How Bark Beetle Attack Changes the Tensile and Compressive Strength of Spruce Wood (Picea abies (L.) H. Karst.)

Abstract

1. Introduction

2. Materials and Methods

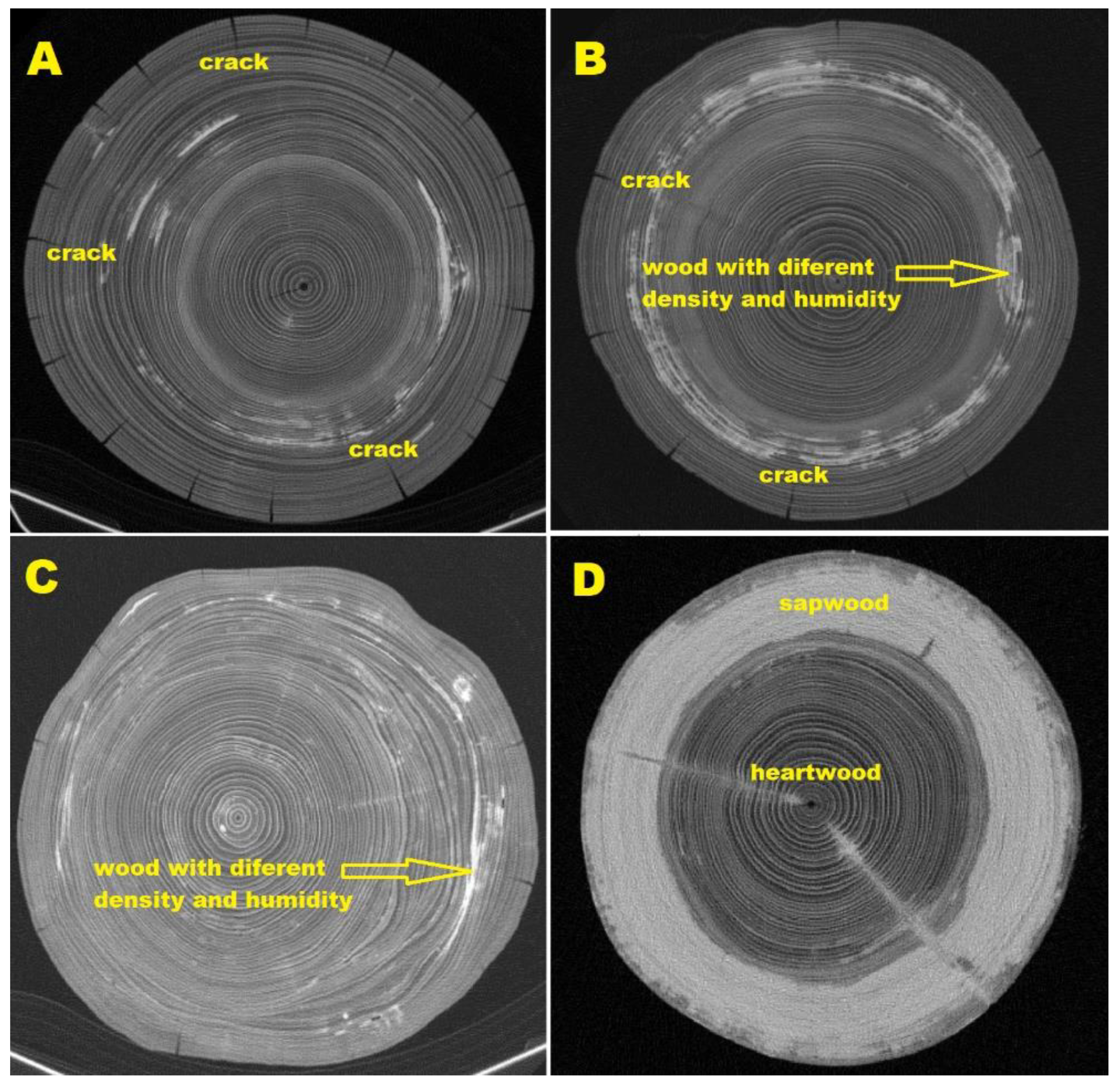

2.1. Materials

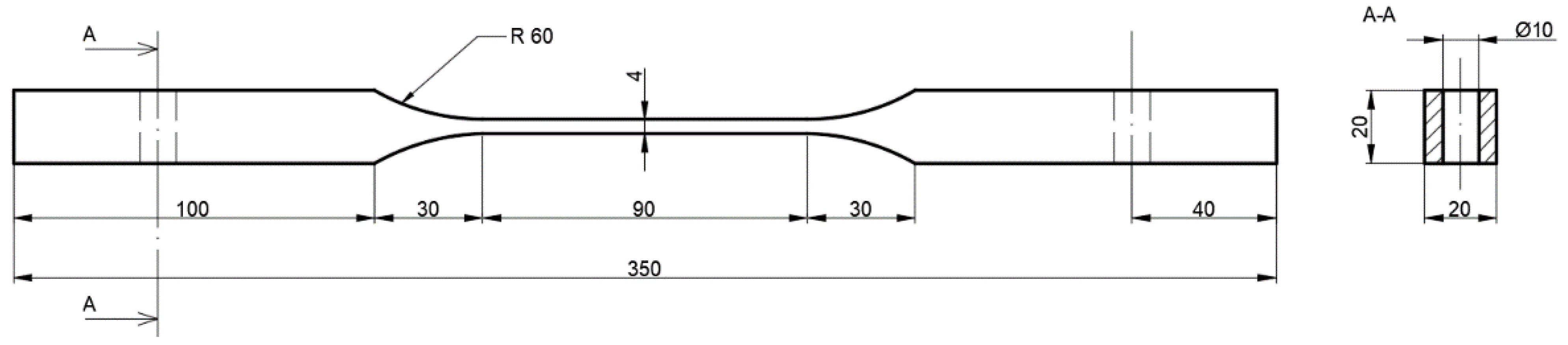

2.2. Methods

2.2.1. Determining Selected Characteristics

2.2.2. Evaluation and Calculation of Tensile and Compressive Strength

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davis, T.S.; Rhoades, P.R.; Mann, A.J.; Griswold, T. Bark beetle outbreak enhances biodiversity and foraging habitat of native bees in alpine landscapes of the southern Rocky Mountains. Sci. Rep. 2020, 10, 16400. [Google Scholar] [CrossRef]

