtained both from the whole tree and from the stem only. A recent study showed that poplar harvesting from SRF can be a substantial source of biomass [34], which can also be used for pellets.

Comparing the cited results with those found in this study, it can be noted that Civitarese et al. [22] found higher heating values ranging from 17.55 MJ/kg for 9-year-old trees, stem only, to 17.85 MJ/kg for 3-year-old trees, stem only. These values were considerably higher than those obtained in the presented study, with values ranging from 14.290 MJ/kg for ES3SRF to 17.415 MJ/kg for PE40TH.

Regarding ash content, the study of Civitarese et al. [22] showed higher values ranging from 1.82% for 6-year-old trees, whole tree, to 2.78% for 3-year-old tress, whole tree, compared with this study’s range of 0.64% for FS70TH to 1.3% for RP3SRF.

Regarding ash melting point, the Italian study found values ranging from 1404.6 °C for 6-year-old trees, whole tree, to 1479.8 °C for 9-year-old trees, whole tree. Italian values were higher than those shown in the presented study. In fact, ash melting point values ranged from 1377.3 °C for FS30CST to 1480.8 °C for ES3SRF.

In contrast, the Civitarese et al. [22] results for heavy metal content were similar to those found in this study.

Finally, it can be said that the results of the present study were comparable with other similar studies, with the exceptions of durability and bulk density. This was probably due to the feedstock used, because leaves and bark negatively affected these parameters. Mechanical properties are further highlighted by the low values of shear resistance for the majority of the investigated types.

Species, and therefore the wood material characteristics, seemed to be the most relevant factor. In fact, pellets from the same species, or similar, in the case of Pinus eldarica and Pinus radiata, showed similar characteristics.

Nevertheless, the management system and, consequently, stem age also seemed to have an important influence. In particular, this study’s results showed that the pellet qualities tended to improve as stem age increased. Moreover, this link between wood age/management system and pellet quality appeared to be more pronounced when dealing with young trees.

In fact, ES6SRF (overall class “O”) and RP6SRF (overall class “G”) showed obviously better qualities than ES3SRF (overall class “G”) and RP3SRF (overall class “M”). Therefore, with regard to dedicated plants, 6-year SRF was found to be the best management system for good pellet quality standards. Wood harvested from thinning interventions at 18 years of age provided a lower quality pellet than 40–50-year-old materials. PE18TH and PR18TH were classified as “M”, whereas PE40TH and PR50TH were classified as class “G” and “O”, respectively. This was not confirmed for beech pellets, because FS30CST and FS70TH were in the same class of “O”. Thus, the link between stem age/management and pellet qualities seemed to lose significance with increasing management cycle age.

5. Conclusions

The analysed pellet samples should not be classified according to EN 17225-2 due primarily to their lower LHV and bulk density values. However, these deficits were also found in commercial pellet samples. According to the proposed classification, the most attractive pellets were obtained from ES6SRF and ES3SRF.

Regarding the classification developed within this study, all the pellet types were found to be suitable for the proposed classification, because none of them exceeded the limits of toxic content. According to this classification, the best types were ES6SRF, FS70TH, and FS30CST.

In terms of the influence of species, management system, and stem age on the pellet qualities, this study showed the presence of a link between cycle duration and pellet qualities, because an increase in stem age resulted in better pellet characteristics. This link seemed to be particularly strong in short rotation systems, for example migrating from 3 years of SRF to 6 years of SRF, and weaker in the long term. In fact, the beech pellets from coppice showed very similar qualities to those from high stand thinning.

The results obtained in this study show the importance of understanding the efficiency level and the capability of managing specific systems, including small-scale scenarios, both for self-consumption and for short supply chain commerce. Overall, the virgin wood material without any additives showed possible deficiencies but also undoubted strength in terms of, for example, pollutant and ash melting point levels, two parameters which are important in small heating systems. The results are very promising for the proposed innovative production of pellets.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/f13040502/s1, Table S1: Pellet type classification according to standard developed * within this study for physical parameters: “M”: medium, “G”: good, and “O”: optimum; Table S2: Classification of various pellet types according to EN ISO 17225–2. Symbols “1” or “0” in columns indicate whether the pellet reached the minimum standard in classification for selected parameter, for which the EN ISO 17225-2 classification doesn’t distinguish different classes. The classification according EN-ISO 17225-2 identified three classes: A1, A2 and B, with A1 as the best pellet quality class and B as the worst.

