Influence of Phenol–Formaldehyde Resin Oligomer Molecular Weight on the Strength Properties of Beech Wood

Abstract

1. Introduction

2. Materials and Methods

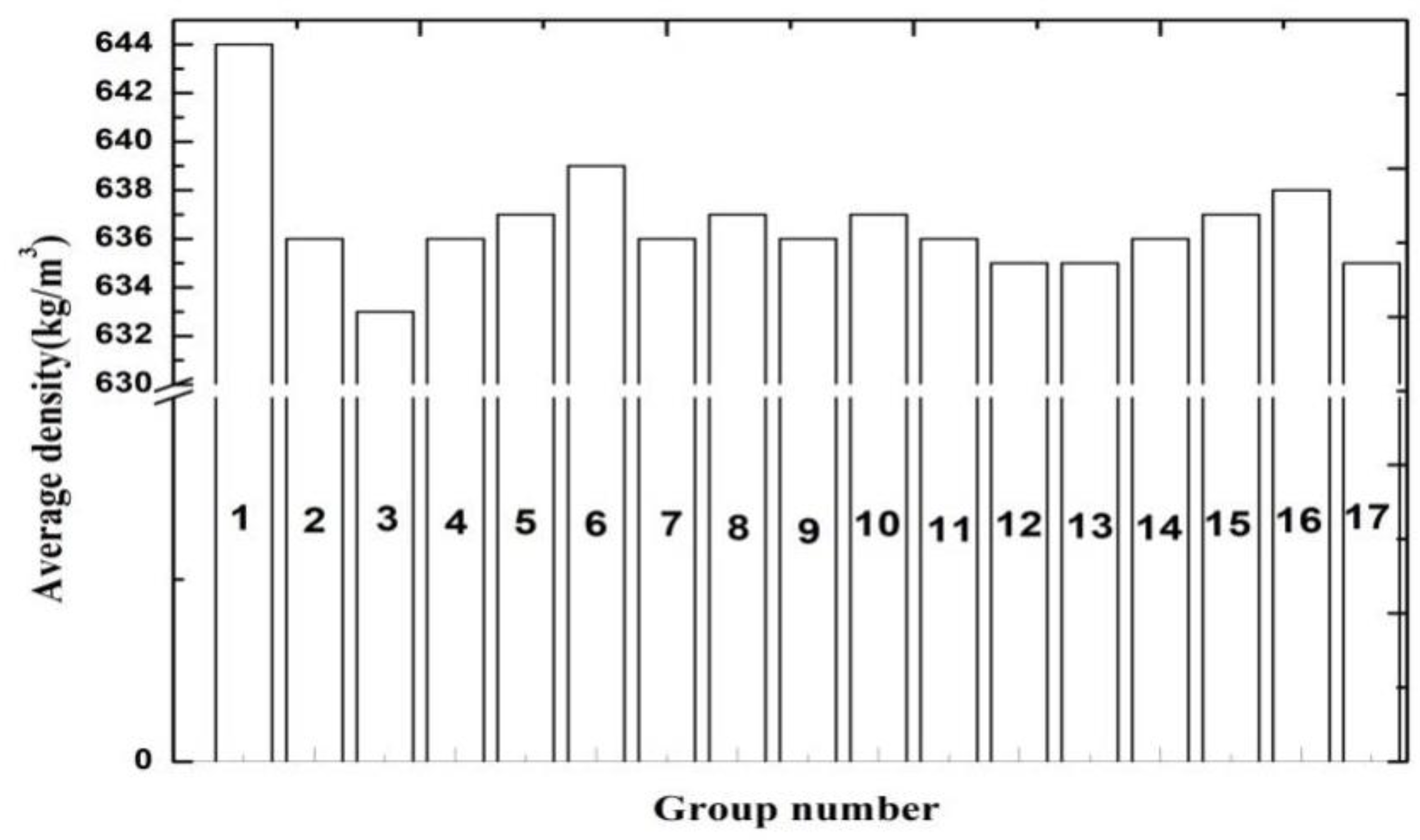

2.1. Wood Samples

2.2. PF Resins

2.3. Wood Treatment

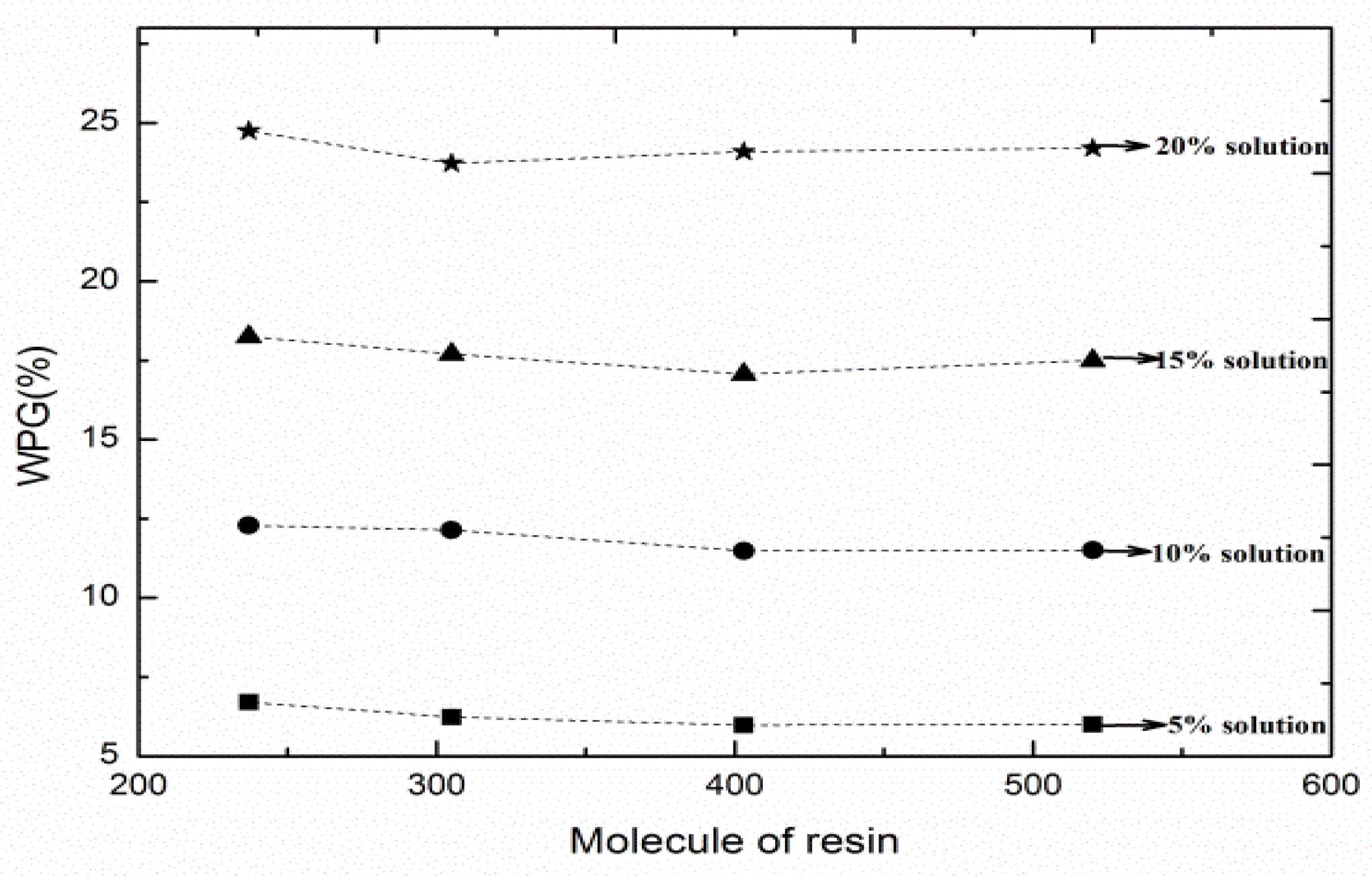

2.4. Weight Percent Gain

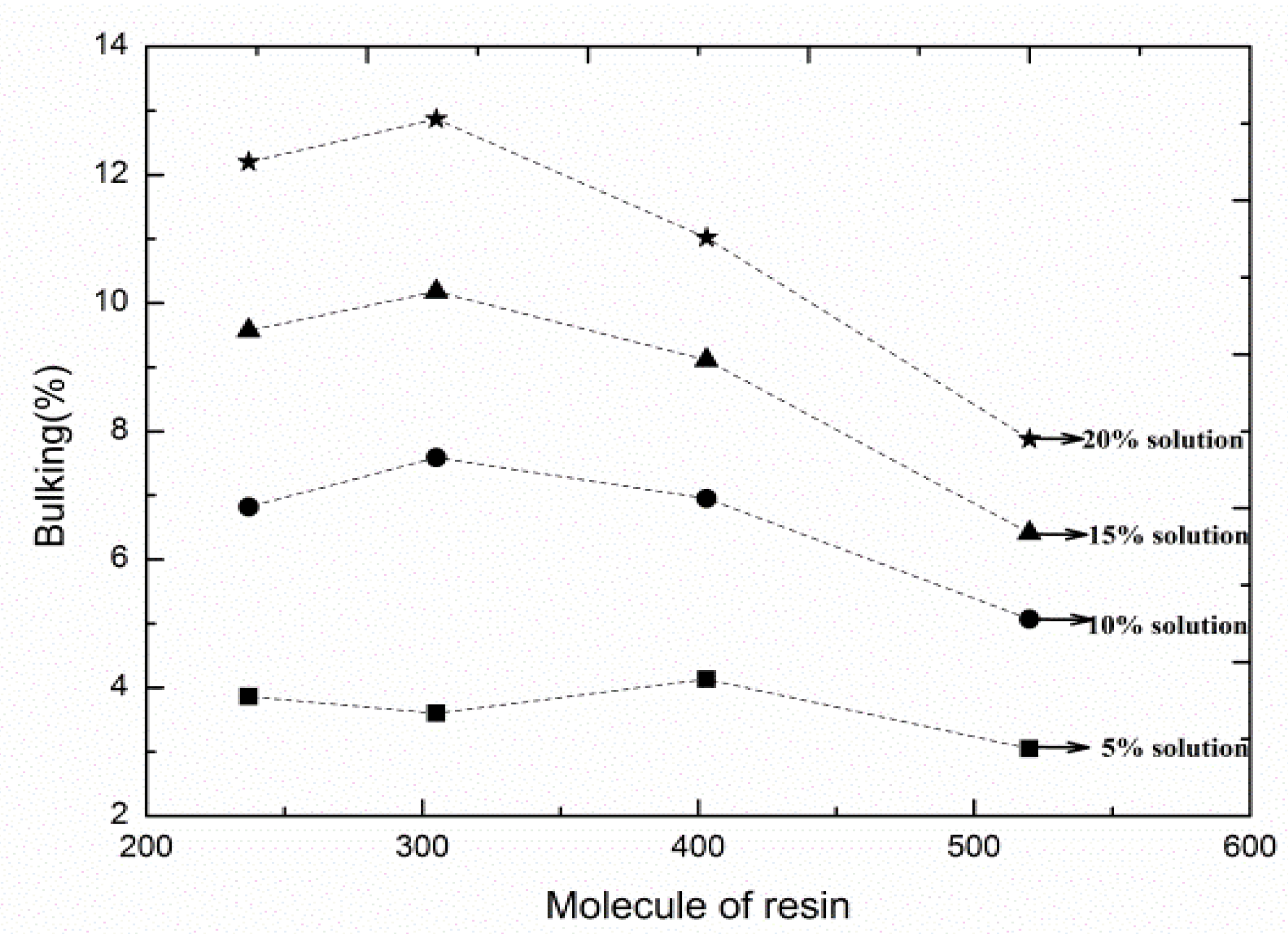