- Edburg, S.L.; Hicke, J.A.; Brooks, P.D.; Pendall, E.G.; Ewers, B.E.; Norton, U.; Gochis, D.; Gutmann, E.D.; Meddens, A.J. Cascading impacts of bark beetle-caused tree mortality on coupled biogeophysical and biogeochemical processes. Front. Ecol. Environ. 2012, 10, 416–424. [Google Scholar] [CrossRef]

- Hlásny, T.; Zimová, S.; Merganičová, K.; Štěpánek, P.; Modlinger, R.; Turčáni, M. Devastating outbreak of bark beetles in the Czech Republic: Drivers, impacts, and management implications. For. Ecol. Manag. 2021, 490, 119075. [Google Scholar] [CrossRef]

- Hlásny, T.; Krokene, P.; Liebhold, A.; Montagné-Huck, C.; Müller, J.; Qin, H.; Raffa, K.; Schelhaas, M.-J.; Seidl, R.; Svoboda, M.; et al. Living with Bark Beetles: Impacts, Outlook and Management Options. From Science to Policy 8; European Forest Institute: Joensuu, Finland, 2019; 50p, Available online: https://efi.int/sites/default/files/files/publication-bank/2019/efi_fstp_8_2019.pdf (accessed on 10 July 2021).

- CSO, Czech Statistical Office 2021 ‘Lesnictví—2020 (Forestry 2020)’. Available online: https://www.czso.cz/csu/czso/lesnictvi-2020 (accessed on 9 November 2021).

- Löwe, R.; Sedmíková, M.; Natov, P.; Jankovský, M.; Hejcmanová, P.; Dvořák, J. Differences in Timber Volume Estimates Using Various Algorithms Available in the Control and Information Systems of Harvesters. Forests 2019, 10, 388. [Google Scholar] [CrossRef]

- Hýsek, Š.; Löwe, R.; Turčáni, M. What Happens to Wood after a Tree Is Attacked by a Bark Beetle? Forests 2021, 12, 1163. [Google Scholar] [CrossRef]

- Jelonek, T.; Klimek, K.; Kopaczyk, J.; Wieruszewski, M.; Arasimowicz-Jelonek, M.; Tomczak, A.; Grzywiński, W. Influence of the Tree Decay Duration on Mechanical Stability of Norway Spruce Wood (Picea abies (L.) Karst.). Forests 2020, 11, 980. [Google Scholar] [CrossRef]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Performance of bark beetle damaged Norway spruce wood against water and fungal decay. BioResources 2018, 13, 3473–3486. [Google Scholar] [CrossRef]

- Little, N.S.; McConnell, T.E.; Irby, N.E.; Shi, S.Q.; Riggins, J.J. Surface free energy of blue-stained southern pine sapwood from bark beetle-attacked trees. Wood Fiber Sci. 2013, 45, 206–214. [Google Scholar]

- Konôpková, A.; Vedernikov, K.E.; Zagrebin, E.A.; Islamova, N.A.; Grigoriev, R.A.; Húdoková, H.; Petek, A.; Kmet’, J.; Petrík, P.; Pashkova, A.S.; et al. Impact of the European bark beetle Ips typographus on biochemical and growth properties of wood and needles in Siberian spruce Picea obovate. Lesn. Cas. 2020, 66, 243–254. [Google Scholar]

- Furniss, M.M.; Solheim, H.; Christiansen, E. Transmission of Blue-Stain Fungi by Ips typographus (Coleoptera: Scolytidae) in Norway Spruce. Ann. Entomol. Soc. Am. 1990, 83, 712–716. [Google Scholar] [CrossRef]

- ČSN 49 0110. Dřevo. Mez pevnosti v tlaku ve směru vláken; Úřad pro Technickou Normalizaci, Metrologii a Státní Zkušebnictví: Praha, Czech Republic, 1979; Volume 8, p. 490110. [Google Scholar]

- ČSN 49 0113. Zkoušky Vlastností Rostlého Dřeva. Metoda Zjišťování Pevnosti v tahu Podél Vláken; Úřad pro Technickou Normalizaci, Metrologii a Státní Zkušebnictví: Praha, Czech Republic, 1991; Volume 8, p. 490113. [Google Scholar]

- Lindgren, O. Medical CT-Scanners for Non—Destructive Wood Density and Moisture Content Measurements. Doctoral Thesis, Luleå University, Skelleftea, Sweden, 1992; p. 92. [Google Scholar]

- Zhou, L.; Chen, Z.; Olsson, L.; Grahn, T.; Karlsson, B.; Wu, H.X.; Lundqvist, S.O.; García-Gil, M.R. Effect of number of annual rings and tree ages on genomic predictive ability for solid wood properties of Norway spruce. BMC Genom. 2020, 21, 323. [Google Scholar] [CrossRef]

- Roszyk, E.; Kwiatkowski, T.; Moliński, W. Mechanical parameters of pine wood in individual annual rings under tensile stress along the grains in dry and wet state. Wood Res. 2013, 58, 571–580, print ISSN 1336-4561. [Google Scholar]

