Abstract

Wood–plastic composites (WPCs) increase the range of applications of materials by creating new material solutions. As part of this research, PLA (polylactic acid)- and HDPE (high-density polyethylene)-based composites were manufactured. Softwood sawdust or conifer bark with different sizes (large and small) were used as filler. In selected cases, the addition of 3% additives, such as calcium oxide in the case of PLA or polyethylene-graft-maleic anhydride in the case of HDPE, were tested. The manufactured composites were examined for their density profile and their susceptibility to drilling, defined by the value of the axial force occurring during drilling. The obtained results revealed that the type of matrix had the greatest influence on the axial forces during drilling. Regardless of the composite formulation, composites based on PLA had 25% to 56% higher axial forces during drilling than those based on HDPE. Furthermore, increasing the proportion of lignocellulosic fillers resulted in a decrease in the value of axial forces during drilling, with PLA composites experiencing a greater decrease than HDPE composites. The type and size of the filler had a minor impact on the axial force values during drilling. The statistical analysis indicated that the additives had a greater influence on HDPE than on PLA.

1. Introduction

Owing to their properties, wood–plastic composites (WPCs) are widely used in a variety of industries. A significant portion of WPCs is made from polymers derived from fossil fuels. For example, polyethylene (PE) is used for decking, construction, and consumer goods; polypropene (PP) for automotive parts, construction, and consumer goods; and polyvinyl chloride (PVC) for decking and construction [1].

Biodegradable thermoplastics, such as poly (lactic acid) (PLA) [2,3], are gaining industry attention as an alternative to WPC production. PLA is easily compostable and has no negative effects on the natural environment [4]. The composite materials within PLA are also ecological due to the fact that the filling material is made of wood fibers. Furthermore, apart from solid wood, WPC fillers can be made of shredded postconsumer wood materials [5,6,7], recycled fibers [8,9], bark [3], bamboo fibers [10], or particles of annual plants [2].

WPCs are typically manufactured using extrusion or injection methods [2,11], resulting in the production of generally finished products that do not require any additional mechanical processing. However, as these materials become more widely used in a variety of products, the demand for machining grows. Drilling mounting holes, profile milling over an existing component edge, or surface grinding to smooth it are examples of such processes.

Little is known about the machinability properties of WPCs in terms of tool wear, cutting resistance, and machining quality. In general, WPC processing can be accomplished with standard tools and woodworking machines. Buehlmann et al. [12] emphasized, however, that increased pigment content in colored composites may result in faster tool wear. While investigating the parameters of the machining process of WPCs in the form of chipboards bonded with thermoplastics, Zbieć et al. [13,14] discovered that cutting parameters are comparable to those of chipboards of similar-density glued with UF resin.

At the same time, unlike chipboards glued with UF resin, thermoplastics in chip-polymer composites reduce tool wear. Wilkowski et al. [15] and Borysiuk et al. [16] both confirmed the good machinability of WPCs in the form of chipboards bonded with thermoplastic compared with traditional wood materials. Wilkowski et al. [15] investigated axial force and cutting torque while drilling three WPC variants (polyethylene (PE), polypropylene (PP), and polystyrene (PS)). The authors discovered a significant reduction in forces for all WPC variants compared with standard three-layer chipboards. The composites bonded with polyethylene had the greatest reduction in forces among the tested composites (PE). Furthermore, as forces decreased, the proportion of thermoplastic increased (30%, 50%, and 70%).

A study by Zajac et al. [17] on the quality assessment of turning machining based on a WPC’s surface roughness parameters did not confirm the theoretical and practical regularity of machining quality reduction with increased feed speed [18]. This perplexing result was explained by the random distribution of the composite’s individual component particles on the cross-section of the workpiece. Bajpai et al. [19] studied the drillability of laminates based on PLA and natural fiber (sisal and Grewia optiva fiber). The authors concluded that there was a significant impact on the quality and efficiency of machining drill types and cutting parameters. At the same time, the research did not indicate any influence of the type of natural fiber on the cutting forces.

To the best of our knowledge, research on the drilling characterization of PLA composites is still scarce and is thus worth investigating. Drilling is one of the most basic processes in processing wood-based materials that are intended for use in the furniture industry. We considered it necessary to study the susceptibility of drilling of WPCs with polylactic acid (PLA) and high-density polyethene (HDPE), as their use in the industry is constantly increasing. Based on the available literature, the hypothesis that the drilling process will be affected by the composition of WPCs was formed.

2. Materials and Methods

The polymer matrices used in the tested WPC panels were polylactic acid (PLA; Ingeo TM Biopolymer 2003D, NatureWorks LLC, Minnetonka, MN, USA) and high-density (HDPE; Hostalen GD 7255, Basell Orlen Polyolefins Sp. Zoo, Pock, Poland). Two types of lignocellulosic material were used as fillers: coniferous sawdust and bark. Calcium oxide (CaO; Avantor Performance Materials Poland SA, Gliwice, Poland) was applied in PLA composites and polyethylene-graft-maleic anhydride (MAHPE; SCONA TSPE 2102 GAHD, BYK-Chemie GmbH, Wesel, Germany) in HDPE. Table 1 and Table 2 describe all 36 variants.