2.5. Bulking Coefficient

2.6. MOE

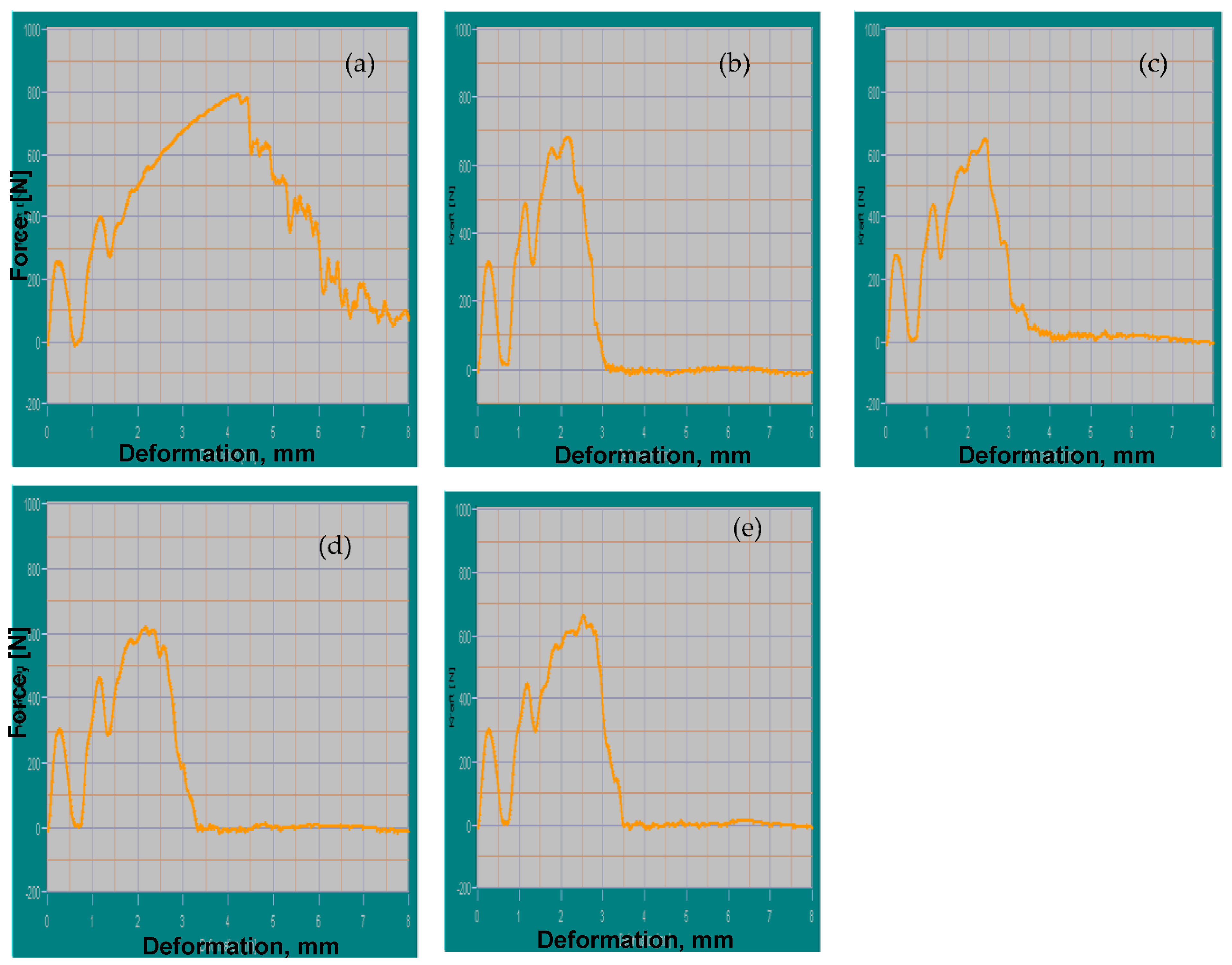

2.7. Bending and Impact Bending Tests

2.8. Morphology Analysis

3. Results

3.1. WPG