- Moliński, W.; Roszyk, E.; Fabisiak, E. Gradient of selected mechanical properties within individual annual rings in the resonance spruce wood (Picea abies L.). Wood Res. 2013, 58, 521–532, print ISSN 1336-4561. [Google Scholar]

- Sonderegger, W.; Niemz, P. The influence of compression failure on the bending, impact bending and tensile strength of spruce wood and the evaluation of non-destructive methods for early detection. Holz Roh Werkst. 2004, 62, 335–342. [Google Scholar] [CrossRef][Green Version]

- Quinn, G.P.; Keough, M.J. Experimental Design and Data Analysis for Biologists; Cambridge University Press: New York, NY, USA, 2002; p. 537. [Google Scholar]

- Babiak, M.; Gaff, M.; Sikora, A.; Hýsek, Š. Modulus of elasticity in three- and four-point bending of wood. Compos. Struct. 2018, 204, 454–465. [Google Scholar] [CrossRef]

- Gindl, W.; Teischinger, A. Axial compression strength of Norway spruce related to structural variability and lignin content. Composites Part A. 2002, 33, 1623–1628. [Google Scholar] [CrossRef]

- Schönfelder, O.; Zeidler, A.; Borůvka, V.; Bílek, L.V. Impact of silvicultural measures on the quality of scots pine wood part II. Effect of site. Wood Res. 2019, 64, 789–798, e-ISSN 2729-8906. [Google Scholar]

- Witomsky, P.; Oleg, W.; Bonarski, J.T. Changes in strength of Scots pine wood (Pinus silvestris L.) decayed by brown rot (Coniophora puteana) and white rot (Trametes versicolor). Constr. Build. Mater. 2016, 102, 162–166. [Google Scholar] [CrossRef]

- Reinprecht, L. Wood Deterioration, Protection and Maintenance, 1st ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2016; p. 376. [Google Scholar] [CrossRef]

- Oltean, L.; Teischinger, A.; Hamsmann, C. Influence of temperature on cracking and mechanical properties of wood during wood drying—A review. Bioresources 2007, 2, 789–811, ISSN 1930-2126. [Google Scholar]

- Kloiber, M.; Tippner, J.; Hrivnák, J. Mechanical properties of wood examined by semi-destructive devices. Mater. Struct. 2014, 47, 199–212. [Google Scholar] [CrossRef]

- Marais, B.N.; Brischke, C.; Militz, H.; Peters, J.H.; Reinhardt, L. Studies into Fungal Decay of Wood In Ground Contact—Part 1: The Influence of Water-Holding Capacity, Moisture Content, and Temperature of Soil Substrates on Fungal Decay of Selected Timbers. Forests 2020, 11, 1284. [Google Scholar] [CrossRef]

- Beagle, E.; Belmont, E. Technoeconomic assessment of beetle kill biomass co-firing in existing coal fired power plants in the Western United States. Energy Policy 2016, 97, 429–438. [Google Scholar] [CrossRef]

- Roszyk, E.; Molinski, W.; Fabisiak, E.; Cunderlik, I. Radial variation of mechanical properties of spruce wood (Picea abies L.) in tension along the grain. Folia For. Polonica. Series B-Drzew. 2010, 41, 33–44, ISSN 0071-6685. [Google Scholar]

- Machado, J.S.; Louzada, J.L.; Santos, A.J.A.; Nunes, L.; Anjos, O.; Rodrigues, J.; Simões, R.M.S.; Pereira, H. Variation of wood density and mechanical properties of blackwood (Acacia melanoxylon R. Br.). Mater. Des. 2014, 56, 975–980, ISSN 0261-3069. [Google Scholar] [CrossRef]

- Zhang, S.Y. Effect of age on the variation, correlations and inheritance of selected wood characteristics in black spruce (Picea mariana). Wood Sci. Technol. 1988, 32, 197–204. [Google Scholar] [CrossRef]

| Age of Log (Years) | Log Number | Distance from Center |

|---|---|---|

| 0; 0.5; 1; 2; 3 | 1; 2; 3; 4; 5 | 1; 2; 3; 4; 5 |

| Age of Log | Density (kg·m−3) | Standard Deviation | Position | Density (kg·m−3) | Standard Deviation |