Author Contributions

Conceptualization, F.L., V.C., R.P. and P.S.M.; Data curation, F.L., V.C., M.W., R.P. and R.V.; Formal analysis, F.L., V.C., R.P. and R.V.; Investigation, F.L., V.C. and R.V.; Methodology, F.L., V.C., M.W., R.P., Z.K., R.V. and M.B.; Supervision, R.P. and P.S.M.; Validation, V.C. and R.P.; Writing—original draft, F.L., V.C., M.W., R.P., Z.K., M.B. and P.S.M.; Writing—review and editing, F.L., V.C., R.P., R.V., M.B. and P.S.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data available on request from the corresponding author, due to privacy restrictions.

Acknowledgments

The study was carried out within the activities of the AGROENER project (Energy from agriculture: sustainable innovations for the bio-economy, financing MiPAAF D.D. n. 26329 of 4 April 2016, http://agroener.crea.gov.it/ accessed on 1 February 2022). This work was also supported by the Italian Ministry for Education, University and Research (MIUR) (Law 232/2016, Italian University Departments of excellence) UNITUS-DAFNE WP3. The publication was co-financed within the framework of the Polish Ministry of Science and Higher Education’s programme: “Regional Initiative Excellence” in the years 2019–2022, Project No. 005/RID/2018/19.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Huang, Y.; Finell, M.; Larsson, S.; Wang, X.; Zhang, J.; Wei, R.; Liu, L. Biofuel pellets made at low moisture content—Influence of water in the binding mechanism of densified biomass. Biomass Bioenergy 2017, 98, 8–14. [Google Scholar] [CrossRef]

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable forest operations (SFO): A new paradigm in a changing world and climate. Sci. Total Environ. 2018, 634, 1385–1397. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet production from woody and non-woody feedstocks: A review on biomass quality evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Van Duren, I.; Voinov, A.; Arodudu, O.; Firrisa, M.T. Where to produce rapeseed biodiesel and why? Mapping European rapeseed energy efficiency. Renew. Energy 2015, 74, 49–59. [Google Scholar] [CrossRef] [Green Version]

- Kizuka, R.; Ishii, K.; Sato, M.; Fujiyama, A. Characteristics of wood pellets mixed with torrefied rice straw as a biomass fuel. Int. J. Energy Environ. Eng. 2019, 10, 357–365. [Google Scholar] [CrossRef] [Green Version]

- Koseki, H. Evaluation of various solid biomass fuels using thermal analysis and gas emission tests. Energies 2011, 4, 616–627. [Google Scholar] [CrossRef] [Green Version]

- Picchio, R.; Spina, R.; Sirna, A.; lo Monaco, A.; Civitarese, V.; del Giudice, A.; Suardi, A.; Pari, L. Characterization of woodchips for energy from forestry and agroforestry production. Energies 2012, 5, 3803–3816. [Google Scholar] [CrossRef]

- Tavankar, F.; Picchio, R.; lo Monaco, A.; Bonyad, A.E. Forest management and snag characteristics in Northern Iran lowland forests. J. For. Sci. 2014, 60, 431–441. [Google Scholar] [CrossRef] [Green Version]

- So, C.L.; Eberhardt, T.L. FTIR-based models for assessment of mass yield and biofuel properties of torrefied wood. Wood Sci. Technol. 2018, 52, 209–227. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Jochem, D.; Weimar, H.; Bösch, M.; Mantau, U.; Dieter, M. Estimation of wood removals and fellings in Germany: A calculation approach based on the amount of used roundwood. Eur. J. For. Res. 2015, 134, 869–888. [Google Scholar] [CrossRef]

- Szewczyk, K.; Polowy, K. Production of fuel wood chips as an example of supply chain reorganisation resulting from socioeconomic changes in Poland. Drewno 2020, 63, 141–154. [Google Scholar] [CrossRef]

- Dias, M.F.; Silva, A.C.; Nunes, L.J.R. Transaction cost theory: A case study in the biomass-to-energy sector. Curr. Sustain. Energy Rep. 2021, 8, 57–69. [Google Scholar] [CrossRef]

- Melis, E.; Vincis, A.; Orrù, P.F. An overview of current models and approaches to biomass supply chain design and management. Curr. Sustain. Energy Rep. 2018, 5, 138–149. [Google Scholar] [CrossRef]

