Effect of Acetylation on the Physical and Mechanical Performances of Mechanical Densified Spruce Wood

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Acetylation Process of Spruce Wood

2.3. Densification Process of Spruce Wood

2.4. Performance Testing

2.4.1. Water Absorption, Thickness Swelling Rate, and Cyclic Set Recovery

2.4.2. Microstructure Observation

2.4.3. Mechanical Performance Testing

3. Results and Discussion

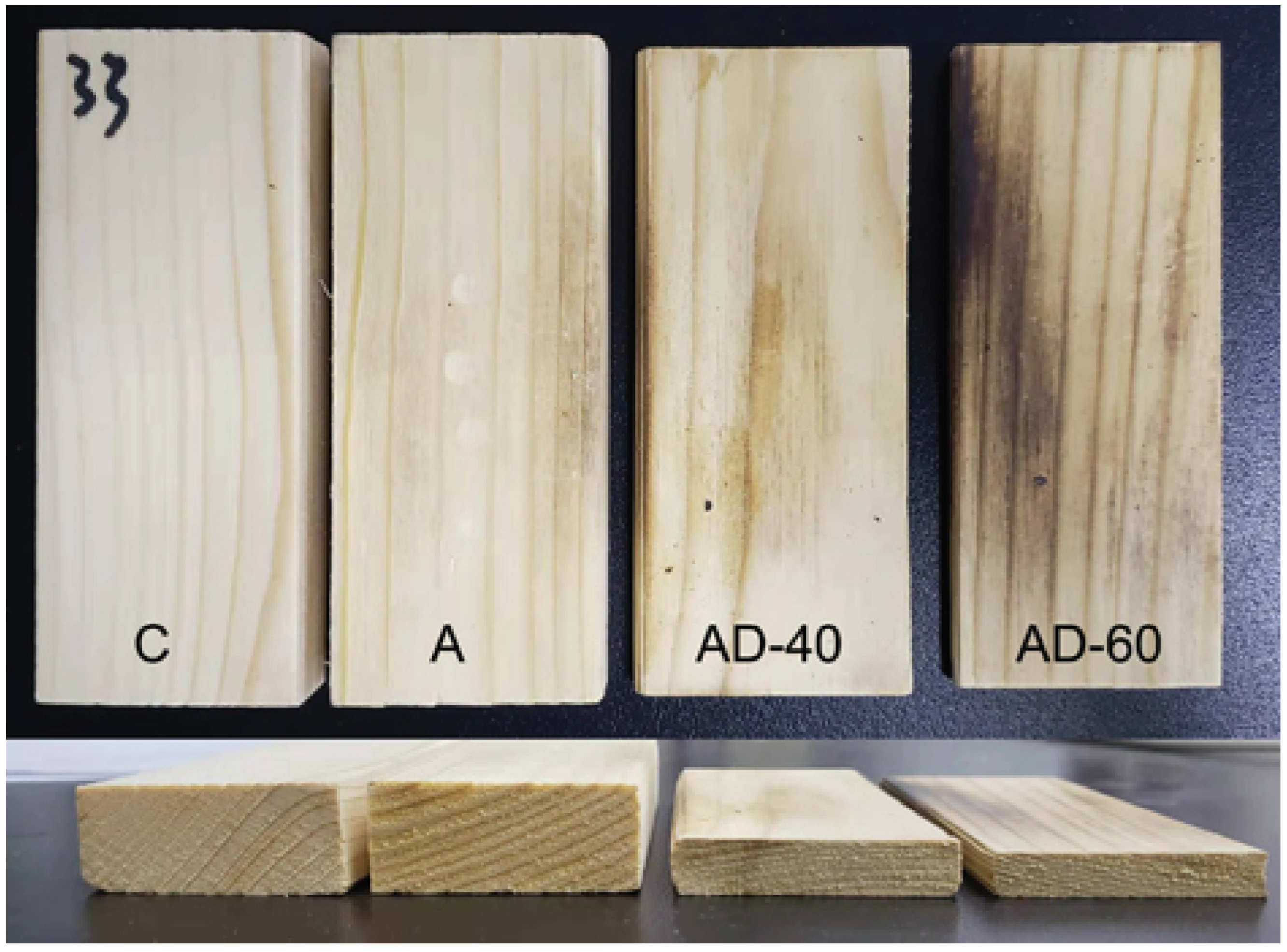