|---|---|---|---|---|---|

| 0 | 486.15 | 25.18 | 1 | 471.64 | 22.57 |

| 0.5 | 472.58 | 19.39 | 2 | 473.92 | 27.47 |

| 1 | 465.32 | 24.84 | 3 | 483.38 | 25.31 |

| 2 | 447.27 | 22.78 | 4 | 466.37 | 20.18 |

| 3 | 452.02 | 20.63 | 5 | 456.29 | 25.32 |

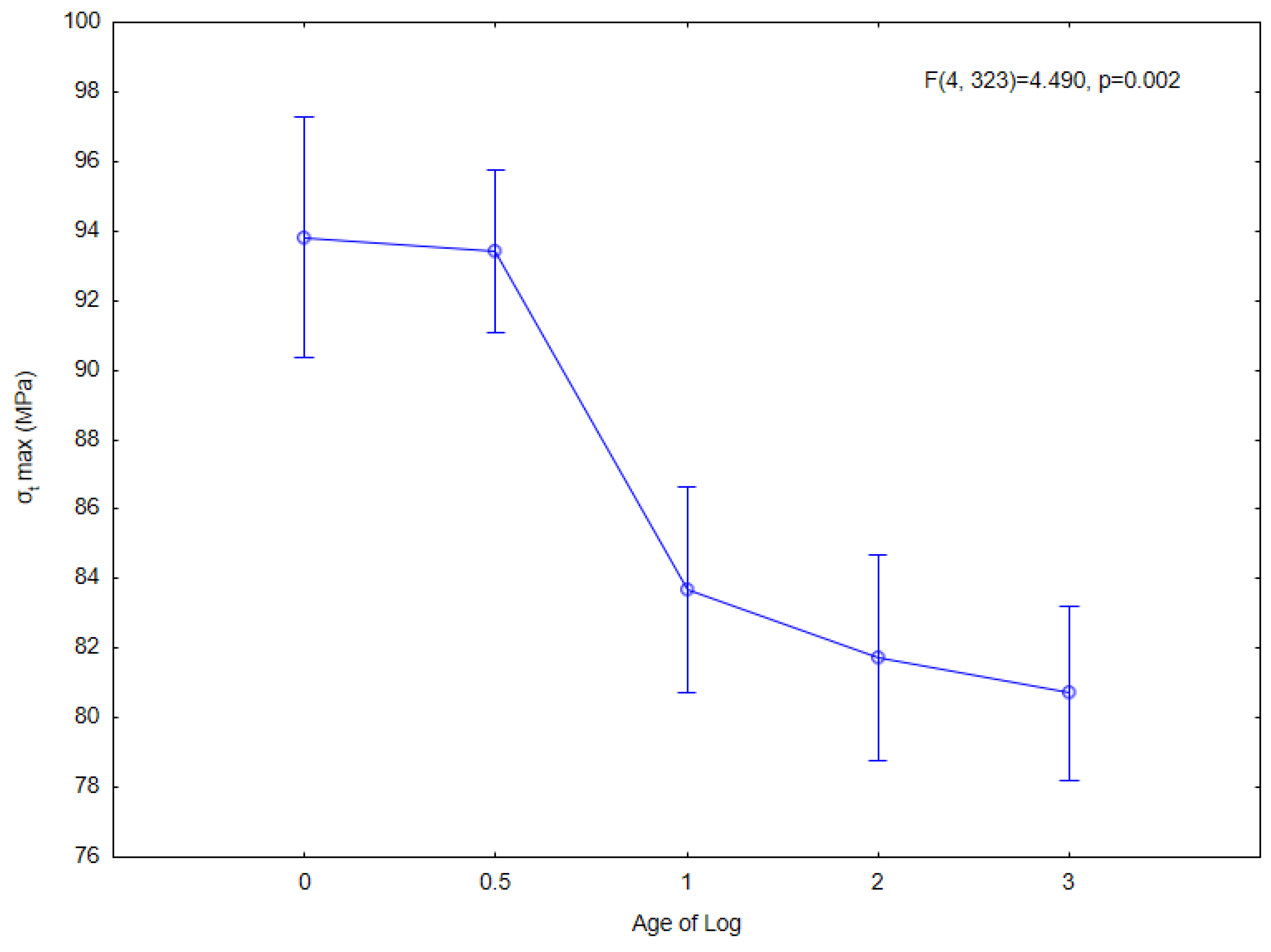

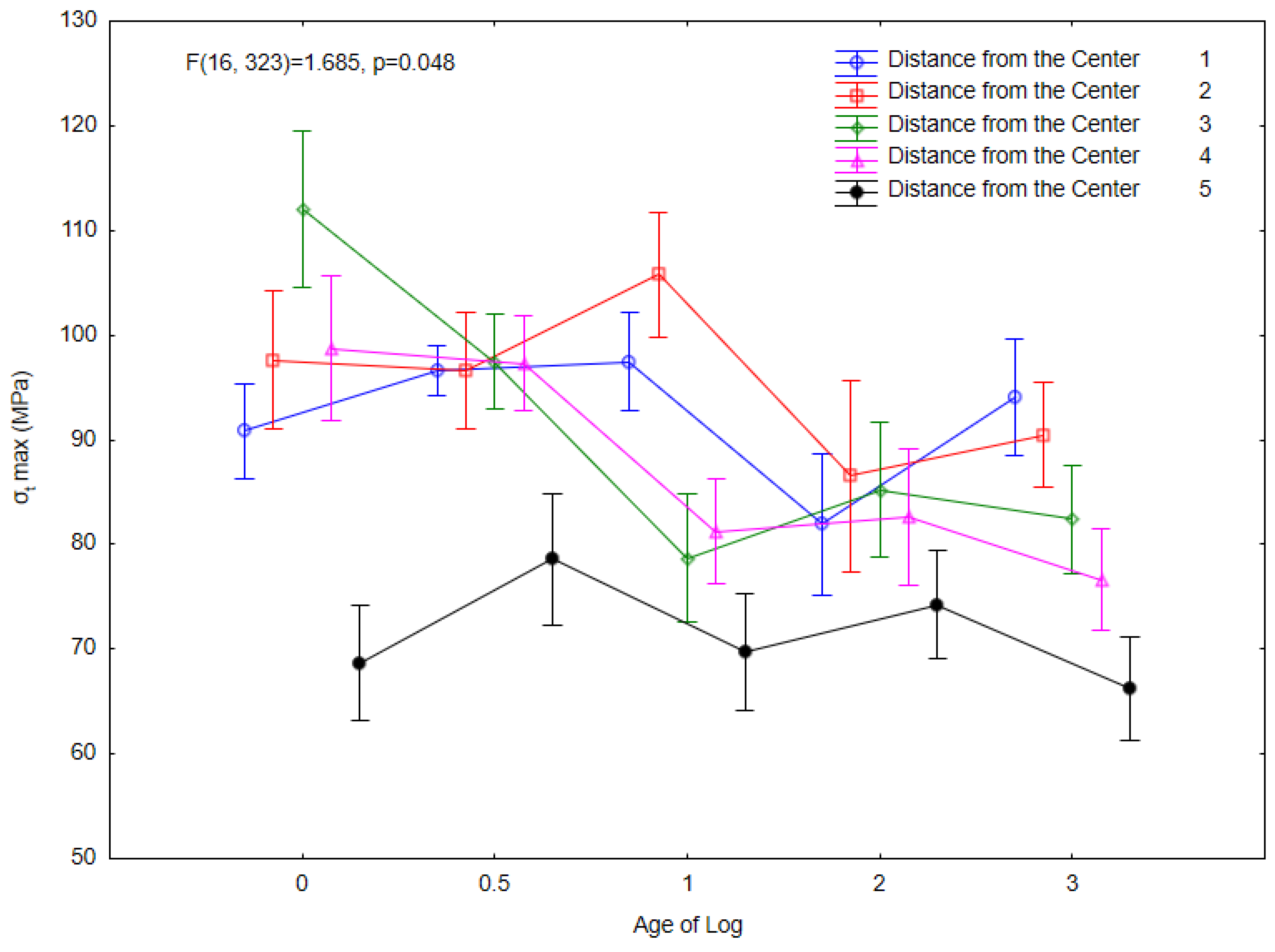

| σt Max (MPa) | (1) 93.815 | (2) 93.437 | (3) 83.687 | (4) 81.749 | (5) 80.709 | N | |