Table 1.

PLA-based composites characteristics.

Table 2.

HDPE-based composites characteristics.

The sawmill lignocellulosic material was dried to 5% humidity before being mechanically comminuted and sorted into two size variants: >35 and 10–35 mesh.

The composites manufacture consisted of two stages:

- (1)

- (2)

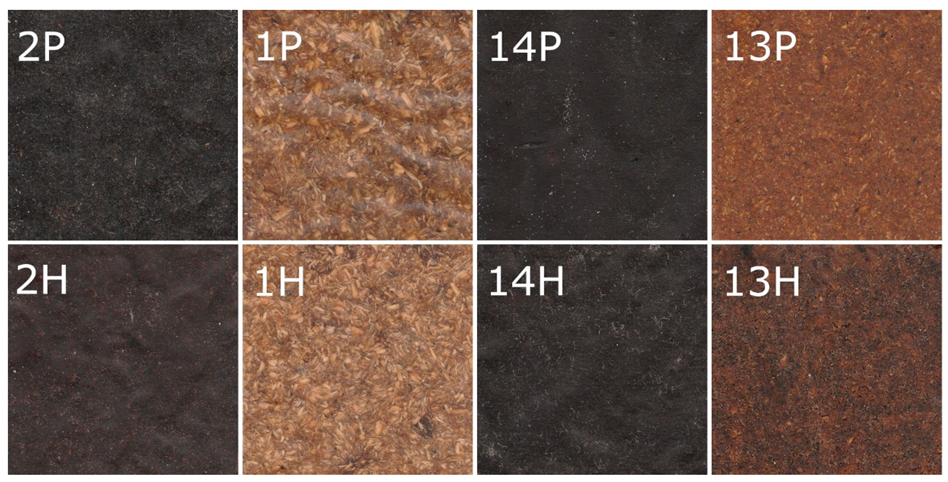

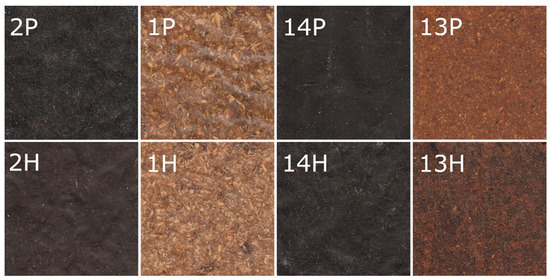

- Manufacture of boards from the granules obtained, with nominal dimensions of 300 × 300 × 2.5 mm in the process of flat pressing in a mold. For this purpose, a one-shelf press (AB AK Eriksson, Mariannelund, Sweden) was used. The settings of the process were as follows: 200 °C, a maximum unit pressing pressure pmax = 1.25 MPa, and pressing time 6 min. After hot pressing, the boards were cooled in the mold for 6 min in a cold press. Figure 1 shows examples of the manufactured panels. The boards were conditioned for 7 days under standard conditions (20 ± 2 °C; 65% ± 5% humidity).

Figure 1. Examples of PLA- and HDPE-based composites.

Figure 1. Examples of PLA- and HDPE-based composites.

The density according to EN 323: 1999 (EN 323, 1999) and density profile were determined for manufactured boards using a Laboratory Density Analyzer DAX GreCon (Fagus-Grecon Greten GmbH & Co. KG, Alfeld, Germany). A density measurement was recorded every 0.02 mm at a measurement speed of 0.05 mm/s.

Machinability tests were carried out on a CNC Busellato Jet 130 (Casadei-Busellato, Thiene, Italy) machining center. For through drilling (through the entire thickness of the board), a new 8 mm diameter polycrystalline diamond DPI single-point drill (Leitz) was used. The following cutting parameters were used: rotational speed of 6000 rpm, feed speed of 1.2 m/min, and 0.2 mm feed per revolution. During the test, through holes were drilled (through the entire thickness of 3 boards, in the package) in the center of the boards with dimensions of 50 × 50 mm. During drilling, the signals of the axial force Fz were recorded using a Kistler 9345A piezoelectric force sensor with a sampling frequency of 12 kHz. For each variant of the plate, 6 cuts were made. The effective value (RMS) of the axial force signals was analyzed.

Statistical Analysis

The results were statistically processed using Statistica 13.3 (TIBCO Software Inc., Palo Alto, CA, USA). The analysis of variance (MANOVA) was used for determining the significant differences (α = 0.05) between factors, and Tukey’s test was used for finding homogeneous groups at a significance level of 0.05.