- Tauro, R.; García, C.A.; Skutsch, M.; Masera, O. The potential for sustainable biomass pellets in Mexico: An analysis of energy potential, logistic costs and market demand. Renew. Sustain. Energy Rev. 2018, 82, 380–389. [Google Scholar] [CrossRef]

- Rodrigues, A.M.; Costa, M.M.G.; Nunes, L.J.R. Short rotation woody coppices for biomass production: An integrated analysis of the potential as an energy alternative. Curr. Sustain. Energy Rep. 2021, 8, 70–89. [Google Scholar] [CrossRef]

- Liu, Z.; Fei, B.; Jiang, Z.; Cai, Z.; Liu, X. Important properties of bamboo pellets to be used as commercial solid fuel in China. Wood Sci. Technol. 2014, 48, 903–917. [Google Scholar] [CrossRef]

- Mola-Yudego, B.; Selkimäki, M.; González-Olabarria, J.R. Spatial analysis of the wood pellet production for energy in Europe. Renew. Energy 2014, 63, 76–83. [Google Scholar] [CrossRef]

- Sgarbossa, A.; Costa, C.; Menesatti, P.; Antonucci, F.; Pallottino, F.; Zanetti, M.; Grigolato, S.; Cavalli, R. A multivariate SIMCA index as discriminant in wood pellet quality assessment. Renew. Energy 2015, 76, 258–263. [Google Scholar] [CrossRef]

- Spinelli, R.; Lombardini, C.; Aminti, G.; Magagnotti, N. Efficient debarking to increase value recovery in small-scale forestry operations. Small-Scale For. 2018, 17, 377–392. [Google Scholar] [CrossRef]

- De Castro, P.G.S.; de Siqueira, H.F.; de Castro, V.R.; Zanuncio, A.J.V.; Zanuncio, J.C.; da Silva Berger, M.; Martins, F.D.R.; de Carneiro, A.C.O.; Gominho, J.; de Oliveira Araújo, S. Quality of Pinus sp. pellets with kraft lignin and starch addition. Sci. Rep. 2021, 11, 900. [Google Scholar] [CrossRef]

- Civitarese, V.; Acampora, A.; Sperandio, G.; Assirelli, A.; Picchio, R. Production of wood pellets from poplar trees managed as coppices with different harvesting cycles. Energies 2019, 12, 2973. [Google Scholar] [CrossRef] [Green Version]

- Scatolino, M.V.; Neto, L.F.C.; Protásio, T.P.; Carneiro, A.C.O.; Andrade, C.R.; Guimarães Júnior, J.B.; Mendes, L.M. Options for generation of sustainable energy: Production of pellets based on combinations between lignocellulosic biomasses. Waste Biomass Valoriz. 2018, 9, 479–489. [Google Scholar] [CrossRef]

- Santana, D.A.R.; Scatolino, M.V.; Lima, M.D.R.; de Oliveira Barros Junior, U.; Garcia, D.P.; Andrade, C.R.; de Cássia Oliveira Carneiro, A.; Trugilho, P.F.; de Paula Protásio, T. Pelletizing of lignocellulosic wastes as an environmentally friendly solution for the energy supply: Insights on the properties of pellets from Brazilian biomasses. Environ. Sci. Pollut. Res. 2021, 28, 11598–11617. [Google Scholar] [CrossRef]

- Gravelsins, A.; Muizniece, I.; Blumberga, A.; Blumberga, D. Economic sustainability of pellet production in Latvia. Energy Procedia 2017, 142, 531–537. [Google Scholar] [CrossRef]

- Alsaleh, M.; Abdul-Rahim, A.S. An evaluation of bioenergy industry sustainability impacts on forest degradation: Evidence from European Union economies. Environ. Dev. Sustain. 2021, 24, 1738–1760. [Google Scholar] [CrossRef]

- Gilvari, H.; van Battum, C.H.H.; van Dijk, S.A.; de Jong, W.; Schott, D.L. Large-scale transportation and storage of wood pellets: Investigation of the change in physical properties. Particuology 2021, 57, 146–156. [Google Scholar] [CrossRef]

- Acda, M.N.; Jara, A.A.; Daracan, V.C.; Devera, E.E. Opportunities and barriers to wood pellet trade in the Philippines. Ecosyst. Dev. J. 2016, 6, 27–31. [Google Scholar]

- Dyjakon, A.; den Boer, J.; Gebresenbet, G.; Bosona, T.; Adamczyk, F. Economic analysis of the collection and transportation of pruned branches from orchards for energy production. Drewno 2020, 63, 125–140. [Google Scholar] [CrossRef]

