Abstract

Invasive plants spread in such a way that they are threats to native species and to biodiversity. In this context, this work aims to determine possible valorizations of Scotch Broom Cytisus scoparius (L.) Link. This species harvested in the Viseu region was used in the present study. The eco-valorization of these renewable resources was made by conversion into liquid mixtures that can later be used in the manufacture of valuable products. For a better understanding of the results obtained, a chemical characterization of the Cytisus scoparius branches (CsB) was made. The ash content, extractives in dichloromethane, ethanol and water, lignin, cellulose and hemicellulose of the initial material were determined. Liquefaction was made in a reactor with different granulometry, temperatures and time. Results show that Broom is mainly composed of cellulose (36.1%), hemicelluloses (18.6%) and lignin (14.6%) with extractives mainly soluble in ethanol, followed by water and a small amount in dichloromethane. Ashes were around 0.69%, mainly composed of potassium and calcium. Generally, smaller size, higher solvent ratio, higher temperature and higher time of liquefaction lead to higher liquefaction. The highest percentage of liquefaction was 95% which is better than most of the lignocellulosic materials tested before.

1. Introduction

Many plants that surround us have not always existed in our territory; they came from other places brought by man from their native habitat. Certain species remain only in places where they have been embedded with native species in a stable way, but others prosper rapidly without the support of man, expanding their populations. These are called invasive plants. The proliferation of these species promotes environmental changes and economic damage so that they can be a threat to natural ecosystems, food production, human health and the economy itself [1]. Therefore, Broom, also called Scotch broom or English broom (Cytisus scoparius (L.) Link), is an example of an invasive plant.

In Portugal, communities are dominated by shrubs of the genera Cytisus, Genista, Adenocarpus and Retama. In accordance with Costa et al. [2], the area of occupation of the class Cytisetea scopario-striati has increased in recent decades, mainly due to the abandonment of agricultural land. Its development in the Iberian Peninsula resulted in fragmented landscapes, determining spatial patterns of richness, composition and specific abundance or the periods of regression of climatic forests [2]. The class Cytisetea scopario-striati develops well on siliceous, poor on bases, non-hydomorphic soils and presents its greatest evolution and diversity in the west of the Iberian Peninsula in the Atlantic and Ibero-Atlantic Mediterranean provinces [2]. According to the national forest inventory, forests represent 40% of Portugal’s mainland, which is equivalent to almost 3.5 million hectares, 1 million more hectares than agriculture. The forests with the highest territorial expression are eucalypts (Eucalyptus globulus Labill) (26%), cork oak (Quercus suber L.) (23%) and pine (Pinus pinaster Ait.) (22%), and the invasive species represent 0.4% [3,4].

Cytisus scoparius can be found in almost all of Europe and Macaronesia. It was introduced in North America, Australia and South Africa. It is common in bushes, scrubs and riparian and the edge of woods and paths. It is used as a medicinal plant, in agroforestry management, as fuel and in the manufacture of outdoor brooms [5]. Cytisus scoparius is a shrub 1 to 2 m high. The stem is green, angled, striated longitudinally and hard, with consistent and flexible branches, usually with five well-defined streaks in an inverted V-shape. The space between the stretch marks is greater than their width. This plant is known to have several antioxidant compounds such as flavones, isoflavones, flavonols and carotenoids [6,7,8].

The emergence of liquefaction techniques at low pressure and temperatures has increased the interest in invasive plants that can be a cheap lignocellulosic alternative to other more valuable materials and constitute an alternative for petroleum-derived fuels. This alternative also has the advantage of contributing to the reduction of greenhouse gas emissions, thus preventing global warming [9]. Liquefaction of moderate to low temperatures has been done using two different types of solvents, phenol [10,11,12,13] or polyalcohols [14,15,16,17,18], with basic (NaOH, KOH) or acid catalysis (sulphuric acid, paratuluenosulphonic acid, hydrochloric acid, oxalic acid or phosphoric acid). Phenol is mostly used when the objective is to prepare resins such as epoxy resins since there is a higher content of phenols in the liquefied material [19]. On the other hand, phenol is more toxic than the polyalcohols used and less green since most of the polyalcohols can be obtained from crude glycerol or other non-petroleum materials. Several lignocellulosic materials have been liquefied with polyalcohols such as agricultural wastes, for example, wheat straw [20], cornstarch [21] or rice straw, oilseed rape straw and corn stover [22], forest management residues, such as several woods [15,23,24], barks [16,25,26] or shells [14,27,28] and also some industrial residues such as orange peel [29]. The lignocellulosic material is composed of carbohydrate polymers (cellulose and hemicelluloses), lignin and a small part of other compounds (extractives, salts and minerals). Cellulose and hemicelluloses, which usually account for two-thirds of the dry mass, are polysaccharides that can be hydrolyzed into sugars and, eventually, by fermentation, converted into ethanol. Lignin cannot be used for ethanol production, so that it can be used for thermal energy production by combustion [9]. To improve the knowledge and evaluation of possible applications, the chemical composition of Broom, Cytisus scoparius, was determined.

This study intends to determine if Cytisus scoparius is a suitable material to produce high quality polyols to be later used for the production of polyurethane foams or adhesives. The knowledge of the chemical composition of the material and the FTIR analysis of initial, liquefied material and solid residue will allow us to understand the chemical changes involved and give some clues on how to improve the liquefaction procedure.