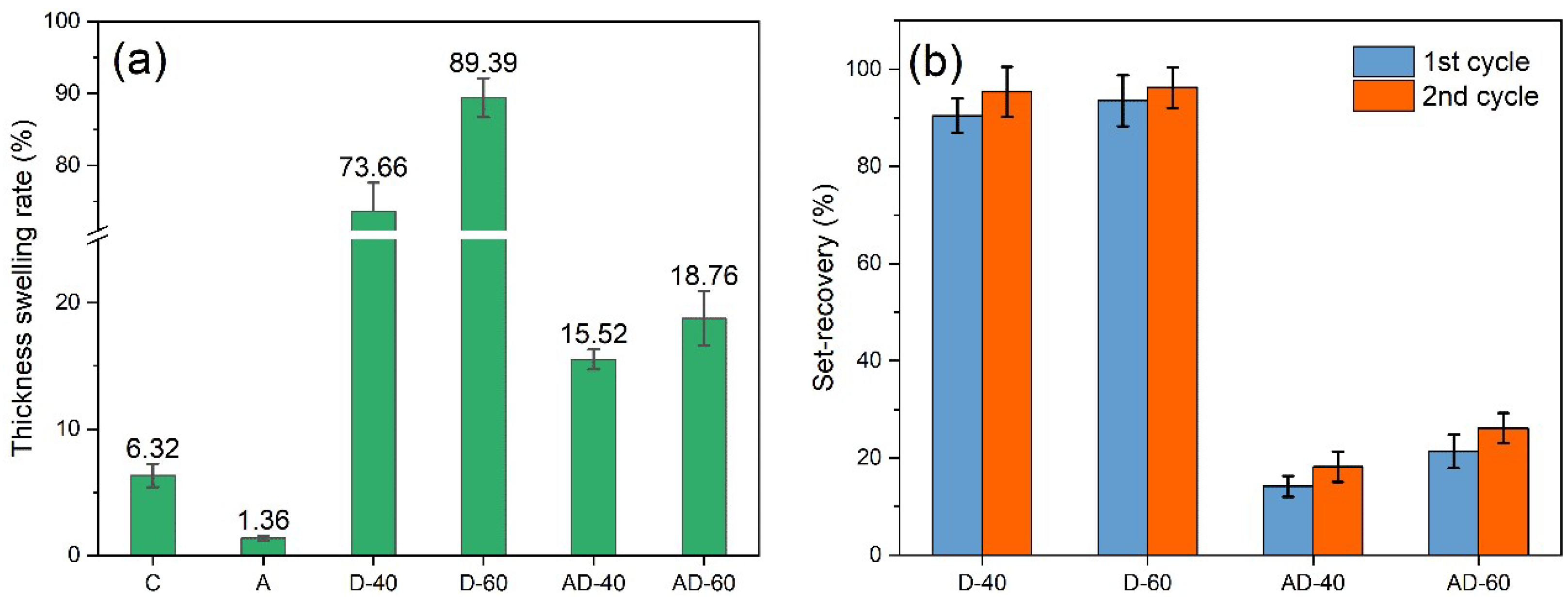

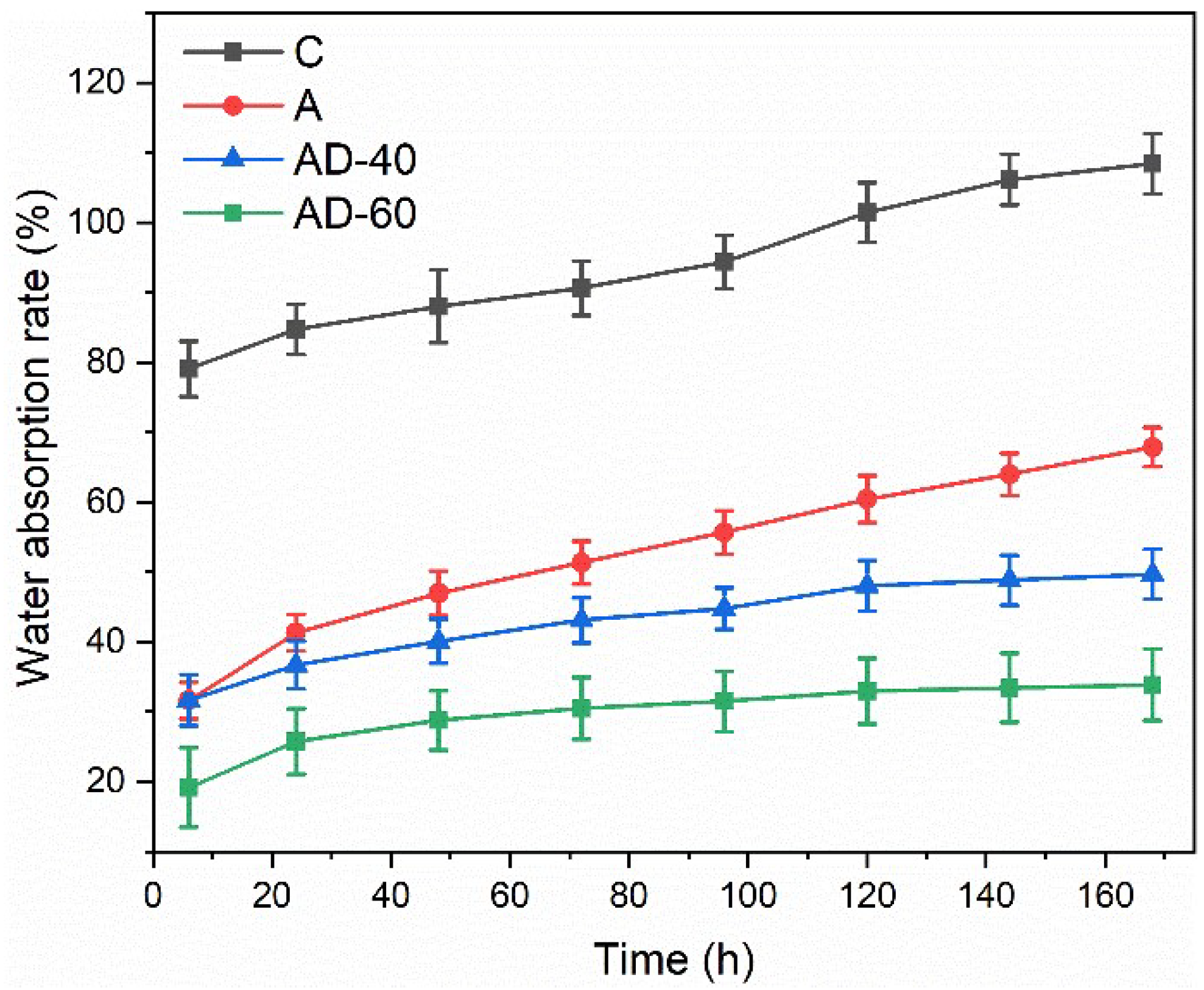

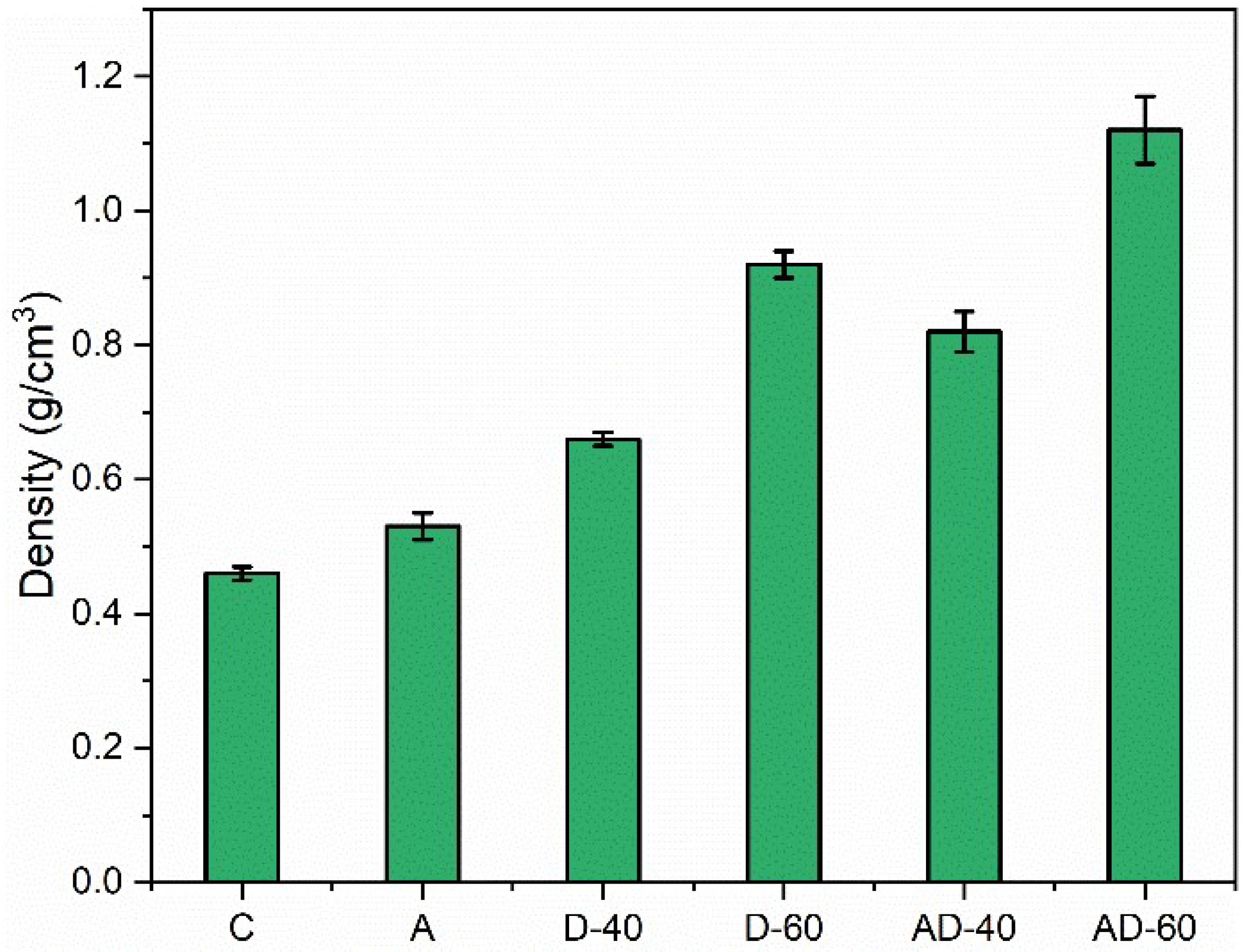

3.1. Set Recovery and Water Absorption Rate Analysis

3.2. Microstructural Analysis

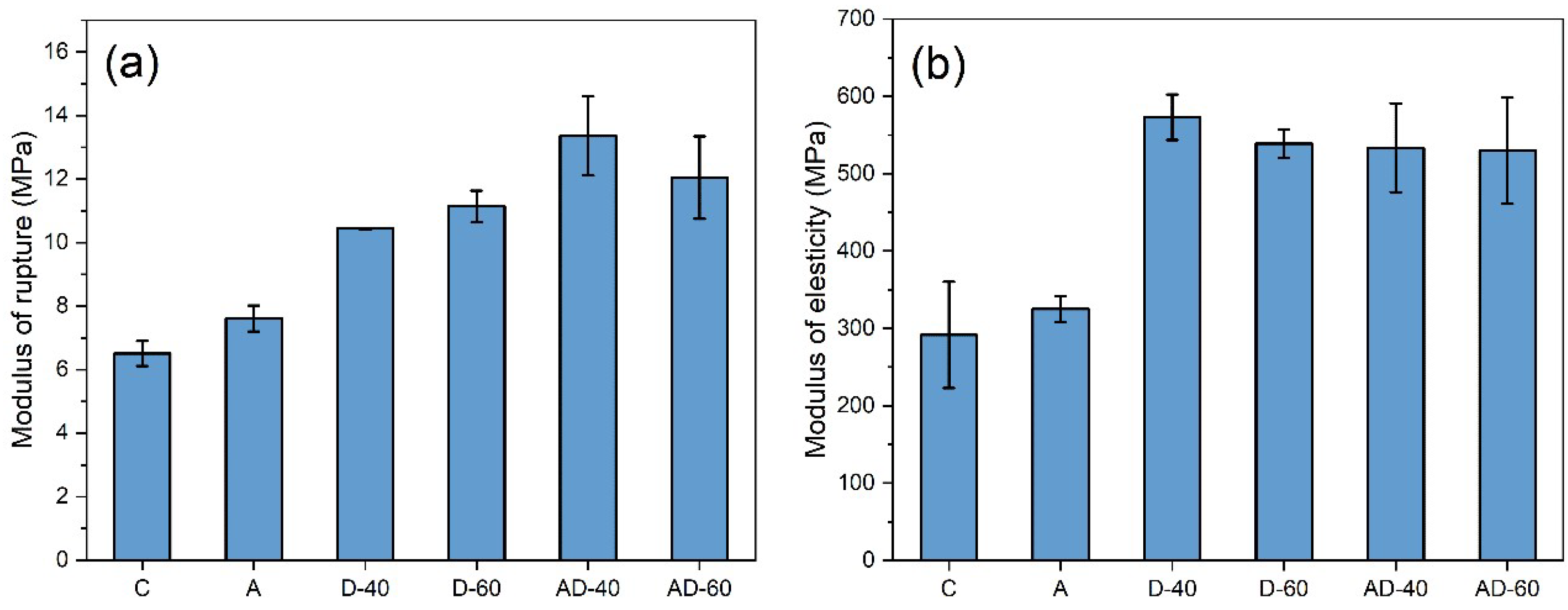

3.3. Mechanical Performance Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dong, Y.; Tan, Y.; Wang, K.; Cai, Y.; Li, J.; Sonne, C.; Li, C. Reviewing wood-based solar-driven interfacial evaporators for desalination. Water Res. 2022, 223, 119011. [Google Scholar] [CrossRef] [PubMed]