3. Results and Discussion

The PLA boards had densities ranging from 1061 to 1232 kg/m3, while the HDPE boards had densities ranging from 1002 to 1105 kg/m3. Table 3 and Table 4 show the values of the mean densities for individual variants. Individual variant density diversity within the same matrices did not exceed 17% for PLA and 11% for HDPE. There was a slight influence from the size of the filler particles, the type of filler, or the addition of additives in this regard. It should be noted, however, that PLA boards with the same filler share and type, as well as filler particle size, were 1 to 18% denser, depending on the variant.

Table 3.

The mean density values for individual variants of panels without additives.

Table 4.

The mean density values for individual variants of panels with additives.

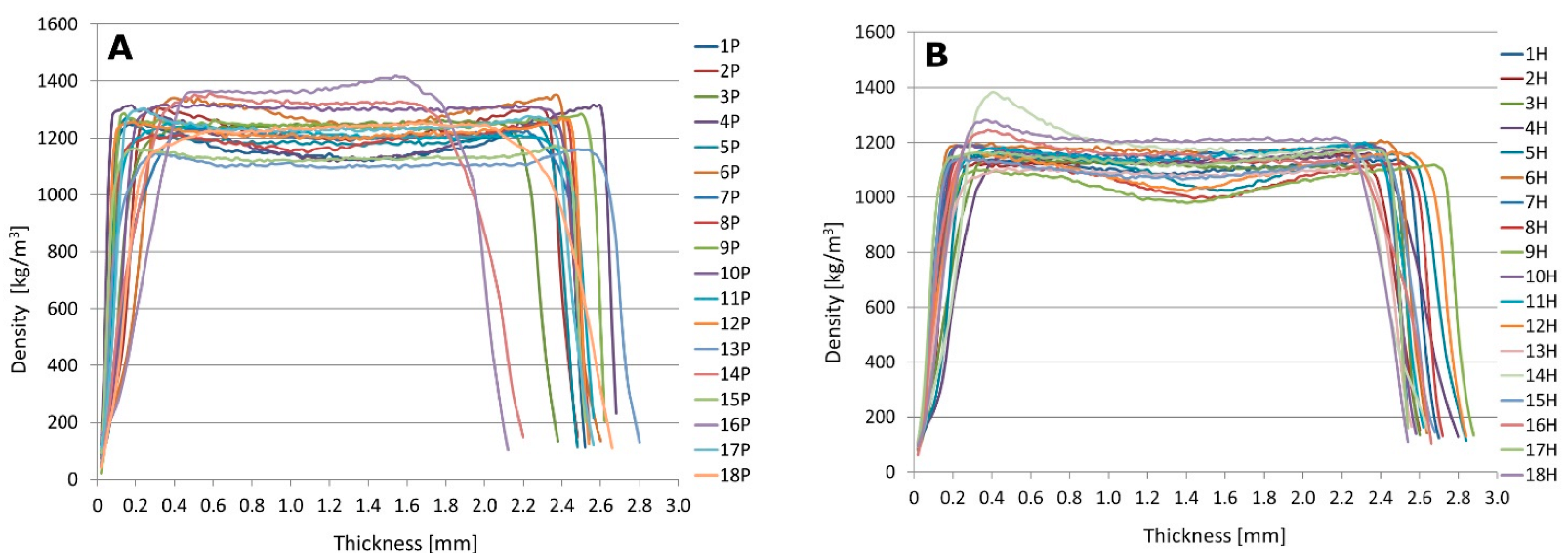

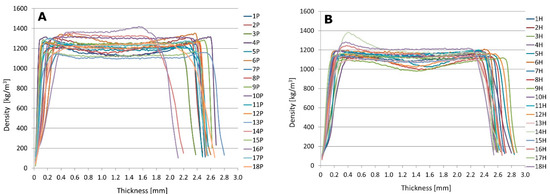

This is because the PLA matrix has a higher density than the HDPE matrix. Andrzejewski et al. [20] discovered similar relationships while researching WPCs based on PLA and PP. The density distribution on the cross-section of all variants of the tested boards was generally uniform (Figure 2). The density differentiation in the thickness of the individual boards did not exceed 100 kg/m3 (only in some variants did it reach 200 kg/m3), demonstrating good homogenization of the composite components and uniform distribution of the filler particles in the polymer matrix. Borysiuk et al. [21] discovered that increasing the filler content in HDPE boards filled with sawdust reduces density in the central zone of the board.

Figure 2.

Density profiles of PLA-based composites (A) and HDPE-based composites (B).