- Paukkunen, S. Opportunities to use thinning wood as raw material for wood pellets. Croat. J. For. Eng. 2014, 35, 23–33. [Google Scholar]

- Dong, L.; Jin, X.; Pukkala, T.; Li, F.; Liu, Z. How to manage mixed secondary forest in a sustainable way? Eur. J. For. Res. 2019, 138, 789–801. [Google Scholar] [CrossRef] [Green Version]

- Mederski, P.S.; Venanzi, R.; Bembenek, M.; Karaszewski, Z.; Rosińska, M.; Pilarek, Z.; Luchenti, I.; Surus, M. Designing thinning operations in 2nd age class pine stands—Economic and environmental implications. Forests 2018, 9, 335. [Google Scholar] [CrossRef] [Green Version]

- Bergström, D. Cost analysis of innovative biomass harvesting systems for young dense thinnings. Croat. J. For. Eng. 2019, 40, 221–230. [Google Scholar] [CrossRef]

- Magagnotti, N.; Spinelli, R.; Kärhä, K.; Mederski, P.S. Multi-tree cut-to-length harvesting of short-rotation poplar plantations. Eur. J. For. Res. 2021, 140, 345–354. [Google Scholar] [CrossRef]

- Mederski, P.S.; Jakubowski, M.; Karaszewski, Z. The Polish landscape changing due to forest policy and forest management. IForest 2009, 2, 140–142. [Google Scholar] [CrossRef]

- Mihelic, M.; Spinelli, R.; Poje, A. Intensifying the management of protection forests in the Alps. Drewno 2018, 61, 23–37. [Google Scholar]

- Picchio, R.; Tavankar, F.; Bonyad, A.; Mederski, P.S.; Venanzi, R.; Nikooy, M. Detailed analysis of residual stand damage due to winching on steep terrains. Small-Scale For. 2019, 18, 255–277. [Google Scholar] [CrossRef] [Green Version]

- Scheidl, C.; Heiser, M.; Vospernik, S.; Lauss, E.; Perzl, F.; Kofler, A.; Kleemayr, K.; Bettella, F.; Lingua, E.; Garbarino, M. Assessing the protective role of alpine forests against rockfall at regional scale. Eur. J. For. Res. 2020, 139, 969–980. [Google Scholar] [CrossRef]

- Lo Monaco, A.; Todaro, L.; Sarlatto, M.; Spina, R.; Calienno, L.; Picchio, R. Effect of moisture on physical parameters of timber from Turkey oak (Quercus cerris L.) coppice in Central Italy. For. Stud. China 2011, 13, 276–284. [Google Scholar] [CrossRef]

- Ruiz, D.; San Miguel, G.; Corona, B.; López, F.R. LCA of a multifunctional bioenergy chain based on pellet production. Fuel 2018, 215, 601–611. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A. Effect of species, particle size and compacting pressure on relaxed density and compressive strength of fuel briquettes. Int. J. Energy Environ. Eng. 2013, 4, 30. [Google Scholar] [CrossRef] [Green Version]

- Goh, C.S.; Aikawa, T.; Ahl, A.; Ito, K.; Kayo, C.; Kikuchi, Y.; Takahashi, Y.; Furubayashi, T.; Nakata, T.; Kanematsu, Y. Rethinking sustainable bioenergy development in Japan: Decentralised system supported by local forestry biomass. Sustain. Sci. 2020, 15, 1461–1471. [Google Scholar] [CrossRef]

- Valverde, J.C.; Arias, D.; Campos, R.; Jiménez, M.F.; Brenes, L. Forest and agro-industrial residues and bioeconomy: Perception of use in the energy market in Costa Rica. Energy Ecol. Environ. 2021, 6, 232–242. [Google Scholar] [CrossRef]

- De Souza, P.L.H.J.; Muñoz, F.; Mendonça, R.T.; Sáez, K.; Olave, R.; Segura, C.; de Souza, D.P.L.; de Paula Protásio, T.; Rodríguez-Soalleiro, R. Influence of lignin distribution, physicochemical characteristics and microstructure on the quality of biofuel pellets made from four different types of biomass. Renew. Energy 2021, 163, 1802–1816. [Google Scholar] [CrossRef]

- Nosek, R.; Holubcik, M.; Jandacka, J. The impact of bark content of wood biomass on biofuel properties. BioResources 2016, 11, 44–53. [Google Scholar] [CrossRef] [Green Version]