- Barbu, M.C.; Tudor, E.M. State of the art of the Chinese forestry, wood industry and its markets. Wood Mater. Sci. Eng. 2021, 16, 1–10. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, K.; Li, J.; Zhang, S.; Shi, S.Q. Environmentally benign wood modifications: A review. ACS Sustain. Chem. Eng. 2020, 8, 3532–3540. [Google Scholar] [CrossRef]

- Liu, R.; Liu, X.; Zhang, Y.; Liu, J.; Gong, C.; Dong, Y.; Li, J.; Shi, J.; Wu, M. Paraffin Pickering Emulsion Stabilized with Nano-SiO2 Designed for Wood Impregnation. Forests 2020, 11, 726. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies-a review. iForest-Biogeosci. For. 2017, 10, 895. [Google Scholar] [CrossRef]

- Liu, X.; Fu, Z.; Zhang, F.; Wu, M.; Dong, Y. Synthesis of silica Janus nanosheets and their application to the improvement of interfacial interaction in wood polymer composites. J. Mater. Res. Technol. 2021, 15, 4652–4661. [Google Scholar] [CrossRef]

- Jakob, M.; Czabany, I.; Veigel, S.; Müller, U.; Gindl-Altmutter, W. Comparing the suitability of domestic spruce, beech, and poplar wood for high-strength densified wood. Eur. J. Wood Prod. 2022, 80, 859–876. [Google Scholar] [CrossRef]

- Huang, C.; Gong, M.; Chui, Y.; Chan, F. Mechanical behaviour of wood compressed in radial direction-part I. New method of determining the yield stress of wood on the stress-strain curve. J. Bioresour. Bioprod. 2020, 5, 186–195. [Google Scholar] [CrossRef]