|---|---|---|---|---|---|---|---|

| Number | (AoL) | ||||||

| 1 | 0 | - | 0.920 | 0.009 | 0.002 | 0.001 | 67 |

| 2 | 0.5 | 0.920 | - | 0.009 | 0.002 | 0.001 | 66 |

| 3 | 1 | 0.009 | 0.009 | - | 0.604 | 0.456 | 68 |

| 4 | 2 | 0.002 | 0.002 | 0.604 | - | 0.781 | 70 |

| 5 | 3 | 0.001 | 0.001 | 0.456 | 0.781 | - | 77 |

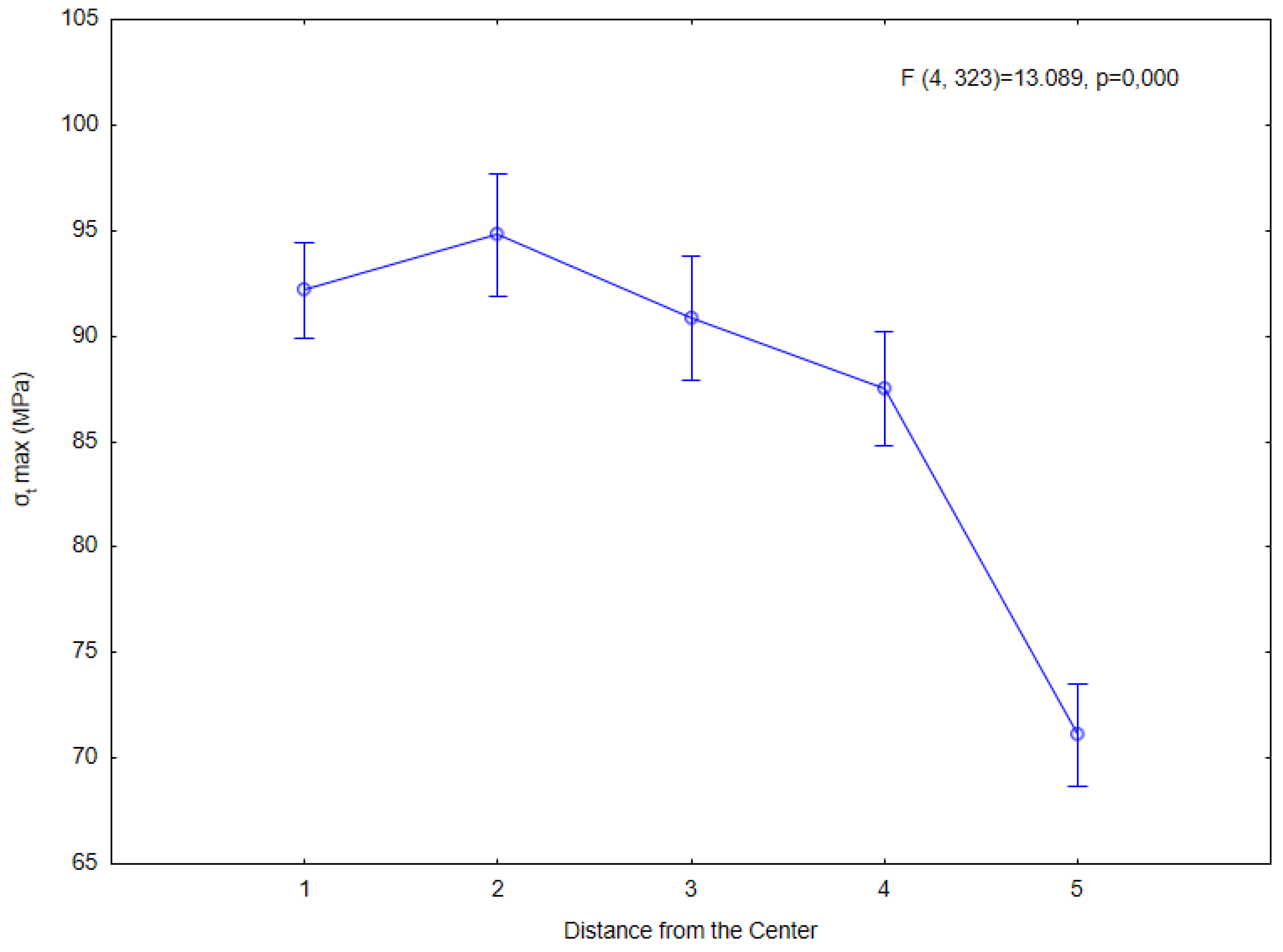

| σt Max (MPa) | (1) 92.177 | (2) 94.791 | (3) 90.840 | (4) 87.535 | (5) 71.096 | N | |