2. Materials and Methods

2.1. Materials

The branches of Cytisus scoparius (CsB) come from the district of Viseu (São Pedro do Sul). The samples were dried at room temperature, crushed in a Retsh SKI mill (Retsch GmbH, Haan, Germany) and sieved using a Retsch AS200 for 30 min at 50 rpm. Five fractions, >35 mesh (>0.425 mm); 35–40 mesh (0.425–0.450 mm); 40–60 mesh (0.425–0.250 mm); 60–80 mesh (0.250–0.180 mm) and <80 mesh (<0.180 mm) fraction was used for the tests. The fractions obtained were dried in a greenhouse at 100 °C for 24 h before each test. The chemical reagents used were analytical-grade reagents.

2.2. Chemical Composition

The CsB were characterized for their ash content, extractives (in dichloromethane, ethanol and hot water), α-cellulose, lignin and hemicelluloses. The 40–60 mesh fraction was dried at 105 °C for at least 24 h and afterward used for the chemical analyses according to Tappi T 264 om-97 [30]. The average chemical composition of each sample was determined in triplicate. The extractives were determined by extraction with different solvents in sequential order of ascending polarity.

The ash content was determined by calcination at 525 °C in accordance to Tappi T 211 om-93 [31]. The inorganic composition was determined by ICP after ash wet digestion in a Leco CHNS-932 Elemental Analyzer (St. Joseph, MI, USA).

Extractives were determined by sequential Soxhlet extraction with 150 mL of dichloromethane, ethanol and hot water extractives in accordance with Tappi T 204 om-88 [32]. A total of 10 g of dried material was placed in a filter paper cartridge inside the Soxhlet and refluxed until extractives were removed. Extractions lasted for 6 h for dichloromethane and 16 h for both ethanol and water. Extractive content was determined in relation to the dry material.

Alkaline extraction was done by reflux with 0.3% (m/v) NaOH under a nitrogen atmosphere.

Lignin was determined by the Klason method in extractive free material. Two hydrolyses were performed, the first in a water bath at 30 °C with 72% H2SO4 for 1 h followed by a second with 3% H2SO4 in an autoclave at 120 °C for 1 h (according to modified Tappi T 204 om-88) [33]. The insoluble residue was filtered in a G2 glass crucible, washed with warm water and acetone, and dried at 100 °C until constant weight. The lignin percentage was determined according to Equation (1).

Soluble lignin was determined by measuring the absorbance at 205 nm.

Cellulose Kürschner–Hoffer was determined by using 1 g of material that was refluxed with 100 mL of nitric acid: ethanol 20:80 solution for 1 h. This procedure was repeated again, and the final insoluble material was filtered using a G2 crucible and by washing with ethanol and hot water.

Hemicelluloses were determined by difference.

2.3. Liquefaction

In order to study the optimal conditions of liquefaction for the branches of Cytisus scoparius shrubs (CsB), different liquefaction reaction times, temperature and size of the samples were tested.

The liquefaction process was conducted in a double shirt reactor (600 mL) heated with oil (Reactor Parr LKT PED). The samples were introduced in the reactor with a mixture of glycerol and ethylene glycol 1:1, catalyzed with sulfuric acid (3%). Liquefied samples were dissolved in methanol and filtered in a G3 crucible.

The liquefaction yield was determined by the insoluble material retained in the crucible according to Equation (2).

The effect of particle size was studied for five fractions, >35 mesh (>0.425 mm); 35–40 mesh (0.425–0.450 mm); 40–60 mesh (0.425–0.250 mm); 60–80 mesh (0.250–0.180 mm) and 80 mesh (<0.180 mm). The temperature ranged between 140 °C and 180 °C and liquefaction time from 15 to 60 min. Studies were made using different ratios of CsB:solvent, 1:5, 1:10 and 1:12.

3. Results and Discussion

3.1. Chemical Composition

Table 1 presents the chemical composition of CsB, where it can be observed that it is composed of 0.69% ashes, similar to the 0.78% obtained by González et al. with Broom from Ourense (north-west Spain) [34]. Ashes are essentially composed by potassium (0.694%) and calcium (0.046%) followed by sodium (0.042%), magnesium (0.030%) and phosphor (0.028%). This ash, given its composition rich in potassium and calcium, can be used in the glass industry to reduce the melting temperature of silica.

Table 1.

Chemical composition of CsB.

Total extractives represented around 9.3%, most of which were soluble in ethanol (6.64%) and hot water (1.98%) and only 0.69% in dichloromethane. This means that extractives from Broom are most likely phenolic compounds and some small sugars that are obtained in ethanol and water extracts, respectively. These extractives are important since they proved to be good for the preparation of formulations for topical application to protect skin against oxidative damage [6,35]. Dichloromethane removes mostly non-polar extractives such as fatty acids, alkanes, waxes, terpenes and terpenoids, as stated before [36]. On the other hand, ethanol extractives are generally composed of lignans, flavonoid, stilbenes and mostly tannins (hydrolyzable and condensed). Some of these tannins have larger molecules and can only be removed by more aggressive extraction procedures such as 1% NaOH solutions. Results show that Broom has a high amount of such compounds. Klason lignin represents 14.57% of Broom, while cellulose Kürscher and Höffer represent around 36.1% and hemicelluloses 18.6%. The determination of the chemical composition will allow us to understand the possible uses of CsB better.