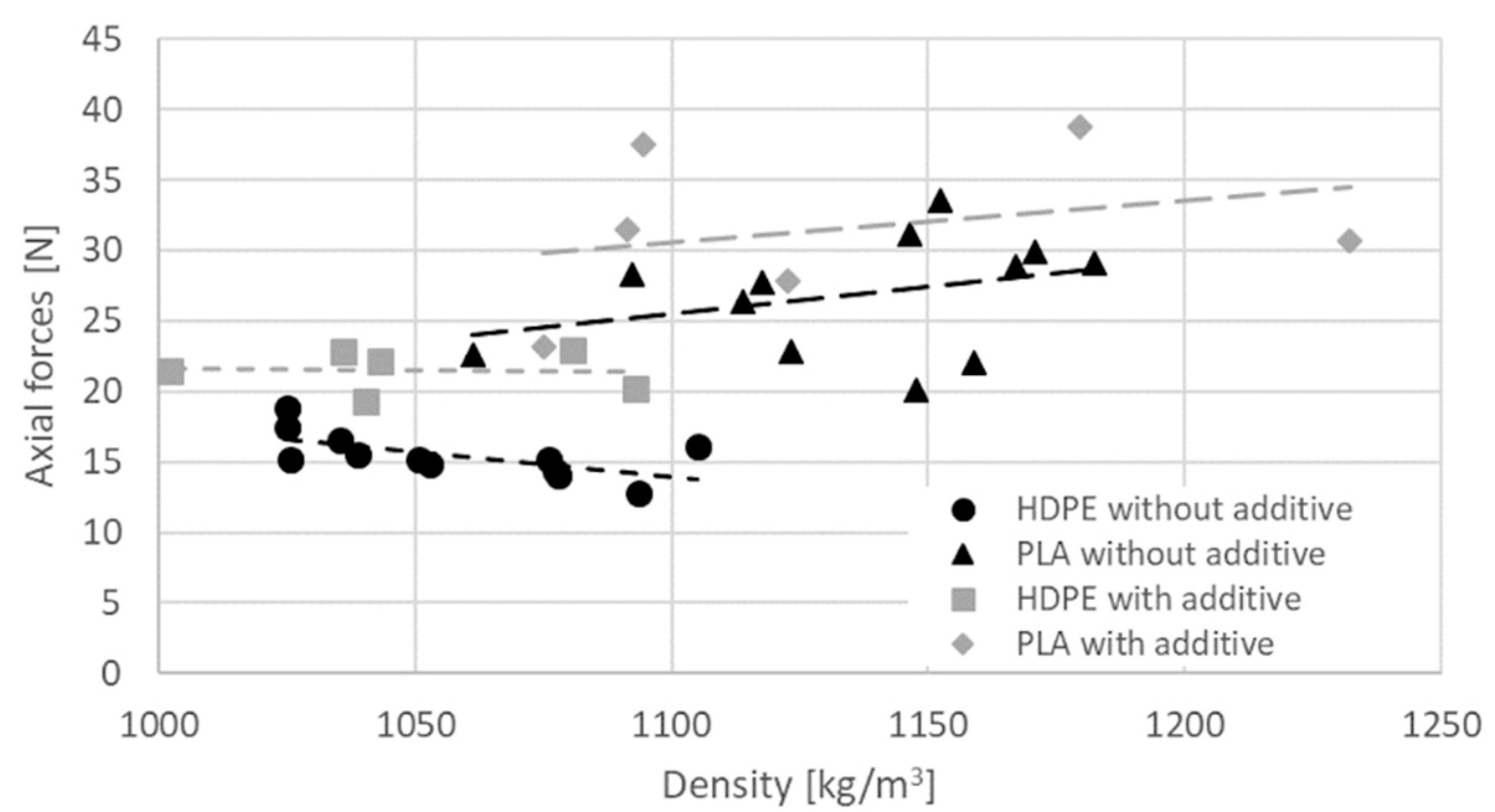

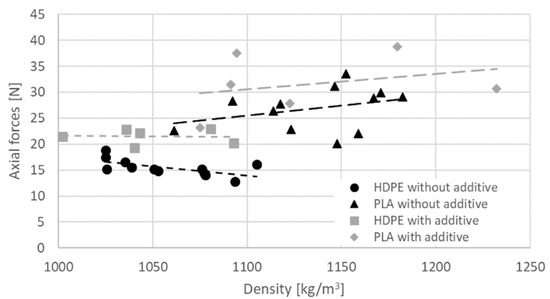

The authors also concluded that the size of the filler particles had a slight influence on density or density profile. This was also confirmed in our research. Density variation may have an impact on board processing. According to Kowaluk [22], the majority of machining parameters (cutting force, feed force, and noise) decreases as the processed material density decreases. The recorded density changes in the tested WPCs had no significant effect on the values of axial forces during drilling (Figure 3).

Figure 3.

Relationship between axial forces during drilling and the density of WPCs.