|---|---|---|---|---|---|---|---|

| Number | DfC | ||||||

| 1 | 1 | - | 0.492 | 0.725 | 0.253 | 0.000 | 50 |

| 2 | 2 | 0.492 | - | 0.331 | 0.082 | 0.000 | 57 |

| 3 | 3 | 0.725 | 0.331 | - | 0.385 | 0.000 | 82 |

| 4 | 4 | 0.253 | 0.082 | 0.385 | - | 0.000 | 80 |

| 5 | 5 | 0.000 | 0.000 | 0.000 | 0.000 | - | 79 |

| No. | Age of Log (Years) | Distance from Center | σt Max (Mpa) Mean | σt Max (Mpa) Std. Err. | σt Max (Mpa) −Std. Err. | σt Max (Mpa) +Std. Err. | N |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 1 | 90.809 | 4.511 | 86.298 | 95.320 | 10 |

| 2 | 0 | 2 | 97.609 | 6.565 | 91.044 | 104.174 | 10 |

| 3 | 0 | 3 | 112.020 | 7.490 | 104.530 | 119.510 | 16 |

| 4 | 0 | 4 | 98.723 | 6.955 | 91.767 | 105.678 | 16 |

| 5 | 0 | 5 | 68.635 | 5.491 | 63.144 | 74.126 | 15 |

| 6 | 0.5 | 1 | 96.658 | 2.362 | 94.296 | 99.020 | 10 |

| 7 | 0.5 | 2 | 96.558 | 5.590 | 90.968 | 102.148 | 10 |

| 8 | 0.5 | 3 | 97.417 | 4.531 | 92.886 | 101.948 | 16 |

| 9 | 0.5 | 4 | 97.320 | 4.495 | 92.825 | 101.815 | 17 |

| 10 | 0.5 | 5 | 78.584 | 6.242 | 72.342 | 84.826 | 13 |

| 11 | 1 | 1 | 97.473 | 4.634 | 92.839 | 102.107 | 10 |

| 12 | 1 | 2 | 105.761 | 5.953 | 99.808 | 111.714 | 10 |

| 13 | 1 | 3 | 78.690 | 6.148 | 72.541 | 84.838 | 18 |