Cytisus scoparius chemical composition is somewhat different from the one presented by González et al. [34]. These authors reported similar ash (0.78%) and extractives content (9.13%) but a higher lignin percentage (26.6%); however, no alkaline extraction was made before lignin determination. Therefore, the existent polyphenols were most likely counted as lignin. In this study, the 20.8% alkaline extract has removed most of the polyphenols reducing the Klason lignin obtained. This extraction might also remove some other non-tannin material, such as lignin [37] and possibly some hemicelluloses, as stated before [38]. On the other hand, the lignin content is not that far from the lignin content (16%) from Broom obtained from agricultural wastelands located in Zachodniopomorskie Voivodeship in Poland [39]. In the study by González et al. [34], cellulose was estimated by glucan to be around 40% and hemicelluloses by their sugar constituents to be around 19% which is similar to the results obtained here. Moreover, some chemical differences are expected since the origin of the plants is different. Results obtained for Cytisus striatus, generally called Portuguese Broom, are not that different, with 0.8% ash content, 4.7% ethanol toluene extractives, 22.4% lignin and 70% holocellulose [40].

3.2. Liquefaction Optimization

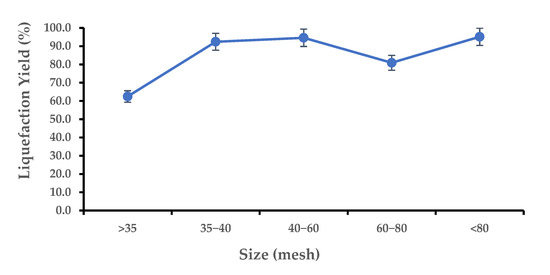

Figure 1 presents the variation of the liquefaction yield with the size of particles. Results show that for the larger particles >35 mesh, the percentage of liquefaction was only around 62.5% which can mean that the size of some of these particles was too big for them to be solubilized. On the other hand, for lower-size particles, the differences between the different sizes are small with 35–40 mesh, 40–60 mesh and <80 mesh (powder) with a very similar value ranging from 92.4 to 95.1%. In relation to 60–80 mesh particles, the percentage of liquefaction was slightly lower (80.9%), which can be due to the different chemical composition in this particle size has observed before [14,17,41]. The different chemical composition of each fraction is particularly important in heterogeneous materials such as in this case where there is a mixture of wood, bark and even flowers with very different chemical composition between each other. This result is extremely important as it allows industries to use larger particles (below 35 mesh), excluding the time-consuming process and complex transformation of Cytisus scoparius bushes to dust.

Figure 1.

Liquefaction yield for different particle size for the Cytisus scoparius branches (CsB) (constant parameters: 180 °C, time 60 min and ratio CsB:solvent of 1:10).

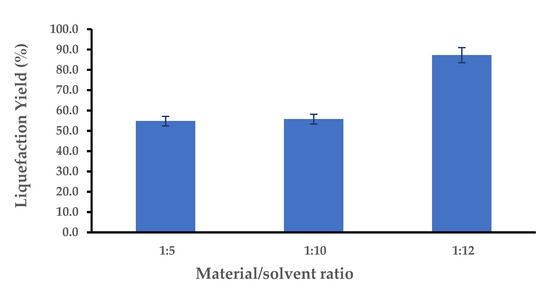

To perform an optimization of the CsB/solvent ratios, tests with different ones were performed using 1:5, 1:10, 1:12 for 60 min (min) at 180 °C. The results obtained are given in Figure 2.

Figure 2.

Study of the ratio CsB:solvent for the samples of the branches (CsB) of Cytisus scoparius (constant parameters: 180 °C, time 60 min and size for the samples <80 mesh).

The results show an increase in liquefaction yield, between 54.8%, 55.8% and 87.2% for a CsB/solvent ratio of 1:5, 1:10 and 1:12, respectively. In fact, this shows that using a higher amount of solvent leads to better liquefaction yields, as proven before [17]; however, it should be noted that more solvent corresponds to a higher cost. Thus, in the choice of solvent ratio, economic and environmental issues should be considered. It was decided to use the 1:10 ratio rather than the 1:5 ratio for the subsequent tests since, although here the difference is small, some earlier tests have shown that 1:5 was not enough in some conditions, and choosing this ratio could affect the study of the other parameters [17].

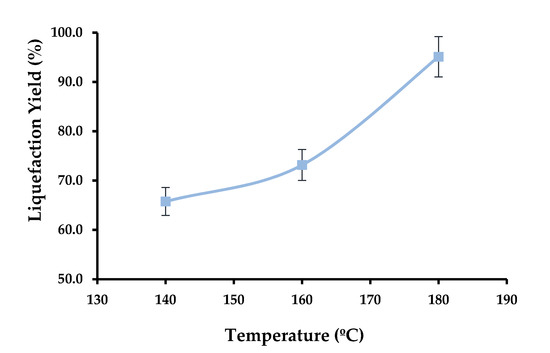

Temperature optimization was performed by varying the temperature between 140 °C and 180 °C, keeping all other parameters constant. The results obtained are shown in Figure 3.

Figure 3.