- Wang, K.; Liu, X.; Dong, Y.; Zhang, S.; Li, J. A biomimetic Janus delignified wood membrane with asymmetric wettability prepared by thiol-ol chemistry for unidirectional water transport and selective oil/water separation. Coll. Surf. A 2022, 652, 129793. [Google Scholar] [CrossRef]

- Kuai, B.; Wang, Z.; Gao, J.; Tong, J.; Zhan, T.; Zhang, Y.; Lu, J.; Cai, L. Development of densified wood with high strength and excellent dimensional stability by impregnating delignified poplar by sodium silicate. Constr. Build. Mater. 2022, 344, 128282. [Google Scholar] [CrossRef]

- Liu, M.; Lyu, S.; Cai, L.; Peng, L.; Tang, J.; Huang, Z.; Lyu, J. Performance improvement of radiata pine wood by combining impregnation of furfuryl alcohol resin and densification for making fretboard materials. Ind. Crops Prod. 2021, 172, 114029. [Google Scholar] [CrossRef]

- Pfriem, A.; Dietrich, T.; Buchelt, B. Furfuryl alcohol impregnation for improved plasticity and fixation during the densification of wood. Holzforschung 2012, 66, 215–218. [Google Scholar] [CrossRef]

- Fu, Q.; Cloutier, A.; Laghdir, A. Optimization of the thermo-hygromechanical (THM) process for sugar maple wood densification. BioResources 2016, 11, 8844–8859. [Google Scholar] [CrossRef]

- Dong, Y.; Altgen, M.; Mäkelä, M.; Rautkari, L.; Hughes, M.; Li, J.; Zhang, S. Improvement of interfacial interaction in impregnated wood via grafting methyl methacrylate onto wood cell walls. Holzforschung 2020, 74, 967–977. [Google Scholar] [CrossRef]

- Zheng, Z.; Chen, C.; Huang, Y.; Ou, R.; Hu, C.; Wang, X.; Zhou, Q.; Tu, D. Developing a Unilaterally Surface-Densified Wood Composite with Excellent Performance through Surface Impregnation of Furfuryl Alcohol Resin. ACS Appl. Polym. Mater. 2022, 4, 5308–5318. [Google Scholar] [CrossRef]

- Luan, Y.; Fang, C.H.; Ma, Y.F.; Fei, B.H. Wood mechanical densification: A review on processing. Mater. Manuf. Process. 2022, 37, 359–371. [Google Scholar] [CrossRef]

- Budakçı, M.; Şenol, S.; Korkmaz, M. Thermo-vibro-mechanic®(TVM) wood densification method: Mechanical properties. BioResources 2022, 17, 1606–1626. [Google Scholar] [CrossRef]

- Shi, J.; Peng, J.; Huang, Q.; Cai, L.; Shi, S.Q. Fabrication of densified wood via synergy of chemical pretreatment, hot-pressing and post mechanical fixation. J. Wood Sci. 2020, 66, 5. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- Hackenberg, H.; Zauer, M.; Dietrich, T.; Hackenberg, K.A.M.; Wagenführ, A. Alteration of Bending Properties of Wood Due to Ammonia Treatment and Additional Densification. Forests 2021, 12, 1110. [Google Scholar] [CrossRef]

- Baar, J.; Hrdlička, P.; Rademacher, P.; Volánek, J.; Rousek, R.; Čermák, P. Decay resistance of ammonia-plasticised and densified beech wood. Wood Mater. Sci. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: Hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Fu, Q.L.; Cloutier, A.; Laghdir, A. Effects of heat and steam on the mechanical properties and dimensional stability of thermo-hygro-mechanically-densified sugar maple wood. BioResources 2017, 12, 9212–9226. [Google Scholar] [CrossRef]

- Gong, M.; Lamason, C.; Li, L. Interactive effect of surface densification and post-heat-treatment on aspen wood. J. Mater. Process. Technol. 2010, 210, 293–296. [Google Scholar] [CrossRef]

- Slabohm, M.; Mayer, A.K.; Militz, H. Compression of Acetylated Beech (Fagus sylvatica L.) Laminated Veneer Lumber (LVL). Forests 2022, 13, 1122. [Google Scholar] [CrossRef]