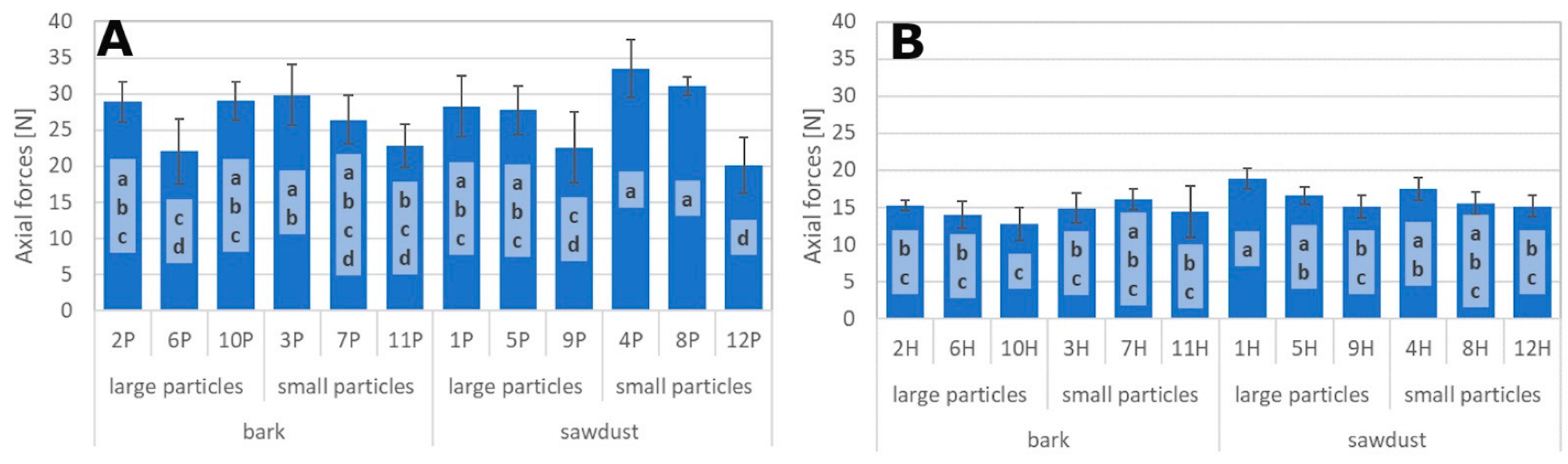

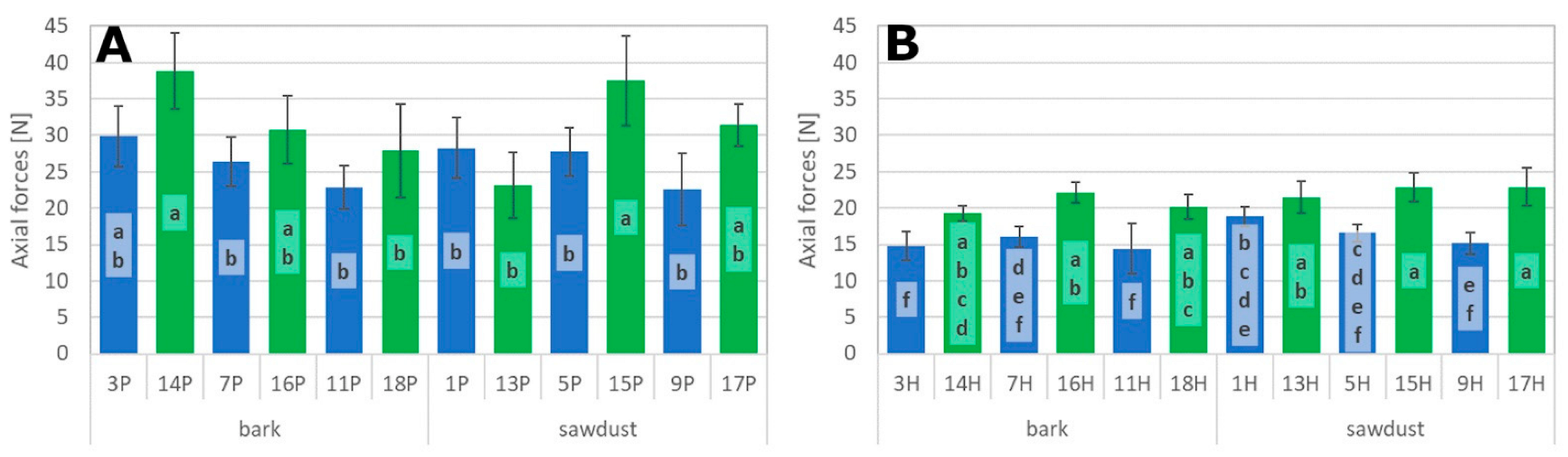

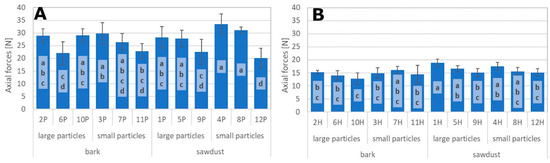

Figure 4 shows the axial force values obtained while drilling individual composite variants. Regardless of variant content, composites made from PLA had from 25% to 56% higher values of axial forces during drilling. The observed differences were significant in each of the cases. PLA stiffness is associated with higher axial drilling forces for PLA-based composites compared with HDPE-based composites. PLA has a modulus of elasticity that is 2.5 to 5 times greater than that of HDPE [23,24].

Figure 4.

Values of axial forces during drilling of PLA-based composites (A) and HDPE-based composites (B) (a, b, c, d—homogeneous groups by Tukey’s test).