Study of the temperature for the samples of the branches (CsB) of Cytisus scoparius (constant parameters: time 60 min, size for the samples <80 mesh and ratio CsB:solvent of 1:10).

The liquefaction yield increased with the increase of temperature liquefaction, achieving a promising value of 95.1% for 180 °C. At lower temperatures, the liquefaction yield was only 65% and 73.5% for 140 °C and 160 °C, respectively. The high percentage of liquefaction for 180 °C is higher than that obtained for other materials in similar conditions, such as, for example, Eucalyptus globulus bark (61.6%) and branches (62.2%) [26]. Until 180 °C, no recondensation reactions were observed, or at least it was not significant, probably due to the use of a co-solvent system by the addition of a low-molecular-weight glycol (glycerol) and ethylene glycol, as mentioned before [15].

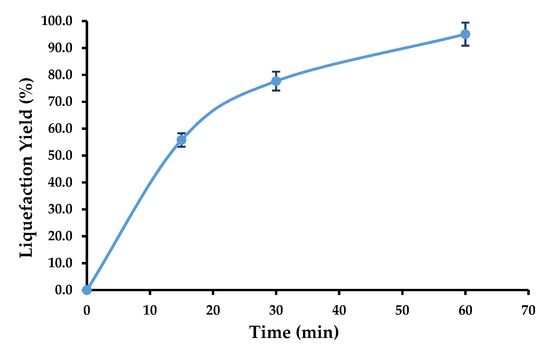

The optimization of liquefaction time was performed by varying the time between 15 and 60 min, keeping all other parameters constant. The results obtained are presented in Figure 4.

Figure 4.

Study of liquefaction yield along liquefaction time for Broom branches for the fraction > 80 mesh (powder) at 180 °C with acid catalysis.

Results show that it takes only 30 min to obtain a good liquefaction yield of 77.7% but also, that higher liquefaction can be obtained for 60 min (95.1%). The liquefaction yield was higher than the obtained for walnut shells (85%) before [42]. No decrease was observed with the increase in temperature, as reported, for instance, by Soares et al. [23] with cork liquefaction. These authors observed a decrease in higher temperatures which was attributed to polycondensation reactions between the liquefaction intermediates. Depending on the final product to be produced, a lower or higher liquefaction can be obtained.

The high percentage of liquefaction (95%) shows that broom can be successfully liquefied bi polyalcohols with acid catalysis. The percentage of liquefaction is higher than the one obtained before for several other lignocellulosic materials such as rice straw, oilseed rape straw, wheat straw or corn stover [22] or orange peel wastes [43]. The low amount of residue allows using the obtained polyol without any separation between the solid residue and the liquefied material, which can be costly. Therefore, Broom has a nice potential to be used for the production of polyurethane foams, as was done before for several lignocellulosic materials, for instance, wood, barks or agricultural wastes [22,43,44,45,46].

3.3. FTIR of Liquefaction

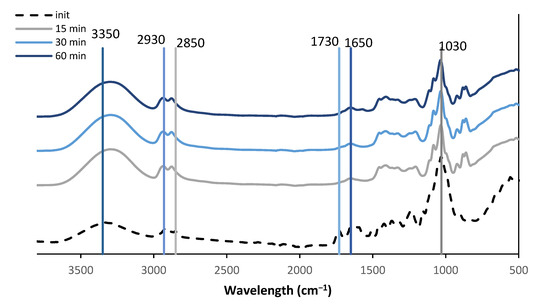

Figure 5 presents the variation of the FTIR spectrum between the initial material and the liquefied polyol at 180 °C for 15 min, 30 min and 60 min. There are no major differences between the spectra of polyols produced with 15 min, 30 min or 60 min reactions. Big differences are observed between the initial and the liquefied material. There is a clear increase in the hydroxyl peak and a shifting of the peak maximum from around 3350 cm−1 to around 3250 cm−1. This is to be expected since the solvents used, glycerol and ethyleneglycol, are alcohols and, therefore, have several hydroxyl groups in their constitution. The shifting for lower wavenumbers can be due to the different functional groups present in liquefied material. Generally, alcohols absorb at higher wavenumbers (3600–3300 cm−1) than carboxylic acids (3300–2500 cm−1), therefore, this shifting to lower wavenumbers could be due to the increase in carboxylic acids. Nevertheless, generally, the C=O of carboxylic acids has a strong absorption at about 1725–1700 cm−1, which is not seen in liquefied spectra.

Figure 5.

FTIR spectra of the initial material and the liquefied polyol at 180 °C for 15 min, 30 min and 60 min at 180 °C with acid catalysis.

The CH peaks are also very different in the polyol and in the initial material. These bands result from the overlapping of -CH2- (2935–2915 cm−1) and -CH3 (2970–2950 cm−1) stretching asymmetric vibrations and -CH2- (2865–2845 cm−1) and -CH3 (2880–2860 cm−1) stretching symmetric vibrations [47]. The original peaks are sharper, and there is an increase in the 2850 cm−1 peak in relation to 2930 cm−1 shifting the maximum to around 2860 cm−1. Similar behavior has been observed before for liquefied cherry seeds [48].