- Schwarzkopf, M. Densified wood impregnated with phenol resin for reduced set-recovery. Wood Mater. Sci. Eng. 2021, 16, 35–41. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, T.; Li, C.; Xiao, X.; Tang, Y.; Fang, X.; Peng, H.; Liu, X.; Dong, Y.; Cai, Y.; et al. Shape-reconfigurable transparent wood based on solid-state plasticity of polythiourethane for smart building materials with tunable light guiding, energy saving, and fire alarm actuating functions. Compos. Part B 2022, 246, 110260. [Google Scholar] [CrossRef]

- Himmel, S.; Mai, C. Effects of acetylation and formalization on the dynamic water vapor sorption behavior of wood. Holzforschung 2015, 69, 633–643. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Lykidis, C.; Papadopoulos, A.N. Durability of Accoya Wood in Ground Stake Testing after 10 Years of Exposure in Greece. Polymers 2020, 12, 1638. [Google Scholar] [CrossRef]

- Sugiyama, M.; Obataya, E.; Norimoto, M. Viscoelastic properties of the matrix substance of chemically treated wood. J. Mater. Sci. 1998, 33, 3505–3510. [Google Scholar] [CrossRef]

- Jebrane, M.; Harper, D.; Labbé, N.; Sèbe, G. Comparative determination of the grafting distribution and viscoelastic properties of wood blocks acetylated by vinyl acetate or acetic anhydride. Carbohyd. Polym. 2011, 84, 1314–1320. [Google Scholar] [CrossRef]

- Lallart, P.Y.; Wehsener, J.; Hartig, J.; Haller, P. Thermo-hydro-mechanical behaviour of acetylated wood: Swelling, compression set recovery and mouldability. Eur. J. Wood Prod. 2017, 75, 281–284. [Google Scholar] [CrossRef]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M.; Lankveld, C. Surface densification of acetylated wood. Eur. J. Wood Prod. 2016, 74, 829–835. [Google Scholar] [CrossRef]

- Obataya, E.; Yamauchi, H. Compression behaviors of acetylated wood in organic liquids. Part II. Drying-set and its recovery. Wood Sci. Technol. 2005, 39, 546–559. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Kirker, G.T.; Bishell, A.B.; Glass, S.V. Effects of wood moisture content and the level of acetylation on brown rot decay. Forests 2020, 11, 299. [Google Scholar] [CrossRef]

- Čermák, P.; Baar, J.; Dömény, J.; Výbohová, E.; Rousek, R.; Pařil, P.; Oberle, A.; Čabalová, I.; Hess, D.; Vodák, M.; et al. Wood-water interactions of thermally modified, acetylated and melamine formaldehyde resin impregnated beech wood. Holzforschung 2022, 76, 437–450. [Google Scholar] [CrossRef]

- Sander, C.; Beckers, E.P.J.; Militz, H.; van Veenendaal, W. Analysis of acetylated wood by electron microscopy. Wood Sci. Technol. 2003, 37, 39–46. [Google Scholar] [CrossRef]

- Pelit, H.; Emiroglu, F. Density, hardness and strength properties of densified fir and aspen woods pretreated with water repellents. Holzforschung 2021, 75, 358–367. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Wang, C.; Li, C.; Liu, Y. Effect of Acetylation on the Physical and Mechanical Performances of Mechanical Densified Spruce Wood. Forests 2022, 13, 1620. https://doi.org/10.3390/f13101620

Guo J, Wang C, Li C, Liu Y. Effect of Acetylation on the Physical and Mechanical Performances of Mechanical Densified Spruce Wood. Forests. 2022; 13(10):1620. https://doi.org/10.3390/f13101620

Chicago/Turabian StyleGuo, Jianhui, Chao Wang, Cheng Li, and Yang Liu. 2022. "Effect of Acetylation on the Physical and Mechanical Performances of Mechanical Densified Spruce Wood" Forests 13, no. 10: 1620. https://doi.org/10.3390/f13101620

APA StyleGuo, J., Wang, C., Li, C., & Liu, Y. (2022). Effect of Acetylation on the Physical and Mechanical Performances of Mechanical Densified Spruce Wood. Forests, 13(10), 1620. https://doi.org/10.3390/f13101620