3.2. Bulking Effect

3.3. MOE

3.4. IBS

3.5. Morphology Analysis

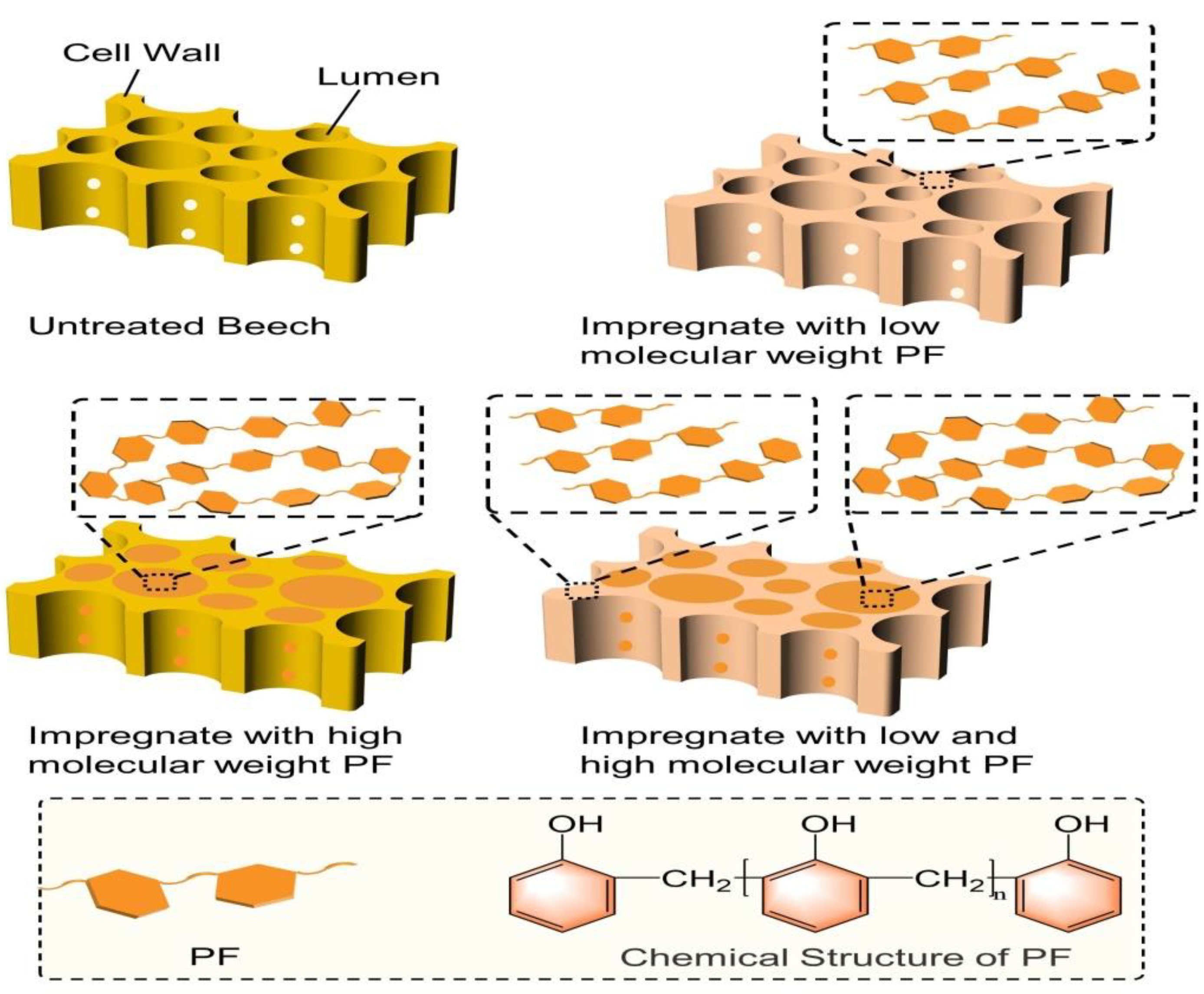

3.6. Mechanism Underlying the Modification of Beech Wood via PF Resin

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Donath, S.; Militz, H.; Mai, C. Wood modification with alkoxysilanes. Wood Sci. Technol. 2004, 38, 555–566. [Google Scholar] [CrossRef]