The peak at 1730 cm−1, corresponding to non-conjugated C=O linkages, completely disappeared in the spectra of the liquefied material, and the 1650 cm−1 band was significantly reduced and narrowed. This might be due to the low amount of lignin in the initial material and to the lower resistance of Broom polysaccharides to hydrolysis. This is in line with the increase observed in this peak in the FTIR spectrum of the solid residue, especially after 60 min liquefaction. Similarly, the peak at 1510 cm−1 also disappears in the polyol spectra, and this peak has been associated with benzene ring stretching vibrations [47,49]. The 1230 cm−1 peak also decreases in the liquefied material. Although there is an apparent decrease in the 1030 cm−1 peak, this might be due to the high increase in the 3350 cm−1 band that proportionally decreases the remaining peaks. There is, however, a narrowing of the peak and the appearance of a more pronounced shoulder at 1100 cm−1. There is a new visible peak appearing at around 850 cm−1 which can be due to stretching vibrations in the pyranose ring [49]. The changes in FTIR spectra for the liquefied material are very different from those observed for sweet cherry seeds, which can be due to the significantly different chemical composition between them.

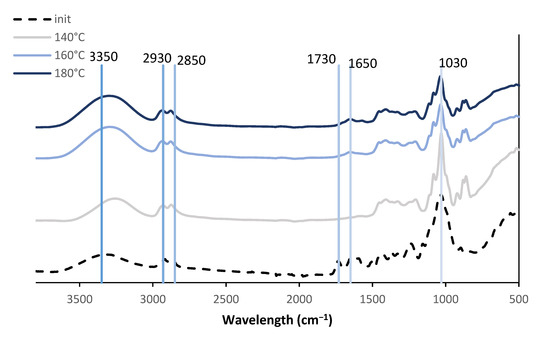

Figure 6 presents the variation of the FTIR spectrum between the initial material and the liquefied polyol for a 60 min reaction at 140 °C, 160 °C and 180 °C. Similar to the results presented in Figure 6, the main differences are observed between the initial and the liquefied material. Nevertheless, at 140 °C, there is a smaller increase in the 3350 cm−1 band and a much higher C-O-C peak at 1030 cm−1 in relation to the other temperatures.

Figure 6.

FTIR spectra of the initial material and the liquefied polyol for a 60 min reaction at 140 °C, 160 °C and 180 °C with acid catalysis.

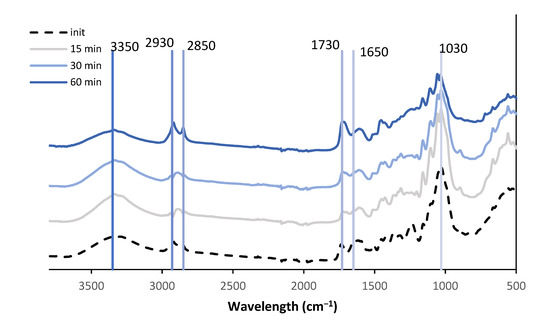

Figure 7 presents the FTIR spectra of the initial material and of the solid residue obtained by liquefaction at 180 °C for 15 min, 30 min and 60 min reaction time. The solid residue spectrum changes rapidly from the initial material and along the reaction time. There is a slight narrowing of the 3350 cm−1 band in the initial of the liquefaction and a decrease for 60 min reaction time. In relation to the CH peaks, there is a decrease of the 2930 cm−1 peak followed by an increase for longer reaction times. The same seems to happen to the 1730 cm−1 peak and somewhat to the 1650 cm−1 band. These changes might be due to an initial cleavage of acetyl or acetoxy groups in hemicelluloses. The fingertip region is much less defined in the solid residue, and there seems to be a decrease at the 1226 cm−1 peak. The C-O-C peak also seems to increase and decrease later.

Figure 7.

FTIR spectra of the initial material and of the solid residue obtained by liquefaction at 180 °C for 15 min, 30 min and 60 min reaction time with acid catalysis.

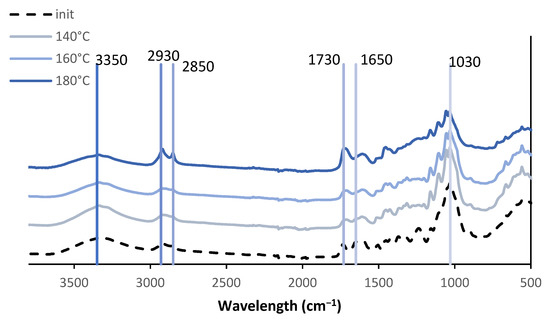

The changes observed in the solid residue along the liquefaction time are similar to those presented in Figure 8 with the increase in liquefaction temperature.

Figure 8.

FTIR spectra of the initial material and of the solid residue obtained by liquefaction for 60 min at temperatures 140 °C, 160 °C and 180 °C with acid catalysis.

FTIR analysis shows that it is not only one of the macromolecular compounds that is being liquefied but rather that all the chemical compounds are affected by polyalcohol liquefaction with acid catalysis.