- Lerma-Arce, V.; Oliver-Villanueva, J.V.; Segura-Orenga, G.; Urchueguia-Schölzel, J.F. Comparison of alternative harvesting systems for selective thinning in a mediterranean pine afforestation (Pinus halepensis mill.) for bioenergy use. IForest 2021, 14, 465–472. [Google Scholar] [CrossRef]

- Toscano, A.; Hellio, C.; Marzo, A.; Milani, M.; Lebret, K.; Cirelli, G.L.; Langergraber, G. Removal efficiency of a constructed wetland combined with ultrasound and UV devices for wastewater reuse in agriculture. Environ. Technol. 2013, 34, 2327–2336. [Google Scholar] [CrossRef]

- Arranz, J.I.; Miranda, M.T.; Montero, I.; Sepúlveda, F.J.; Rojas, C. V Characterization and combustion behaviour of commercial and experimental wood pellets in South West Europe. Fuel 2015, 142, 199–207. [Google Scholar] [CrossRef]

- Todorović, N.; Popović, Z.; Milić, G. Estimation of quality of thermally modified beech wood with red heartwood by FT-NIR spectroscopy. Wood Sci. Technol. 2015, 49, 527–549. [Google Scholar] [CrossRef]

- Pretzsch, H.; Rais, A. Wood quality in complex forests versus even-aged monocultures: Review and perspectives. Wood Sci. Technol. 2016, 50, 845–880. [Google Scholar] [CrossRef]

- Lo Monaco, A.; Calienno, L.; Pelosi, C.; Balletti, F.; Agresti, G.; Picchio, R. Technical properties of beech wood from aged coppices in central Italy. IForest 2015, 8, 82–88. [Google Scholar] [CrossRef] [Green Version]

- European Union. New European Forest Strategy for 2030. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52021DC0572 (accessed on 15 August 2021).

- Mederski, P.S.; Bembenek, M.; Karaszewski, Z.; Pilarek, Z.; Łacka, A. Investigation of log length accuracy and harvester efficiency in processing of oak trees. Croat. J. For. Eng. 2018, 39, 173–181. [Google Scholar]

- Rosińska, M.; Bembenek, M.; Picchio, R.; Karazzewski, Z.; Đuka, A.; Mederski, P.S. Determining harvester productivity curves of thinning operations in birch stands of Central Europe. Croat. J. For. Eng. 2022, 43, 1–12. [Google Scholar] [CrossRef]

- Pari, L.; Civitarese, V.; del Giudice, A.; Assirelli, A.; Spinelli, R.; Santangelo, E. Influence of chipping device and storage method on the quality of SRC poplar biomass. Biomass Bioenergy 2013, 51, 169–176. [Google Scholar] [CrossRef]

- Ceulemans, R.; McDonald, A.J.S.; Pereira, J.S. A comparison among eucalypt, poplar and willow characteristics with particular reference to a coppice, growth-modelling approach. Biomass Bioenergy 1996, 11, 215–231. [Google Scholar] [CrossRef]

- Giungato, P.; Barbieri, P.; Cozzutto, S.; Licen, S. Sustainable domestic burning of residual biomasses from the Friuli Venezia Giulia region. J. Clean. Prod. 2018, 172, 3841–3850. [Google Scholar] [CrossRef]

- Maesano, M.; Picchio, R.; lo Monaco, A.; Neri, F.; Lasserre, B.; Marchetti, M. Productivity and energy consumption in logging operation in a Cameroonian tropical forest. Ecol. Eng. 2013, 57, 149–153. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; de Paula Protásio, T. Comparative energy properties of torrefied pellets in relation to pine and elephant grass pellets. BioResources 2018, 13, 2898–2906. [Google Scholar] [CrossRef] [Green Version]

- Royo, J.; Canalís, P.; Quintana, D.; Díaz-Ramírez, M.; Sin, A.; Rezeau, A. Experimental study on the ash behaviour in combustion of pelletized residual agricultural biomass. Fuel 2019, 239, 991–1000. [Google Scholar] [CrossRef] [Green Version]

- De Souza, H.J.P.L.; Arantes, M.D.C.; Vidaurre, G.B.; Andrade, C.R.; de Carneiro, A.C.O.; de Souza, D.P.L.; de Protásio, T.P. Pelletization of eucalyptus wood and coffee growing wastes: Strategies for biomass valorization and sustainable bioenergy production. Renew. Energy 2020, 149, 128–140. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).