- Klüppel, A.; Mai, C. The influence of curing conditions on the chemical distribution in wood modified with thermosetting resins. Wood Sci. Technol. 2013, 47, 643–658. [Google Scholar] [CrossRef]

- Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes; John Wiley and Sons: Hoboken, NJ, USA, 2007; Volume 5. [Google Scholar]

- Xie, Y.; Hill, C.A.; Xiao, Z.; Mai, C.; Militz, H. Dynamic water vapour sorption properties of wood treated with glutaraldehyde. Wood Sci. Technol. 2011, 45, 49–61. [Google Scholar] [CrossRef][Green Version]

- Müller, M.; Radovanovic, I.; Grüneberg, T.; Militz, H.; Krause, A. Influence of various wood modifications on the properties of polyvinyl chloride/wood flour composites. J. Appl. Polym. Sci. 2012, 125, 308–312. [Google Scholar] [CrossRef]

- Furuno, T.; Imamura, Y.; Kajita, H. The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: A properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci. Technol. 2004, 37, 349–361. [Google Scholar]

- Gabrielli, C.; Kamke, F.A. Treatment of chemically modified wood with VTC process to improve dimensional stability. Forest Prod. J. 2008, 58, 82–86. [Google Scholar]

- Wang, X.; Chen, X.; Xie, X.; Cai, S.; Yuan, Z.; Li, Y. Multi-Scale Evaluation of the Effect of Phenol Formaldehyde Resin Impregnation on the Dimensional Stability and Mechanical Properties of Pinus Massoniana Lamb. Forests 2019, 10, 646. [Google Scholar] [CrossRef]

- Anwar, U.M.K.; Paridah, M.T.; Hamdan, H.; Sapuan, S.M.; Bakar, E.S. Effect of curing time on physical and mechanical properties of phenolic-treated bamboo strips. Ind. Crop Prod. 2009, 29, 214–219. [Google Scholar] [CrossRef]

- Persson, P.V.; Hafren, J.; Fogden, A.; Daniel, G.; Iversen, T. Silica Nanocasts of Wood Fibers: A Study of Cell-Wall Accessibility and Structure. Biomacromolecules 2004, 5, 1097–1101. [Google Scholar] [CrossRef]

- Epmeier, H.; Westin, M.; Rapp, A. Differently modified wood: Comparison of some selected properties. Scand. J. Forest Res. 2004, 19, 31–37. [Google Scholar] [CrossRef]

- Biziks, V.; Bicke, S.; Militz, H. Penetration depth of phenol-formaldehyde (PF) resin into beech wood studied by light microscopy. Wood Sci. Technol. 2019, 53, 165–176. [Google Scholar] [CrossRef]

- Gabrielli, C.P.; Kamke, F.A. Phenol–formaldehyde impregnation of densified wood for improved dimensional stability. Wood Sci. Technol. 2010, 44, 95–104. [Google Scholar] [CrossRef]

- Ryu, J.Y.; Imamura, Y.; Takahashi, M.; Kajita, H. Effect of molecular weight and some other properties of resins on the biological resistance of phenolic resin treated wood. Mokuzai Gakkaishi 1993, 39, 486–492. [Google Scholar]

- Imamura, Y.; Kajita, H.; Higuchi, N. Modification of wood by treatment with low molecular phenol-formaldehyde resin (1). Influence of neutral and alkaline resins (in Japanese). In Proceedings of the Abstracts of the 48th Annual Meeting of Japan Wood Research Society, Shizuoka, Japan, 3–5 April 1998. [Google Scholar]