4. Conclusions

Results have shown that in relation to macromolecular compounds, Broom is mainly composed of cellulose, followed by hemicelluloses and lignin. Alkaline extract represented more than 20% and is probably composed of tannins. Extractives were more than 9%, with ethanol soluble representing more than half, followed by water soluble and dichloromethane extractives. These phenolic compounds can be retrieved before liquefaction in a biorefinery approach. Ashes were around 0.69%. No significative differences were found for the different fractions, although the 40–60 mesh fraction presented the best results. A higher amount of solvent improved the liquefaction percentage. The same was observed for higher temperatures and the time of liquefaction. At the ideal conditions, a high percentage of liquefaction (95%) could be achieved, better than most lignocellulosic materials. These conditions were 180 °C, 60 min for the 40–60 mesh fraction. The results have proven that Broom can be a valuable material that, once liquefied, can be later used for the manufacture of goods without any further separation to substitute petroleum-based products such as, for instance, polyurethane foams.

Author Contributions

Conceptualization, L.C.-L. and B.E.; methodology, L.C.-L., Y.D. and B.E.; formal analysis, L.C.-L. and Y.D.; investigation, L.C.-L., Y.D., D.A. and B.E.; resources, L.C.-L., Y.D., I.D., J.F., A.F. and B.E.; writing—original draft preparation, Y.D.; writing—review and editing, L.C.-L. and B.E.; supervision, L.C.-L. All authors have read and agreed to the published version of the manuscript.

Funding

This work is funded by National Funds through the FCT—Foundation for Science and Technology. I.P. within the scope of the project Ref UIDB/00681/2020 (CERNAS) and Ref UIDB/05507/2020 (CI&DEI).

Acknowledgments

We would like to thank the CERNAS and CI&DEI Researchs Centres and the Polytechnic Institutes of Viseu for their support and the PROJ/IPV/ID&I/021 “Valorização de resíduos: potencial de aproveitamento do caroço de cereja (VALCER)” by Yulia’s Research Grant.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Marchante, H.; Morais, M.; Freitas, H.; Marchante, E. Guia Prático para a Identificação de Plantas Invasoras em Portugal; Imprensa da Universidade de Coimbra/Coimbra University Press: Lisboa, Portugal, 2014; ISBN 978-989-26-0785-6. [Google Scholar]

- Costa, J.C.; Aguiar, C.; Capelo, J.; Lousã, M.; Antunes, J.H.S.; Honrado, J.J.; Izco, J.; Ladero, M. A Classe Cytisetea Scopario-Striati Em Portugal Continental. Quercetea 2003, 4, 45–70. [Google Scholar]

- o Inventário Florestal Nacional—PDF Free Download. Available online: https://docplayer.com.br/146300038-6-o-inventario-florestal-nacional.html (accessed on 17 July 2021).

- Caetano, M.; Igreja, C.; Marcelino, F.; Costa, H. Estatísticas e Dinâmicas Territoriais Multiescala de Portugal Continental 1995–2007–2010 Com Base Na Carta de Uso e Ocupação Do Solo (COS); Direção-Geral do Território: Lisbon, Portugal, 2017. [Google Scholar]

- Pinela, J.; Barros, L.; Carvalho, A.M.; Ferreira, I.C. Influence of the Drying Method in the Antioxidant Potential and Chemical Composition of Four Shrubby Flowering Plants from the Tribe Genisteae (Fabaceae). Food Chem. Toxicol. 2011, 49, 2983–2989. [Google Scholar] [CrossRef] [PubMed]

- González, N.; Otero, A.; Conde, E.; Falqué, E.; Moure, A.; Domínguez, H. Extraction of Phenolics from Broom Branches Using Green Technologies. J. Chem. Technol. Biotechnol. 2017, 92, 1345–1352. [Google Scholar] [CrossRef]

- Nirmal, J.; Babu, C.S.; Harisudhan, T.; Ramanathan, M. Evaluation of Behavioural and Antioxidant Activity of Cytisus Scoparius Link in Rats Exposed to Chronic Unpredictable Mild Stress. BMC Complement. Altern. Med. 2008, 8, 15. [Google Scholar] [CrossRef]

- Raja, S.; Ahamed, K.N.; Kumar, V.; Mukherjee, K.; Bandyopadhyay, A.; Mukherjee, P.K. Antioxidant Effect of Cytisus Scoparius against Carbon Tetrachloride Treated Liver Injury in Rats. J. Ethnopharmacol. 2007, 109, 41–47. [Google Scholar] [CrossRef]

- Gil, N.R.S. Pré-Tratamento de Materiais Lenhocelulósicos para Produção de Bioetanol. Ph.D. Thesis, Universidade da Beira Interior, Covilha, Portugal, 2008. [Google Scholar]

- Lin, R.; Sun, J.; Yue, C.; Wang, X.; Tu, D.; Gao, Z. Study on Preparation and Properties of Phenol-Formaldehyde-Chinese Fir Liquefaction Copolymer Resin. Maderas. Cienc. Tecnol. 2014, 16, 159–174. [Google Scholar] [CrossRef][Green Version]

- Mun, S.P.; Gilmour, I.A.; Jordan, P.J. Effect of Organic Sulfonic Acids as Catalysts during Phenol Liquefaction of Pinus Radiata Bark. J. Ind. Eng. Chem. 2006, 12, 720–726. [Google Scholar]

- Zhang, Q.; Zhao, G.; Jie, S. Liquefaction and Product Identification of Main Chemical Compositions of Wood in Phenol. For. Stud. China 2005, 7, 31–37. [Google Scholar] [CrossRef]

- Li, G.; Hse, C.; Qin, T. Wood Liquefaction with Phenol by Microwave Heating and FTIR Evaluation. J. For. Res. 2015, 26, 1043–1048. [Google Scholar] [CrossRef]