| 14 | 1 | 4 | 81.224 | 5.003 | 76.221 | 86.227 | 13 |

| 15 | 1 | 5 | 69.768 | 5.582 | 64.186 | 75.350 | 17 |

| 16 | 2 | 1 | 81.907 | 6.687 | 75.220 | 88.594 | 10 |

| 17 | 2 | 2 | 86.555 | 9.158 | 77.397 | 95.713 | 10 |

| 18 | 2 | 3 | 85.209 | 6.440 | 78.769 | 91.650 | 16 |

| 19 | 2 | 4 | 82.588 | 6.558 | 76.030 | 89.145 | 18 |

| 20 | 2 | 5 | 74.241 | 5.139 | 69.102 | 79.380 | 16 |

| 21 | 3 | 1 | 94.037 | 5.548 | 88.489 | 99.585 | 10 |

| 22 | 3 | 2 | 90.485 | 5.004 | 85.481 | 95.489 | 17 |

| 23 | 3 | 3 | 82.384 | 5.181 | 77.202 | 87.565 | 16 |

| 24 | 3 | 4 | 76.643 | 4.902 | 71.741 | 81.545 | 16 |

| 25 | 3 | 5 | 66.199 | 4.910 | 61.289 | 71.109 | 18 |

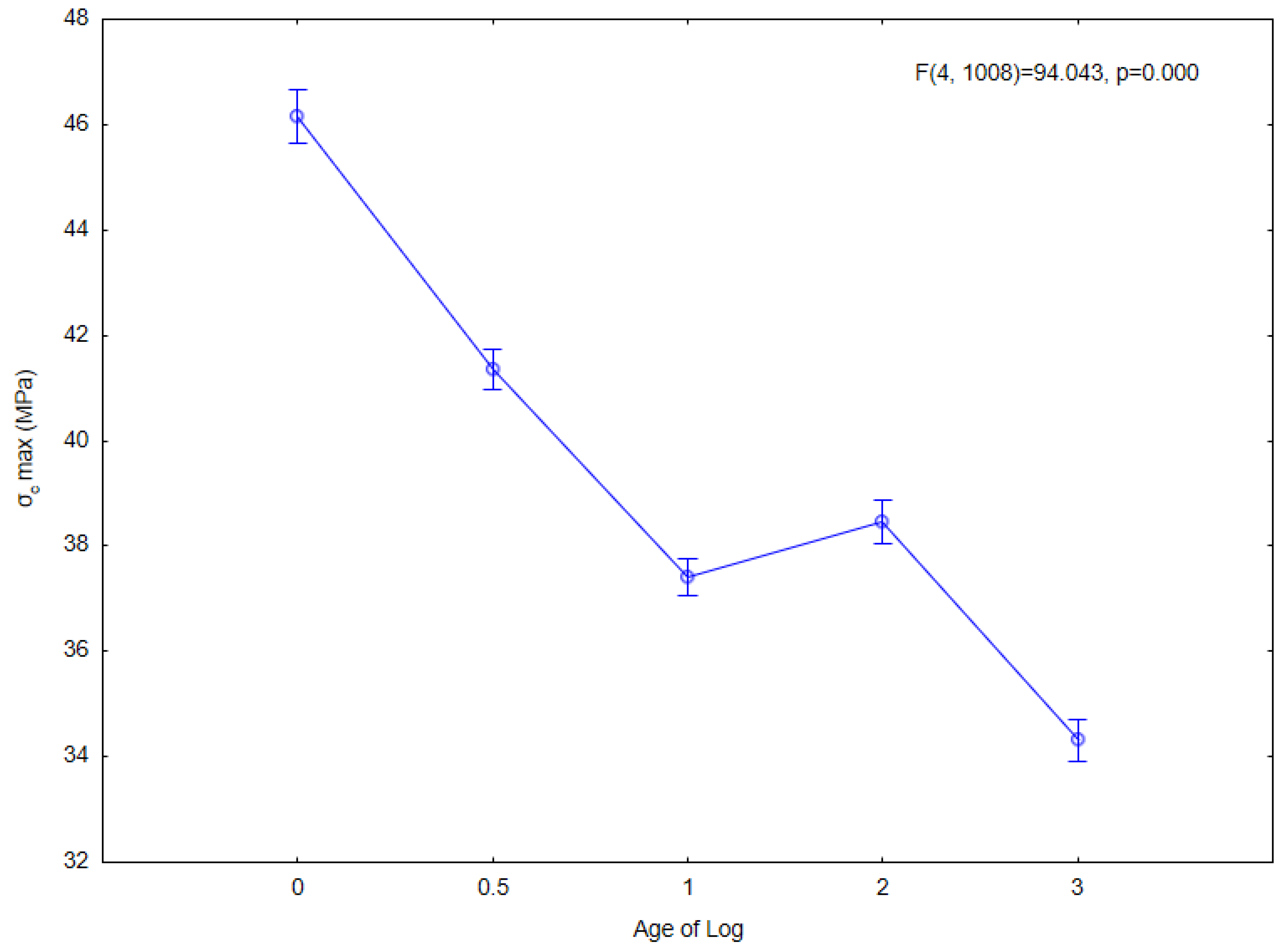

| σc Max (MPa) | (1) 46.144 | (2) 41.353 | (3) 37.409 | (4) 38.462 | (5) 34.318 | N | |

|---|---|---|---|---|---|---|---|

| Number | AoL | ||||||

| 1 | 0 | 0.000 | 0.000 | 0.000 | 0.000 | 203 | |

| 2 | 1 | 0.000 | 0.000 | 0.000 | 0.000 | 192 | |

| 3 | 2 | 0.000 | 0.000 | 0.042 | 0.000 | 205 | |

| 4 | 3 | 0.000 | 0.000 | 0.042 | 0.000 | 198 | |

| 5 | 4 | 0.000 | 0.000 | 0.000 | 0.000 | 235 | |

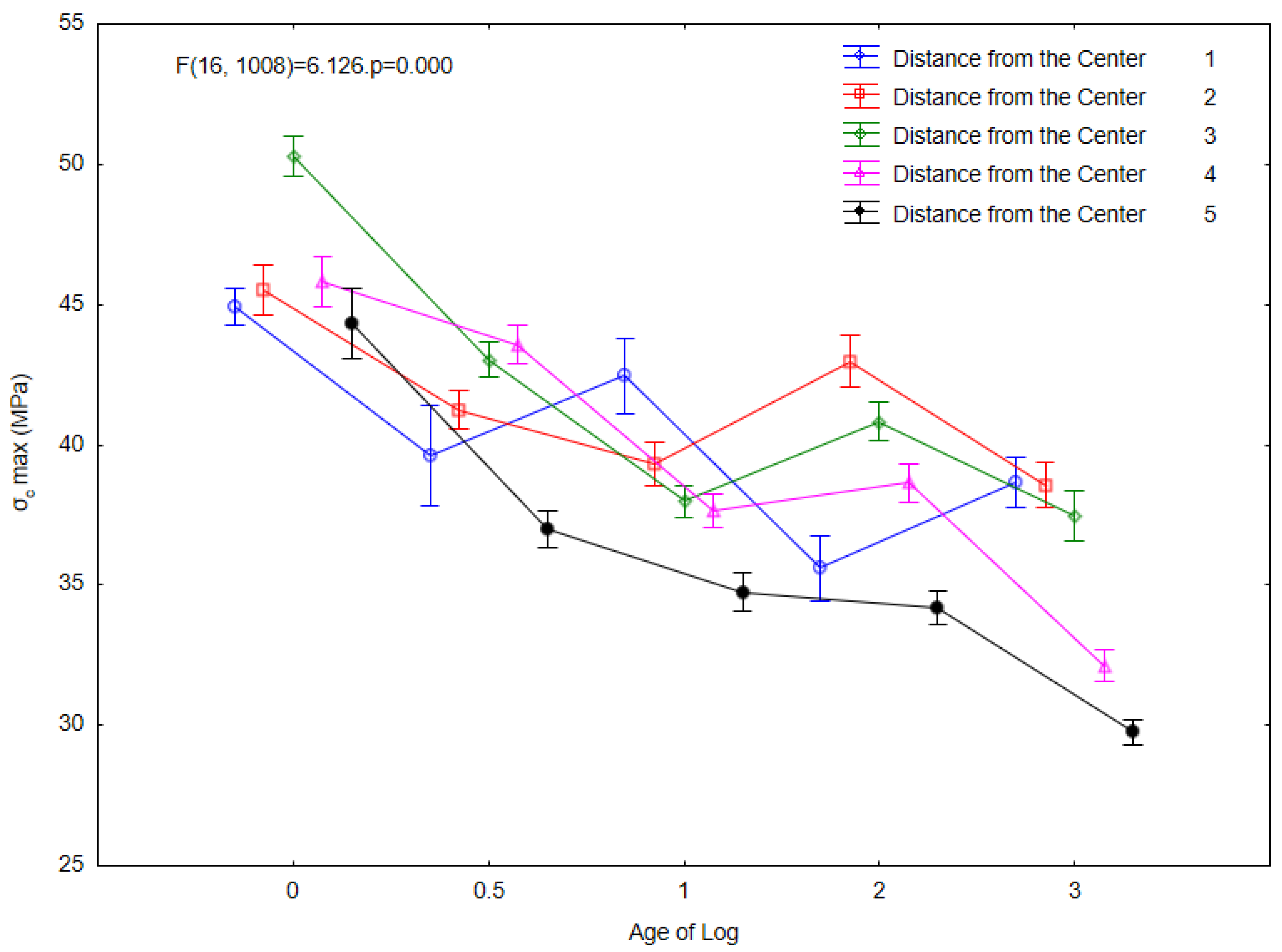

| σc Max (MPa) | (1) 39.909 | (2) 41.547 | (3) 41.395 | (4) 39.897 | (5) 35.770 | N | |