It should also be noted that the type of matrix, compared with factors such as the type, proportion, and size of the filler, had a significant (67.05%) effect on the value of the axial force (Table 5). Wilkowski et al. [15] also noted the effect of matrix type (PE, PP, and PS) on cutting forces when drilling WPCs. The authors found that composites made of polyethylene baize had the lowest cutting forces. In our study, both PLA and HDPE composites had lower axial forces during drilling compared with the data available in the literature [25].

Table 5.

Analysis of variance for selected factors and interactions between the factors influencing the axial force during drilling.

When the type, share, and size of the filler were considered, only the size of the filler particles had a significant effect on the values of axial forces during drilling (Table 5). This is because uncontrolled mechanical division of larger filler particles into smaller elements and partial destruction of the cell wall structure may occur during the extrusion process [26,27,28,29]. The moisture content of the wood as well as the geometry and operating parameters of the extruder screw all play a role in this division. Furthermore, during extrusion, the lignocellulosic filler particles compacted to approximately 1300 kg/m3 density [11].

Increased lignocellulosic filler content resulted in a decrease in the value of axial forces during drilling (the percentage effect was 6.62%), with a greater decrease observed in composites based on PLA. The percentage effect of filler type (0.88%) was relatively small compared with that of other factors significantly affecting the values of axial forces (type of matrix, filler share). It is also worth noting that the percentage effects of interactions between the studied factors on axial forces were relatively small, ranging from 0.60% to 2.33% in cases where they were significant (Table 5). Furthermore, the type, proportion, and size of the filler, as well as the interactions between the factors studied, had a smaller influence on the axial forces than the influence of factors not studied (error = 14.34%).

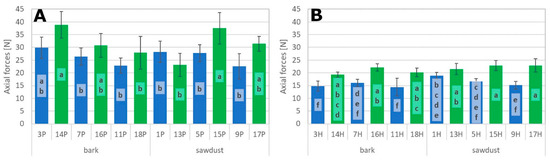

The addition of additives to the composites (CaO for PLA and MAHPE for HDPE) increased the value of axial forces during drilling in general (Figure 5). The percentage effect of CaO addition in PLA-based composites was 16.64% (Table 6), and, in most cases, this effect was insignificant (Figure 5A). This is because CaO is both a humectant and a biocide [30]. In the case of PLA-based composites, factors not included in the current study had a much greater percentage impact than the additive used (error = 70.84%).

Figure 5.

Values of axial forces during drilling: (A) PLA-based composites with (green) and without (blue) addition of CaO; (B) HDPE-based composites with (green) and without (blue) addition of MAHPE (a, b, c, d, e, f—homogeneous groups by Tukey’s test).

Table 6.

Analysis of variance for selected factors and interactions between the factors influencing the axial force during drilling PLA-based composite with addition of CaO.

In the case of HDPE-based composites, the percentage effect of MAHPE addition on the increase in the value of axial forces during drilling was 59.36% (Table 7). This effect was significant in the majority of cases (Figure 5B). This is because the addition of coupling agents (such as MAHPE) improves the mechanical properties of the WPCs produced by better bonding the matrix and filler particles [26,31,32,33,34,35,36,37]. This results in increased material resistance during the drilling process. The addition of MAHPE had a much larger percentage effect (59.36%) on the increase in the value of axial forces during drilling than the nonstudied factors (error = 34.67%) (Table 7).

Table 7.

Analysis of variance for selected factors and interactions between the factors influencing the axial force during drilling HDPE-based composite with addition of MAHPE.

4. Conclusions

Drilling is one of the machining methods available for WPCs. The following conclusions could be drawn from the drilling of PLA and HDPE composites:

- The type of matrix had the greatest impact on the axial force values during drilling. Regardless of the composite formulation, composites based on PLA had higher axial forces than composites based on HDPE.

- The increase in the share of lignocellulosic fillers generally influenced the decrease in the value of axial forces during drilling, with PLA-based composites showing a more significant decrease than HDPE-based composites.

- The type and size of the filler had a minor impact on the axial force values during drilling.

- The increase in axial forces in the case of PLA was due to factors other than the presence of additives. In the case of HDPE, additives had a greater contribution to increasing the values of axial forces than other nonstudied factors.

Author Contributions

Conceptualization, P.B. and R.A.; methodology, P.B., R.A. and J.W.; validation, P.B., R.A. and J.W.; formal analysis, R.A., A.A. and J.W.; investigation, J.W. and A.T.; data curation, P.B. and R.A.; writing—original draft preparation, P.B., R.A. and A.T.; writing—review and editing, A.A., J.W. and L.S.H.; visualization, R.A. and A.A.; supervision, P.B., R.A. and L.S.H.; project administration, P.B. All authors have read and agreed to the published version of the manuscript.