- Cruz-Lopes, L.P.; Domingos, I.; Ferreira, J.; Esteves, B. Chemical Composition and Study on Liquefaction Optimization of Chestnut Shells. Open Agric. 2020, 5, 905–911. [Google Scholar] [CrossRef]

- Kurimoto, Y.; Tamura, Y. Species Effects on Wood-Liquefaction in Polyhydric Alcohols. Holzforschung 1999, 53, 617–622. [Google Scholar] [CrossRef]

- D’Souza, J.; Wong, S.Z.; Camargo, R.; Yan, N. Solvolytic Liquefaction of Bark: Understanding the Role of Polyhydric Alcohols and Organic Solvents on Polyol Characteristics. ACS Sustain. Chem. Eng. 2015, 4, 851–861. [Google Scholar] [CrossRef]

- Esteves, B.; Dulyanska, Y.; Costa, C.; Ferreira, J.V.; Domingos, I.; Pereira, H.; de Lemos, L.T.; Cruz-Lopes, L.V. Cork Liquefaction for Polyurethane Foam Production. BioResources 2017, 12, 2339–2353. [Google Scholar] [CrossRef]

- Jin, Y.; Ruan, X.; Cheng, X.; Lü, Q. Liquefaction of Lignin by Polyethyleneglycol and Glycerol. Bioresour. Technol. 2011, 102, 3581–3583. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, M.; Tukamoto, K.; Tomita, B. Application of Liquefied Wood to a New Resin System-Synthesis and Properties of Liquefied Wood/Epoxy Resins. Holzforschung 2000, 54, 93–100. [Google Scholar] [CrossRef]

- Chen, F.; Lu, Z. Liquefaction of Wheat Straw and Preparation of Rigid Polyurethane Foam from the Liquefaction Products. J. Appl. Polym. Sci. 2009, 111, 508–516. [Google Scholar] [CrossRef]

- Huang, Y.; Zheng, Y.; Zheng, Z.; Zhou, Q.; Feng, H. Study on Liquefaction Technology of Cornstarch in Polyhydric Alcohols. J. Southwest For. Univ. 2011, 31, 72–74. [Google Scholar]

- Zhang, J.; Hori, N.; Takemura, A. Optimization of Agricultural Wastes Liquefaction Process and Preparing Bio-Based Polyurethane Foams by the Obtained Polyols. Ind. Crops Prod. 2019, 138, 111455. [Google Scholar] [CrossRef]

- Pan, H.; Zheng, Z.; Hse, C.Y. Microwave-Assisted Liquefaction of Wood with Polyhydric Alcohols and Its Application in Preparation of Polyurethane (PU) Foams. Eur. J. Wood Wood Prod. 2012, 70, 461–470. [Google Scholar] [CrossRef]

- Zheng, Z.; Pan, H.; Huang, Y.; Chung, Y.; Zhang, X.; Feng, H. Rapid Liquefaction of Wood in Polyhydric Alcohols under Microwave Heating and Its Liquefied Products for Preparation of Rigid Polyurethane Foam. Open Mater. Sci. J. 2011, 5, 1–8. [Google Scholar] [CrossRef]

- Esteves, B.; Cruz-Lopes, L.; Ferreira, J.; Domingos, I.; Nunes, L.; Pereira, H. Optimizing Douglas-Fir Bark Liquefaction in Mixtures of Glycerol and Polyethylene Glycol and KOH. Holzforschung 2018, 72, 25–30. [Google Scholar] [CrossRef]

- Fernandes, A.; Cruz-Lopes, L.; Dulyanska, Y.; Domingos, I.; Ferreira, J.; Evtuguin, D.; Esteves, B. Eco Valorization of Eucalyptus globulus Bark and Branches through Liquefaction. Appl. Sci. 2022, 12, 3775. [Google Scholar] [CrossRef]

- Ye, L.; Zhang, J.; Zhao, J.; Tu, S. Liquefaction of Bamboo Shoot Shell for the Production of Polyols. Bioresour. Technol. 2014, 153, 147–153. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Du, M.; Hu, L. Factors Influencing Polyol Liquefaction of Nut Shells of Different Camellia Species. BioResources 2016, 11, 9956–9969. [Google Scholar] [CrossRef][Green Version]

- Duarte, J.; Cruz-Lopes, L.; Dulyanska, Y.; Domingos, I.; Ferreira, J.; de Lemos, L.T.; Esteves, B. Orange Peel Liquefaction Monitored by FTIR. J. Int. Sci. Publ. 2017, 5, 309–313. [Google Scholar]

- 264 Om-97; Preparation of Wood in Chemical Analysis. Tappi Press: Atlanta, GA, USA, 1997.

- 211 Om–93; Ash in Wood, Pulp, Paper and Paperboard: Combustion at 525. Tappi Press: Atlanta, GA, USA, 1993.