|---|---|---|---|---|---|---|---|

| Number | DfC | ||||||

| 1 | 1 | 0.009 | 0.013 | 0.984 | 0.000 | 69 | |

| 2 | 2 | 0.009 | 0.801 | 0.010 | 0.000 | 143 | |

| 3 | 3 | 0.013 | 0.801 | 0.017 | 0.000 | 244 | |

| 4 | 4 | 0.984 | 0.010 | 0.017 | 0.000 | 296 | |

| 5 | 5 | 0.000 | 0.000 | 0.000 | 0.000 | 281 | |

| No. | Age of Log (Years) | Distance from Center | σc Max (MPa) Mean | σc Max (MPa) Std. Err. | σc Max (MPa) −Std. Err. | σc Max (MPa) +Std. Err. | N |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 1 | 44.934 | 0.654 | 44.280 | 45.588 | 11 |

| 2 | 0 | 2 | 45.523 | 0.885 | 44.638 | 46.408 | 32 |

| 3 | 0 | 3 | 50.283 | 0.715 | 49.568 | 50.997 | 38 |

| 4 | 0 | 4 | 45.803 | 0.895 | 44.908 | 46.698 | 66 |

| 5 | 0 | 5 | 44.332 | 1.246 | 43.086 | 45.578 | 56 |

| 6 | 0.5 | 1 | 39.588 | 1.789 | 37.800 | 41.377 | 10 |

| 7 | 0.5 | 2 | 41.245 | 0.676 | 40.569 | 41.921 | 19 |

| 8 | 0.5 | 3 | 43.043 | 0.600 | 42.443 | 43.643 | 48 |

| 9 | 0.5 | 4 | 43.565 | 0.696 | 42.869 | 44.261 | 67 |

| 10 | 0.5 | 5 | 36.987 | 0.648 | 36.339 | 37.635 | 48 |

| 11 | 1 | 1 | 42.472 | 1.340 | 41.133 | 43.812 | 10 |

| 12 | 1 | 2 | 39.319 | 0.771 | 38.548 | 40.090 | 27 |

| 13 | 1 | 3 | 37.985 | 0.578 | 37.408 | 38.563 | 57 |

| 14 | 1 | 4 | 37.672 | 0.598 | 37.074 | 38.269 | 55 |

| 15 | 1 | 5 | 34.740 | 0.675 | 34.065 | 35.415 | 56 |

| 16 | 2 | 1 | 35.600 | 1.174 | 34.426 | 36.774 | 10 |

| 17 | 2 | 2 | 42.981 | 0.915 | 42.066 | 43.895 | 30 |

| 18 | 2 | 3 | 40.828 | 0.667 | 40.161 | 41.495 | 52 |

| 19 | 2 | 4 | 38.655 | 0.690 | 37.964 | 39.345 | 50 |

| 20 | 2 | 5 | 34.185 | 0.623 | 33.561 | 34.808 | 56 |

| 21 | 3 | 1 | 38.673 | 0.909 | 37.764 | 39.582 | 28 |

| 22 | 3 | 2 | 38.564 | 0.810 | 37.754 | 39.374 | 35 |

| 23 | 3 | 3 | 37.459 | 0.889 | 36.569 | 38.348 | 49 |

| 24 | 3 | 4 | 32.121 | 0.569 | 31.552 | 32.690 | 58 |

| 25 | 3 | 5 | 29.750 | 0.460 | 29.289 | 30.210 | 65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Löwe, R.; Sedlecký, M.; Sikora, A.; Prokůpková, A.; Modlinger, R.; Novotný, K.; Turčáni, M. How Bark Beetle Attack Changes the Tensile and Compressive Strength of Spruce Wood (Picea abies (L.) H. Karst.). Forests 2022, 13, 87. https://doi.org/10.3390/f13010087

Löwe R, Sedlecký M, Sikora A, Prokůpková A, Modlinger R, Novotný K, Turčáni M. How Bark Beetle Attack Changes the Tensile and Compressive Strength of Spruce Wood (Picea abies (L.) H. Karst.). Forests. 2022; 13(1):87. https://doi.org/10.3390/f13010087

Chicago/Turabian StyleLöwe, Radim, Miroslav Sedlecký, Adam Sikora, Anna Prokůpková, Roman Modlinger, Karel Novotný, and Marek Turčáni. 2022. "How Bark Beetle Attack Changes the Tensile and Compressive Strength of Spruce Wood (Picea abies (L.) H. Karst.)" Forests 13, no. 1: 87. https://doi.org/10.3390/f13010087

APA StyleLöwe, R., Sedlecký, M., Sikora, A., Prokůpková, A., Modlinger, R., Novotný, K., & Turčáni, M. (2022). How Bark Beetle Attack Changes the Tensile and Compressive Strength of Spruce Wood (Picea abies (L.) H. Karst.). Forests, 13(1), 87. https://doi.org/10.3390/f13010087