- Xie, Y.; Fu, Q.; Wang, Q.; Xiao, Z.; Militz, H. Effects of chemical modification on the mechanical properties of wood. Eur. J. Wood Wood Prod. 2013, 71, 401–416. [Google Scholar] [CrossRef]

- Lopes, D.B.; Mai, C.; Militz, H. Mechanical properties of chemically modified portuguese pinewood. Maderas Cienc. Tecnol. 2015, 17, 179–194. [Google Scholar] [CrossRef]

- Hillis, W.E. High temperature and chemical effects on wood stability. Wood Sci. Technol. 1984, 18, 281–293. [Google Scholar] [CrossRef]

- Hermoso, E.; Fernández-Golfín, J.; Conde, M.; Troya, M.T.; Mateo, R.; Cabrero, J. Characterization of thermally modified Pinus radiata timber. Maderas Cienc. Technol. 2015, 17, 493–504. [Google Scholar]

- Kielmann, B.C.; Militz, H.; Mai, C.; Adamopoulos, S. Strength changes in ash, beech and maple wood modified with a N-methylol melamine compound and a metal-complex dye. Wood Res. 2013, 58, 343–350. [Google Scholar]

- Evans, P.D.; Schmalzl, K.J. A Quantitative Weathering Study of Wood Surfaces Modified by Chromium VI and Iron III Compounds. Part 1. Loss in Zero-Span Tensile Strength and Weight of Thin Wood Veneers. Holzforschung 1989, 43, 289–292. [Google Scholar] [CrossRef]

- Mai, C.; Xie, Y.; Xiao, Z.; Bollmus, S.; Vetter, G.; Krause, A.; Militz, H. Influence of the modification with different aldehydebased agents on the tensile strength of wood. In European Conference on Wood Modification; Bangor University: Cardiff, Wales, 2007; pp. 49–56. [Google Scholar]

- Dieste, A.; Krause, A.; Bollmus, S.; Militz, H. Physical and mechanical properties of plywood produced with 1.3-dimethylol-4.5-dihydroxyethyleneurea (DMDHEU)-modified veneers of Betula sp. and Fagus sylvatica. Holz Als Roh-Und Werkst. 2008, 66, 281. [Google Scholar] [CrossRef]

- Xie, Y.; Krause, A.; Militz, H.; Turkulin, H.; Richter, K.; Mai, C. Effect of treatments with 1.3-dimethylol-4, 5-dihydroxy-ethyleneurea (DMDHEU) on the tensile properties of wood. Holzforschung 2007, 61, 43–50. [Google Scholar] [CrossRef]

- Pittman, C.U., Jr.; Kim, M.G.; Nicholas, D.D.; Wang, L.; Kabir, F.A.; Schultz, T.P.; Ingram, L.L., Jr. Wood enhancement treatments I. Impregnation of southern yellow pine with melamine-formaldehyde and melamine-ammeline-formaldehyde resins. J. Wood Chem. Technol. 1994, 14, 577–603. [Google Scholar] [CrossRef]

- Modzel, G.; Kamke, F.A.; Carlo, D.F. Comparative analysis of wood: Adhesive bondline. Wood Sci. Technol. 2011, 45, 147–158. [Google Scholar] [CrossRef]

- Biziks, V.; Bicke, S.; Koch, G.; Militz, H. Effect of phenol-formaldehyde (PF) resin oligomer size on the decay resistance of beech wood. Holzforschung 2021, 75, 574–583. [Google Scholar] [CrossRef]

- Nishida, M.; Tanaka, T.; Miki, T.; Hayakawa, Y.; Kanayama, K. Integrated analysis of solid-state NMR spectra and nuclear magnetic relaxation times for the phenol formaldehyde (PF) resin impregnation process into soft wood. RSC Adv. 2017, 7, 54532–54541. [Google Scholar] [CrossRef]