- Prozil, S.O.; Evtuguin, D.V.; Lopes, L.P.C. Chemical Composition of Grape Stalks of Vitis vinifera L. from Red Grape Pomaces. Ind. Crops Prod. 2012, 35, 178–184. [Google Scholar] [CrossRef]

- Neto, C.P.; Seca, A.; Fradinho, D.; Coimbra, M.A.; Domingues, F.; Evtuguin, D.; Silvestre, A.; Cavaleiro, J.A.S. Chemical Composition and Structural Features of the Macromolecular Components of Hibiscus Cannabinus Grown in Portugal. Ind. Crops Prod. 1996, 5, 189–196. [Google Scholar] [CrossRef]

- González, D.; Campos, A.R.; Cunha, A.M.; Santos, V.; Parajó, J.C. Manufacture of Fibrous Reinforcements for Biodegradable Biocomposites from Citysus Scoparius. J. Chem. Technol. Biotechnol. 2011, 86, 575–583. [Google Scholar] [CrossRef]

- González, N.; Ribeiro, D.; Fernandes, E.; Nogueira, D.R.; Conde, E.; Moure, A.; Vinardell, M.P.; Mitjans, M.; Domínguez, H. Potential Use of Cytisus Scoparius Extracts in Topical Applications for Skin Protection against Oxidative Damage. J. Photochem. Photobiol. B Biol. 2013, 125, 83–89. [Google Scholar] [CrossRef]

- Esteves, B.; Ayata, U.; Cruz-Lopes, L.; Brás, I.; Ferreira, J.; Domingos, I. Changes in the Content and Composition of the Extractives in Thermally Modified Tropical Hardwoods. Maderas. Cienc. Tecnol. 2022, 24, 1–14. [Google Scholar] [CrossRef]

- Chupin, L.; Motillon, C.; Charrier-El Bouhtoury, F.; Pizzi, A.; Charrier, B. Characterisation of Maritime Pine (Pinus pinaster) Bark Tannins Extracted under Different Conditions by Spectroscopic Methods, FTIR and HPLC. Ind. Crops Prod. 2013, 49, 897–903. [Google Scholar] [CrossRef]

- Kofujita, H.; Ettyu, K.; Ota, M. Characterization of the Major Components in Bark from Five Japanese Tree Species for Chemical Utilization. Wood Sci. Technol. 1999, 33, 223–228. [Google Scholar] [CrossRef]

- Smuga-Kogut, M.; Szymanowska, D.; Markiewicz, R.; Piskier, T.; Kobus-Cisowska, J.; Cielecka-Piontek, J.; Schöne, H. Evaluation of the Potential of Fireweed (Epilobium angustifolium L.), European Goldenrod (Solidago virgaurea L.), and Common Broom (Cytisus scoparius L.) Stems in Bioethanol Production. Energy Sci. Eng. 2020, 8, 3244–3254. [Google Scholar] [CrossRef]

- Gil, N.; Domingues, F.C.; Amaral, M.E.; Duarte, A.P. Optimization of diluted acid pretreatment of Cytisus striatus and Cistus ladanifer for bioethanol production. J. Biobased Mater. Bioenergy 2012, 6, 292–298. [Google Scholar] [CrossRef]

- Sen, A.; Miranda, I.; Esteves, B.; Pereira, H. Chemical Characterization, Bioactive and Fuel Properties of Waste Cork and Phloem Fractions from Quercus cerris L. Bark. Ind. Crops Prod. 2020, 157, 112909. [Google Scholar] [CrossRef]

- Domingos, I.; Ferreira, J.; Esteves, B.; Cruz-Lopes, L. Liquefaction and Chemical Composition of Walnut Shells. Open Agric. 2022, 7, 249–256. [Google Scholar] [CrossRef]

- Domingos, I.; Ferreira, J.; Cruz-Lopes, L.; Esteves, B. Polyurethane Foams from Liquefied Orange Peel Wastes. Food Bioprod. Process. 2019, 115, 223–229. [Google Scholar] [CrossRef]

- Gama, N.V.; Soares, B.; Freire, C.S.; Silva, R.; Brandão, I.; Neto, C.P.; Barros-Timmons, A.; Ferreira, A. Rigid Polyurethane Foams Derived from Cork Liquefied at Atmospheric Pressure: Rigid Polyurethane Foams Derived from Cork Liquefied. Polym. Int. 2015, 64, 250–257. [Google Scholar] [CrossRef]

- Cinelli, P.; Anguillesi, I.; Lazzeri, A. Green Synthesis of Flexible Polyurethane Foams from Liquefied Lignin. Eur. Polym. J. 2013, 49, 1174–1184. [Google Scholar] [CrossRef]

- Kahlerras, Z.; Irinislimane, R.; Bruzaud, S.; Belhaneche-Bensemra, N. Elaboration and Characterization of Polyurethane Foams Based on Renewably Sourced Polyols. J. Polym. Environ. 2020, 28, 3003–3018. [Google Scholar] [CrossRef]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H. Chemical Changes of Heat Treated Pine and Eucalypt Wood Monitored by FTIR. Maderas. Cienc. Tecnol. 2013, 15, 245–258. [Google Scholar] [CrossRef]

- Cruz-Lopes, L.; Dulyanska, Y.; Domingos, I.; Ferreira, J.; Fragata, A.; Guiné, R.; Esteves, B. Influence of Pre-Hydrolysis on the Chemical Composition of Prunus Avium Cherry Seeds. Agronomy 2022, 12, 280. [Google Scholar] [CrossRef]

- Michell, A.; Higgins, H. Infrared Spectroscopy in Australian Forest Products Research; CSIRO Forestry: Victoria, Australia, 2002. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).