Funding

The presented research was financed under the “Strategic research and development program: environment, agriculture, and forestry” (BIOSTRATEG, grant no. BIOSTRATEG3/344303/14/NCBR/2018). The funding institution was The National Centre for Research and Development, Poland.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Partanen, A.; Carus, M. Biocomposites, Find the Real Alternative to Plastic—An Examination of Biocomposites in the Market. Reinf. Plast. 2019, 63, 317–321. [Google Scholar] [CrossRef]

- Kuciel, S.; Liber-Kneć, A.; Mikuła, J.; Kuźniar, P.; Korniejenko, K.; Żmudka, S.; Łagan, S.; Ryszkowska, J.; Gajewski, J.; Sałasiński, K.; et al. Kompozyty Polimerowe Na Osnowie Recyklatów z Włóknami Naturalnymi: Praca Zbiorowa; Kuciel, S., Ed.; Politechnika Krakowska: Kraków, Poland, 2010; ISBN 9788372425607. [Google Scholar]

- Borysiuk, P.; Boruszewski, P.; Auriga, R.; Danecki, L.; Auriga, A.; Rybak, K.; Nowacka, M. Influence of a Bark-Filler on the Properties of PLA Biocomposites. J. Mater. Sci. 2021, 56, 9196–9208. [Google Scholar] [CrossRef]

- Markarian, J. Biopolymers Present New Market Opportunities for Additives in Packaging. Plast. Addit. Compd. 2008, 10, 22–25. [Google Scholar] [CrossRef]

- Gozdecki, C.; Kociszewski, M.; Zajchowski, S.; Patuszyński, K. Wood-Based Panels as Filler of Wood-Plastic Composites. Ann. Warsaw Agric. Univ. For. Wood Technol. 2005, 56, 255–258. [Google Scholar]

- Chaharmahali, M.; Tajvidi, M.; Najafi, S.K. Mechanical Properties of Wood Plastic Composite Panels Made from Waste Fiberboard and Particleboard. Polym. Compos. 2008, 29, 606–610. [Google Scholar] [CrossRef]

- Gozdecki, C.; Kociszewski, M.; Wilczyński, A.; Zajchowski, S. The Possibility of Using Wood Dust for Manufacturing Wood-Plastic Composites. In Proceedings of the XX International Symposium: “Adhesives in Woodworking Industry”, Zvolen, Slovakia, 29 June–1 July 2011; pp. 86–91. [Google Scholar]

- Myers, G.E.; Clemons, C.M. Wastepaper Fiber in Plastic Composites Made by Melt Blending: Demonstration of Commercial Feasibility; Final Report for Solid Waste Reduction and Recycling Demonstration Grant Program Project No 91-5; Wisconsin Department of Natural Resources, Forest Products Laboratory: Madison, WI, USA, 1993. [Google Scholar]

- Ashori, A.; Nourbakhsh, A. Characteristics of Wood-Fiber Plastic Composites Made of Recycled Materials. Waste Manag. 2009, 29, 1291–1295. [Google Scholar] [CrossRef]

- Nurul Fazita, M.R.; Jayaraman, K.; Bhattacharyya, D.; Mohamad Haafiz, M.K.; Saurabh, C.K.; Hazwan Hussin, M.; Abdul Khalil, H.P.S. Green Composites Made of Bamboo Fabric and Poly (Lactic) Acid for Packaging Applications—A Review. Materials 2016, 9, 435. [Google Scholar] [CrossRef]

- Klysov, A.A. Wood-Plastic Composites; Wiley-Interscience: Hoboken, NJ, USA, 2007; ISBN 978-0-470-14891-4. [Google Scholar]

- Buehlmann, U.; Saloni, D.; Lemaster, R.L. Wood Fiber-Plastic Composites: Machining and Surface Quality. In Proceedings of the 15th International Wood Machining Seminar, Anaheim, CA, USA, 30 July–1 August 2001; pp. 1–13. [Google Scholar]

- Zbieć, M.; Borysiuk, P.; Mazurek, A. Polyethylene Bonded Composite Chipboard. In Proceedings of the 7th International Science Conference: “Chip and Chipless Woodworking Processes”, Terchová, Slovakia, 9–11 September 2010; pp. 237–242. [Google Scholar]

- Zbiec, M.; Borysiuk, P.; Mazurek, A. Thermoplastic Bonded Composite Chipboard Part 2—Machining Tests. In Proceedings of the Proceedings of the 8th International Science Conference: “Chip and Chipless Woodworking Processes”, Zvolen, Slovakia, 6–8 September 2012; pp. 399–405. [Google Scholar]

- Wilkowski, J.; Borysiuk, P.; Górski, J.; Czarniak, P. Analiza Wzgle{ogonek}dnych Wskaźników Skrawalności Płyt Wiórowych Spajanych Termoplastami Poużytkowymi. Drewno 2013, 190, 139–144. [Google Scholar] [CrossRef]

- Borysiuk, P.; Wikowski, J.; Krajewski, K.; Auriga, R.; Skomorucha, A.; Auriga, A. Selected Properties of Flat-Pressed Wood-Polymer Composites for High Humidity Conditions. BioResources 2020, 15, 5141–5155. [Google Scholar] [CrossRef]