- Yi, T.; Guo, C.; Zhao, S.; Zhan, K.; Gao, W.; Yang, L.; Du, G. The simultaneous preparation of nano cupric oxide (CuO) and phenol formaldehyde (PF) resin in one system: Aimed to apply as wood adhesives. Eur. J. Wood Wood Prod. 2020, 78, 471–482. [Google Scholar] [CrossRef]

- Kordkheili, H.Y.; Pizzi, A. Improving properties of phenol-lignin-glyoxal resin as a wood adhesive by an epoxy resin. Eur. J. Wood Wood Prod. 2021, 79, 199–205. [Google Scholar] [CrossRef]

- Vitas, S.; Segmehl, J.S.; Burgert, I.; Cabane, E. Porosity and pore size distribution of native and delignified beech wood determined by mercury intrusion porosimetry. Materials 2019, 12, 416. [Google Scholar] [CrossRef] [PubMed]

- Hass, P.; Wittel, F.K.; McDonald, S.A.; Marone, F.; Stampanoni, M.; Herrmann, H.J.; Niemz, P. Pore Space Analysis of Beech Wood: The Vessel Network. Holzforschung 2010, 64, 639–644. [Google Scholar] [CrossRef]

- Wang, X.; Chen, X.; Xie, X.; Yuan, Z.; Cai, S.; Li, Y. Effect of phenol formaldehyde resin penetration on the quasi-static and dynamic mechanics of wood cell walls using nanoindentation. Nanomaterials 2019, 9, 1409. [Google Scholar] [CrossRef] [PubMed]

- Pečnik, J.G.; Kutnar, A.; Militz, H.; Schwarzkopf, M.; Schwager, H. Fatigue behavior of beech and pine wood modified with low molecular weight phenol-formaldehyde resin. Holzforschung 2021, 75, 37–47. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Z.; Yang, K.; Mei, C.; Van den Bulcke, J.; Van Acker, J. Understanding the effect of combined thermal treatment and phenol–formaldehyde resin impregnation on the compressive stress of wood. Wood Sci. Technol. 2022, 56, 1071–1086. [Google Scholar] [CrossRef]

- Hong, S.; Gu, Z.; Chen, L.; Zhu, P.; Lian, H. Synthesis of phenol formaldehyde (PF) resin for fast manufacturing laminated veneer lumber (LVL). Holzforschung 2018, 72, 745–752. [Google Scholar] [CrossRef]

| Resin | Molecular Weight Mn (g/mol) | Solid Content (%) | Catalyst | Amount of Formaldehyde (%) | Free Phenol (%) |

|---|---|---|---|---|---|

| A | 237 | 44.1 | NaOH | <1 | <4 |

| B | 305 | 45.8 | NaOH | <1 | <4 |

| C | 403 | 47.02 | NaOH | <1 | <4 |

| D | 520 | 46.6 | NaOH | 1.88 | 0.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lang, Q.; Biziks, V.; Militz, H. Influence of Phenol–Formaldehyde Resin Oligomer Molecular Weight on the Strength Properties of Beech Wood. Forests 2022, 13, 1980. https://doi.org/10.3390/f13121980

Lang Q, Biziks V, Militz H. Influence of Phenol–Formaldehyde Resin Oligomer Molecular Weight on the Strength Properties of Beech Wood. Forests. 2022; 13(12):1980. https://doi.org/10.3390/f13121980

Chicago/Turabian StyleLang, Qian, Vladimirs Biziks, and Holger Militz. 2022. "Influence of Phenol–Formaldehyde Resin Oligomer Molecular Weight on the Strength Properties of Beech Wood" Forests 13, no. 12: 1980. https://doi.org/10.3390/f13121980

APA StyleLang, Q., Biziks, V., & Militz, H. (2022). Influence of Phenol–Formaldehyde Resin Oligomer Molecular Weight on the Strength Properties of Beech Wood. Forests, 13(12), 1980. https://doi.org/10.3390/f13121980