- Zajac, J.; Mitaľ, D.; Radchenko, S.; Kokuľa, P.; Olexa, Ľ.; Čep, R. Short-Term Testing of Cutting Materials Using the Method of Interrupted Cut. Appl. Mech. Mater. 2014, 616, 236–243. [Google Scholar]

- Somsakova, Z.; Zajac, J.; Michalik, P.; Kasina, M. Machining of Wood Plastic Composite (Pilot Experiment). Mater. Plast. 2012, 49, 55–57. [Google Scholar]

- Bajpai, P.K.; Debnath, K.; Singh, I. Hole Making in Natural Fiber-Reinforced Polylactic Acid Laminates: An Experimental Investigation. J. Thermoplast. Compos. Mater. 2017, 30, 30–46. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M.; Barczewski, M.; Łuczak, P. Cork-Wood Hybrid Filler System for Polypropylene and Poly(Lactic Acid) Based Injection Molded Composites. Structure Evaluation and Mechanical Performance. Compos. Part B Eng. 2019, 163, 655–668. [Google Scholar] [CrossRef]

- Borysiuk, P.; Auriga, R.; Kośka, P. Influence of the Filler on the Density Profile of Wood Polymer Composites. Ann. WULS, For. Wood Technol. 2019, 106, 31–37. [Google Scholar] [CrossRef]

- Kowaluk, G. Machining Processes for Wood-Based Composite Materials. In Machining Technology for Composite Materials; Elsevier: Amsterdam, The Netherlands, 2012; pp. 412–425. ISBN 9780857090300. [Google Scholar]

- Osswald, T.A.; Baur, E.; Brinkmann, S.; Oberbach, K.; Schmachtenbe, E. International Plastics Handbook; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2006; ISBN 9781569903995. [Google Scholar]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Auriga, R.; Borysiuk, P.; Waracka, A.; Auriga, A. Susceptibility of Drilling Particleboard with Share of Hemp Shives. Biul. Inf. OB-RPPD 2021, 3–4. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Letman, M.; Viksne, A.; Rence, L. A Comparison of Compounding Processes and Wood Type for Wood Fibre—PP Composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 789–797. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Perre, P.; Cloutier, A. Effects of Composite Processing Methods on Wood Particle Development and Length Distribution: Consequences on Mechanical Properties of Wood-Thermoplastic Composites. Wood Fiber Sci. 2010, 42, 62–70. [Google Scholar]

- Gacitua, W.; Bahr, D.; Wolcott, M. Damage of the Cell Wall during Extrusion and Injection Molding of Wood Plastic Composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1454–1460. [Google Scholar] [CrossRef]

- Hietala, M.; Niinimäki, J.; Oksman, K. Processing of Wood Chip-Plastic Composites: Effect on Wood Particle Size, Microstructure and Mechanical Properties. Plast. Rubber Compos. 2011, 40, 49–56. [Google Scholar] [CrossRef]

- Commission Delegated Regulation (EU) No 1062/2014. Off. J. Eur. Union 2014, 294, 20–30.

- Li, T.Q.; Li, R.K.Y. A Fracture Mechanics Study of Polypropylene-Wood Flours Blends. Polym. Plast. Technol. Eng. 2001, 40, 1–21. [Google Scholar] [CrossRef]

- Balasuriya, P.W.; Ye, L.; Mai, Y.W. Morphology and Mechanical Properties of Reconstituted Wood Board Waste-Polyethylene Composites. Compos. Interfaces 2003, 10, 319–341. [Google Scholar] [CrossRef]

- Kuan, H.C.; Huang, J.M.; Ma, C.C.M.; Wang, F.Y. Processability, Morphology and Mechanical Properties of Wood Flour Reinforced High Density Polyethylene Composites. Plast. Rubber Compos. 2003, 32, 122–126. [Google Scholar] [CrossRef]

- Lee, S.Y.; Yang, H.S.; Kim, H.J.; Jeong, C.S.; Lim, B.S.; Lee, J.N. Creep Behavior and Manufacturing Parameters of Wood Flour Filled Polypropylene Composites. Compos. Struct. 2004, 65, 459–469. [Google Scholar] [CrossRef]

- Cai, X.; Riedl, B.; Bouaziz, M. Lignocellulosic Composites with Grafted Polystyrene Interfaces. Compos. Interfaces 2005, 12, 25–39. [Google Scholar] [CrossRef]

- Cui, Y.; Lee, S.; Noruziaan, B.; Cheung, M.; Tao, J. Fabrication and Interfacial Modification of Wood/Recycled Plastic Composite Materials. Compos. Part A Appl. Sci. Manuf. 2008, 39, 655–661. [Google Scholar] [CrossRef]

- San, H.P.; Nee, L.A.; Meng, H.C. Physical and Bending Properties of Injection Moulded Wood Plastic Composites Boards. ARPN J. Eng. Appl. Sci. 2008, 3, 13–19. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).